A kind of preparation method of molybdenum catalyst and its application

A catalyst and solvent technology, which is applied in the field of molybdenum catalyst preparation, can solve the problems of unsuitability for large-scale industrialization, ineffective recovery of catalysts, low peroxide selectivity, etc., and achieve trace peroxide residues and excellent catalytic activity , The effect of high conversion rate of oxidant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of platinum catalyst in the present invention is as follows:

[0042] First, 100 g of pentaerythritol and 0.36 g of formic acid were added to the reaction kettle, and after nitrogen replacement, heated to 100° C., 258 g of ethylene oxide was added to the kettle within 1 h, and then the reaction was continued for 5 h, and the ethylene oxide was removed under reduced pressure. The macromolecule alcohol was obtained, and Mn=481 by GPC analysis.

[0043] Take 100 g of macromolecular alcohol obtained above, 50 g of ammonium dimolybdate, and 30 g of ethylbenzene into another reaction kettle, and react at 100 ° C for 60 h. After the reaction is completed, the temperature is lowered to room temperature, and possible residual solid substances are removed by filtration to obtain a molybdenum catalyst. , No. Mo-1.

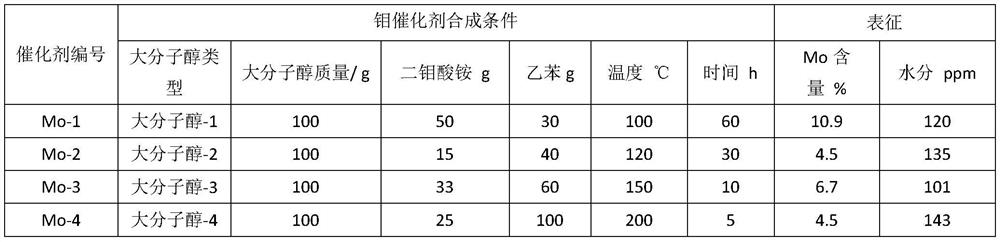

[0044] The preparations of other catalysts are the same as the above-mentioned methods, and the specific feeding amounts and conditions are con...

Embodiment 2-5

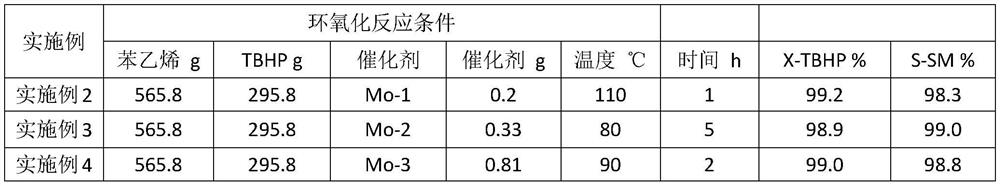

[0051] For the four catalysts prepared in Example 1, the epoxidation reactions were evaluated respectively:

[0052] Take the evaluation of catalyst Mo-1 as an example to introduce the evaluation method:

[0053] 565.8g of styrene, 5.6g of hydroquinone, and 0.2g of catalyst Mo-1 were added to the epoxidation reaction kettle. After nitrogen replacement was completed, the temperature was raised to 110°C, and 295.8g of tert-butyl was added to the system within 1 hour. base hydrogen peroxide (concentration is 55%), the reaction was continued for 1 h after the addition, and then the temperature was lowered to 30°C. After analysis, the conversion rate of tert-butyl hydroperoxide was 99.2%, and the selectivity of ethylene oxide was 98.3%.

[0054] The evaluation of other catalysts is the same as the above method, and the specific feeding amount and conditions are controlled in the following table.

Embodiment 8-11

[0062] After evaluating the reaction and cooling down as above, solids were all precipitated, and solid substances were obtained by simple sedimentation and decantation. After unified and simple drying treatment (100 ° C drying for 4 h), solid substances 0.16g, 0.24g, and 0.54g were obtained in Examples 2-5, respectively. , 0.88g. These four solids are numbered Mo-1', Mo-2', Mo-3', Mo-4', respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com