Method for producing sodium fatty acid methyl ester sulfonate

A technology of sodium fatty acid methyl ester sulfonate and production method, which is applied in the direction of sulfonate preparation, organic chemistry, etc., can solve the problems of inability to realize large-scale, continuous and stable industrial production, and achieve easy industrial operation, improved safety, The effect of eliminating the safety problem of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

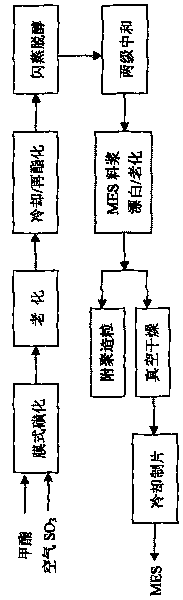

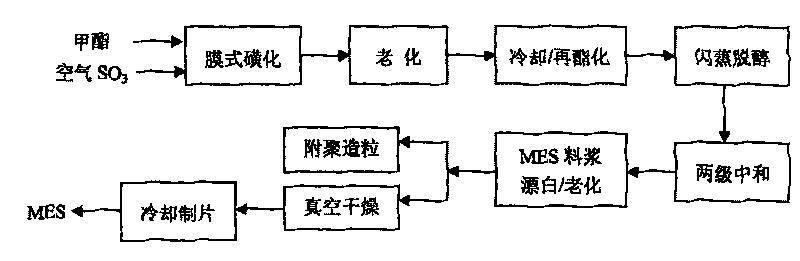

Method used

Image

Examples

Embodiment 1

[0025] A kind of production method of sodium fatty acid methyl ester sulfonate, comprises the following steps: (1) sulfonation: adopt the hydrogenated palm-methyl stearate that the product code name provided by Malaysia Corning Company to be ME.C16-60MY as raw material, its The specific specifications and carbon chain distribution are as follows:

[0026] Iodine value %I 2 0.15

[0027]Acid value mgKOH / g 0.2

[0028] Free glycerin% 0.005

[0029] Moisture % 0.05

[0030] Saponification value mgKOH / g 199

[0031] Average molecular weight 281

[0032] Carbon chain distribution:

[0033] C14 and below 1.0

[0034] C16 61.7

[0035] C18 37.0

[0036] C18 and above 0.3

[0037] The above raw materials are subjected to SO in a multi-tubular membrane reactor 3 Sulfonation reaction, methyl stearate and SO 3 The molar ratio of SO is 1:1.08, SO 3 The gas concentration of / air is at 5%, and the feeding temperature of methyl stearate is at 60 DEG C; (2) Aging: agin...

Embodiment 2

[0044] A kind of production method of sodium fatty acid methyl ester sulfonate, comprises the following steps: (1) sulfonation: adopt the hydrogenated palm-stearic acid methyl ester that the product code name provided by Malaysia Corning Company is ME.C16-95MY as raw material, raw material main indicators:

[0045] Iodine value %I 2 0.12

[0046] Acid value mgKOH / g 0.1

[0047] Free glycerin% 0.015

[0048] Moisture % 0.05

[0049] Saponification value mgKOH / g 190

[0050] Average molecular weight 272

[0051] The above raw materials are subjected to SO in a multi-tubular membrane reactor 3 Sulfonation reaction, methyl stearate and SO 3 The molar ratio is 1:1.20, SO 3 The gas concentration of / air is at 6%, and the feeding temperature of methyl stearate is at 65 ℃; (2) Aging: aging reaction is carried out continuously in the stirring reaction kettle connected with each other, and adds accounting for fatty acid methyl ester sulfonic acid 3 % catalyst, t...

Embodiment 3

[0058] A kind of production method of sodium fatty acid methyl ester sulfonate, comprises the following steps: (1) sulfonation: adopt the hydrogenated palm-stearic acid methyl ester that the product code name provided by Malaysia Corning Company is ME.C16-60MY as raw material, raw material main indicators:

[0059] Iodine value %I 2 0.1

[0060] Acid value mgKOH / g 0.1

[0061] Free glycerin% 0.01

[0062] Moisture % 0.02

[0063] The above raw materials are subjected to SO in a multi-tubular membrane reactor 3 Sulfonation reaction, methyl stearate and SO 3 The molar ratio is 1:1.15, SO 3 The gas concentration of / air is at 5%, and the feeding temperature of methyl stearate is at 62 DEG C; (2) aging: aging reaction is carried out continuously in the stirred reaction still connected in series, and adds and accounts for fatty acid methyl ester sulfonic acid 2 % catalyst, the catalyst is any one of ammonium sulfate, sodium sulfate or potassium sulfate, the aging tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com