Method for ultrasonic extraction of rice grain crude fat

A technology of rice grains and crude fat, which is applied in the preparation of test samples, etc., can solve the problems of low extraction efficiency, many organic solvents, and large sample requirements, and achieve the effect of less solvent consumption, satisfactory processing, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Ultrasonic extraction of crude fat from rice grains was performed according to the following steps:

[0037] (1) Drying and pulverizing the rice grains;

[0038] (2) Add an appropriate amount of powder sample prepared in step (1) to the extract and mix thoroughly;

[0039] (3) Extract crude fat under ultrasonic conditions, make the fat enter the extraction solution, and then remove insoluble impurities to obtain a fat solution.

[0040] As an optional mode, in the method for ultrasonically extracting crude fat from rice grains, a step (4) is further included: removing the extract of the fat solution prepared in step (3) to obtain a crude fat product.

[0041] As an optional mode, in the above-mentioned method for ultrasonically extracting crude fat from rice grains, the step (4) specifically includes: subjecting the fat solution prepared in step (3) to vacuum condensation and rotary evaporation at 40-60°C to remove the extracted liquid; then dry the produc...

Embodiment 2

[0047] The present invention is further described by following tests:

[0048] (1) Determination method of rice crude fat extraction rate:

[0049] Centrifuge the centrifuge tube after extraction at 5000rpm for 10 minutes, put the supernatant in a round bottom flask (bottle weight m 1 ), vacuum condensation and rotary evaporation at 40°C, and then bake the round bottom flask at 105°C to constant weight (m 2 ), the calculated crude fat content m 2 -m 1 .

[0050] At the same time, an equal amount of sample was taken according to the GB / T14772-93 method, and the crude fat of rice grain was extracted by Soxhlet extraction method, and the fat content was obtained as m 3 , then the fat extraction rate (m 2 -m 1 ) / m 3 .

[0051] (2) Extraction of rice crude fat:

[0052]Rice crude fat extraction: dry the rice grains until the water content is less than 10%, crush and pass through a 100-mesh sieve, weigh 2g of the sample in a 50ml centrifuge tube, add 16-30ml of extractant, ...

Embodiment 3

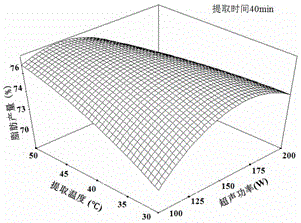

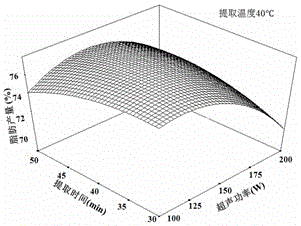

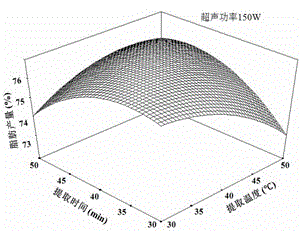

[0079] Such as figure 1 , 2 , Shown in 3, the embodiment of the present invention has adopted the ultrasonic extraction rice grain crude fat of optimization, and extraction process method comprises:

[0080] The rice grains are dried until the water content is less than 10%, crushed and passed through a 100-mesh sieve, and weigh ≥1.5g in a 50ml centrifuge tube. Add chromatographically pure grade n-hexane and mix evenly. The ratio of solid to liquid is 1g:8~15ml. Place it in an ultrasonic device with distilled water as the solvent, and extract for 37min at an ultrasonic power of 123W and a temperature of 42°C.

[0081] The crude fat extraction rate of rice grains under the ultrasonic method was 77.31%.

[0082] As a comparison, the same amount of sample was taken according to the GB / T14772-93 method, and the rice grain crude fat was extracted by the Soxhlet extraction method, and the extraction rate of the rice grain crude fat was the same as 77.31%. Soxhlet extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com