Method for determining total solanesol in tobaccos and tobacco products

A technology for tobacco products and total solanesol, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unfavorable batch operation, consumption of organic solvents, low detection efficiency, etc., achieve less solvent consumption, reduce pollution, and accurately The effect of high precision and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

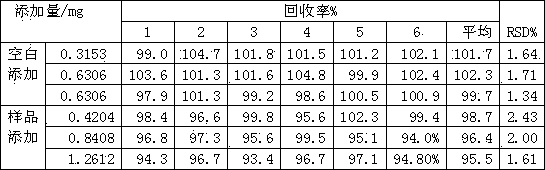

[0018] A method for measuring total solanesol in tobacco and tobacco products, the steps comprising:

[0019] 1. Simultaneous ultrasonic extraction and saponification of tobacco solanesol: Take tobacco or tobacco products and grind them into tobacco powder, place them in a centrifugal glass tube, add extraction solvent and saponification agent, and simultaneously ultrasonically extract and saponify tobacco solanesol;

[0020] 2. Washing and separation of tobacco solanesol extract: cool the extract to room temperature, add a certain volume of water, oscillate fully, and centrifuge;

[0021] 3. Pipette 0.500mL of the upper layer solution, dilute the mobile phase to 5.000mL, and filter it with a 0.22um organic filter membrane into a liquid chromatography ampoule for testing.

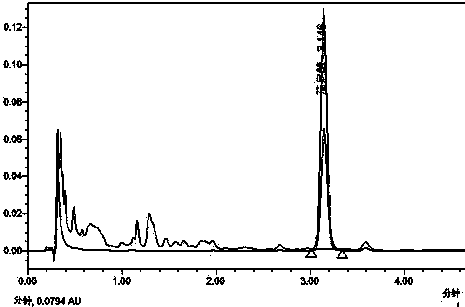

[0022] 4. Carry out liquid chromatographic determination of the obtained liquid to be tested.

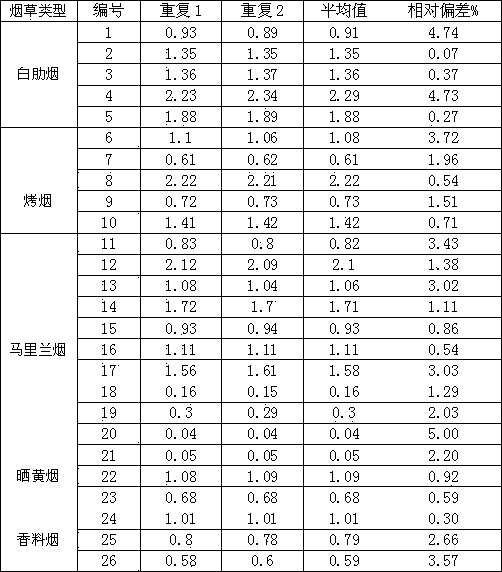

[0023] Further, the tobacco or tobacco products in the step 1 include various types of cured tobacco leaves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com