Automatic cleaning device for glass sample bottles

A technology for automatic cleaning and sample bottles, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of large amount of organic solvent, consumption of organic solvent, low cleaning efficiency, etc., and achieve high degree of automation, Achieve quantitative recovery and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

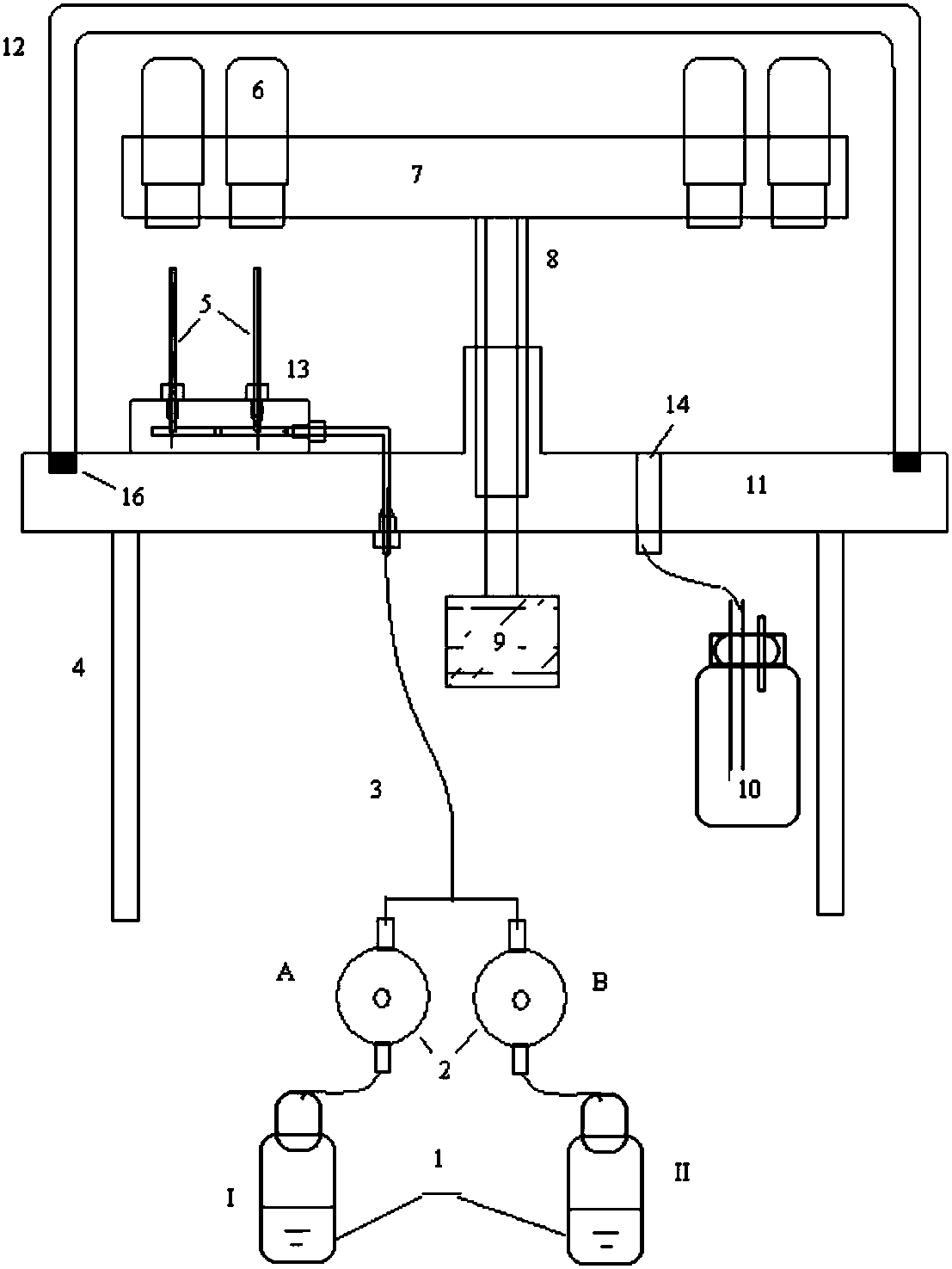

[0036] Step 1, connect the devices in order, add chromatographically pure methylene chloride in reagent bottle I, and add chromatographically pure n-hexane in reagent bottle II;

[0037] Step 2. Turn on the power, select the plunger pump made of PEEK, and set the cleaning event as follows: from 0 to 6 minutes, run pump A, set the flow rate of dichloromethane to 2.5ml / min; from 6 to 12 minutes, run pump B, set The flow rate of n-hexane is 2.5ml / min, and the total running time is 12min;

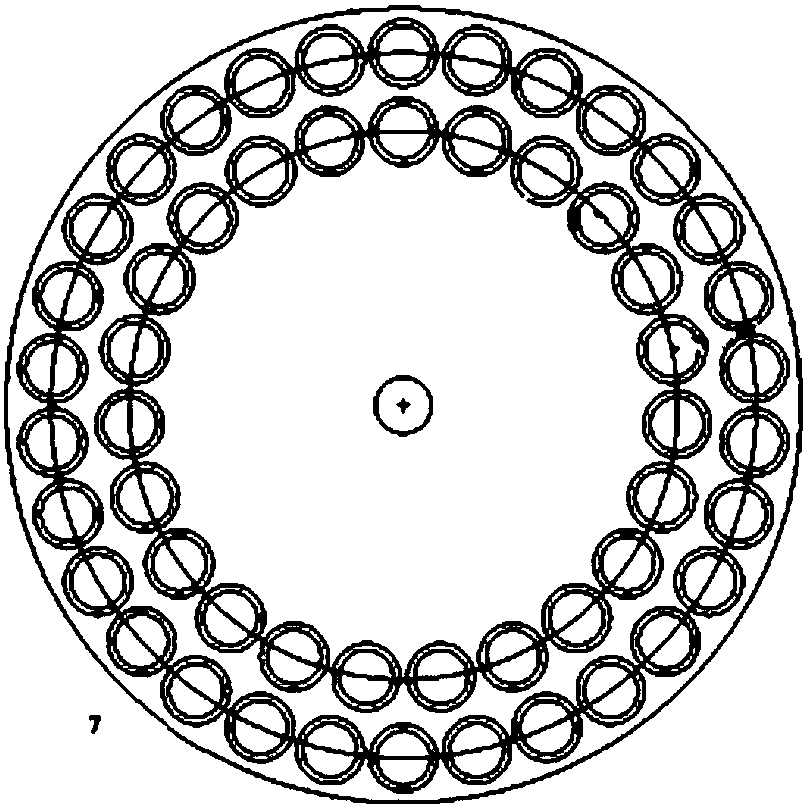

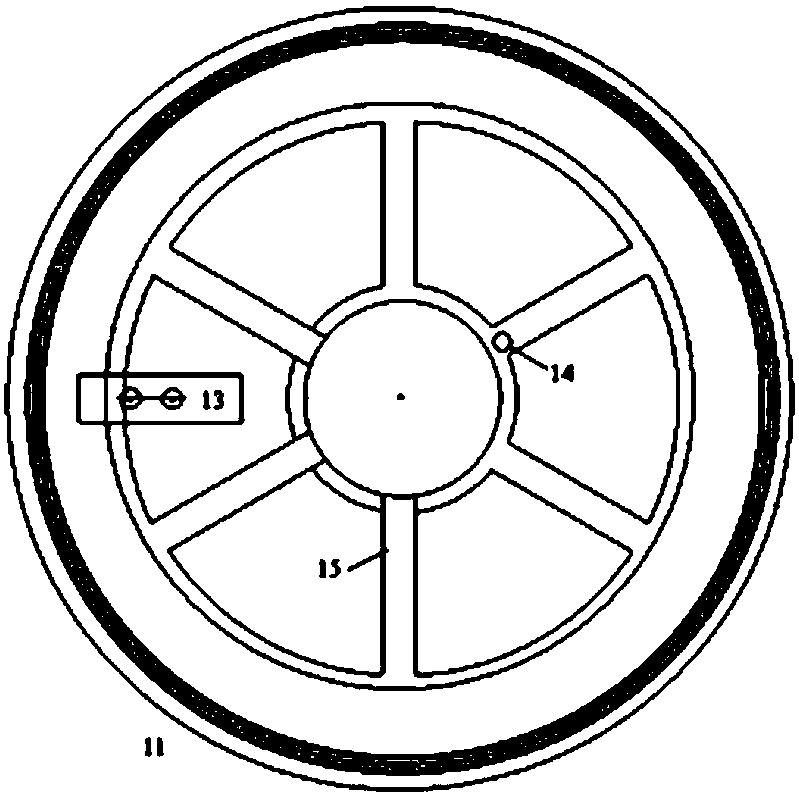

[0038] Step 3: Select a roulette with 60 positions and 1.5ml sample bottles, place the sample bottles upside down in the fixed slots respectively; use double nozzles for cleaning.

[0039] Step 4. Close the glass cover to ensure the seal;

[0040] Step 5. Connect the waste liquid collection bottle;

[0041] Step 6. Turn on the speed regulating motor and set the speed to 1r min -1 ;

[0042] Step 7. Start the plunger pump and start cleaning;

[0043] Step 8: After cleaning, take out the sam...

Embodiment 2

[0045] Step 1. Connect the devices in sequence, add chromatographically pure methanol to reagent bottle I, and add chromatographically pure n-hexane to reagent bottle II;

[0046] Step 2. Turn on the power, select a stainless steel plug pump, and set the cleaning event as follows: from 0 to 10 minutes, run pump B, set the flow rate of n-hexane to 5ml / min; from 10 to 15 minutes, run pump A, set the flow rate of methanol to 2.5ml / min, the total running time is 15min;

[0047] Step 3: Select a roulette with 120 positions and 1.5ml sample bottles, place the sample bottles upside down in the fixed slots respectively; use three nozzles for cleaning.

[0048] Step 4. Close the glass cover to ensure the seal;

[0049] Step 5. Connect the waste liquid collection bottle;

[0050] Step 6. Turn on the speed regulating motor and set the speed to 10r min -1 ;

[0051] Step 7. Start the plunger pump and start cleaning;

[0052] Step 8: After cleaning, take out the sample bottle.

Embodiment 3

[0054] Step 1, connect the devices in order, add chromatographically pure methanol in reagent bottle I, and add chromatographically pure methylene chloride in reagent bottle II;

[0055] Step 2. Turn on the power, select a stainless steel plug pump, and set the cleaning event as follows: from 0 to 10 minutes, run pump B and set the flow rate of methylene chloride to 5ml / min; from 10 to 15 minutes, set the flow rate of pump A to 2.5ml / min. min, the flow rate of pump B is 2.5ml / min; from 15 to 20min, run pump A, set the flow rate of methanol to 5ml / min; the total running time is 20min;

[0056] Step 3: Select a roulette with 30 positions and 5ml sample bottles, place the sample bottles upside down in the fixed slot; use a single nozzle for cleaning.

[0057] Step 4. Close the glass cover to ensure the seal;

[0058] Step 5. Connect the waste liquid collection bottle;

[0059] Step 6. Turn on the speed regulating motor and set the speed to 5r min -1 ;

[0060] Step 7. Start t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com