Method for extracting panax notoginseng saponins by using continuous countercurrent ultrasonic extraction combined film technology

A technology of total Panax notoginseng saponins and countercurrent ultrasound, which is applied in the directions of drug combinations, pharmaceutical formulations, and medical preparations containing active ingredients, etc., can solve the problem of severe foaming of Panax notoginseng saponins, difficulty in forming a large concentration difference, and difficulty in ultrasonic waves being effective. problems such as conduction, to achieve the effect of shortening the extraction cycle, reducing energy consumption, and preventing hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

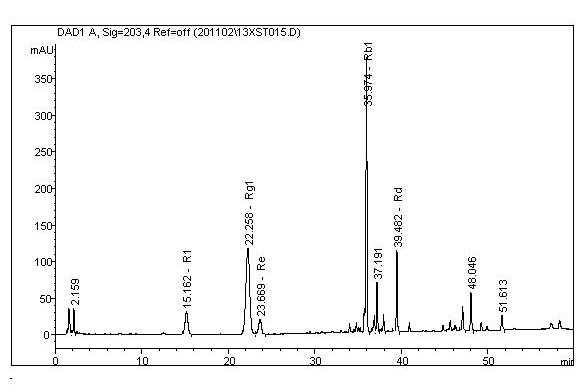

Embodiment 1

[0058] Take 30 kg of Panax notoginseng cut coarse powder, feed it from the inlet of the continuous countercurrent ultrasonic extraction tube head, add 8 times the amount of 75% ethanol (240kg) from the solvent inlet at the tail of the continuous countercurrent ultrasonic extraction tube, and perform continuous countercurrent ultrasonic extraction , set the ultrasonic frequency to 40KHz, set the ultrasonic temperature to 20°C, conduct continuous countercurrent ultrasonic extraction for 20 minutes, collect the ethanol ultrasonic extract, filter, the filtrate temperature is 20°C, and the filtrate is concentrated with a nanofiltration membrane with a relative molecular weight cut-off of 100-400, and the operating pressure When it reaches 0.2MPa, the permeate flows out, and the flow rate is very slow. Increase the operating pressure to 2.9MPa, and the flow rate is stable until there is no permeate flow out. Add water to the membrane concentrate until the alcohol content reaches 15%, ...

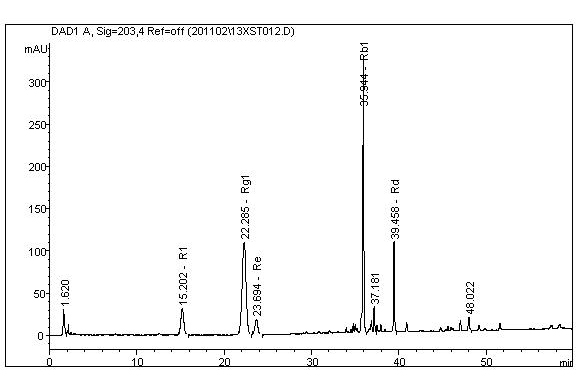

Embodiment 2

[0060] Take 30 kg of Panax notoginseng coarse powder, feed it from the feed inlet at the head of the continuous countercurrent ultrasonic extraction tube, add 15 times the amount of 40% ethanol (450kg) from the solvent inlet at the tail of the continuous countercurrent ultrasonic extraction tube, and perform continuous countercurrent ultrasonic extraction. Set the ultrasonic frequency to 20KHz, set the ultrasonic temperature to 50°C, conduct continuous countercurrent ultrasonic extraction for 60 minutes, collect the ultrasonic extract, filter, the filtrate temperature is 50°C, and the filtrate is concentrated with an ultrafiltration membrane with a relative molecular weight cut-off of 1000, when the operating pressure reaches 0.1MPa , there is a permeate outflow, the flow rate is very slow, increase the operating pressure to 0.4MPa, the flow rate is stable, until the membrane is concentrated and there is no permeate outflow, the membrane concentrate is decompressed until it has ...

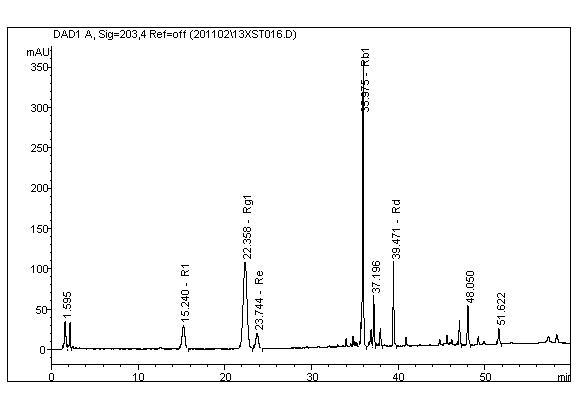

Embodiment 3

[0062] Take 30 kg of Panax notoginseng cut coarse powder after soaking and wetting with 20% ethanol, feed it from the inlet of the continuous countercurrent ultrasonic extraction tube head, and add 6 times the amount of 90% ethanol from the solvent inlet at the tail of the continuous countercurrent ultrasonic extraction tube ( 180kg), carry out continuous countercurrent ultrasonic extraction, set the ultrasonic frequency to 80KHz, set the ultrasonic temperature to 30°C, conduct continuous countercurrent ultrasonic extraction for 40min, collect the ultrasonic extract, filter, the filtrate temperature is 30°C, and the filtrate is ultrafiltered with a relative molecular weight cut-off of 25,000 Membrane concentration, when the operating pressure reaches 0.1MPa, the permeate flows out, and the flow rate is very slow. Increase the operating pressure to 0.7MPa, and the flow rate is stable. When the membrane is concentrated, there is no permeate flow out, and the membrane concentrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com