Light oil and water-borne light oil preparation method based on clear paint prepared from oleoresin

A technology of oleoresin and water-based varnish, which is applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc. It can solve the problems of water resistance, high VOC, heavy pollution, etc., and achieve less solvent consumption, Simple construction and low damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

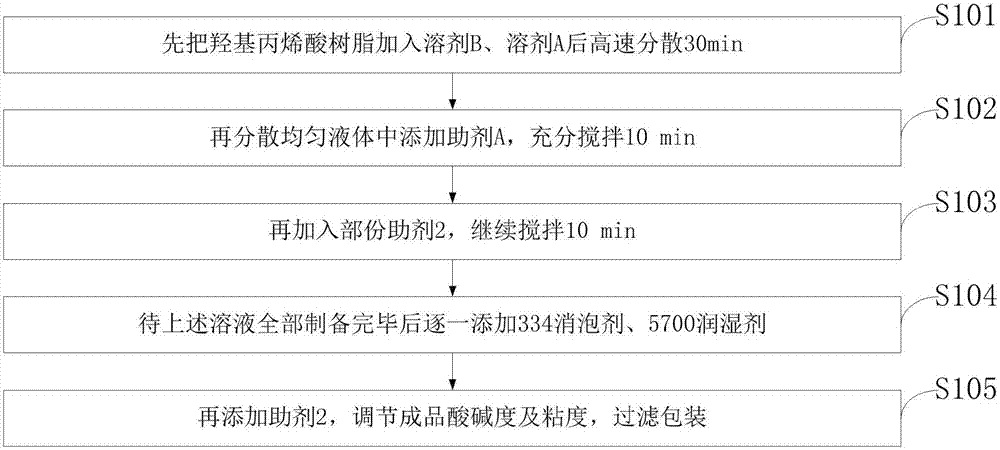

Method used

Image

Examples

Embodiment 1

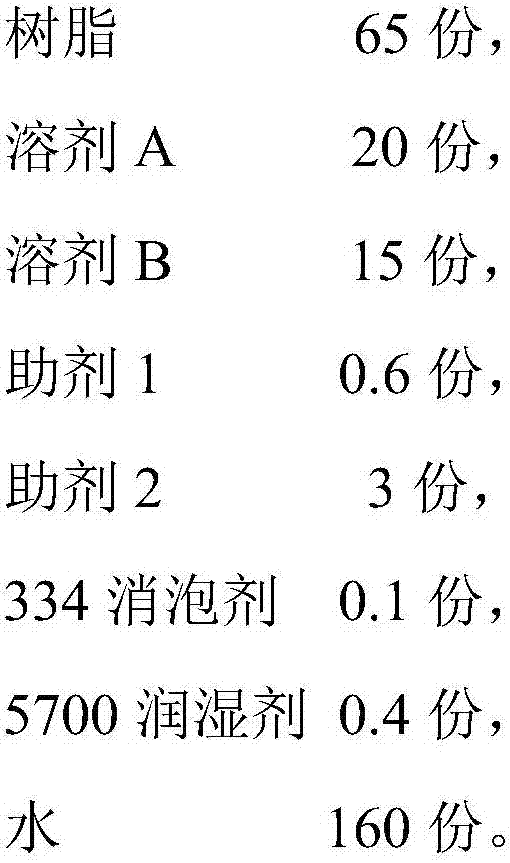

[0045] The transparent varnish prepared by the oleoresin provided by the embodiment of the present invention is changed to water-based varnish, and when high-gloss varnish is required, it is formulated in the following proportions:

[0046]

Embodiment 2

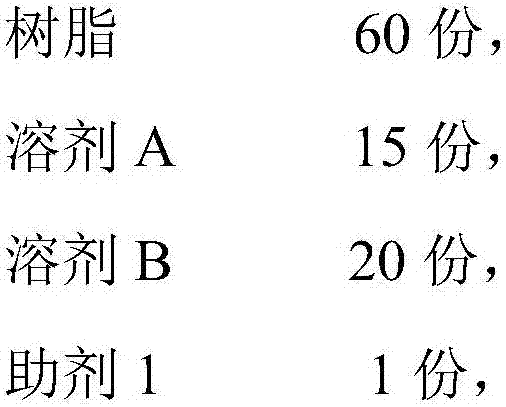

[0048] The transparent varnish prepared by the oleoresin provided by the embodiment of the present invention is changed to water-based varnish, and when low-gloss varnish is required, it is formulated in the following proportions:

[0049]

[0050]

Embodiment 3

[0052] The transparent varnish prepared by the oleoresin provided by the embodiment of the present invention is changed to water-based varnish, and when a matte varnish is needed, it is formulated in the following proportions:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com