Metal-coated MFI hierarchical pore structure packaging catalyst and packaging method and application thereof

A catalyst and multi-stage pore technology, which is applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of non-reduced crystallinity of molecular sieve matrix, uneven distribution of metal nanoparticles, uneven particle size, etc., and achieve rapid preparation methods. Simple, no reduction in crystallinity, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The preparation method of the encapsulated catalyst of the Ni@ZSM-5-200 hierarchical porous structure described in this example includes the following steps:

[0079] (1) Ni-ethylenediamine complex solution, SiO with MFI structure 2 / Al 2 o 3 =200 ZSM-5 molecular sieves, tetrapropylammonium hydroxide and deionized water mix uniformly to obtain a mixed solution, wherein the mass ratio of Ni, ZSM-5 molecular sieves and deionized water is 0.04:1:2;

[0080] (2) Transfer the mixed liquid obtained in step (1) into a crystallization kettle and crystallize at 170°C for 12 hours, take it out, filter it, dry it, roast it at 500°C for 5 hours, and reduce it under a hydrogen atmosphere at 500°C for 4 hours to obtain Ni@ The encapsulated catalyst of ZSM-5-200 hierarchical pore structure is named A-1.

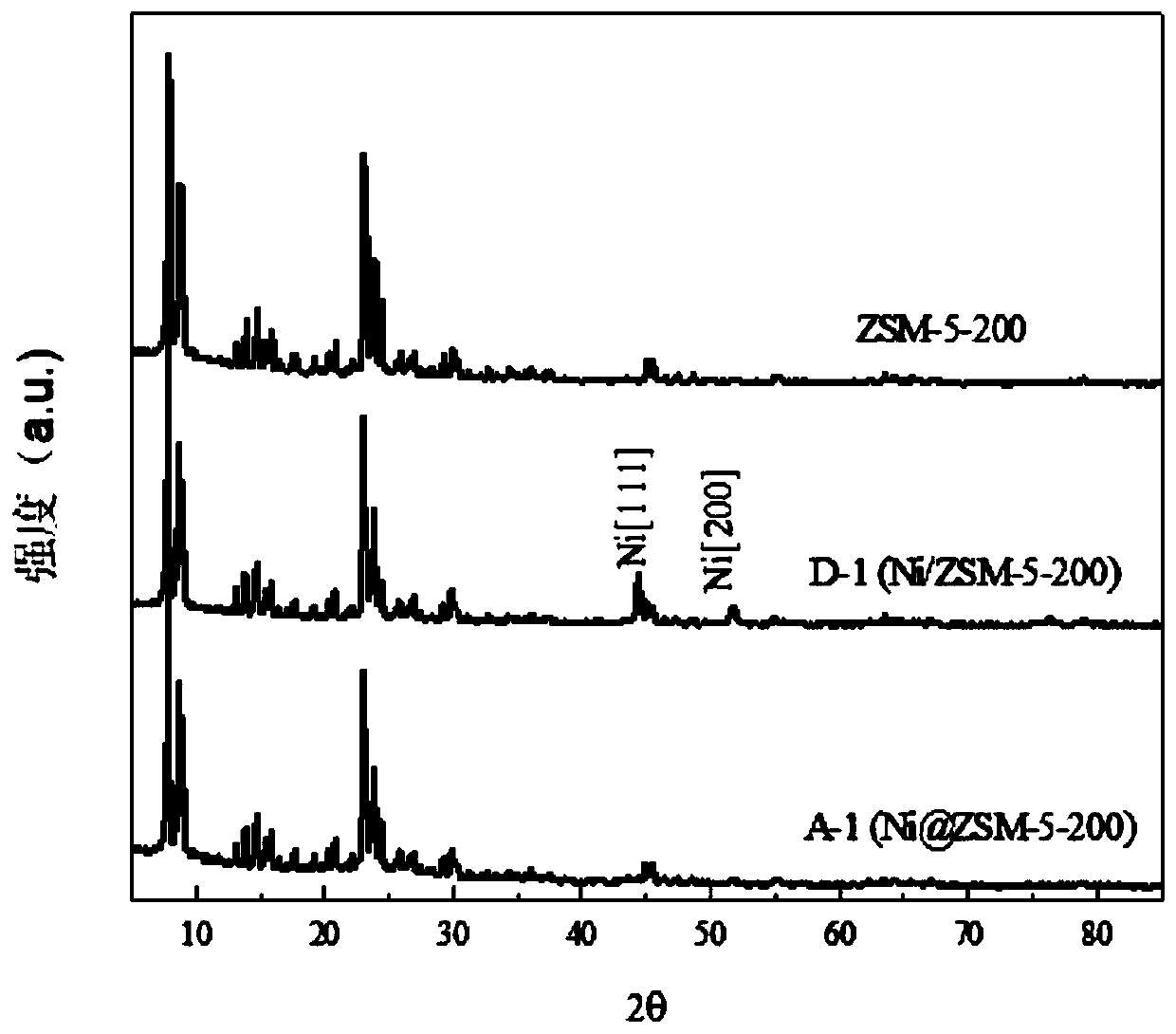

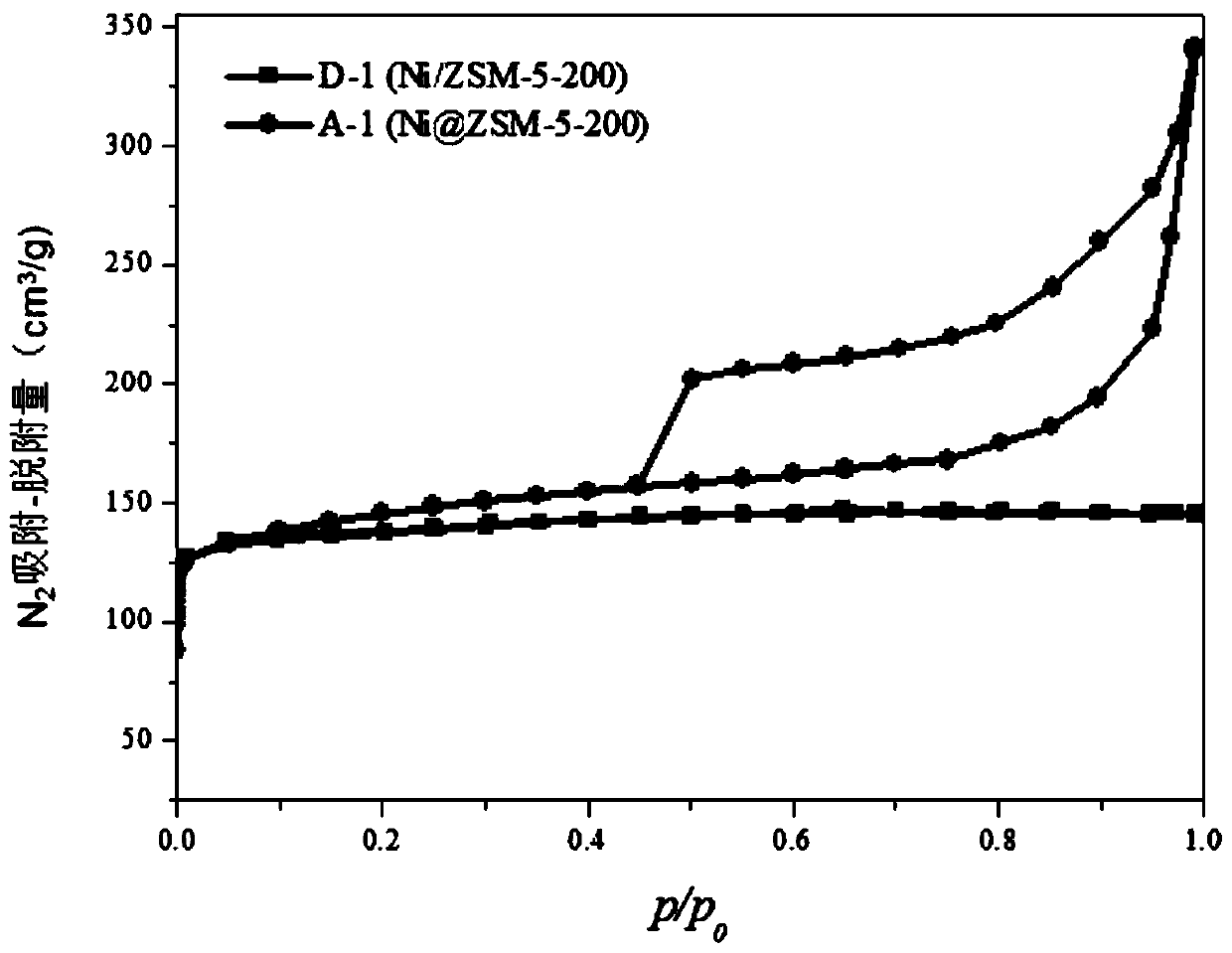

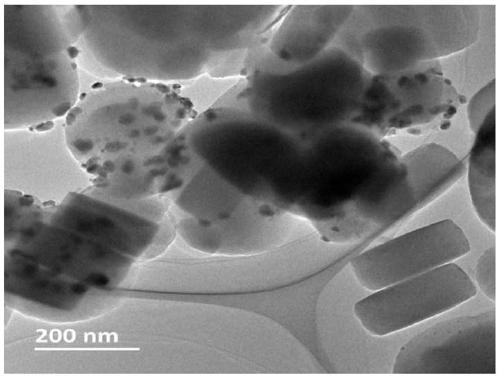

[0081] The XRD of the catalyst obtained in this embodiment is as follows: figure 1 Shown: by figure 1 The characteristic diffraction peaks of the MFI structure can be observed, ...

Embodiment 2

[0100] The preparation method of the encapsulated catalyst of Ni@Silicalite-1 hierarchical porous structure described in this embodiment comprises the following steps:

[0101] (1) Ni-ethylenediamine complex solution, pure silicon Silicalite-1 molecular sieve with MFI structure, tetrapropyl ammonium hydroxide and deionized water are mixed uniformly to obtain a mixture, wherein, Ni, pure silicon Silicalite-1 molecular sieve The mass ratio to deionized water is 0.04:1:2;

[0102] (2) Transfer the mixture obtained in step (1) into a crystallization kettle for crystallization treatment at 170°C for 12 hours, take it out, filter, dry, roast at 500°C for 5 hours, and reduce it in a hydrogen atmosphere at 500°C for 8 hours to obtain Ni@ The encapsulated catalyst of Silicalite-1 hierarchical pore structure is named A-2.

[0103] In the X-ray diffraction analysis results of the catalyst obtained in this embodiment, the characteristic diffraction peak of the MFI structure was observed,...

Embodiment 3

[0109] The preparation method of the encapsulated catalyst of the Ni@ZSM-5-200 hierarchical porous structure described in this example includes the following steps:

[0110] (1) Ni-ethylenediamine complex solution, SiO with MFI structure 2 / Al 2 o 3 =200 ZSM-5 molecular sieves, tetrapropyl ammonium hydroxide and deionized water mix uniformly to obtain a mixture, wherein the mass ratio of Ni, ZSM-5 molecular sieves and deionized water is 0.02:1:2;

[0111] (2) Transfer the mixture obtained in step (1) into a crystallization kettle, crystallize at 170°C for 12 hours, take it out, filter, dry, roast at 500°C for 5 hours, and reduce it in a hydrogen atmosphere at 500°C for 8 hours to obtain Ni@ ZSM-5-200 encapsulated catalyst with hierarchical pore structure, named A-3.

[0112] The characteristic diffraction peak of MFI structure is observed in the X-ray diffraction pattern of the catalyst obtained in this embodiment, but there is no diffraction peak of metal Ni particles, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com