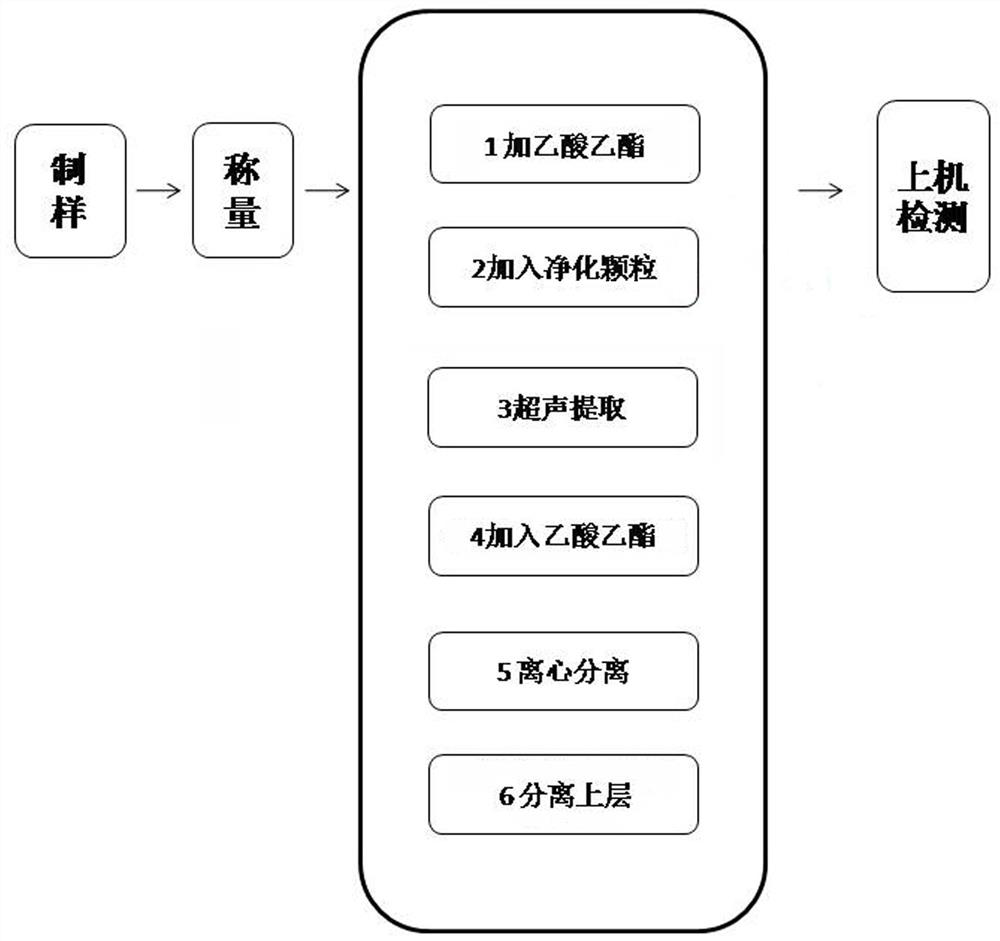

Sample treatment method and automatic treatment device

A technology for sample processing and processing agent, applied in the field of sample processing and automatic processing devices, can solve the problems of harmful workers' health, low extraction and purification efficiency, and limited instrument precision, and achieves favorable separation and high sealing performance. , the effect of reducing the impact on the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

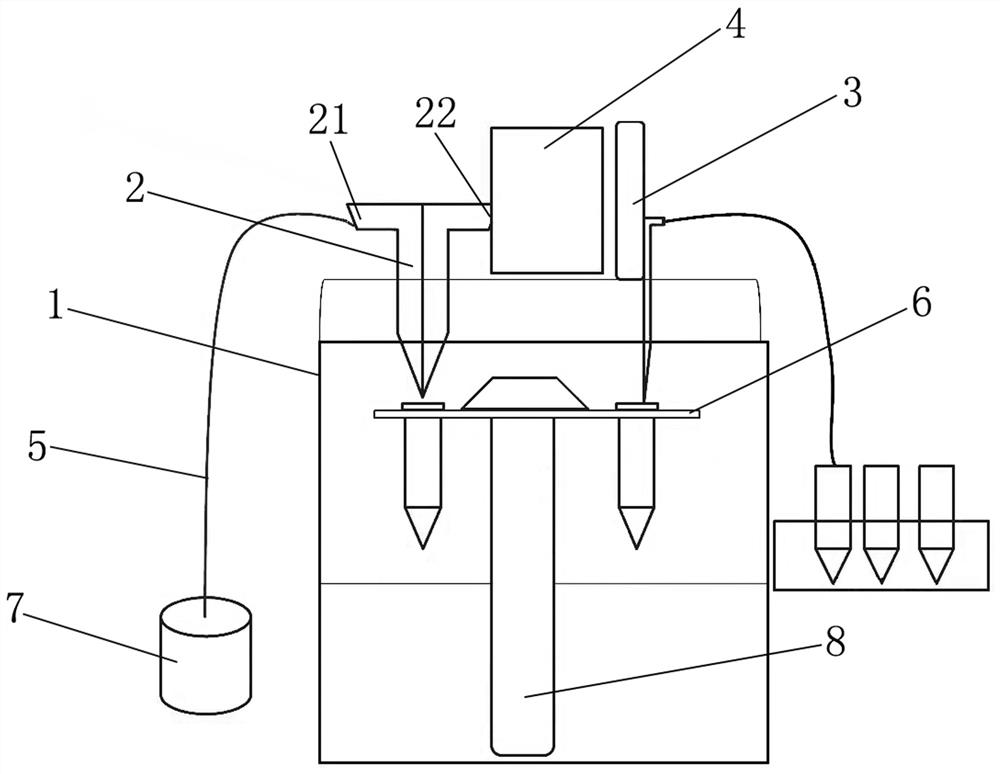

[0026] like figure 2 The shown automatic sample processing device includes a box body 1 , a first mechanical arm 2 , a second mechanical arm 3 , an adsorbent storage tank 4 , a hose 5 , a centrifuge tube plate 6 , a solvent storage tank 7 , and a rotor 8 .

[0027] A rotor 8 is arranged on the inner central axis of the box body 1, and a fence is arranged outside the rotor 8 to prevent the ultrasonic water from affecting the centrifugal operation.

[0028] The center of circle of described centrifuge tube plate 6 is fixed on centrifuge rotor 8 axles, and there are some grooves for placing centrifuge tubes on it.

[0029] The hose 5 is connected to the inside of the solvent storage tank 7 and the first sampling port 21, and between the sampling port of the second mechanical arm 3 and the sample collection tube, for transferring the treatment agent or the supernatant in the centrifuge tube.

[0030] The first mechanical arm 2 is fixed on the top of the box body 1, and is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com