Patents

Literature

32results about How to "Less solvent usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

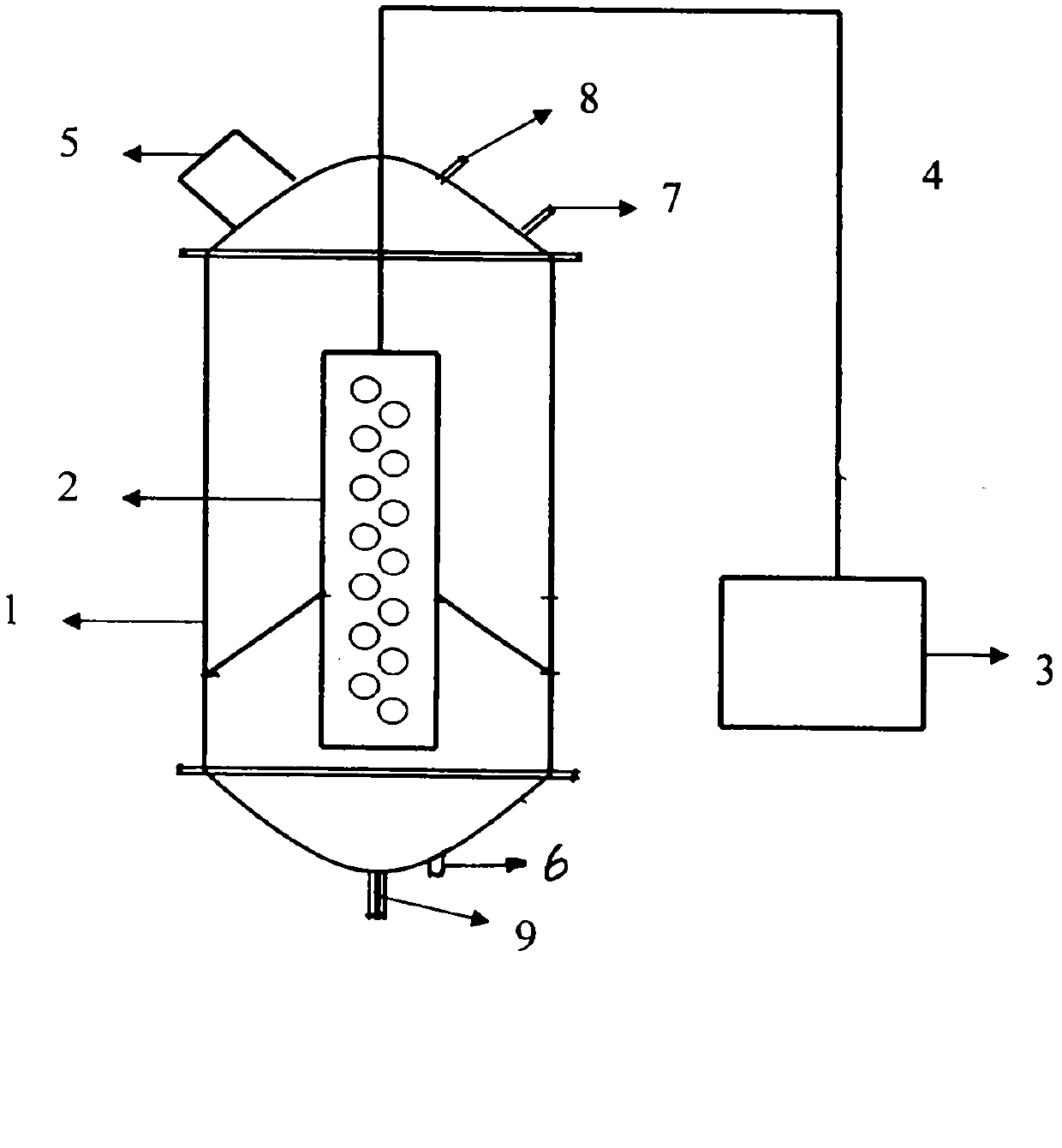

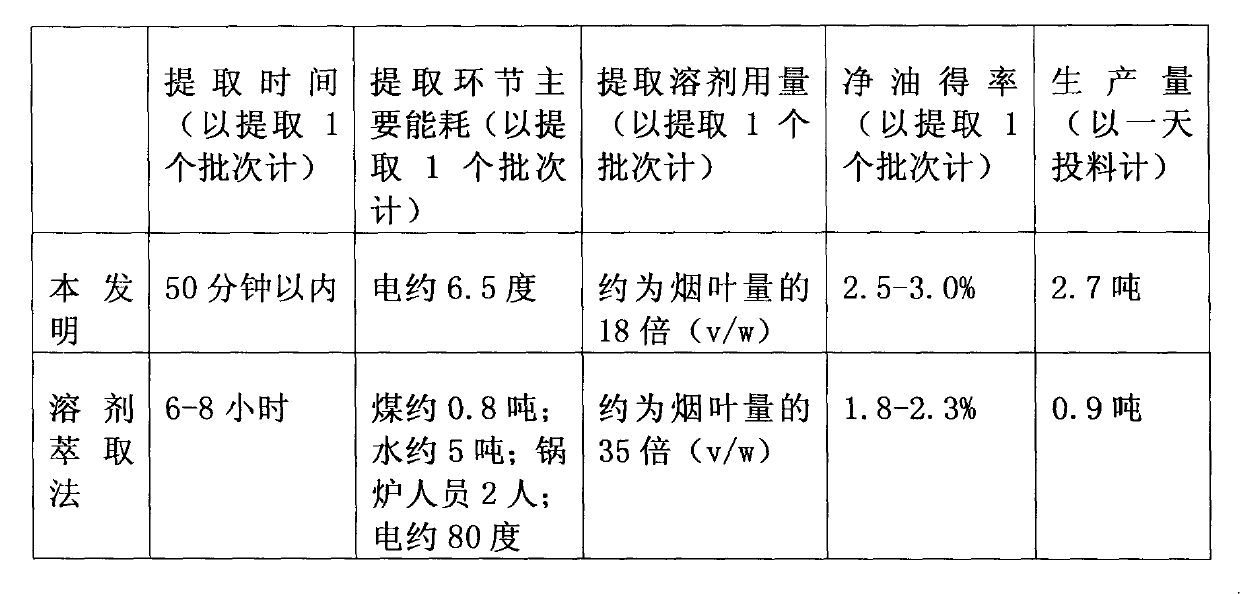

Production method for extracting absolute oil of tobacco leaves

The invention relates to a production method for extracting the absolute oil of tobacco leaves, which comprises the following steps of: taking the tobacco leaves and / or waste tobacco dust as raw materials, drying, crushing, and putting the crushed raw materials into an extraction device with an ultrasonic generator; and extracting by using fat soluble organic solvent, dissolving by using water soluble organic solvent, filtering, and concentrating filter liquor under reduced pressure to obtain the required absolute oil of the tobacco leaves. In the method, the tobacco leaves can be infiltratedquickly by the solvent and oil cells can be ruptured by utilizing the principle of high penetrating power of ultrasonic waves in a liquid medium at normal temperature within a short time, so that tobacco tar is leached by the solvent as soon as possible. Due to short-time extraction at the normal temperature, less using amount of solvent and high oil yield, energy consumption is reduced obviously, the production capacity is improved, the production cost is reduced greatly, and the danger of operation is reduced relatively.

Owner:CHANGNING DEKANG BIOTECH

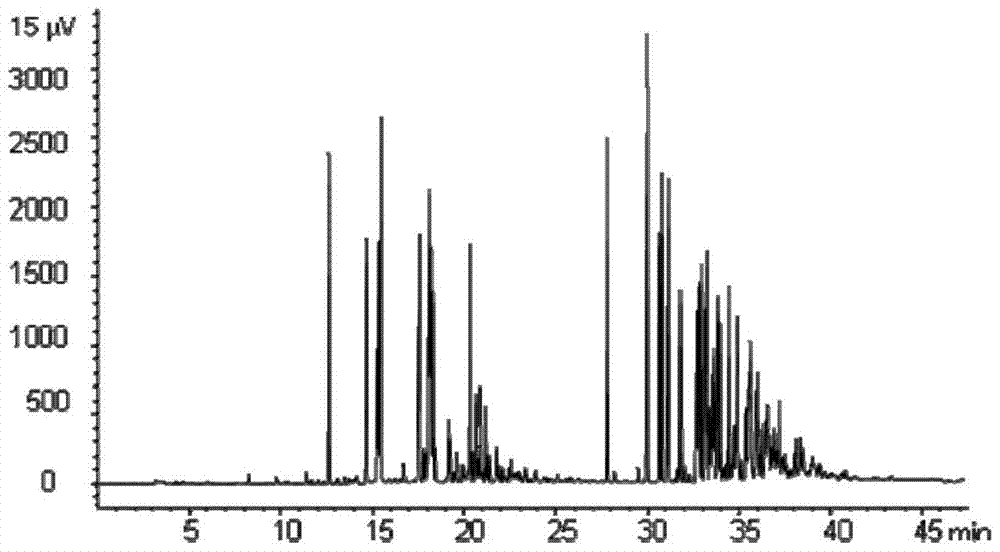

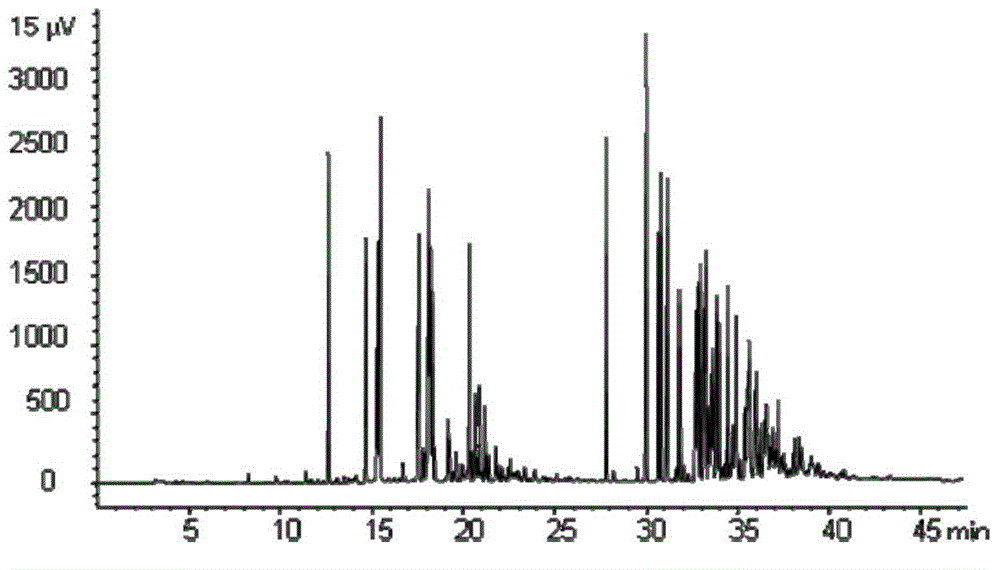

Double-column solid phase extraction method of nitrogen-containing compounds in diesel oil

ActiveCN106318438ASeparation cross amount is smallLess fixedComponent separationSolid sorbent liquid separationStationary phaseNitrogen

A double-column solid phase extraction method of nitrogen-containing compounds in diesel oil comprises the following steps: 1, producing solid phase extraction columns, wherein the stationary phase of the solid phase extraction column A is a silica gel and acidic alumina mixture, and the stationary phase of the solid phase extraction column B is a silica gel and alkaline alumina mixture; and 2, eluting: wetting the solid phase extraction column A by a first eluent, adding a diesel oil sample from an upper layer, flushing the solid phase extraction column A with the first eluent to obtain saturated hydrocarbons, flushing the solid phase extraction column A with a second eluent to obtain aromatic hydrocarbons, flushing the solid phase extraction column A with a third eluent to obtain neutral nitrogen-containing compounds, serially connecting the solid phase extraction column A with the solid phase extraction column B, and flushing the solid phase extraction columns A and B with a fourth eluent to obtain alkaline nitrogen-containing compounds, wherein the column A is arranged above the column B.

Owner:PETROCHINA CO LTD +1

Degreasing method of crude montan wax

InactiveCN103074108ALess solvent usageReasonable workmanshipMineral wax recovery/refiningNatural resin purificationSolventCoal

The invention relates to a refining method of montan wax, and belongs to the technical field of the coal chemical engineering and the fine chemical engineering. The method for producing degreased montan wax by extracting resin impurities from crude montan wax treated as a raw material through a small-molecular-weight ester solvent sequentially comprises the following steps: 1, adding the crude montan wax and the small-molecular-weight ester solvent to a reactor according to a solid-liquid ratio of 1:3-6, and carrying out primary extraction at 70-125DEG C under a stirring condition for 2-4h; 2, cooling extracts obtained in step 1 to room temperature, and carrying out filtering separation to obtain a degreased filter cake and a resin-containing filtrate; 3, adding the degreased filter cake to the small-molecular-weight ester solvent, and carrying out secondary extraction at 70-125DEG C under a stirring condition to obtain a degreased filter cake and a resin-containing filtrate; and 4, carrying out normal or reduced pressure distillation of the degreased filtrate obtained in step 3 to recover the solvent and obtain the degreased montan wax, wherein a montan resin is a byproduct. The method has the advantages of small solvent application amount and reasonable technology.

Owner:云天化集团有限责任公司 +1

Method for preparing paeoniflorin

InactiveCN101418025AReduce extraction timeLess solvent usageSugar derivativesChemistryChromatography column

The invention relates to a method for preparing paeoniflorin, which is simple in operation and low in equipment investment. The method comprises the following process steps: a raw material containing paeoniflorin is placed into microwave extraction equipment and added with water for microwave extraction; filtrate is collected and filtered, so that the filtrate passes through a macroporous absorbent resin column for sample loading, water is used to elute impurities first, 20 to 80 percent ethanol is used for elution, ethanol eluate is collected, and the ethanol is decompressed, reclaimed and concentrated; the concentrated liquid is added into a chromatography column filled with active carbon, and then eluted by water; and eluate is collected, concentrated by a reverse osmosis membrane and dried to obtain the paeoniflorin. The method has the advantages of lowering production cost, improving product quality and facilitating industrialized operation.

Owner:ANHUI GUANGYINTANG CHINESE MEDICINE

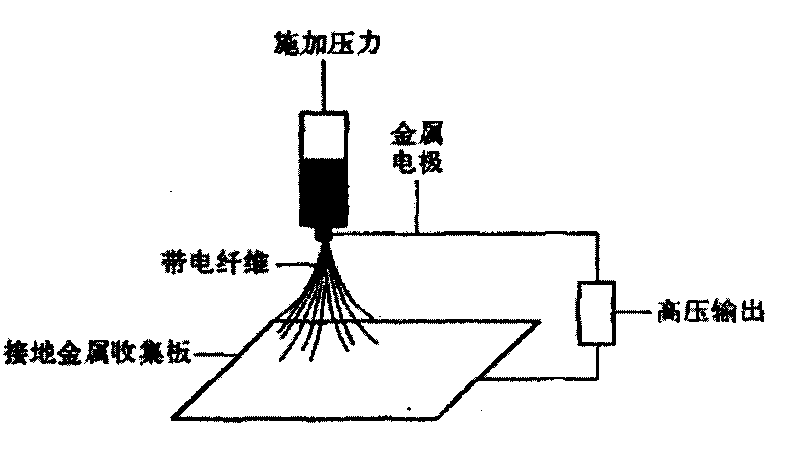

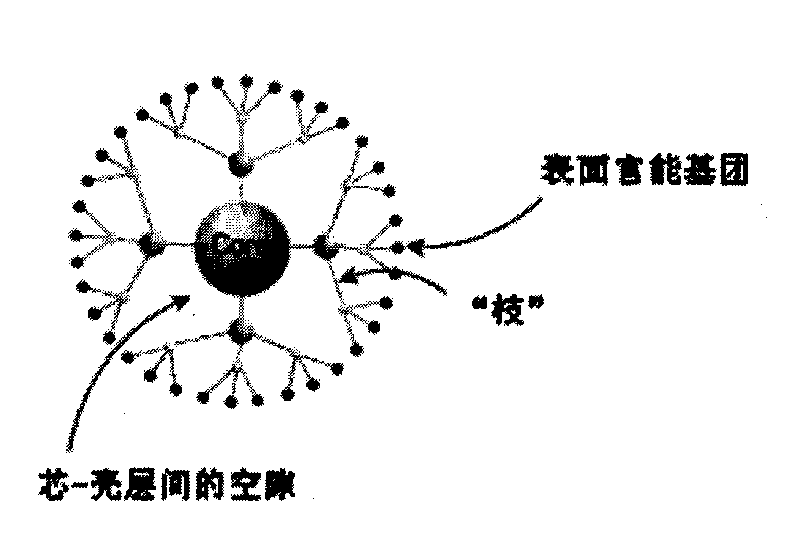

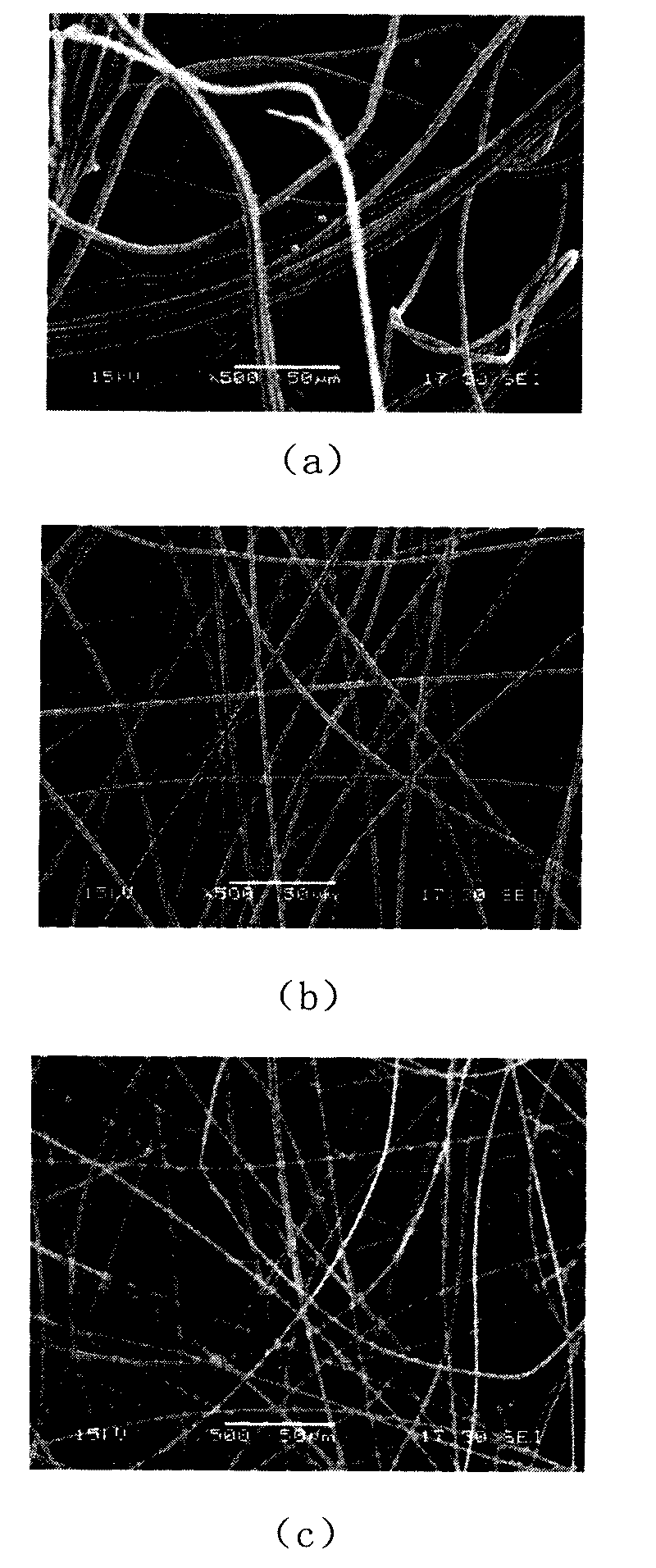

Super-branched polyester and preparation method as well as application in high-speed stretch electrostatic spinning thereof

ActiveCN101735442ALow viscosityLess solvent usageArtifical filament manufactureElectrospinningChemistry

The invention relates to a preparation method of super-branched polyester as well as application in high-speed electrostatic spinning thereof. The adopted preparation route is to carry out acyl halogenation or direct esterification on H2O. After the super-branched polyester is applied to a high-speed electrostatic spinning solution, the critical spinning concentration and the spinning quality of the spinning solution are greatly improved, and the problems of winding and stranding in the spinning process are effectively solved.

Owner:EAST CHINA UNIV OF SCI & TECH

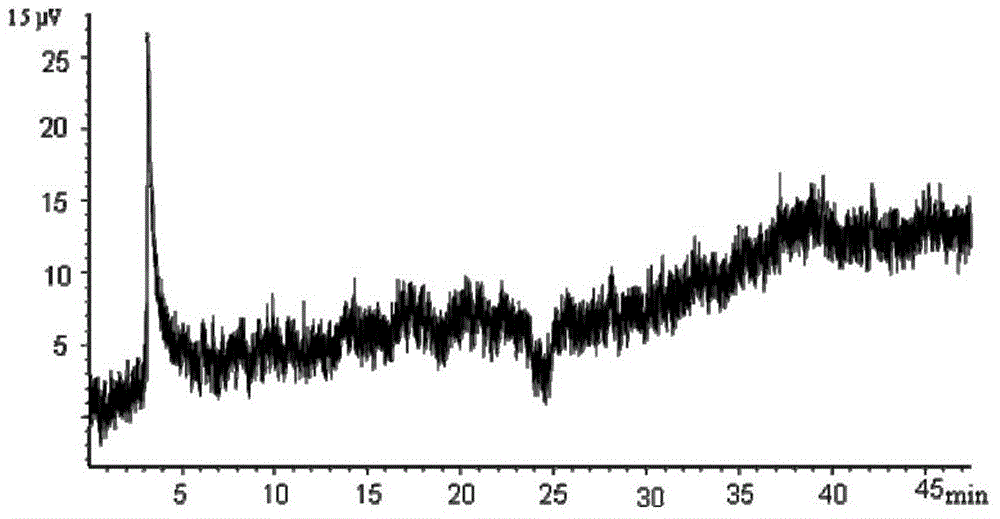

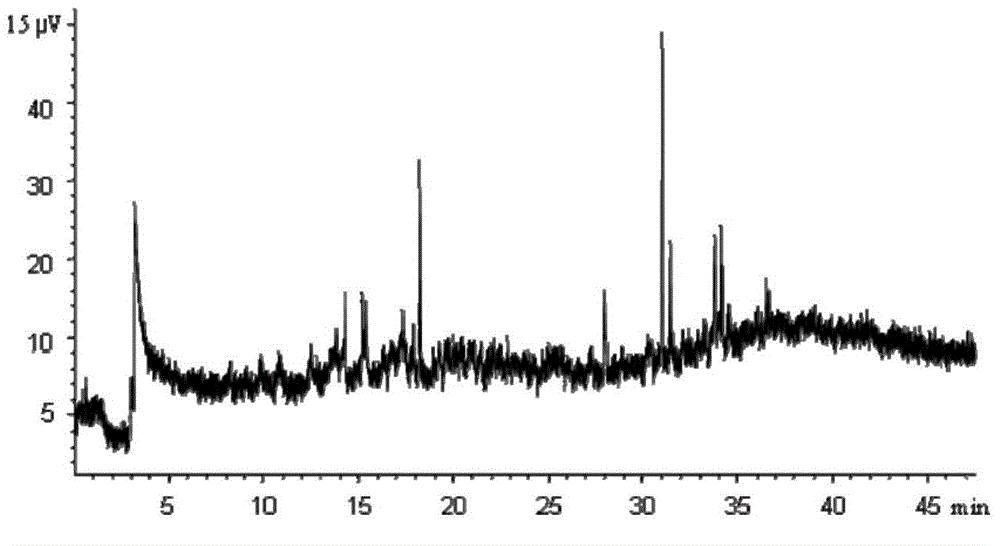

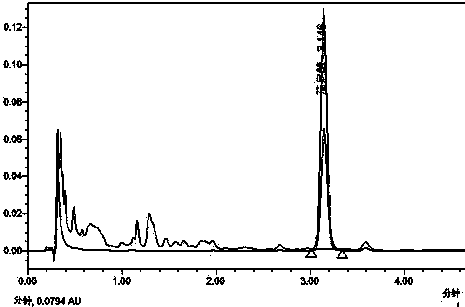

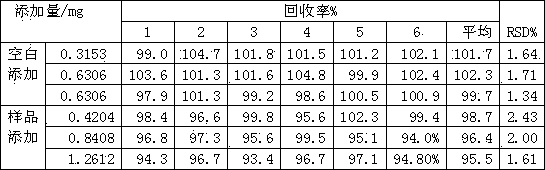

Method for determining total solanesol in tobaccos and tobacco products

The invention discloses a method for determining total solanesol in tobaccos and tobacco products. The method comprises the following steps of: 1, carrying out simultaneous supersonic extraction and saponification on tobacco solanesol, specifically, taking the tobaccos or the tobacco products and grinding the tobaccos or the tobacco products into tobacco powder; placing the tobacco powder into a centrifugal glass tube and adding an extraction solvent and a saponification agent respectively; simultaneously carrying out the supersonic extraction and the saponification on the tobacco solanesol; 2, washing and separating a tobacco solanesol extracting solution, specifically, cooling the extracting solution to a room temperature and adding a certain volume of water; completely vibrating and centrifuging; 3, taking 0.500mL of an upper-layer solution and diluting a flowing phase until the volume is 5.000mL; filtering the solution to a liquid chromatogram ampere bottle by using a 0.22-micron organic filtering membrane to be detected; and 4, carrying out liquid chromatogram determination on the obtained solution to be detected. According to the method disclosed by the invention, the extraction, the saponification and the separation are all finished in the centrifugal tube; the method has the advantages of small solvent dosage, simplicity in operation, cost saving, pollution reduction and improvement of working efficiency; the method is suitable for analyzing samples in a large batch, and the accuracy and the precision of determined results are high.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Process of extracting chili (capsicum) oleoresin

InactiveUS20040191364A1Good colorImproved pungencyTea extractionAnimal feeding stuffOleoresinSolvent

The present invention relates to a process for obtaining oleoresin of improved color and pungency from chili, the said process comprising steps of: treating powder or flakes of chili by mixing with a multi enzyme preparation, incubating at a particular range pH, drying the enzyme treated chili powder / flakes to bring down the moisture level of about 5-12%, powdering or pelletizing to a particle size of about 20-30 mesh, soaking and extracting using a mixture of solvent for a period ranging between 1h to 3h; repeating the extraction and pooling the extracts, and concentrating the pooled extract to obtain oleoresin with enriched pungency and color.

Owner:COUNCIL OF SCI & IND RES

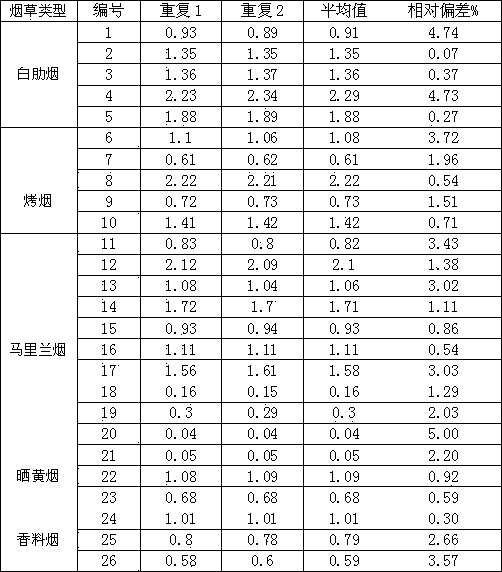

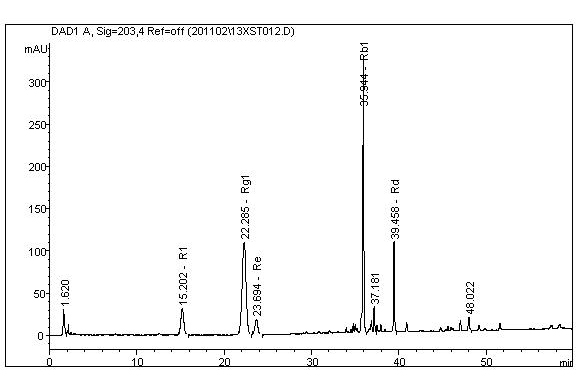

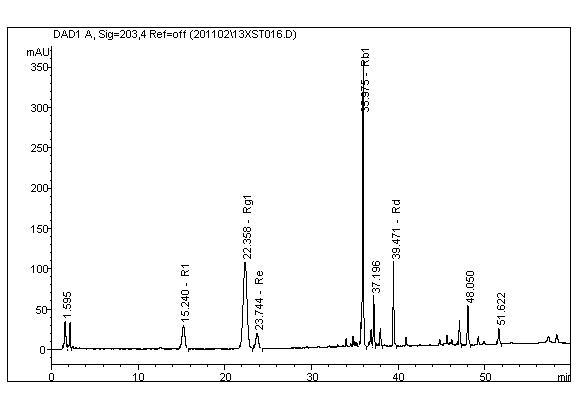

Method for extracting panax notoginseng saponins by using continuous countercurrent ultrasonic extraction combined film technology

ActiveCN102100712AImprove the extraction effectLess solvent usageAntipyreticAnalgesicsUltrafiltrationNanofiltration

The invention discloses a method for extracting panax notoginseng saponins by using a continuous countercurrent ultrasonic extraction combined film technology, belonging to the technical field of extraction and separation of plant effective components. The method mainly comprises the following steps of: adding 40-90 percent ethanol having 6-15 times by weight of the pseudo-ginseng crude powder and carrying out continuous countercurrent ultrasonic extraction for 20-120min at a temperature of 20-50 DEG C with the ultrasonic frequency of 20-80KHz; carrying out membrane concentration on filtering liquid by using 1,000-2,500 parts of ultrafiltration membrane or 100-800 parts of nanofiltration membrane at 20-50 DEG C under 0.4-4.1MPa; adding water into the liquid for diluting after the filtering liquid is subjected to pressure reduction and concentrating to be alcohol-free, or directly adding water for diluting; filtering macroporous adsorption resins and eluting with water, and eluting by using 50-90 percent ethanol; carrying out membrane concentration on peralkaline anion resins by using 100-800 parts of nanofiltration membrane under 0.4-4.1MPa; decoloring; carrying out pressure reduction and concentration; and spray-drying. With low-temperature extraction, high extraction ratio, continuous production and high purification ratio, the quality of the product is guaranteed and the method is simple.

Owner:YUNNAN PHYTOPHARML +1

Method for preparing 1, 3-cyclohexanediamine by hydrogenation of m-xylylenediamine

ActiveCN111116381ALess solvent usageIncrease productivityOrganic compound preparationAmino compound preparationMother liquorDimethylamines

The invention relates to a method for preparing 1, 3-butanediol by hydrogenation of m-xylylenediamine. According to the method, hydrogenation of high-concentration m-xylylenediamine can be realized toprepare the high-cis-form-content 1, 3-cyclohexanediamine. The method comprises the following steps: adding a certain mass of m-xylylenediamine into a system containing a catalyst, a solvent, a reaction additive and high-pressure hydrogen at a constant speed so that the m-xylylenediamine is kept at a relatively low concentration in the whole reaction process through controlling the feeding rate of m-xylylenediamine. High-concentration hydrogenation mother liquor can be obtained while high-selectivity selectivity and yield of 1, 3-cyclohexylenediamine are realized. By adding a nitrogen-containing rigid cyclic compound into a reaction system, the content of cis-form bodies in a hydrogenation product 1, 3-cyclohexanediamine can be effectively increased, and a 1, 3-cyclohexanediamine productwith a cis-form body / trans-form body ratio of 80 / 20 or above is obtained. The method is easy to implement and has an industrial application prospect.

Owner:WANHUA CHEM GRP

Synthesis method of tetra (4-dimethylaminophenyl) porphyrin and derivatives thereof

The invention relates to a synthesis method of tetra(4-dimethylaminophenyl)porphyrin and derivatives thereof and belongs to the field of organic chemistry, comprising the following steps: adopting xylene as solvent, adding 4-dimethylaminobenzaldehyde in the presence of substituted acetic acid and nitrobenzene, introducing pyrrole with carrier gas, adopting methanol for performing Soxhlet extraction, drying the extracted product to obtain the desired tetra(4-dimethylaminophenyl)porphyrin; methylating tetra(4-dimethylaminophenyl)porphyrin in a reaction kettle to obtain tetra(4-trimethylaminophenyl)porphyrin iodide; converting tetra(4-trimethylaminophenyl)porphyrin iodide to tetra(4-trimethylaminophenyl)porphyrin hydroxide with anion exchange resin. The introduced pyrrole in the preparation method of the invention is uniform and is controlled to low concentration, thus reducing the self polymerization of pyrrole, improving the yield to be up to 57%, and significantly reducing the dosage of methyl iodide which is toxic and expensive; the product yield is increased by 10% compared with the prior art, and the resin used in the preparation method can be reused, so that the method is economic and environmentally friendly.

Owner:FUDAN UNIV

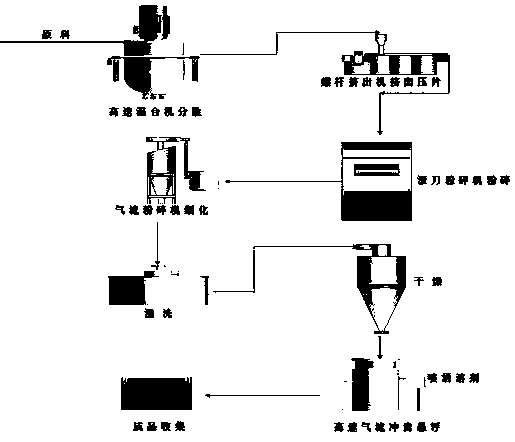

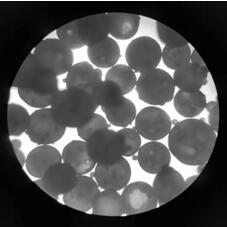

High-sphericity fine thermoplastic powder coating material and preparation method thereof

InactiveCN111334132ALess solvent usageUniform particle sizePowdery paintsGrain treatmentsSurface modificationPolymer chemistry

The invention relates to a thermoplastic powder coating material and a preparation method thereof, particularly to a high-sphericity fine thermoplastic powder coating material and a preparation methodthereof. The preparation method of the coating material comprises the following steps: adding a thermoplastic polymer, a pigment, an antioxidant, a filler and a soluble salt into a high-speed mixer,stirring at a high speed, uniformly dispersing, and extruding and tabletting through a screw extruder; feeding the tablets into a hob crusher, and coarsely crushing to obtain coarse powder; crushing the coarse powder by using a jet mill under a freezing condition, carrying out graded screening to obtain a fine polymer coarse material with a particle size of less than 30 [mu]m, soaking the fine polymer coarse material in clear water, cleaning, removing most soluble salts, carrying out centrifugal dehydration, and drying to obtain pretreated micronized polymer coarse powder; and suspending the pretreated fine polymer coarse powder in a high-speed airflow impact type powder surface modification device through high-speed airflow, and spraying a solvent at the same time so as to obtain the coating material. According to the invention, the solvent consumption is greatly reduced, and the obtained coating material powder has good fluidity.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

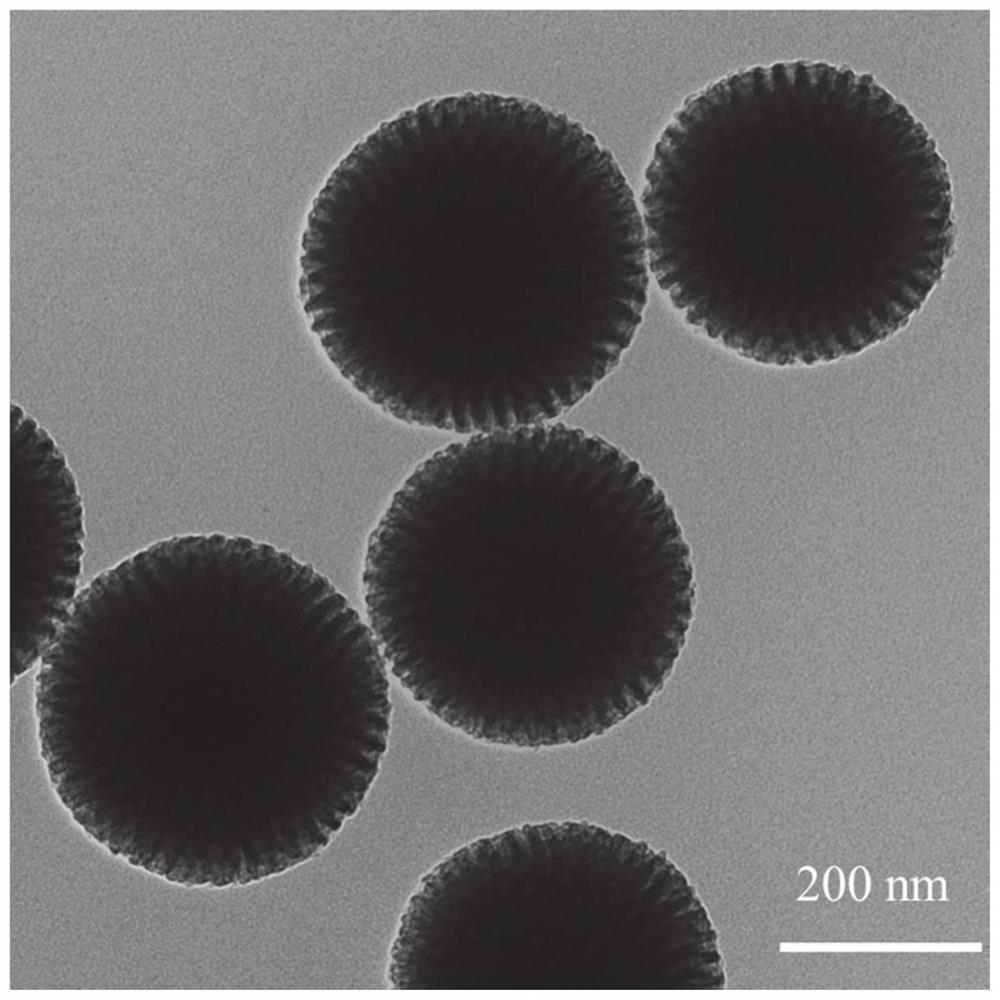

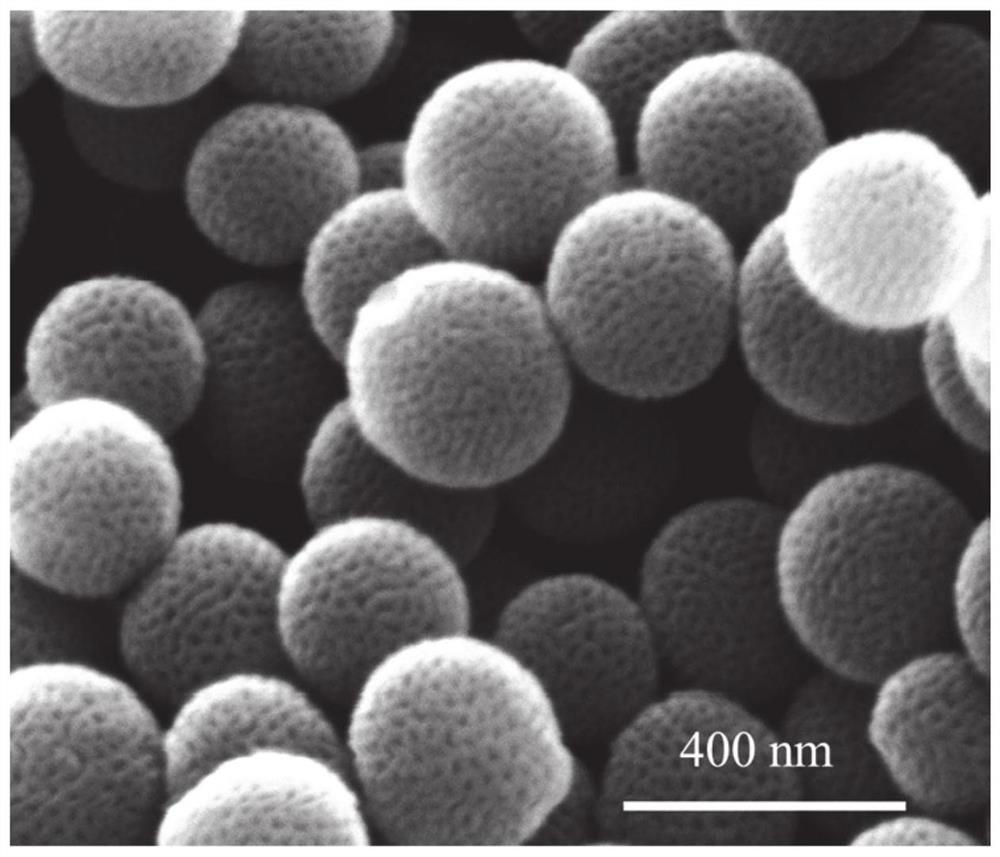

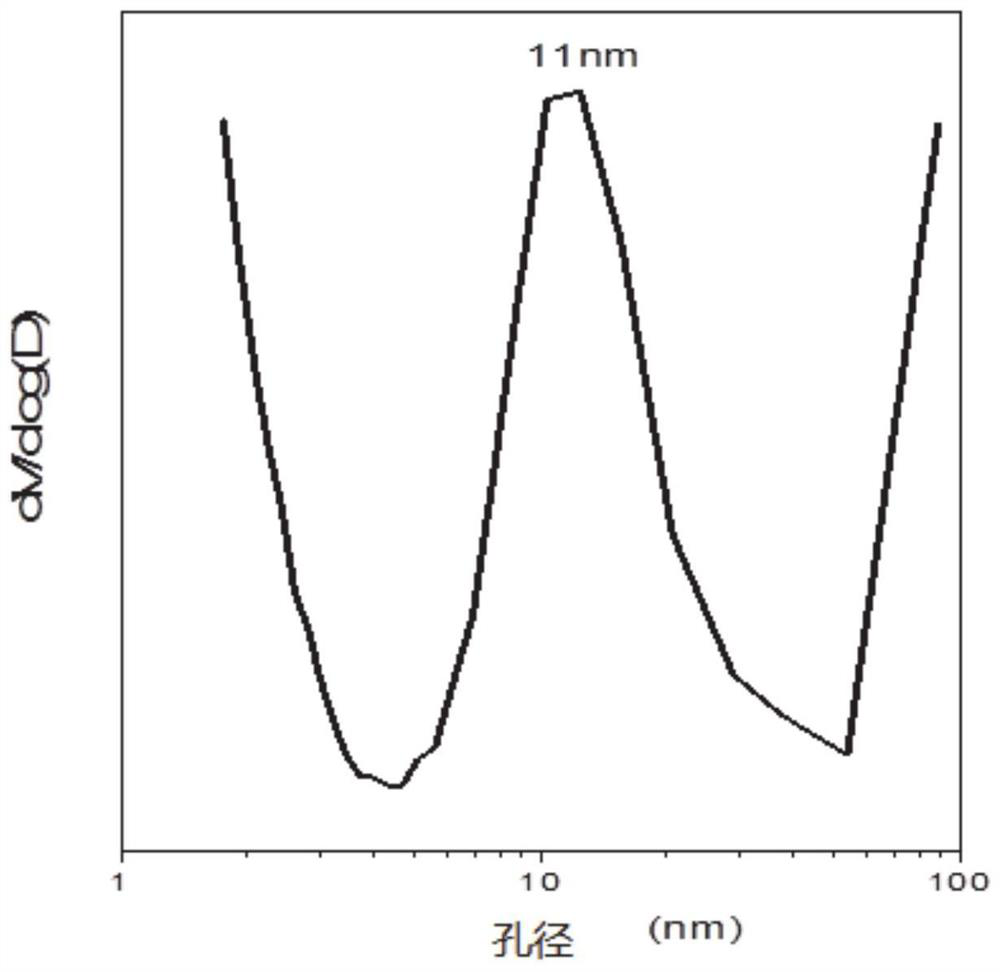

Mesoporous nano carbon sphere as well as preparation method and application thereof

PendingCN112758910ALess solvent usageAvoid reagent waste and contaminationCarbon preparation/purificationDrug deliveryAdsorption separation

The invention discloses mesoporous nano carbon spheres as well as a preparation method and an application thereof, and belongs to the technical field of nano materials. The preparation method comprises the following steps: dissolving a template agent in a water-alcohol solution, adding a pore-enlarging agent into the solution, and adjusting the pH value to be alkaline to obtain a dispersion liquid II; and adding a phenolic polymer monomer and formaldehyde into the dispersion liquid II, stirring at 25-70 DEG C to carry out polymerization reaction, and after the reaction is finished, separating, washing, drying and carbonizing to obtain the mesoporous carbon nanospheres, and the template agent is an amphoteric polymer; the pore-enlarging agent is a hydrophobic organic matter; the method has the advantages of simple operation, low cost, high yield, uniform product, stable output and the like, and has commercialization prospects; the pore channels of the prepared mesoporous carbon nanospheres are vertical pore channels and are in a radial shape from inside to outside, the diameters of the mesoporous carbon nanospheres are about 150-200nm, and the prepared mesoporous carbon nanospheres have excellent physical and chemical properties, so that the mesoporous carbon nanospheres are suitable for being applied to the fields of adsorption, separation, catalysis, energy storage and conversion, drug delivery and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for production of oxidized cyclic phenol sulfide

The invention discloses a process for producing an oxidized cyclic phenol sulfide, which comprises oxidizing a cyclic phenol sulfide represented by the general formula (1) as a raw material with an oxidizing agent by using a solvent other than a halogenated hydrocarbon in an amount of not smaller than 2 parts by weight and less than 10 parts by weight relative to 1 part by mass of the cyclic phenol sulfide, thereby producing an oxidized cyclic phenol sulfide represented by the general formula (2), wherein R represents a linear or branched alkyl group having 1 to 6 carbon atoms; and m represents an integer of 4 to 8, wherein R represents a linear or branched alkyl group having 1 to 6 carbon atoms; m represents an integer of 4 to 8; and n represents a number of 1 or 2.

Owner:HODOGAYA KAGAKU IND

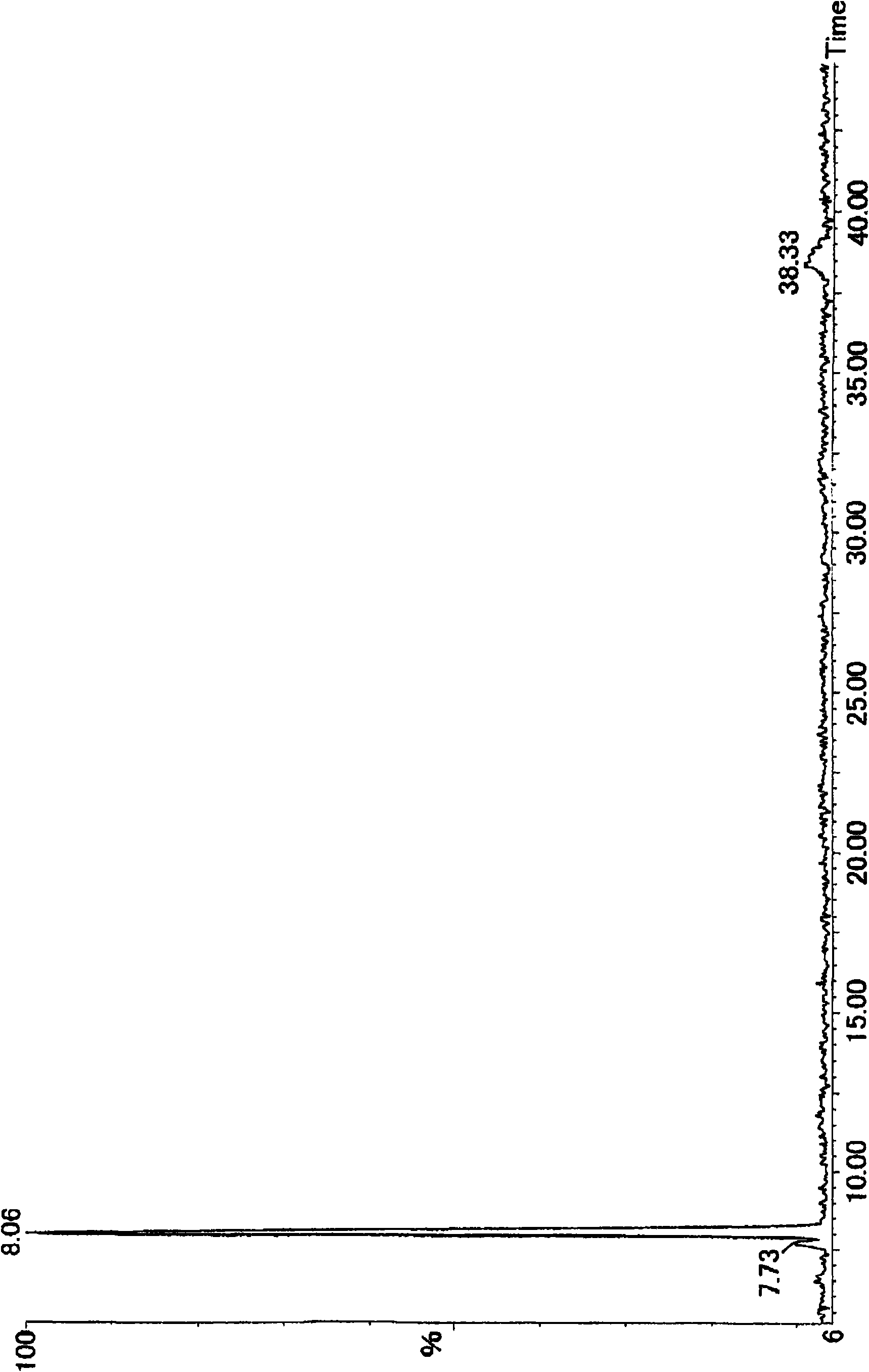

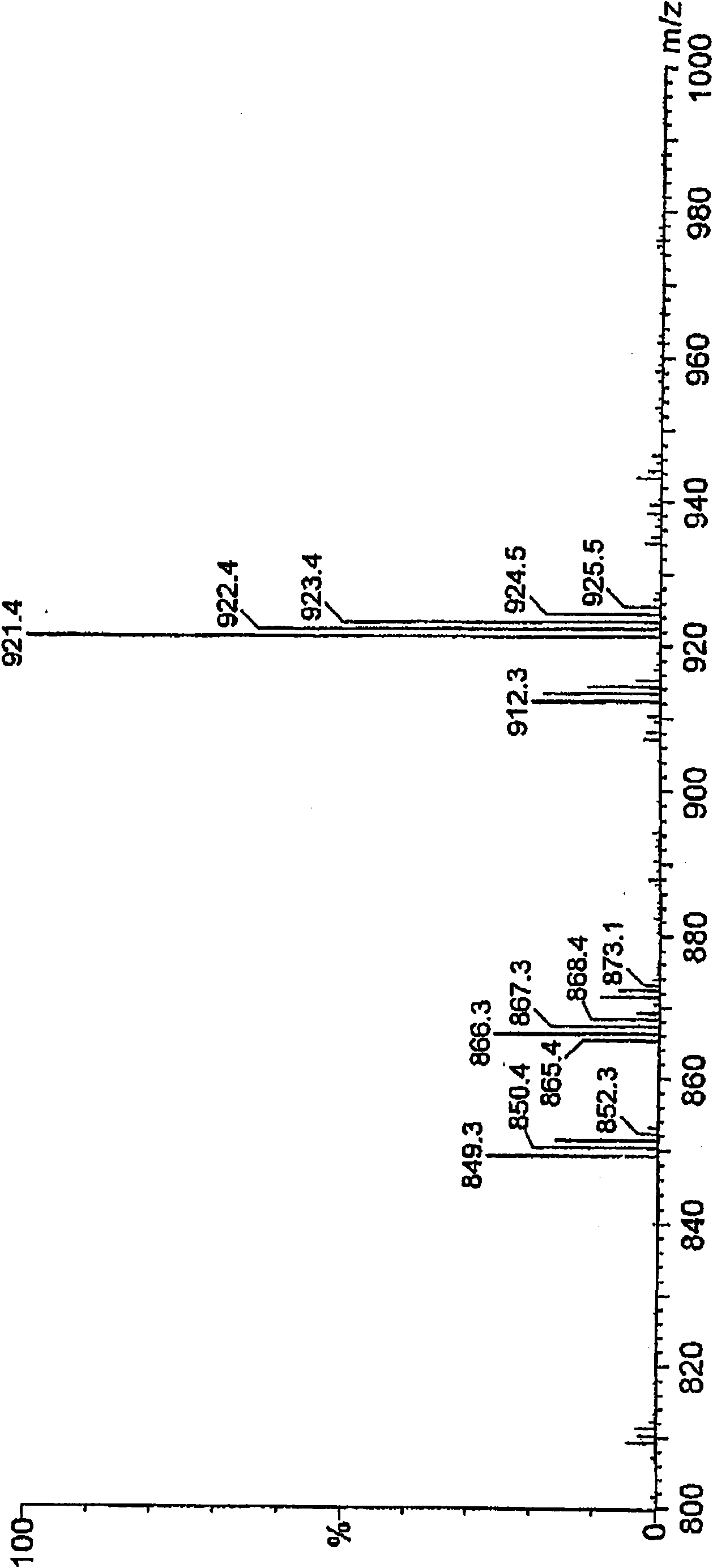

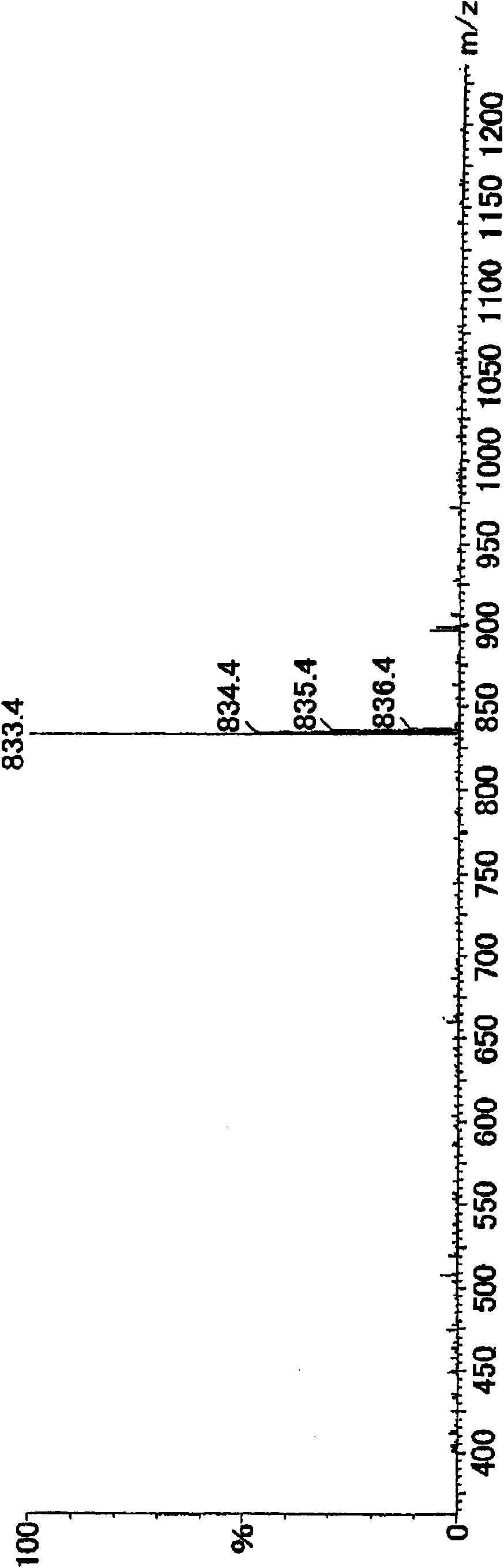

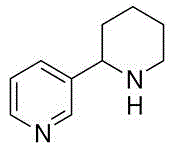

Preparation method of anabasine

The invention discloses a preparation method of anabasine. The preparation method comprises the following steps: raw material treatment, enzymolysis, ethanol ultrasonic extraction, purification, refinement and freeze-drying to obtain the anabasine. The method has the advantages of high efficiency and high speed, and is suitable for producing high-purity anabasine.

Owner:NANJING ZELANG MEDICAL TECH

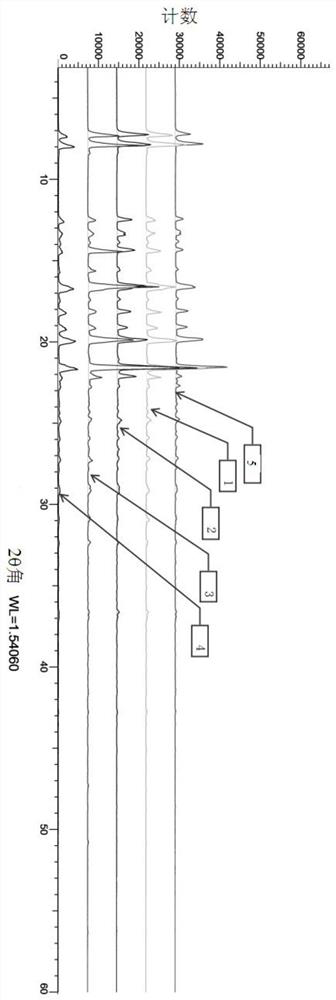

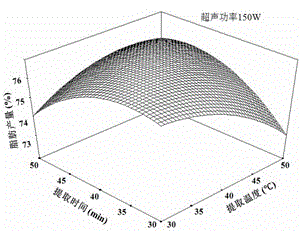

Method for extracting gynostemma pentaphylla seed oil through ultrasonic wave

InactiveCN103409231AShort extraction timeLess solvent usageFatty-oils/fats productionSolventChemistry

The invention discloses a method for extracting gynostemma pentaphylla seed oil through ultrasonic wave. The method comprises the following steps: peeling gynostemma pentaphylla fruit, picking seeds and then cleaning the seeds, drying, grinding and then filtering by a screen with 65 meshes, weighing powder, taking petroleum ether with the boiling range from 30 to 60 DEG C as extracting solution, and fully shaking up and then extracting under the ultrasonic condition. The method has the advantages that the extracting time is short, the solvent dosage is small, the extracting efficiency is high, the solvent recovering rate is high, the quality of the seed oil is good, the cost is low, and the investment is small.

Owner:SHAANXI NORMAL UNIV

Extracting method of tea polyphenol

PendingCN109535119AReduce extraction timeLess solvent usageOrganic chemistryChemistryControllability

The invention belongs to the technical field of tea polyphenol, and particularly relates to an extracting method of the tea polyphenol. A technology comprises six steps of soaking, extracting, centrifuging, precipitating, suction filtration, decreaming and leaching. By regulating technological parameters in all steps, effective components can be reserved to a larger extent, the added value of products can be increased, the extraction rate of the tea polyphenol can be effectively increased, the content of impurities can be reduced, and the quality of products is increased; particularly, coupling of a flash extraction technology and a micro-control extraction technology is adopted, so that the extracting method has the characteristics of high efficiency, fastness, low energy consumption, environment protection and strong controllability.

Owner:GUIZHOU INST OF TECH

Method for ultrasonic extraction of rice grain crude fat

InactiveCN105021435ALess solvent usageShorten the timePreparing sample for investigationAnimal scienceRice grain

The invention discloses a method for ultrasonic extraction of rice grain crude fat, and belongs to the crop physiological technology research field. The method includes the steps: drying and crushing rice grains; taking a suitable amount of the powder sample, adding an extracting solution and fully mixing; under an ultrasonic condition, extracting the crude fat, making fat enter the extracting solution, then removing insoluble impurities, and thus obtaining a fat solution. The method can achieve high-efficiency extraction of the rice grain crude fat with less solvent amount, lower temperature and power and shorter time, not only is applies to a small amount of sample, but also can satisfy processing of mass samples.

Owner:SICHUAN AGRI UNIV

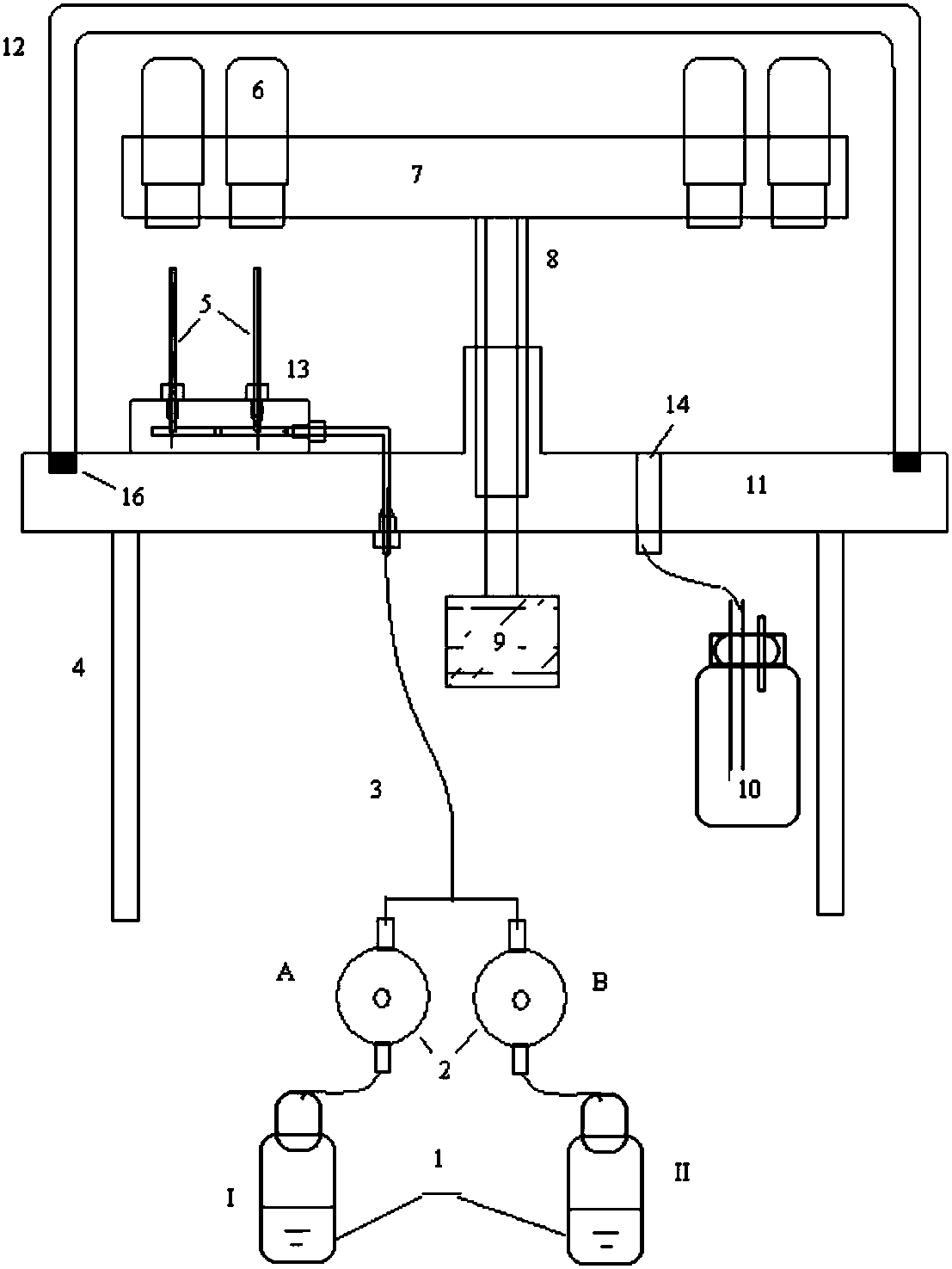

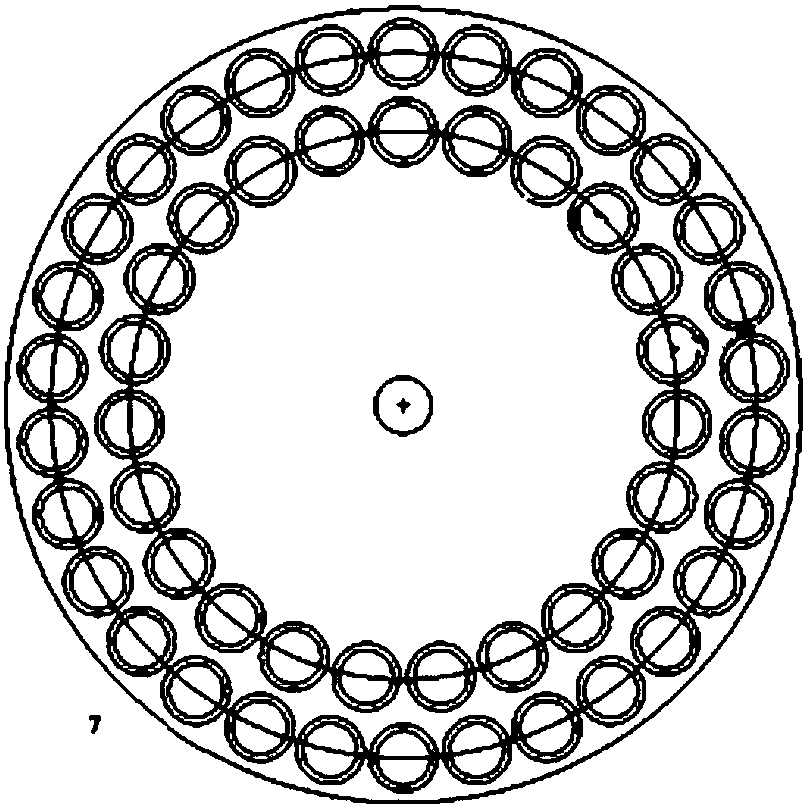

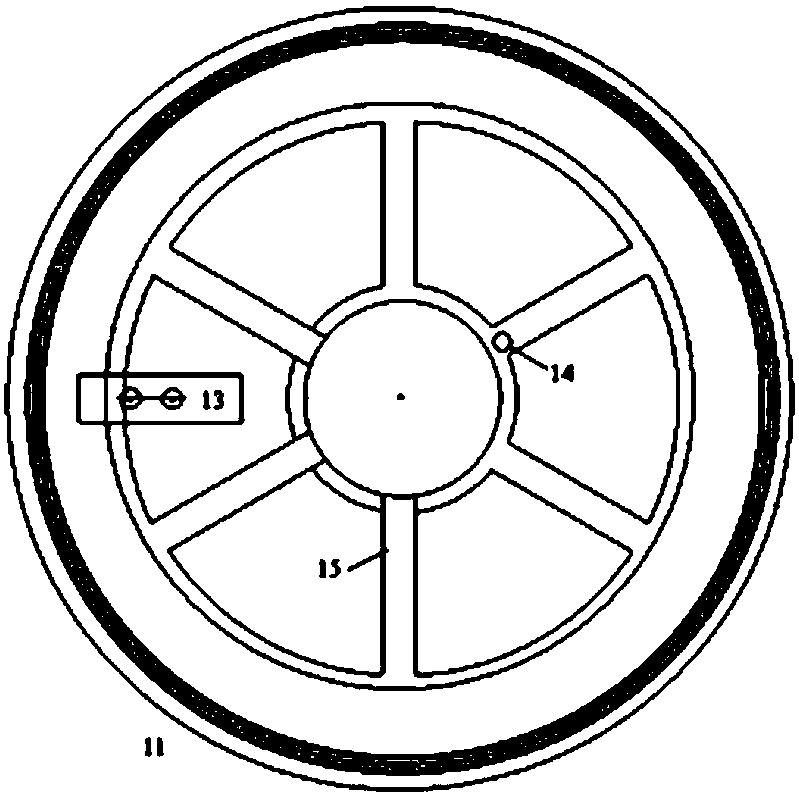

Automatic cleaning device for glass sample bottles

The invention belongs to the technical field of laboratory equipment cleaning and particularly relates to a device capable of cleaning sample introduction bottles automatically. The automatic cleaningdevice for the glass sample bottles aims at overcoming defects of the prior art and achieving the effects that interactive cleaning is conducted in a manner that different types of solvent can be adopted based on different pollutants in the sample bottles, and the automatic cleaning device is high in efficiency and portable. According to the technical scheme, the automatic cleaning device for theglass sample bottles comprises solvent bottles, plunger pumps, a pipeline, support feet, solvent spray heads, the sample bottles, a sample bottle wheel disc, a seal shaft, a speed reduction motor, abase plate, a glass housing, a nozzle base and a seal plug; the base plate is a disc, wherein a through hole is formed in the center of the disc; the glass housing is buckled onto the base plate; theseal plug is arranged between the lower edge of the glass housing and the base plate; the speed reduction motor is arranged below the base plate; the seal shaft is arranged on the speed reduction motor, penetrates the central through hole of the base plate and extends into the glass housing; and the sampled bottle wheel disc is arranged at the upper end, inside the glass housing, of the seal shaft.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate

InactiveCN101362735AReduce manufacturing costLess solvent usageOrganic chemistrySolventBenzyl chloroformate

The invention discloses a method for preparing 2[[(benzyloxy) carbonyl] amino]-4-thiazolyl acetate. In the method, alcohol is used as a reactant and a solvent; 1.0mol to 1.5mol of benzyl chloroformate and equal molar weight of alkaline are added in; 0.01mol to 0.10mol of 4-dimethylaminopyridine is used as a catalyst for reaction at -10 DEG C to 0 DEG C for 1h to 2h; the temperature is increased to 0 DEG C to 15 DEG C for 4h to 10h and filtration is carried out; the filtrate is added with 1.0mol of 2-amino-4-thiazolyl acetate for further reaction for 12h to 24h at the same temperature, and then the 2(((benzyloxy) carbonyl) amino)-4-thiazolyl acetate is produced. The method for preparing the 2(((benzyloxy) carbonyl) amino)-4-thiazolyl acetate has few reaction processes, low cost, simple operation, few 'three wastes'(waste gas, waste water and waste residues) and is in favor of industrialized production.

Owner:SHANDONG JINCHENG PHARMA & CHEM

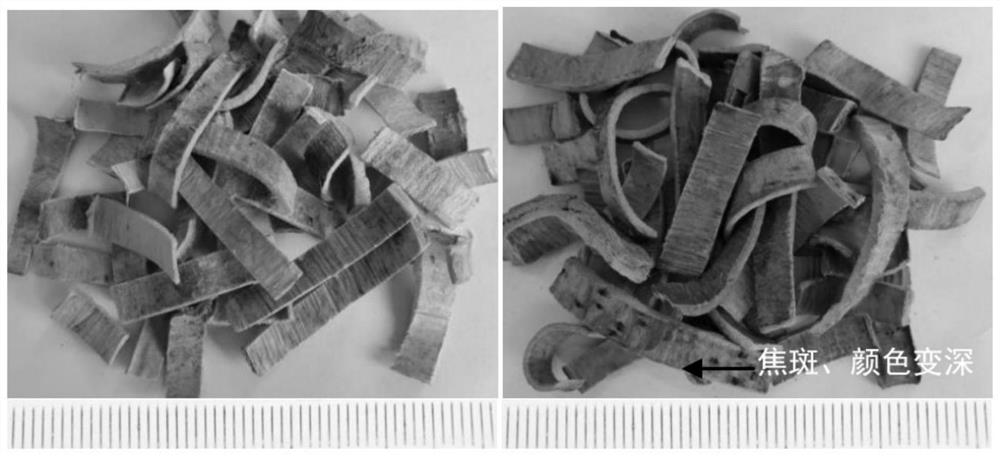

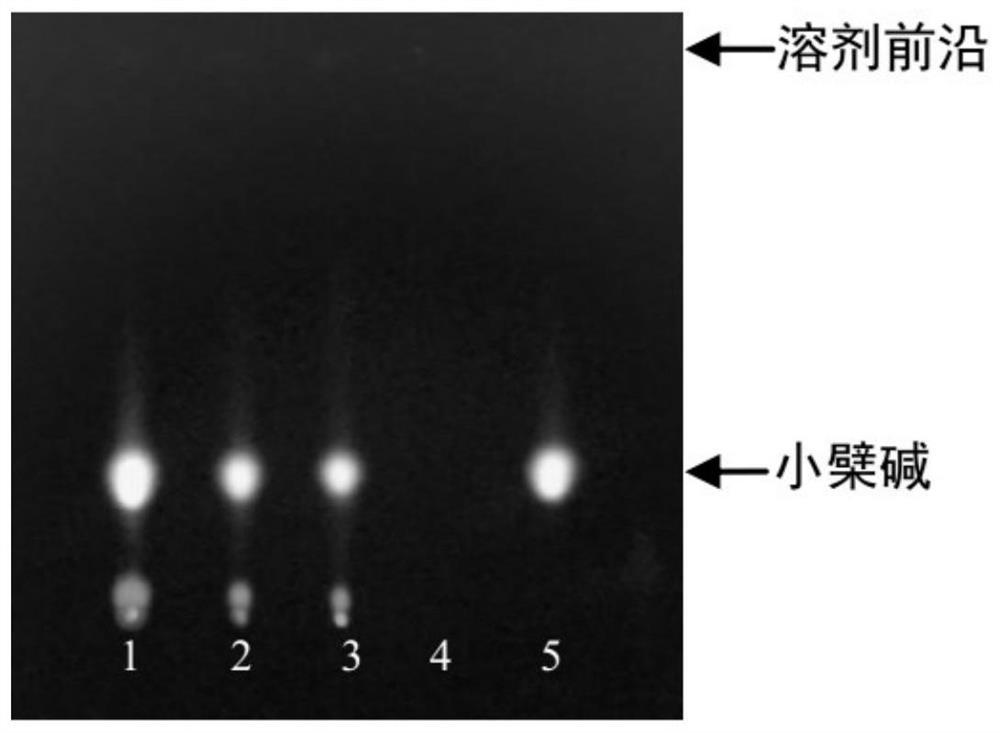

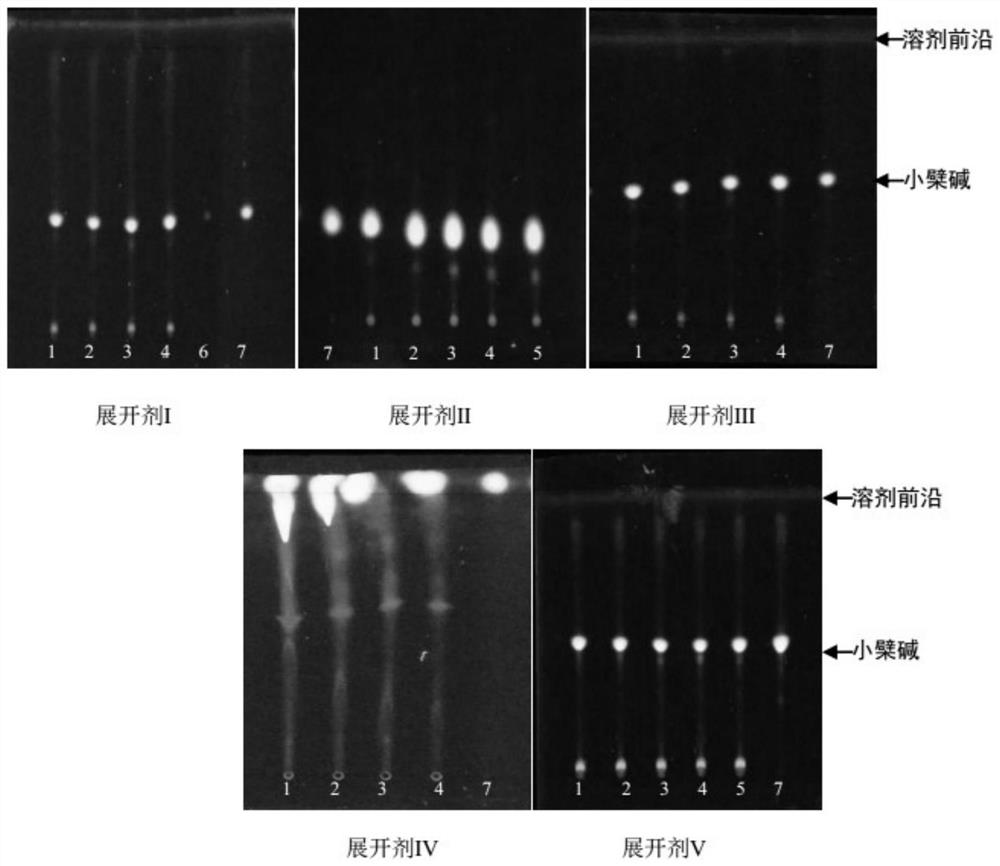

Thin layer chromatography identification method for golden cypress and golden cypress wine roasted product

PendingCN113252836ALess solvent usageSpot concentrationComponent separationThin-layer chromatographySolvent

The invention discloses a thin layer chromatography identification method for golden cypress and a golden cypress wine roasted product. The thin layer chromatography identification method comprises the following steps: (1) grinding a sample into powder to obtain medicinal material powder, mixing the obtained medicinal material powder with a first solvent, and extracting in an ultrasonic or heating reflux manner to obtain an extracting solution; (2) carrying out solid-liquid separation on the extracting solution obtained in the step (1), and adding a second solvent into the obtained liquid to prepare a test solution; and (3) carrying out sample application on the test solution and the reference solution obtained in the step (2) on a silica gel plate, spreading, taking out, drying, and inspecting under an ultraviolet lamp. According to the method provided by the invention, after the developing is finished in the developing solvent, the visual inspection is directly performed at 365 nm, so that the method is convenient and visual and the problems that in the prior art, a thin-layer plate needs to be placed in a saturated developing solvent in ammonia steam to be developed, a diluted bismuth potassium iodide test solution needs to be sprayed after development, then inspection is conducted, and operation is complex are solved.

Owner:山西省药品审评中心

Production of benzyl lidocaine halogenated amine

ActiveCN1982289ALess solvent usageShort reaction timeOrganic compound preparationCarboxylic acid amides preparationSolventKetone

Production of benzyl-lidocaine ammonium halide is carried out by reacting lidocaine with benzyl halide at 60-160degree in organic solvent, stopping reaction, cooling and crystallizing to obtain the final product. The organic solvent is selected from C5-C10 cyclanes, C6-C10 aryl halide and C4-C8 ketone. It has short reactive time and more solvent and can be used for large-scale industrial production.

Owner:浙江合糖科技有限公司

Method for extracting fraxinellone through subcritical fluid

InactiveCN102863414AImprove extraction efficiencyLess solvent usageOrganic chemistrySolventChemistry

The invention discloses a method for extracting fraxinellone through subcritical fluid. The method comprises the steps as follows: drying and crushing cortex dictamni, and adding to a subcritical extracting kettle; adding a polar organic solvent, and dynamically extracting for 30 to 80 minutes at 80 to 120 DEG C under pressure of 0.2 to 1Mpa to obtain extract; recovering reagent under reduced pressure to obtain concentrated solution; adding the concentrated solution to macroporous resin to be absorbed; eluting with 4 to 7 times of 60-90% ethanol solution based on column volume; concentrating eluant; extracting the concentrated eluant with petroleum ether for two to three times; collecting the petroleum ether layer, and recovering the reagent to obtain fraxinellone. With the adoption of the method for extracting fraxinellone disclosed by the invention, little solvent is used, energy comsumption is low, high efficiency is ensured, and industrial operation is easy to carry out.

Owner:NANJING ZELANG AGRI DEV

Separating purification method for atalantia buxifolia alkali

The invention relates to the technical field of extraction of plant effective components, in particular to a separating purification method for atalantia buxifolia alkali. The technical scheme of the method comprises the following steps of (1) performing continuous countercurrent ultrasonic extraction on single leaf atalantia buxifolia roots by utilizing 90% ethanol solution, and obtaining ethanol extract; (2) utilizing acid water of pH2-3 to dissolute the ethanol extract, and filtering the extract; (3) mixing concentrated ammonia or sodium hydroxide solution with filtrate till a pH value reaches 9-11, and utilizing an organic solvent to extract the filtrate; and (4) concentrating extract liquid, filling the extract liquid into a preparation type high performance liquid chromatograph, and obtaining an atalantia buxifolia alkali product. The separating purification method for the atalantia buxifolia alkali can extract and separate a product with the purity of 95% above from raw materials and achieve the effective separation of the atalantia buxifolia alkali.

Owner:NANJING ZELANG MEDICAL TECH

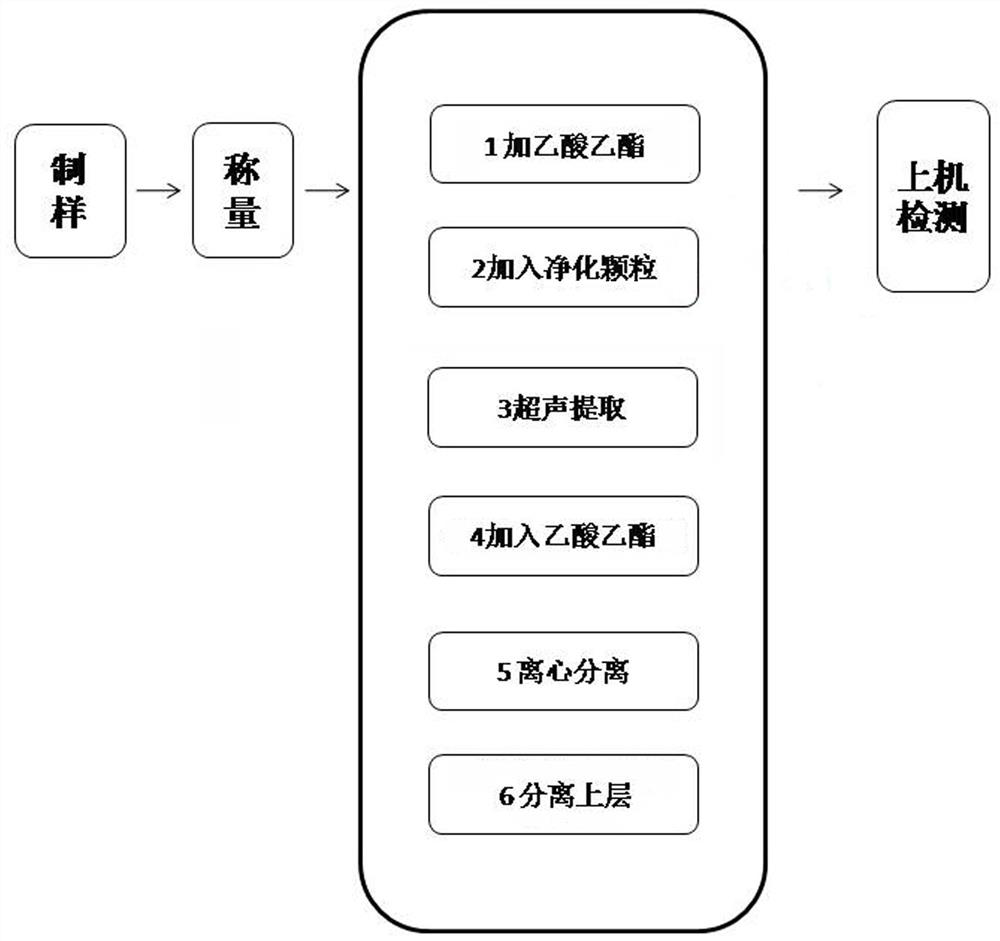

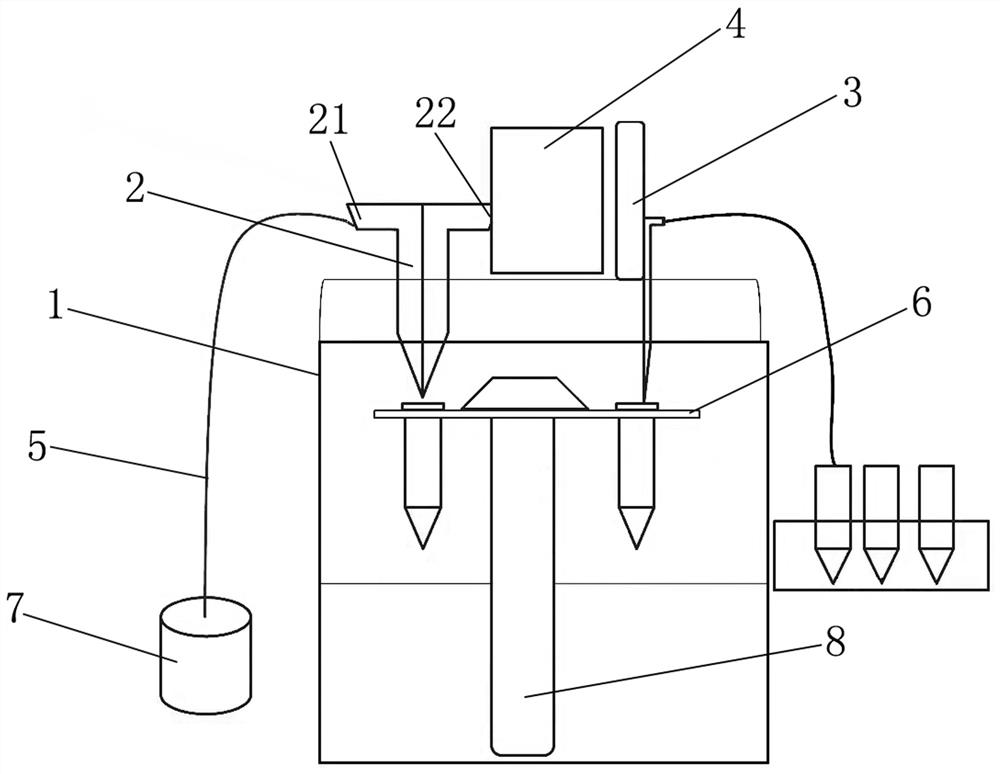

Sample treatment method and automatic treatment device

ActiveCN111965291ALess solvent usageGood purification effectComponent separationChemistryMolecular sieve

The invention discloses a sample treatment method and an automatic treatment device. The treatment method comprises the following steps of: modifying a ZSM-5 molecular sieve, adding a treatment agentand the ZSM-5 molecular sieve into a sample, performing ultrasonic extraction, carrying out centrifuging and separating supernatant. The automatic sample treatment device comprises a box body, a firstmechanical arm, a second mechanical arm, an adsorbent storage tank and a solvent storage tank. During working, the first mechanical arm adds a treatment agent and a molecular sieve into a centrifugetube, a rotor carrying the centrifuge tube descends to perform ultrasonic extraction and centrifugation on a solution in the tube, and then the second mechanical arm sucks supernatant for detection. According to the sample treatment method and the automatic treatment device, the treatment efficiency can be improved, the automation of the whole sample treatment process is completed, and the operation accuracy and safety are improved.

Owner:长治市农产品质量安全检验监测中心

Method for preparing hydrochloric venlafaxine new crystal C

InactiveCN101205191AEasy to operateLess solvent usageOrganic compound preparationAmino-hyroxy compound preparationSolventCombinatorial chemistry

The invention relates to a preparation method for crystal form C of the venlafaxine hydrochloride, which comprises the following steps: A. dissolver; B. crystallization and pumping filtration; C. vacuum drying. The preparation method of the invention for crystal form C of the venlafaxine hydrochloride has simple operation, requires a small used amount of the solvents, requires a simple process of the solvent recycling and has low cost, and is beneficial to the large-scale industrialized production. The utilization of the preparation method of the invention can lead to the acquisition of the crystal form C of the venlafaxine hydrochloride and the purity of the products is high and meets the requirement of the drug specification; the products are easy to be stored, the resistance can be kept stable for a long time and the yield of the products is high.

Owner:ZHEJIANG APELOA JIAYUAN PHARMA

Double-column solid-phase extraction method for nitrogen-containing compounds in diesel oil

ActiveCN106318438BEfficient separationReduce dosageComponent separationSolid sorbent liquid separationStationary phaseNitrogen

A double-column solid phase extraction method of nitrogen-containing compounds in diesel oil comprises the following steps: 1, producing solid phase extraction columns, wherein the stationary phase of the solid phase extraction column A is a silica gel and acidic alumina mixture, and the stationary phase of the solid phase extraction column B is a silica gel and alkaline alumina mixture; and 2, eluting: wetting the solid phase extraction column A by a first eluent, adding a diesel oil sample from an upper layer, flushing the solid phase extraction column A with the first eluent to obtain saturated hydrocarbons, flushing the solid phase extraction column A with a second eluent to obtain aromatic hydrocarbons, flushing the solid phase extraction column A with a third eluent to obtain neutral nitrogen-containing compounds, serially connecting the solid phase extraction column A with the solid phase extraction column B, and flushing the solid phase extraction columns A and B with a fourth eluent to obtain alkaline nitrogen-containing compounds, wherein the column A is arranged above the column B.

Owner:PETROCHINA CO LTD +1

Preparation method of gambogic acid

The invention discloses a preparation method of gambogic acid. The preparation method specifically comprises the following steps that (1) the traditional Chinese medicine resina garciniae morellae isdried, smashed, sieved and packed into an extraction container; (2) the resina garciniae morellae is subjected to reflux extraction for several times by using an organic solvent, the extraction liquidis combined, the organic solvent is recycled, the extraction liquid is concentrated to be at the appropriate amount; (3) the extraction liquid is packed into a device with the weak polarity microporous adsorption resin to be adsorbed, eluant is injected into the device to conduct elution; (4) silica gel separation treatment is conducted; and (5) crystallization and refining treatment is conducted. The preparation method of gambogic acid replaces a traditional extraction method with adsorption of weak polarity microporous adsorption resin, thus the using amount of the solvent is decreased, andenvironmental protection and cost reduction are achieved. Meanwhile, the method is simple, convenient and rapid, the separation efficiency is high, and a good effect is achieved.

Owner:湖州展舒生物科技有限公司

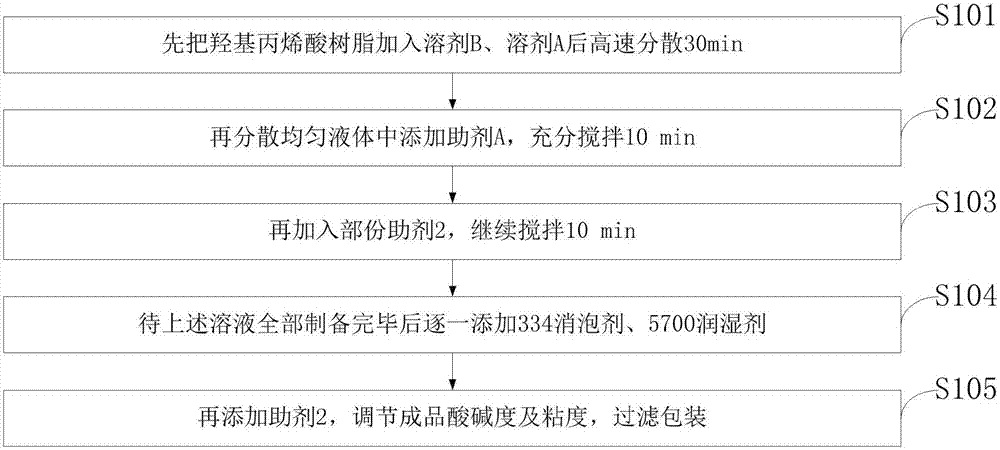

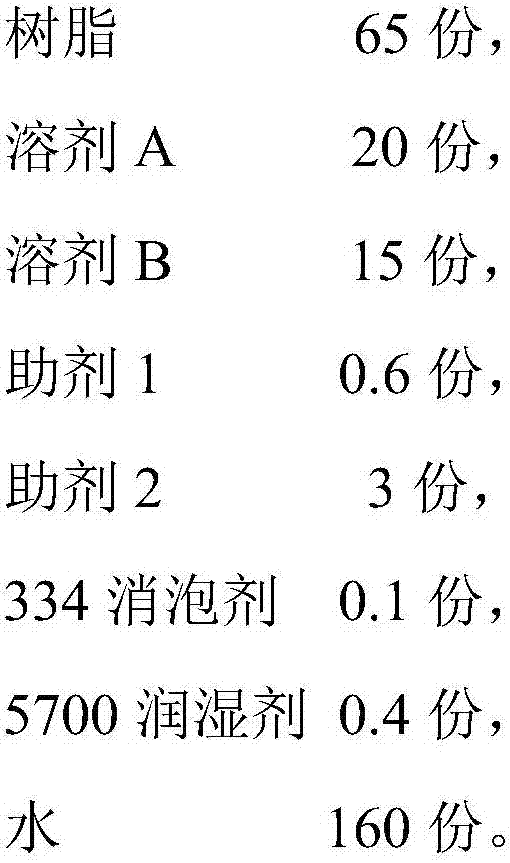

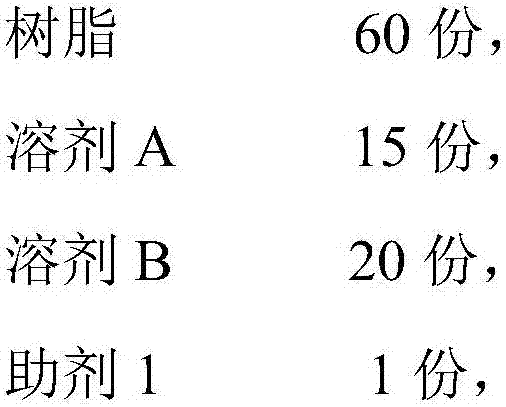

Light oil and water-borne light oil preparation method based on clear paint prepared from oleoresin

InactiveCN107236383AHigh hardnessLess solvent usageAntifouling/underwater paintsPaints with biocidesSolventChemistry

The invention belongs to the technical field of water-borne paint, and discloses light oil and a water-borne light oil preparation method based on clear paint prepared from oleoresin. The light oil comprises resin, solvent A, solvent B, additive 1, additive 2, antifoaming agent 334, wetting and emulsifying agent and water. The water-borne light oil preparation method includes: adding the solvent A and the solvent B in the resin, adding the additive 1 and part of the additive 2, keeping stirring, adding the antifoaming agent 334 and wetting agent 5700 one by one, keeping stirring uniformly, adding the left additive 2, adjusting acidity, alkalinity and viscosity of a finished product, filtering and packaging. According to the water-borne light oil preparation method, the clear paint, which is an oily film forming matter, is treated by special additives and turned into the pure water-borne light oil, the paint film formed from the light oil is ensured to have hardness, pollution resistance, water resistance and scratch resistance of an oily paint film, and as compared with oily light oil, the water-borne light oil needs less diluting solvent during construction, and thereby having less pollution, less harm to constructors and being more environmental friendly.

Owner:FUJIAN PUTIAN CAILON CHEM CO LTD

Crystallization process of dexibuprofen

ActiveCN112500283ALess solvent usageHigh cost advantageOrganic chemistry methodsCarboxylic compound separation/purificationPhenethylaminesDexibuprofen

The invention discloses a crystallization process of dexibuprofen, which comprises the following steps: step 1, dissolving a dexibuprofen crude product in acetone to obtain an acetone solution, filtering, and concentrating the acetone in filtrate under reduced pressure until the acetone is dry to obtain a solid; step 2, adding acetone into the solid, heating to dissolve, cooling, and stirring to slowly separate out crystals; step 3, after observing that crystals are separated out, keeping the temperature and the rotating speed unchanged, and evaporating out acetone by using micro negative pressure; and step 4, after the material is completely converted into white crystals, starting vacuum to continue to evaporate acetone, and then transferring the solid into a vacuum oven for drying to obtain a finished product. According to the prepared dexibuprofen crystal, the crystal form consistent with that of an original product can be stably obtained, the granularity is uniform, and after crushing, the particle size meeting the requirements of a dexibuprofen preparation can be obtained; the yield can reach 93-98%, the ee% value is greater than or equal to 99.0%, the content of a resolving agent S-phenylethylamine is less than or equal to 0.1%, and the quality is stable and reliable.

Owner:湖南华纳大药厂手性药物有限公司 +2

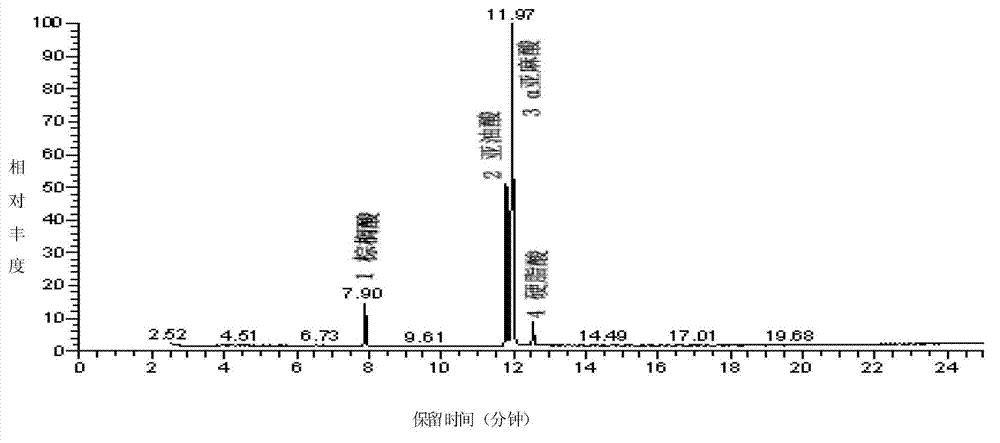

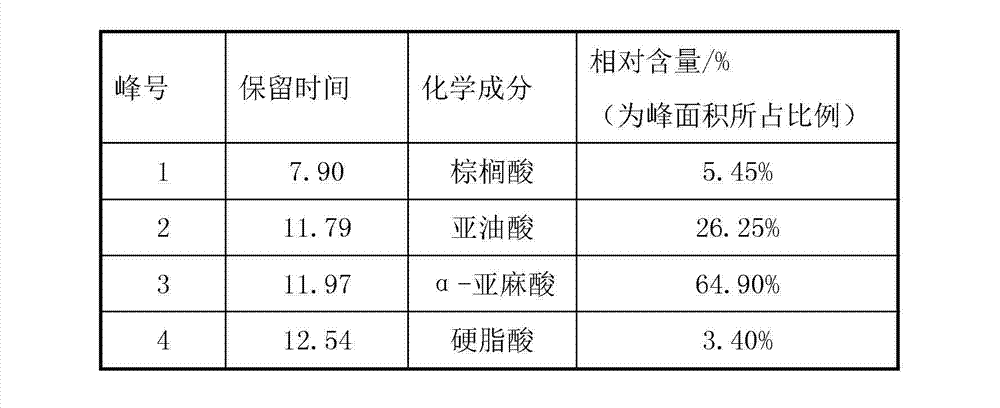

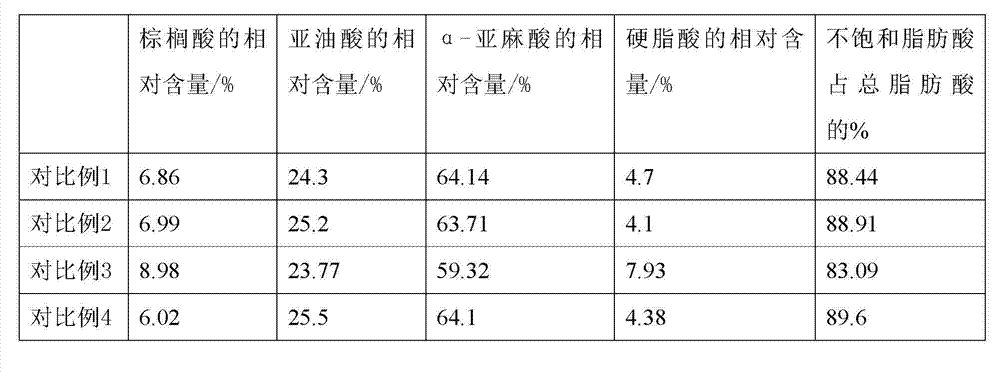

Method for extracting unsaturated fatty acid from bischofia polycarpa fruits

InactiveCN103113981AHigh extraction rateLess solvent usageFatty-oils/fats productionUnsaturated fatty acidSolvent

The invention discloses a method for extracting unsaturated fatty acid from bischofia polycarpa fruits. The method comprises the following steps: 1) crushing the bischofia polycarpa fruits which are dried to reach constant weight, thus obtaining the crushed bischofia polycarpa fruits; 2) adding normal hexane serving as a solvent to the crushed bischofia polycarpa fruits based on the solid-to-liquid ratio of 1g: 5-8ml, and ultrasonically extracting for 0.8 to 1.2 hours at ultrasonic power of 200 to 500w and extraction temperature of 25 DEG C, and then respectively extracting the liquid and the residue; 3) cleaning the residue through the normal hexane so as to obtain the washing solution; and 4) combining the extracting solution with the washing solution, and carrying out rotary evaporation to recover the normal hexane, so as to obtain the bischofia polycarpa fruits containing the unsaturated fatty acid. The method for extracting the unsaturated fatty acid from the bischofia polycarpa fruits has the characteristics of being simple in process, high in yield and free from pollution in the process.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

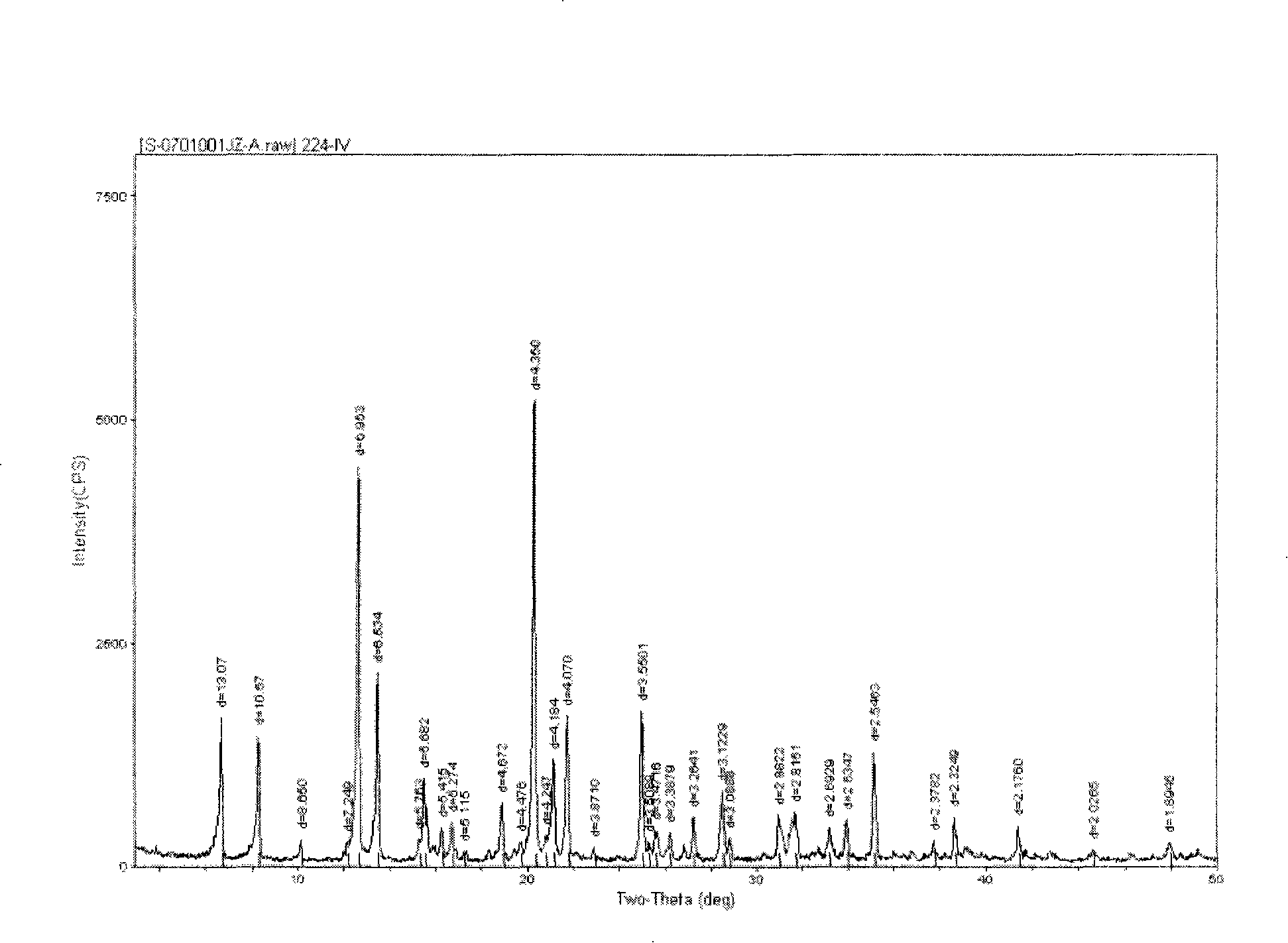

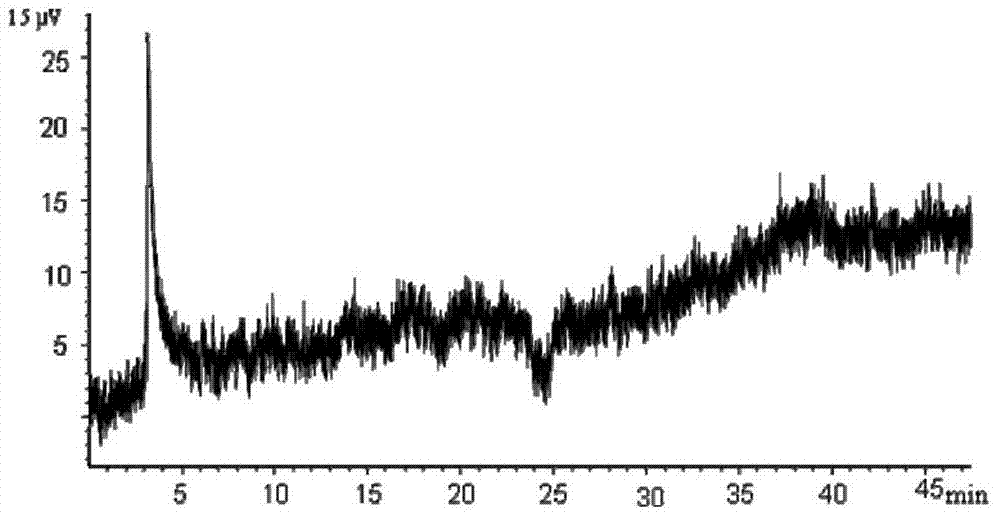

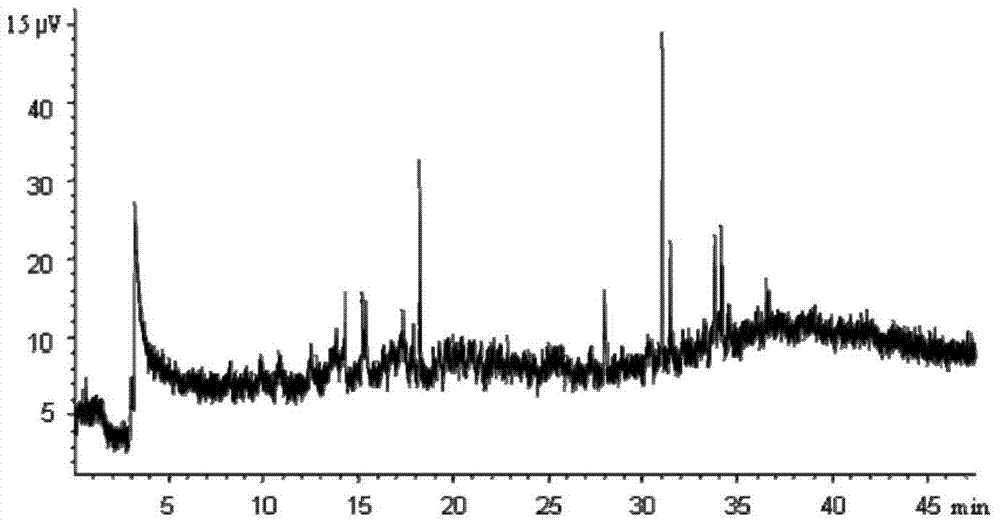

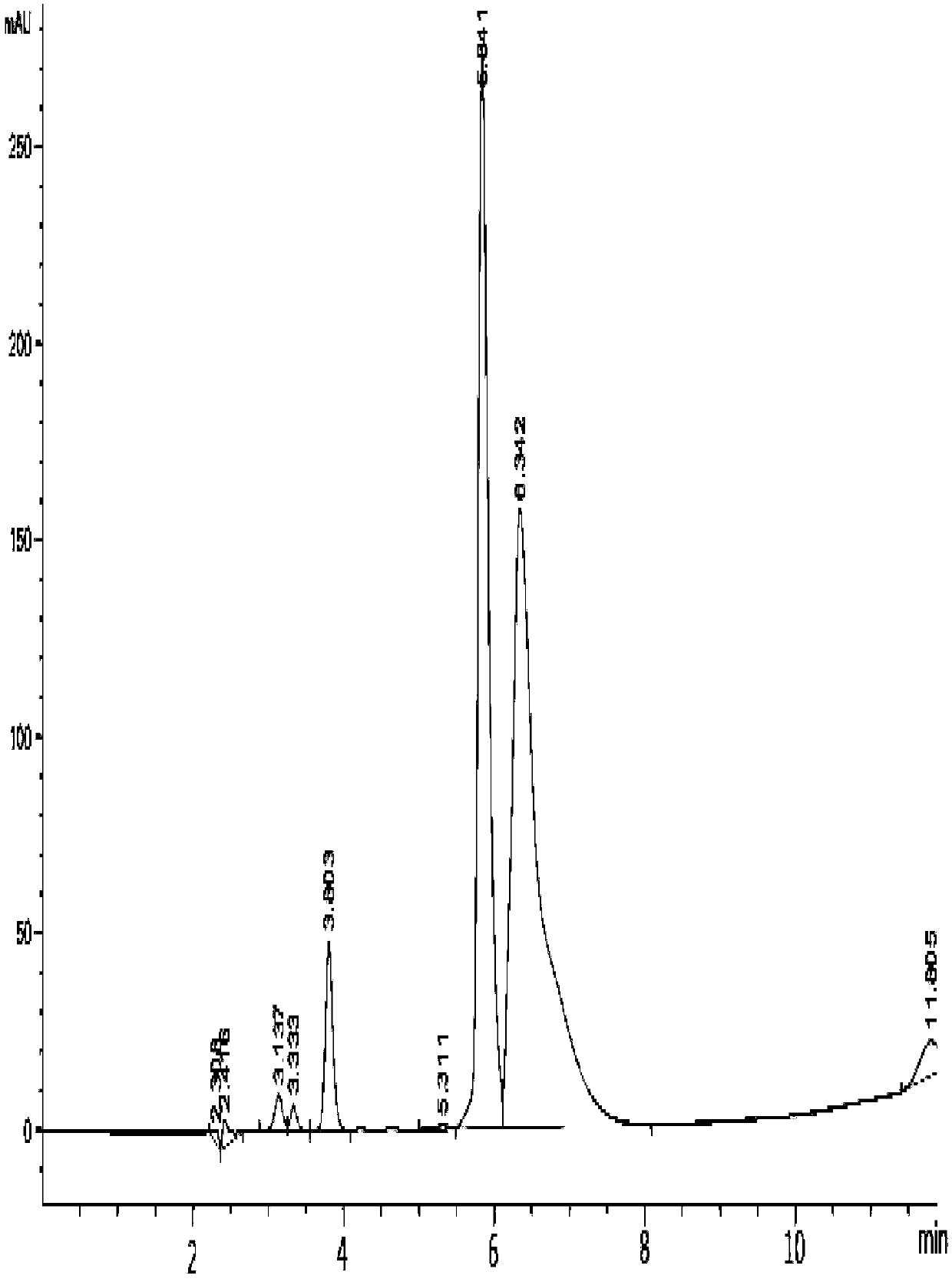

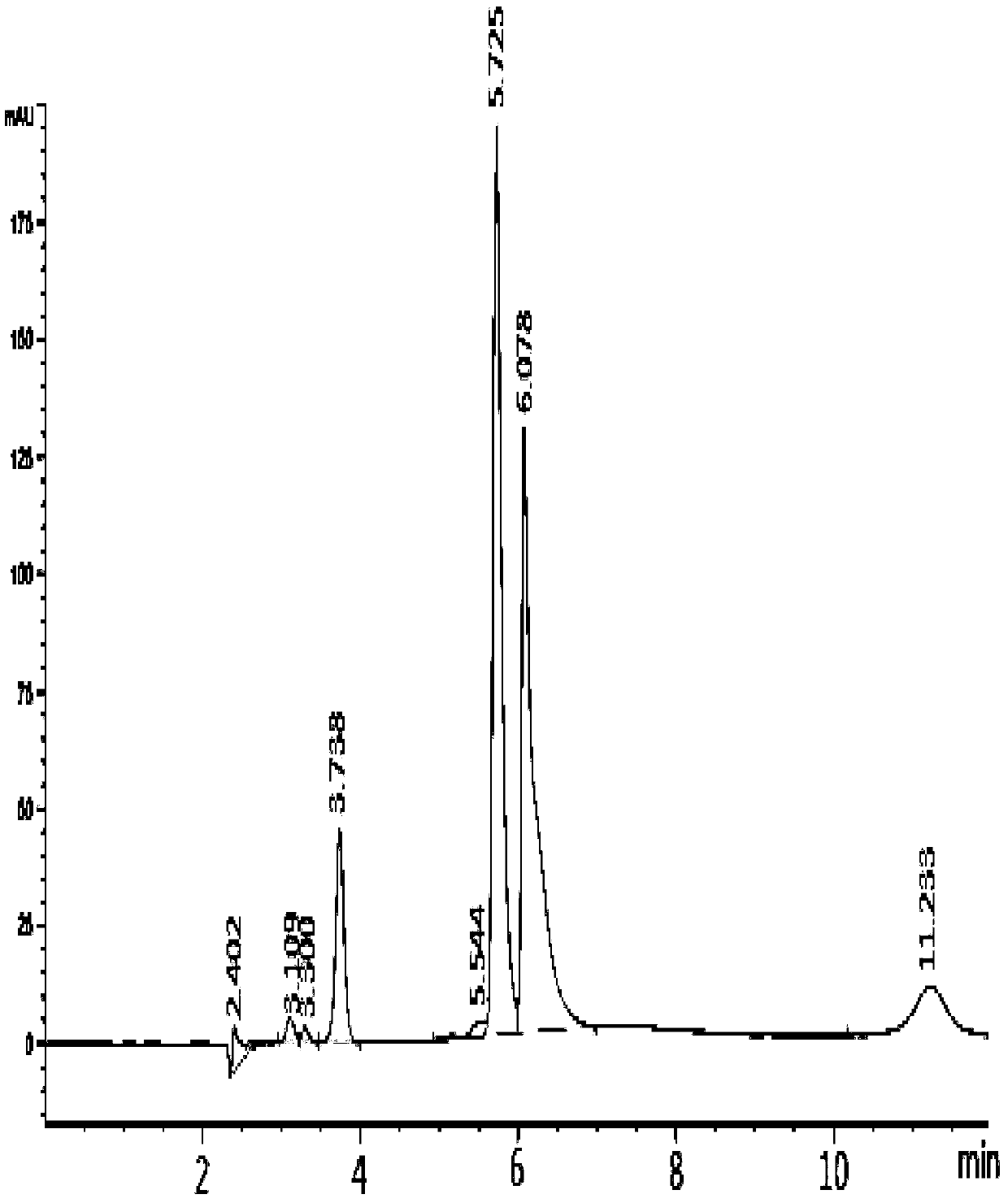

![Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate](https://images-eureka.patsnap.com/patent_img/284c6a4a-838a-447d-a259-d865b36f28ef/a200810140234c00021.PNG)

![Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate](https://images-eureka.patsnap.com/patent_img/284c6a4a-838a-447d-a259-d865b36f28ef/a200810140234d00031.PNG)

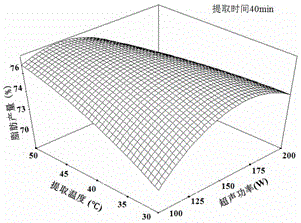

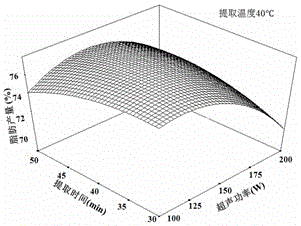

![Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate Preparation method of ethyl 2-[[(bezyloxy)carbonyl]amido]-4-thiazolyl acetate](https://images-eureka.patsnap.com/patent_img/284c6a4a-838a-447d-a259-d865b36f28ef/a200810140234d00041.PNG)