Mesoporous nano carbon sphere as well as preparation method and application thereof

A nano-carbon sphere and mesoporous technology, applied in the field of nano-materials, can solve the problems of waste of resources, environmental pollution, not easy to scale up production, and non-compliance with green chemistry, and achieve reduced solvent consumption, excellent physical and chemical properties, and stable output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

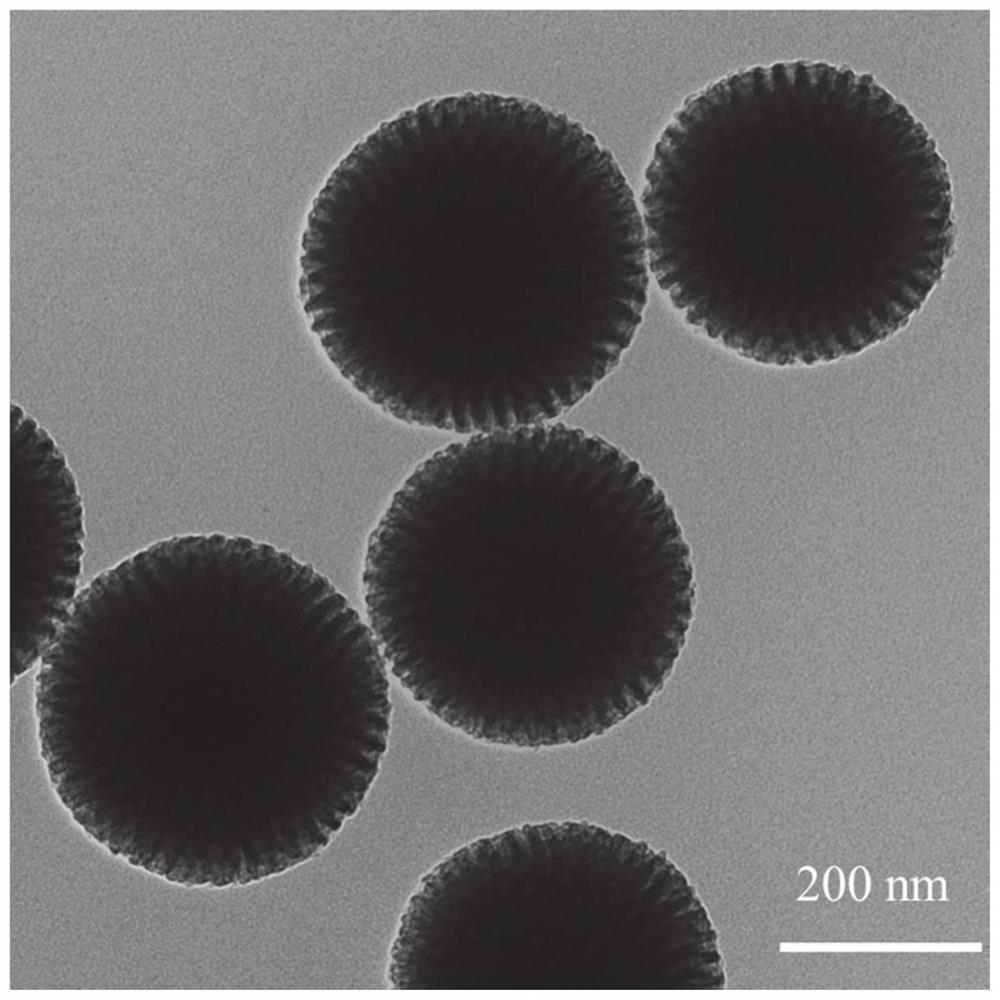

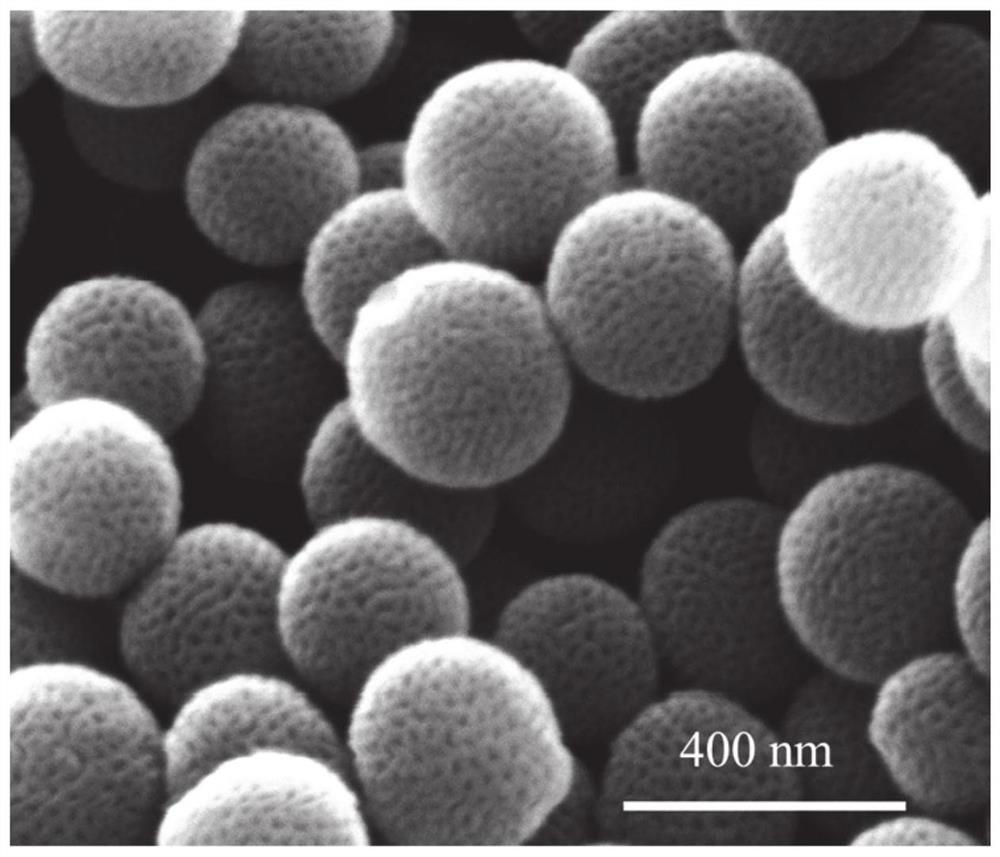

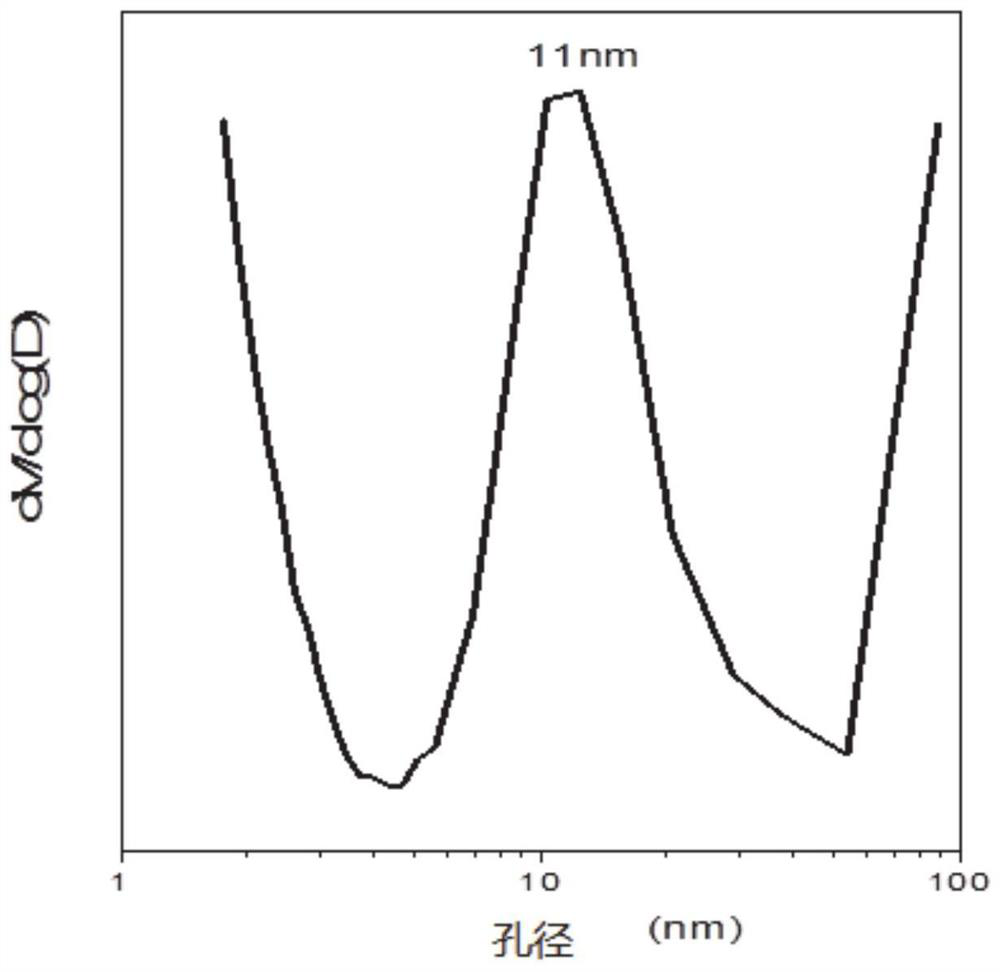

Embodiment 1

[0059] Weigh 20mg Dissolve F127 in a mixed solvent of 7mL water and 7mL ethanol, add 100μL 1,3,5-trimethylbenzene and 155μL ammonia water under stirring at 25°C, then add 0.25g resorcinol and 0.15mL formaldehyde, and pass through at 200rpm Stirring was continued for 3 hours, followed by centrifugation at 6000 rpm for 4 minutes to centrifuge the product, wash it twice with water and ethanol, and finally dry it in an oven at 60° C. for 20 hours. Raise the dried triblock copolymer / resorcinol formaldehyde resin nanopolymer balls to 450°C at a rate of 10°C / min under a nitrogen atmosphere, keep it warm for 5 hours, and then increase the temperature at a rate of 10°C / min to 450°C. To 1000 ℃, keep 3h. Finally, the temperature is naturally lowered to room temperature to obtain mesoporous carbon nanospheres.

Embodiment 2

[0061] Weigh 40mg Dissolve F127 in a mixed solvent of 14mL water and 6mL ethanol, add 200μL 1,3,5-trimethylbenzene and 310μL ammonia water while stirring at 25°C, then add 0.5g resorcinol and 0.3mL formaldehyde, and pass through at 400rpm Stirring was continued for 3 hours, followed by centrifugation at 8000 rpm for 3 minutes to centrifuge the product, wash it twice with water and ethanol, and finally dry it in an oven at 70° C. for 12 hours. Raise the dried triblock copolymer / resorcinol-formaldehyde resin nanopolymer spheres to 450°C at a rate of 4°C / min under nitrogen atmosphere, keep it warm for 4 hours, and then increase the temperature at a rate of 4°C / min Rise to 700°C and keep for 4h. Finally, the temperature is naturally lowered to room temperature to obtain mesoporous carbon nanospheres.

Embodiment 3

[0063] Weigh 40mg Dissolve F127 in a mixed solvent of 12mL water and 8mL ethanol, add 200μL 1,3,5-trimethylbenzene and 310μL ammonia water while stirring at 40°C, then add 0.4g resorcinol and 0.3mL formaldehyde, and pass through at 7000rpm Continuous stirring for 10 hours, followed by centrifugation at 10,000 rpm for 3 minutes to centrifuge the product, wash it twice with water and ethanol, and finally place it in an oven at 80° C. for 6 hours. Raise the dried triblock copolymer / resorcinol-formaldehyde resin nanopolymer balls to 300°C at a rate of 10°C / min under a nitrogen atmosphere, keep the temperature for 6 hours, and then increase the temperature at a rate of 10°C / min Rise to 600°C and keep for 6h. Finally, the temperature is naturally lowered to room temperature to obtain mesoporous carbon nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com