Production method for extracting absolute oil of tobacco leaves

A production method and tobacco leaf technology, applied in the field of chemical preparation, can solve the problems of low production cost, high operation risk, high production cost, etc., and achieve the effects of reduced production cost, easy operation and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

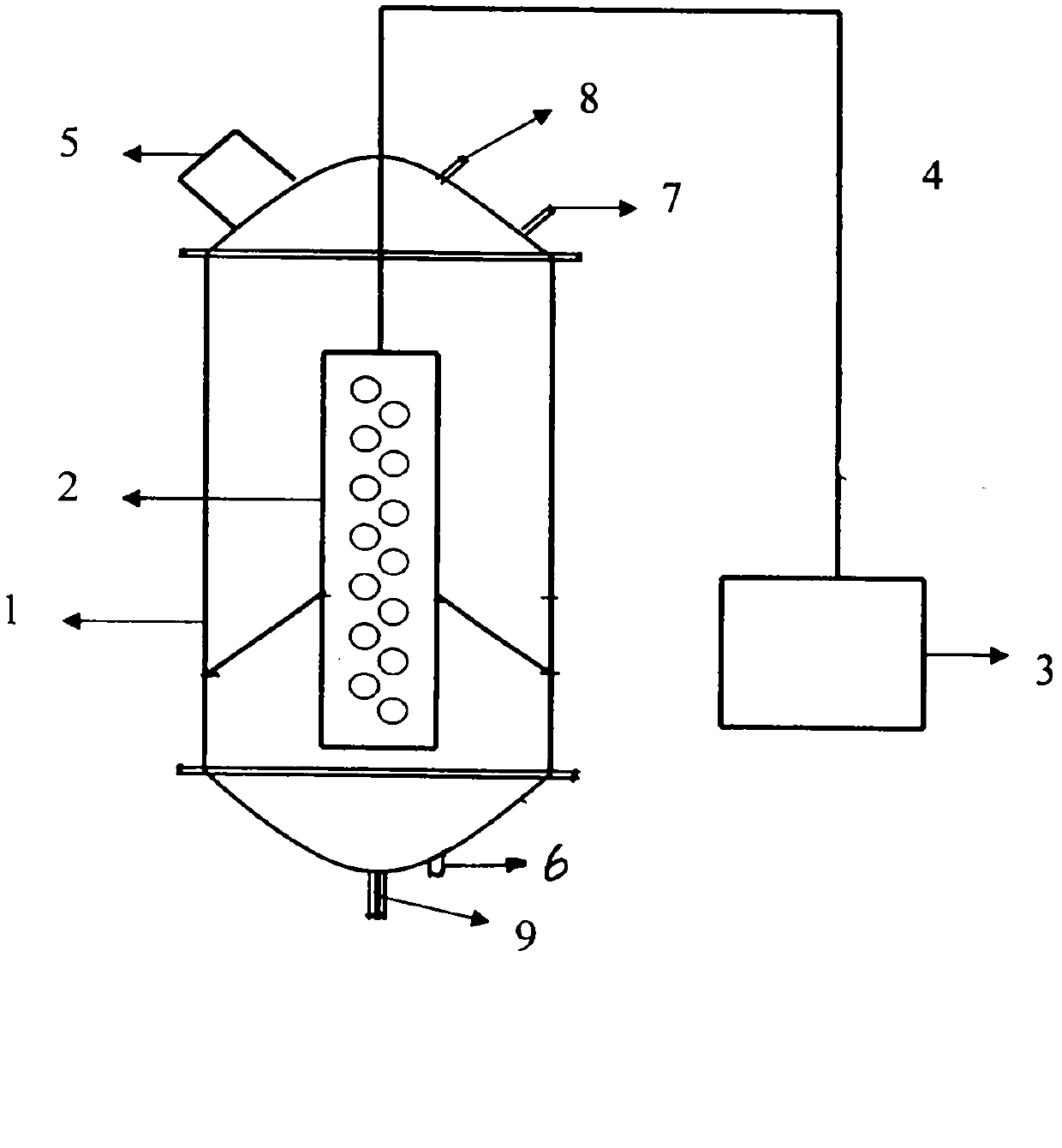

Method used

Image

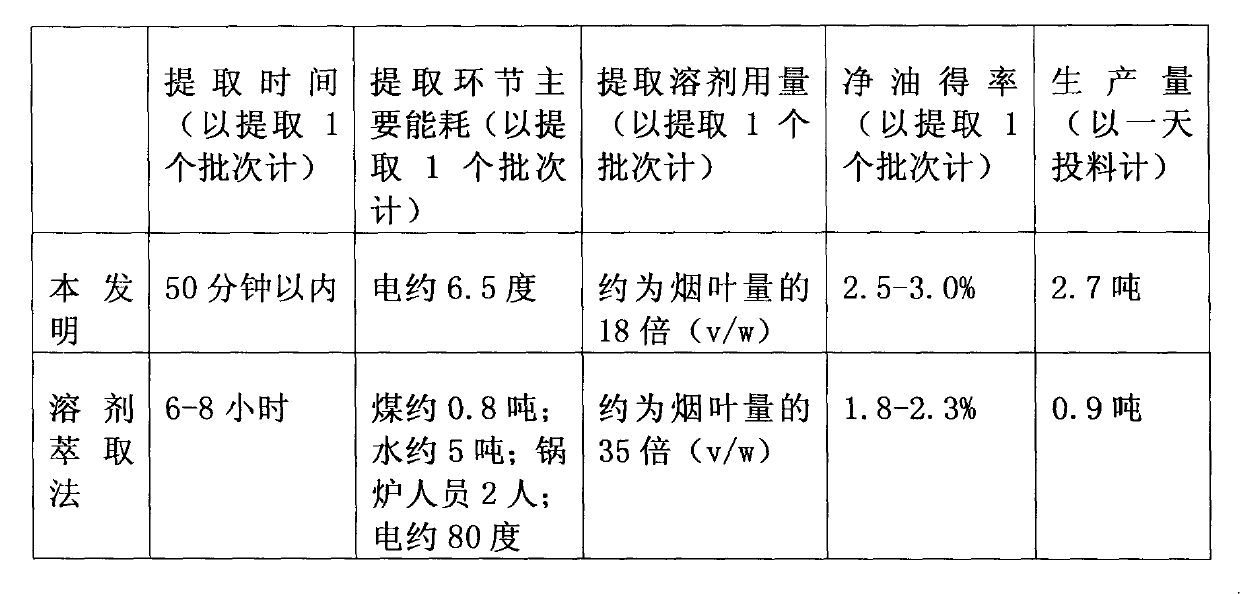

Examples

example 1

[0018] Example 1: Get 300 kilograms of tobacco leaves, dry until the moisture is 11wt%, crush until the particle size is less than 5mm, put into a 4-ton straight extraction tank with an ultrasonic generator, add 3000 liters of petroleum ether, soak for 40 minutes, start Ultrasonic generator ultrasonic extraction for 20 minutes, release the extract; then add 1800 liters of petroleum ether, start the ultrasonic generator ultrasonic extraction for 10 minutes, release the extract; combine the two extracts, concentrate under vacuum and decompression, and start to control the temperature at 40 ℃, vacuum degree 0.06mpa, when the solvent is recovered, the temperature rises to 55℃, vacuum degree 0.08mpa, and then concentrates for about 20 minutes to obtain 2.74 kg of extract with a specific gravity of 1.19; add 15 liters of 95% extract to the extract while stirring The alcohol was stirred for 30 minutes, left to stand for 8 hours, filtered, and the filtrate was concentrated under reduce...

example 2

[0019] Example 2: Get 210 kilograms of tobacco leaves and 90 kilograms of waste tobacco dust, dry them until the moisture is 10wt%, grind them to a particle size of less than 5mm, put them into a 4-ton straight extraction tank with an ultrasonic generator, and add 3200 liters of No. 6 Solvent oil, after soaking for 50 minutes, start the ultrasonic generator for ultrasonic extraction for 25 minutes, and release the extract; then add 1900 liters of No. 6 solvent oil, start the ultrasonic generator for ultrasonic extraction for 15 minutes, and release the extract; combine the secondary extracts , concentrated under reduced pressure in vacuum, started to control the temperature at 45°C, and the vacuum degree was 0.06mpa. When the solvent was recovered, the temperature rose to 55°C, and the vacuum degree was 0.08mpa, and then concentrated for about 30 minutes to obtain 2.68 kg of extract, with a specific gravity of 1.21; Put the paste into a dissolving tank with an interlayer, add 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com