Production method of high-boiling-point aromatic solvent oil

A high-boiling-point aromatics and production method technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrogenation treatment process, etc., can solve the problems of C10 aromatics utilization, resource waste, etc., achieve low hydrogen consumption, save production costs, and rational route design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

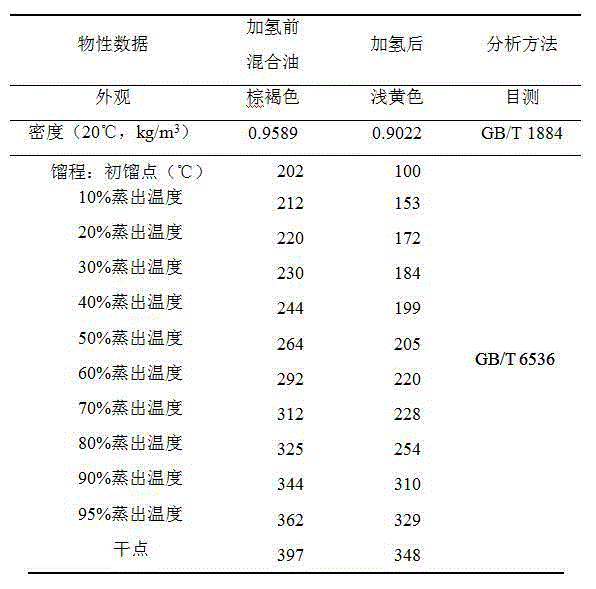

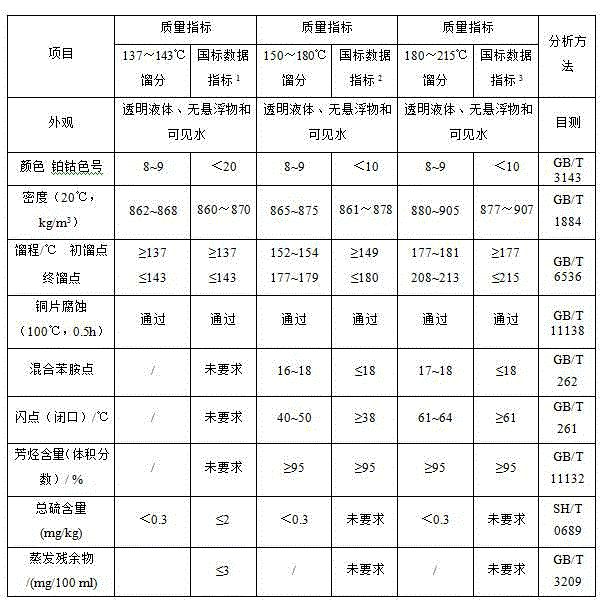

Embodiment 1

[0020] Take C10 heavy aromatics for hydrogenation and lightening. The total weight of the active ingredient oxide in the hydrogenation catalyst is 25% of the weight of the amorphous silicon-aluminum composite carrier; the weight ratio of silicon oxide to aluminum oxide in the amorphous silicon-aluminum composite carrier is 38:62 ; The weight ratio of nickel oxide, molybdenum oxide, tungsten oxide, and phosphorus oxide in the active ingredient oxide is: 10:81:8.2:0.8; the reaction temperature is 320°C, the hydrogen pressure is 5MPa, the hydrogen-oil volume ratio is 600, and the volume space velocity is 1.9 h -1 . After rectification and separation, the fraction before 137°C can be used as gasoline blending oil or further separated to obtain No. 6 solvent oil (distillation range 60-90°C) and No. 90 solvent oil (90-120°C), and 137-143°C fraction is mixed Xylene, the main product 150-180°C and 180-215°C fractions, and still liquid with a boiling point higher than 215°C accounted f...

Embodiment 2

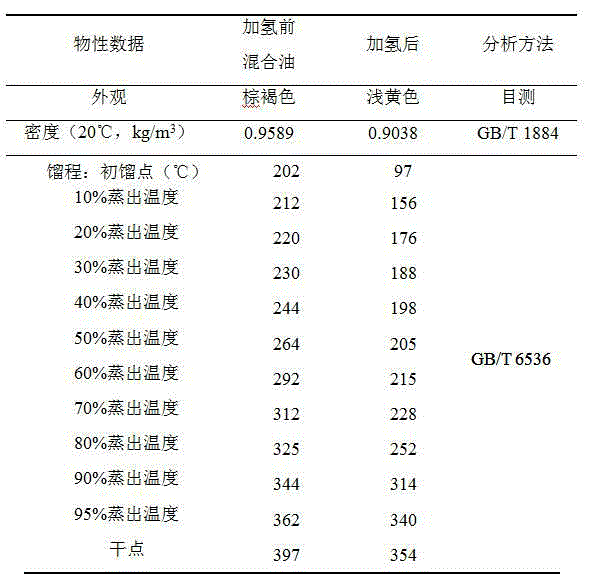

[0024] The C10 tail oil after cutting and extracting the light components is hydrogenated and lightened. The total weight of the active component oxide in the hydrogenation catalyst is 50% of the weight of the amorphous silicon-aluminum composite carrier; the silicon oxide and the amorphous silicon-aluminum composite carrier are The weight ratio of alumina is 64.5:35.5; the weight ratio of nickel oxide, molybdenum oxide, tungsten oxide, and phosphorus oxide in the active ingredient oxide is: 22:71:3.5:3.5, the reaction temperature is 385°C, the hydrogen pressure is 9.5MPa, and the hydrogen oil volume Ratio 2800, volumetric space velocity 1.0 h -1 . After rectification, the fraction before 137°C, the fraction at 137-143°C are mixed xylenes, the fractions at 150-180°C and 180-215°C of the main products, and the still liquor with a boiling point higher than 215°C account for 10% and 5% respectively. %, 8%, 22%, 55%. Among them, 55% of the still liquid with a boiling point highe...

Embodiment 3

[0028] C10 heavy aromatics and C10 tail oil after cutting and extracting light components are mixed at a volume ratio of 2:1 for hydrogenation and lightening. The total weight of the active component oxides in the hydrogenation catalyst is 32.5% of the weight of the amorphous silicon-aluminum composite carrier %; the weight ratio of silicon oxide to aluminum oxide in the amorphous silicon-aluminum composite carrier is 65.5:34.5; the weight ratio of nickel oxide, molybdenum oxide, tungsten oxide, and phosphorus oxide in the active ingredient oxide is: 12:78.5:4.5:5; the reaction The temperature is 340°C, the hydrogen pressure is 6MPa, the volume ratio of hydrogen to oil is 1000, and the volume space velocity is 1.8 h -1 . After rectification, the fraction before 137°C, the fraction at 137-143°C are mixed xylenes, the fractions at 150-180°C and 180-215°C of the main products, and the still liquor with a boiling point higher than 215°C account for 5% and 8% respectively. %, 15%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com