CO gas-phase oxidative coupling oxalate synthesizing palladium catalyst reactivating method

The technology of a palladium catalyst and an oxidizing couple is applied in the field of regeneration after the deactivation of the catalyst for the synthesis of dimethyl oxalate by CO gas phase oxidative coupling, and can solve the problems of inability to remove impurities, permanent deactivation of the catalyst, high processing cost and the like, Achieve the effect of easy industrial operation, good safety and excellent activity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

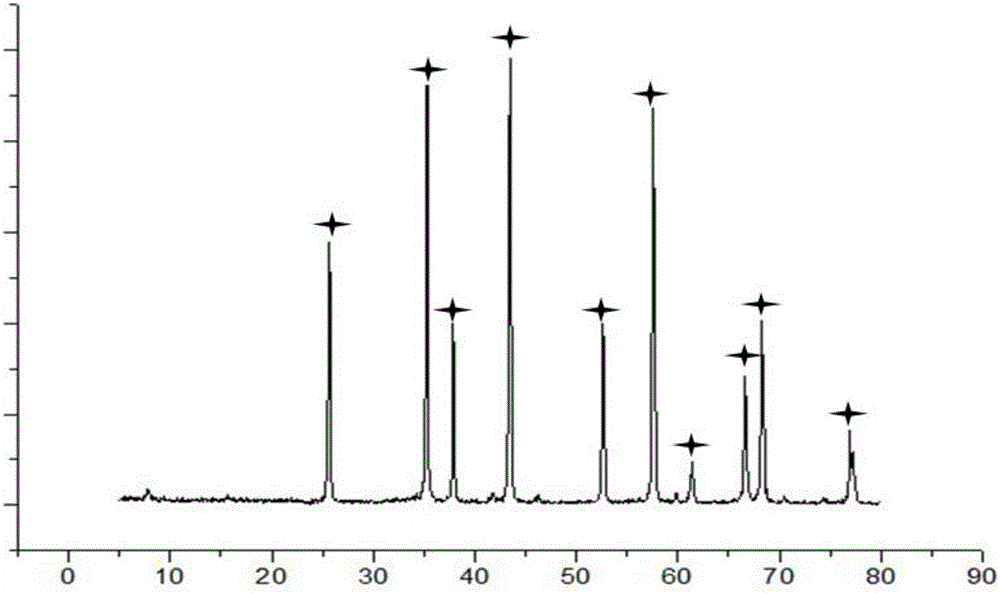

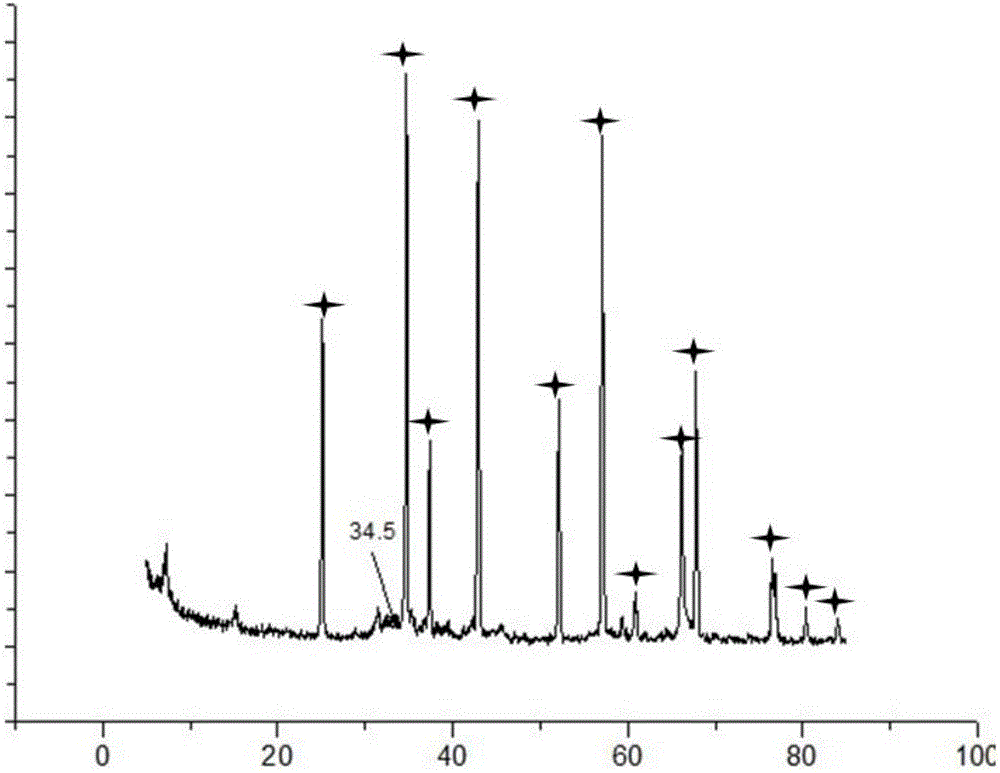

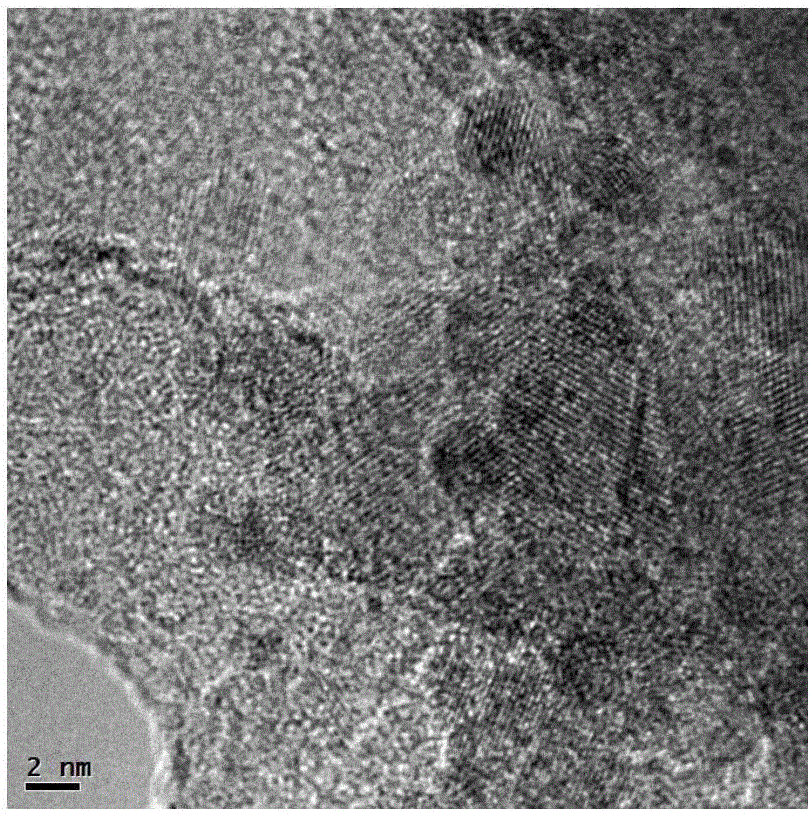

[0030] (1) Catalyst regeneration

[0031] 15g of deactivated Pd / a-Al 2 o 3 The catalyst is put into a muffle furnace and roasted at 600°C for 4 hours, and the calcined catalyst is added to a hydrochloric acid solution with a mass fraction of 5% and a volume of 15ml, sealed and placed in an oven for 2 days at 60°C; the catalyst after standing Dry it in an oven at 150°C for 12 hours, then put it in a muffle furnace for calcination at 500°C for 4 hours; wash the calcined catalyst fully with deionized water, and put it in an oven for full drying. Add the dried catalyst to a sodium hydroxide solution with a volume of 15ml of sodium borohydride, wherein the concentration of sodium borohydride is 0.8g / L, and the concentration of sodium hydroxide is 10mg / L; filter after soaking for 3h; Fully washed with deionized water and fully dried in an oven to obtain a regenerated catalyst sample.

Embodiment 2

[0033] In Example 1, the hydrochloric acid was changed to nitric acid with a mass fraction of 10%, the sodium borohydride concentration in the reducing solution was changed to 1.2 g / L, and the sodium hydroxide was changed to a concentration of 15 mg / L sodium bicarbonate.

Embodiment 3

[0035] In Example 1, the sodium borohydride in the reducing solution was changed to potassium borohydride with a concentration of 1.0 g / L, and the sodium hydroxide was changed to potassium hydroxide with a concentration of 12 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com