Preparation method of polyamide-imide lithium battery membrane

A technology of lithium polyamide-imide and polyamide-imide, which is applied in the field of lithium battery applications, can solve the problems of low puncture strength of nanofiber separators, affecting mechanical properties such as puncture strength, and difficult to completely remove pore-forming substances. , to achieve the effect of easy recycling, easy industrial operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

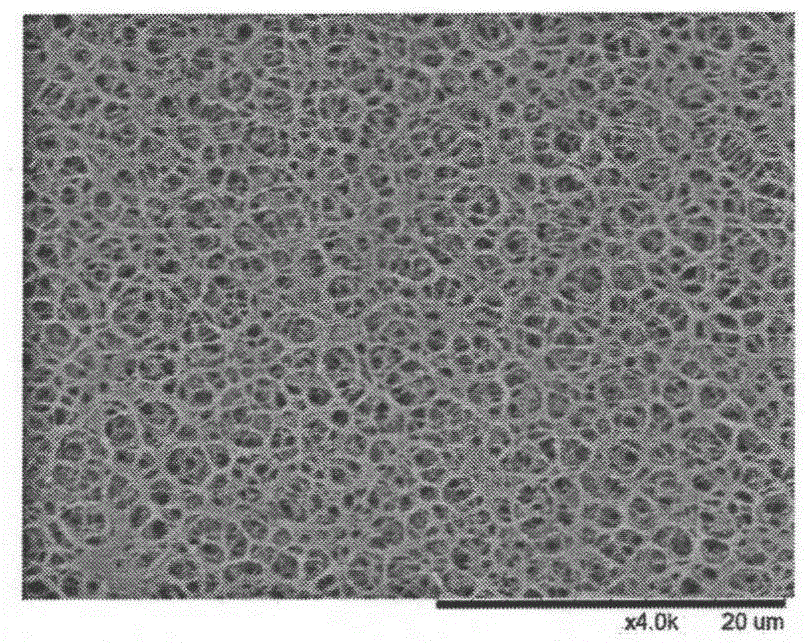

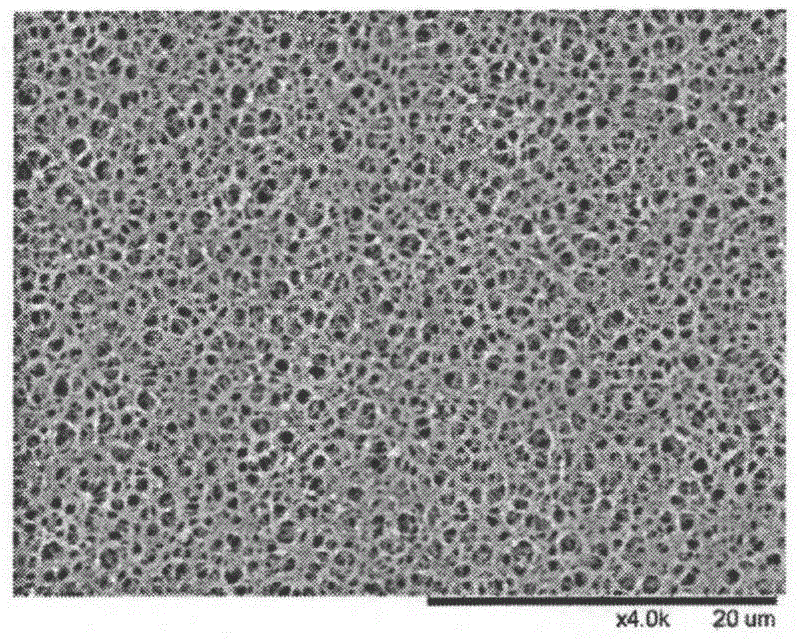

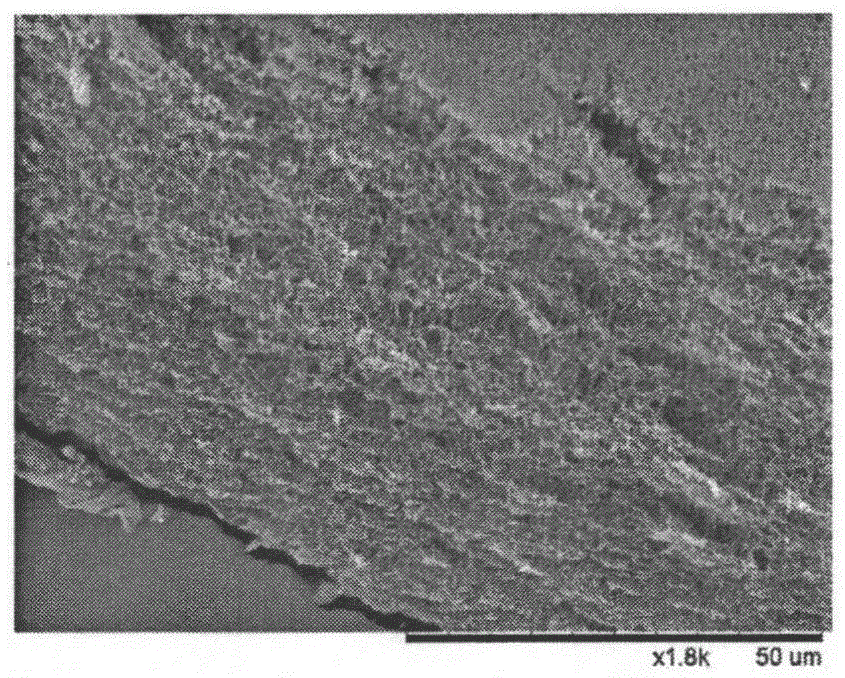

Image

Examples

Embodiment 1

[0029] A preparation method of a polyamide-imide lithium battery diaphragm, the specific steps are:

[0030] Accurately weigh 50g of polyamideimide solid powder, bake at 80°C to constant weight, dissolve it in NMP to obtain a polyamideimide solution with a mass concentration of 40%, add 15g of lithium chloride to it, seal and mix Stir evenly to obtain the coating liquid;

[0031] Put the coating solution at 50°C for defoaming, transport it to the scraping substrate through a metering pump, adjust the scraping gap to 100 μm, and scrape the primary film on the scraping substrate with a scraper. The primary film is gradually solidified and formed by a gradient coagulation bath to obtain a solidified film. The gradient coagulation bath is an aqueous solution of an aprotic polar solvent whose concentration gradually decreases, and the number of gradient coagulation baths is 3 levels. Concentration is 80% NMP-water solution→second stage: mass concentration is 55% NMP-water solution...

Embodiment 2~8

[0035] The preparation method of the polyamide-imide membrane of embodiment 2~8 is similar to embodiment 1, and only process condition is different, and specific process condition sees the following table:

[0036]

[0037]

Embodiment 9

[0039] The separators obtained in the above embodiments 1 to 8 are subjected to various performance tests, which are listed in the following table:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com