Patents

Literature

799results about "Dc motor starters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

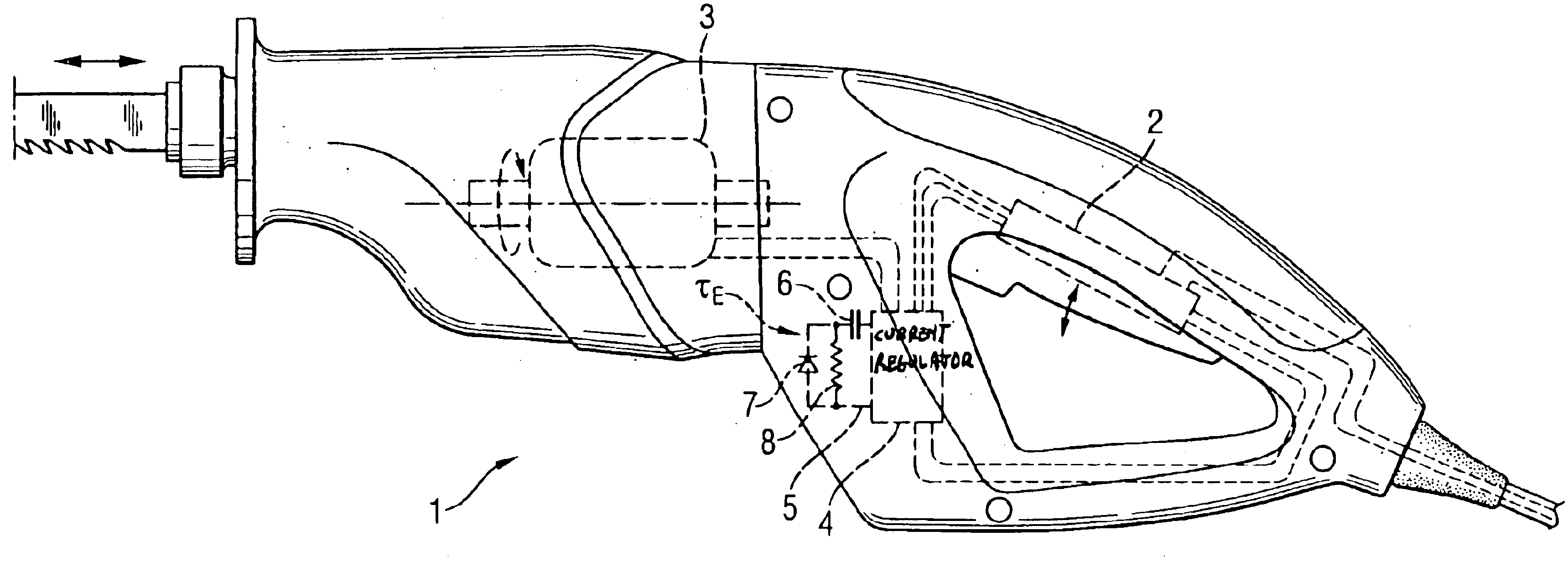

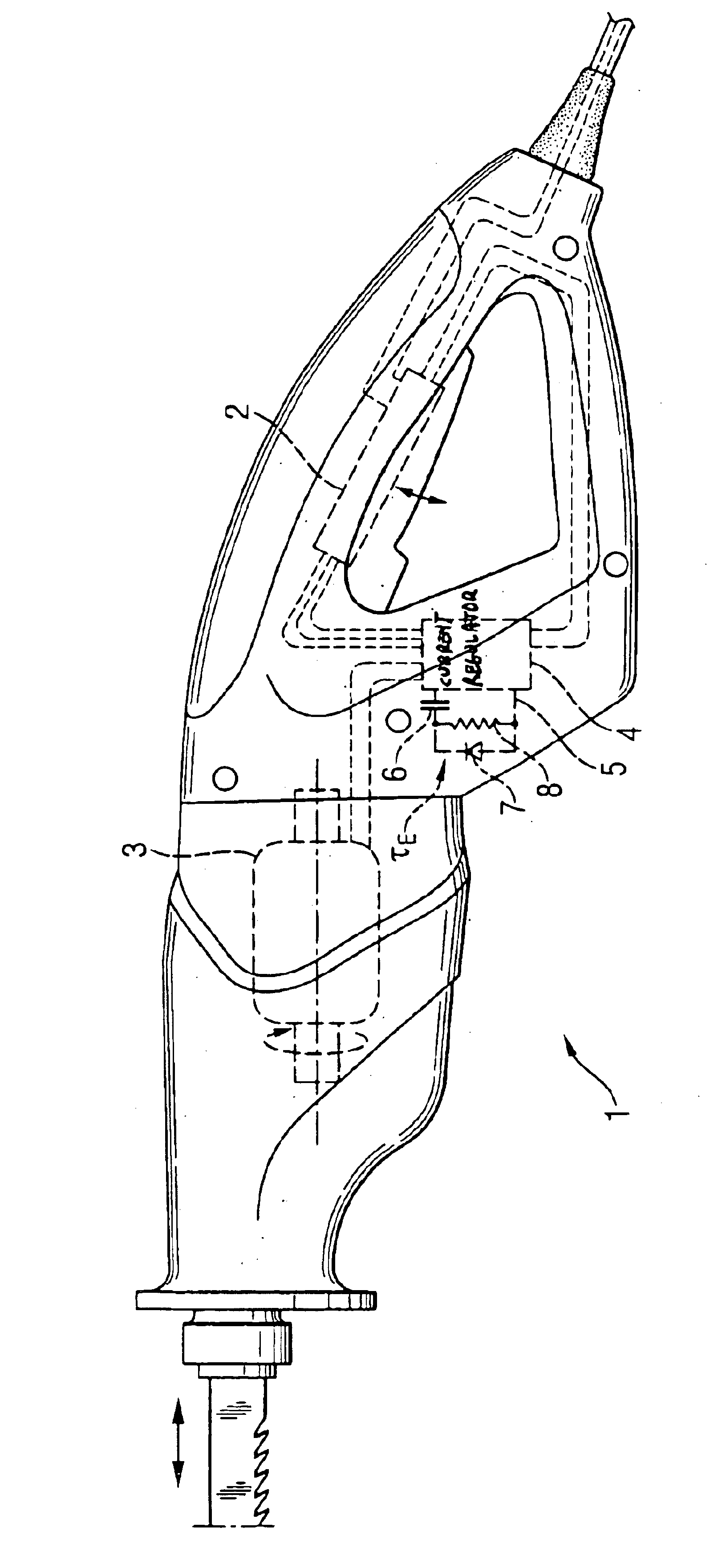

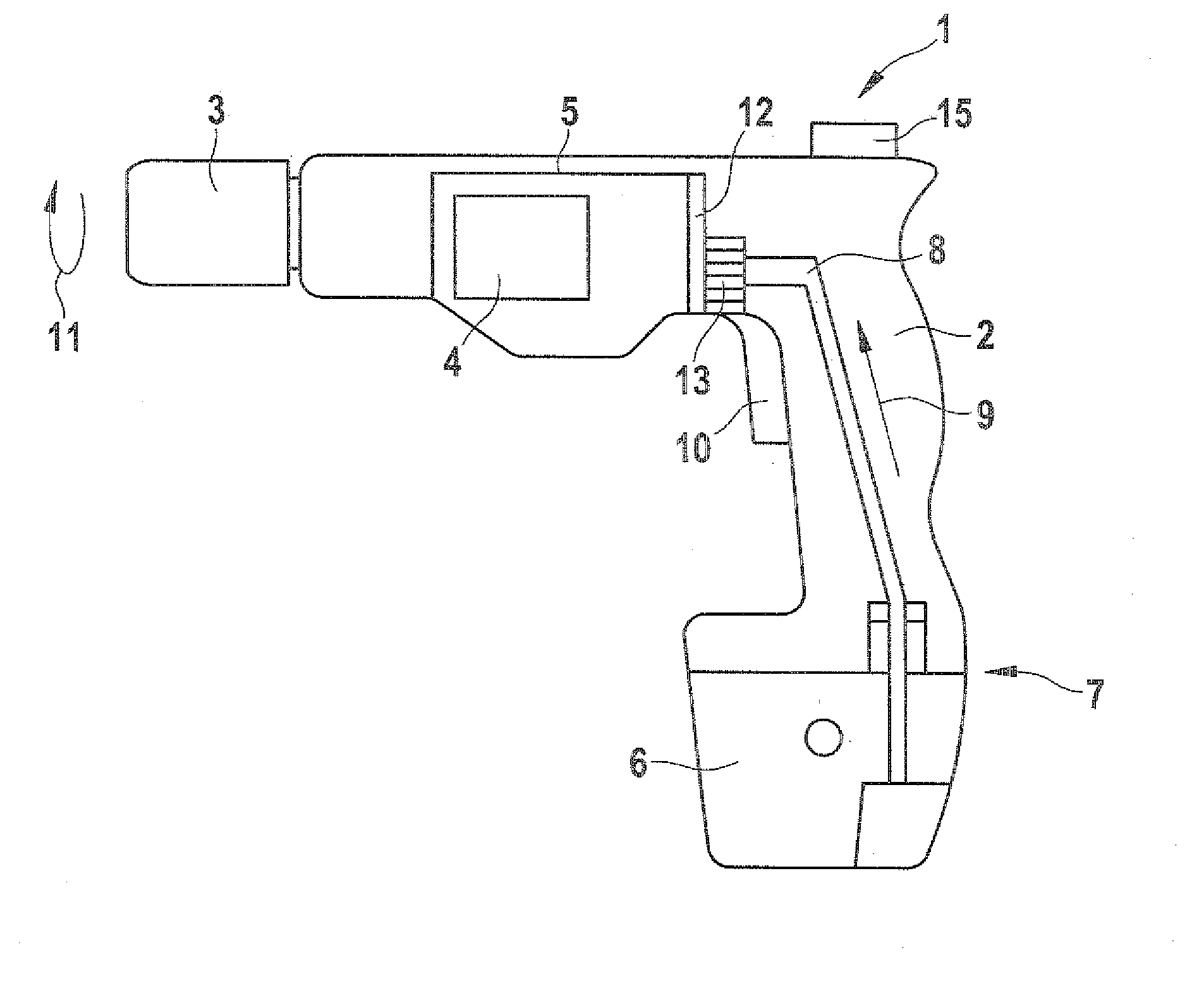

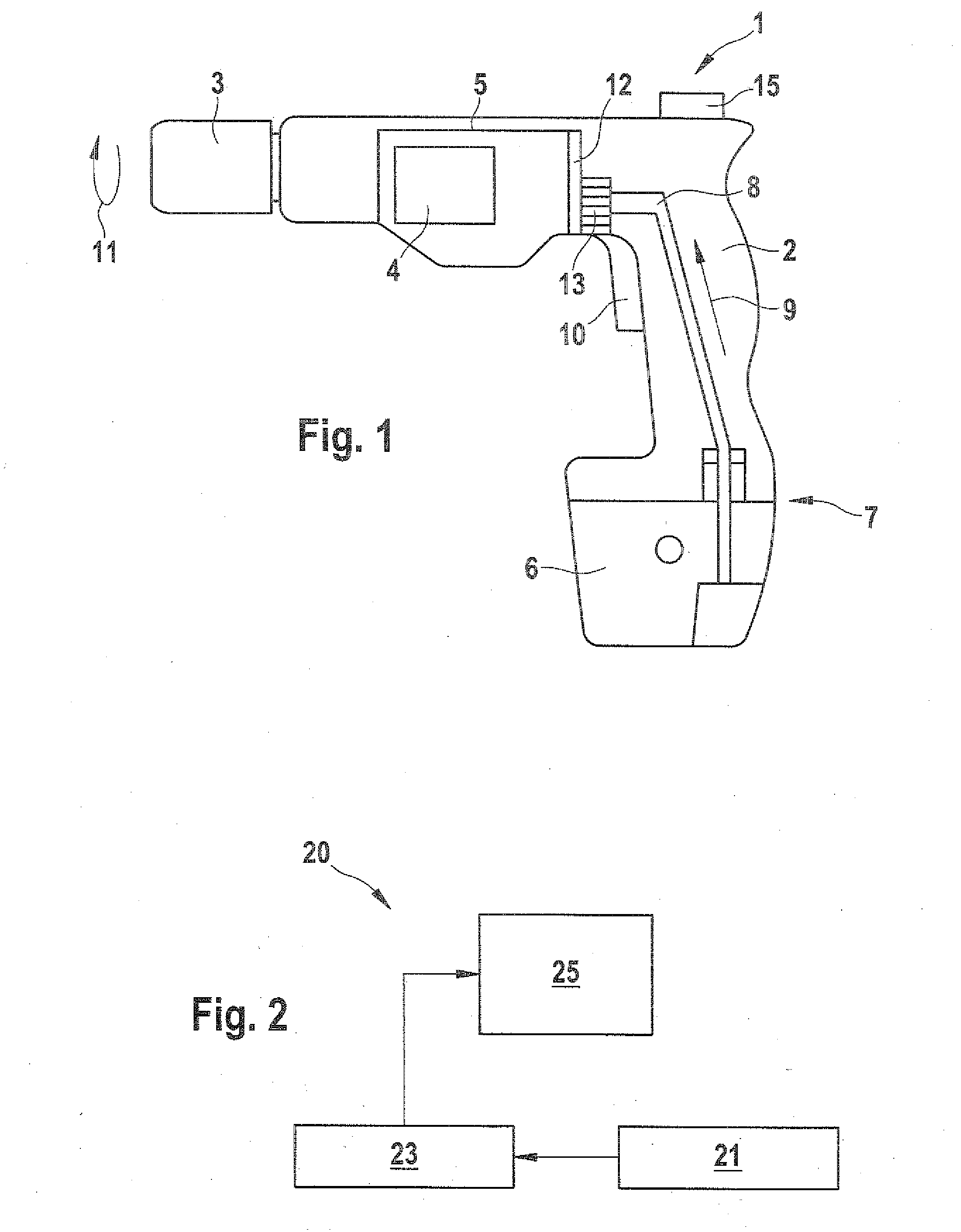

Electrical hand tool machine with soft-start

An electrical hand tool machine (1) having a motor switch (2) configured as a button and a current regulator (4) disposed in the current circuit of an electrical motor (3), having a soft-start input (5), in whose branch current a timing capacitor (6) is arranged. A current-direction-dependent element (7) is arranged between the soft-start input (5) and the capacitor (6).

Owner:HILTI ELLSCHAFAT

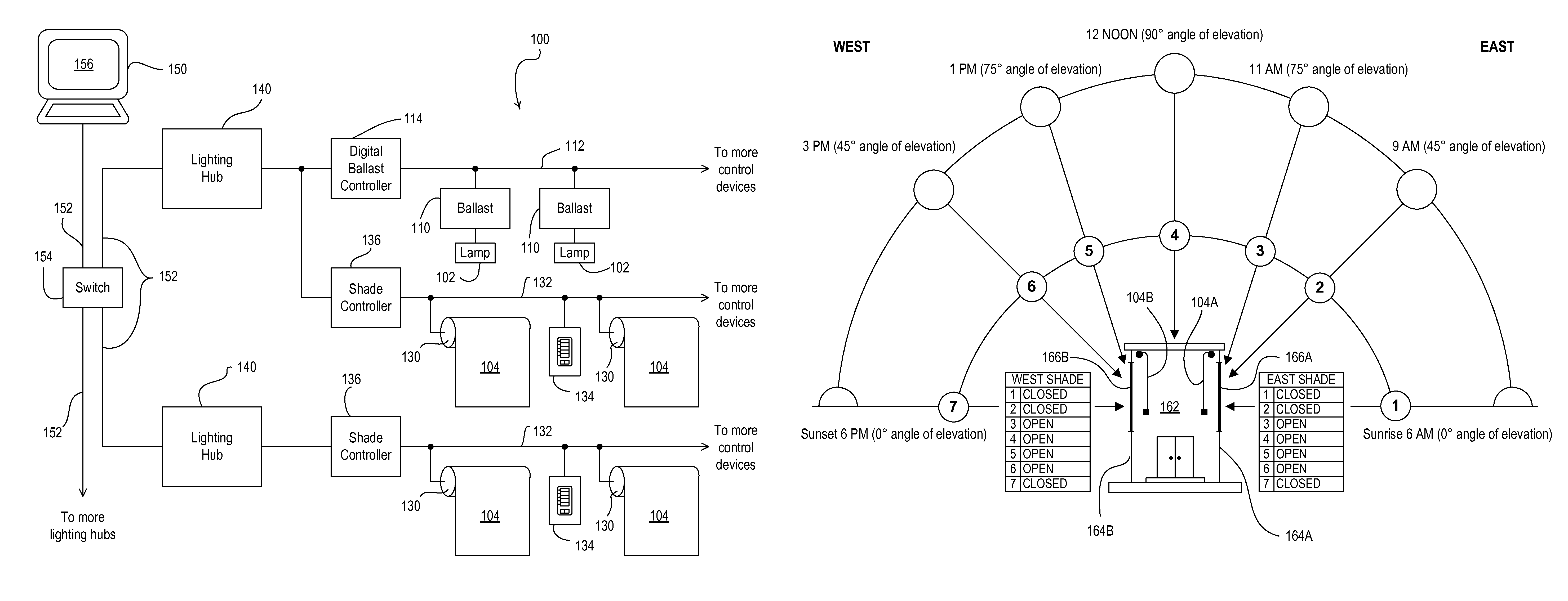

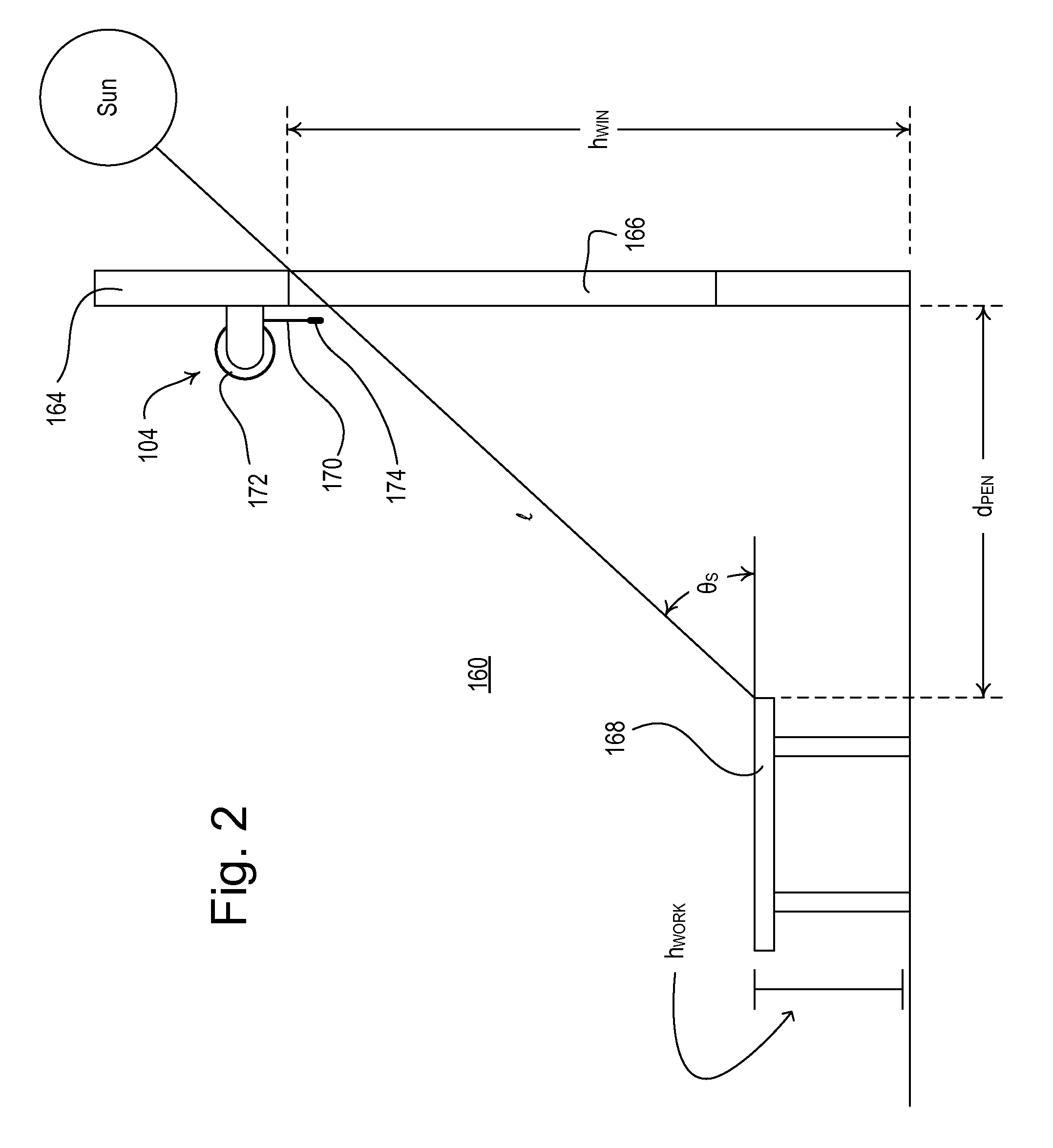

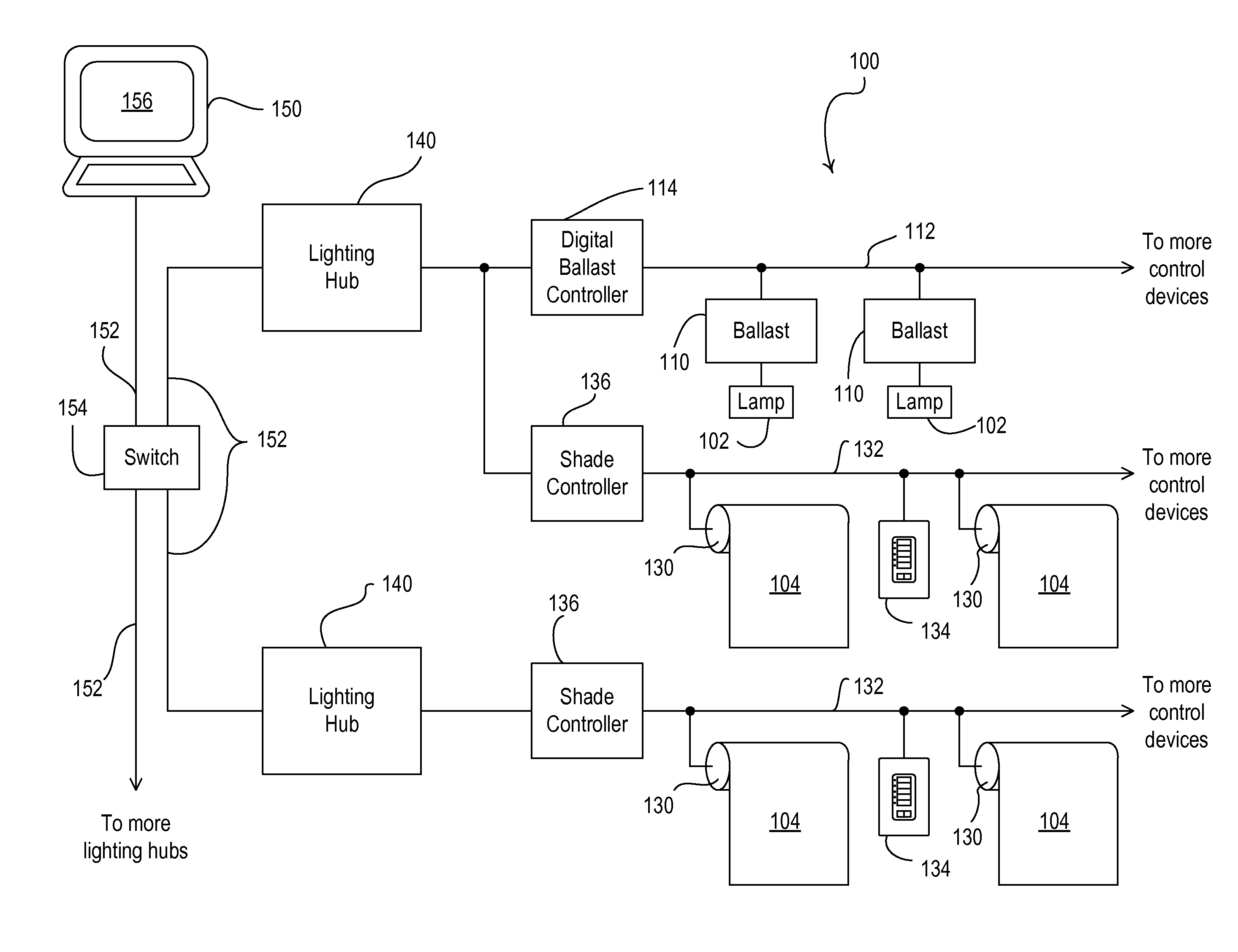

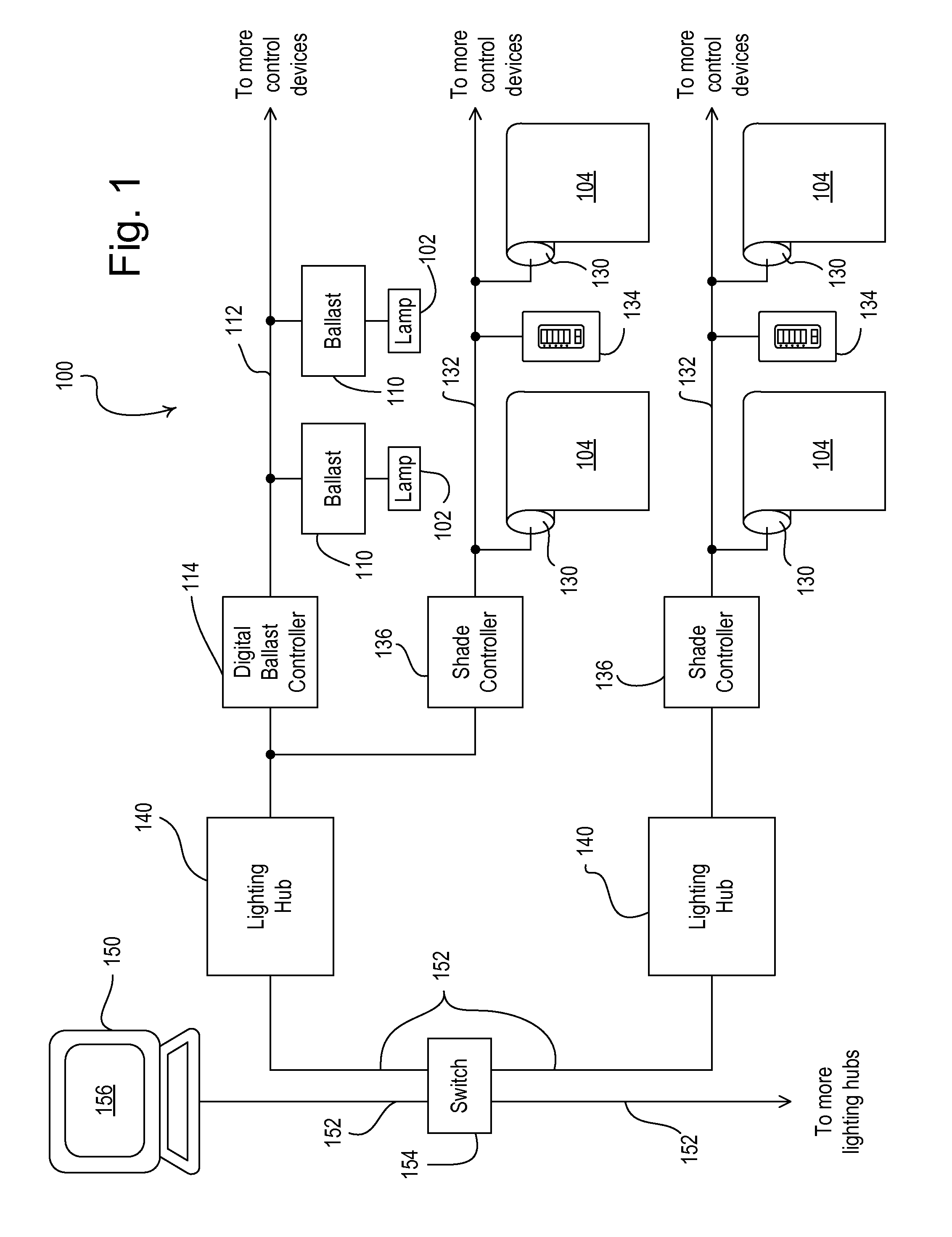

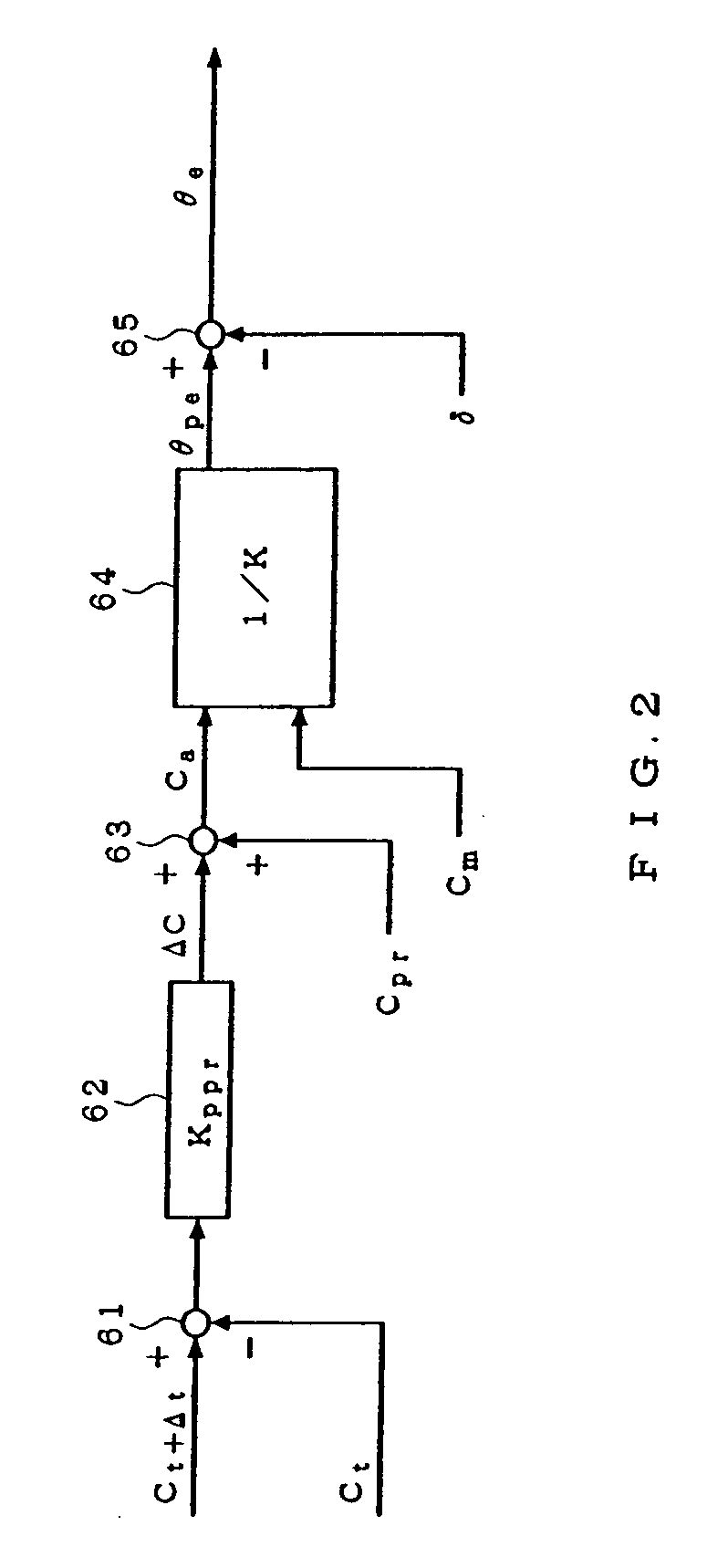

Method of automatically controlling a motorized window treatment while minimizing occupant distractions

ActiveUS8288981B2Minimize distractionDC motor speed/torque controlDoor/window protective devicesPresent dayDistraction

A load control system provides for automatically controlling a position of a motorized window treatment to control the amount of sunlight entering a space of a building through a window located in a façade of the building in order to control a sunlight penetration distance within the space and minimize occupant distractions. The load control system automatically generates a timeclock schedule having a number of timeclock events for controlling the position of the motorized window treatment during the present day. A user is able to select a desired maximum sunlight penetration distance for the space and a minimum time period that may occur between any two consecutive timeclock events. In addition, a maximum number of movements that may occur during the timeclock schedule may also be entered. The load control system uses these inputs to determine event times and corresponding positions of the motorized window treatment for each timeclock event of the timeclock schedule.

Owner:LUTRON TECH CO LLC

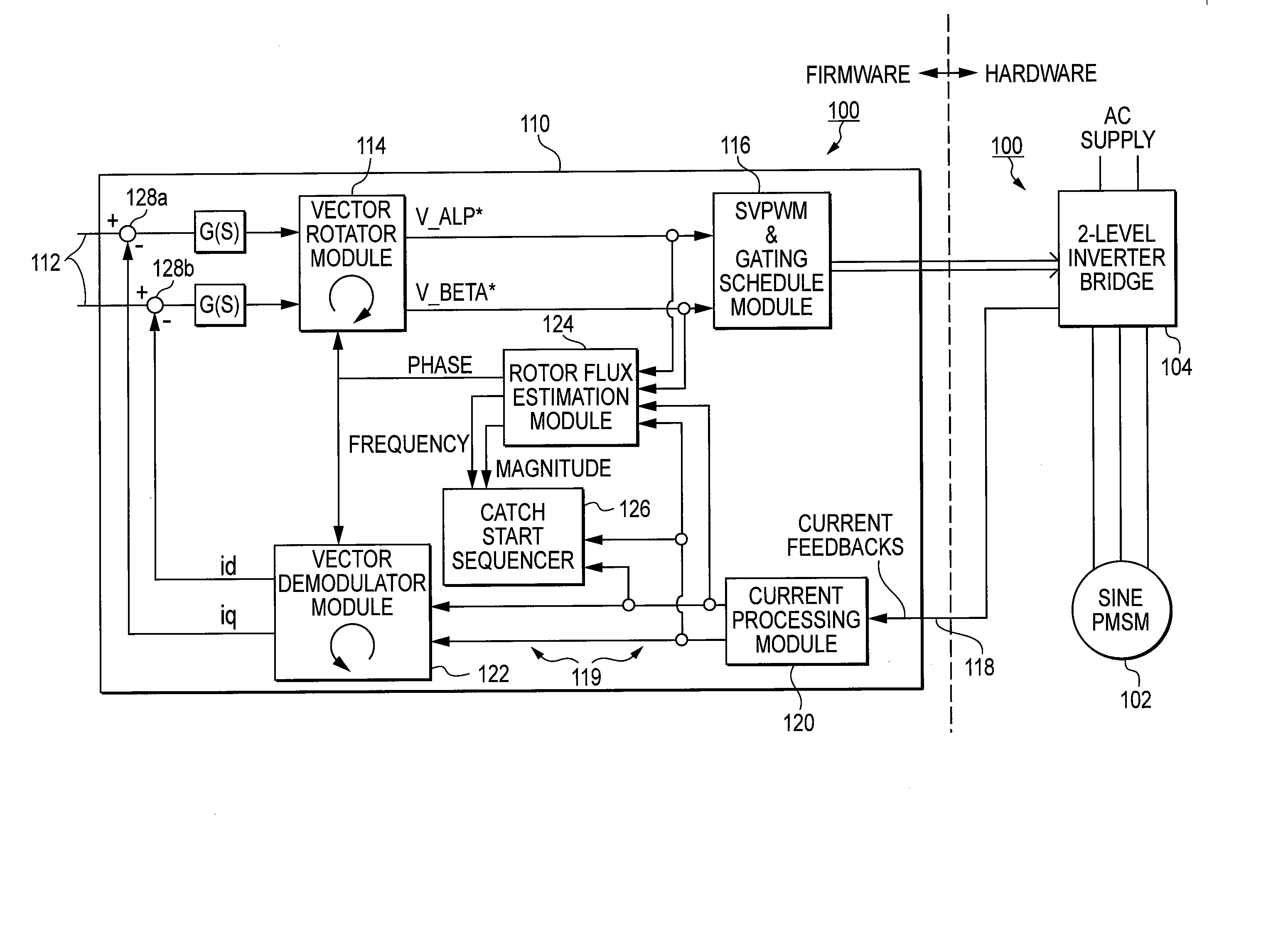

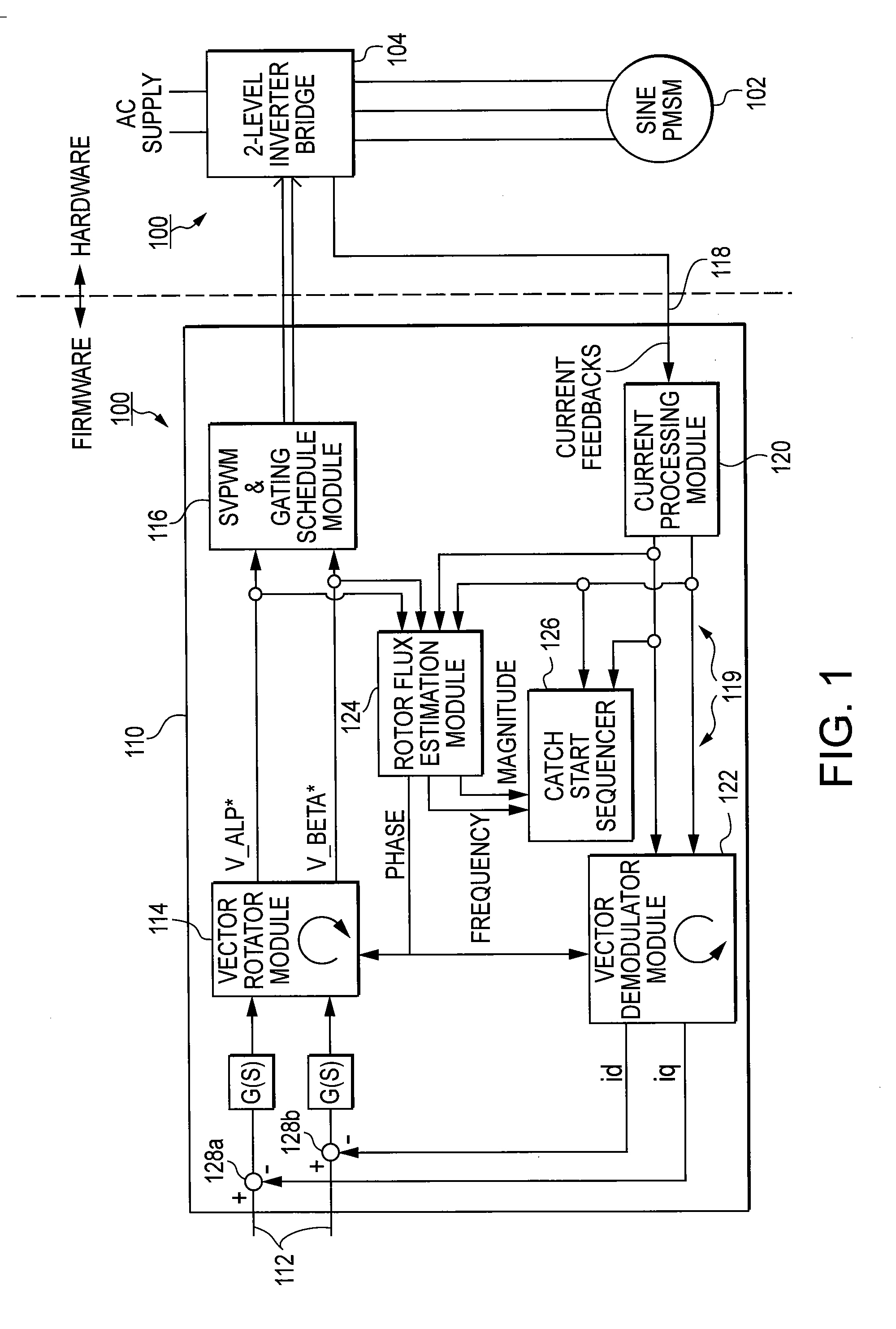

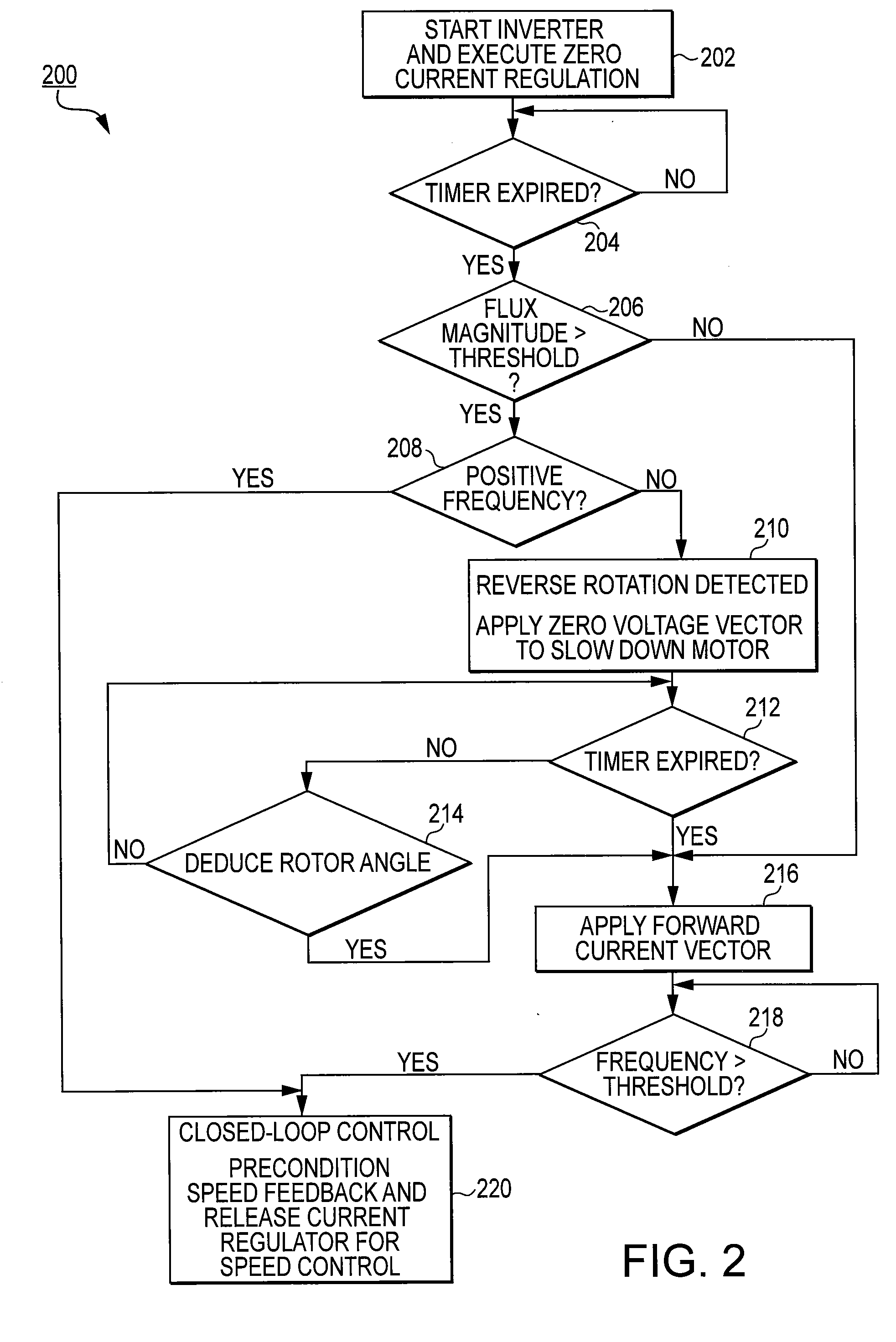

Method and system for starting a sensorless motor

ActiveUS20070001635A1Preventing over current shutdownHigh currentAC motor controlSynchronous motors startersMotor driveEngineering

A motor drive system for a sensorless motor includes a catch start sequencer that controls the motor drive system to robustly start the motor in the event the motor rotor is rotating in forward or reverse direction prior to activating the motor drive system. In particular, the catch start sequencer causes the motor drive system to initially find and track the rotor position, and then determines the speed and possibly the direction of rotation of the rotor. If the rotor is rotating in the reverse direction, the catch start sequencer controls the motor drive system to slow the speed of rotation and to then start the rotor rotating in the forward direction.

Owner:INFINEON TECH AMERICAS CORP

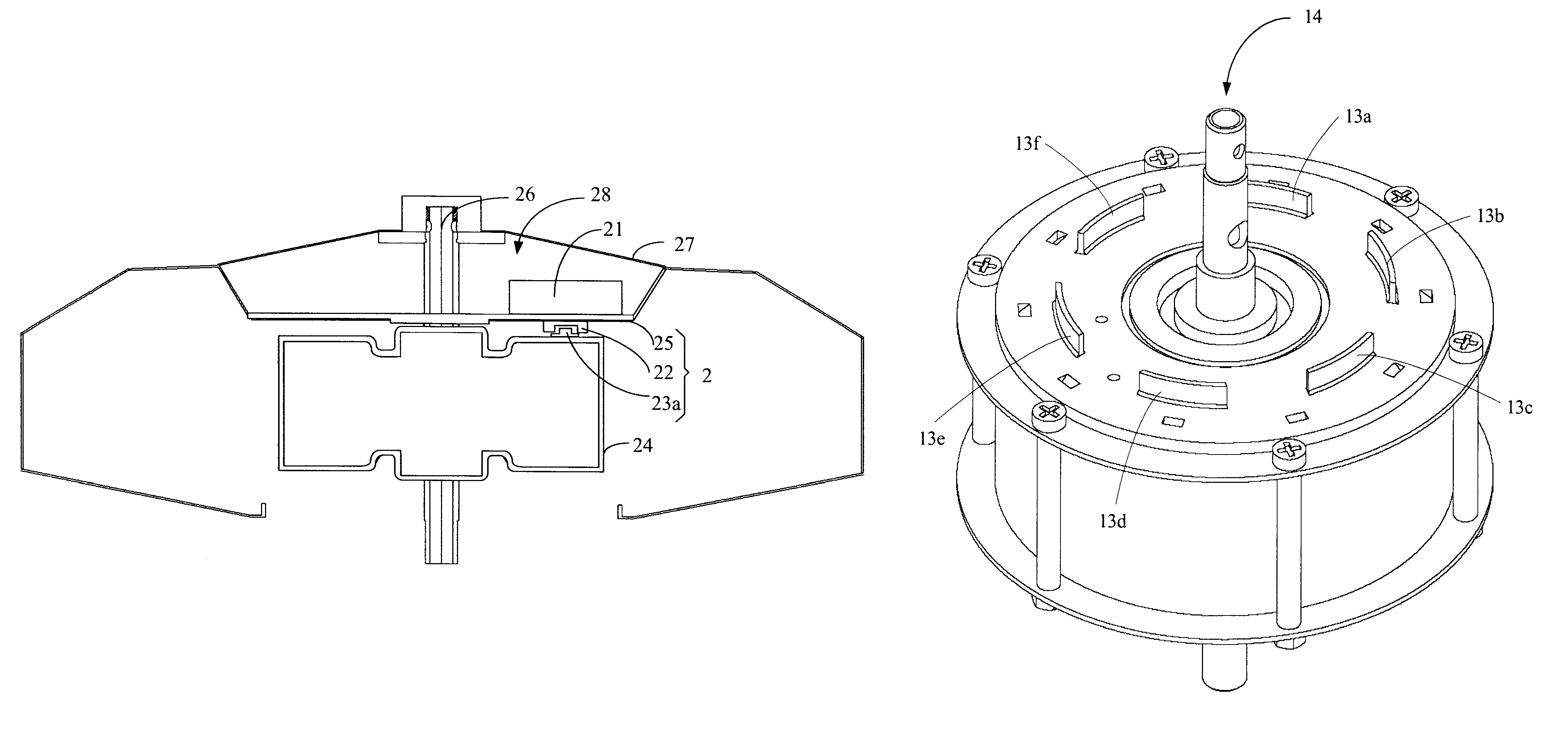

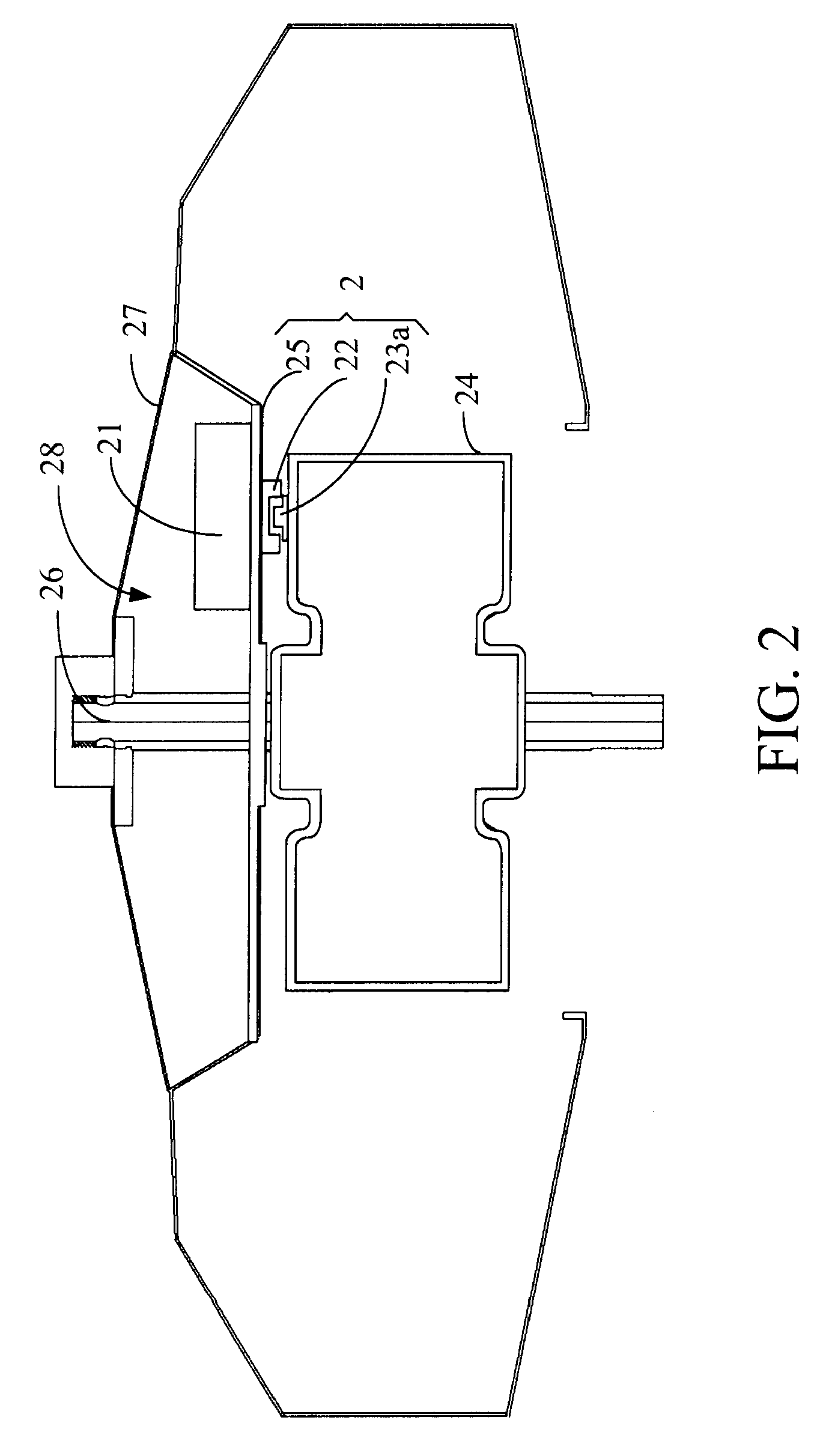

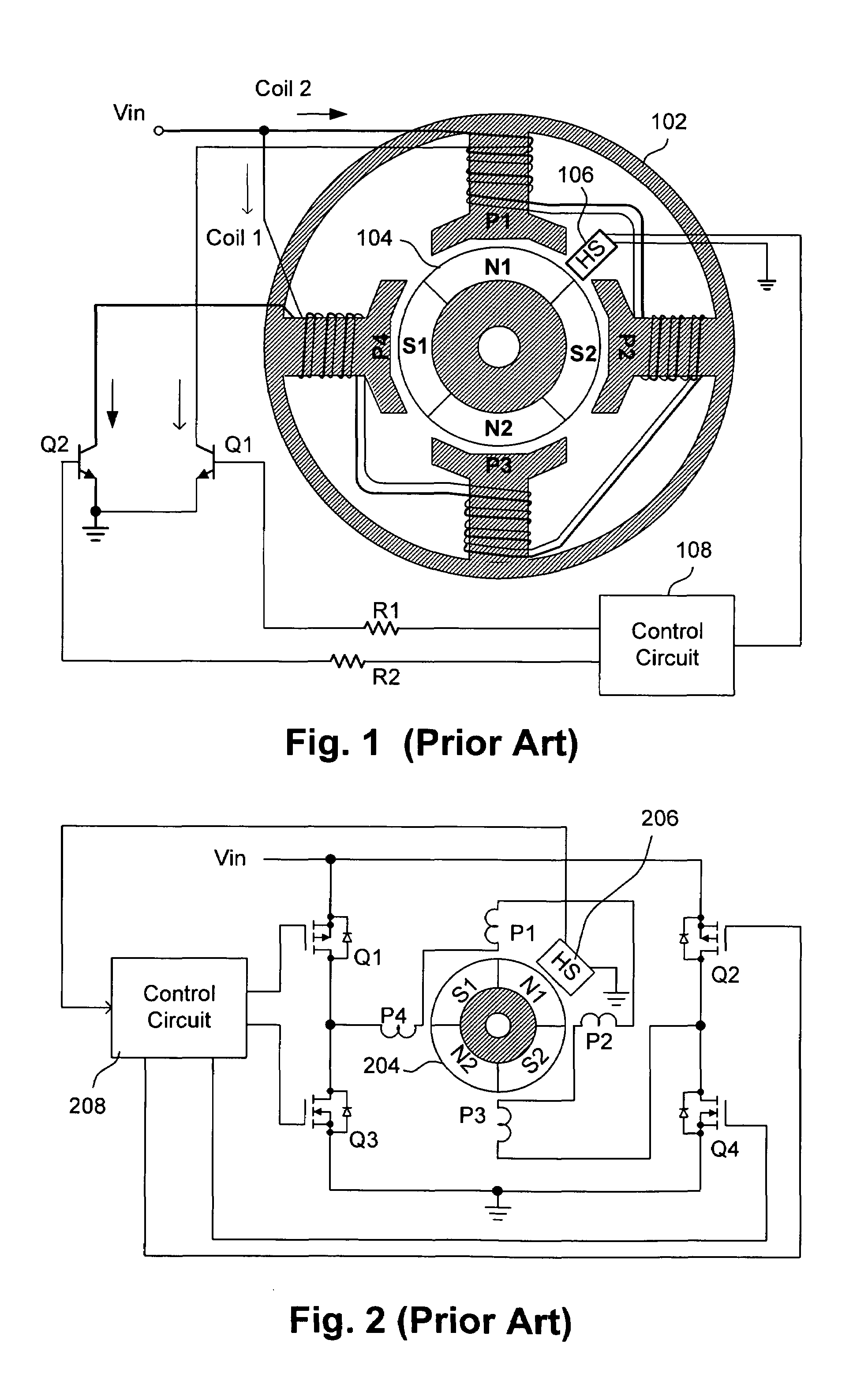

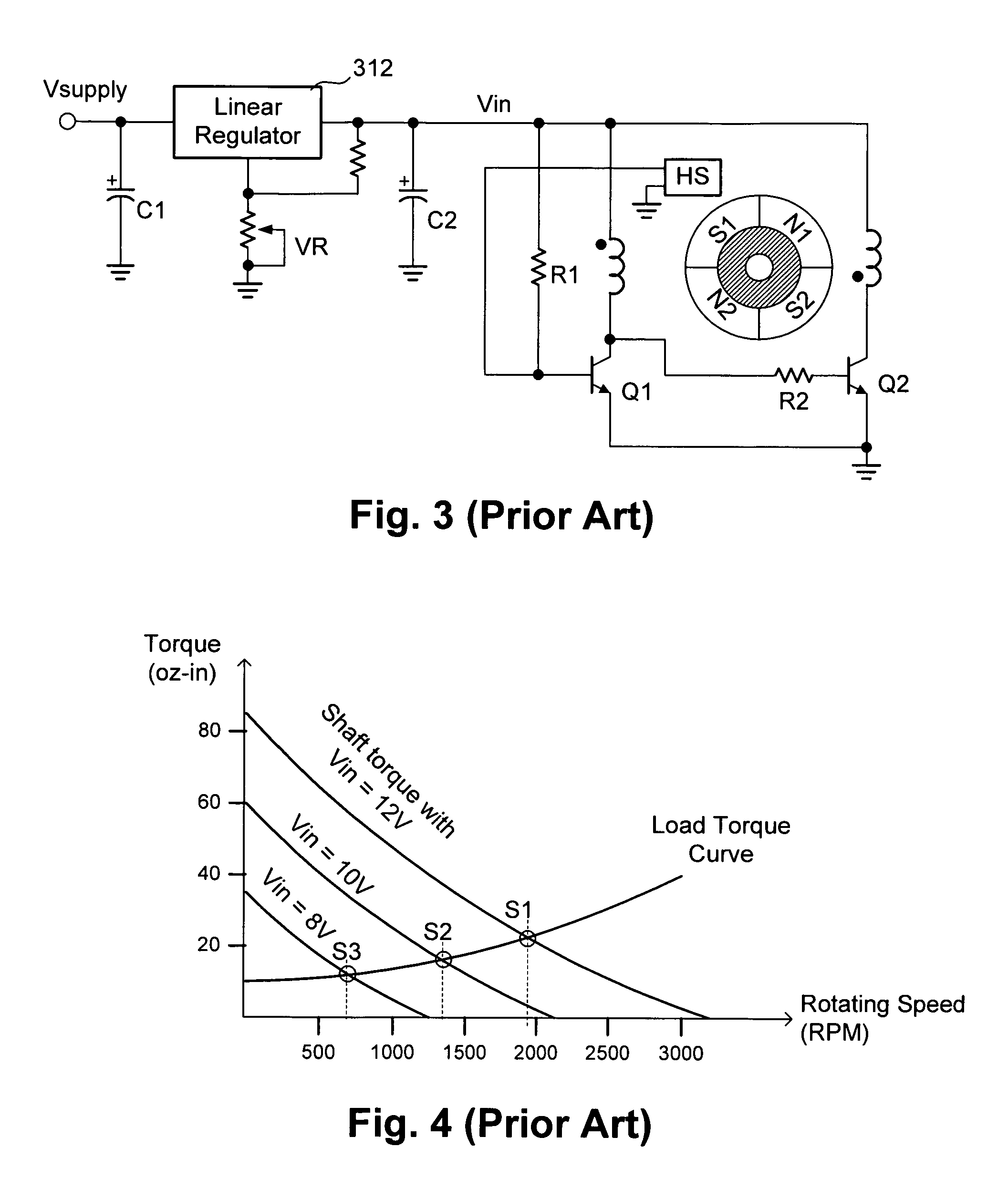

Driving apparatus for a ceiling fan

InactiveUS7664377B2Reduce the amount presentReduce in quantityPiezoelectric/electrostriction/magnetostriction machinesElectric testing/monitoringBrushless motorsCeiling fan

A driving apparatus for a DC brushless motor of a ceiling fan is provided. By setting at least one coder and one sensor outside the DC brushless motor, the driving apparatus can sense the position of magnetic poles of the motor for driving the motor. Meanwhile, a controller set with the motor stores the rotation speed of the motor before being turned off by detecting the turn-off time of a turn-on / off signal.

Owner:RHINE ELECTRONICS

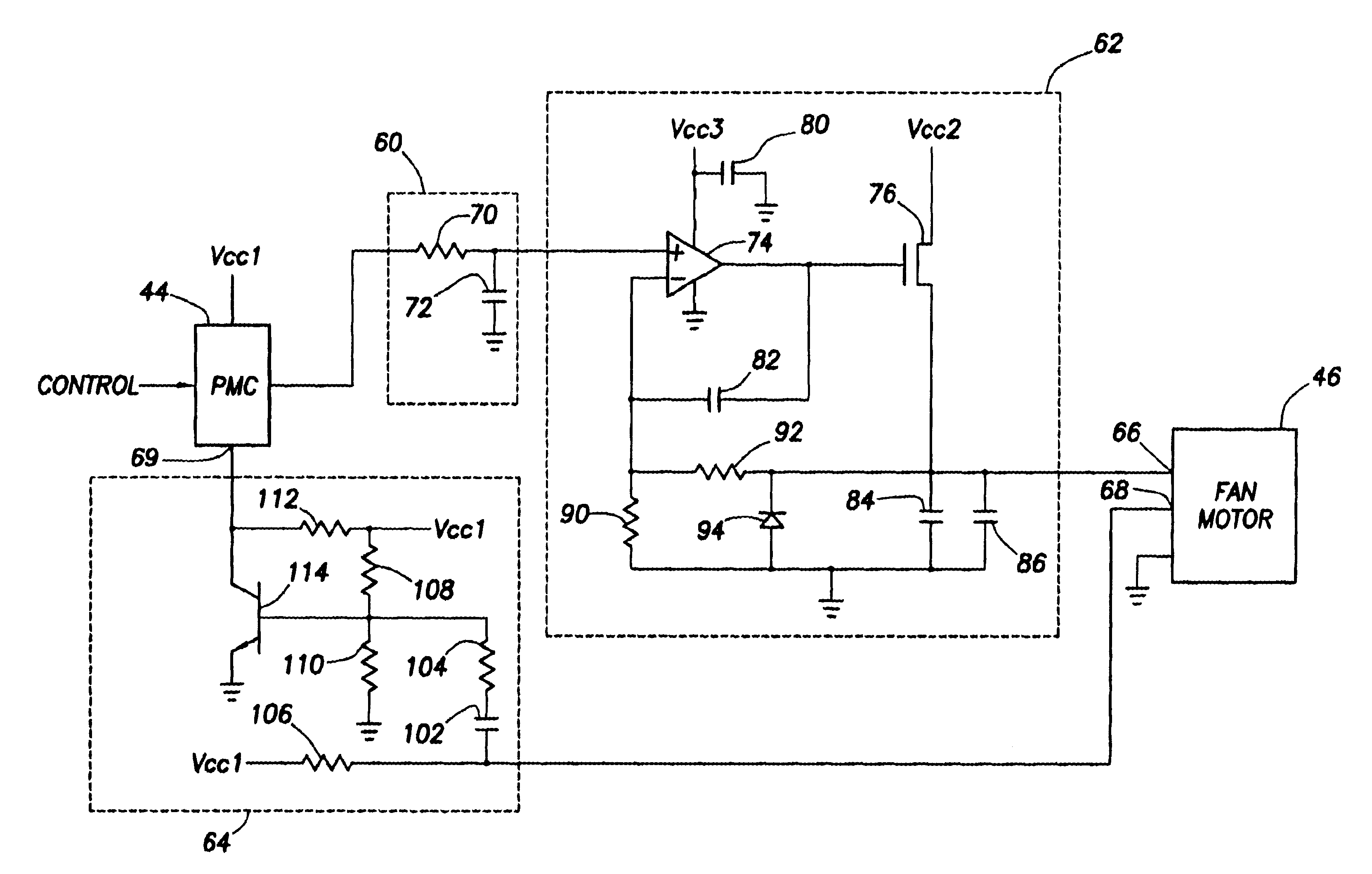

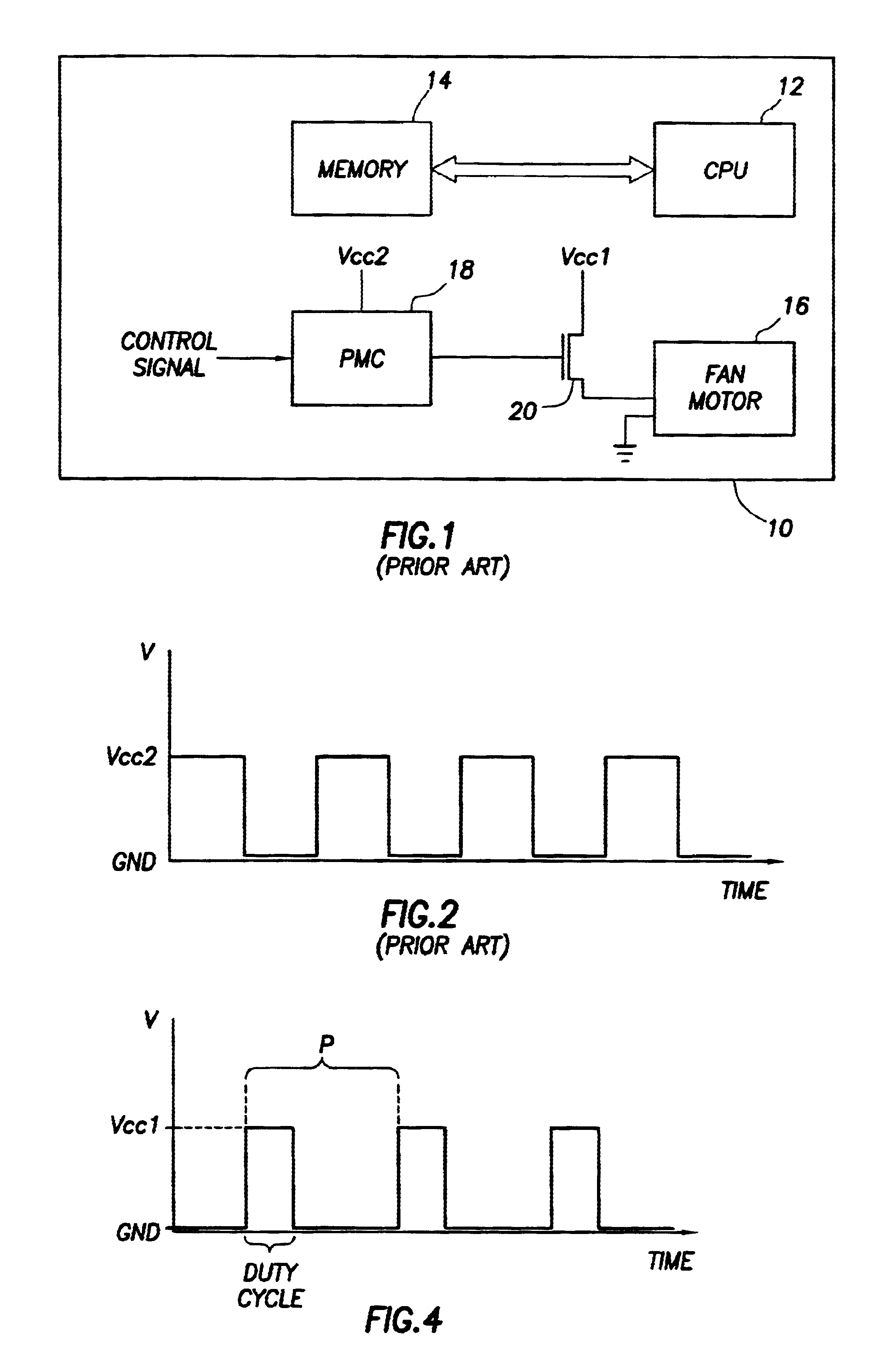

Fan speed controller with conditioned tachometer signal

The speed of a fan motor is controlled by varying a DC voltage to the fan motor. A series pass transistor is used to vary the DC voltage to the fan motor. A power management controller sets the fan motor speed by outputting pulses to a pulse-to-DC voltage converter that changes the pulses to a proportional DC control voltage for controlling the series pass transistor. A tachometer output amplifier circuit is used to remove DC components and amplify to useful logic levels a low level tachometer output signal from the fan motor. The amplified tachometer signal is used by the power management controller in controlling the rotational speed of the fan motor.

Owner:DELL PROD LP

Method of Automatically Controlling a Motorized Window Treatment While Minimizing Occupant Distractions

ActiveUS20100071856A1Minimize distractionLimited penetration distanceDC motor speed/torque controlCurtain accessoriesPresent dayDistraction

A load control system provides for automatically controlling a position of a motorized window treatment to control the amount of sunlight entering a space of a building through a window located in a façade of the building in order to control a sunlight penetration distance within the space and minimize occupant distractions. The load control system automatically generates a timeclock schedule having a number of timeclock events for controlling the position of the motorized window treatment during the present day. A user is able to select a desired maximum sunlight penetration distance for the space and a minimum time period that may occur between any two consecutive timeclock events. In addition, a maximum number of movements that may occur during the timeclock schedule may also be entered. The load control system uses these inputs to determine event times and corresponding positions of the motorized window treatment for each timeclock event of the timeclock schedule.

Owner:LUTRON TECH CO LLC

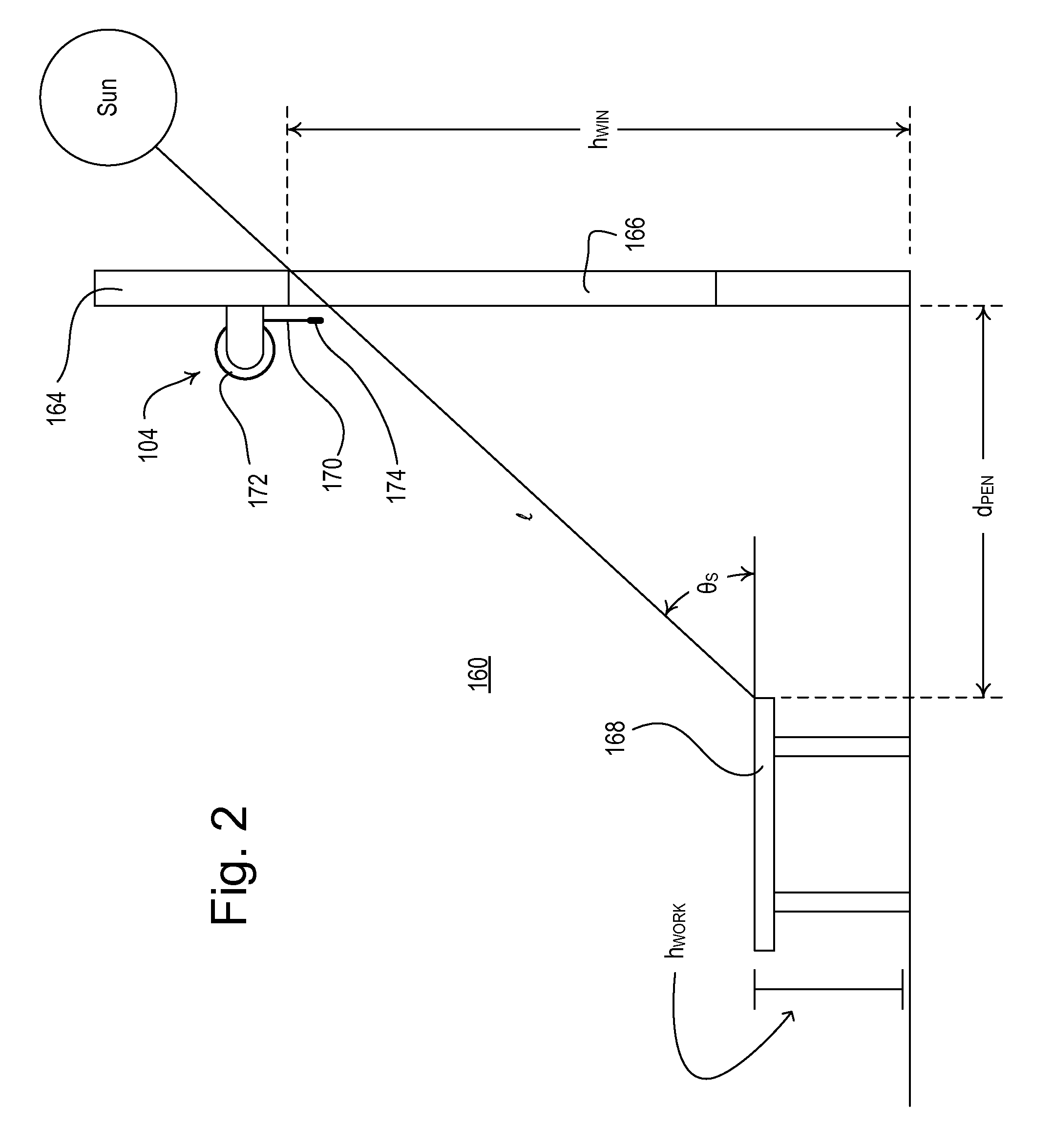

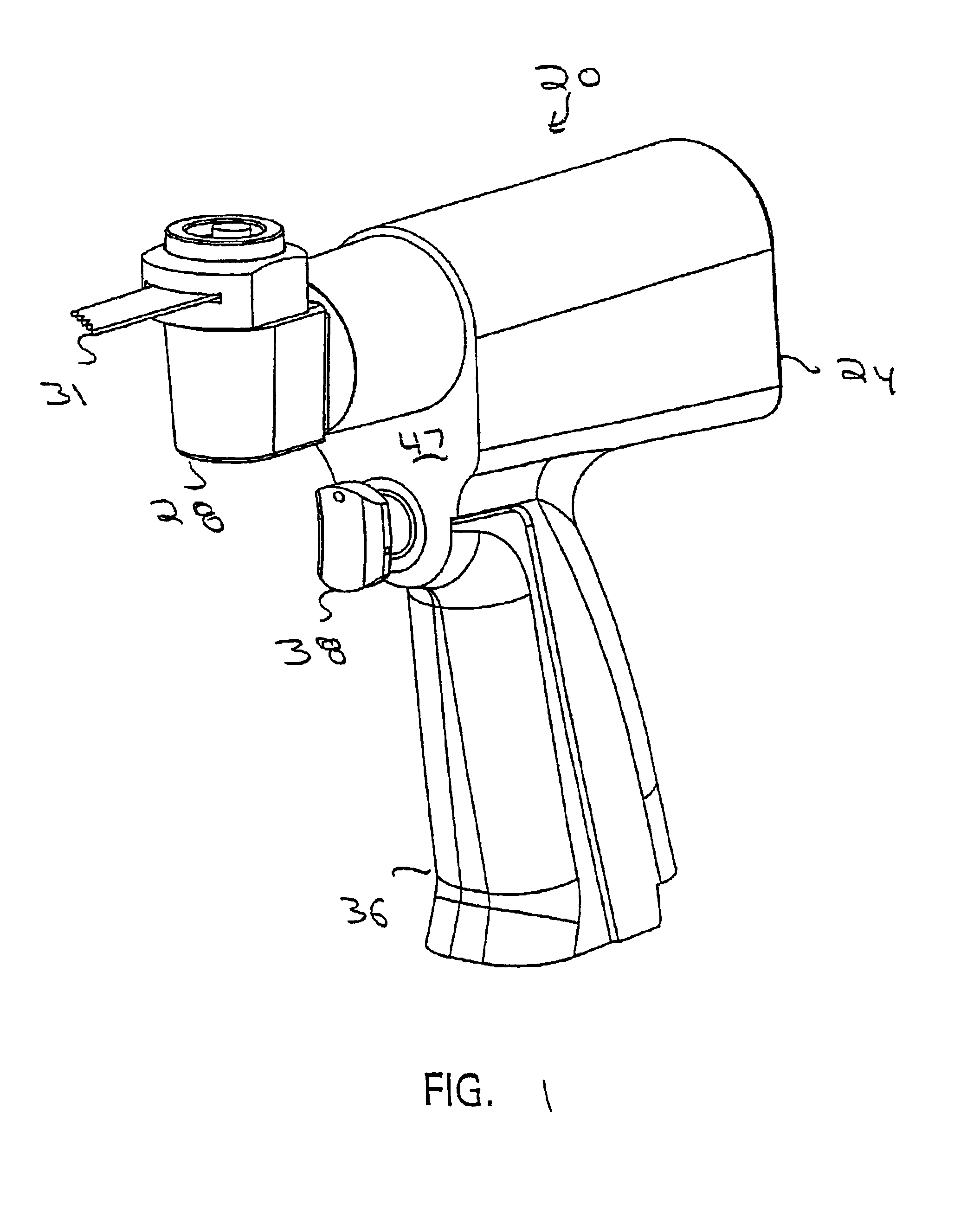

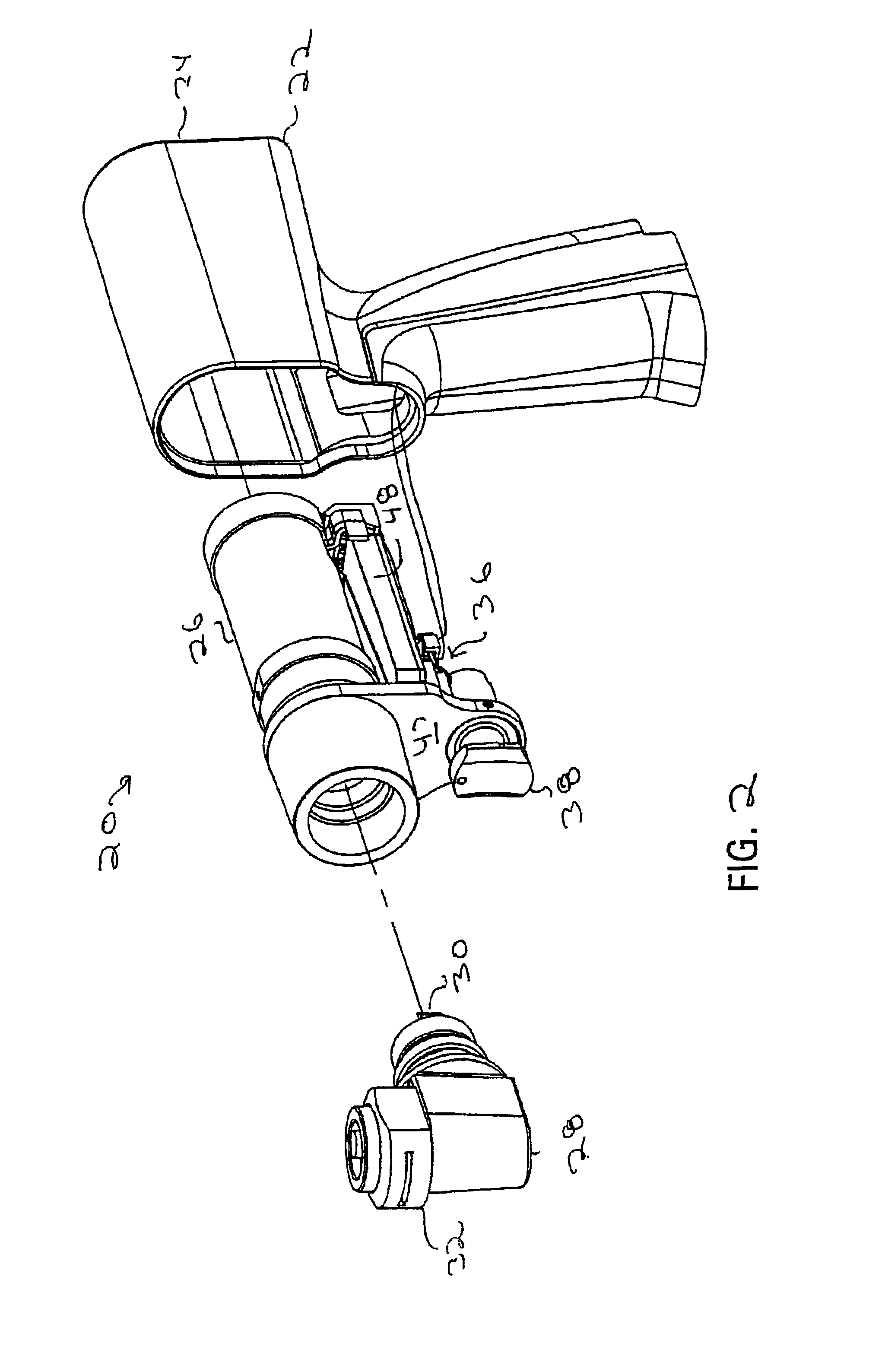

Cordless, powered surgical tool

InactiveUS6960894B2Reduce noiseAvoid difficult choicesSynchronous motors startersAC motor controlComputer moduleControl theory

A powered tool for performing surgical procedures. The tool includes a handpiece in which a power generating unit is housed. A control member is mounted to the handpiece. The control member is mounted to the handpiece so that the orientation of the control member can be selectively set relative to the point to which it is mounted to the handpiece and so it can move relative to a reference point on the handpiece. A control module monitors the orientation of the control member and its position relative to the reference point. Based on the control member orientation and position, the control module generates signals to regulate the operation of the power generating unit. When the power generating unit is a motor, the control module generates signals to ensure that the maximum speed at which the motor can be driven is less than the no load speed.

Owner:STRYKER CORP

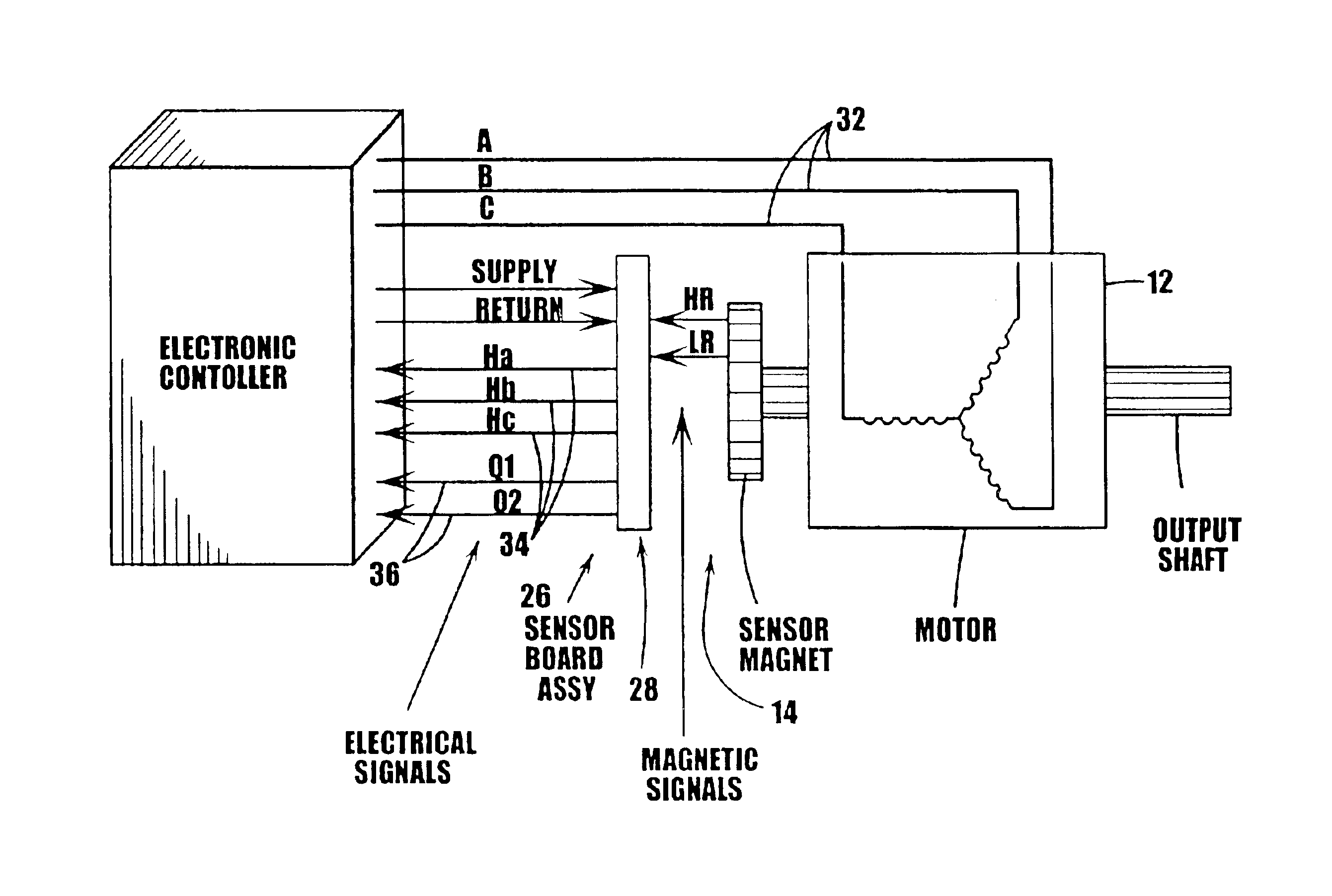

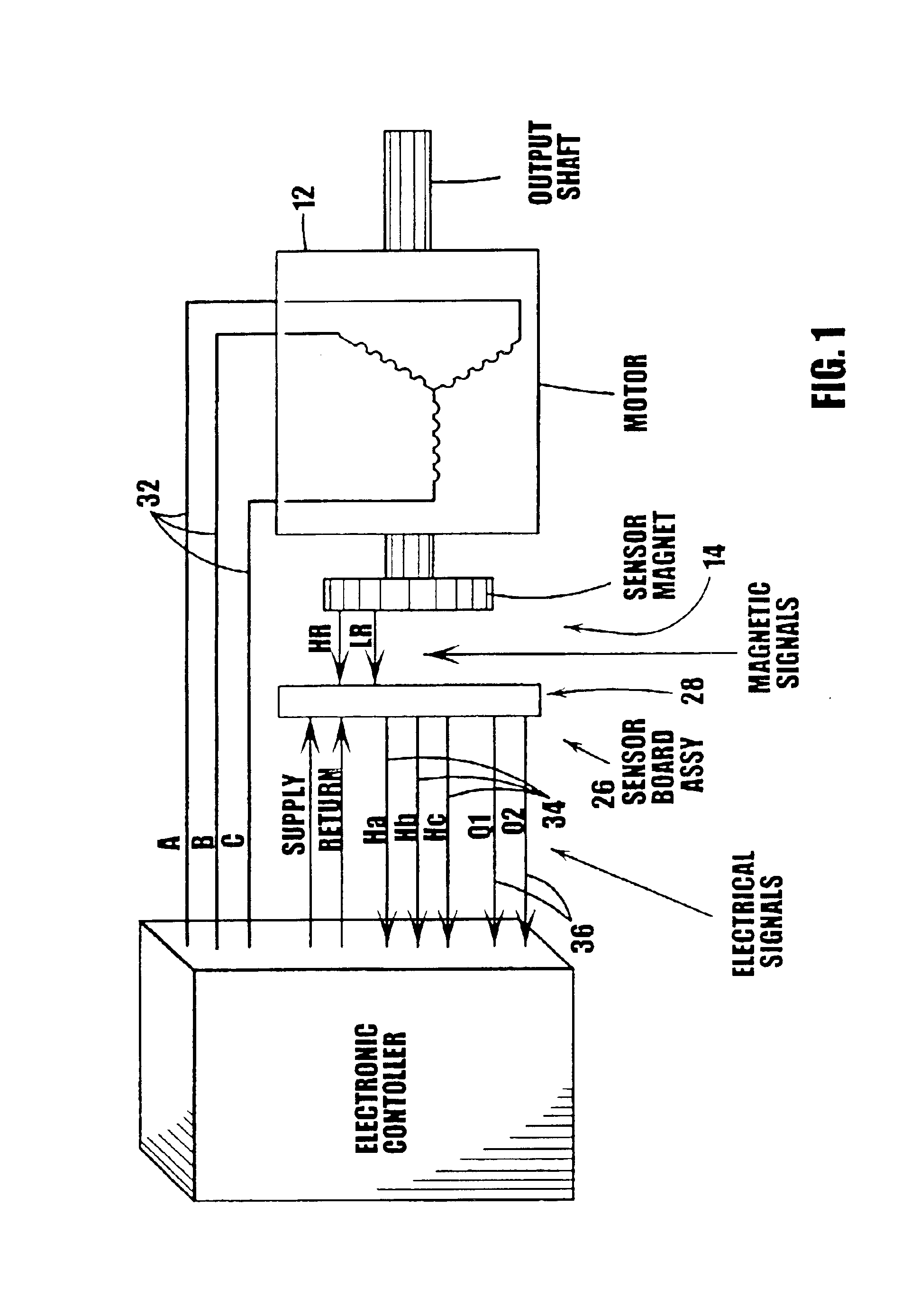

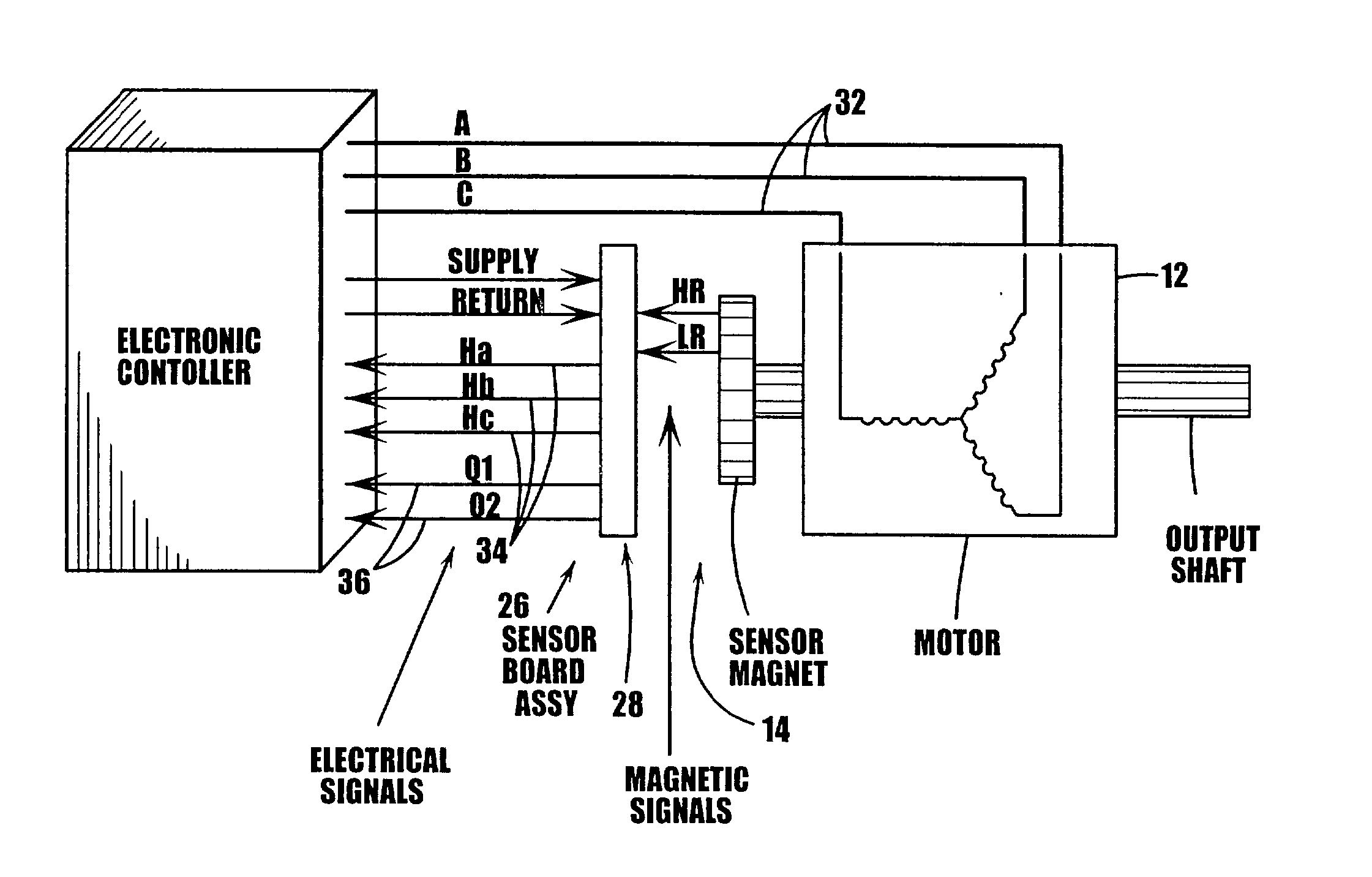

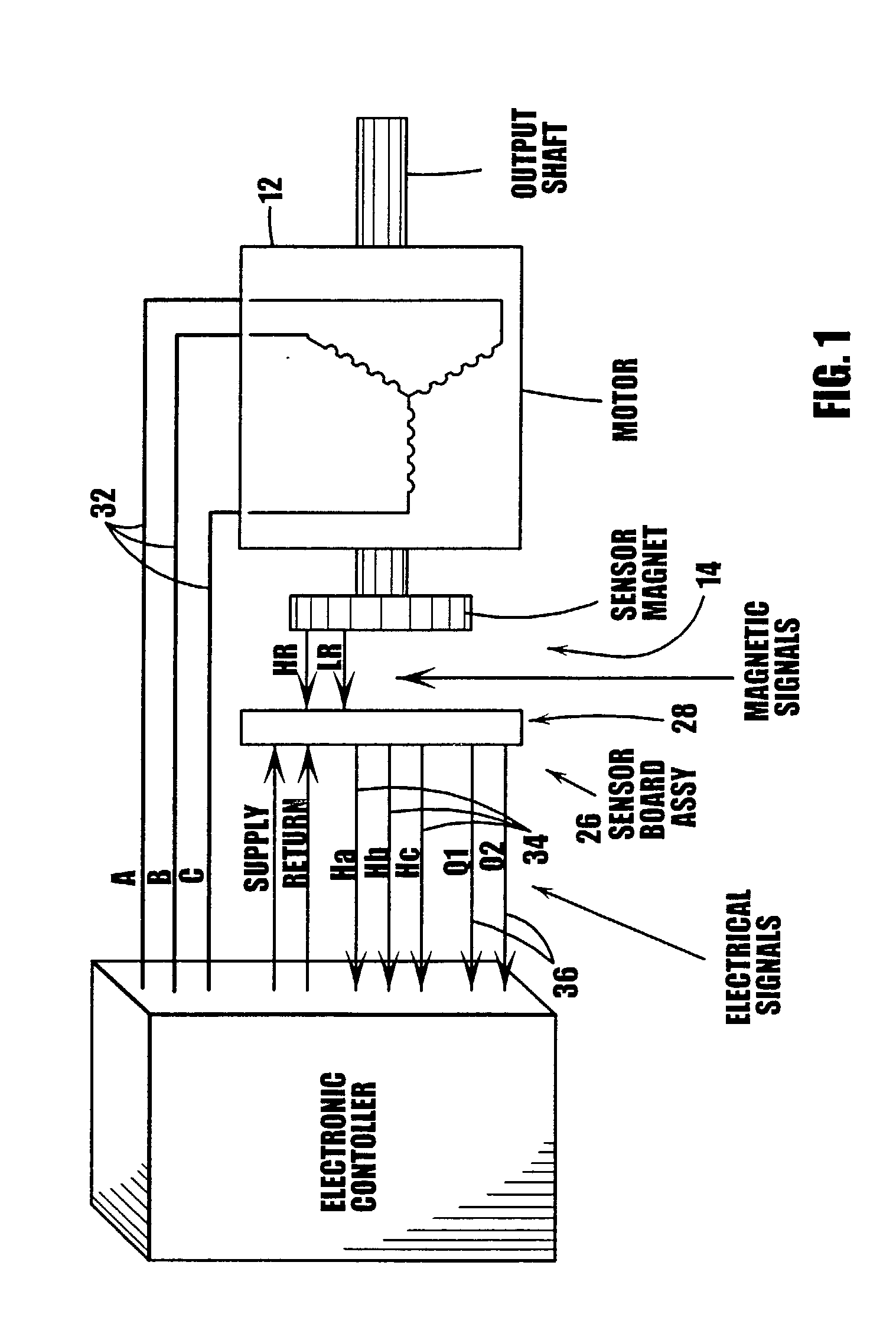

Method and apparatus for calibrating and initializing an electronically commutated motor

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Method and apparatus for calibrating and initializing an electronically commutated motor

Disclosed herein is a method and system for initializing a rotating device such as an electronically commutated electric machine. The system comprises: an electric machine; a position sensor subsystem operatively connected to the electric machine configured to measure a position and transmit a position signal to a controller. The controller executes a method initializing position for the electric machine, the method comprising: establishing a sensor subsystem datum indicative of a measurement reference point for a sensor subsystem; obtaining a calibration value corresponding to a distance to a selected magnetic reference position for the electric machine, relative to the sensor subsystem datum; and measuring a position and calculating a position delta relative to an initial reference. The method also includes: estimating an offset from the sensor subsystem datum to an initial reference; determining an absolute position estimate of the electric machine relative to the magnetic reference position. The absolute position estimate is responsive to the calibration value, the position delta, and the offset from the sensor subsystem datum to the initial reference.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Excitation circuit and control method for flux switching motor

InactiveUS6943510B2Improves torque/speed performance of motorEliminate needDC motor speed/torque controlAC motor controlMicrocontrollerPower factor

An excitation circuit for a flux switching motor. The circuit includes a low-value film capacitor across the DC side of a bridge rectifier. A plurality of electronic switches are arranged in an H-bridge configuration for switching current flow through an armature winding of the motor in accordance with a PWM control scheme and single-pulse control scheme controlled by a microcontroller. A start-up diode is placed across the field winding of the motor and is electronically switched out of the circuit after a startup phase of the motor has completed. The circuit implements armature energy recirculation through the field winding during startup to promote more uniform and quicker startup of the motor. The use of a film capacitor improves the power factor of the circuit, helps to eliminate the introduction of harmonics into the AC voltage source, and helps in mitigating EMI. Reverse commutation is used to bring the motor to a quick stop when it is powered off.

Owner:BLACK & DECKER INC

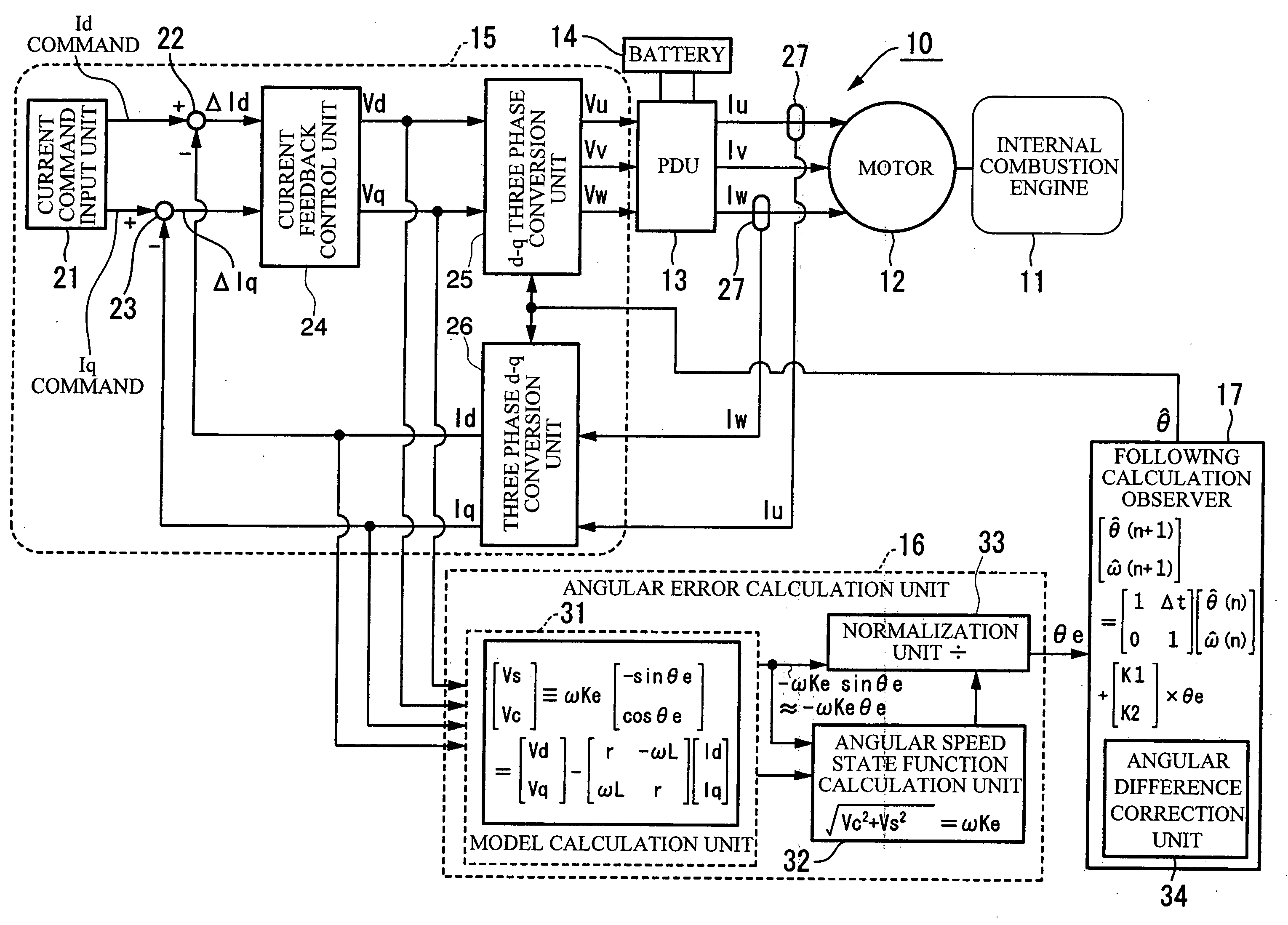

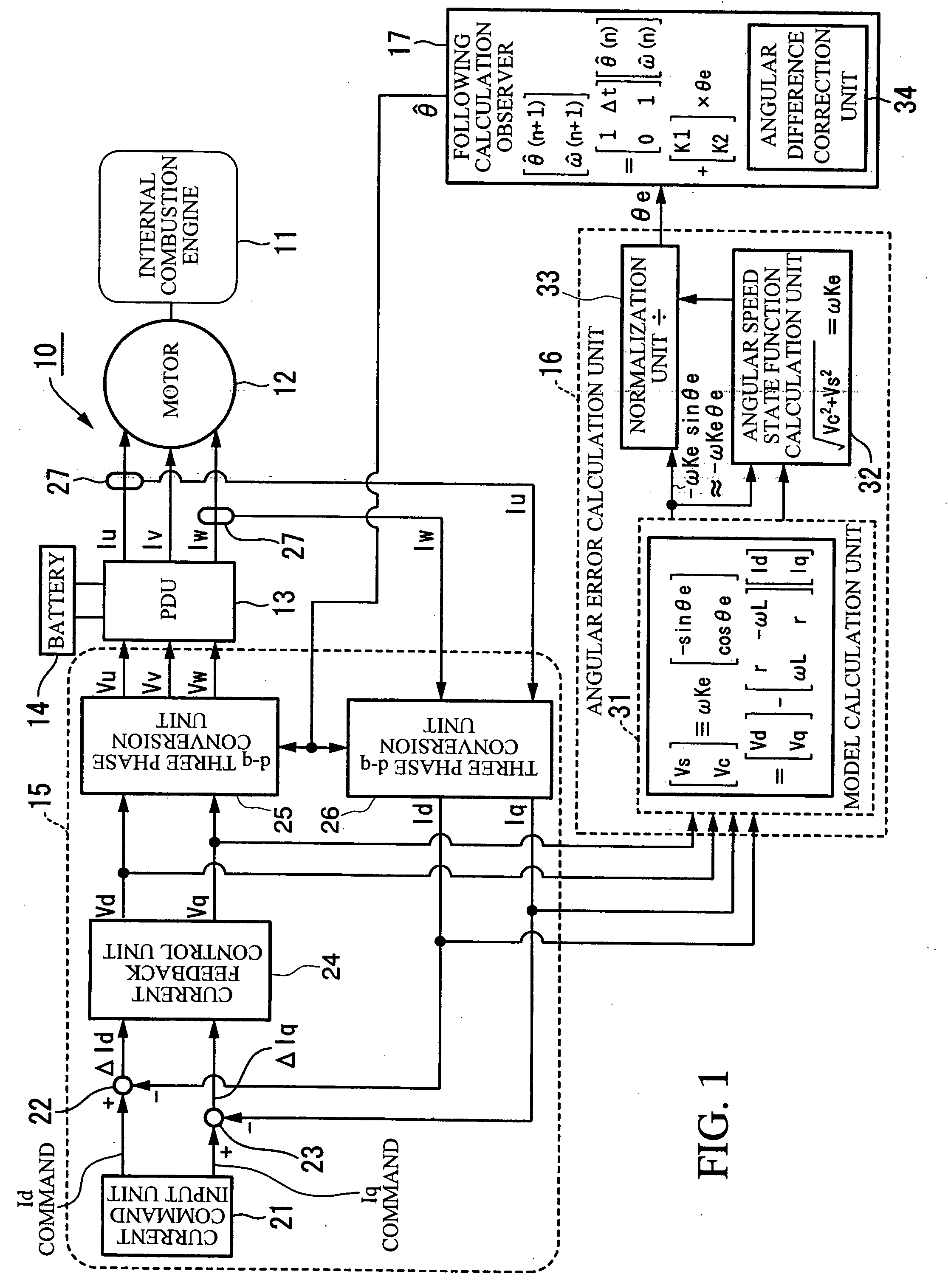

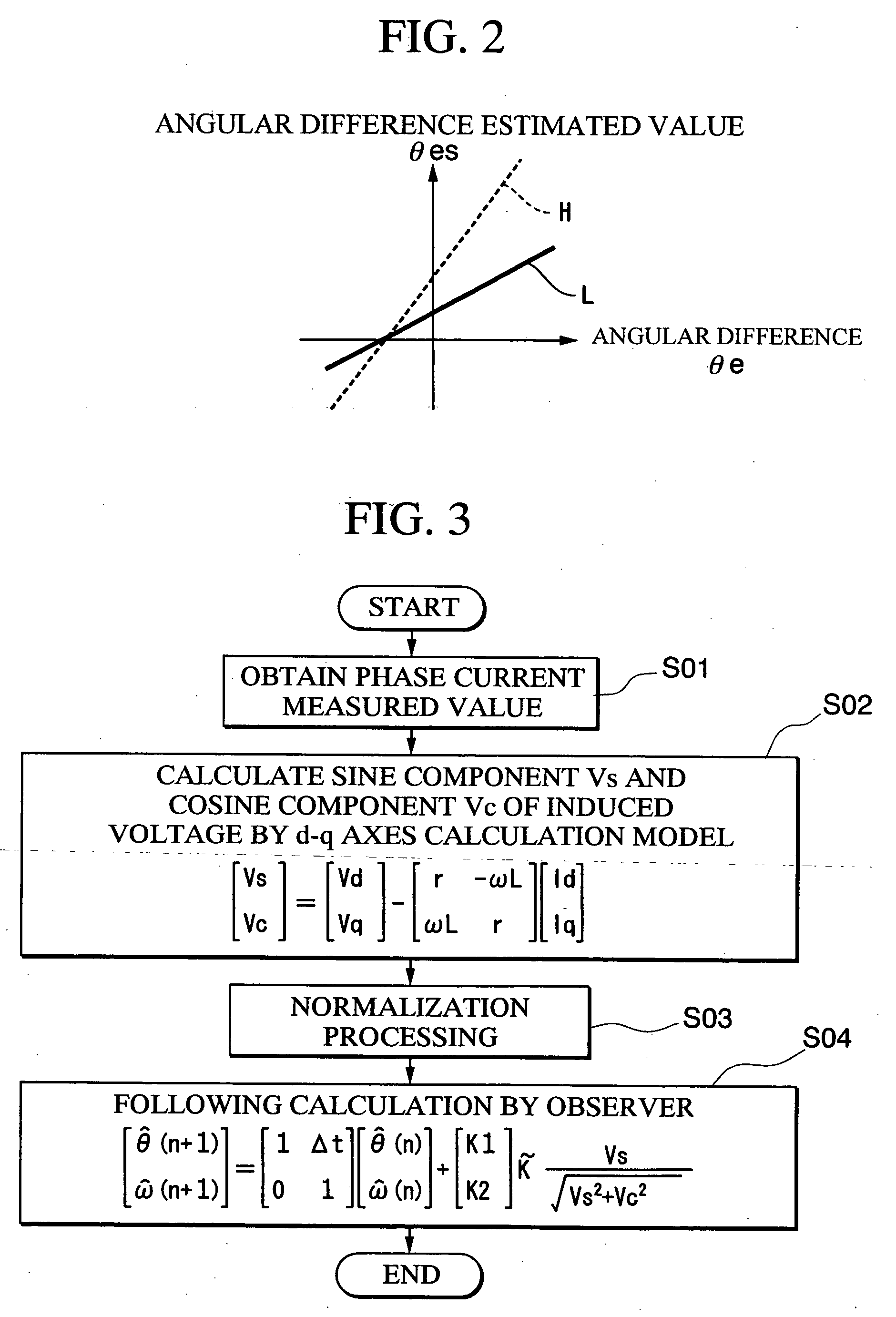

Control apparatus for brushless DC motor

ActiveUS20050029972A1Improve estimation accuracySynchronous motors startersVector control systemsPhase currentsConductor Coil

Owner:HONDA MOTOR CO LTD

Method for controlling an electric motor to reduce EMI

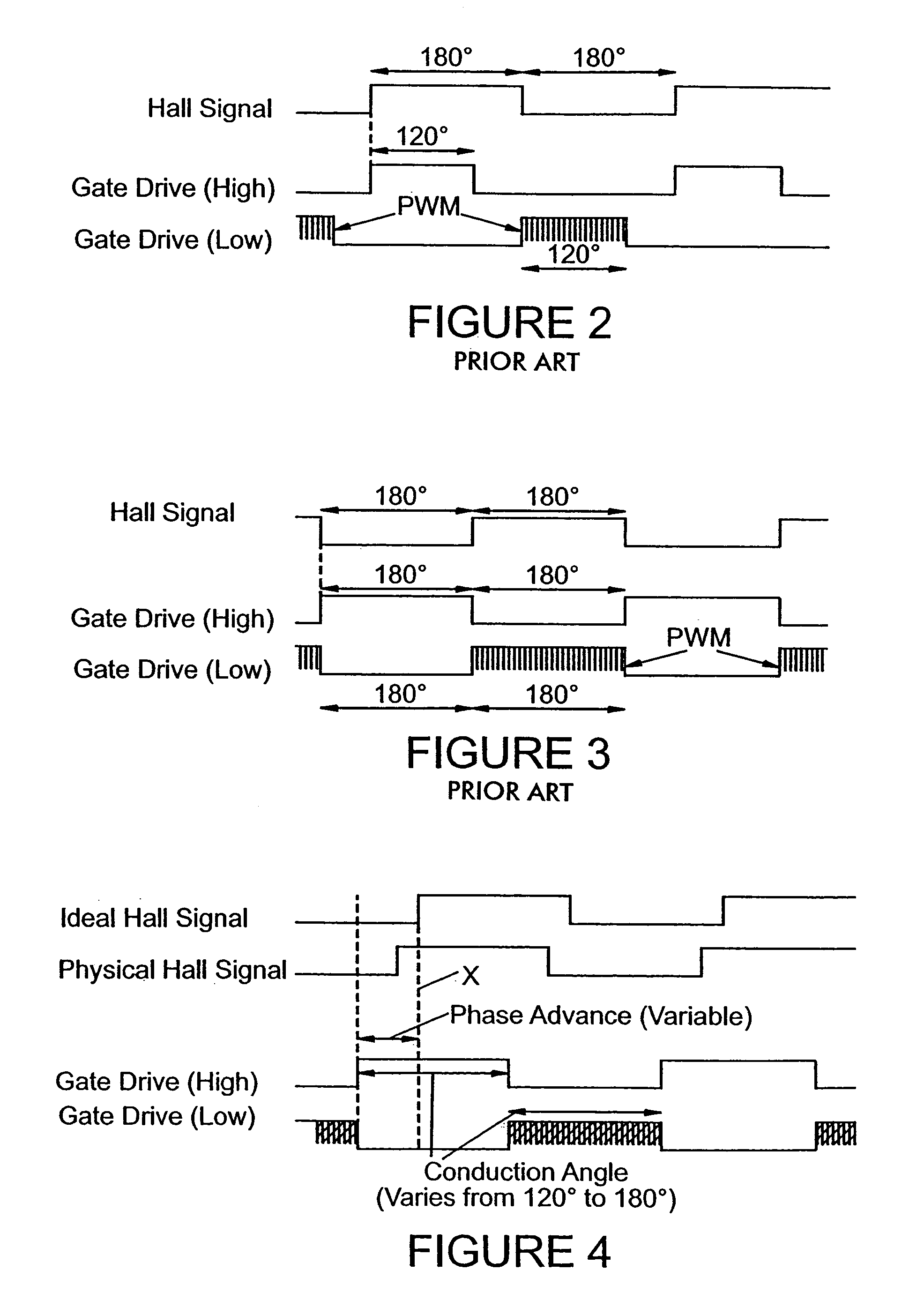

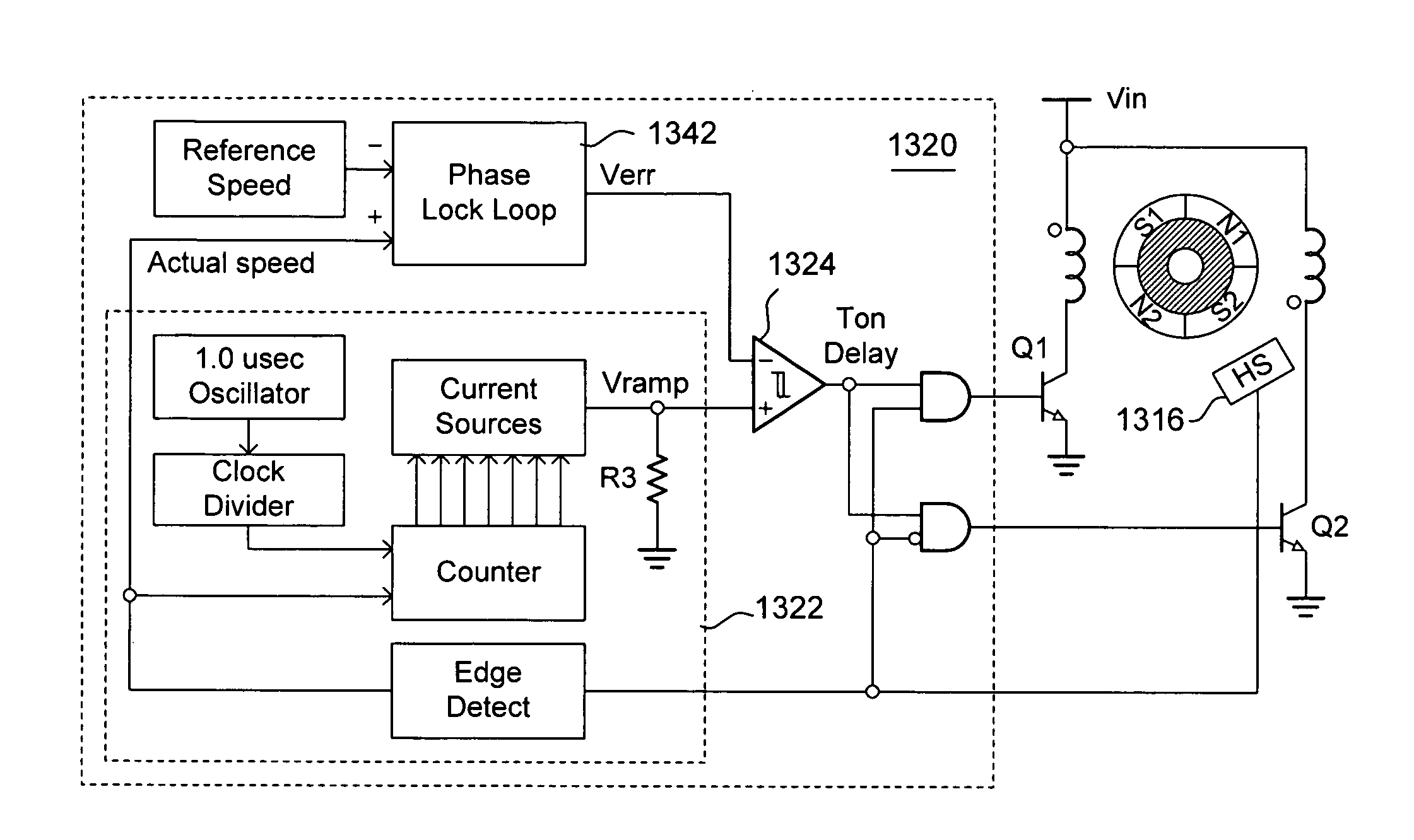

InactiveUS7202622B2Reduce the amount requiredLow costDC motor speed/torque controlSynchronous motors startersPhase advanceDC-BUS

A method for reducing EMI emissions in the control of an electric motor supplied by a switching inverter fed by a DC bus comprising controlling a phase advance of a conduction angle period during which a phase of the motor is fed power by the inverter to control the conduction angle to control the speed of the motor, thereby to reduce the number of switching operations of the inverter and thereby reduce EMI.

Owner:INFINEON TECH AMERICAS CORP

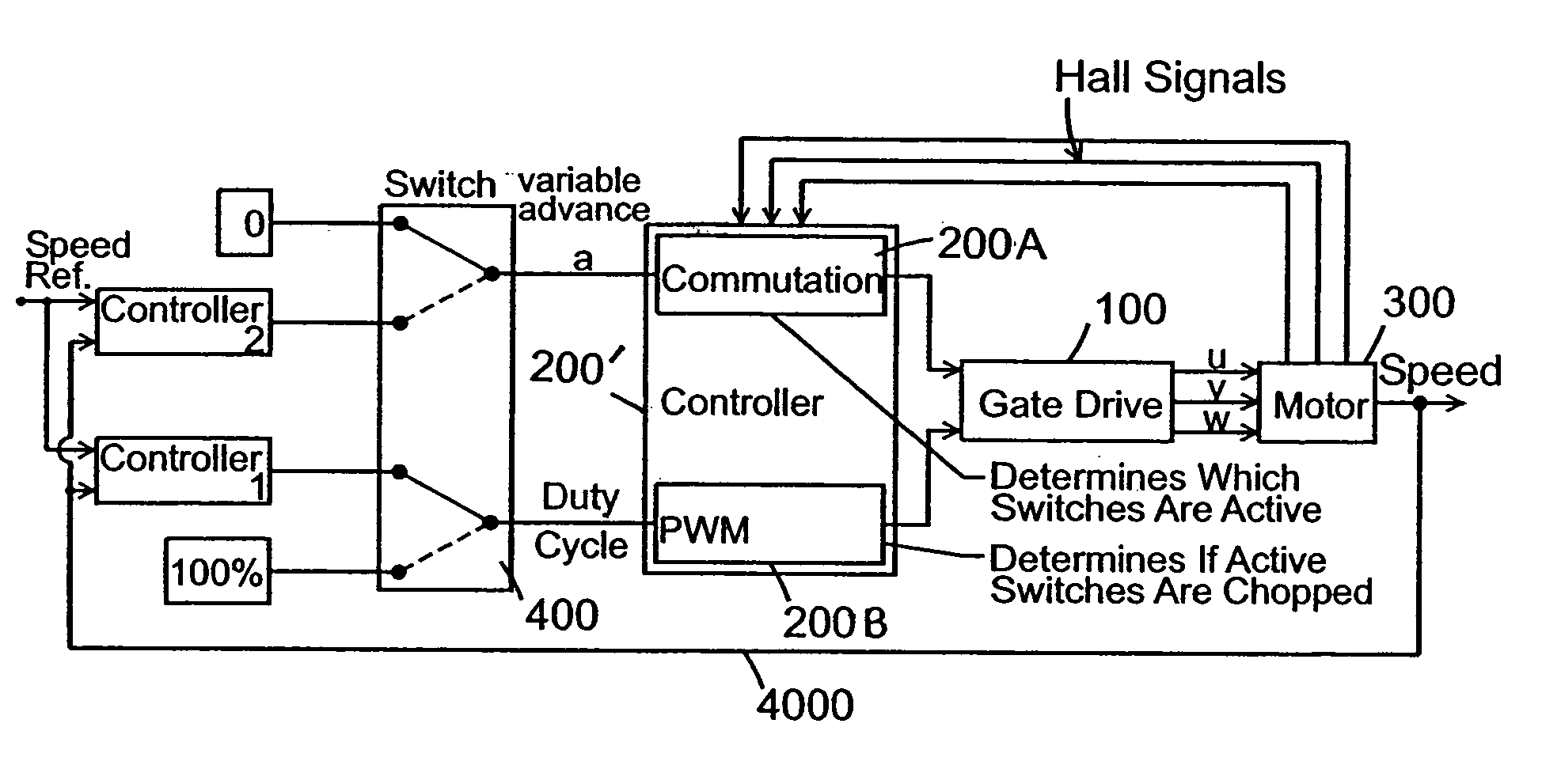

Speed control of brushless DC motors

InactiveUS7259531B1Convenient speed adjustmentEliminate degradationAC motor controlSynchronous motors startersEngineeringControl circuit

The speed control apparatus comprises a plurality of Hall sensors, a plurality of switches, a turn-on control circuit, and a gate drive logic. The Hall sensors are configured to detect magnetic rotor sections of a poly-phase brushless DC motor at different positions. The switches apply voltages on a plurality of windings to respectively produce magnetic north or south on stator poles of the poly-phase BLDC motor. The turn-on control circuit generates a conduction time reduction after each output transition of the Hall sensors. The gate drive logic separately turns on or turns off the switches according to different output transitions of the Hall sensors to respectively apply voltages on the windings with the conduction time reduction.

Owner:GREEN MARK TECH

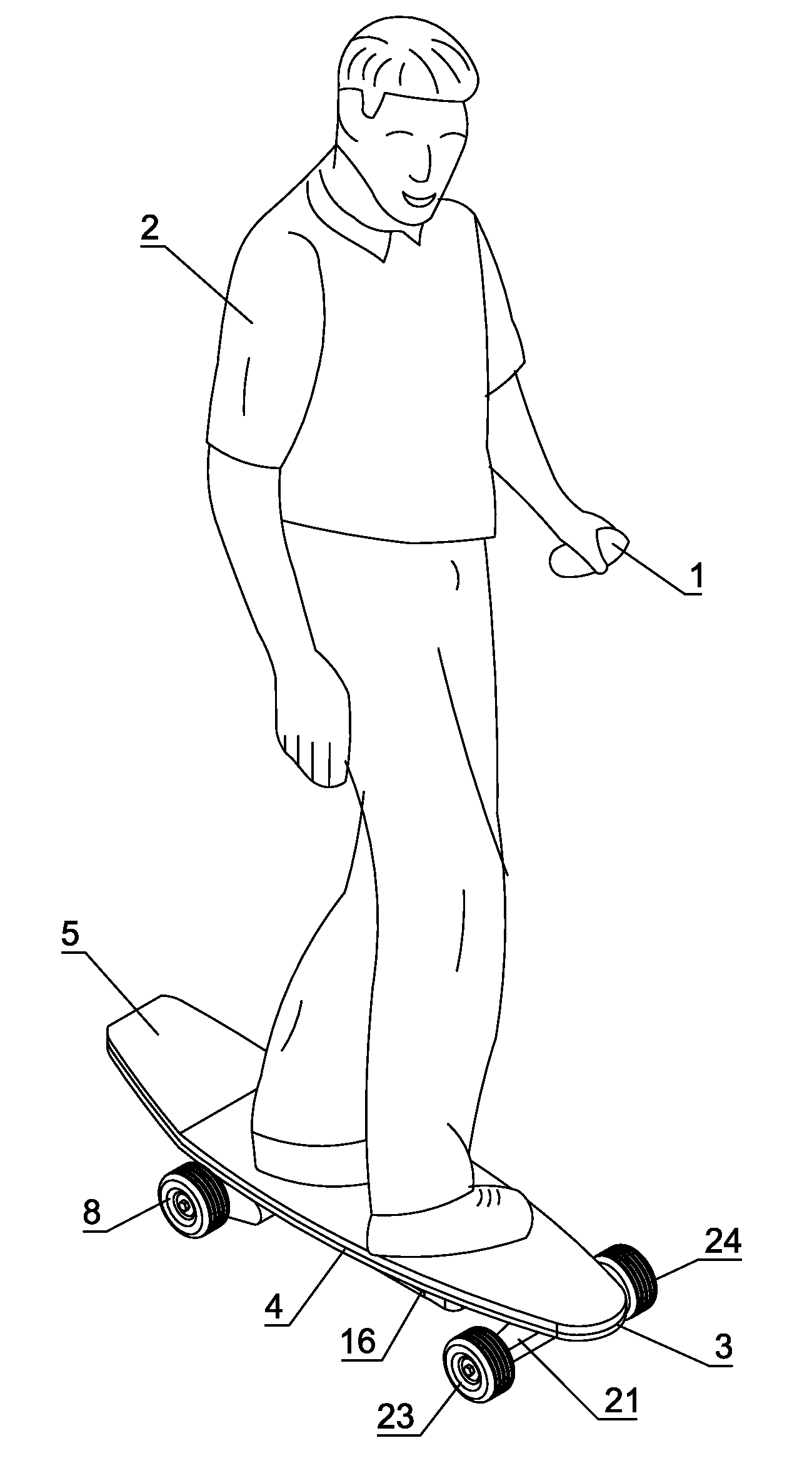

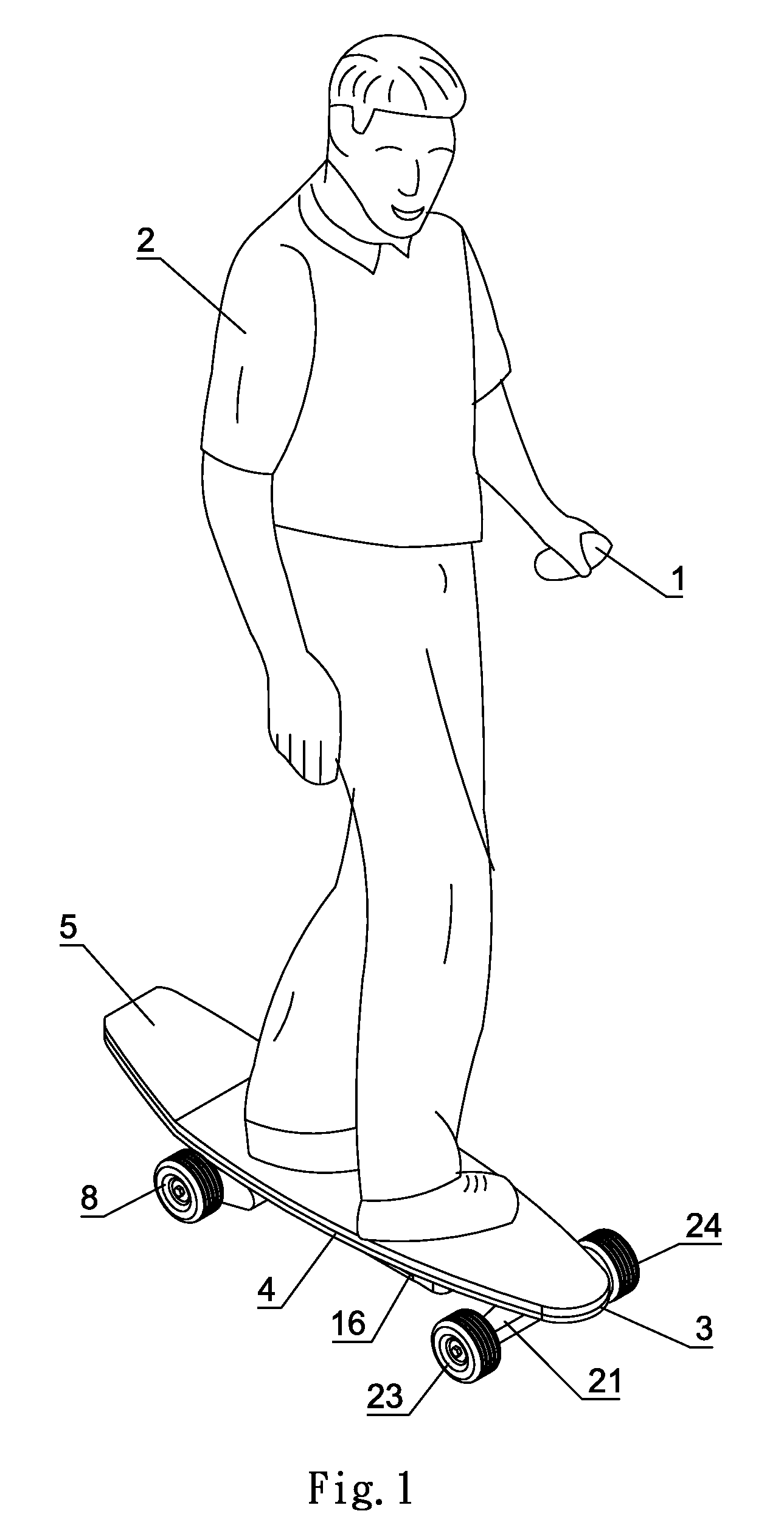

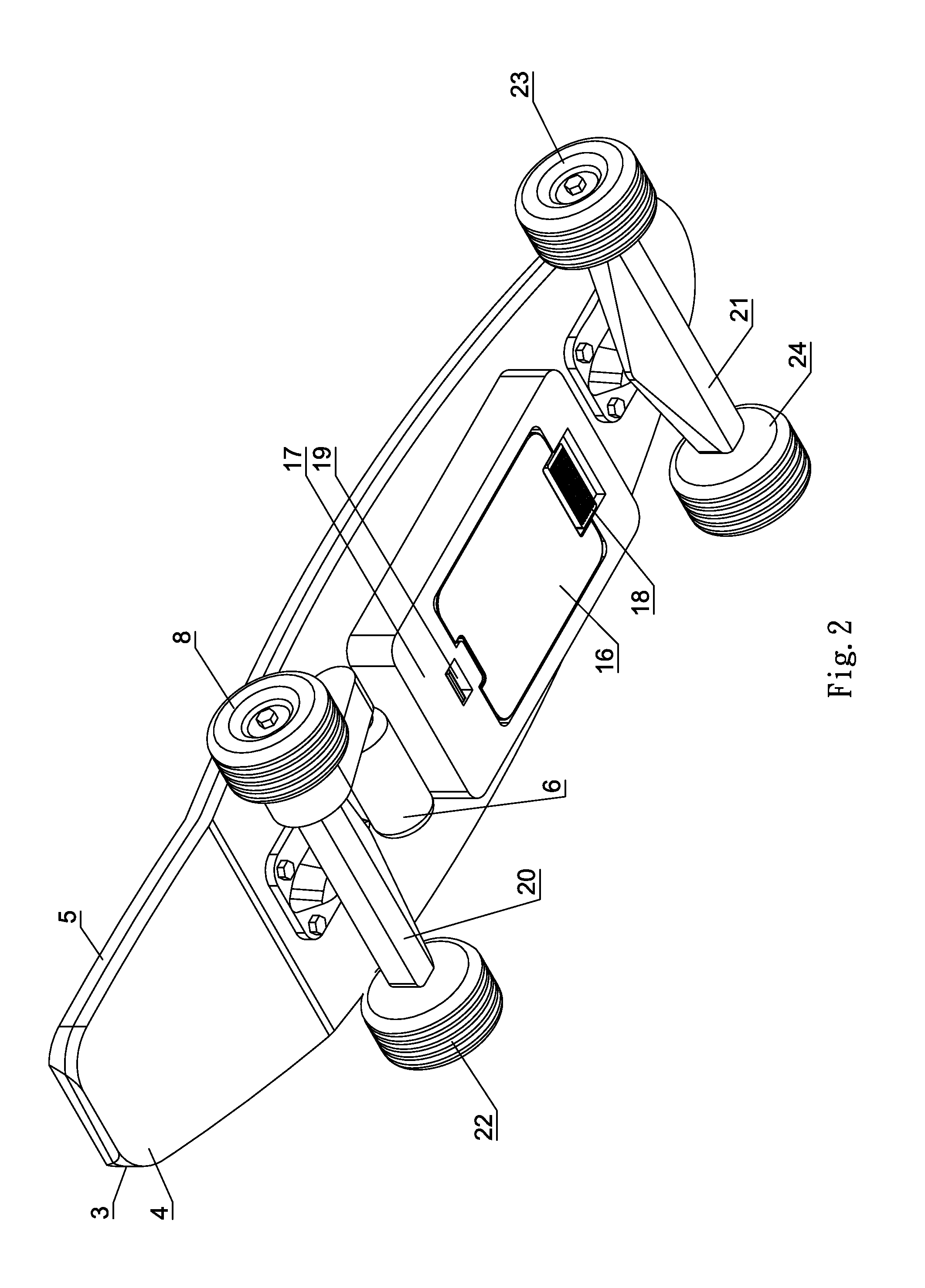

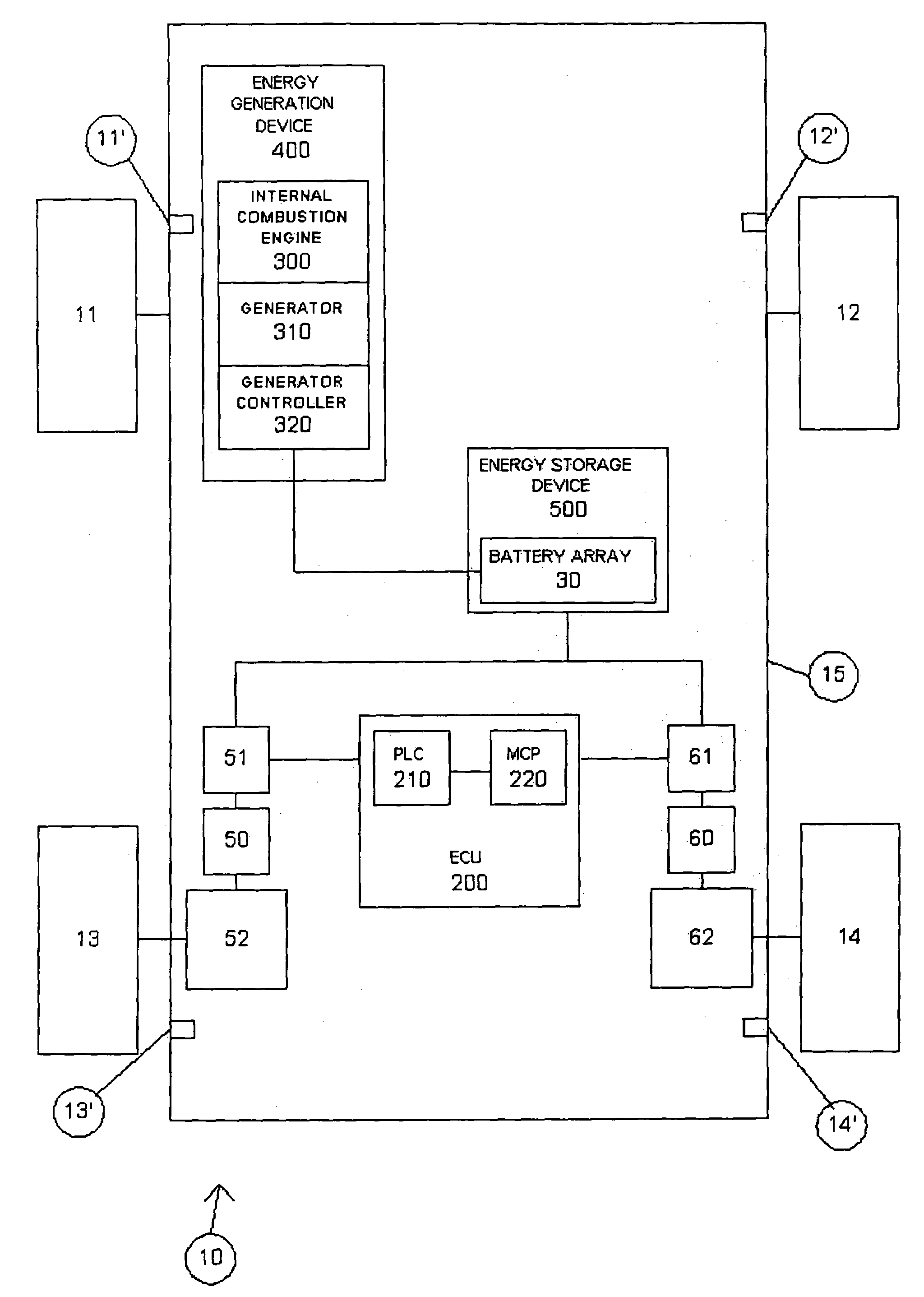

Remote Control Electric Powered Skateboard

InactiveUS20100222941A1High speedShort timeSynchronous motors startersAC motor controlBrushless motorsElectric machine

A remote control electric powered skateboard has a brushless motor or a brushless hub motor installed on the lower surface of the skateboard for connecting to a battery device through a controller, so that the motors could be electrified. A driving device disposed between either afore motors and at least one wheel is controlled by the remote control, thereby permitting an automatic comparison. When the electrification of the remote control executes, the remote control spontaneously generates an initial code for a receiver in the controller to robotically distinguish and lock the code. Turning off the remote control provides an automatic decoding. A receiver receives control signals from the remote control for the controller to interpret, and accordingly the controller generates and sends distinct commands to either motor, which allows the skateboard to implement various actions correspondingly. An auxiliary remote device disposed on the joint between a front support and a plywood is foldable or could stand on the skateboard; the height of the auxiliary remote device is adjustable for meeting divergent demands from dissimilar riders. A remote handle further provides the same operating means as that of the remote control for offering a supplementary supporting function.

Owner:CHANG WESLEY WENTI

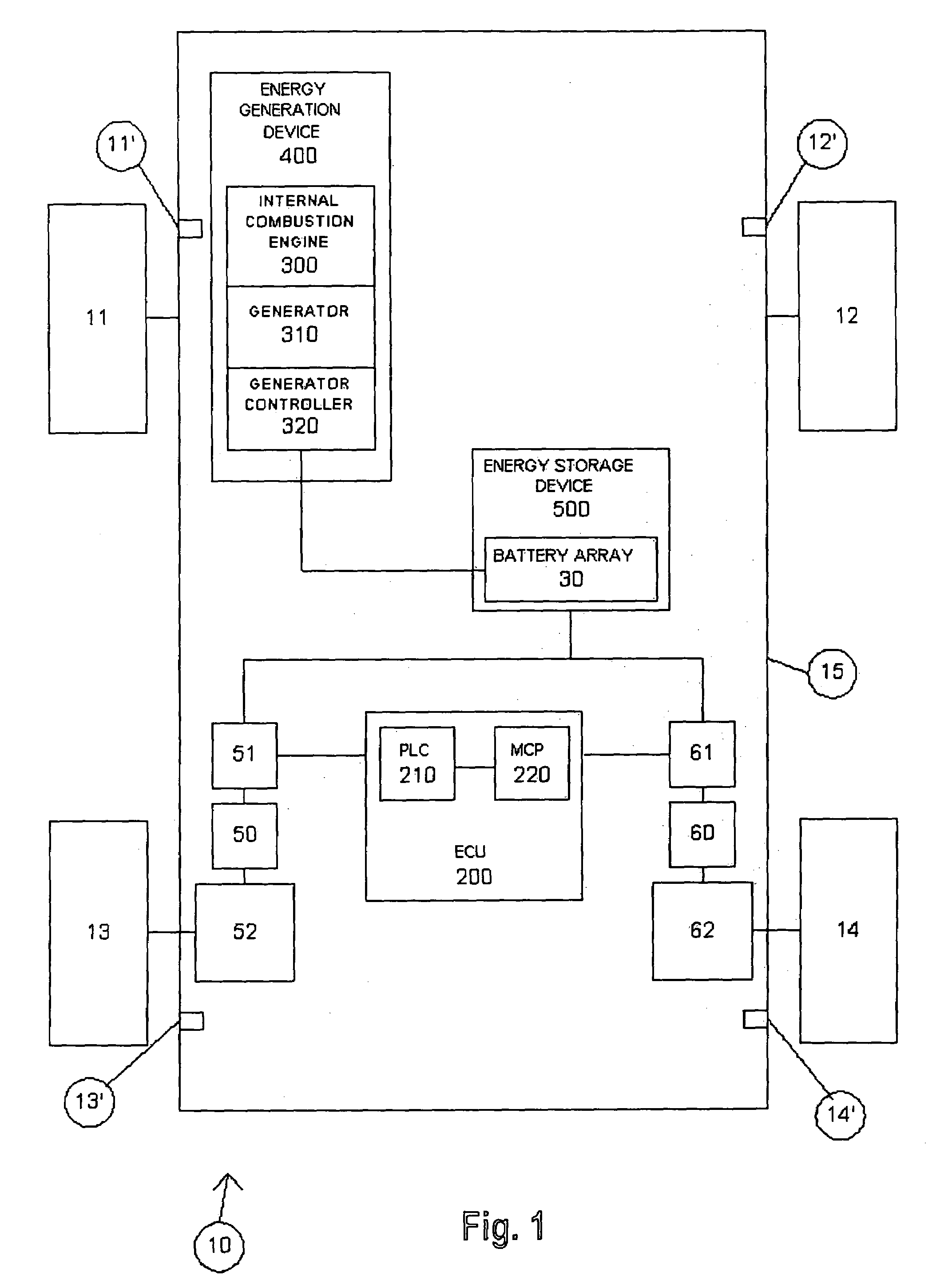

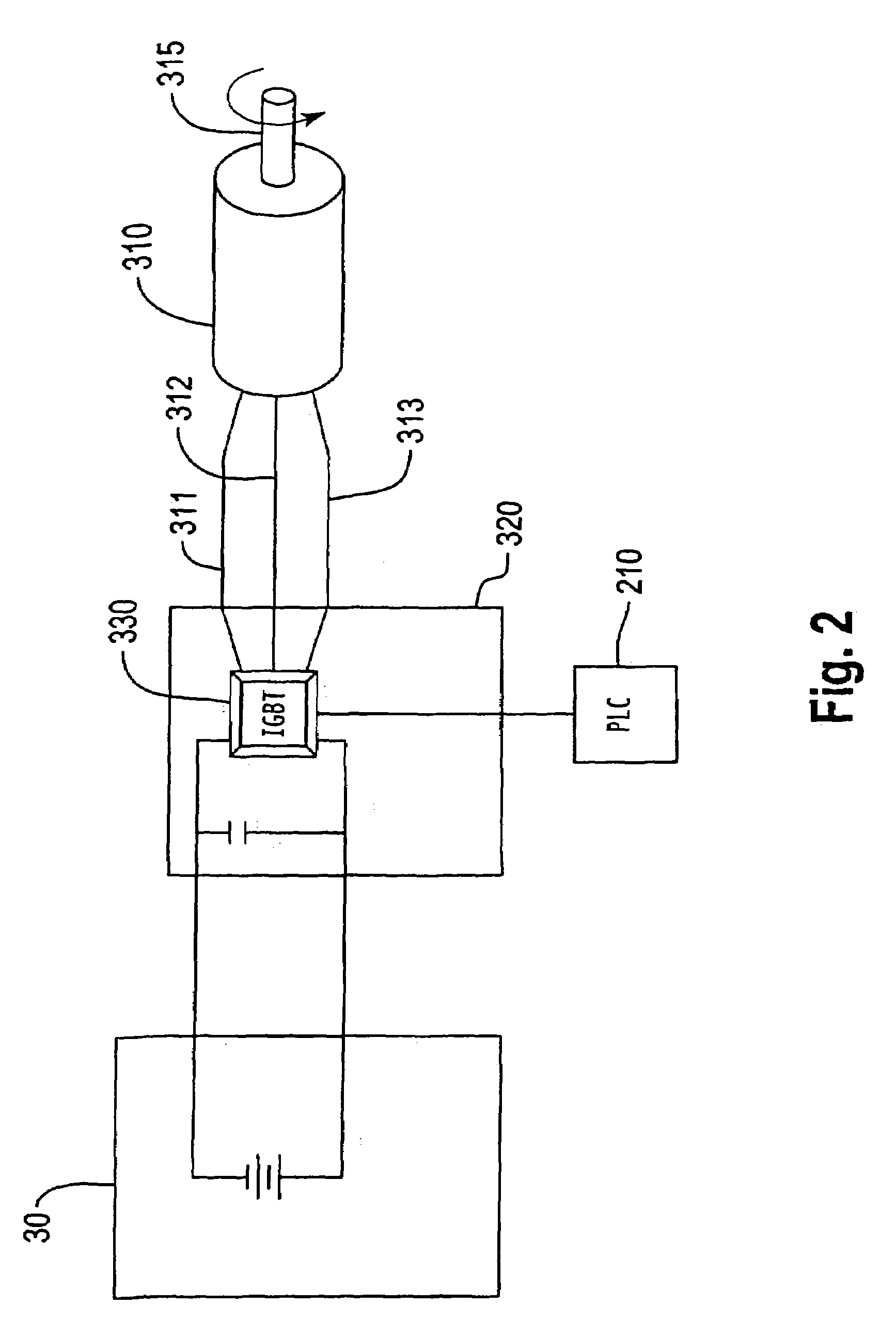

Method and apparatus for adaptive control of traction drive units in a hybrid vehicle

InactiveUS7071642B2Reduce stepsDC motor speed/torque controlAc motor stoppersElectric vehicleControl theory

Owner:TRANSPORTATION TECH

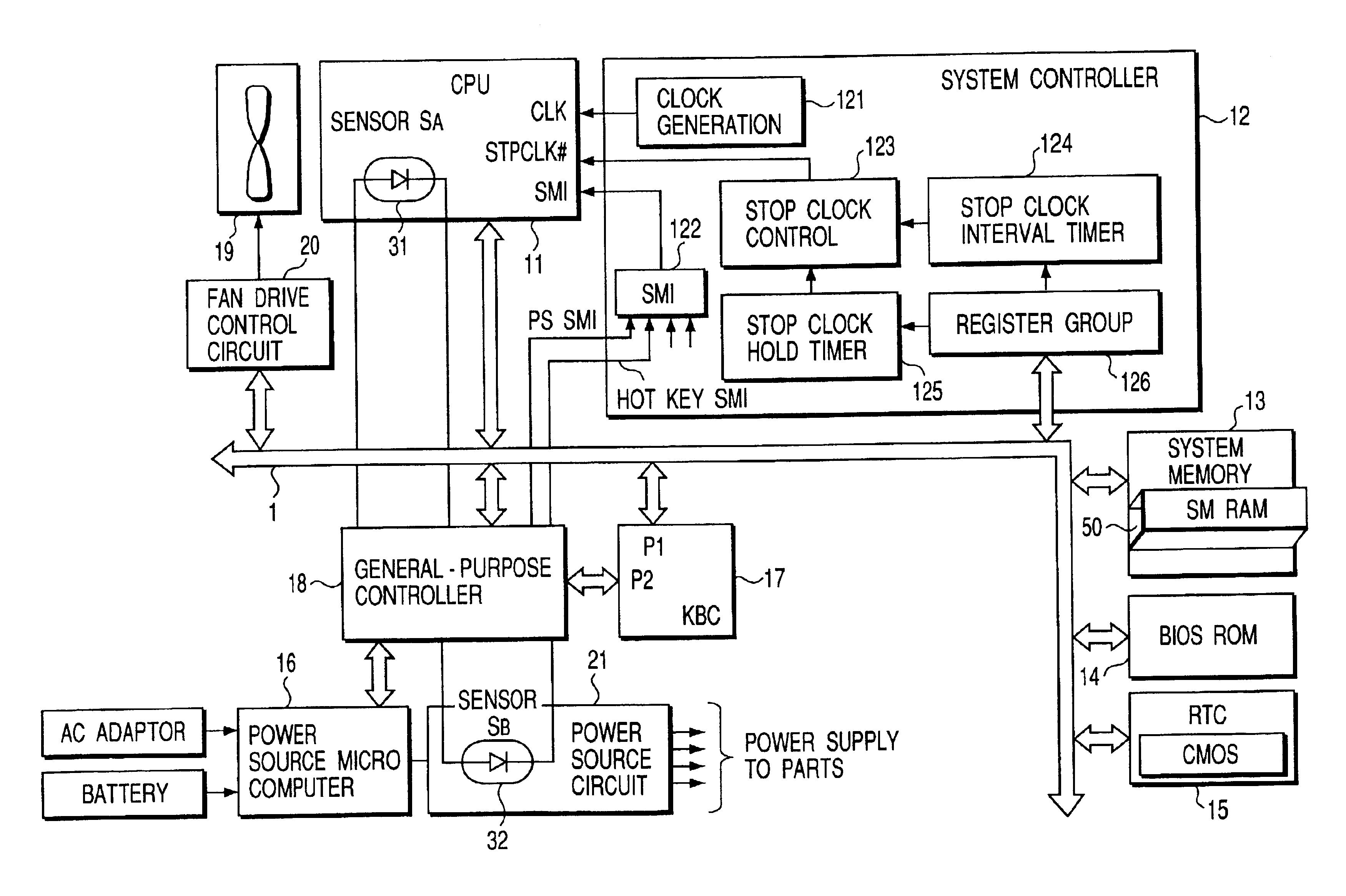

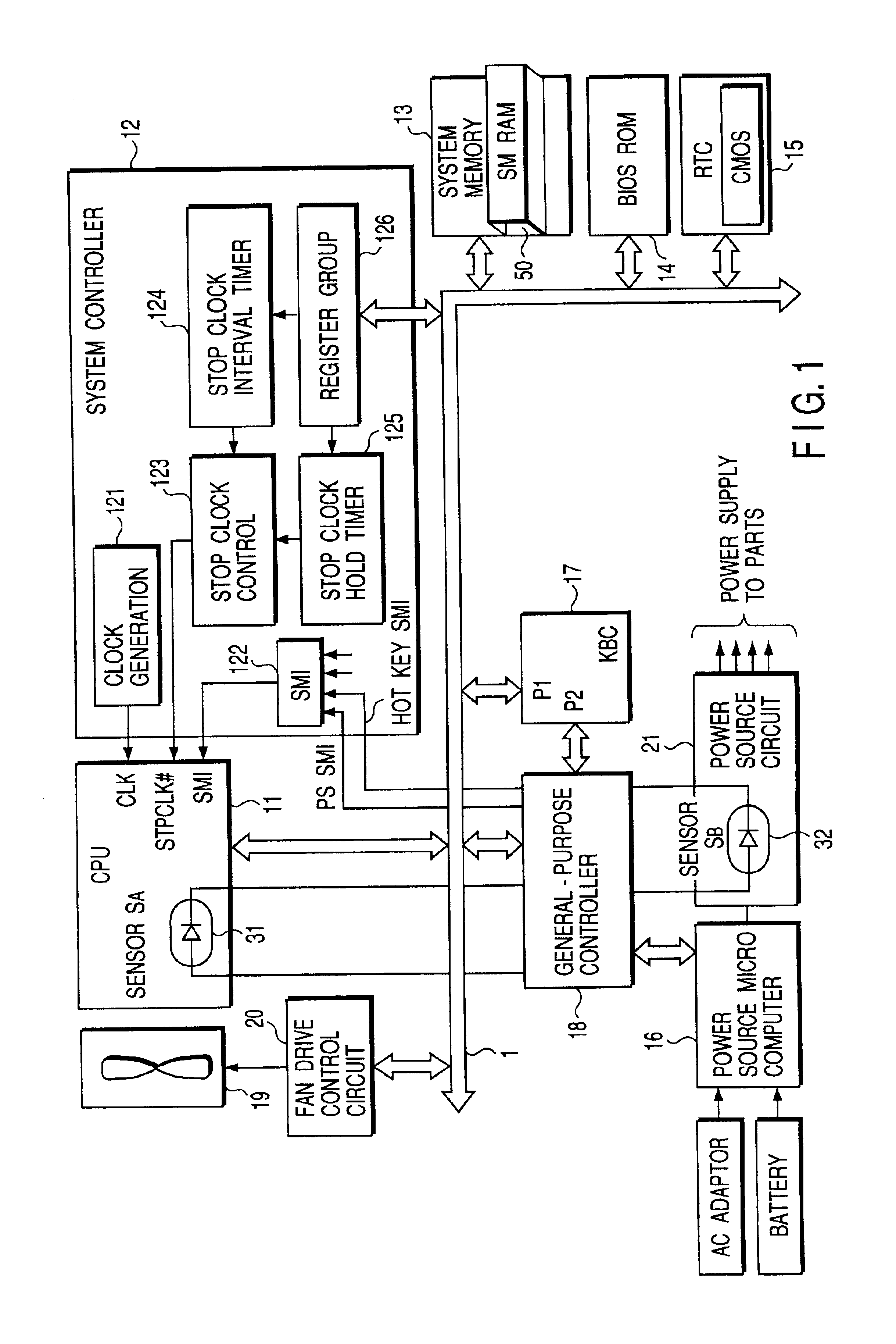

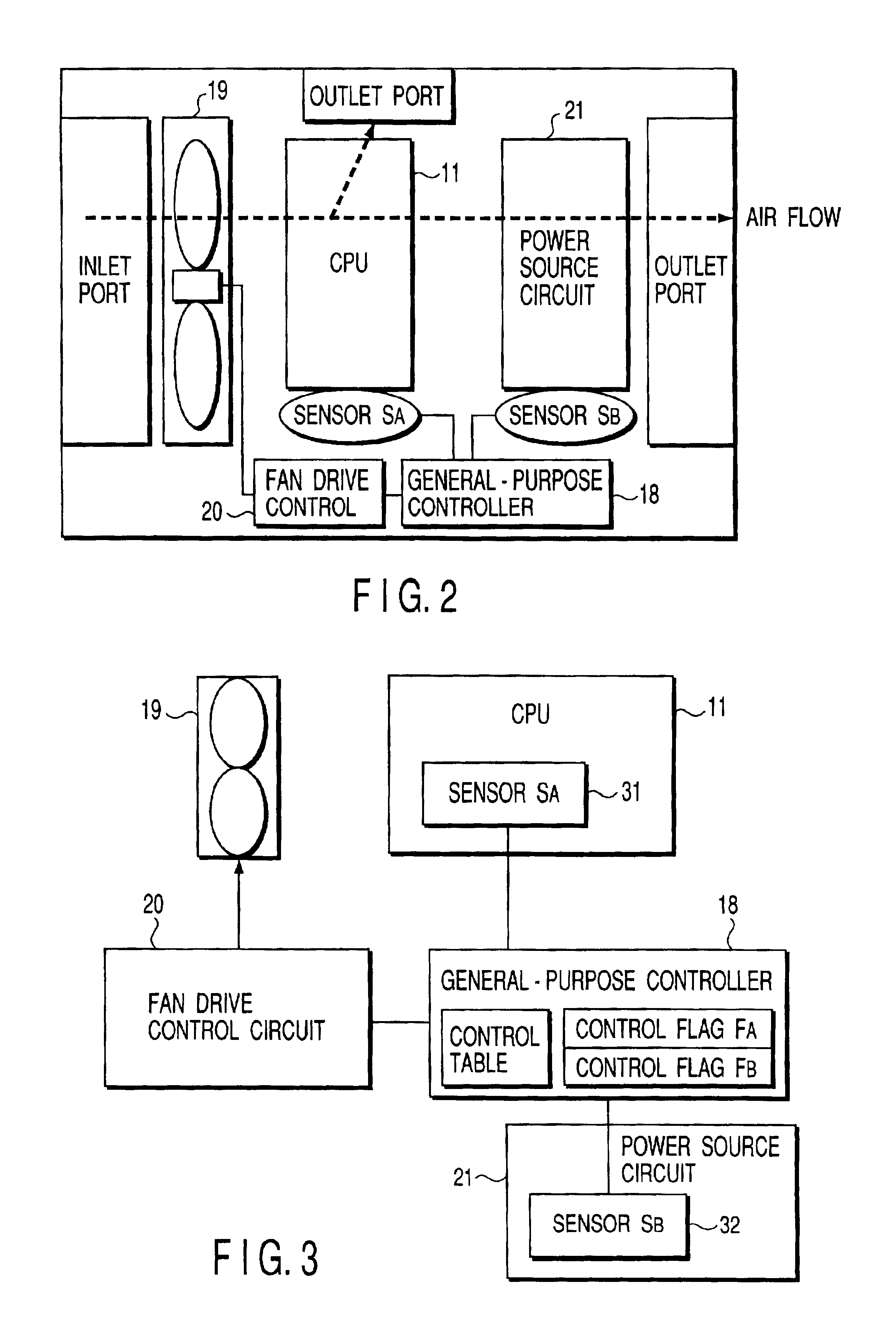

Computer system and method of controlling rotation speed of cooling fan

InactiveUS6888332B2Reduce noiseEfficient and safe coolingSpace heating and ventilationTemperatue controlComputerized systemProcess engineering

A computer system includes a first heat generating element in which a heat generation amount is changed, a second heat generating element, a fan configured to cool the first and second heat generating elements, a first temperature sensor configured to detect a temperature of the first heat generating element, a second temperature sensor configured to detect a temperature of the second heat generating element, and a controller configured to control a rotation speed of the cooling fan, based on the temperatures detected by the first and second temperature sensors.

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

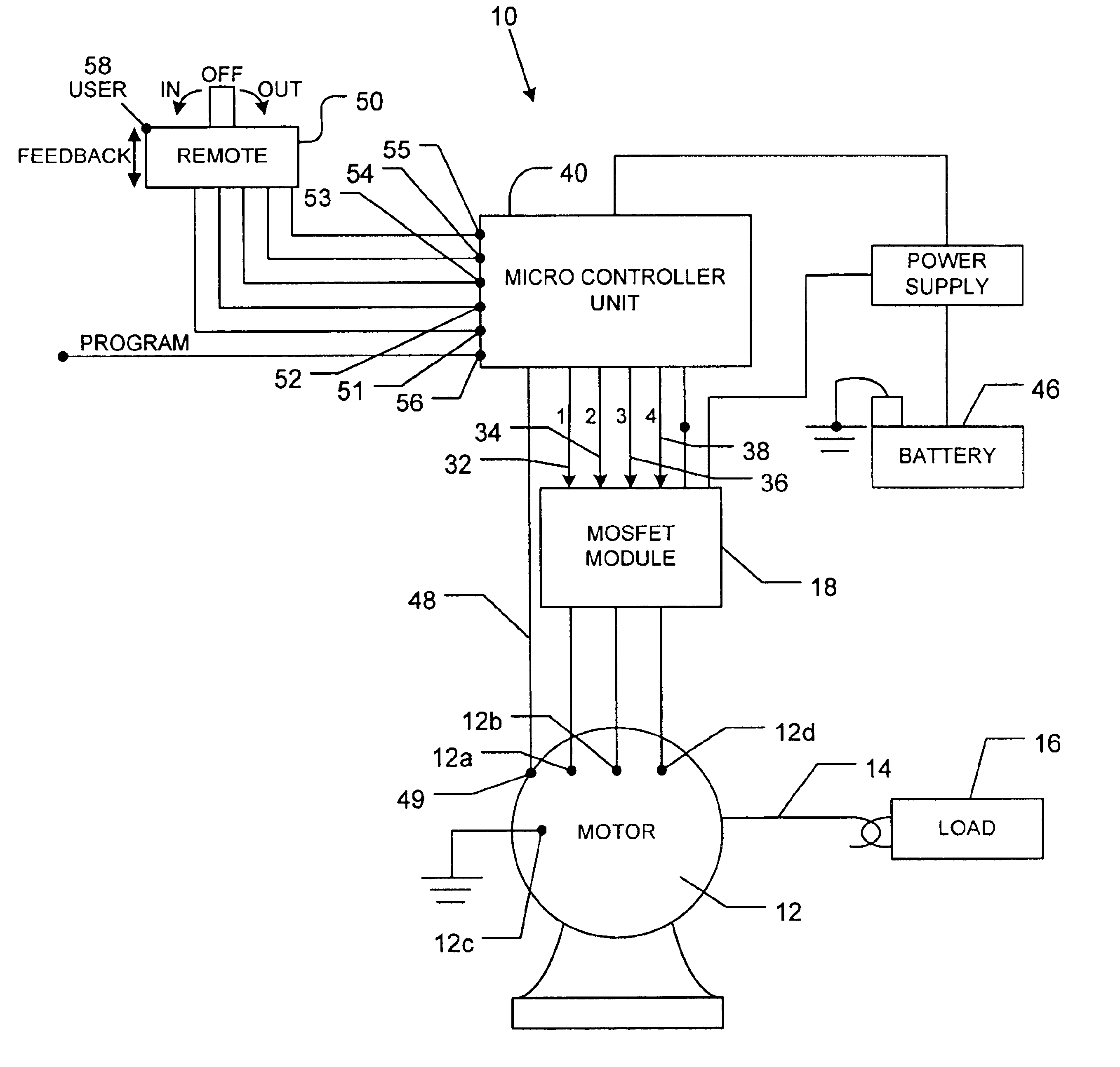

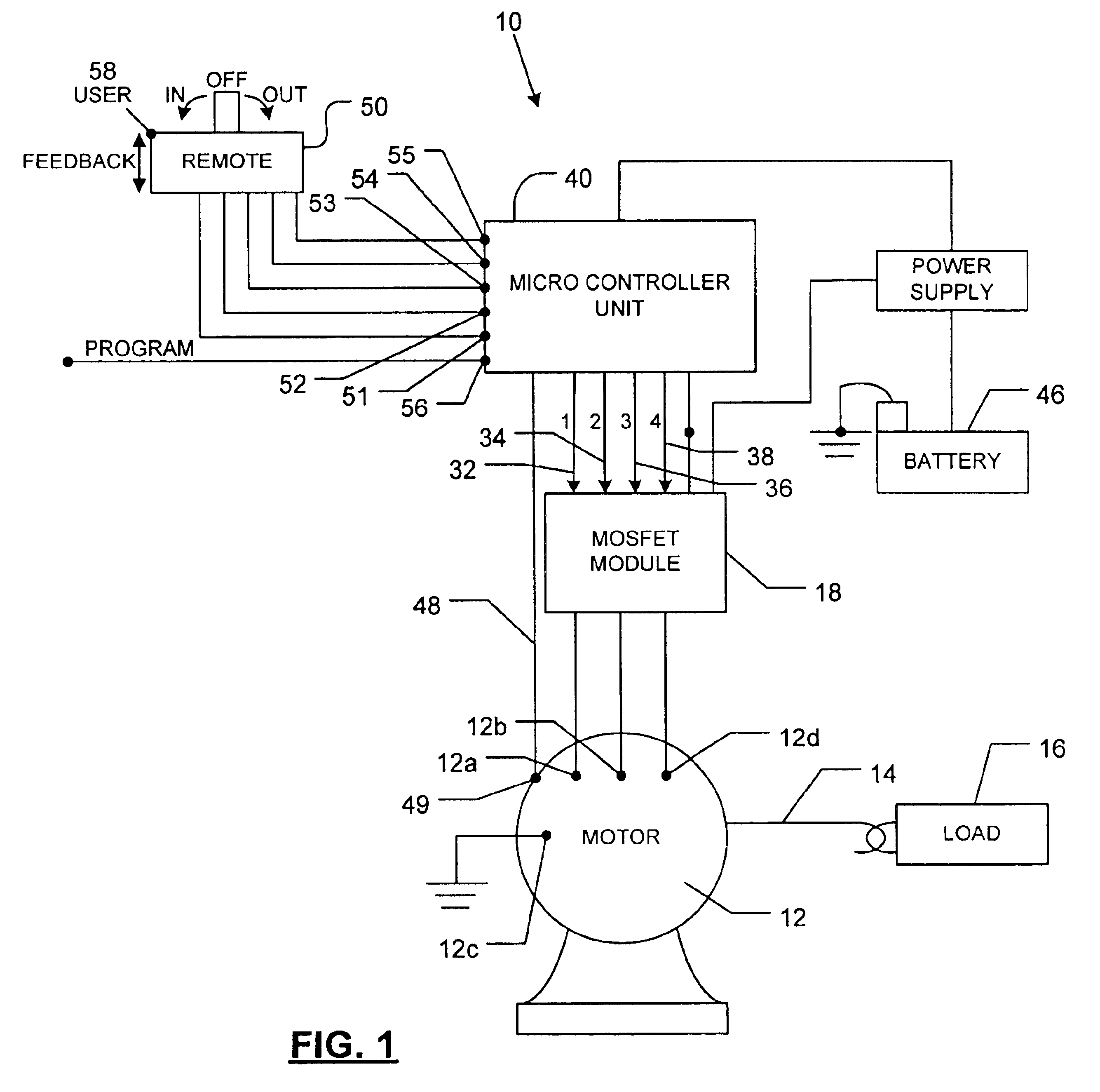

Winch controller

ActiveUS6864650B2Lower average currentAvoid overall overheatingDC motor speed/torque controlElectric motor controlMOSFETWinch

A solid state controller is provided for a winch and includes fault detection for several parameters and overload interrupt controlled by the controller. The system uses a single controller that can be programmed for several different products and utilizes MOSFET switches for alternating the direction of current

Owner:WARN INDUSTRIES +1

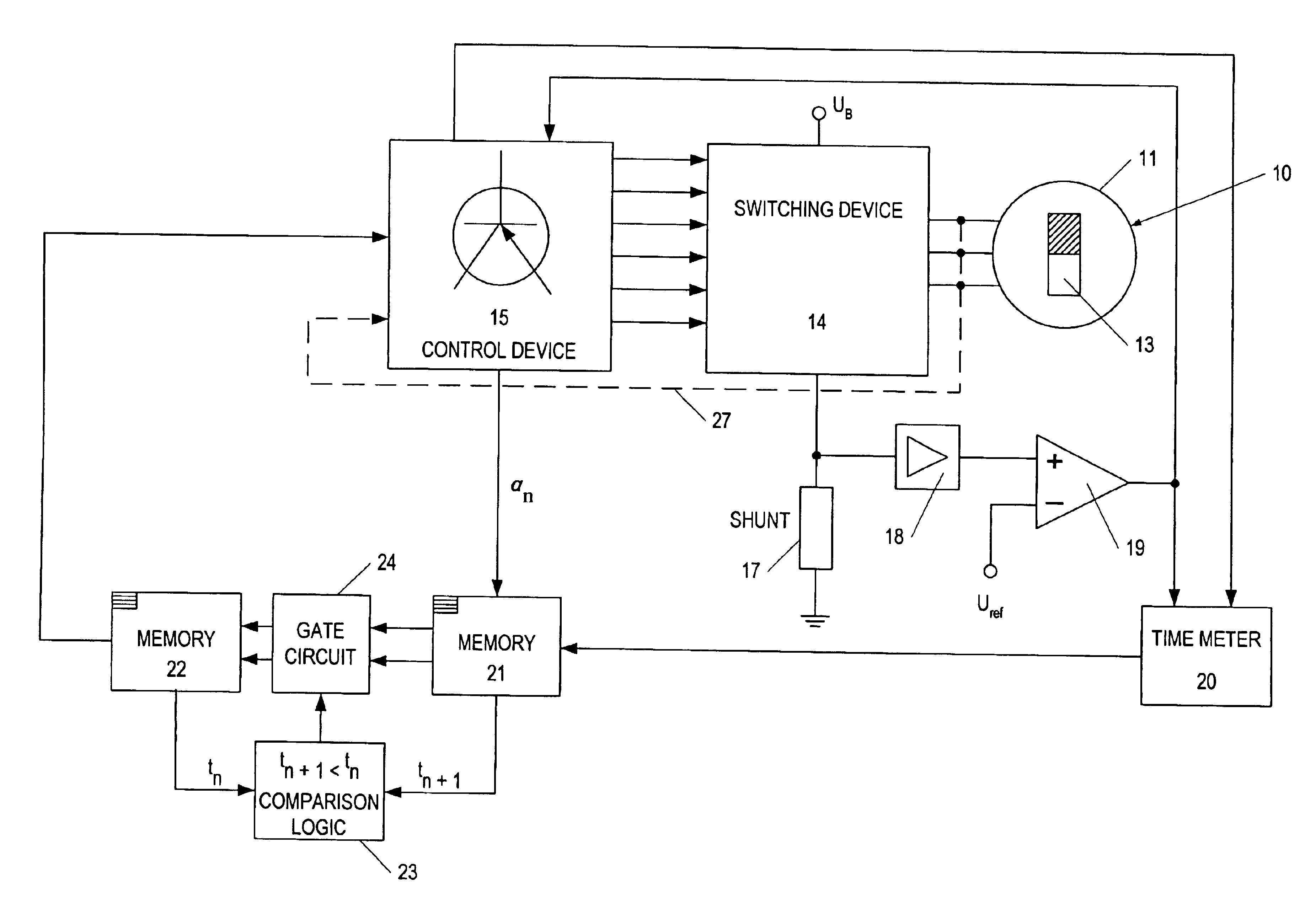

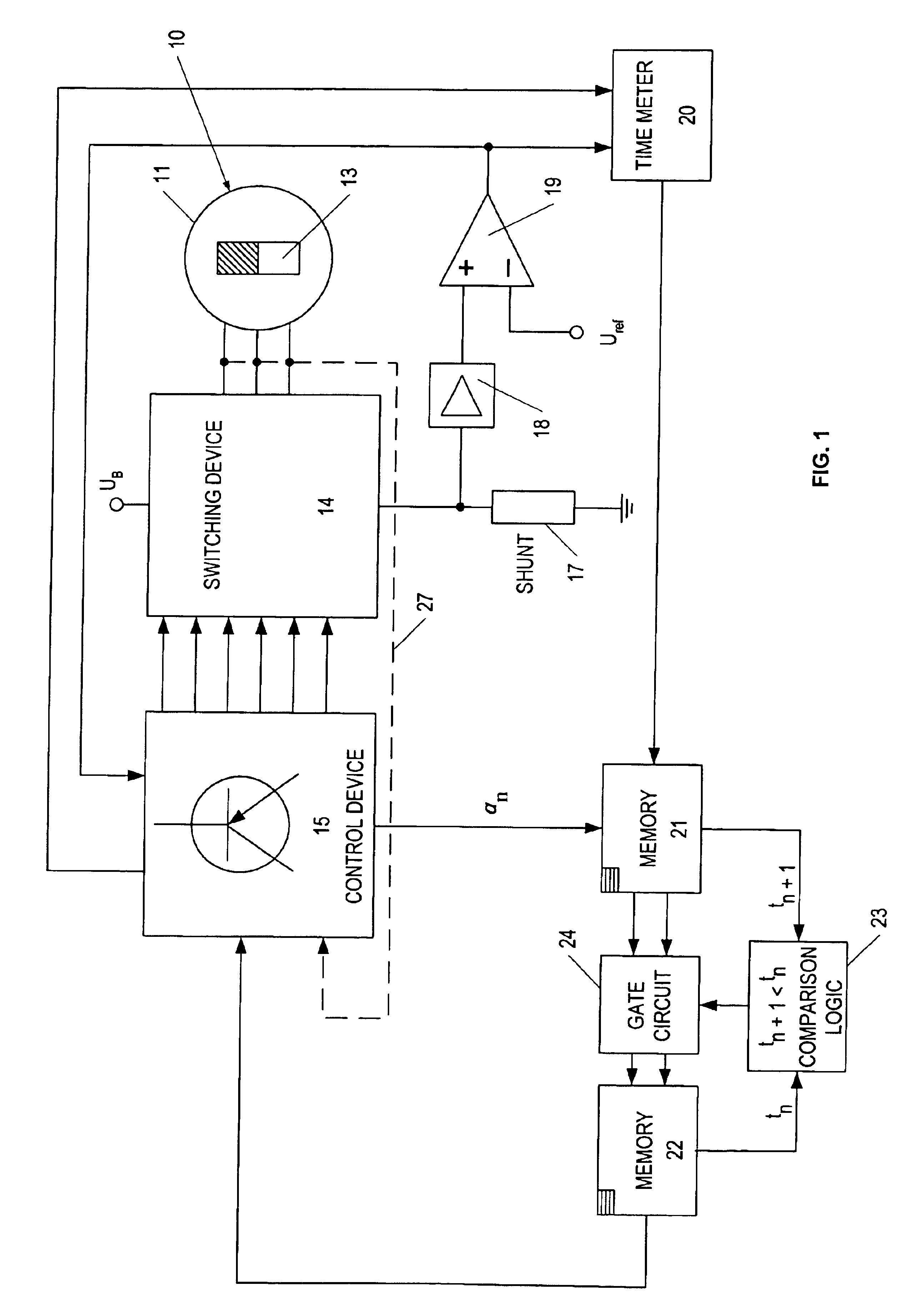

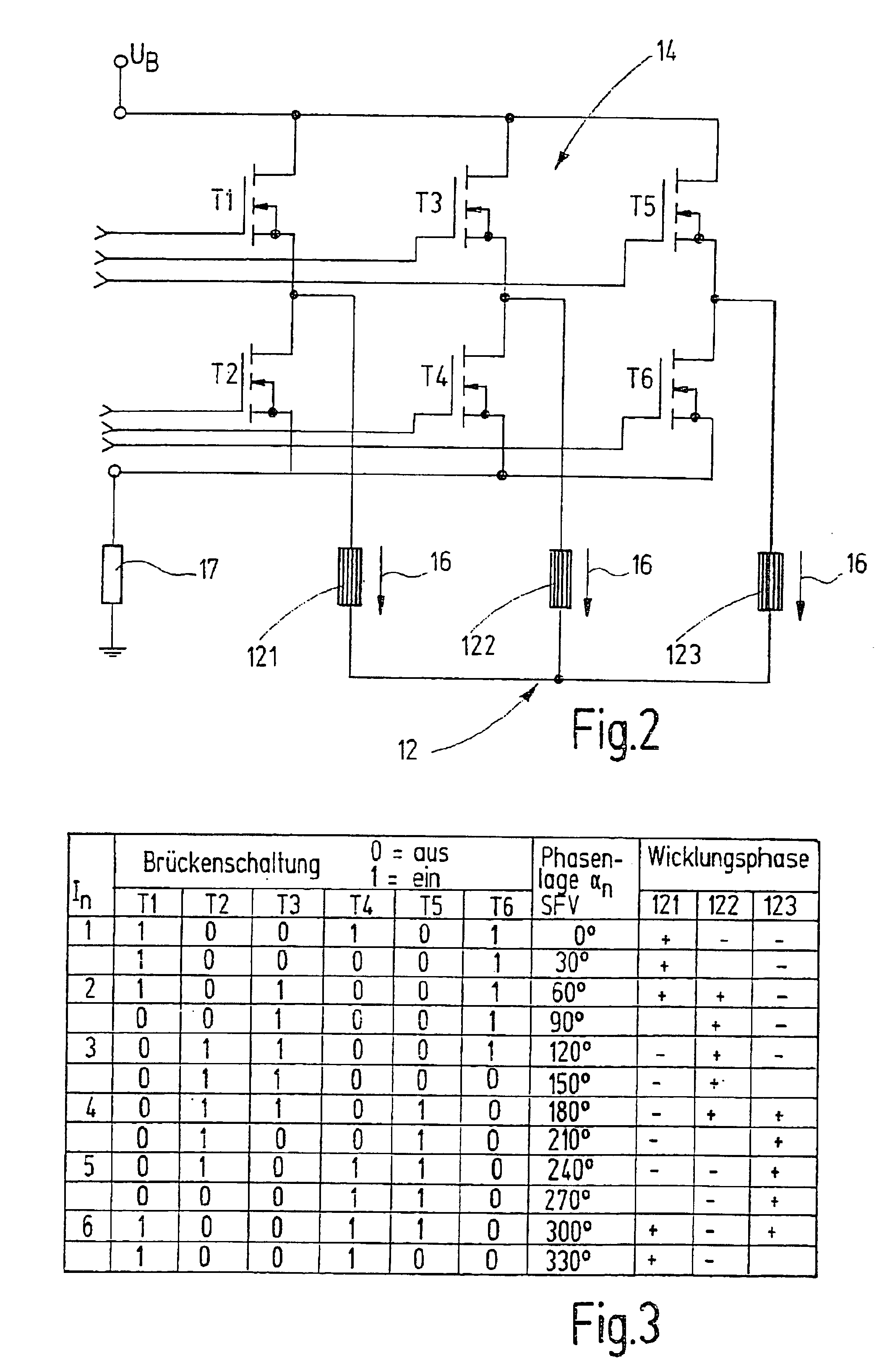

Method for starting a brushless d.c. motor

Owner:ROBERT BOSCH GMBH

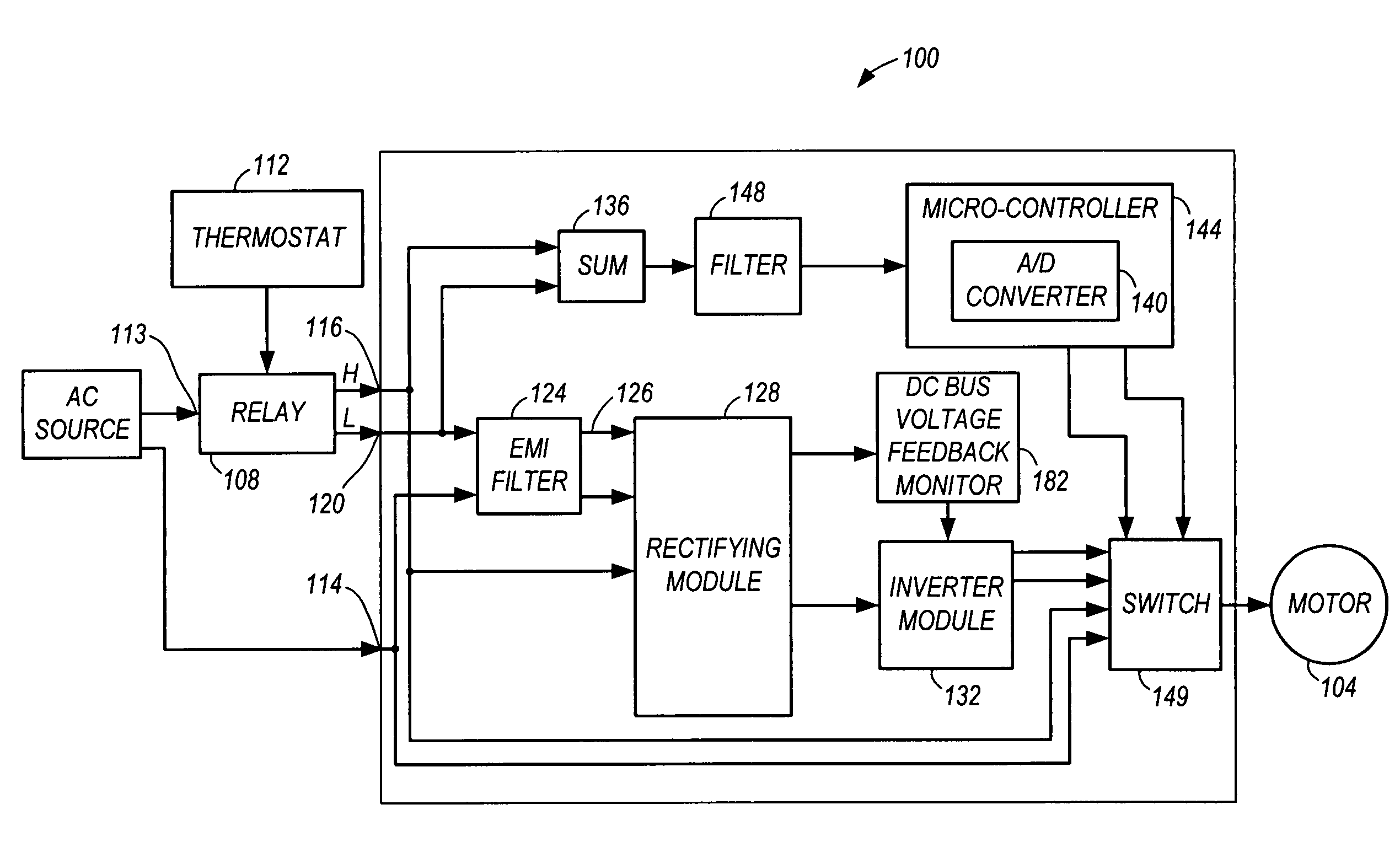

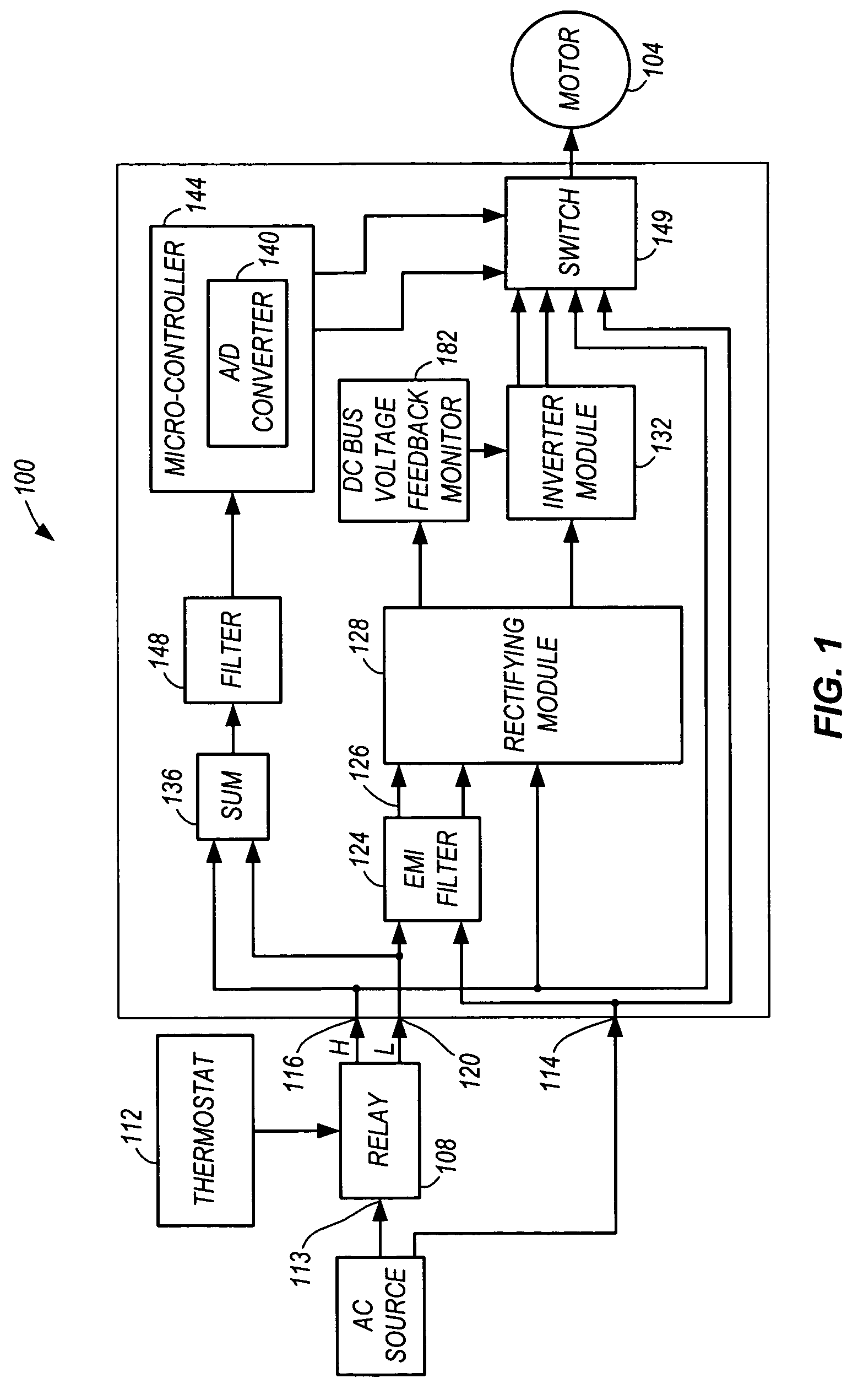

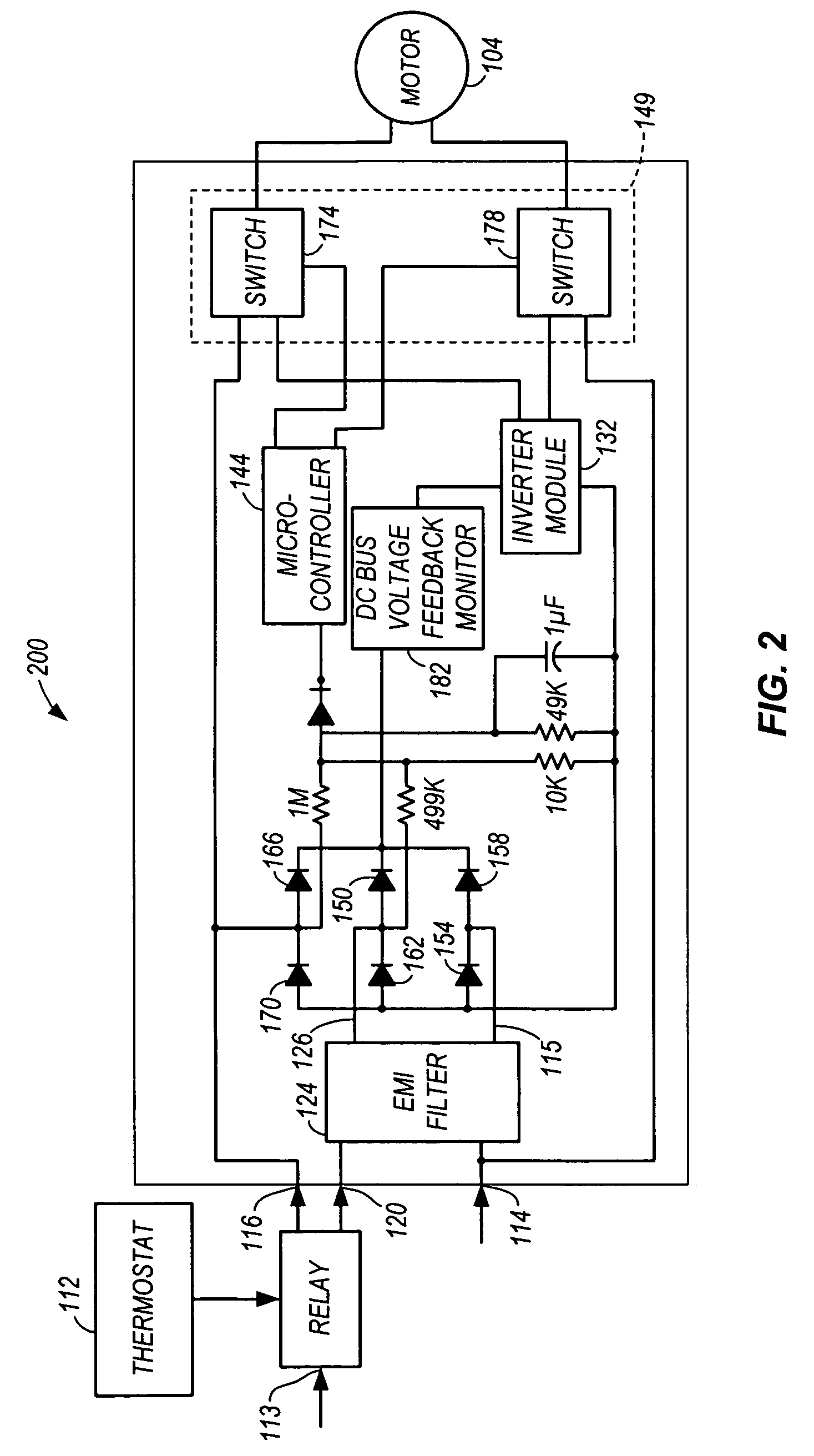

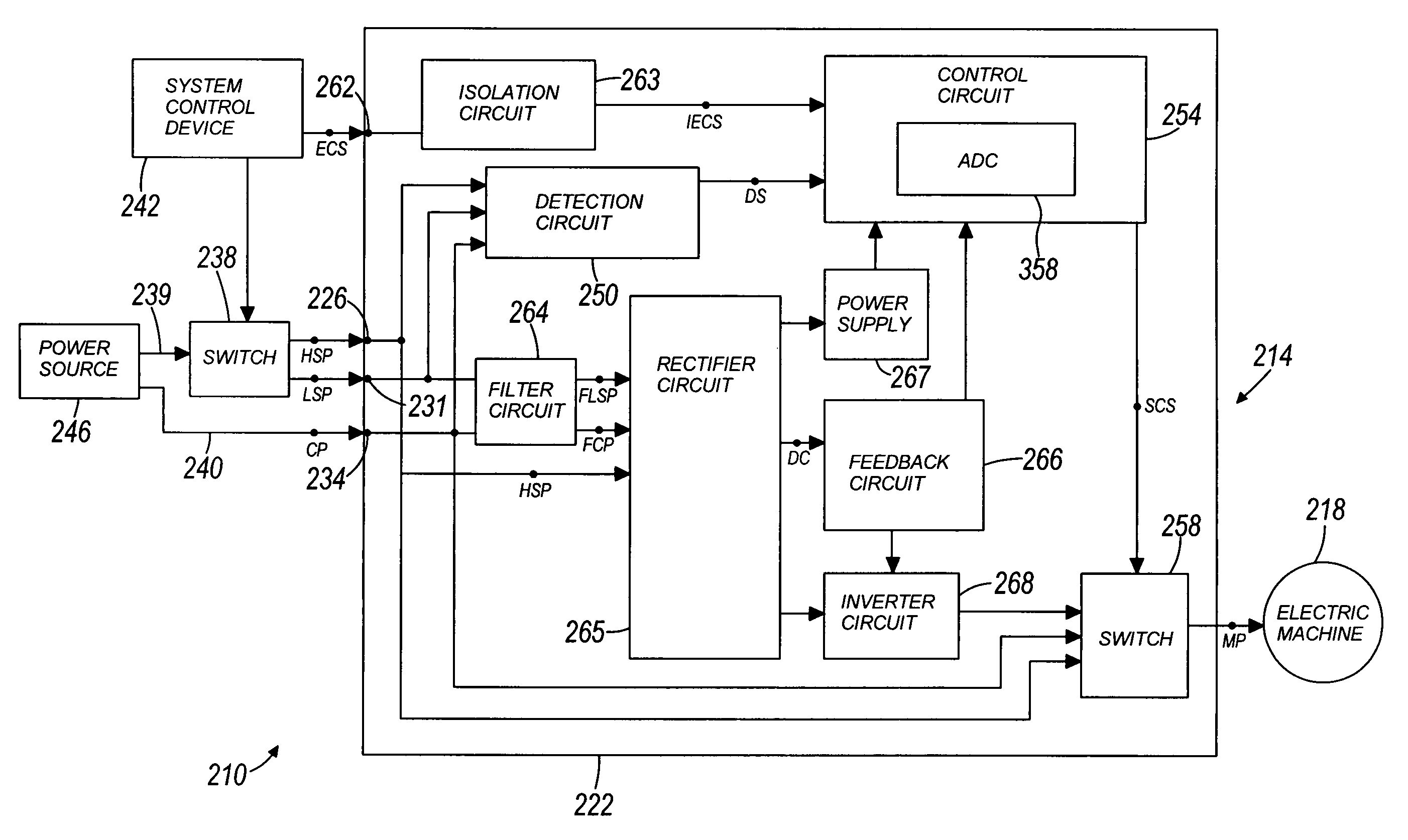

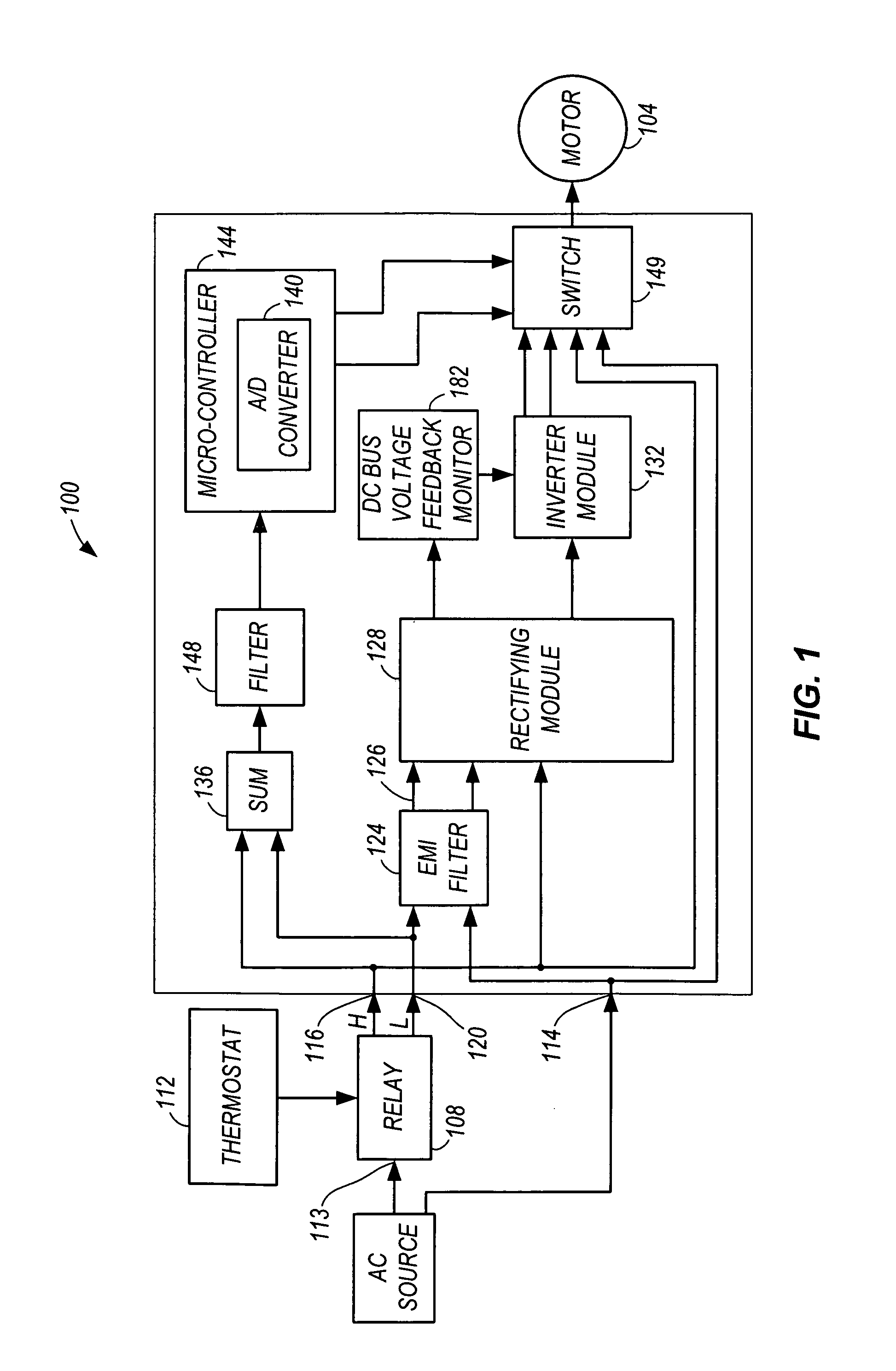

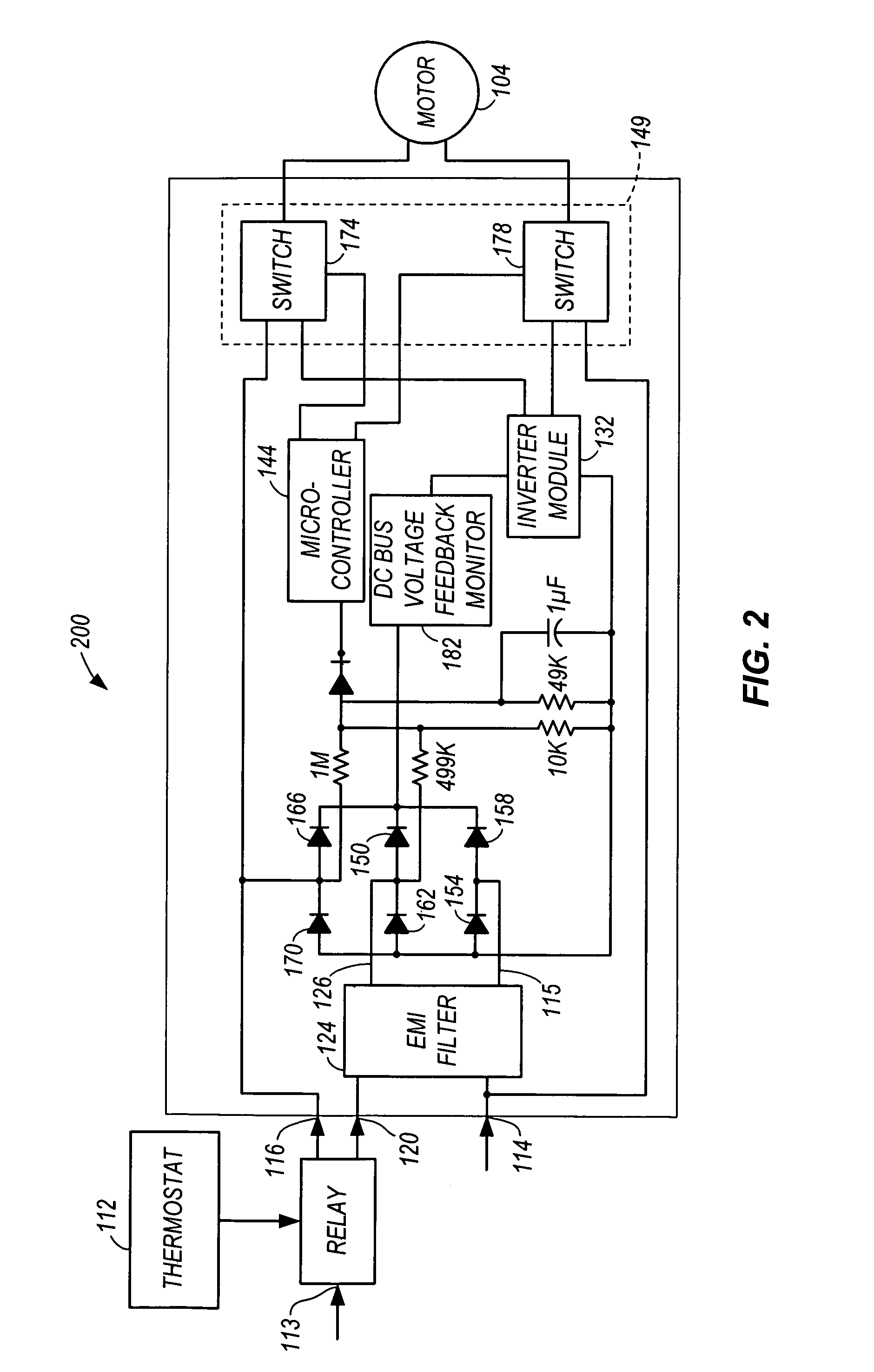

Electric machine and method of operating the electric machine

A method of and apparatus for controlling an electric machine. The method can include using a controller to detect whether power is present at a first node of the controller, detect whether power is present at a second node of the controller, generate at least one signal based at least in part on the detection, and energize the electric machine using a detected power when the at least one signal indicates power is present at at least one of the first node, the second node, and a combination of the first node and the second node.

Owner:REGAL BELOIT AMERICA

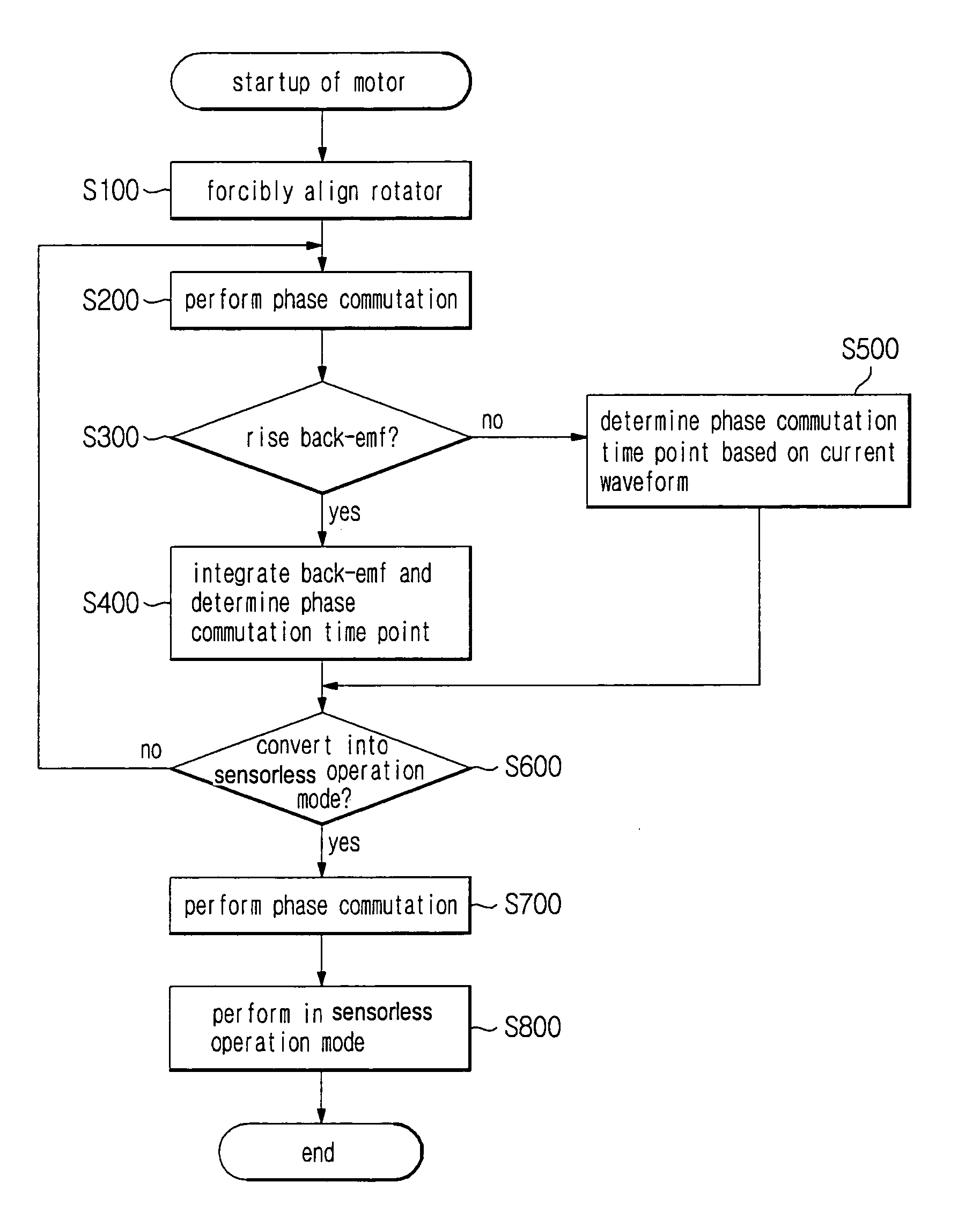

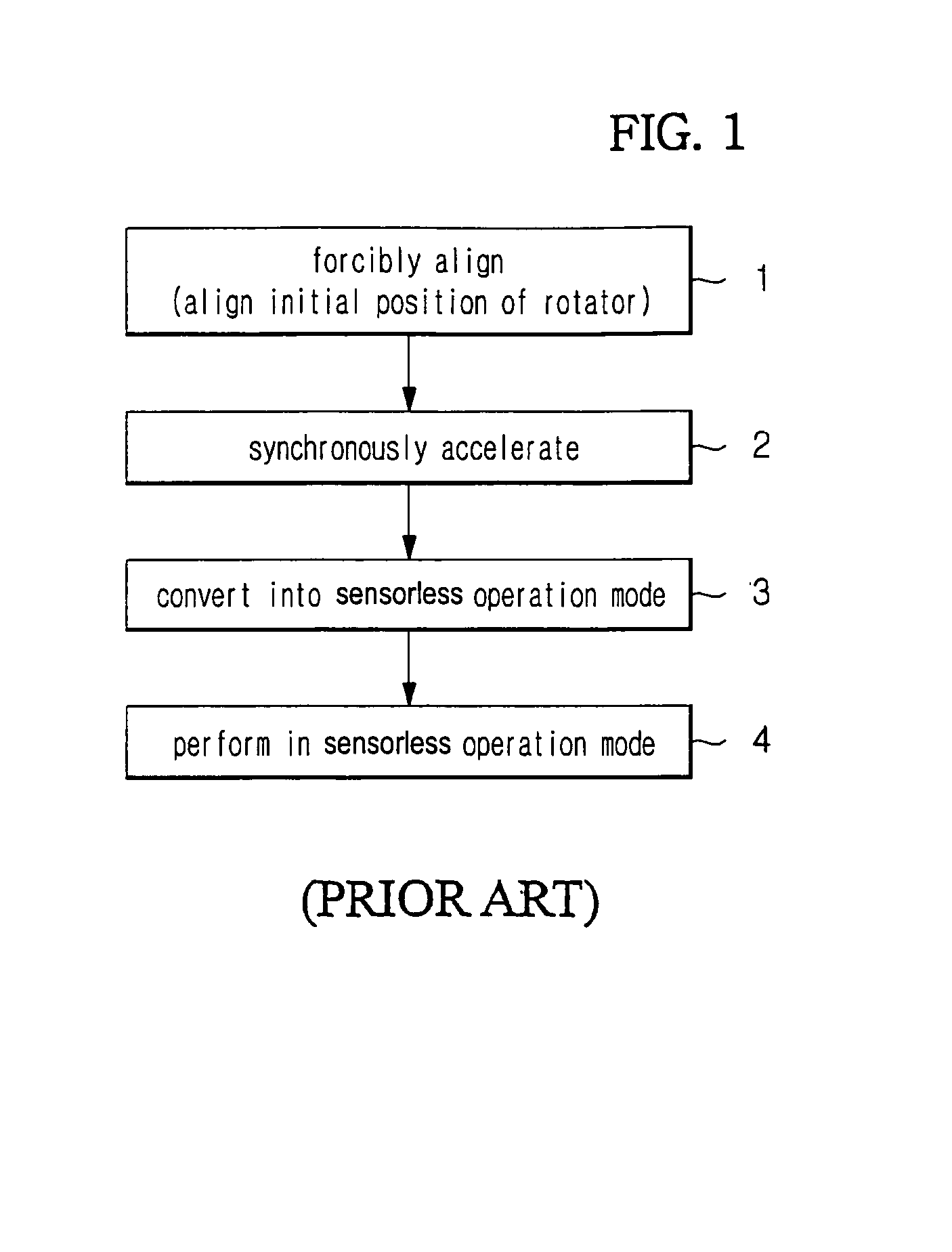

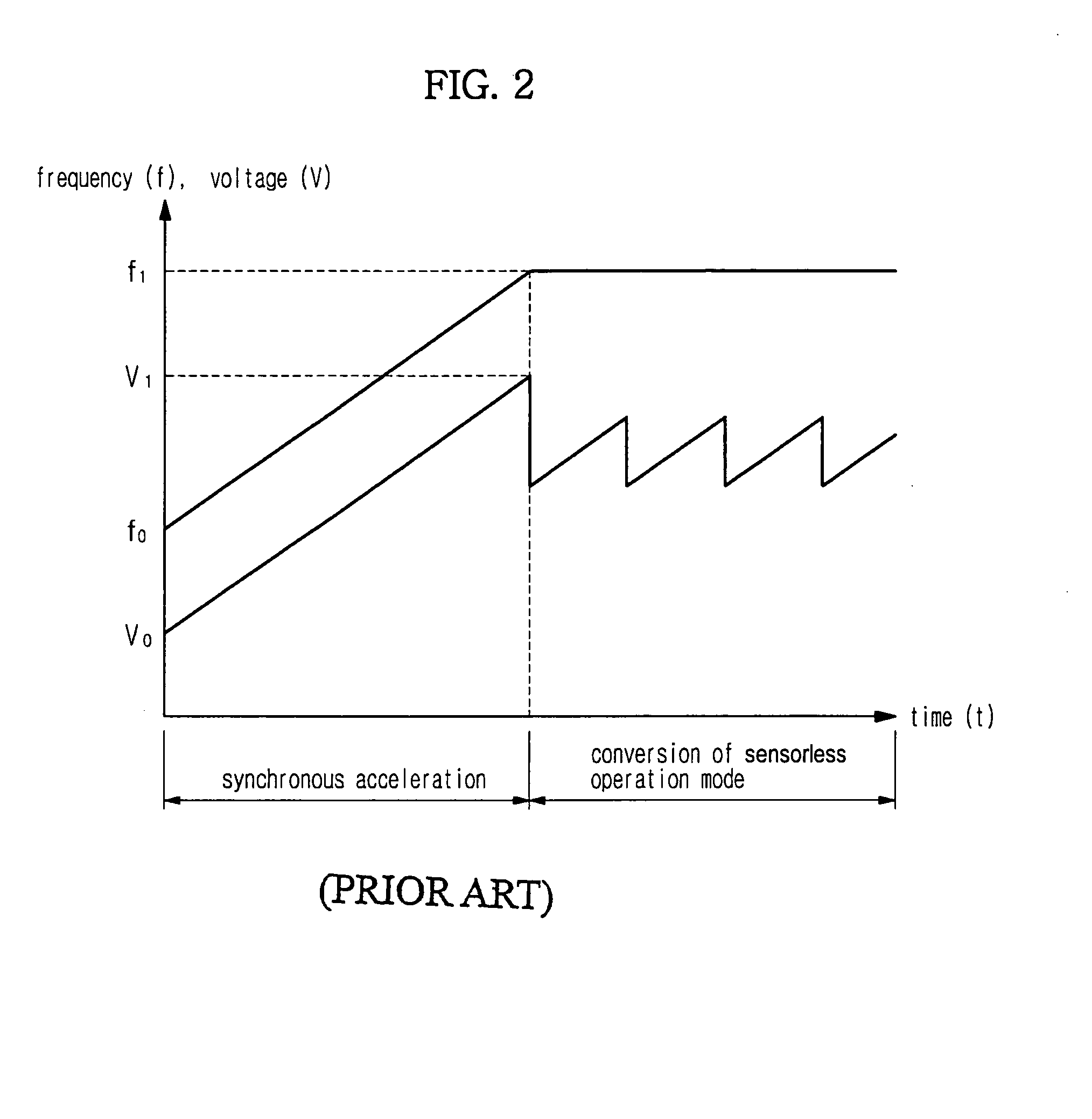

Startup control method of brushless DC motor

InactiveUS7095204B2Current is limitedReduce vibrationAC motor controlSynchronous motors startersFailure rateOperation mode

A startup control method of a BLDC motor is disclosed. The method can control the BLDC motor to prevent the generation of a transient current such that the vibration of the BLDC motor can be reduced at the startup stage and perform a stable conversion into a sensorless operation mode such that the startup failure rate of the BLDC motor can be reduced. The startup control method includes commutating a current applied to stator windings according to a rotor position. The method of operating the BLDC motor includes a rotor position that is forcibly aligned and so that phase commutation is performed, a back-electromotive force (back-emf) is detected from a lead voltage of a phase of a voltage which is not applied thereto after performing phase commutation and a determination is performed as to whether the detected back-emf is in a rising interval. The lead voltage of the phase of the voltage which is not applied thereto is integrated, such that if the back-emf is in a rising interval and if an instance that the integration result is greater than a predetermined value a phase commutation time point is set and conversion into a sensorless operation mode is performed if the back-emf detected from the lead voltage is in a stable interval, based on a frequency of the voltage applied to the stator winding.

Owner:SAMSUNG ELECTRONICS CO LTD

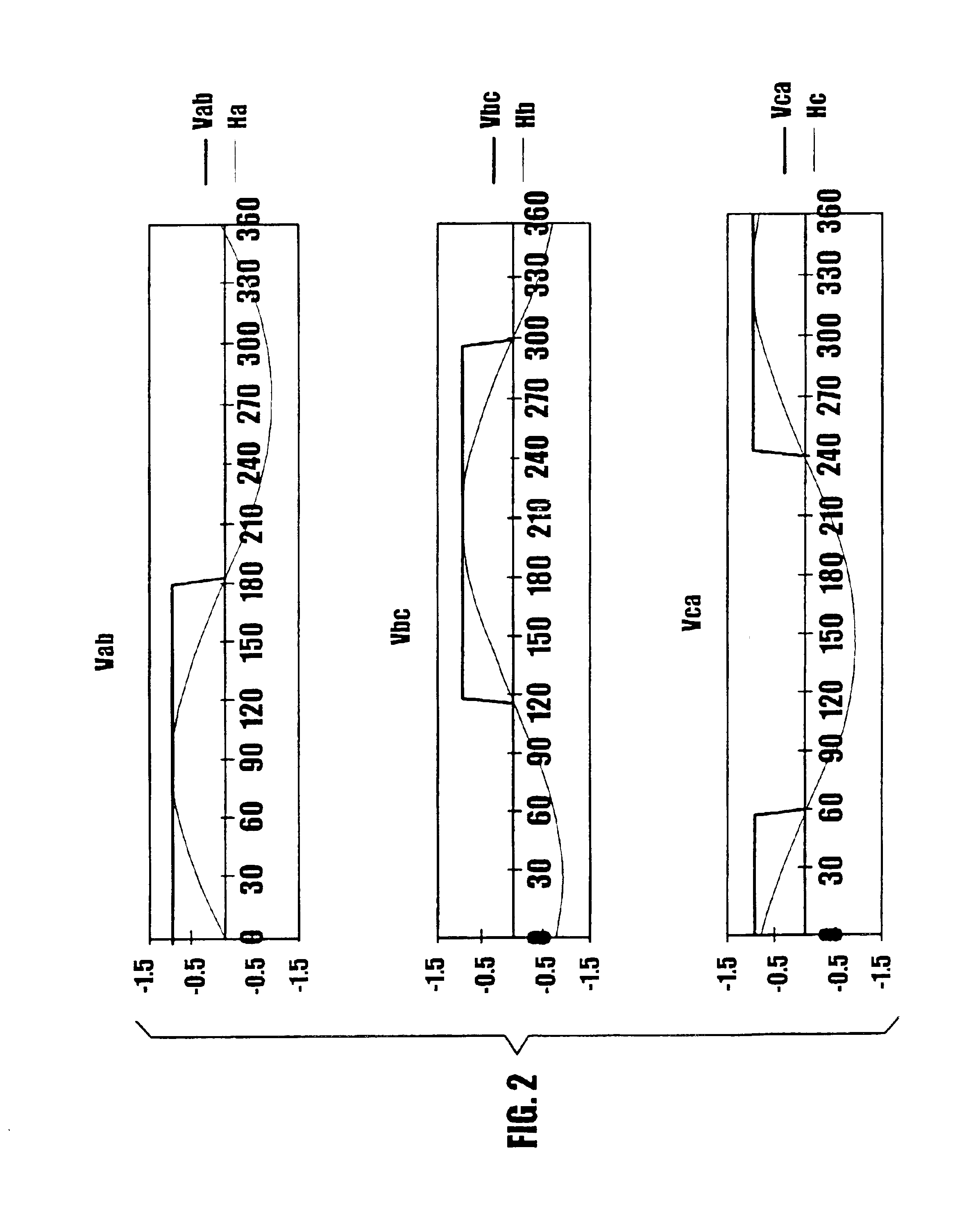

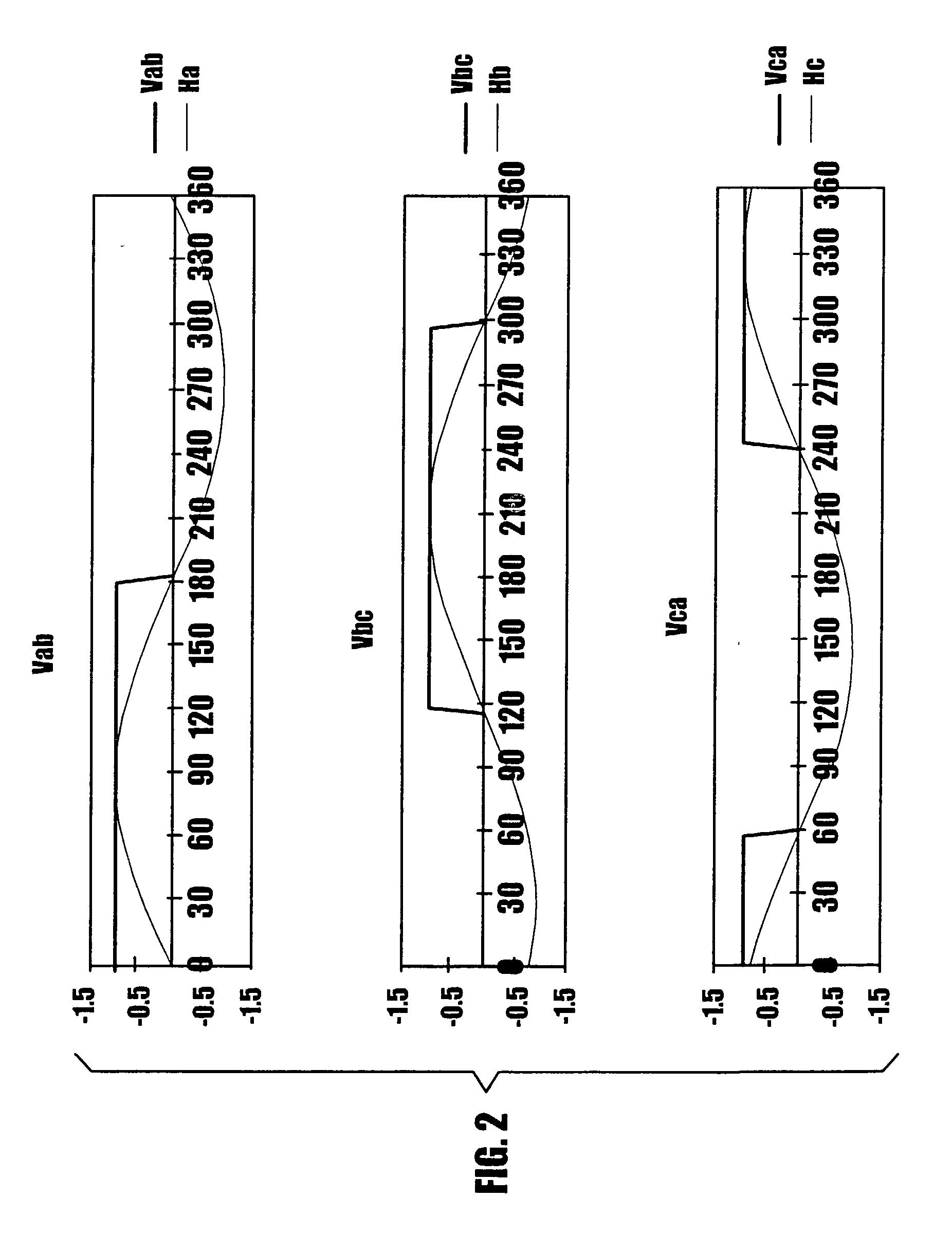

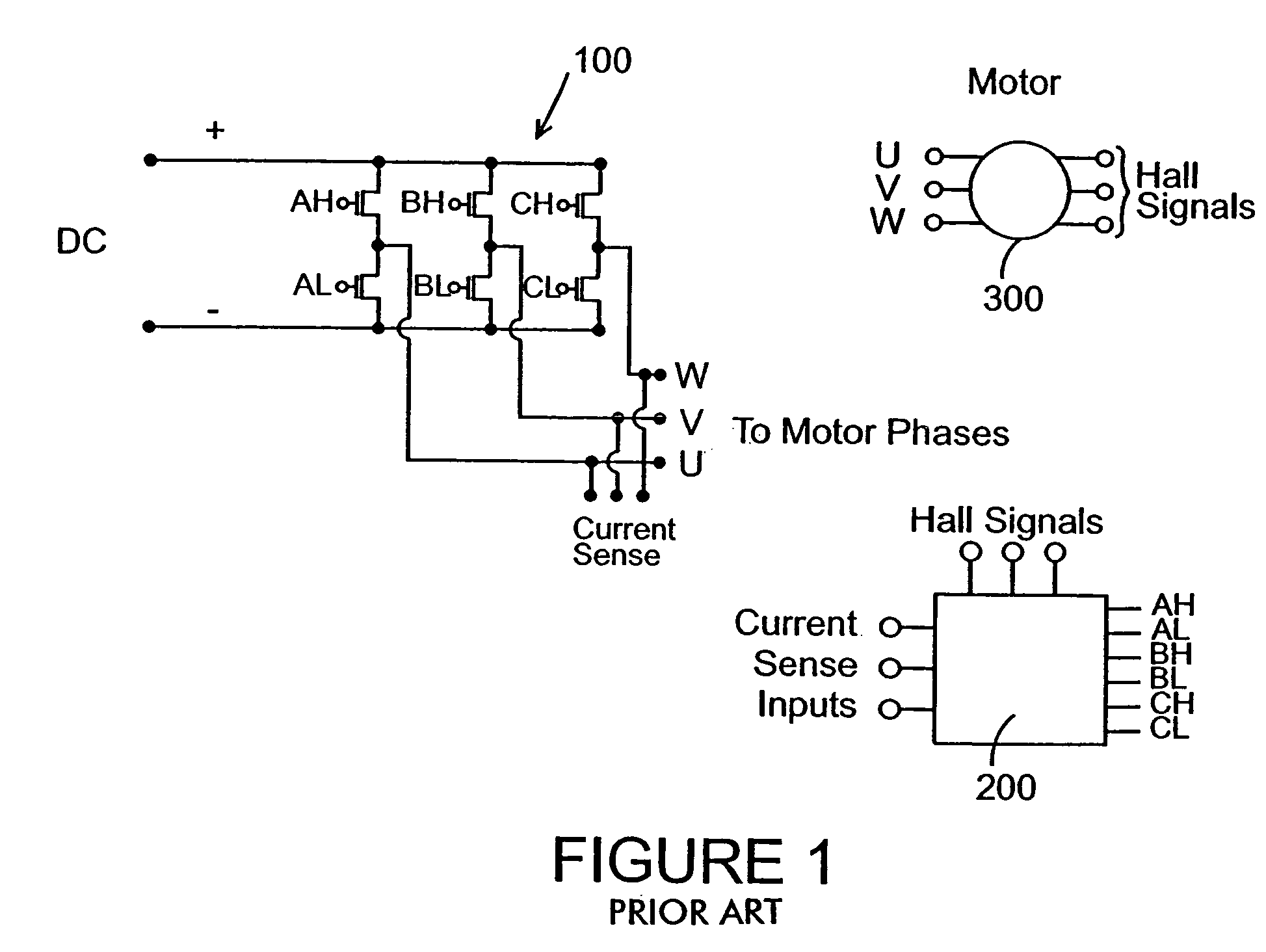

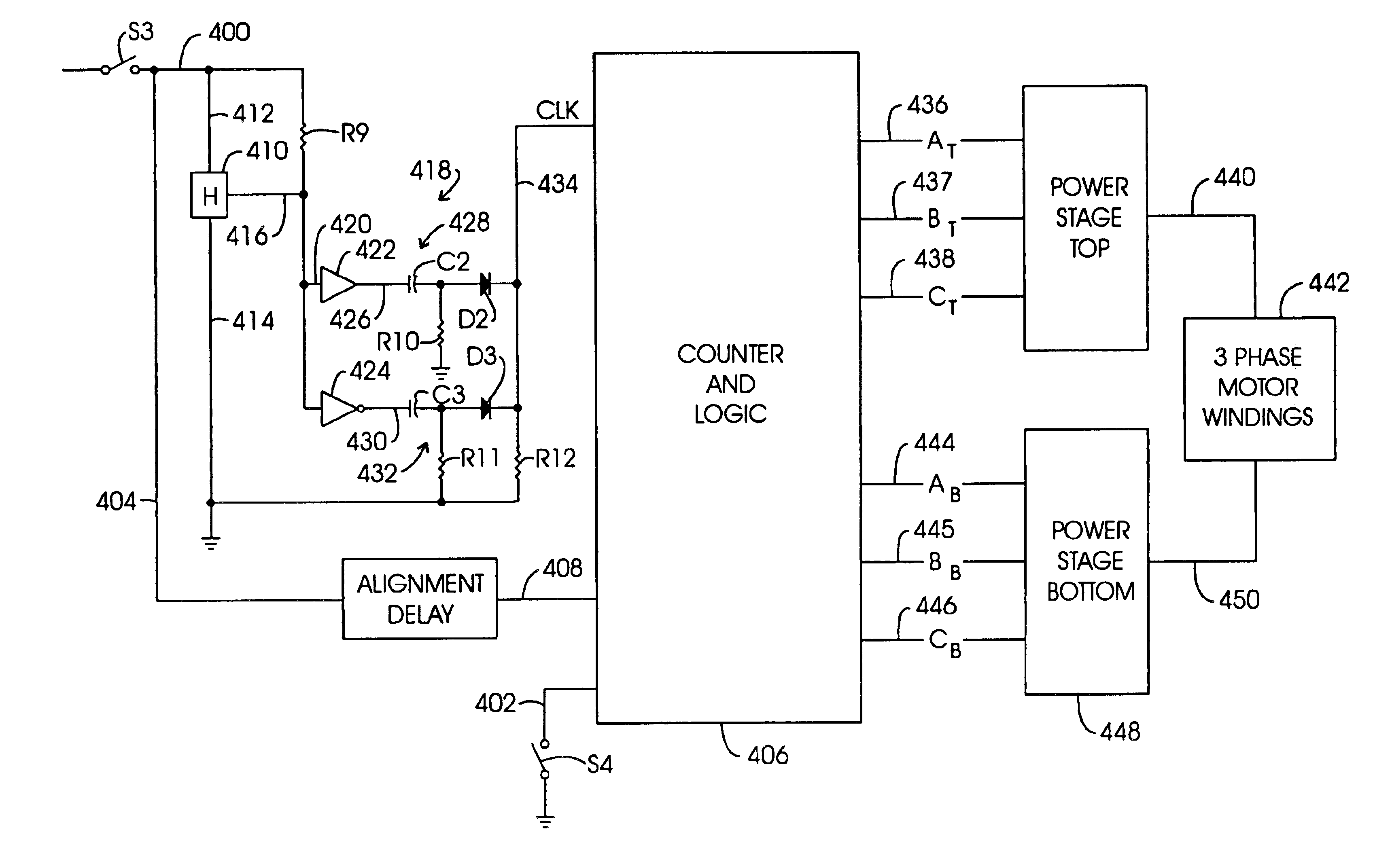

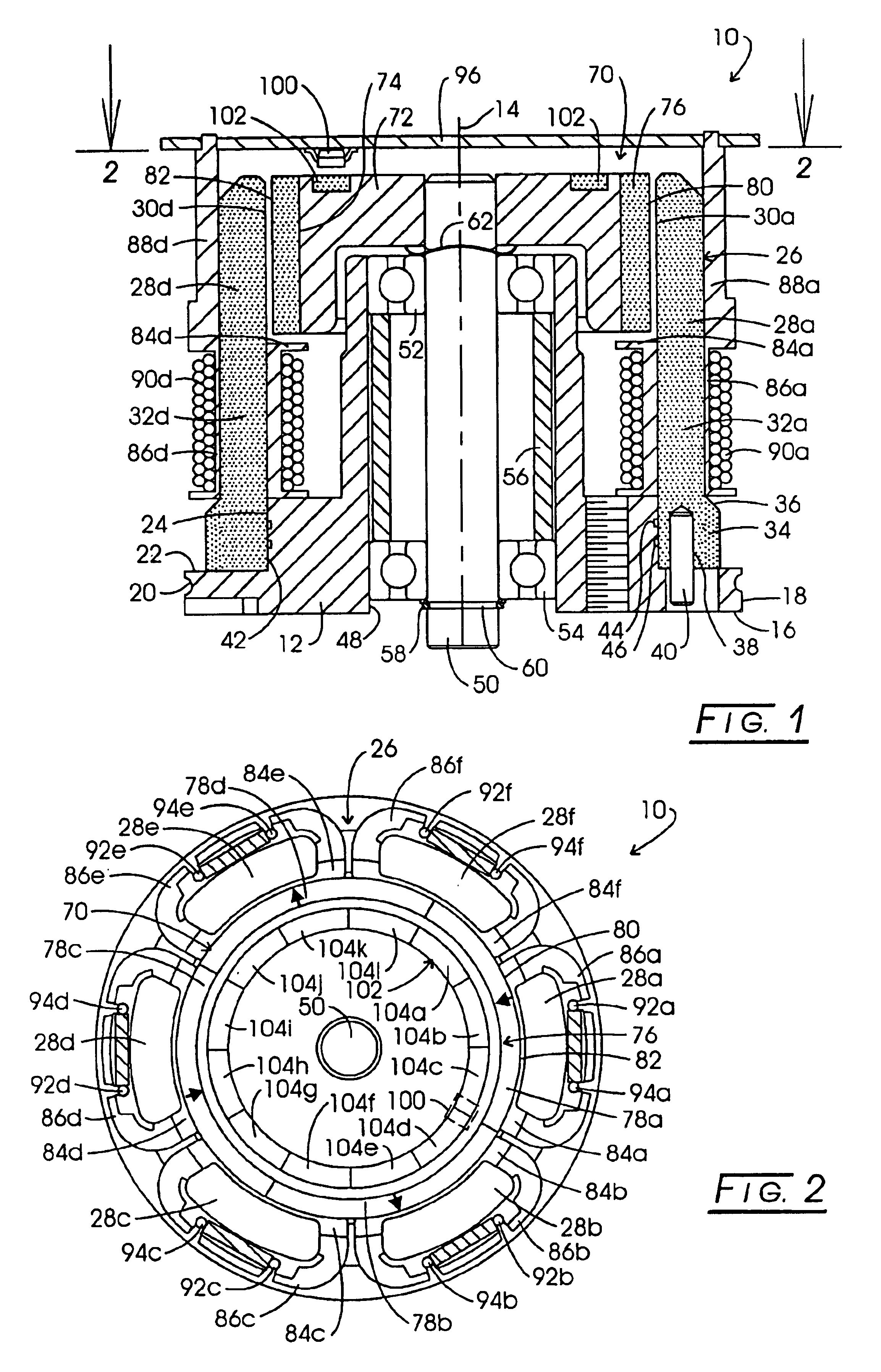

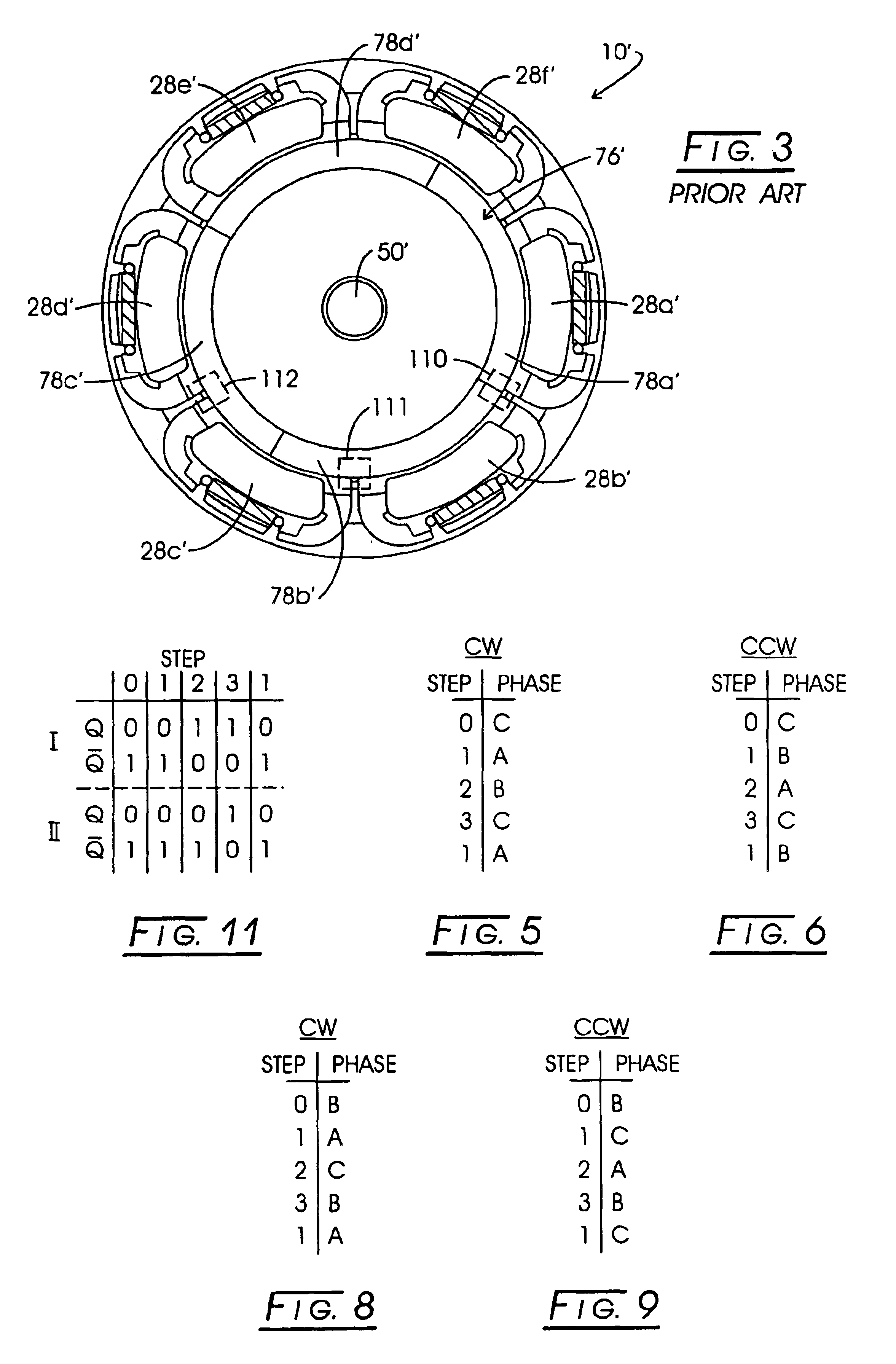

Multiphase motors with single point sensing based commutation

InactiveUS6891343B2Improve performanceAC motor controlSynchronous motors startersElectric machineThree-phase

System, method and apparatus for commutating a multiphase motor utilizing a single sensor. Commutation is carried out by employing a sensible system which incorporates phase commutating transition attributes. A motor is started by assigning a starting phase for a given direction of motor direction. An aligning phase initially is energized to orient the rotor so as to provide adequate starting phase start-up torque. Following such alignment and start-up, the motor is operated in response to transitions of the sensible system. In one aspect, a reference phase attribute may be incorporated in the sensible system to provide a mandated reference phase energization when the rotor is oriented for reference phase activation. Further described is a sensible system magnetic region configuration which is combined with a single package Hall effect sensor to provide three-phase unipolar and four-phase commutation with absolute phase defining information.

Owner:PETERSEN TECH

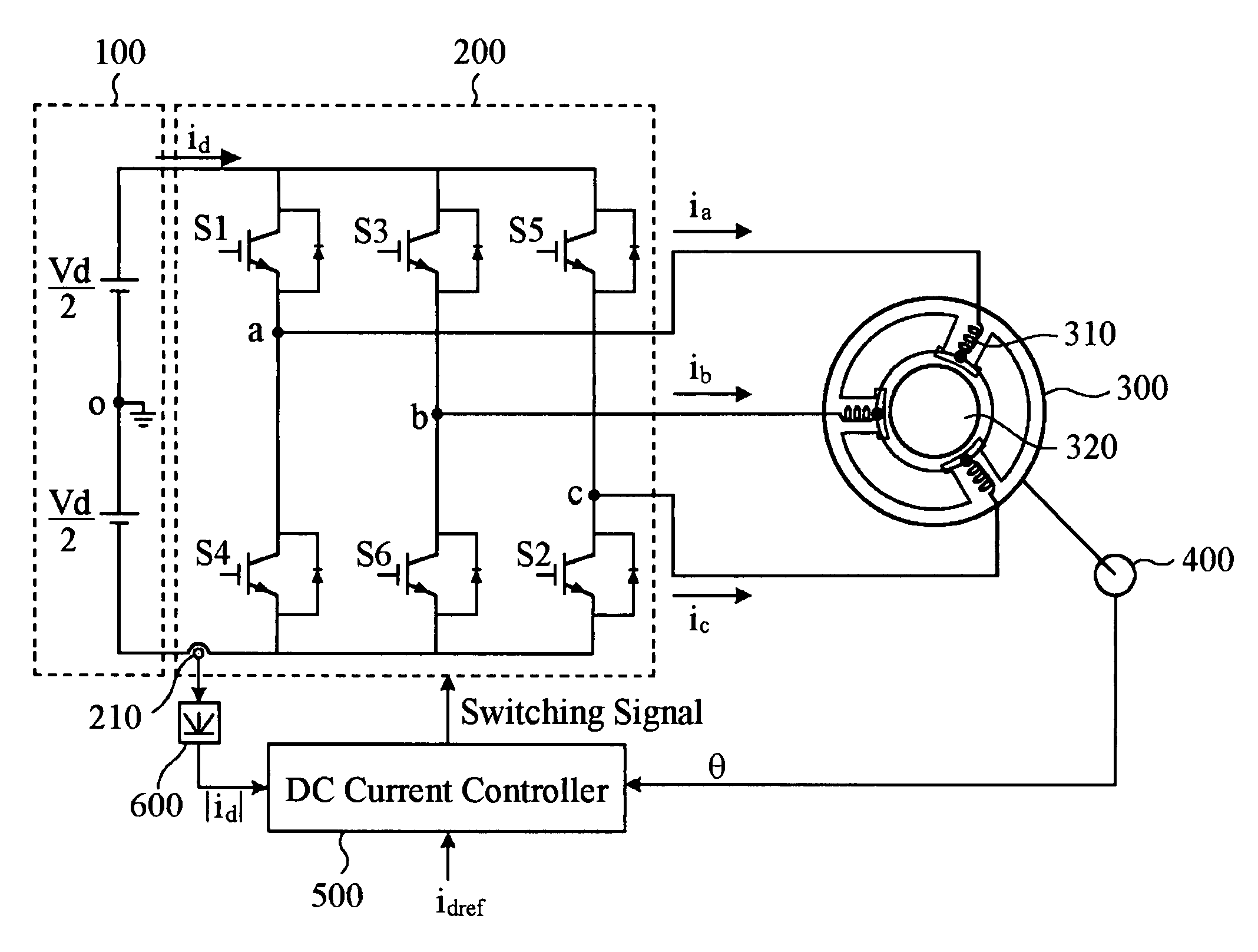

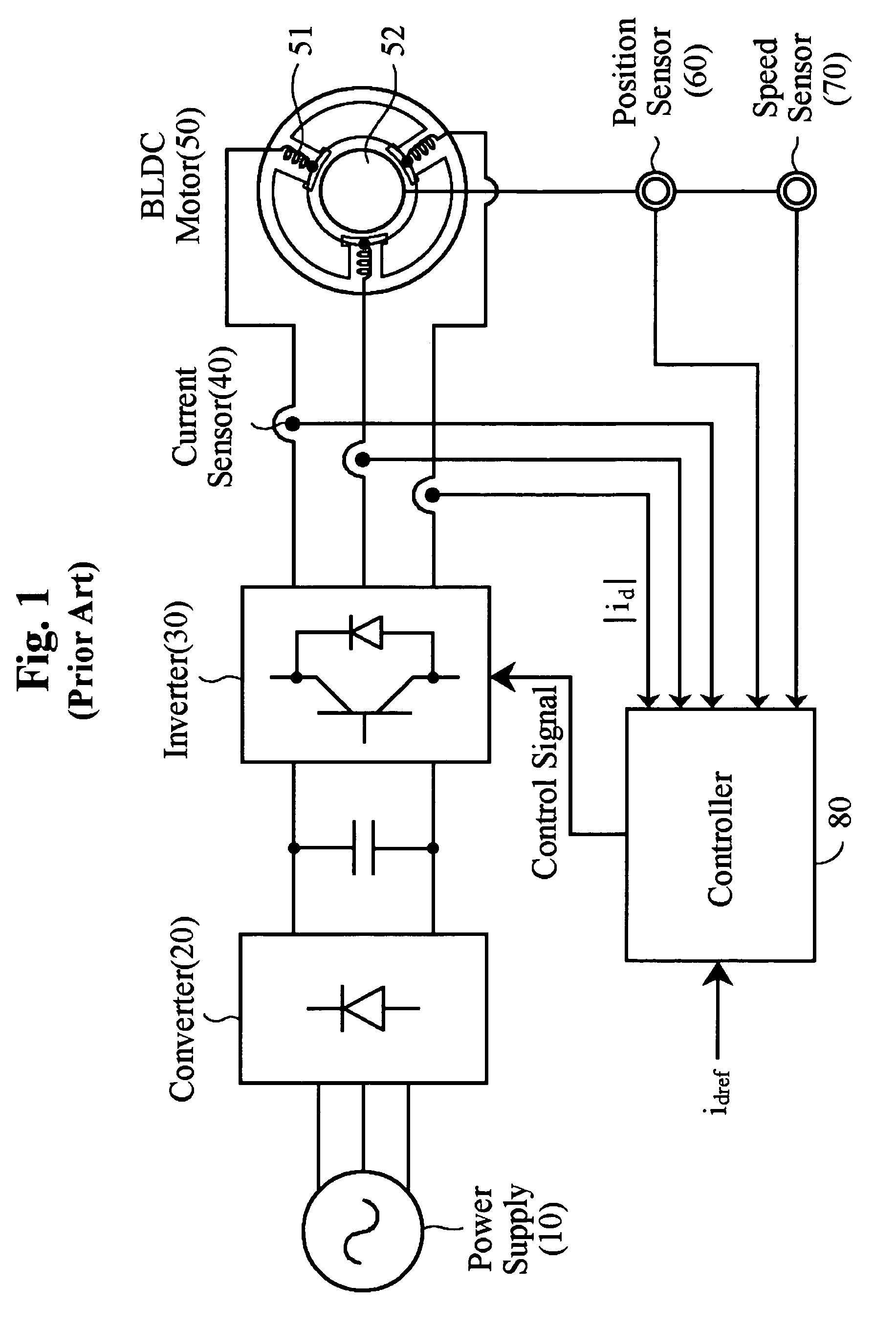

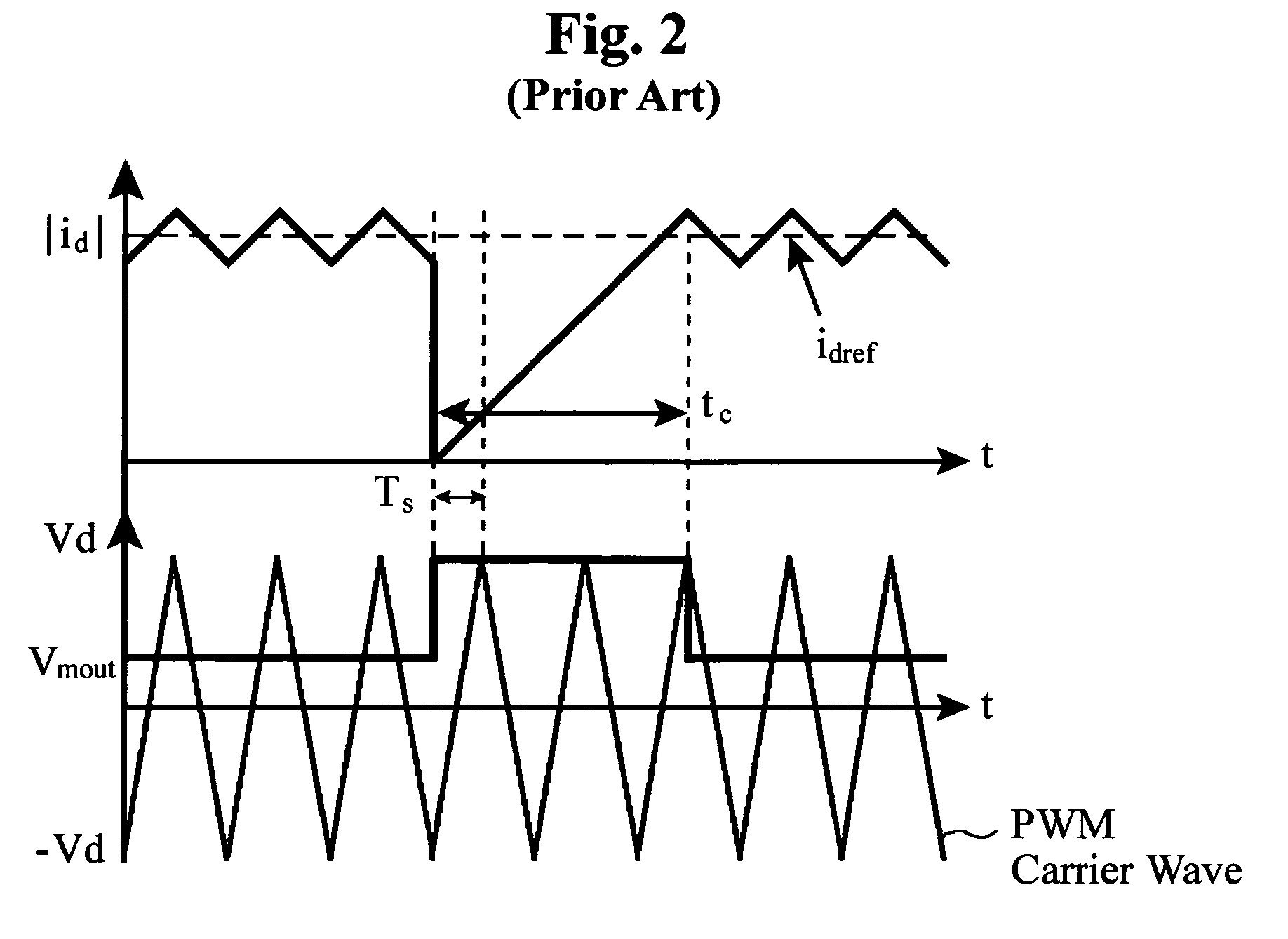

Brushless DC motor system and method of controlling the same

InactiveUS7141943B2Reduce a torque rippleDC motor speed/torque controlAC motor controlReference currentDc current

A brushless DC (BLDC) motor system and a method of controlling the same are provided. The BLDC motor system comprises a BLDC motor including a rotator and a stator, a plurality of switches, a DC current sensor, a position detector and a controller. The stator has a plurality of coils to which currents having different phase are applied. The switches are driven with switching pulses for switching the currents applied to the coils. The position detector detects a position change of the rotator to thereby generate a counter-electromotive force and the DC current sensor senses currents when the currents are applied from the switches to the coils. Based on a magnitude of the counter electromotive force, the controller generates a compensation voltage in order to control the switches during the commutation interval. Further, a duty ratio of the switching pulse is controlled based on the differences between the currents applied to the coils and a reference current.

Owner:KOREA INST OF SCI & TECH

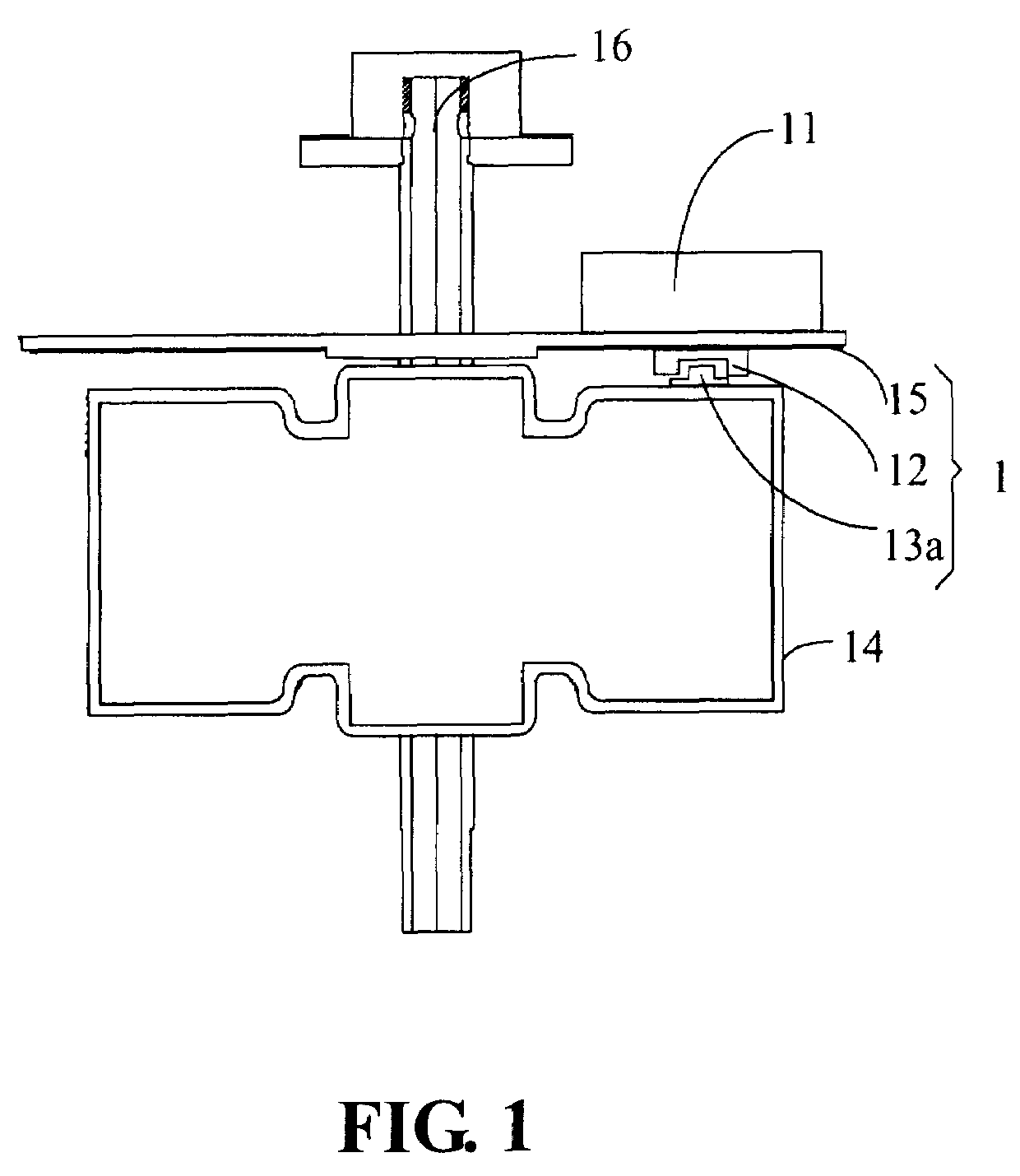

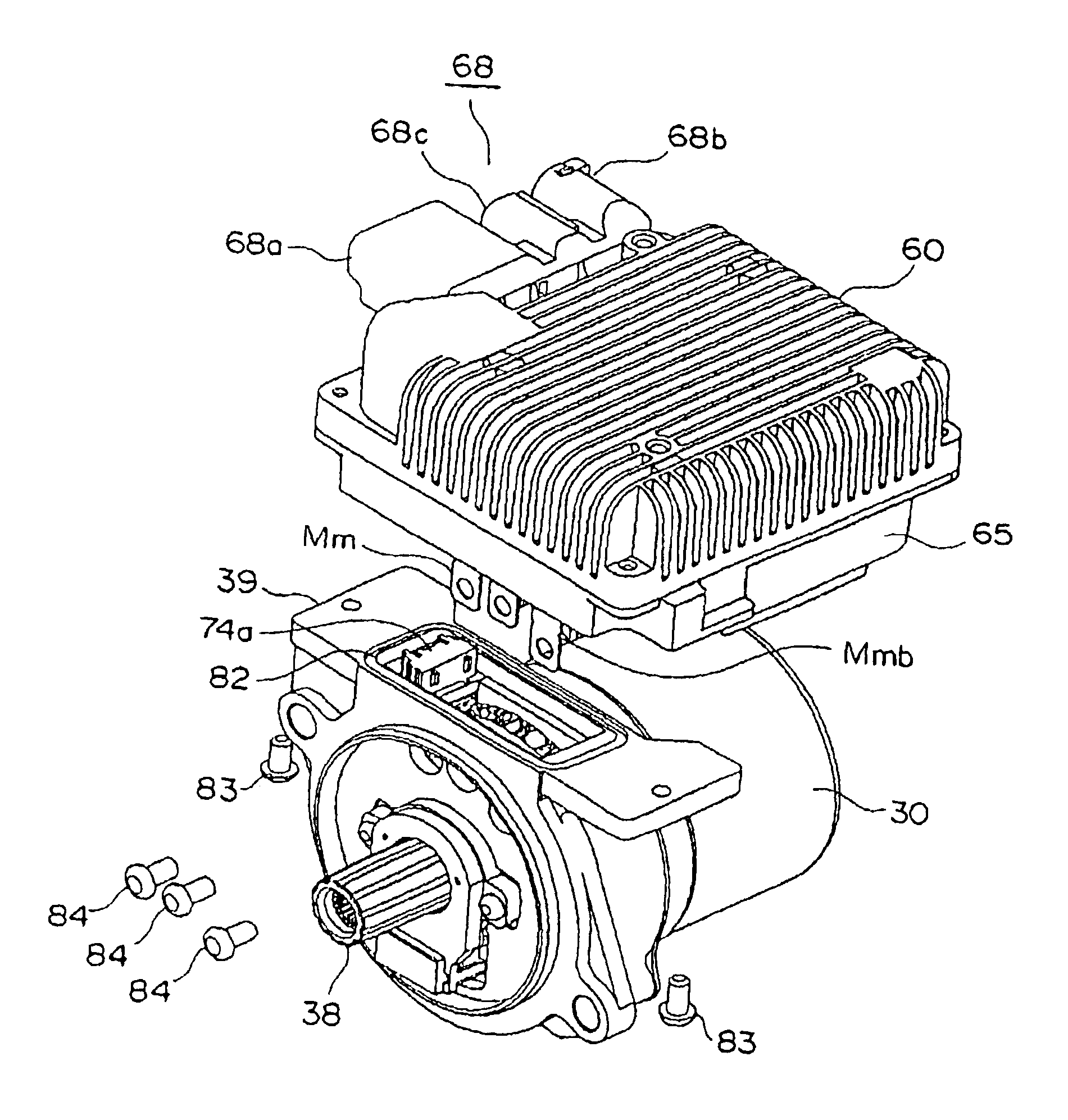

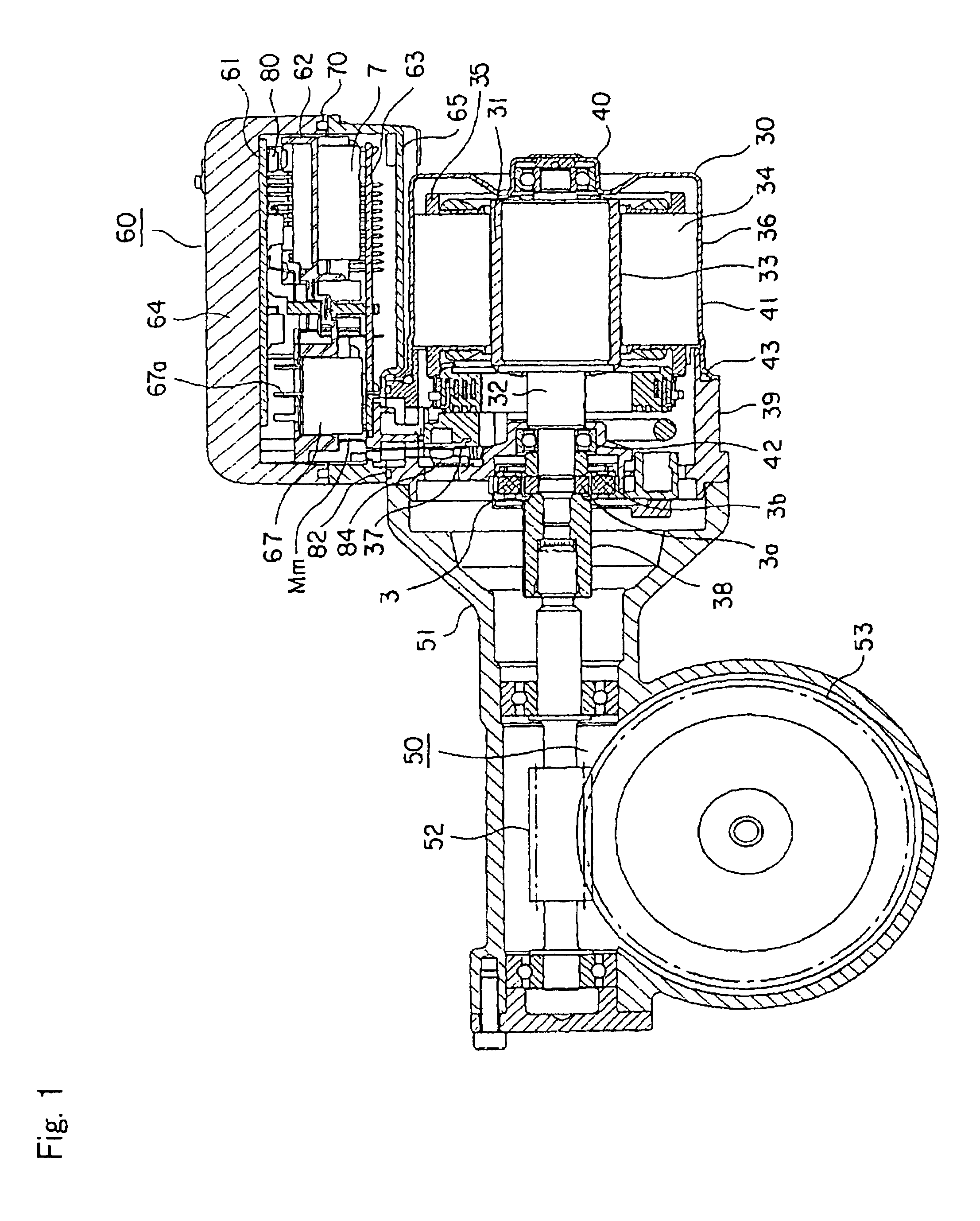

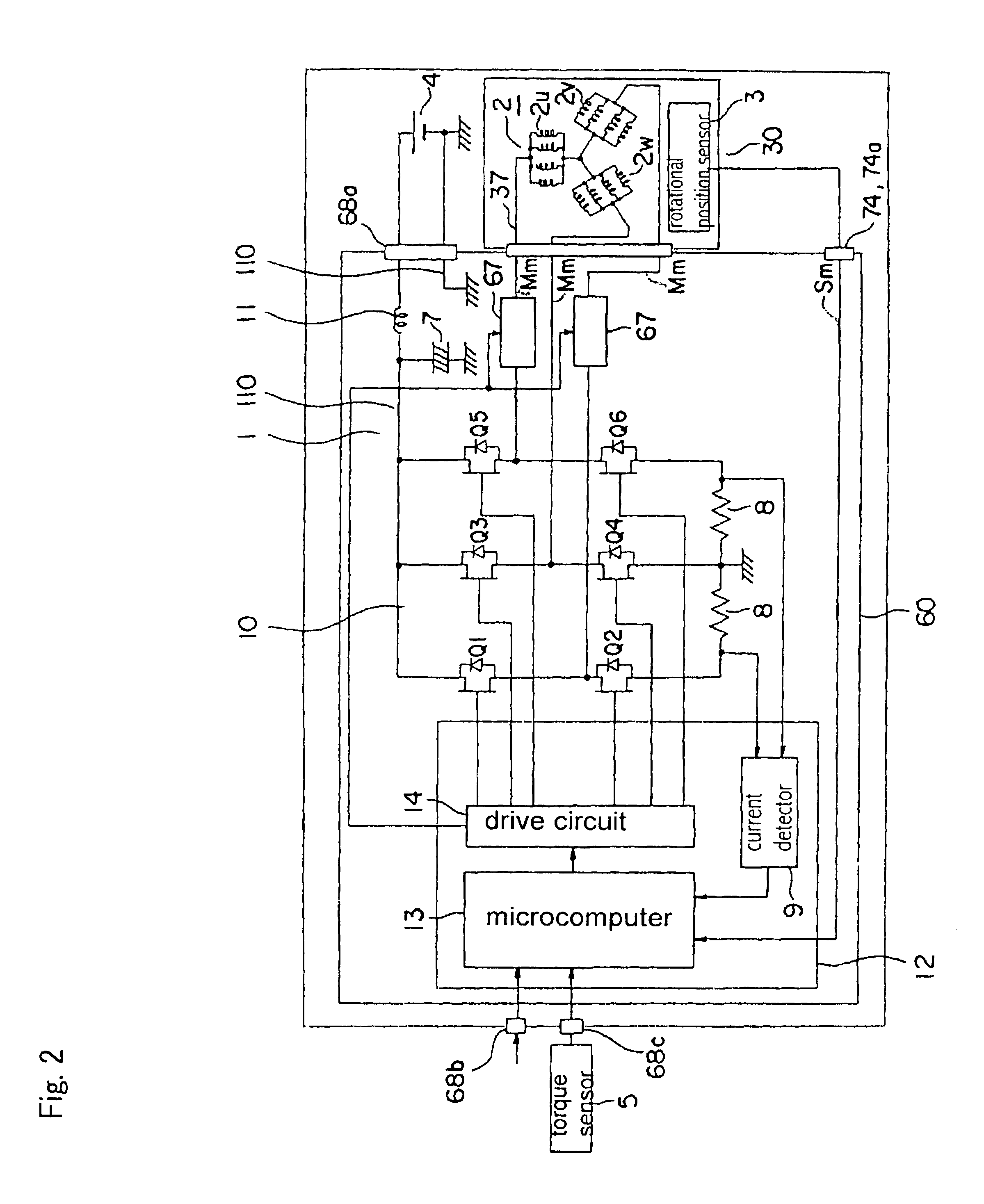

Electric power steering apparatus

InactiveUS6906483B2Reduce the impactLow costAssociation with control/drive circuitsDC motor speed/torque controlElectric power steeringElectric power system

An electric power steering removes external wiring connecting between an electric motor and a control unit, whereby the influence of radiation noise caused by a PWM operation can be reduced. In addition, the heat radiation and assemblability of the electric motor and the control unit can be improved, while achieving high power output. A housing 64 with a metal substrate 61 fixedly secured thereto is arranged at a side opposite to an electric motor 30. The cooling fins are formed on an outer side of a housing 64 and on an outer side and an inner side of a cover 65. A metal substrate 61, a large current substrate 62 and a control substrate 63 are arranged inside of the housing 64 and the cover 65 in a laminated structure.

Owner:MITSUBISHI ELECTRIC CORP

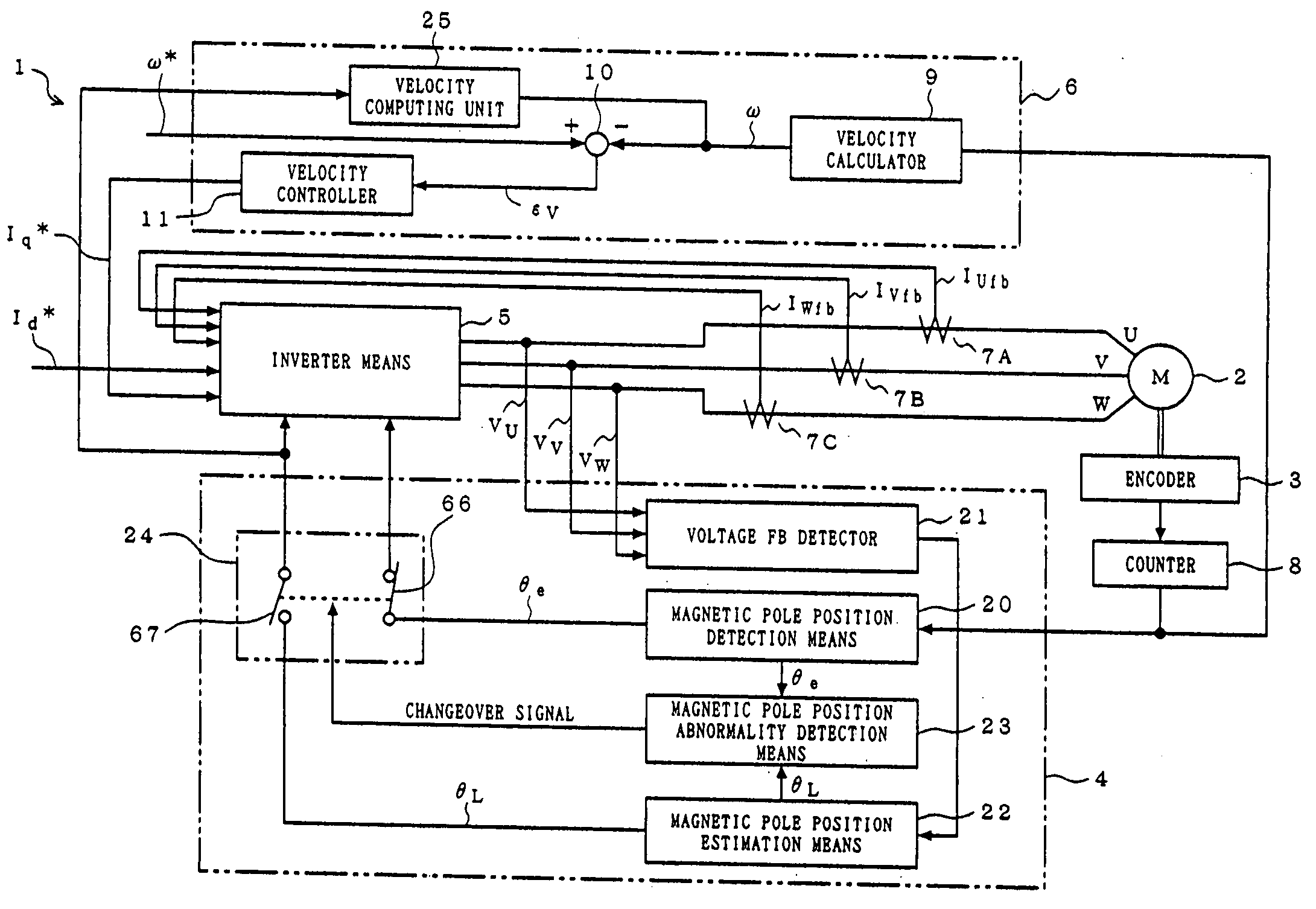

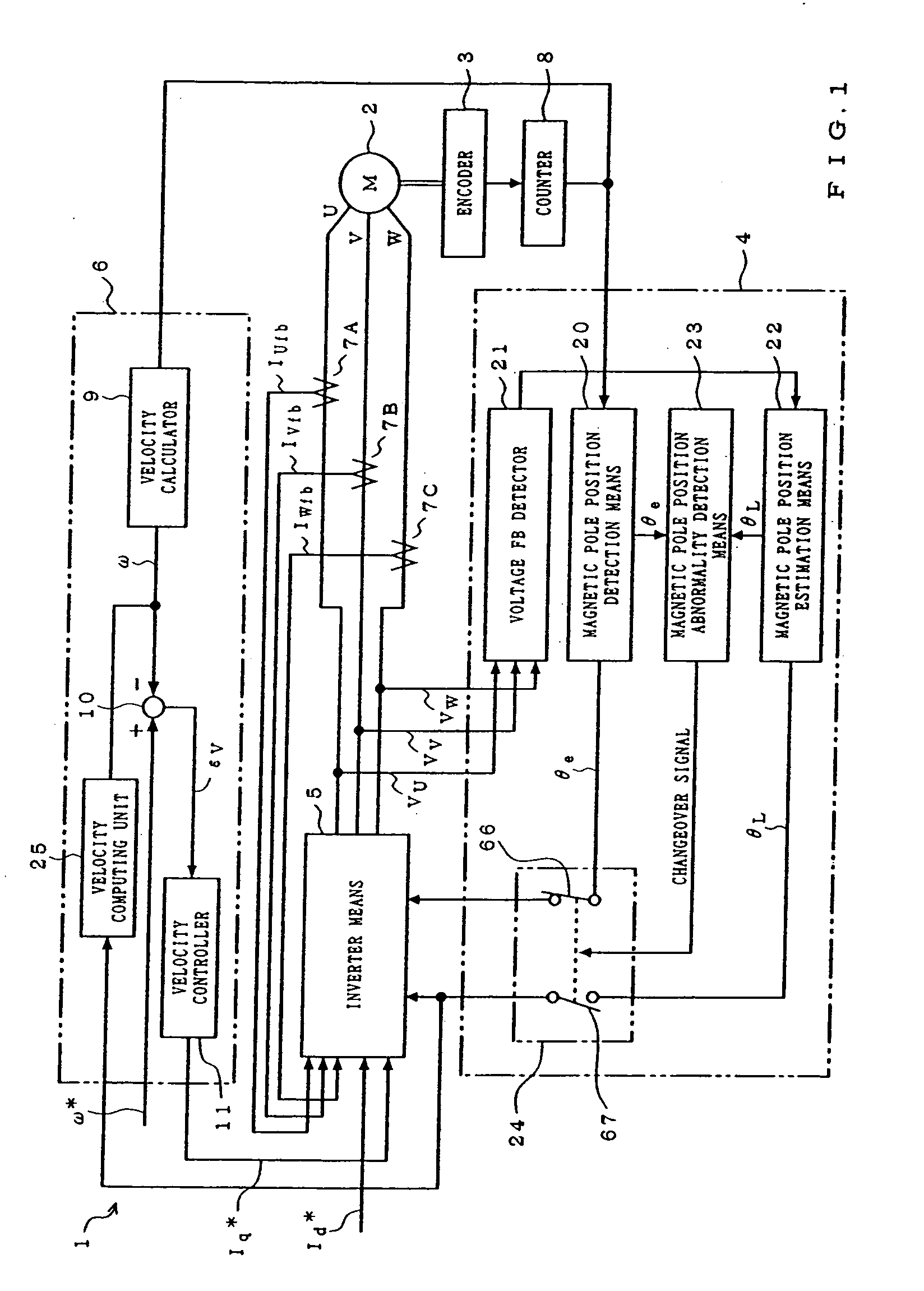

Motor Controller

InactiveUS20040257027A1Commutation monitoringSynchronous motors startersSynchronous motorMagnetic poles

A motor controller is provided. This motor controller comprises, a synchronous motor, a feed back detector which is mounted on the synchronous motor and detects the position and velocity of the rotor of the synchronous motor, magnetic pole position detection means for detecting an magnetic pole position of the rotor of the synchronous motor, inverter means for controlling an electric power to be supplied to the synchronous motor according to the magnetic pole position detected by the magnetic pole position detection means, magnetic pole position estimation means for estimating the magnetic pole position of the rotor of the synchronous motor from the induced voltage of the stator windings of the synchronous motor, and magnetic pole position abnormality detection means for detecting the abnormality of the feed back detector by always comparing the magnetic pole position detected by the magnetic pole position detection means and the estimated magnetic pole position estimated by the magnetic pole position estimation means.

Owner:ROCKWELL AUTOMATION TECH +1

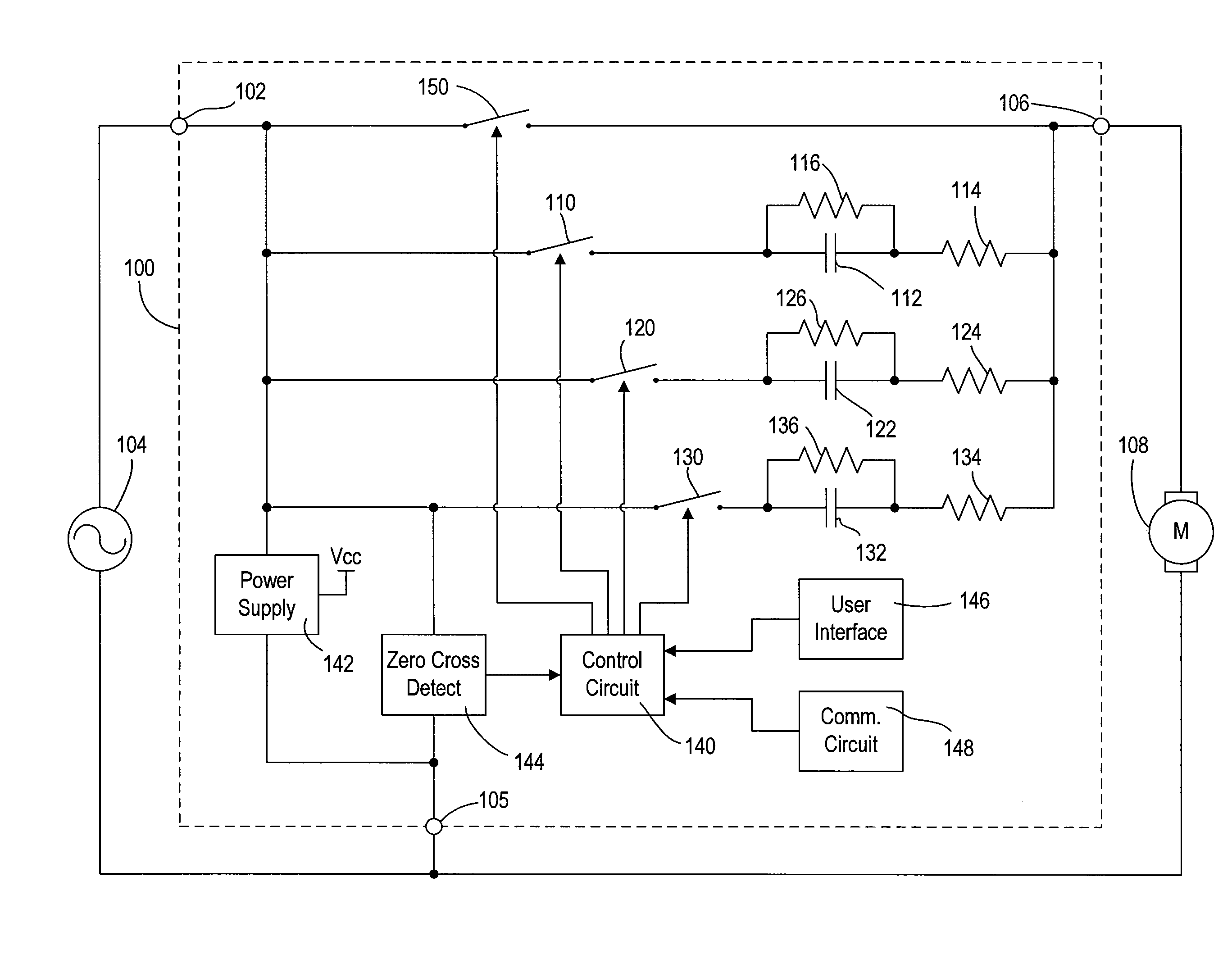

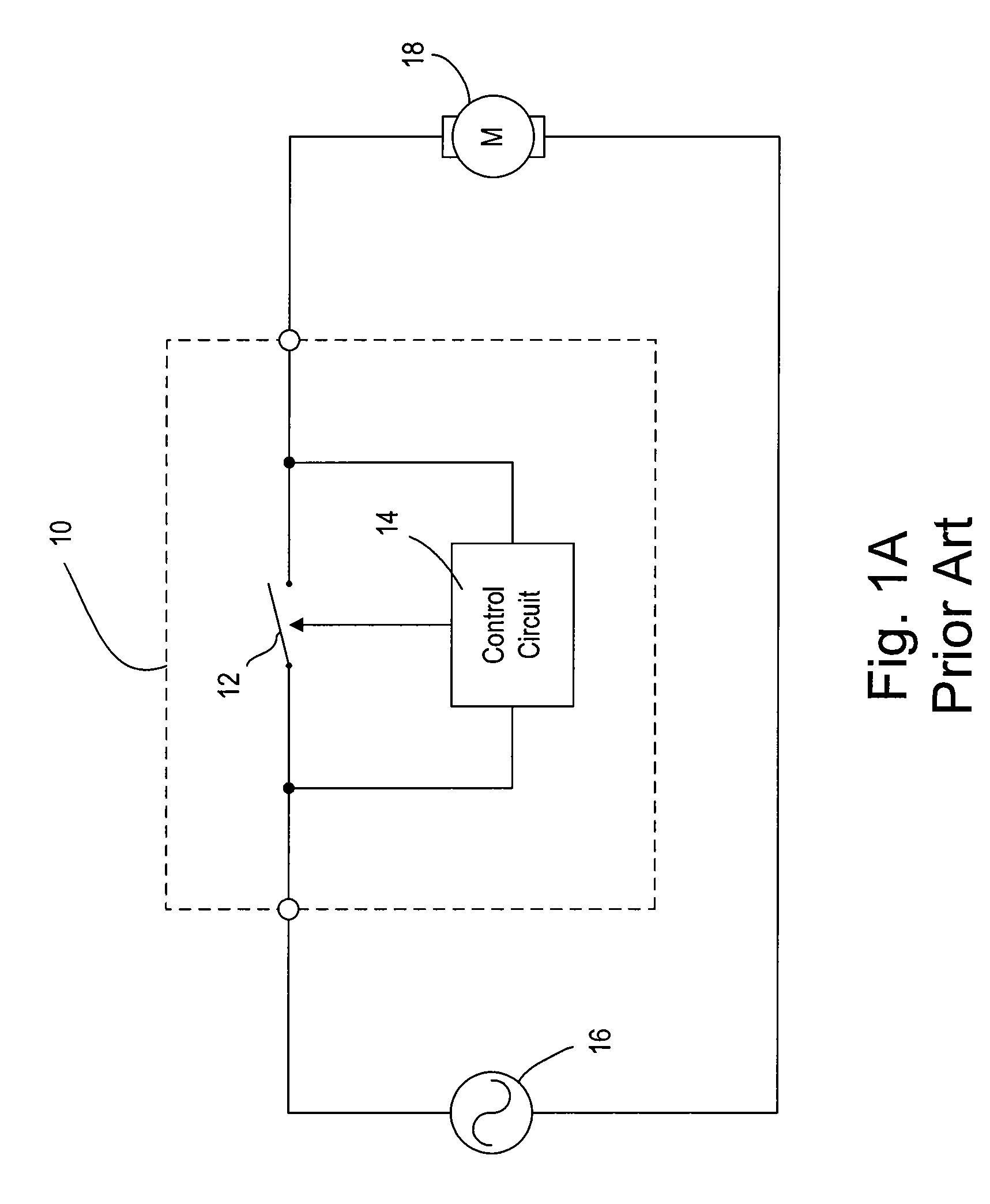

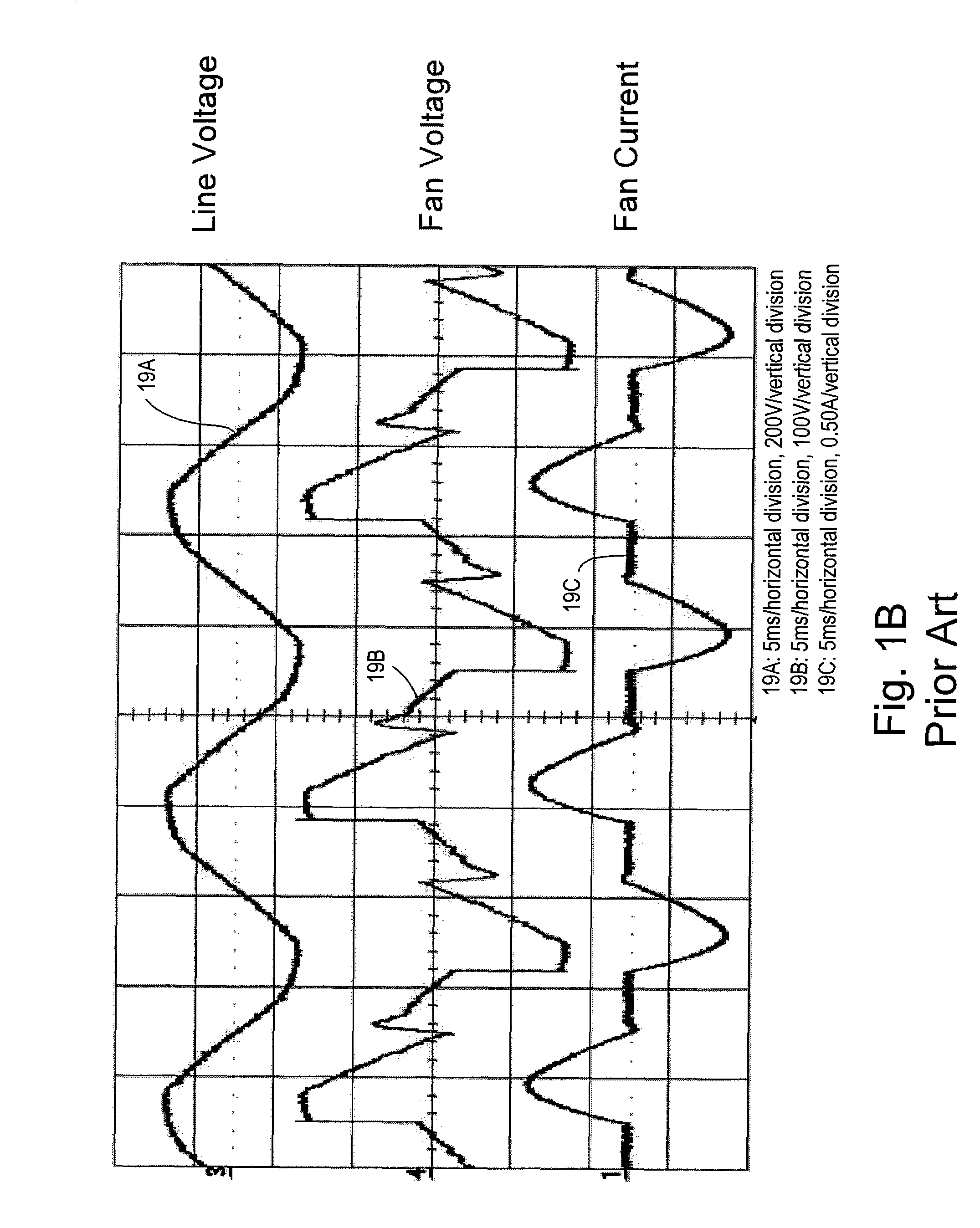

Method and apparatus for quiet fan speed control

An AC motor speed controller includes a plurality of capacitors that may be selectively switched, by means of controllably conductive switches, into series electrical connection with an AC motor and an AC voltage source to control the speed of the motor. To change the speed of the motor, a control circuit renders a first switch conductive, in response to a first detected AC voltage zero crossing, to charge a first capacitor to a predetermined voltage. The control circuit then renders a second switch conductive, in response to a subsequent second detected AC voltage zero crossing, to charge a second capacitor to the predetermined voltage. The control circuit then renders both switches simultaneously conductive at a predetermined time after a subsequent third detected AC voltage zero crossing. The capacitors will thereby be charged to the same voltage prior to being switched into series with the motor, thereby resulting in reduced acoustic noise when changing motor speeds.

Owner:LUTRON TECH CO LLC

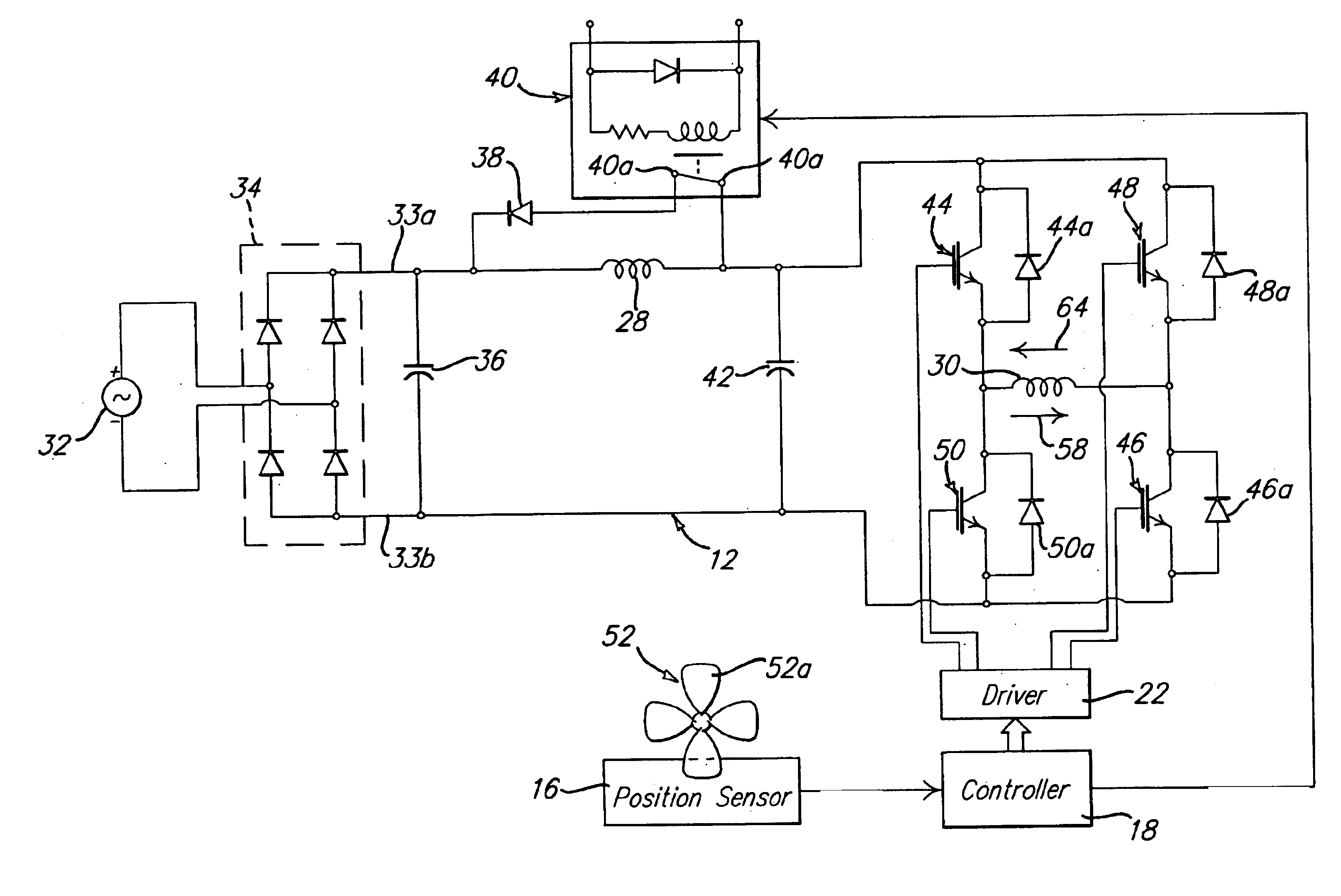

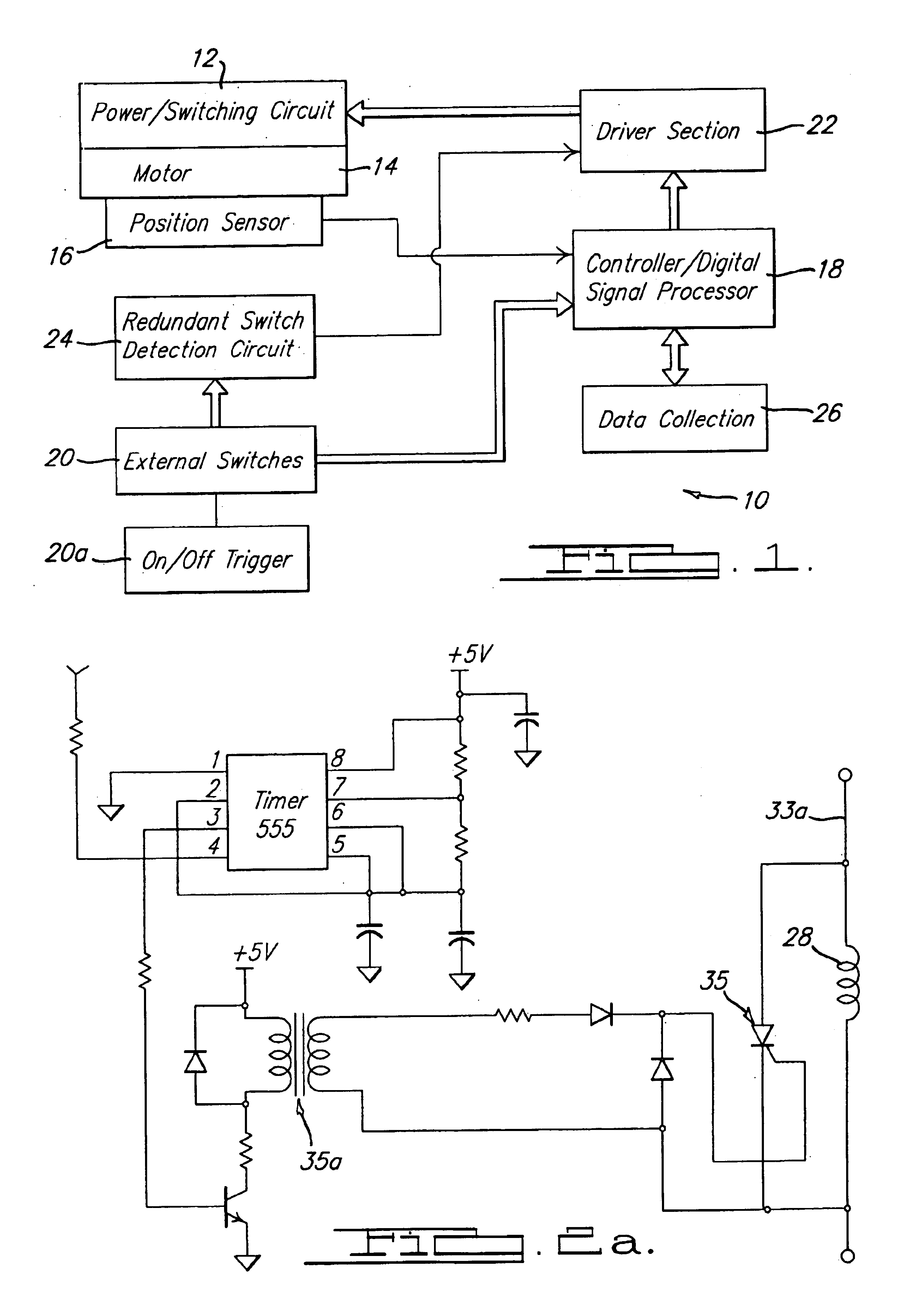

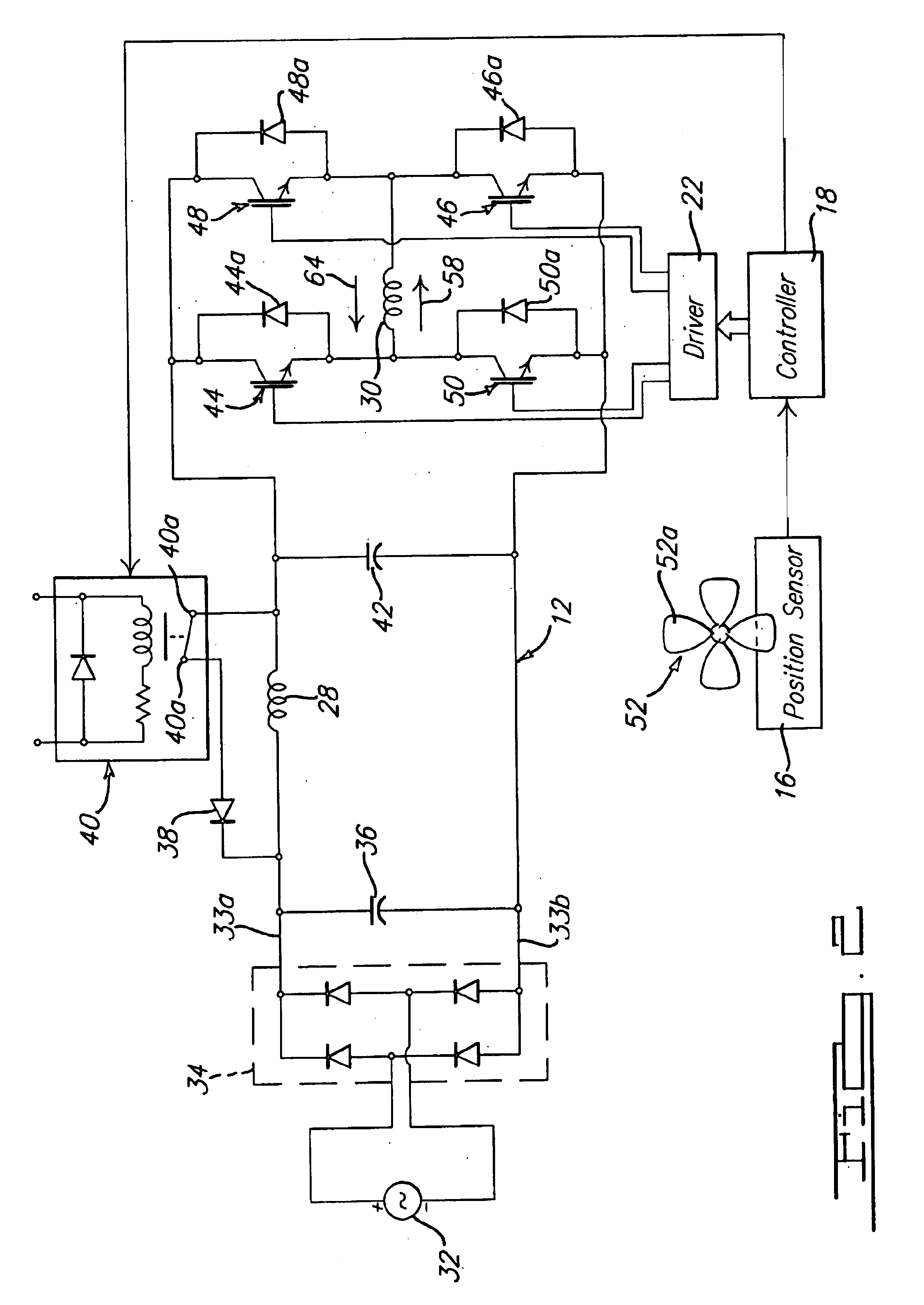

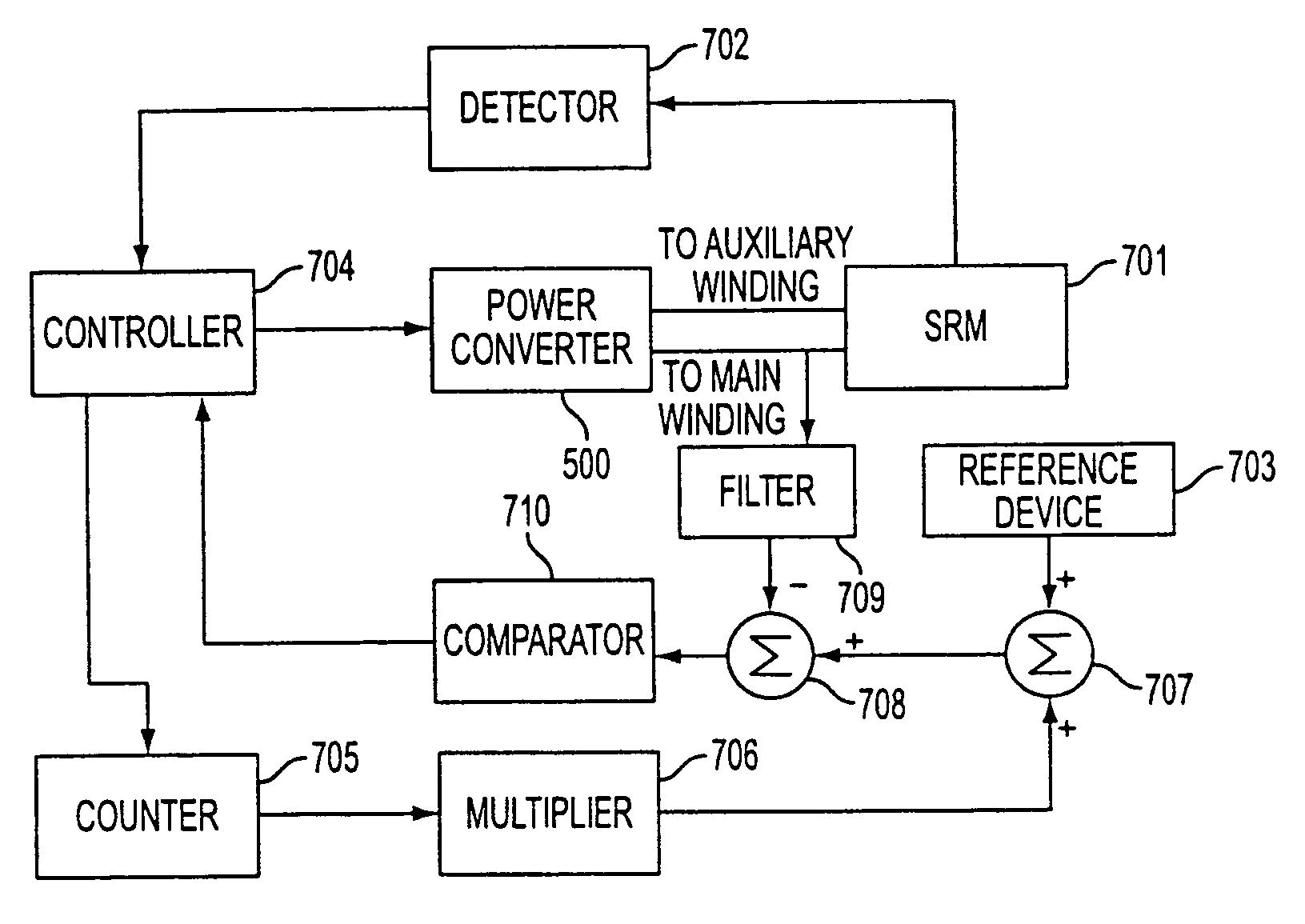

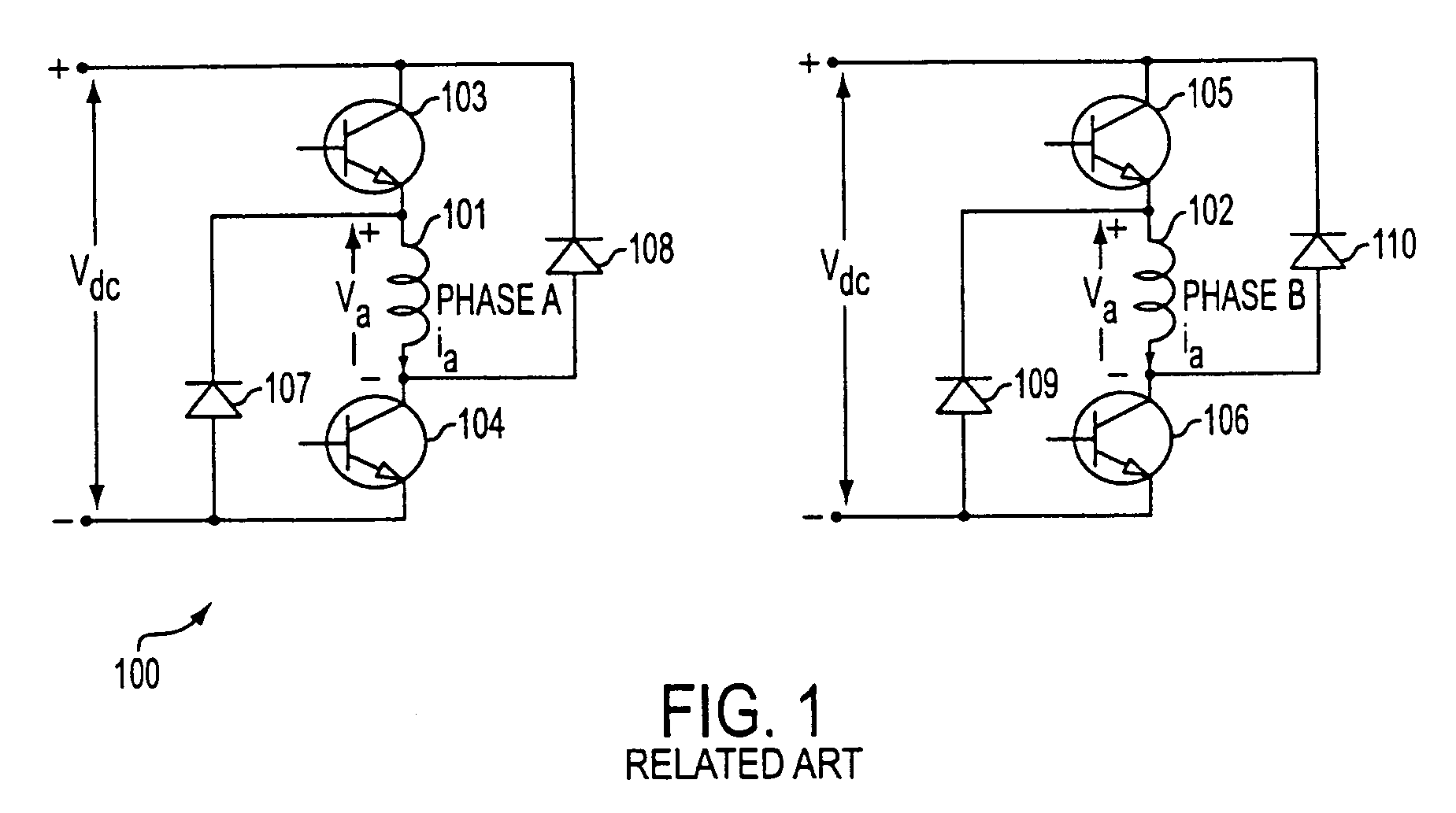

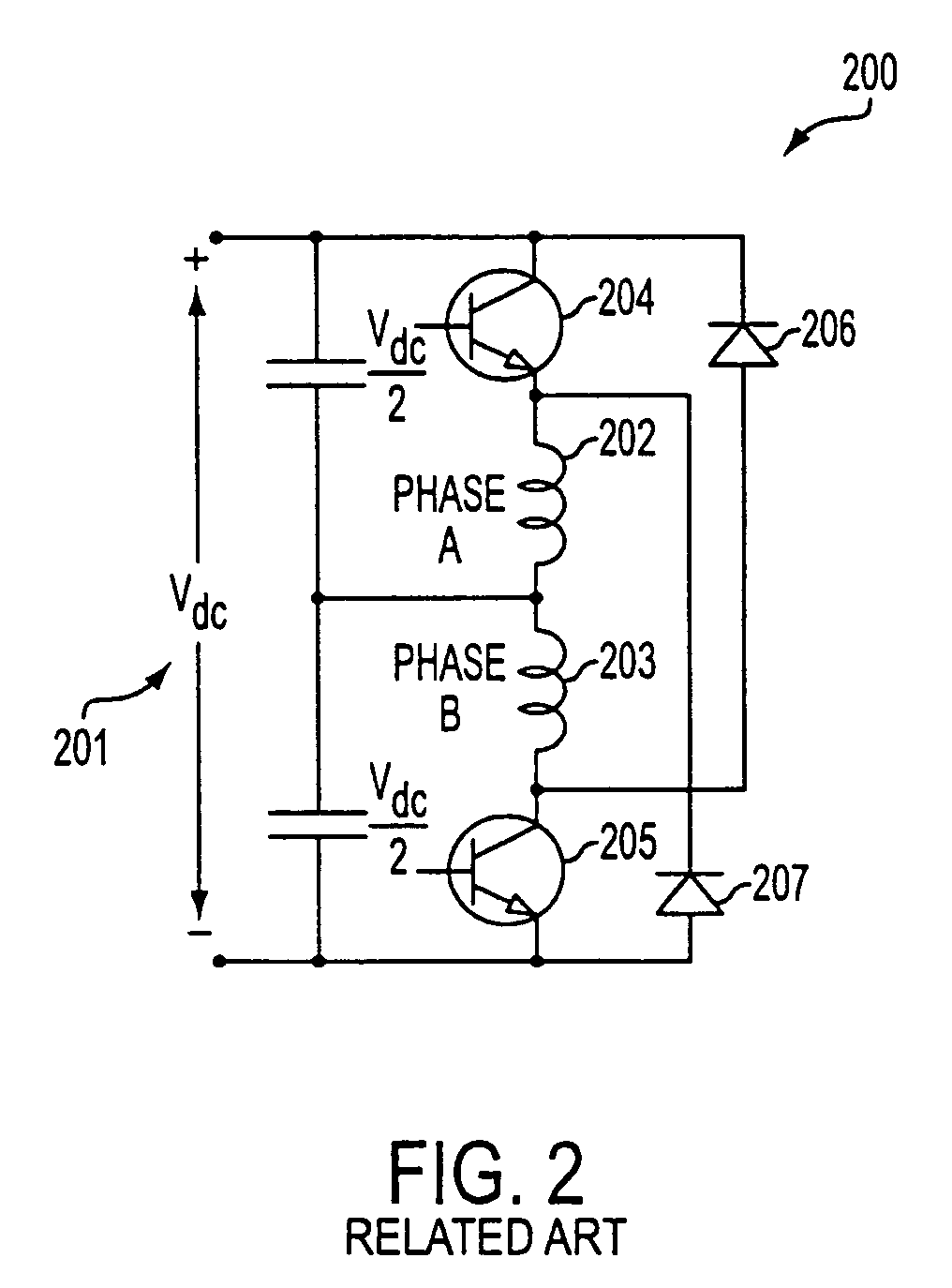

Method, apparatus, and system for drive control, power conversion, and start-up control in an SRM or PMBDCM drive system

InactiveUS7271564B2Low costReduce in quantityAC motor controlSynchronous motors startersFour quadrantsEngineering

A power converter for a switched reluctance motor or a permanent magnet brushless direct current (dc) motor may include first and second partial circuits for forming multiple conduction circuits in cooperation with first and second phase windings of the motor. The controller also includes a switch operable to open and close a first conduction circuit, which includes the first phase winding, and to regulate energization of the first and second phase windings of the motor through opening and closing the first conduction circuit. Control of the switch provides four-quadrant operation of the motor through regulated energization of the first and second phase windings.

Owner:VIRGINIA TECH INTPROP INC +1

Method for operating an electrical power tool, and a drive unit for an electric power tool

InactiveUS20100065293A1Shutoff is preventedRestraint torsionDC motor speed/torque controlDrilling rodsMaximum torqueElectric power system

The invention relates to a method for operating a handheld electric power tool, having an electric motor that is drivable at a rated torque as the maximum allowable motor torque by the application of a maximum allowable motor current. The method includes the steps of manually furnishing a specification of a maximum torque, in which the maximum torque is within a setting range between a minimum set torque and the rated torque, operating the electric motor by applying a motor voltage which corresponds to an rpm desired by the user, and limiting the motor current to a current value that depends on the furnished specification of the maximum torque.The invention also related to a drive unit for an electric power tool, which includes an electric motor drivable at a rated torque as a maximum allowable motor torque by application of a maximum allowable motor current. A setting element manually furnishes a specification of a maximum torque, the maximum torque being within a range between zero and the rated torque. A triggering unit operates the electric motor by applying a motor voltage that corresponds to an rpm desired by the user. A motor controller limits the motor current to a current value that depends on the furnished specification of the maximum torque.

Owner:ROBERT BOSCH GMBH

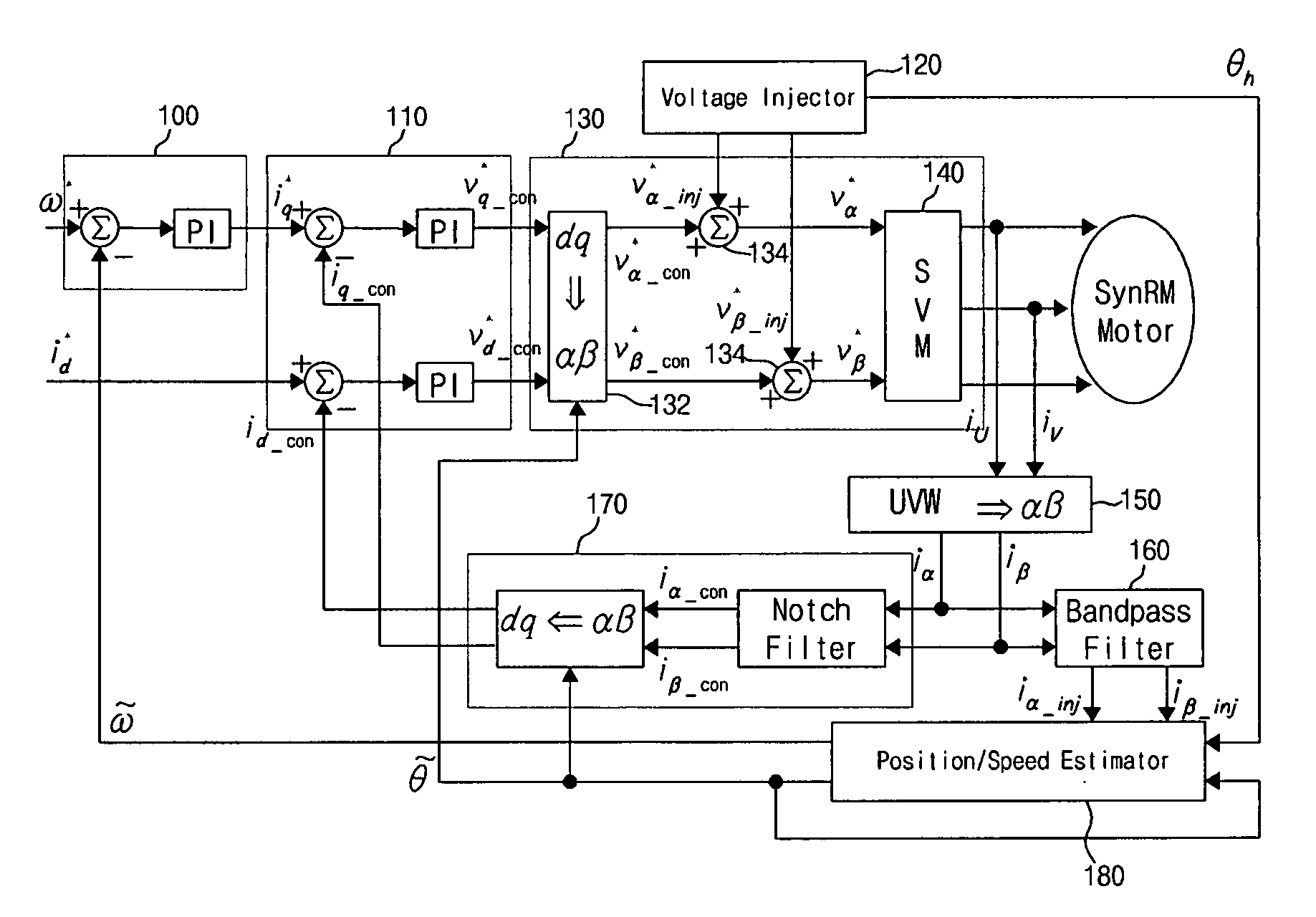

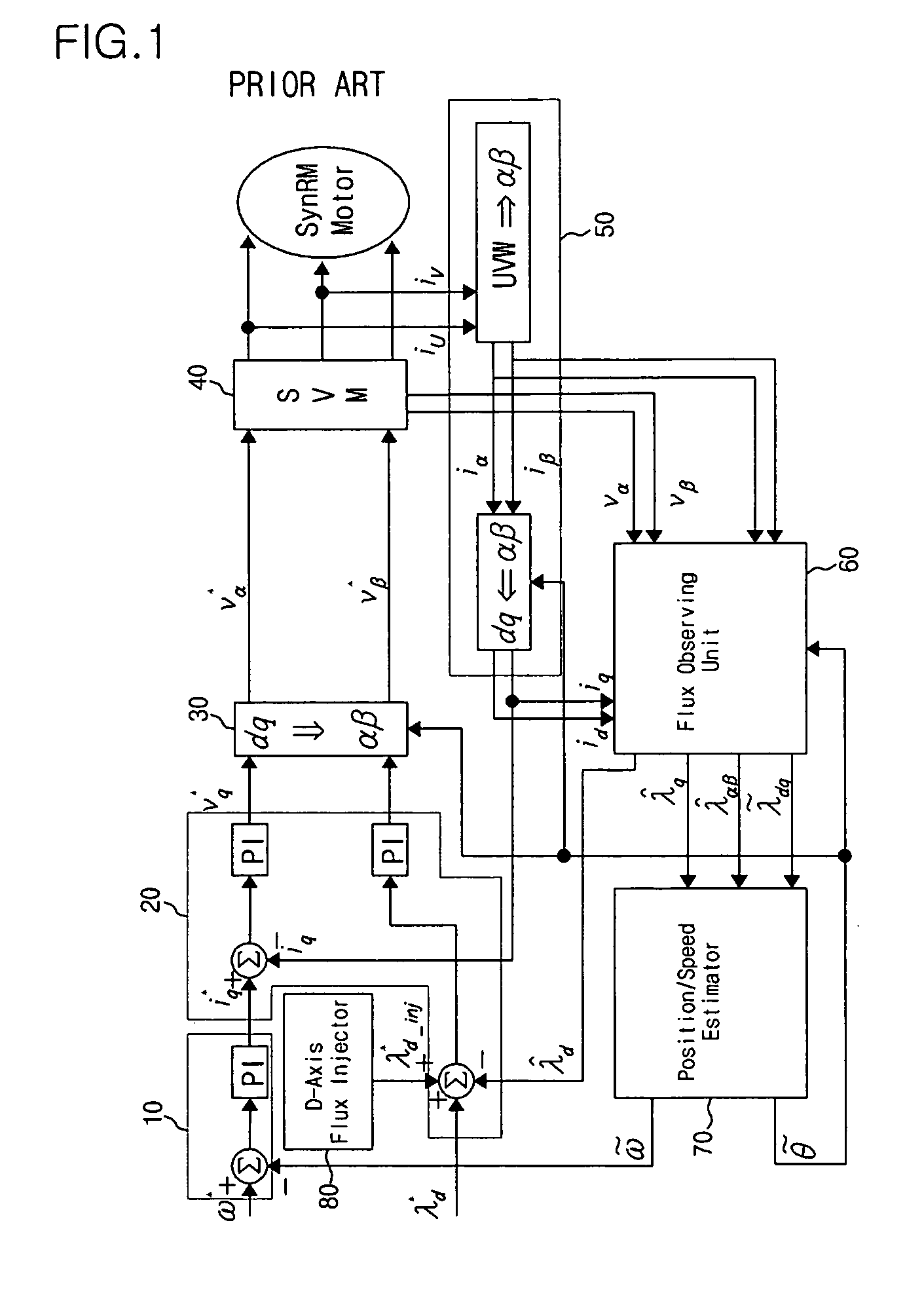

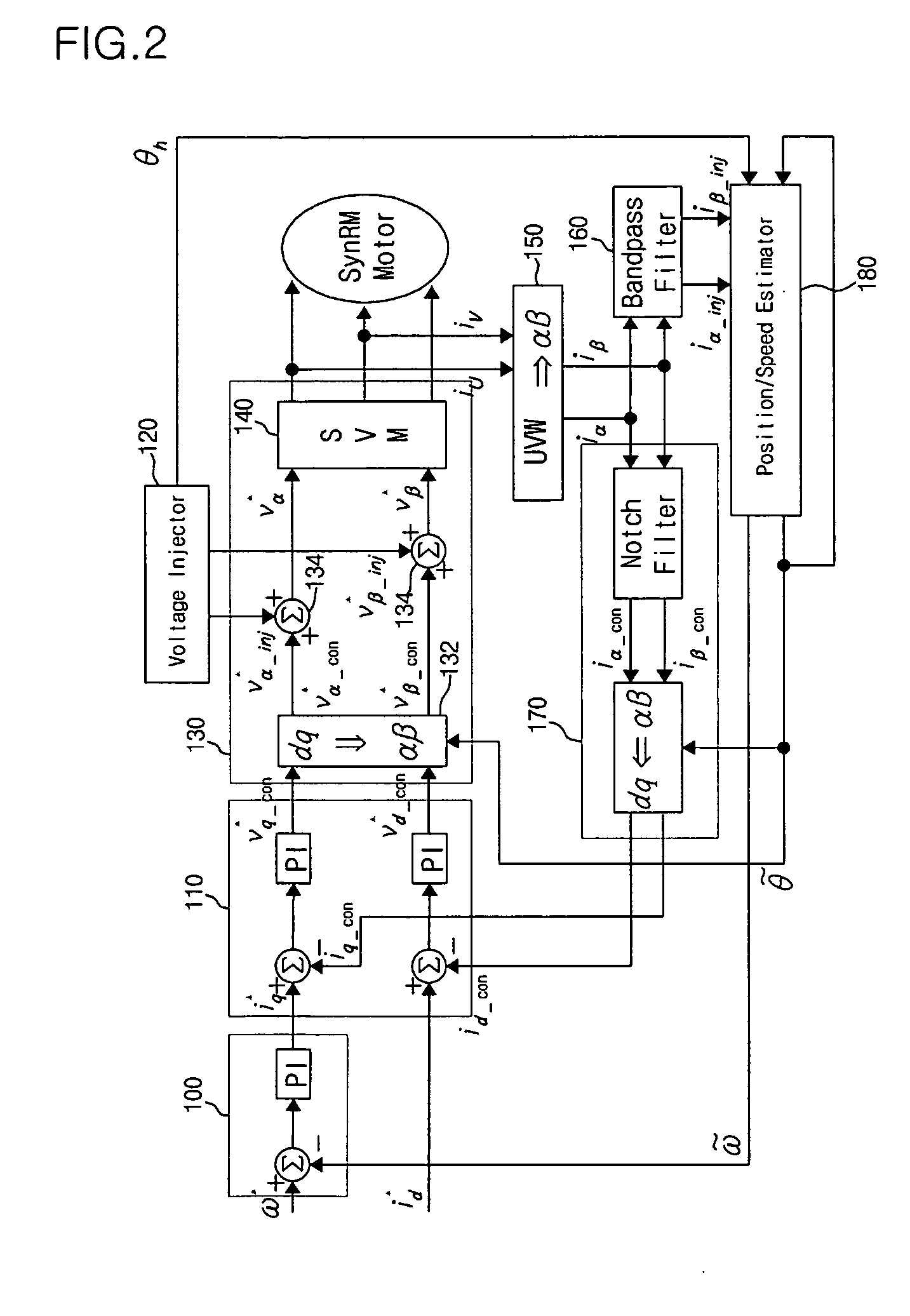

Method and device for controlling startup of motor

ActiveUS20060119305A1AC motor controlDC motor speed/torque controlVoltage generatorSynchronous reluctance motor

Disclosed is a method and device for controlling the startup of a synchronous reluctance motor. The device includes: a voltage injector which generates injection voltages to estimate an initial position of the rotor; a motor drive voltage generator which converts stationary-coordinate-system voltages including the injection voltages to three-phase motor drive voltages and applies the three-phase motor drive voltages to the motor; a current extractor which extracts response current components iα-inj, iβ-inj in respect to the injection voltages from two-phase stationary-coordinate-system currents converted from three-phase currents detected upon rotation of the motor; and a position / speed estimator which extracts response current components related to a rotor position from the response current components iα-inj, iβ-inj in respect to the injection voltages to calculate a rotor position error (e), and estimates the speed and position {tilde over (ω)},{tilde over (θ)} of the rotor from the calculated rotor position error (e).

Owner:LG ELECTRONICS INC

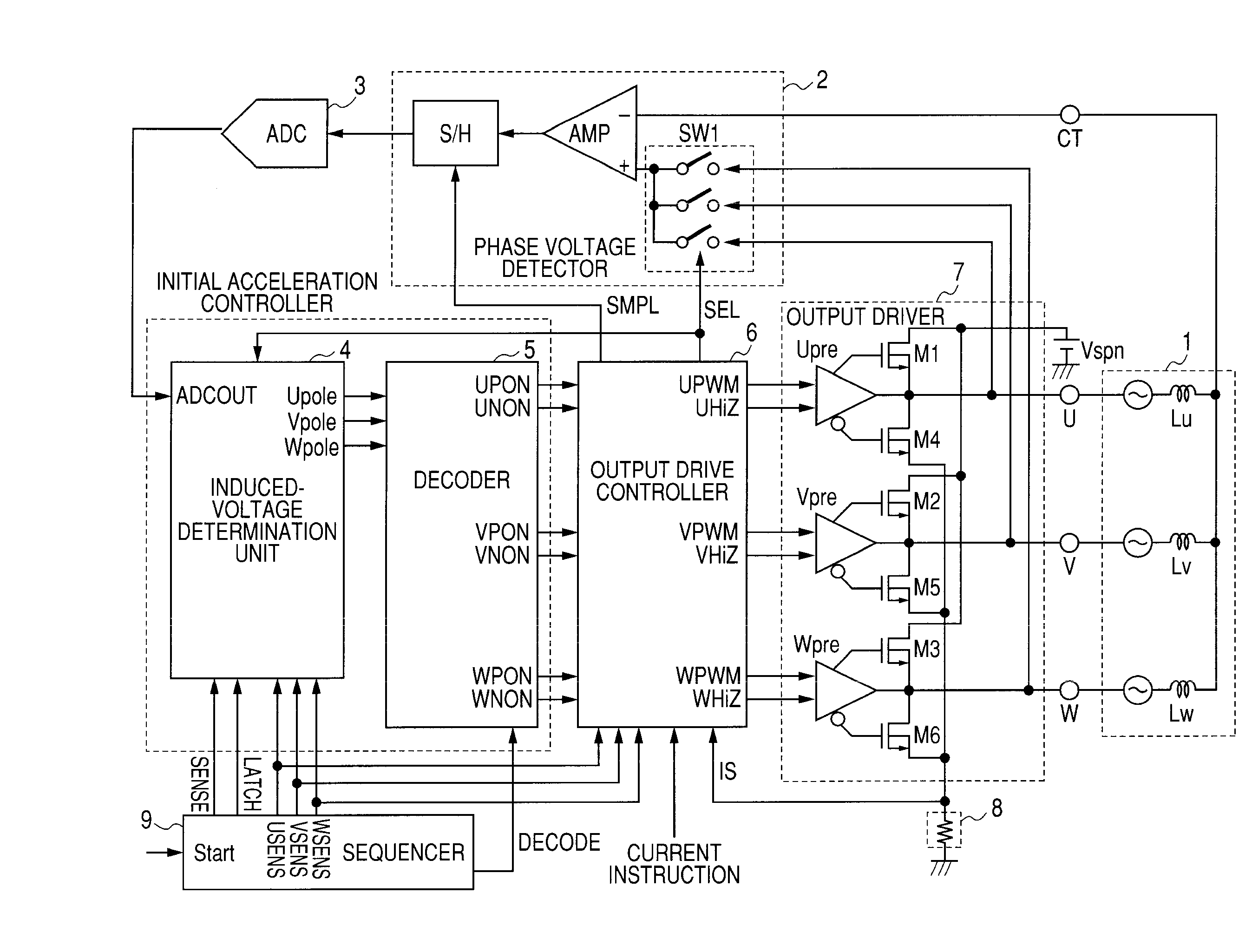

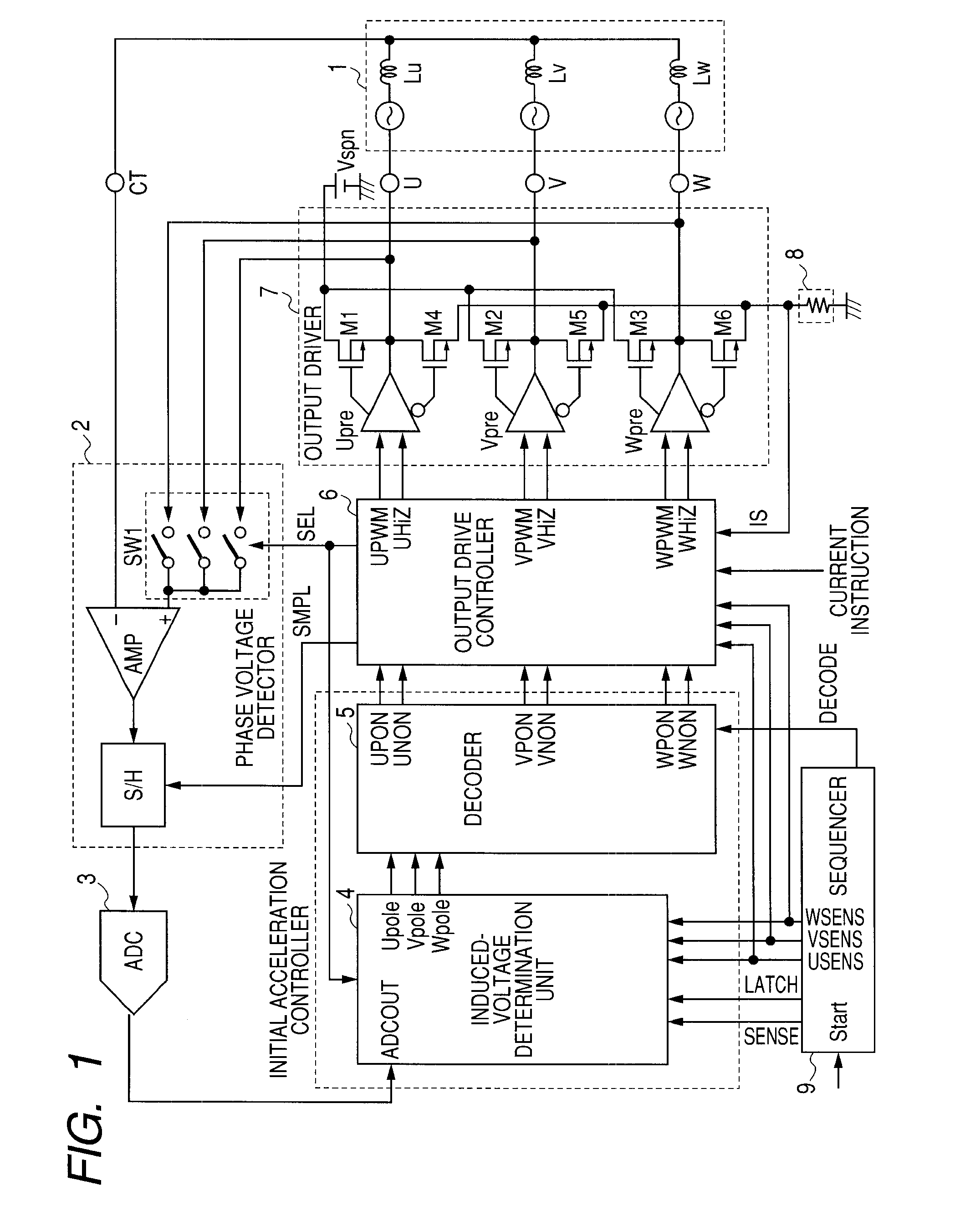

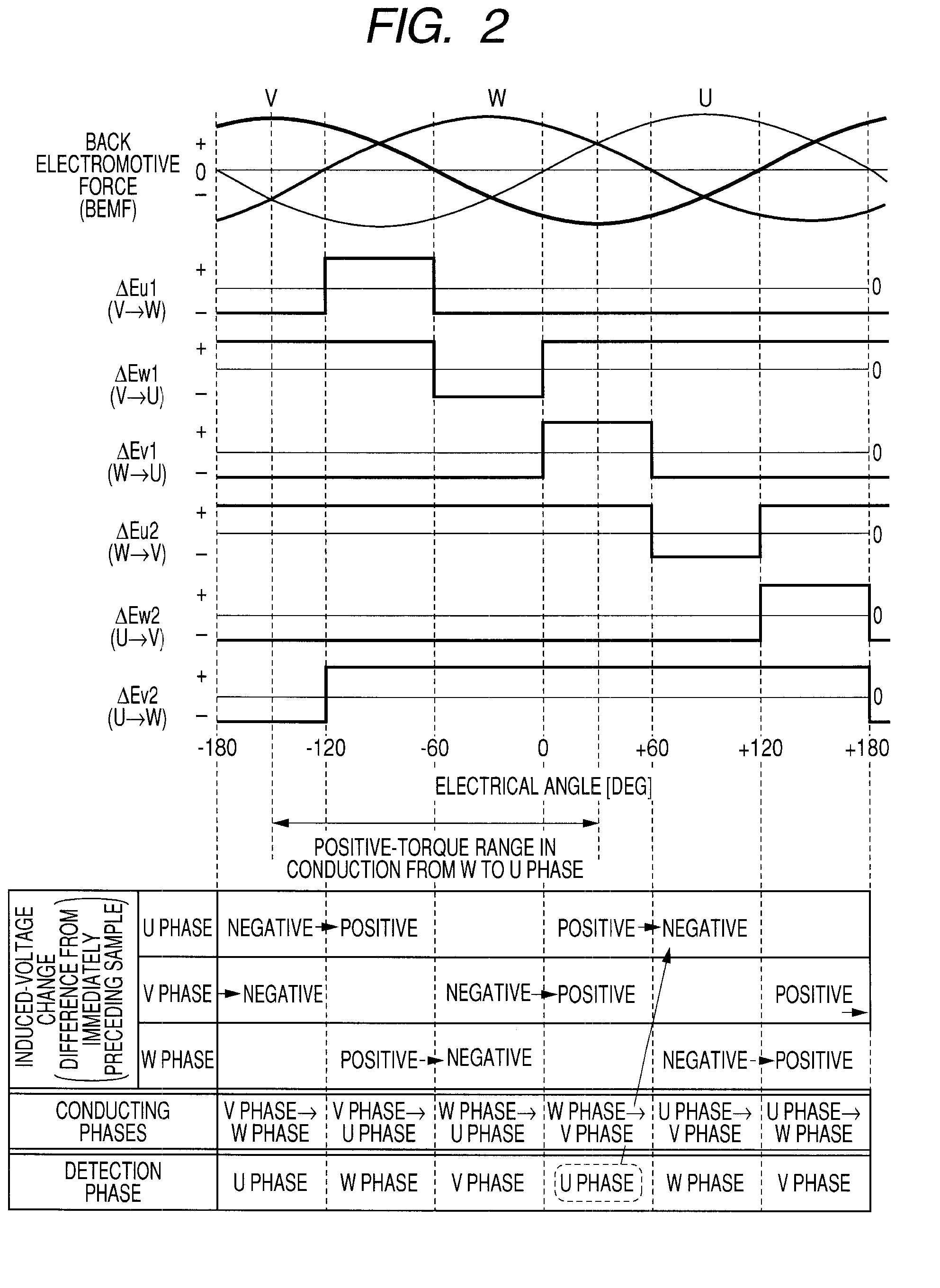

Drive control device of motor and a method of start-up

InactiveUS20080100243A1Avoid noiseReduce startup timeDC motor speed/torque controlAC motor controlMotor driveControl signal

A motor drive control device and motor startup method prevent startup noise and reduce startup time. At startup, a current to which a rotor does not react is passed through two phase coils of a polyphase DC motor in succession, and a voltage polarity induced in a non-conducting phase is detected. A first operation decodes the detected signal, and determines phase coils of the motor through which a current should pass to rotate the rotor and the energization direction. A second operation forms a control signal for passing a current according to the determination to drive the motor, detects a voltage peak induced in the non-conducting phase during the drive, and performs switching control of a conducting phase. In normal operation, the position of the rotor is detected based on a back EMF in each phase, and rotation control is performed.

Owner:RENESAS ELECTRONICS CORP

Electric machine and method of operating the electric machine

InactiveUS7327118B2Electronic commutation motor controlAC motor controlElectric machineControl theory

A method of and apparatus for controlling an electric machine. The method can include using a controller to detect whether power is present at a first node of the controller, detect whether power is present at a second node of the controller, generate at least one signal based at least in part on the detection, and energize the electric machine using a detected power when the at least one signal indicates power is present at at least one of the first node, the second node, and a combination of the first node and the second node.

Owner:REGAL BELOIT AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com