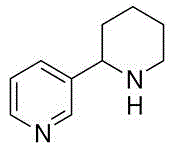

Preparation method of anabasine

A technology of anathanaine and anabenaline, which is applied in the field of preparation of anabenaline, can solve problems such as rare anabenaline, and achieve the effects of continuous preparation, small amount of solvent, and simple and easy-to-operate method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take dried quinoa quinoa, crush it, and pass it through a 20-mesh sieve; weigh a certain amount of coarse powder, add 70% ethanol with a weight-to-volume ratio of 1:2 to soak, and add 0.1% pectinase by weight of the coarse powder to adjust the pH value. 4. Soak the enzymatic hydrolysis for 1 hour at a temperature of 45°C; after the enzymatic hydrolysis, perform ultrasonic extraction on the obtained enzymatic hydrolyzate at a frequency of 20KHz and a temperature of 50°C for 1 hour, filter, collect the filtrate, and repeat the extraction of the filter residue once Collect the extract and add it into the hollow cellulose ultrafiltration membrane with a molecular weight cut-off of 2000 for ultrafiltration, and then concentrate the permeated liquid with a hollow cellulose nanofiltration membrane with a molecular weight cut-off of 100, collect the concentrated solution, and add 1 / 3 of the concentrated solution volume, 1 / 4 and 1 / 6 of the chloroform were stirred, allowed to stan...

Embodiment 2

[0022] Take the dried quinoa quinoa and grind it through a 60-mesh sieve; weigh a certain amount of coarse powder, add 75% ethanol with a weight-to-volume ratio of 1:4 to soak, and add 0.3% cellulase by weight of the coarse powder at a pH of 5 , the temperature is 45°C and the enzymatic hydrolysis is soaked for 2 hours; after the enzymatic hydrolysis, the obtained enzymatic hydrolyzate is ultrasonically extracted for 1.5 hours at a frequency of 30KHz and a temperature of 60°C, filtered, the filtrate is collected, and the filter residue is repeatedly extracted twice Collect the extract and add it into the hollow cellulose ultrafiltration membrane with a molecular weight cut-off of 6000 for ultrafiltration, and then concentrate the permeated liquid with a hollow cellulose nanofiltration membrane with a molecular weight cut-off of 300, collect the concentrated solution, and add 1 / 3 of the concentrated solution volume, 1 / 4 and 1 / 6 of the chloroform were stirred, allowed to stand fo...

Embodiment 3

[0024] Grind the dried quinoa quinoa and pass through a 80-mesh sieve; weigh a certain amount of coarse powder, add 80% ethanol with a weight-to-volume ratio of 1:5 to soak, and add hemicellulase at a pH value of 0.5% by weight of the coarse powder 5. Soak the enzymatic hydrolysis for 3 hours at a temperature of 50°C; after the enzymatic hydrolysis, perform ultrasonic extraction on the obtained enzymatic hydrolyzate at a frequency of 40KHz and a temperature of 70°C for 2 hours, filter, collect the filtrate, and repeat the extraction of the filter residue twice Collect the extract and add it into the hollow cellulose ultrafiltration membrane with a molecular weight cut-off of 10000 for ultrafiltration, and then concentrate the permeated liquid with a hollow cellulose nanofiltration membrane with a molecular weight cut-off of 500, collect the concentrated solution, and add 1 / 3 of the concentrated solution volume, 1 / 4 and 1 / 6 of the chloroform were stirred, allowed to stand for st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com