Super-branched polyester and preparation method as well as application in high-speed stretch electrostatic spinning thereof

A technology of hyperbranched polyester, spinning solution, applied in the manufacture of rayon, chemical characteristics of fibers, textiles and papermaking, etc., can solve the control without involving the spinning shape, increase the processing temperature, cannot generally improve the spinning phenomenon and other problems, to solve the phenomenon of fiber entanglement and filament doubling, improve the fiber morphology, and reduce the amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

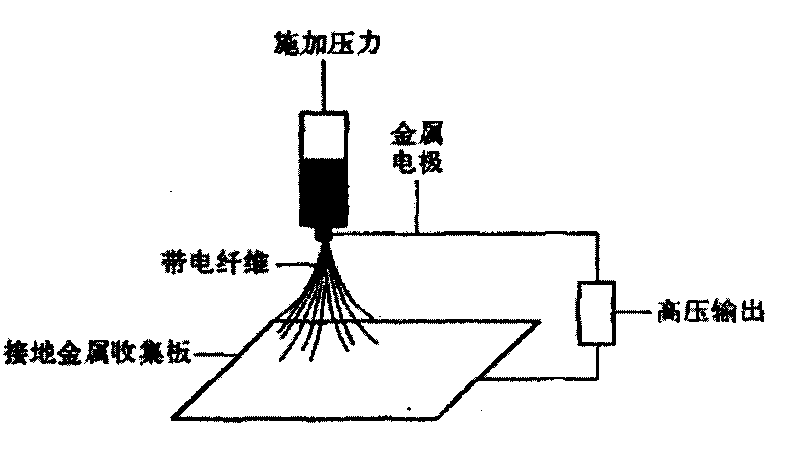

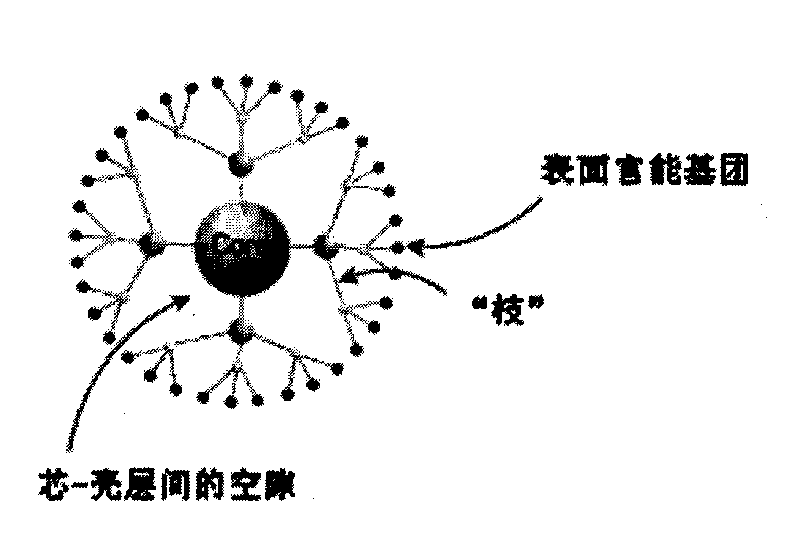

Method used

Image

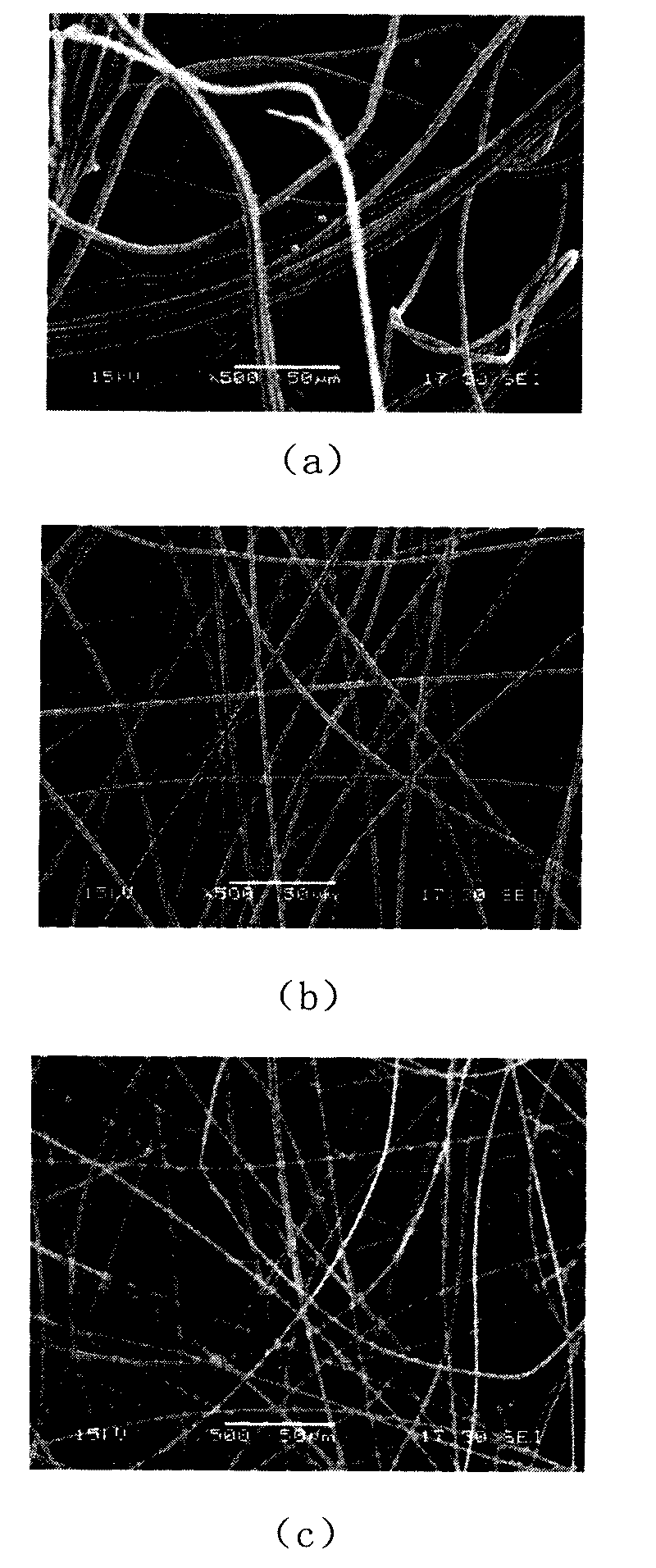

Examples

Embodiment 1

[0045] Preparation of hyperbranched polymers with acetyl-terminated polymers and their use as electrospinning additives:

[0046]

[0047] Under anhydrous and anaerobic conditions, add 5.0g (2.9mmol) H2O, 0.15g 4-dimethylaminopyridine (DMAP) (3-4% relative to the mass fraction of H20) to the Schlenk bottle in sequence according to a certain stoichiometric ratio. %), 11.2ml (138.7mmol) pyridine as catalyst, and 15ml tetrahydrofuran as solvent, slowly add 10.0ml (138.7mmol) acetyl chloride dropwise to the system using a dropping funnel, and react overnight in an ice-water bath. Add an appropriate amount of 1mol / L dilute HCl dropwise to the crude product to remove unreacted pyridine and DMAP, then extract and separate the liquids with saturated NaCl and ethyl acetate solution three times, take the upper organic phase and wash it with anhydrous MgSO 4 After drying for 2h, the target product was obtained after removing ethyl acetate with a rotary evaporator, and the productive r...

Embodiment 2

[0049] Preparation of hyperbranched polymers with n-octanoyl end groups and their use as electrospinning additives:

[0050] 1) Preparation of n-octanoyl chloride:

[0051]

[0052] Under anhydrous conditions, add 2.2ml (13.9mmol) n-octanoic acid) and 2.0ml (27.8mmol) thionyl chloride to the Schlenk bottle according to a certain stoichiometric ratio, and reflux and condense at 70-75°C under nitrogen protection After 2 hours, the excess thionyl chloride was removed by a rotary evaporator to obtain a light yellow transparent liquid which was n-octanoyl chloride with a yield of 95%.

[0053] 2) Synthesis of n-octanoate of H20

[0054]

[0055] Under anhydrous and anaerobic conditions, add 2.0g (1.2mmol) H2O, 0.06g 4-dimethylaminopyridine (DMAP) (3-4% of %), 4.5ml (56.2mmol) pyridine as catalyst, 15ml tetrahydrofuran as solvent, slowly add 10.0ml (56.2mmol) n-octanoyl chloride dropwise to the system using a dropping funnel, and react overnight in an ice-water bath to obtai...

Embodiment 3

[0059] Synthesis of H20 perfluorooctanoate and its use as spinning additive:

[0060] 1) Synthesis of perfluorooctanoyl chloride:

[0061]

[0062] The preparation of perfluorooctanoyl chloride (PFOC) is to add 10g (0.024mmol) perfluorooctanoic acid, 5.7g (0.048mmol) thionyl chloride and a small amount of DMF (0.5 ml) as a catalyst, obtained by reflux condensation at 70-75°C for 2h under nitrogen protection. The obtained crude product was placed in a separatory funnel and allowed to stand for layers. The upper layer was a yellow liquid, and the lower layer was a white liquid. Remove the layer of white liquid with a strong pungent odor. Afterwards, excess thionyl chloride was removed by a rotary evaporator to obtain a colorless and transparent liquid which was perfluorooctanoyl chloride, with a yield of 97.0%.

[0063] 2) Synthesis of perfluorooctanoate of H20:

[0064]

[0065] Under anhydrous and anaerobic conditions, add 1.0g (0.58mmol) H20, 0.04g4-dimethylaminopyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com