High-sphericity fine thermoplastic powder coating material and preparation method thereof

A powder coating and thermoplastic technology, used in the field of high sphericity fine thermoplastic powder coatings and preparation, can solve the problems of low fluidity affecting coating quality, and achieve the effects of good powder fluidity, reduced solvent consumption and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

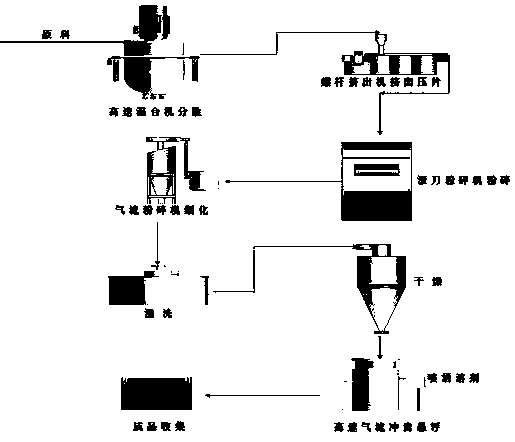

[0053] as per figure 1 Process flow shown:

[0054] Step 1: Take 1.2Kg of thermoplastic polymer polyethylene, 40g of pigment, 30g of antioxidant 1010, 300g of talcum powder filler, and 500g of sodium chloride soluble salt and add it to a plastic high-speed mixer and stir at a high speed. The stirring speed is 500rpm; the time of stirring is controlled After 30 minutes, disperse evenly, and then extrude into tablets through a co-rotating twin-screw extruder at 170°C;

[0055] Step 2: Put the compressed tablet obtained in Step 1 into a hob mill for coarse crushing to obtain a coarse powder; crush the obtained coarse powder through a jet mill, classify and sieve to obtain a fine polymer coarse material with a particle size below 30 μm , the grading speed of the jet mill is controlled at 1600rpm, and the air inlet of the jet mill assists in entering the liquid nitrogen gas;

[0056] Step 3: Soak the micronized coarse polymer material prepared in step 2 in clean water and wash it...

Embodiment 2

[0060] Step 1: Take 1.3Kg of thermoplastic polymer polyethylene, 40g of pigment, 40g of antioxidant 168, 300g of talcum powder filler, and 500g of sodium chloride soluble salt and add it to a plastic high-speed mixer and stir at a high speed. The stirring speed is 600rpm; the stirring time is controlled After 30 minutes, disperse evenly, and then extrude into tablets through a co-rotating twin-screw extruder at 170°C;

[0061] Step 2: Put the compressed tablet obtained in Step 1 into a hob mill for coarse crushing to obtain a coarse powder; crush the obtained coarse powder through a jet mill, classify and sieve to obtain a fine polymer coarse material with a particle size below 30 μm , the grading speed of the jet mill is controlled at 1600rpm, and the air inlet of the jet mill assists in entering the liquid nitrogen gas;

[0062] Step 3: Soak the micronized coarse polymer material prepared in step 2 in clean water and wash it, remove most of the soluble salts, centrifugally d...

Embodiment 3

[0065] Step 1: Take 1.4Kg of thermoplastic polymer polyethylene, 50g of pigment, 30g of antioxidant 1010, 300g of mica powder filler, 500g of sodium chloride soluble salt and add it into a plastic high-speed mixer and stir at a high speed. The stirring speed is 600rpm; the time of stirring is controlled After 30 minutes, disperse evenly, and then extrude into tablets through a co-rotating twin-screw extruder at 170°C;

[0066] Step 2: Put the compressed tablet obtained in Step 1 into a hob mill for coarse crushing to obtain a coarse powder; crush the obtained coarse powder through a jet mill, classify and sieve to obtain a fine polymer coarse material with a particle size below 30 μm , the grading speed of the jet mill is controlled at 1600rpm, and the air inlet of the jet mill assists in entering the liquid nitrogen gas;

[0067] Step 3: Soak the micronized coarse polymer material prepared in step 2 in clean water and wash it, remove most of the soluble salts, centrifugally d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com