Patents

Literature

537 results about "1-Chloropropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Chloropropane's production and use as a chemical intermediate may result in its release to the environment through various waste streams. 1-Chloropropane is an impurity in commercial allyl chloride, therefore, production and use of allyl chloride may result in release of 1-chloropropane to the environment through various waste streams. 1 ...

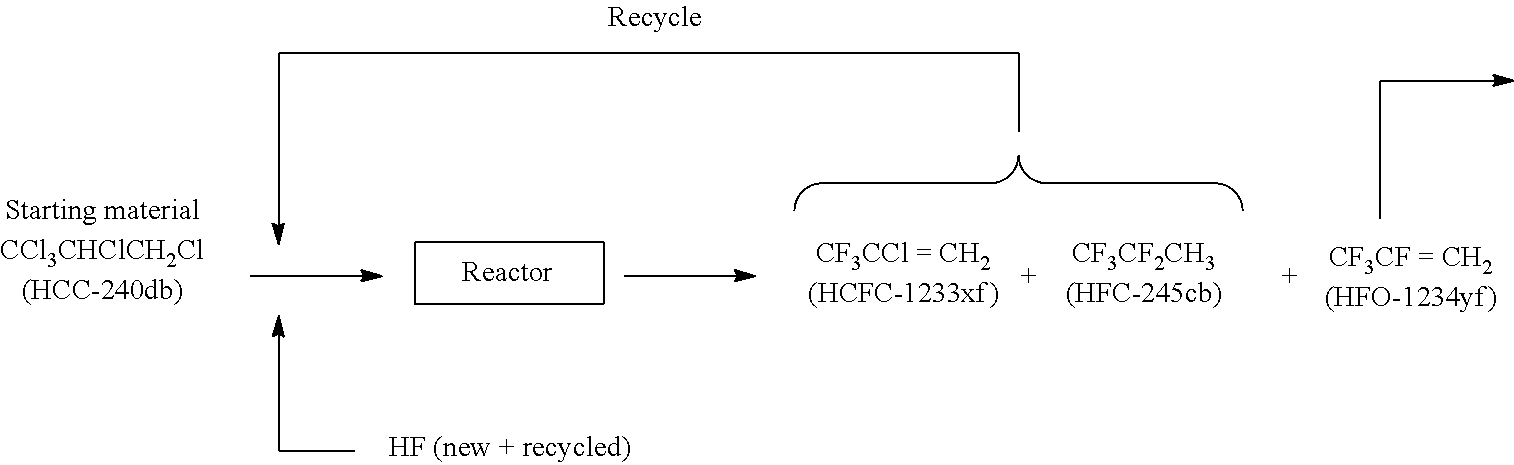

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

Method for producing fluorinated organic compounds

ActiveUS8084653B2Preparation by hydrogen halide split-offPreparation by halogen replacementActivated carbonGas phase

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

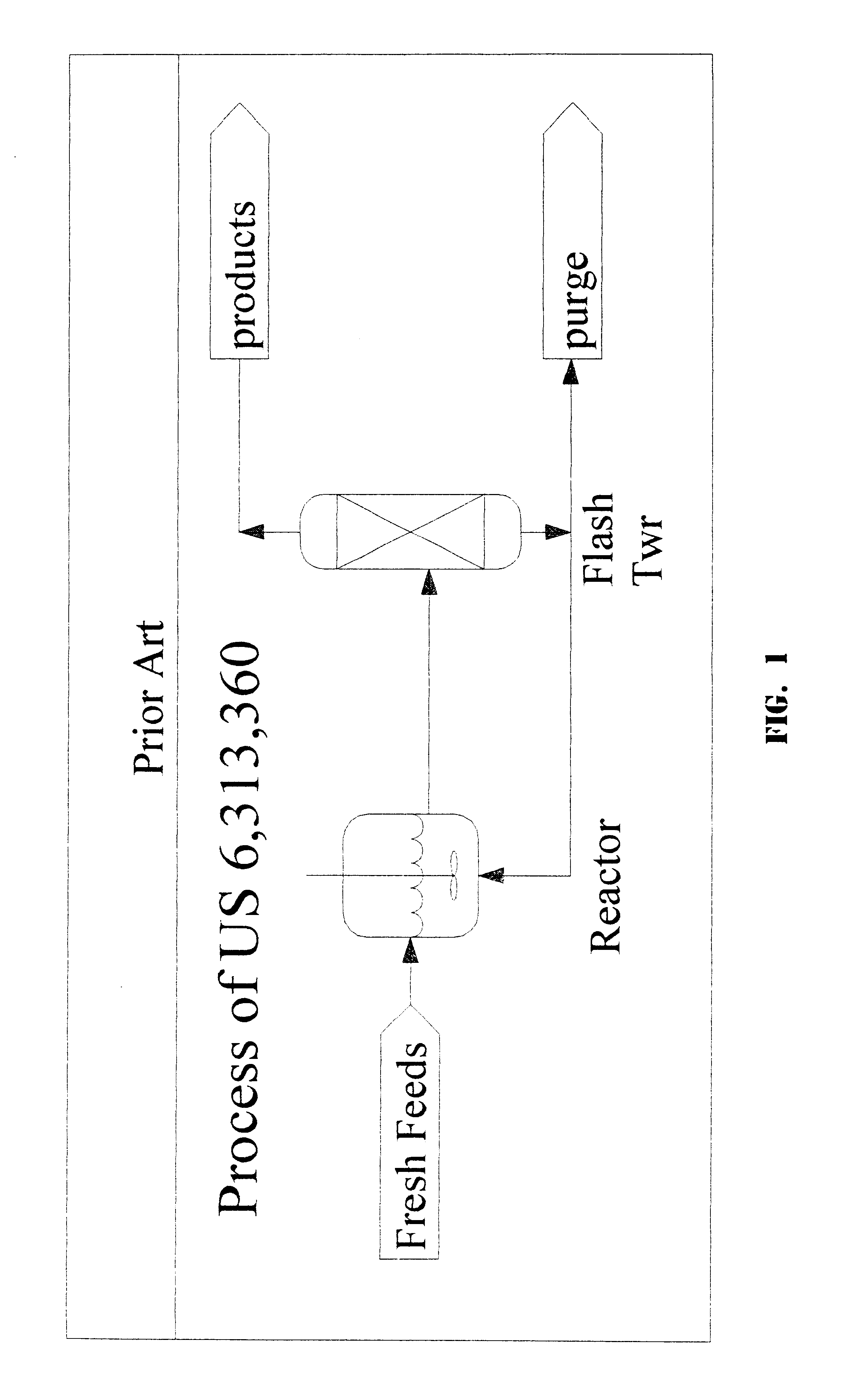

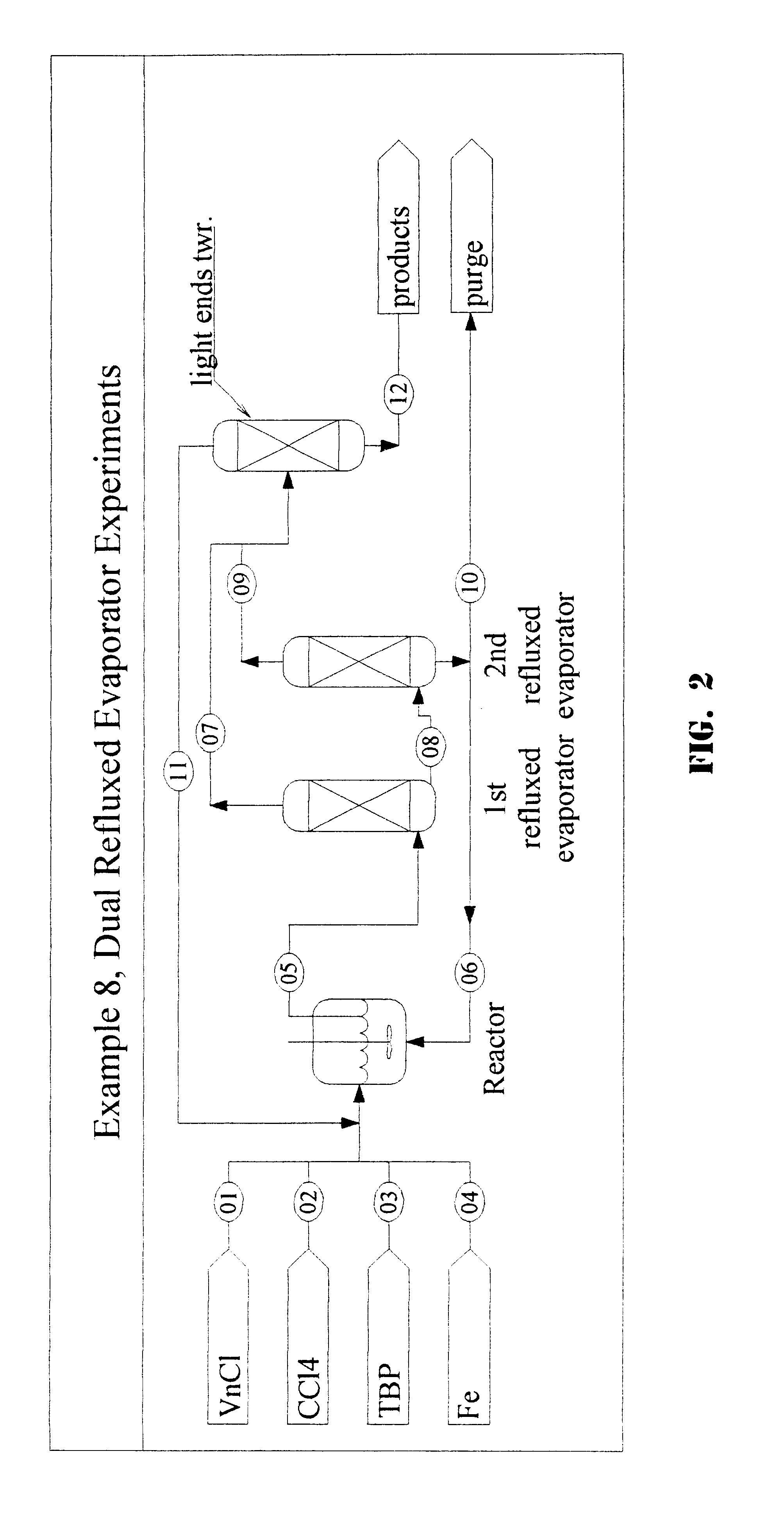

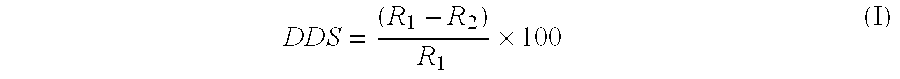

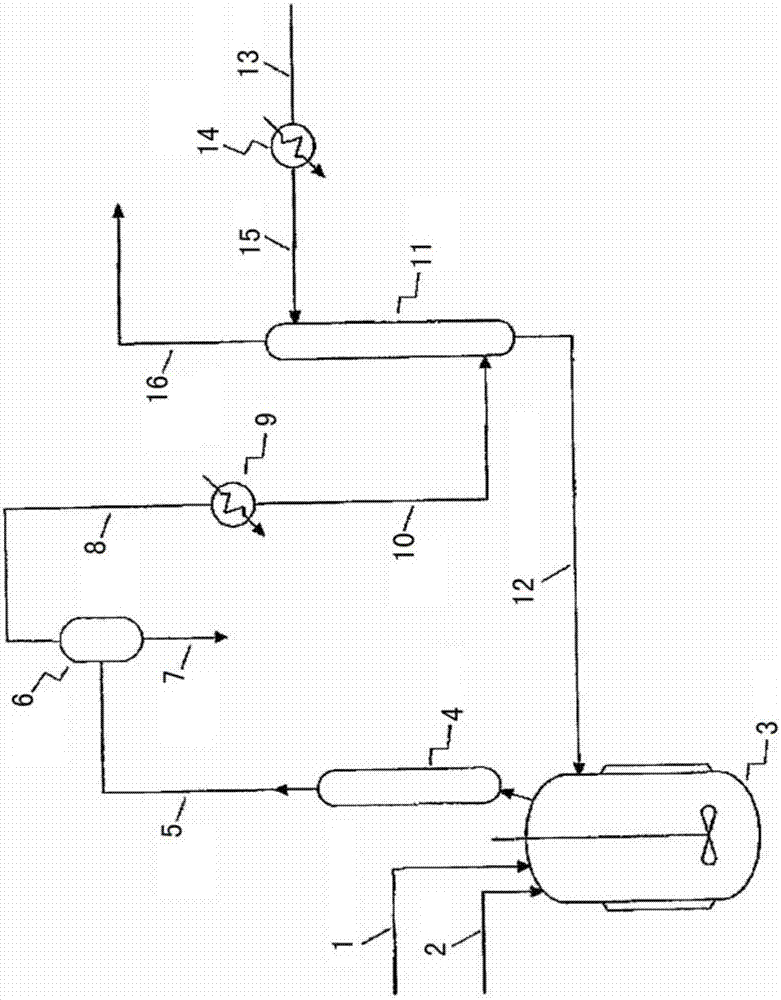

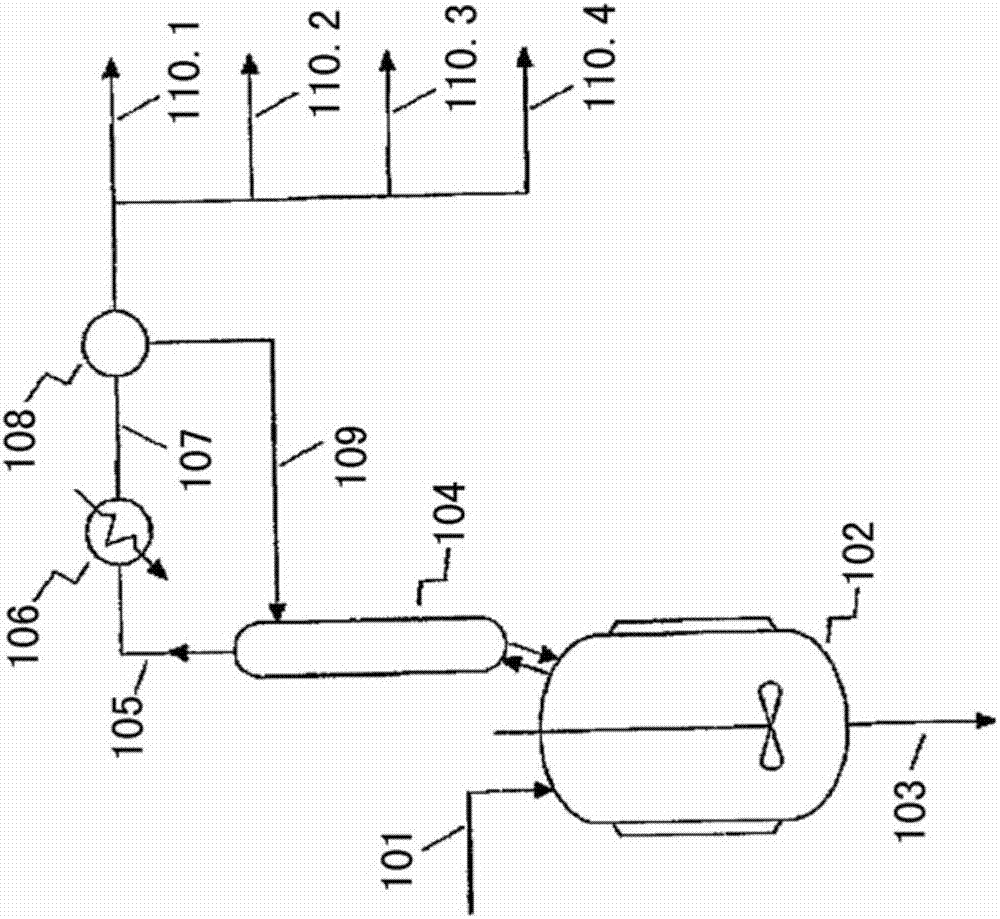

1,1,1,3,3-pentachloropropane process purge stream concentration using a secondary refluxed evaporator and secondary product recovery

InactiveUS6720466B2Maximize recoveryReduce decreaseOrganic chemistry methodsHalogenated hydrocarbon separation/purificationDistillationProduct recovery

A process for economically producing 1,1,1,3,3-pentachloropropane under conditions which preserve the activity of the catalyst. In a preferred embodiment, a two-stage distillation process is employed. In the two-stage process, the size of the equipment, temperature and vacuum are varied.

Owner:OCCIDENTAL CHEM CORP

Dehydrochlorination stabilization of polychlorinated alkanes

InactiveUS6534688B2Suppression problemReduces and preventsHalogenated hydrocarbon separation/purificationAlkaneMonomethyl ether

Owner:OCCIDENTAL CHEM CORP

Epoxy resin polymer mortar and production process thereof

InactiveCN104261765AImprove stress resistanceImprove impact resistancePolymer sciencePhenylacetic acid

The invention relates to epoxy resin polymer mortar and a production process thereof. The mortar is prepared from the following components in parts by weight: 15-20 parts of epoxy resin slurry, 2-4 parts of an active diluent, 6-8 parts of a curing mixture and 70-80 parts of a base material which are mixed, stirred and mixed, wherein the epoxy resin slurry is prepared from bisphenol A epoxy resin E51, modified epoxy resin, organic bentonite and dioctyl phthalate; the active diluent is prepared from epoxy chloropropane, fatty alcohol and trichloropropane; the curing mixture is prepared from 85 parts of modified phenolic aldehyde amine, hydroxy-terminated liquid nitrile rubber, 2-(3, 4-expoy cyclohexyl) ethyl triethoxyl silane, lauryl phenylacetate and resorcinol; the base material is prepared from ordinary portland cement, quartz sands, hydrophobic expanded perlite, refined graphite powder and sericite powder. The epoxy resin polymer mortar provided by the invention not only has excellent mechanical property and wear resistance, but also has a good adhesive performance, and can be integrally formed with substrate concrete.

Owner:XIAOLANGDI WATER CONSERVANCY & HYDROPOWER ENG CO LTD

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

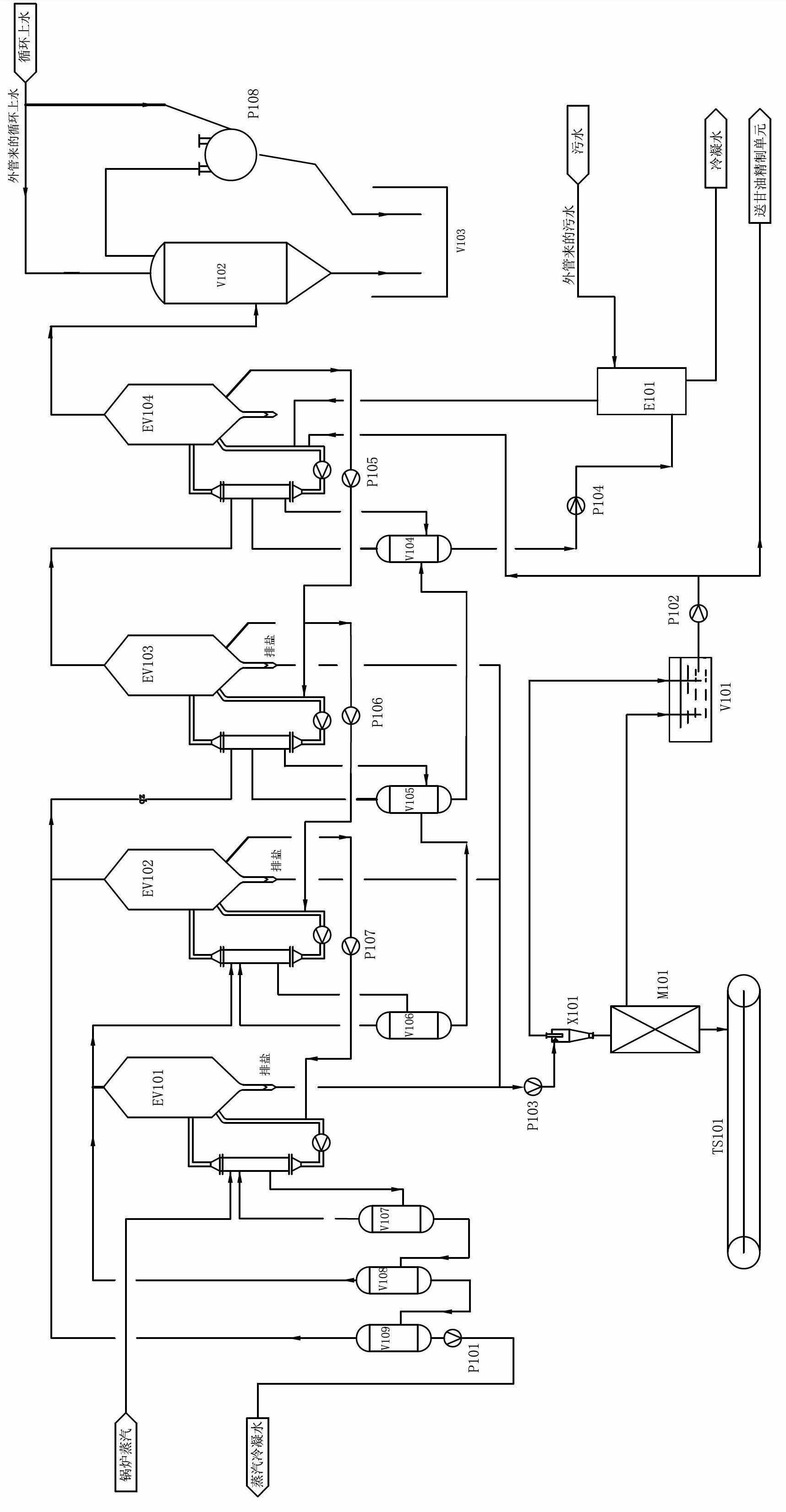

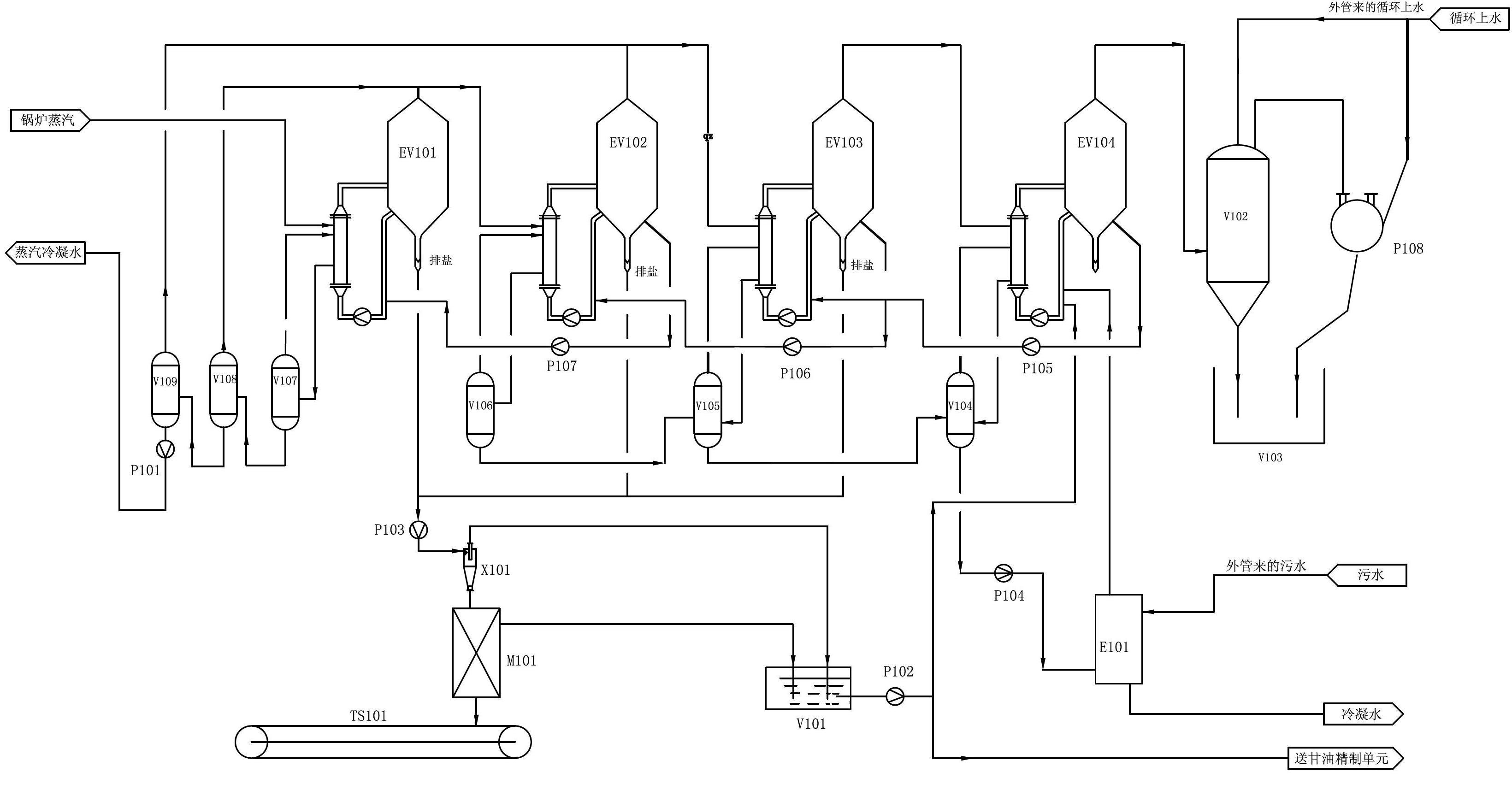

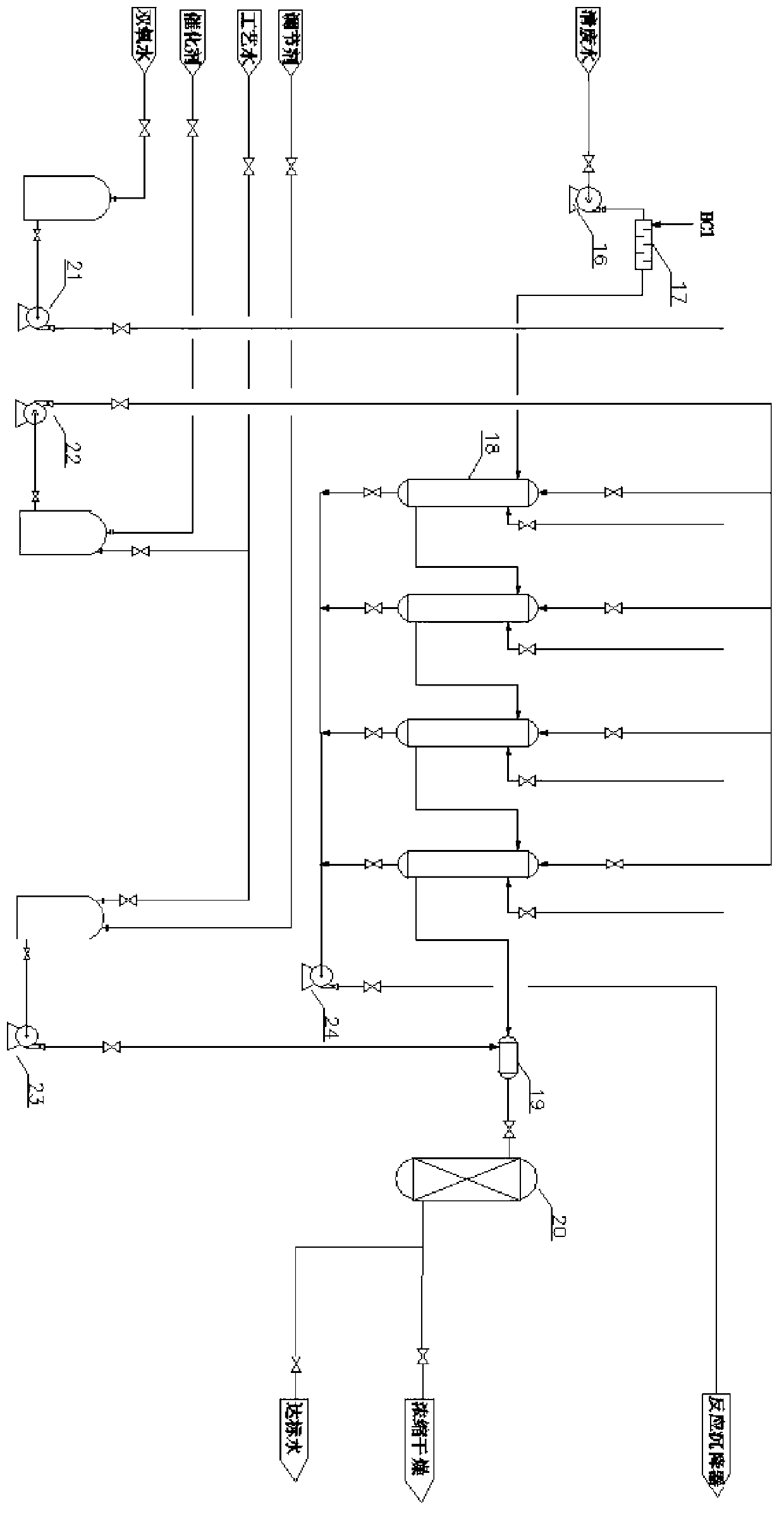

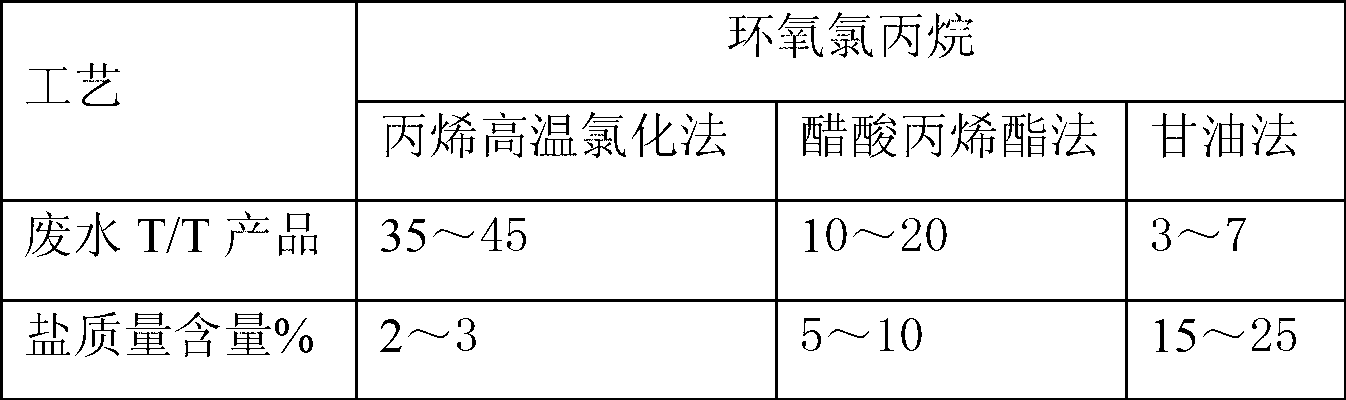

Method for processing wastewater from production of epoxy chloropropane by using glycerol as material

InactiveCN102689936AEasy to handleEfficient recyclingNature of treatment waterWater/sewage treatment by heatingGlycerolEvaporation

The invention relates to a method for processing high-salinity organic wastewater generated in a saponification cyclization procedure in a process of producing epoxy chloropropane by using glycerol as material. The processing method comprises the following steps: firstly carrying out four-effect evaporation on the high-salinity organic wastewater to obtain concentrated salt slurry; then dewatering and centrifugally separating the concentrated salt slurry to obtain sodium chloride solid; conveying mother liquor with high glycerin content to a glycerin refining unit to be used as the material, condensing and recovering wastewater vapor. The method and a device for processing wastewater disclosed by the invention are simple, easy to operate and control, high in efficiency and obvious in economic benefit, not only can effectively process industrial wastewater to be up to the national emission standard, but also can effectively recover sodium chloride in the wastewater, and create a new profit growth point for an enterprise.

Owner:西安汉术化学工程股份有限公司

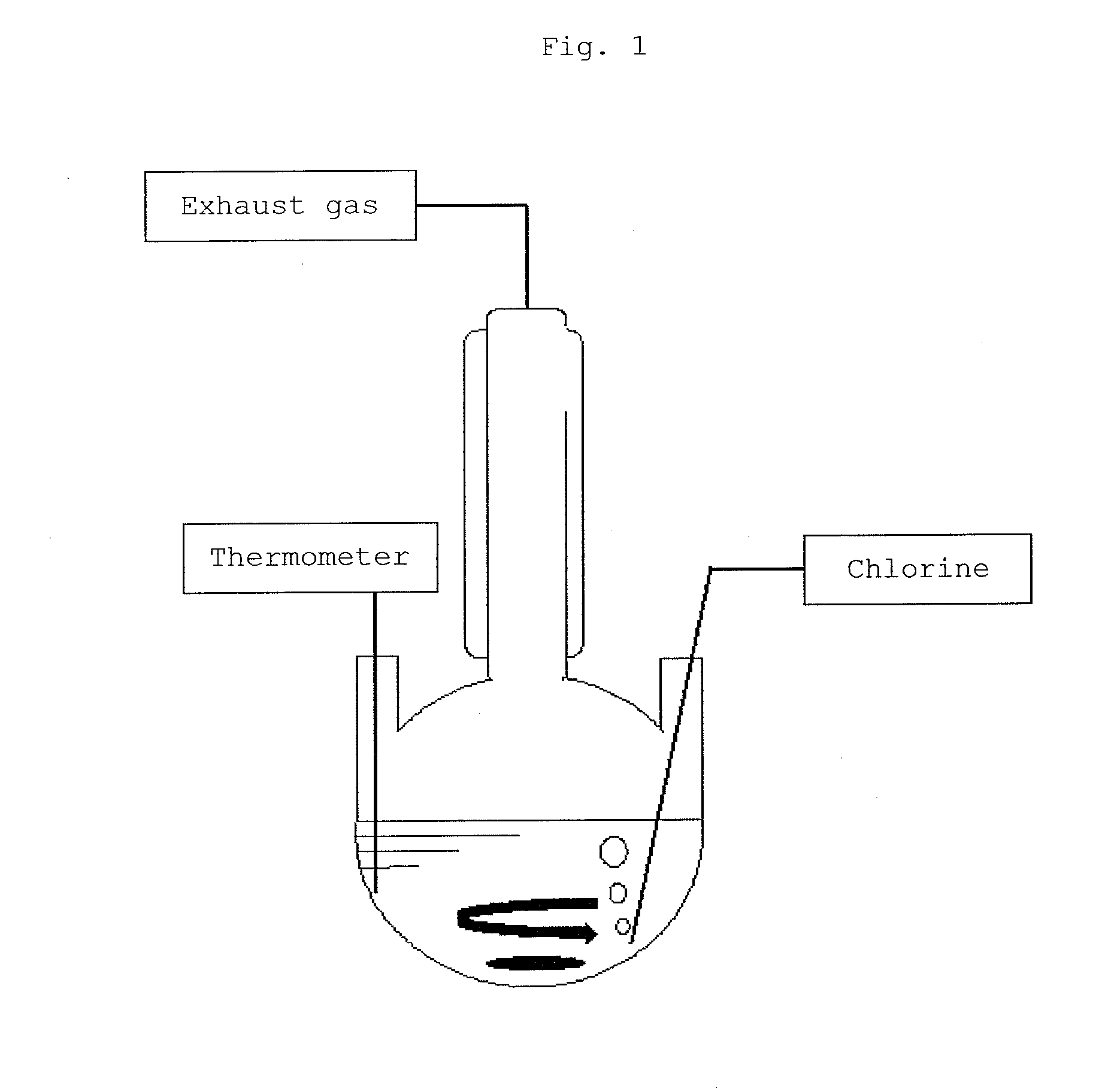

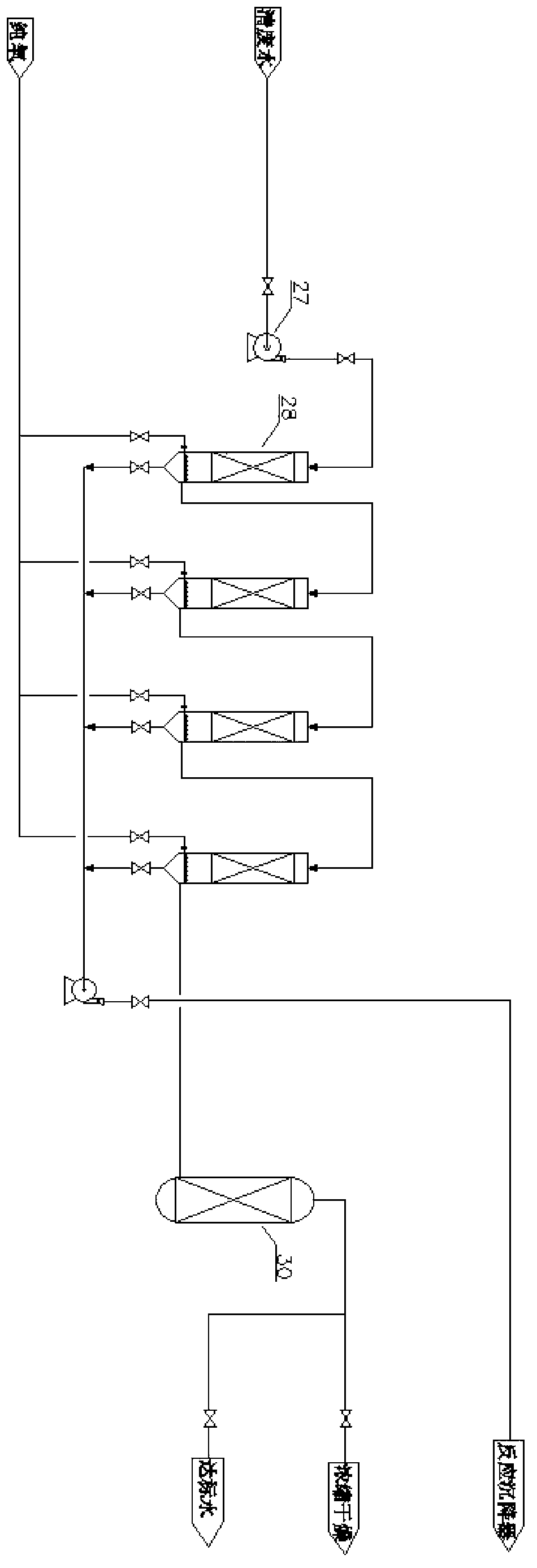

Method for preparing epoxy chloropropane by using glycerol method

This invention discloses a glycerol method for preparing epoxy chloropropane. The method comprises: (1) introducing dried HCl gas through 95% glycerol at 90-110 deg.C in the presence of absolute acetic acid, and reacting for 1-3 h; (2) adding the obtained dichloropropanol into a round bottom flask loaded with solid super-strong alkali catalyst, equipping condensing and drying tubes, stirring, heating to 70-90 deg.C, reacting for 3-5 h, filtering, and separating the catalyst to obtain chloropropane.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Method for producing a chlorinated hydrocarbon having 3 carbon atoms

InactiveUS20130165705A1High selectivityExcellent in reaction conversionPreparation by hydrogen halide split-offPreparation by halogen additionChlorideCarbon tetrachloride

A method of producing a chlorinated hydrocarbon having 3 carbon atoms, comprising a conversion step for converting a chloropropane represented by the following formula (1) into a chloropropane represented by the following formula (2) by reacting it with chlorine in the presence of anhydrous aluminum chloride.CCl3—CCl(2-m)Hm—CCl(3-n)Hn (1)(In the above formula (1), m is 1 or 2, and n is an integer of 0 to 3.)CCl3—CCl(3-m)H(m-1)—CCl(3-n)Hn (2)(In the above formula (2), m and n are the same integers as in the formula (1), respectively.)

Owner:TOKUYAMA CORP

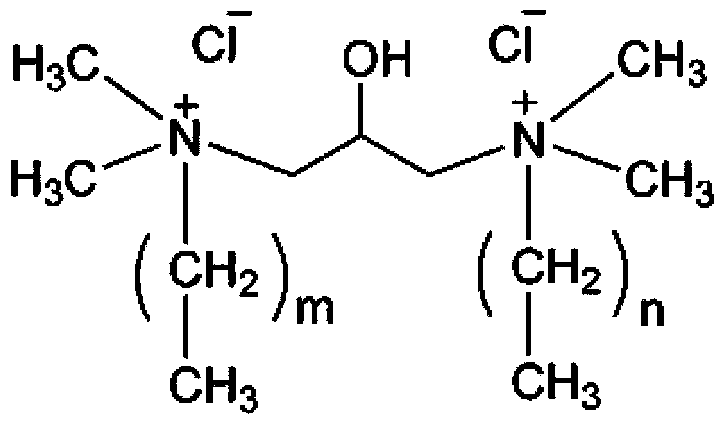

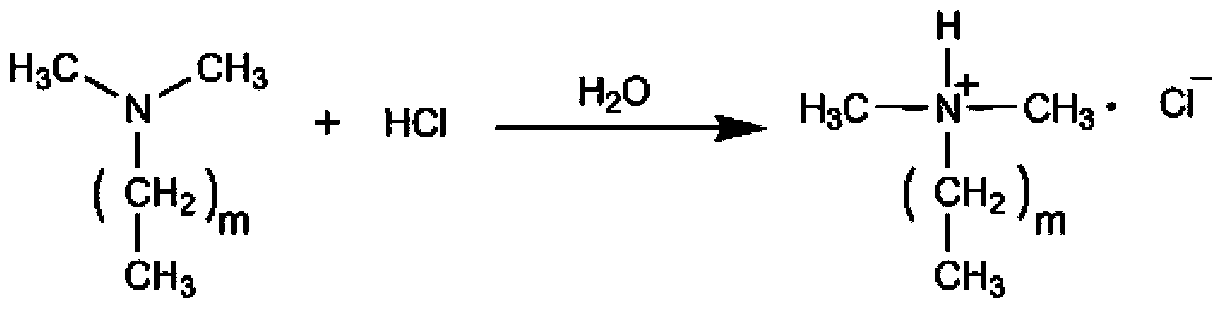

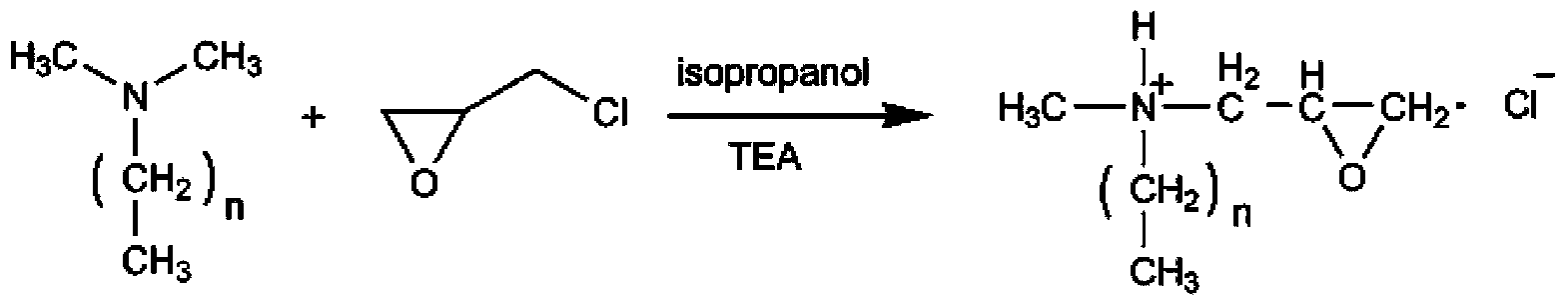

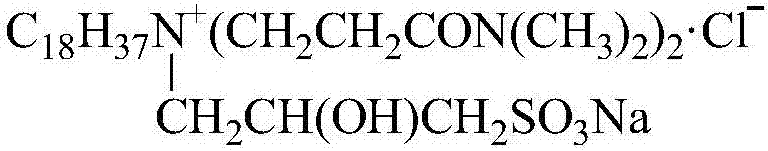

Cationic gemini surfactant preparation method

ActiveCN103406063AReduce special requirementsReduce reaction exothermOrganic compound preparationTransportation and packagingEpichlorohydrin1-Chloropropane

The invention belongs to the technical field of surfactants, and provides a method for preparing a cationic gemini surfactant (CH3(CH2)m-N(CH3)2-CH2CH(OH)CH2-N(CH3)2(CH2)nCH3.Cl2) by taking epoxy chloropropane and alkyl dimethyl tertiary amine (CH3-(CH2)n-N(CH3)2, wherein n equals to 7, 9, 11, 13, 15 or 17) as raw materials and taking 2-hydroxyl-1.3-propylidene as a linking group. The method provided by the invention overcomes the defect in the prior art that one extremely excessive material is required for improving the reaction yield, dispenses with separation and purification procedures for a finished product, is short in reaction period, leaves no epoxy chloropropane in the finished product, and is suitable for industrial scale production.

Owner:SHANGHAI FINE CHEM CO LTD +1

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Treatment method of wastewater generated in cyclization step in production process of epoxy chloropropane from glycerol

ActiveCN103342434ARealize "Zero Emissions"Realize resourcesMultistage water/sewage treatmentNature of treatment waterDecompositionSnow melting

The invention relates to a treatment method for high-salinity organic wastewater generated in a production process of epoxy chloropropane from glycerol. The treatment method comprises the steps of: performing hydrolysis reaction on the high-salinity organic wastewater; performing advanced oxidization or wet oxidization; and concentrating and drying. The method is simple and convenient in process flow, easy to operate and control, and environment-friendly; inorganic precipitates in the wastewater can be recovered for producing building materials; organic chlorine-containing compounds in the wastewater are decomposed into glycerol, and the decomposition rate is up to more than 95%; two major pollutants in the wastewater, namely, calcium chloride and glycerol, are utilized for generating an environment-friendly snow-melting agent, so that the pollutant resource recovery is realized. Organic pollutants in the wastewater generated in the advanced oxidization or wet oxidization can be mineralized; calcium chloride in the wastewater is utilized for producing industrial calcium chloride. The treatment method has the beneficial effect that 'zero release' of the wastewater generated in a cyclization step in the production process of epoxy chloropropane from glycerol can be realized.

Owner:NINGBO HUANYANG CHEM

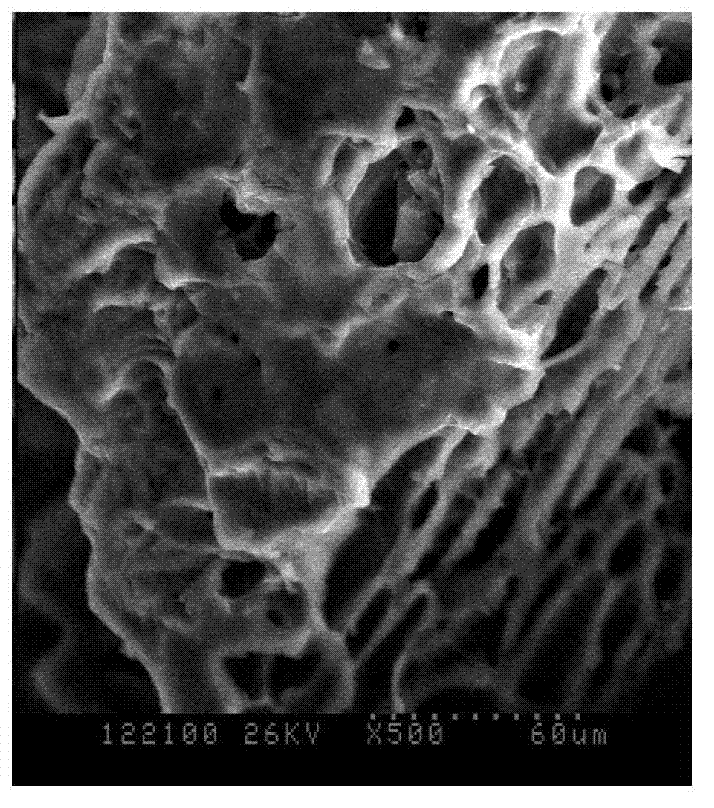

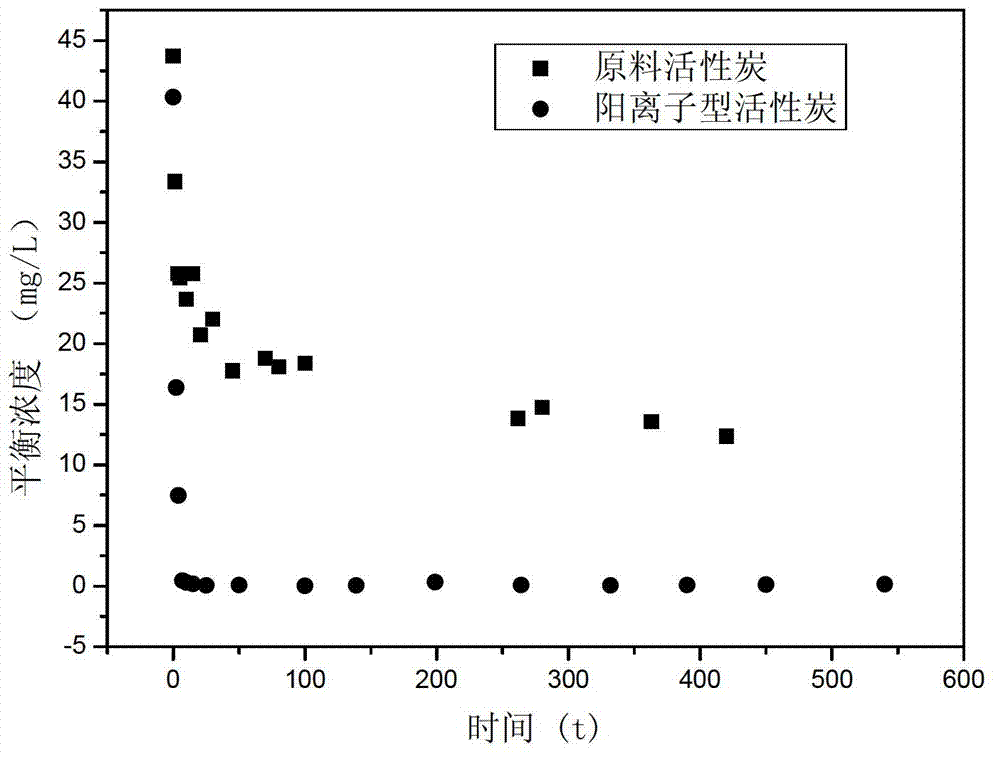

Preparation method for cationic-type activated carbon

ActiveCN102806073ATo overcome the characteristics of poor selectivityRemove fitOther chemical processesWater/sewage treatment by sorptionEpoxyWater baths

The invention relates to a preparation method for cationic-type activated carbon. The preparation method comprises the steps of washing, drying and crushing activated carbon, and oxidizing the activated carbon by concentrated hydrochloric acid or sulfuric acid so that the surface of the activated carbon has hydroxy; heating to the temperature of 80-87 DEG C under the condition of water bath, then adding epoxy chloropropane and N-N dimethylformamide, and stirring and reacting for 0.5-1.5h; and adding ethanediamine to react for 1-1.5h, then continuously dripping triethylamine to react for 0.5-1h, cooling to room temperature, and washing and drying so as to obtain the cationic-type activated carbon. An activated carbon product is the cationic-type activated carbon with positive charges, has a cationic group and a hydroxyl group, further has biodegradability, and is applicable to removing anionic-type pollutants in water.

Owner:SHANDONG UNIV

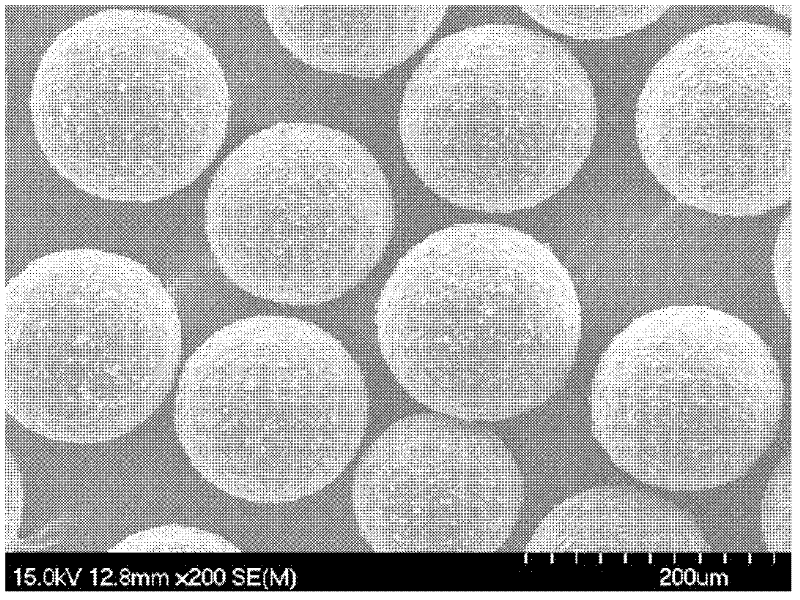

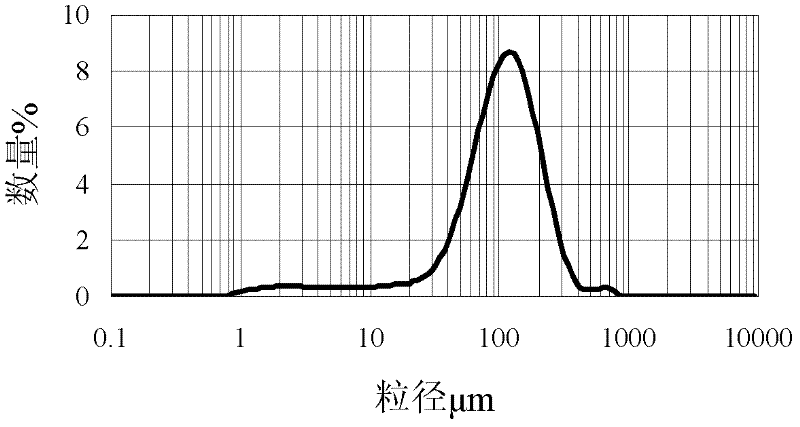

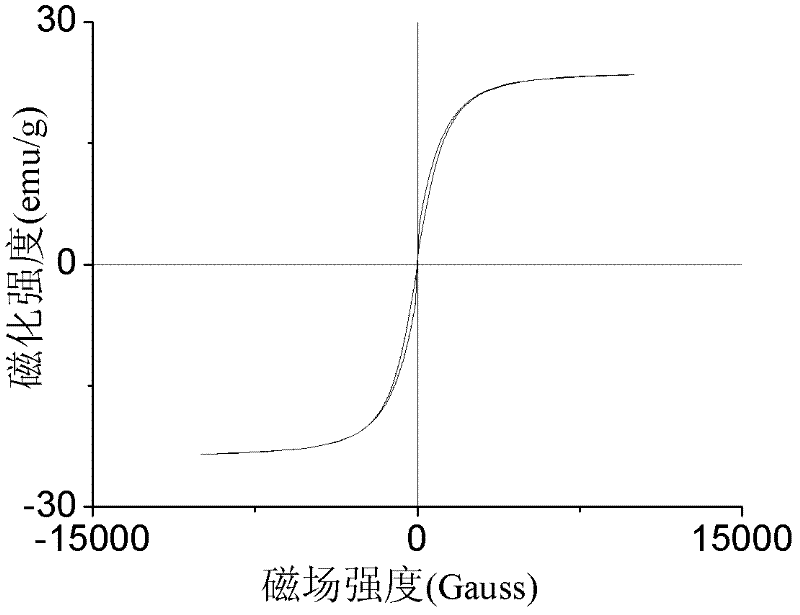

Endotoxin adsorption medium based on magnetic chitosan microballoon and its application method

InactiveCN102350309AHigh selectivitySimple and efficient operationOther chemical processesAlkali metal oxides/hydroxidesIonChemistry

The invention discloses an endotoxin adsorption medium based on magnetic chitosan microballoon and an application method, wherein the preparation method of endotoxin adsorption medium comprises the following steps: (1) dispersing a magnetic material in an acetic acid solution, adding chitosan to prepare water phase I, transferring water phase I to liquid paraffin containing span 80, taking glutaraldehyde as a cross-linking agent, preparing chitosan microballoon by using an anti-phase suspension method; (2) dispersing magnetic chitosan microballoon in a mixed solution of dimethyl sulfoxide and sodium hydroxide, adding chloropropylene oxide for activating, washing by deionized water till neutralizing to obtain an activated product; (3) placing the activated product in an endotoxin affinity ligand solution for immobilizing to obtain the endotoxin adsorption medium based on the magnetic chitosan microballoon. The endotoxin adsorption medium of the present invention has high selectivity of endotoxin and simple operation, and can be used for removing the endotoxin in a plurality of biological products.

Owner:ZHEJIANG UNIV OF TECH

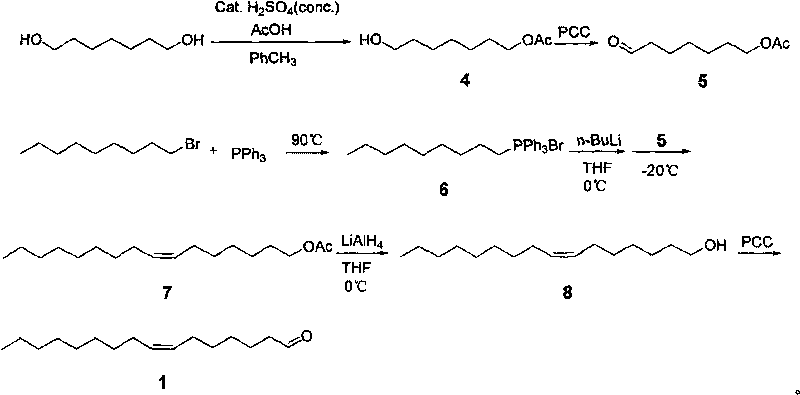

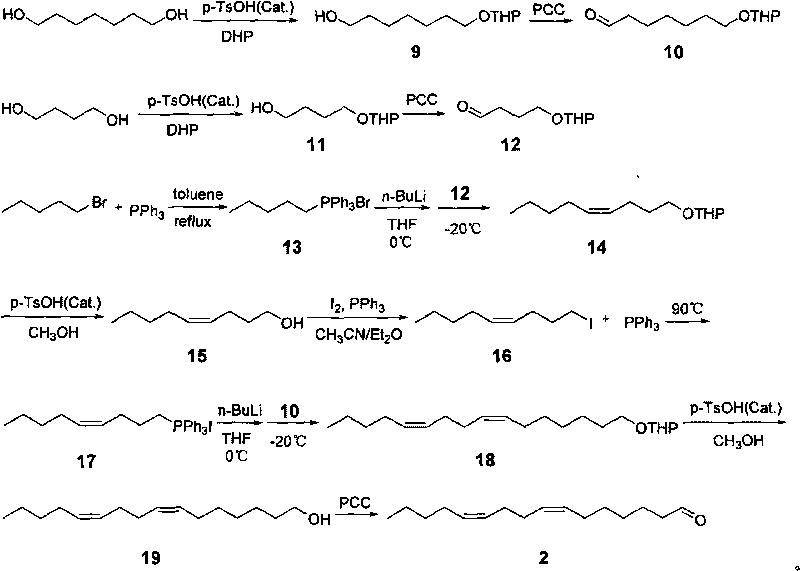

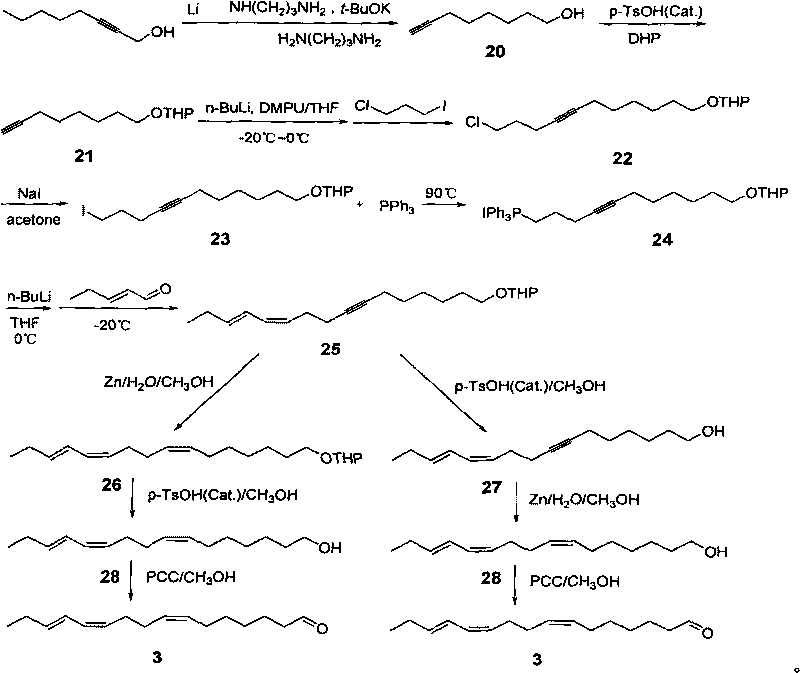

Method for synthesizing phyllocnistis citrella stainton pheromone compound

InactiveCN101712601AIncrease profitSimple and safe operationCarbonyl compound preparation by oxidationAlcoholButanediol

The invention relates to a method for synthesizing a phyllocnistis citrella stainton pheromone compound. (Z)-7-hexadecene aldehyde is synthesized by using 1,7-heptandiol and bromo-n-nonane as starting materials and through six steps of reactions (comprising a Witting reaction); (Z,Z)-7,11-hexadecadienoic aldehyde is synthesized by using the 1,7-heptandiol, 1,4-butanediol and bromo-n-pentane as starting materials and through multi-step of reactions (comprising two Witting reactions); and (Z,Z,E)-7,11,13-hexadecatrienoic aldehyde is synthesized by using 2-octyne-1-alcohol, 1-iodine-3-chloropropane and trans-2-amylene aldehyde as starting materials and through multi-step of reactions (comprising a coupling reaction and a Witting reaction). The invention has the advantages of low price and easy obtaining of raw materials, simple and reasonable synthesizing route, convenient and safe operation and high utilization rate of the raw materials.

Owner:WENZHOU MEDICAL UNIV +1

CMC starch glue

InactiveCN104559832AImprove adhesionImprove quick-dry performanceNon-macromolecular adhesive additivesStarch derivtive adhesivesEpoxyNuclear chemistry

The embodiment of the invention discloses a CMC starch glue which comprises the following components in percentage by mass: 6-8% of corn starch, 5-8% of sodium hydroxide (30% of solution), 0.5-2% of hydrogen peroxide (30% of solution), 0.3-1% of borax, 6-12% of epoxy chloropropane, 0.05-0.2% of sodium carboxymethylcellulose and the balance of water, totaling 100%. By adding sodium carboxymethylcellulose to consume redundant water and forming high polymers by virtue of hydroxylation reaction during starch dextrinization, the initial adhesive force and quick dryness of the starch glue are improved.

Owner:林贤文

Preparation method of hybrid membrane for removing strontium ions in radioactive wastewater

ActiveCN106328235AEliminate hazardsStrong adsorption and removal capacityRadioactive decontaminationCross-linkEpoxy

The invention discloses a preparation method of a hybrid membrane for removing strontium ions in radioactive wastewater. The preparation method comprises the following steps that a chitosan-epoxy chloropropane cross-linking product and a metal titanium precursor are prepared and then added into a polyvinyl alcohol aqueous solution to obtain a membrane coating solution; a support body is coated with the membrane coating solution until a membrane is obtained, and the membrane is separated from the support body and dried to obtain the hybrid membrane without the support body, or the membrane and the support body are not separated and dried to obtain the hybrid membrane with the support body; or the membrane coating solution is dissolved with solvent firstly, then the support body is coated with the membrane coating solution until the membrane is obtained, and the membrane is separated from the support body to obtain the hybrid membrane without the support body, or the membrane and the support body are not separated to obtain the hybrid membrane with the support body. The hybrid membrane prepared through the method is good in temperature resistance and high in adsorption efficiency, has the high adsorption capacity on strontium ions in water and not only can be used for adsorption removal of the strontium ions in the radioactive wastewater but also can be used for adsorption separation of strontium ions in nonradioactive wastewater.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

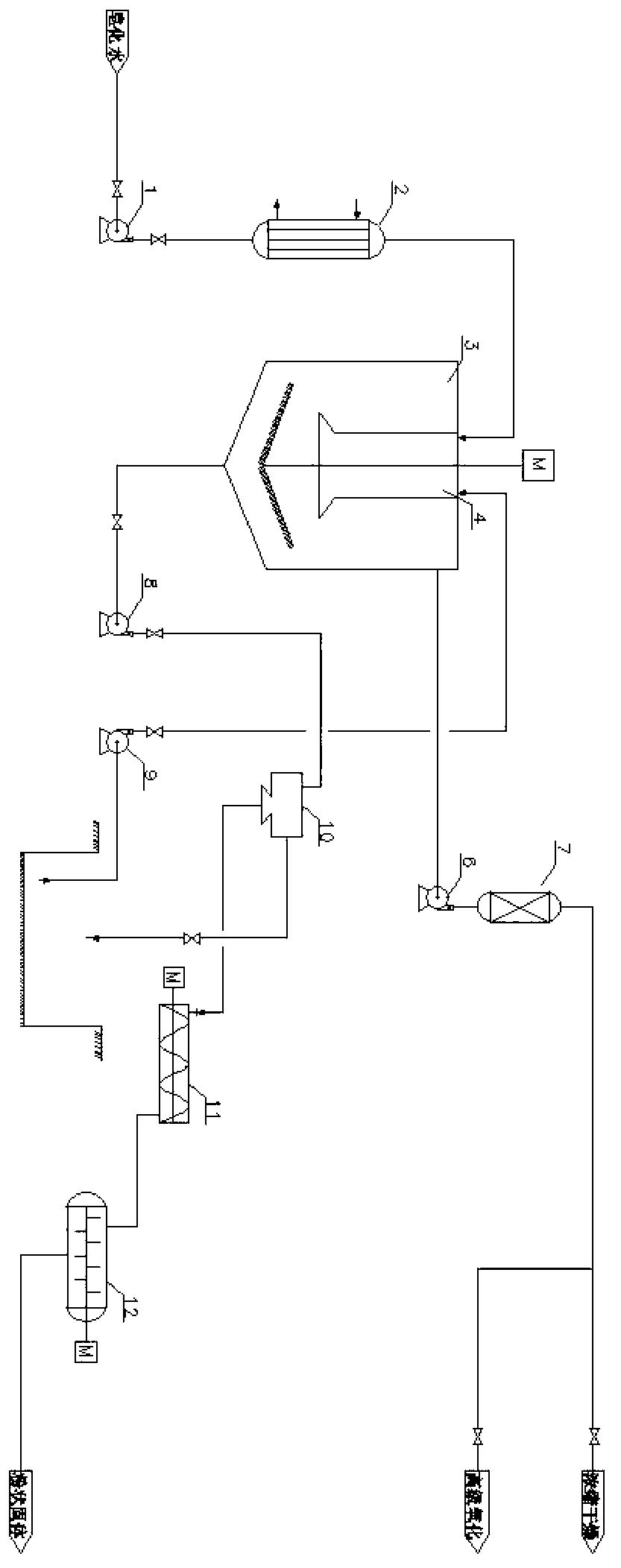

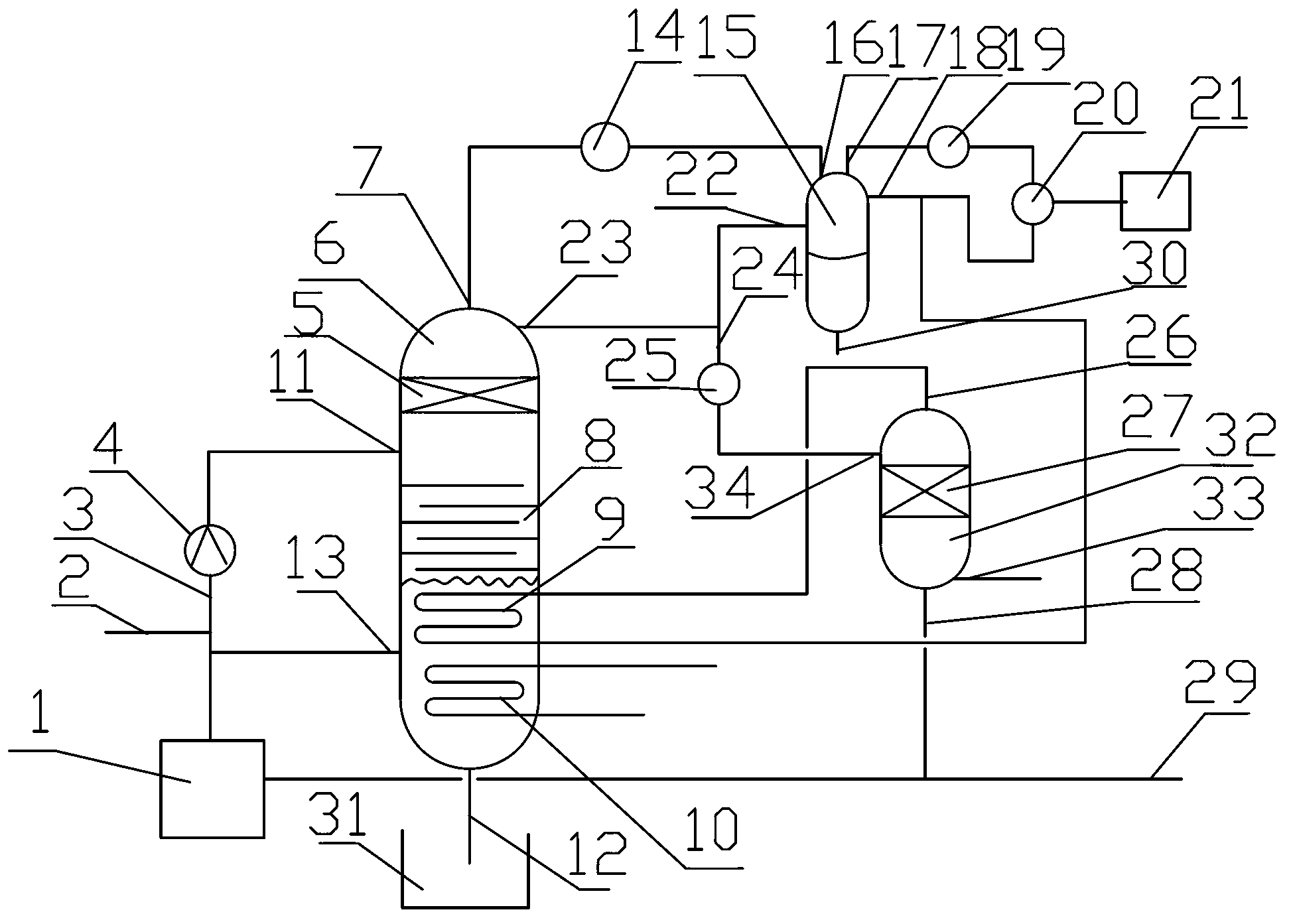

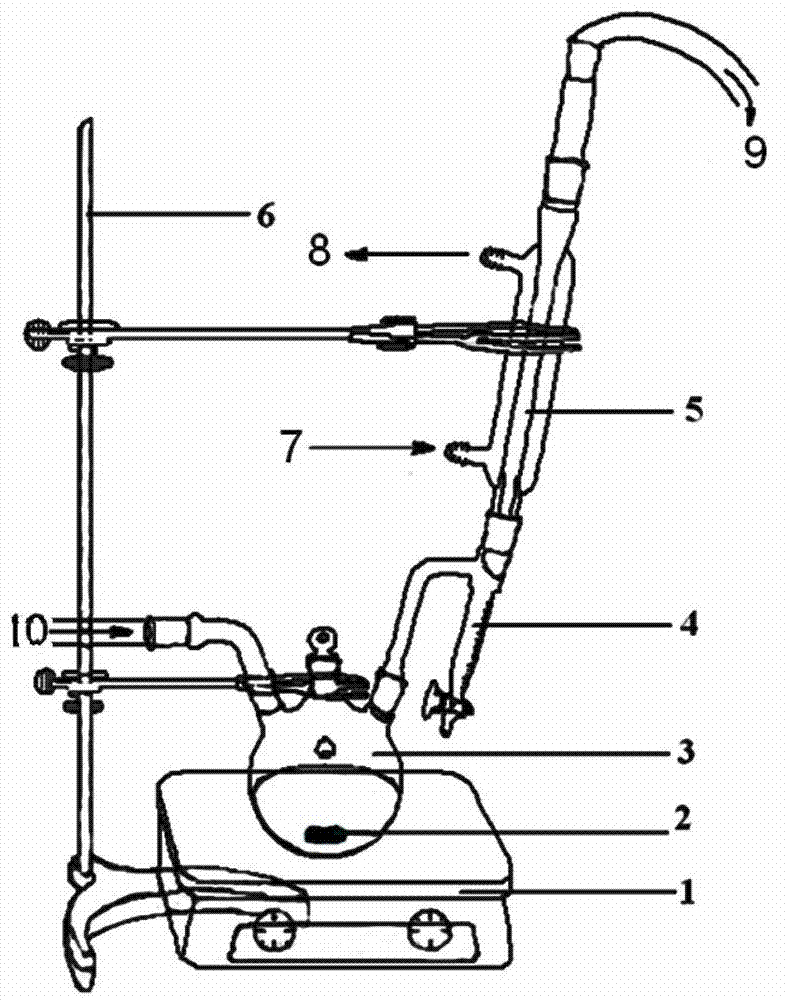

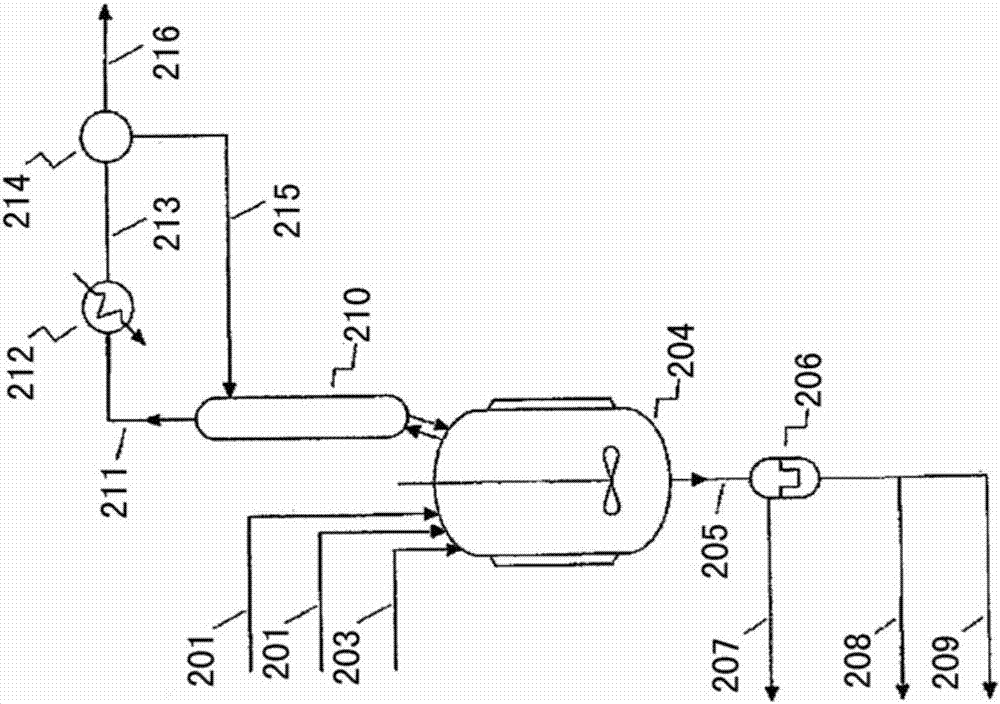

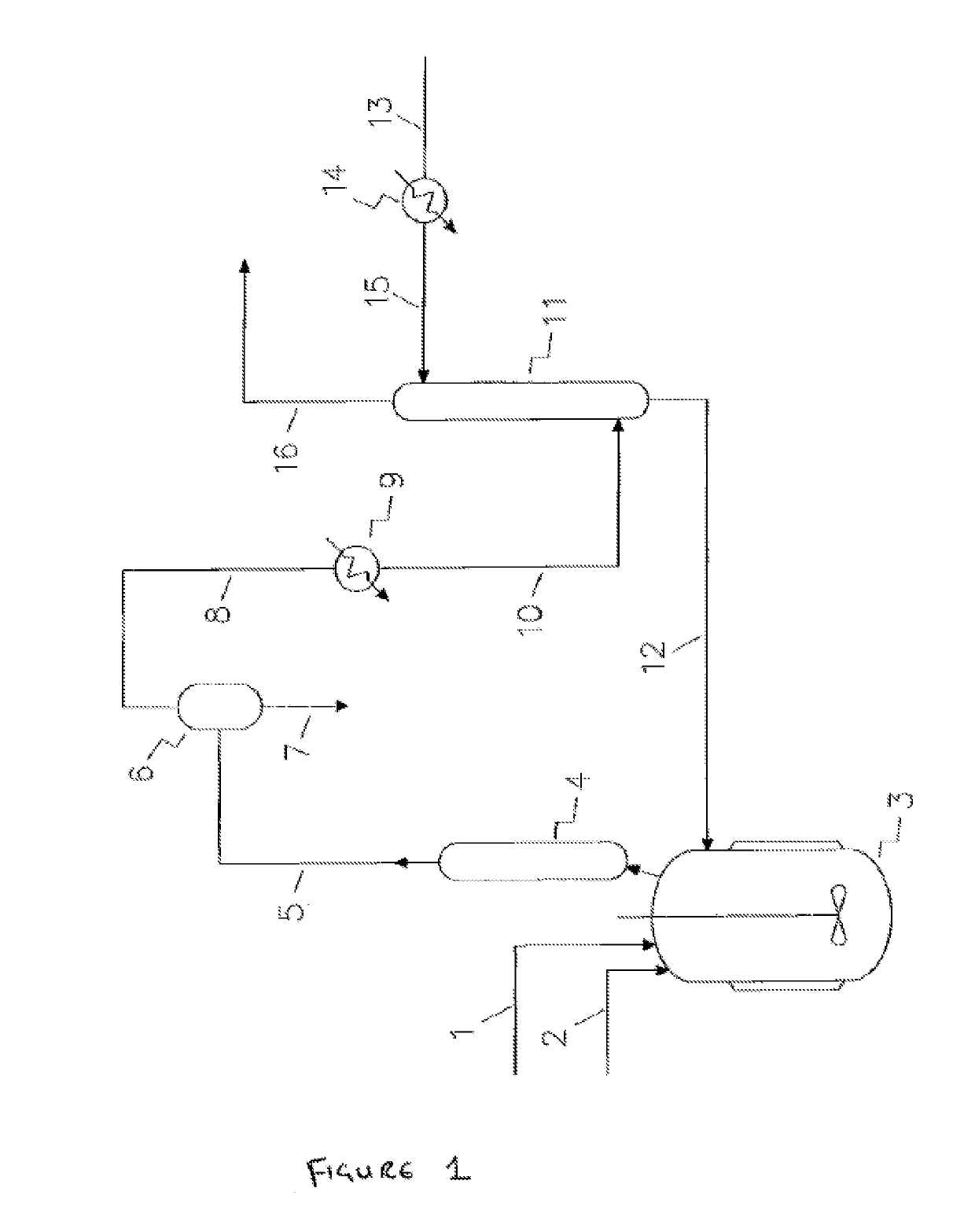

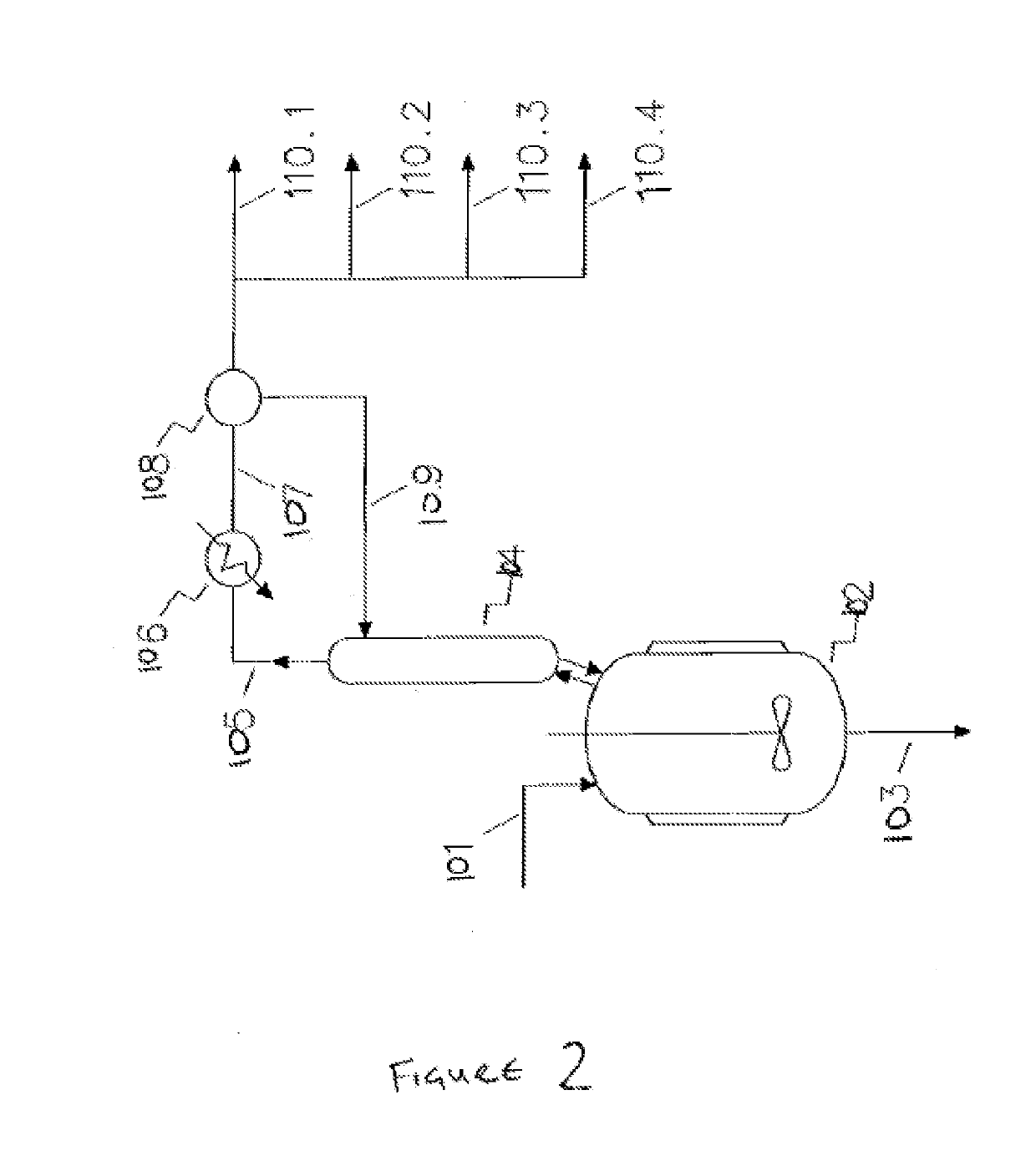

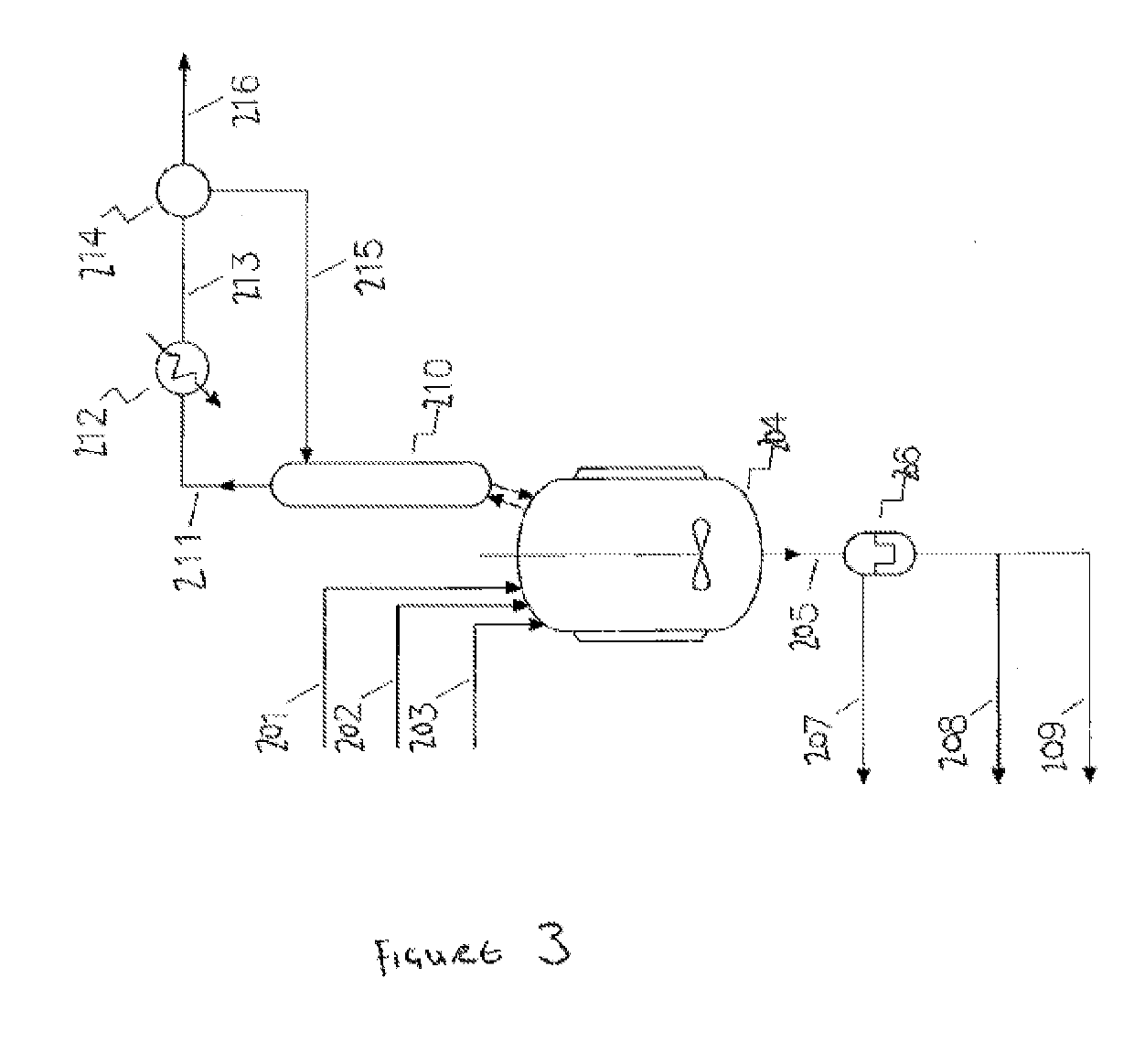

Method and system thereof for synthesizing epoxy chloropropane by dichloropropanol

The invention provides a method and a system of the method for synthesizing epoxy chloropropane by dichloropropanol. By utilizing the method and the system, the defect that a large number of wastewater is generated by a steam direct heating steam stripping saponification method is overcome. The method comprises the following steps that: an indirect heating circulation injection saponification reactor is adopted; dichlorohydrin, alkali and circulation saponification liquid enter a kettle body through an outer circulation pump for cyclization reaction to generate the epoxy chloropropane; azeotrope formed by the generated epoxy chloropropane and water is instantly steamed from the top of the kettle body; the azeotrope enters into an oil-water separator after being condensed as an oil layer is crude epoxy chloropropane; a part of a water layer flows back to the saponification reactor; a part of the water layer enters into a water-phase steam stripping tower; the epoxy chloropropane flowing out from the top of the steam stripping tower is subjected to heat exchange with the saponification liquid for condensing; the epoxy chloropropane flows back to the oil-water separator after being condensed so as to recover the epoxy chloropropane in water phase; steam stripping tower residual liquid of the epoxy chloropropane is removed, wherein a part of the residual liquid is used for preparing alkali liquid and a part of the residual liquid is discharged; and salty mud generated in the kettle body is settled to a swinging filter machine from the bottom of saponification reactor, wherein filter residue is recovery salt, and filter liquid is saponification waste liquid.

Owner:CHANGZHOU UNIV

Cationic electromigration imidazoline quaternary ammonium salt and application thereof

InactiveCN102924379AAvoid the tendency of "secondary corrosion"Low labor intensity of technical constructionOrganic chemistryEpoxySodium chloroacetate

The invention discloses a cationic electromigration imidazoline quaternary ammonium salt which is prepared by the following steps: (1) synthesizing imidazoline from C5-C18 fatty acid and diethylenetriamine; and (2) carrying out cationization reaction on the imidazoline and quaternizing reagent (comprising sodium monochloroacetate, epoxy chloropropane, epoxyethane, chloroacetic acid ethanol ammonium salt and sodium 3-chloro-2-hydroxypropyl sulfonate) in a mol ratio of 1:(1.0-1.2) at 70-90 DEG C under the condition of the pH value 3-4 for 6-8 hours, thereby obtaining the cationic electromigration imidazoline quaternary ammonium salt. When being used in a concrete reinforcing bar corrosion inhibitor, the cationic electromigration imidazoline quaternary ammonium salt can be used for reinforcing bar restoration in new concrete structures and built concrete structures. The restoration belongs to nondestructive restoration, and has the advantages of high migration rate and environment friendliness.

Owner:SOUTH CHINA UNIV OF TECH

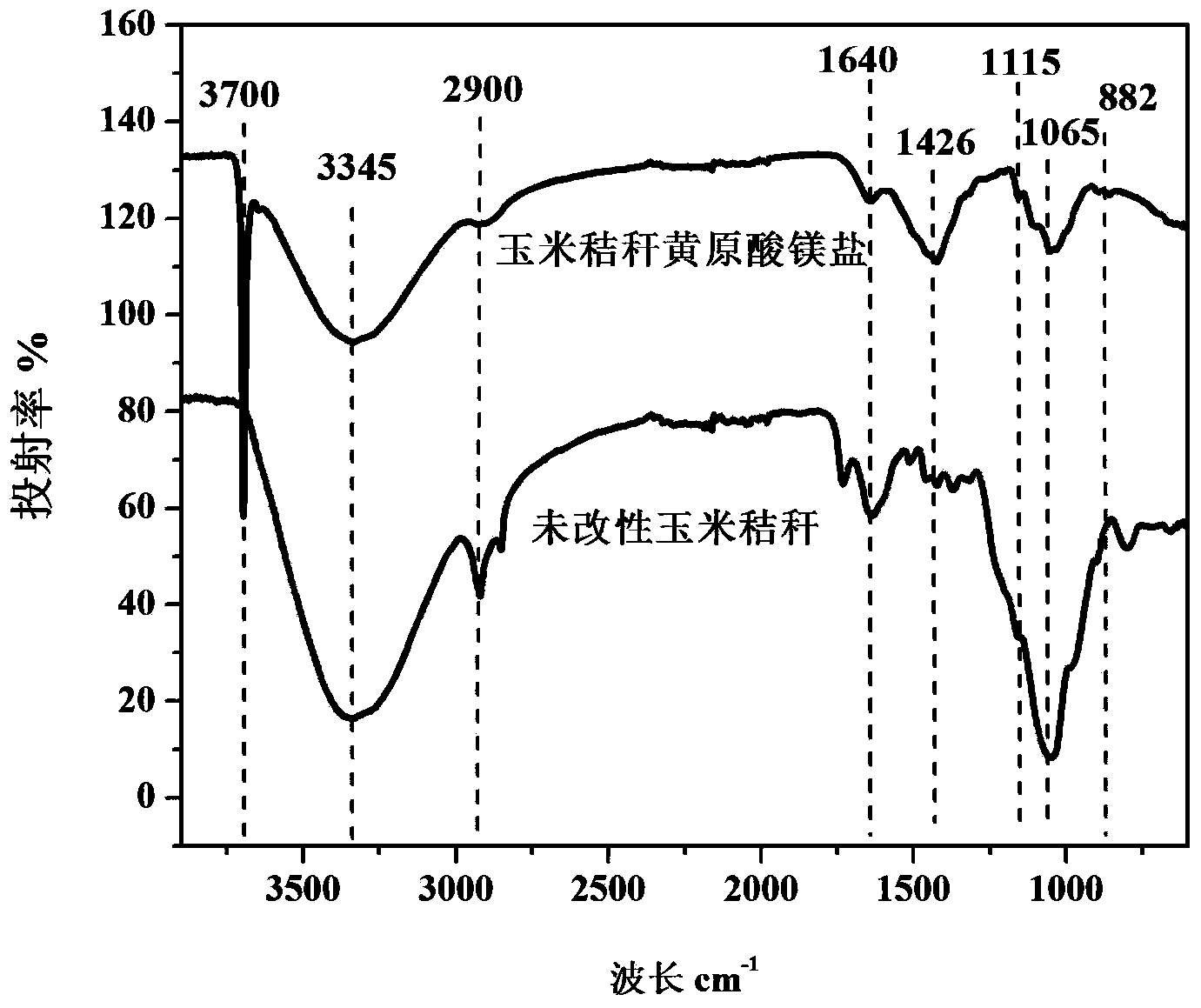

Preparation method for adsorption material for polluted water heavy metals and treatment method for polluted water heavy metals

InactiveCN103447005AImprove adsorption capacityEasy to handleOther chemical processesWater contaminantsEpoxyAdsorption effect

The invention discloses a preparation method for an adsorption material for polluted water heavy metals and a treatment method for polluted water heavy metals. The adsorption material for polluted water heavy metals is obtained by directly using maize straw as a raw material, and performing an xanthogenate modification treatment on the raw material by sodium hydroxide, epoxy chloropropane, carbon disulfide, magnesium sulphate and the like. The adsorption material prepared by the method disclosed by the invention is used for treating heavy-metal polluted water, and suitable for the conditions of neutral and acidic water environments; the adsorption material is low in dosage, high in removal rate, and capable of obtaining a good adsorption effect. The preparation method and the treatment method disclosed by the invention provide a new way for effective utilization for maize straw.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

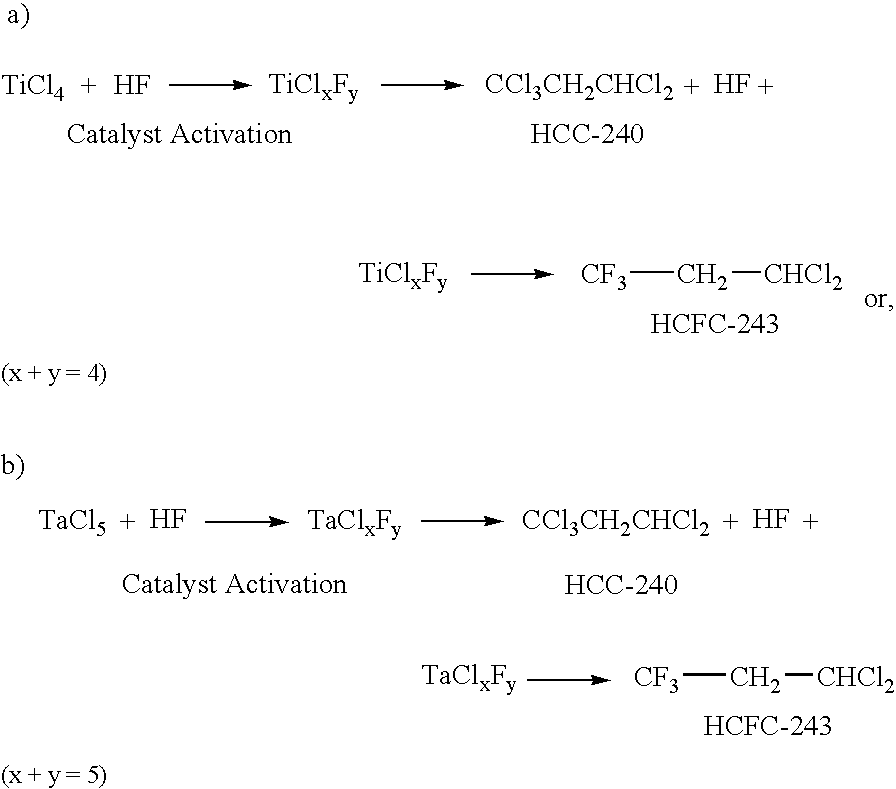

Process for the preparation of 1,1-dichloro-3,3,3-trifluoropropane

InactiveUS20060058560A1Physical/chemical process catalystsHalogenated hydrocarbon preparationHydrogen fluorideChlorofluorocarbon

A convenient and economical process for the preparation of 1,1-dichloro-3,3,3-trifluoropropane (HCFC-243) by the reaction of 1,1,1,3,3-pentachloropropane (HCC-240) with hydrogen fluoride in the presence of an activated hydrofluorination catalyst. Also, the selective fluorination of hydrochlorocarbons and / or hydrochlorofluorocarbons, or mixtures thereof is shown. A HCFC-243 reaction product yield of greater than 40% is obtained.

Owner:HONEYWELL INT INC

Preparation and application of flax adsorbent

InactiveCN103464115AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionFiberEpoxy

The invention discloses a preparation method and application technology of an epoxy chloropropane modified flax adsorbent. The preparation method is characterized by washing waste short fiber flax of a flax textile factory by using water, drying and crushing; processing by using NaOH and OP water solution and drying to obtain degummed flax; adding the following components in percentage by mass in a reactor: 22-40% of epoxy chloropropane, 12-25% of degummed flax, 4-8% of NaOH, 5-10% of isopropyl alcohol and 32-55% of water, wherein the sum of all the components is 100%; stirring at the constant temperature of 55-65 DEG C, carrying out backflow reaction for 1.0-4h, cooling, washing by using de-ionized water, carrying out suction extracting and filtering until the filtrate is neutral, washing by using a small amount of ethanol, drying in a 50-55 DEG C vacuum drying box, so as to obtain the epoxy chloropropane modified flax. The adsorbent has very high adsorbing capacity to basic dye, has high regeneration property, can be used repeatedly for several times, and is low in cost and environment-friendly.

Owner:UNIV OF JINAN

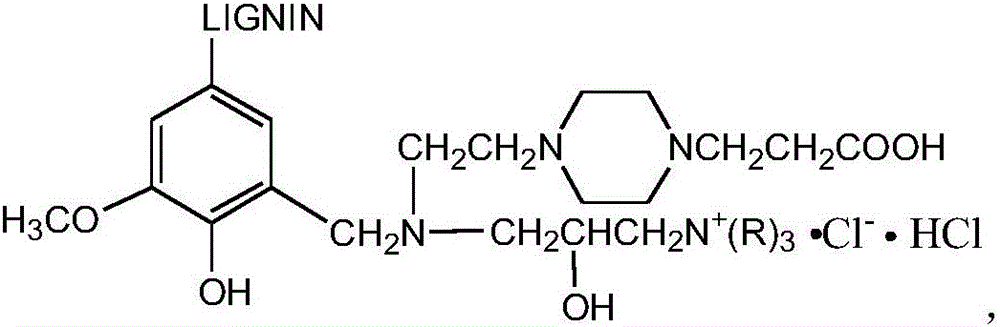

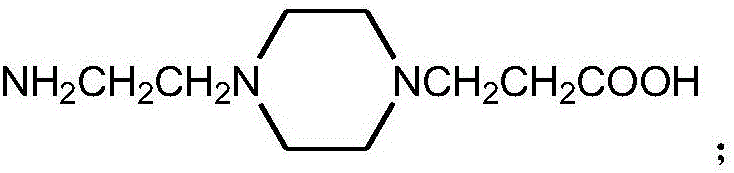

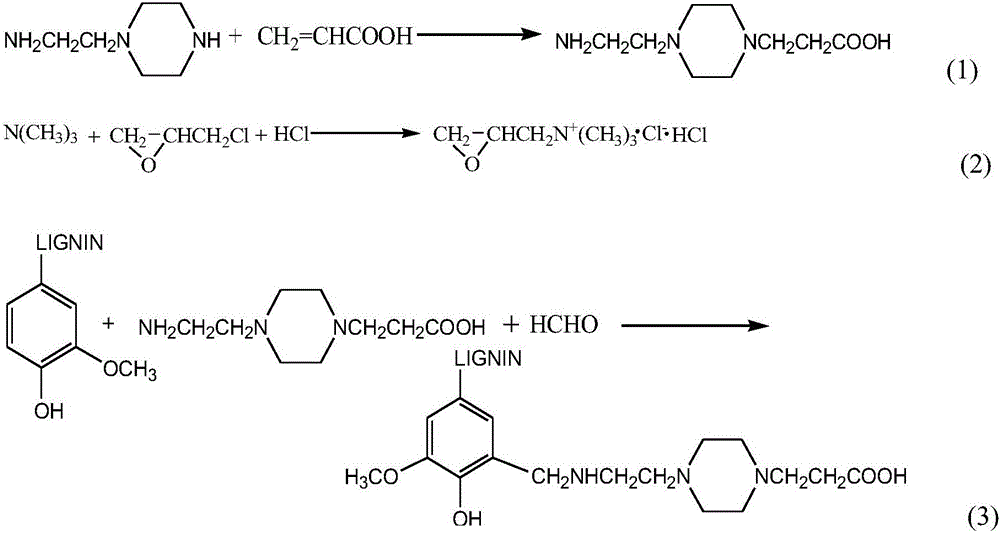

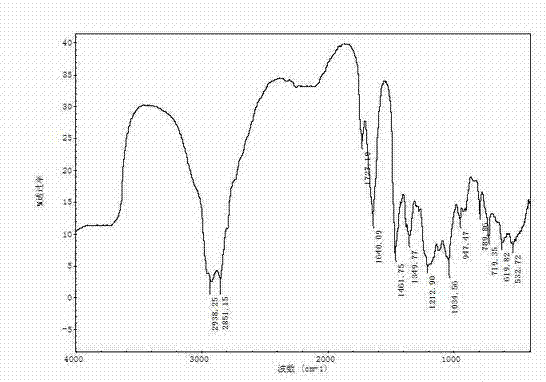

Lignin cyclamine cationic-type asphalt emulsifier and preparation method thereof

InactiveCN106084250AGood emulsifying effectImprove hydrophilicityBuilding insulationsCarbon numberEpoxy

The invention discloses a lignin cyclamine cationic-type asphalt emulsifier and a preparation method and application thereof. The molecular structure general formula of the emulsifier is as shown in the description, wherein R is a methyl group (-CH3) or an ethyl group (-C2H5) or a hydroxyethyl group (-C2H4OH), and LIGNIN represents a lignin molecular chain. The lignin cyclamine cationic-type asphalt emulsifier is prepared from, by mass, 100 parts of lignin, 159-230 parts of water, 19-27 parts of sodium hydroxide, 42-50 parts of N-aminoethylpiperazine, 23-29 parts of acrylic acid, 30-36 parts of formaldehyde (37%), 35-82 parts of tertiary amine with a low carbon number, 42-50 parts of industrial hydrochloric acid (30%) and 31-37 parts of epoxy chloropropane. According to the lignin cyclamine cationic-type asphalt emulsifier, the synthesis raw materials are easy to obtain, the production cost is low, the technology is simple, and high-temperature reacting is not needed; the emulsifier can emulsify different types of asphalt, the prepared emulsified asphalt is fine and uniform, the storage stability is good, and rapid-cracking cationic-type emulsified asphalt can be prepared.

Owner:SHANDONG UNIV

Preparation method of strontium ferrite-SiO2/carbon nanotube/hydrogenated bisphenol A epoxy resin composite wave-absorbing material

InactiveCN102924874ALow reflectivity lossHigh transparencyMagnetic/electric field screeningSilicic acidBisphenol

The invention provides a preparation method of a strontium ferrite-SiO2 / carbon nanotube / hydrogenated bisphenol A epoxy resin composite wave-absorbing material. The preparation method comprises the following steps: preparing a strontium ferrite-SiO2 composite material from nitrate, ethyl orthosilicate, absolute ethanol and the like by a sol-gel process; and preparing the strontium ferrite-SiO2 / carbon nanotube / hydrogenated bisphenol A epoxy resin composite wave-absorbing material from the strontium ferrite-SiO2 composite material, carbon nanotube, hydrogenated bisphenol A, epoxy chloropropane and the like. The composite material has the advantages of favorable transparency, low viscosity and easy casting, has electric loss and magnetic loss properties, and thus, has important application value in the fields of stealth technology, electromagnetic shielding, human body safety protection and the like.

Owner:STATE GRID CORP OF CHINA +1

Dewatering demulsifier for triple composite driven extract and its production

ActiveCN101029253AExcellent demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationDemulsifierEpoxy

A triple composite-driven extract dewatering demulsifier and its production are disclosed. The demulsifier consists of drier 45-65wt%, water 30-45wt% and methanol 5-10wt%; drier consists of AE surface activator 15-30wt%, SP surface activator 10-40wt%, AT surface activator 15-35wt%, epoxy chloropropane 5-8wt%, which are synthesized by caustic potash, epoxypropane, triethenoid tetrammine, epoxyethane and acetic acid. The additive amount is between 80-100mg / 1 and water content is<0.2%, oil content is<500mg / 1. It has better demusifying effect.

Owner:PETROCHINA CO LTD

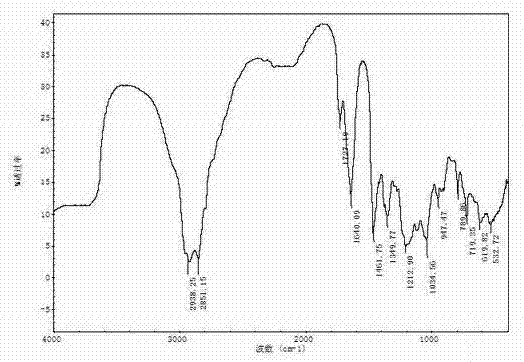

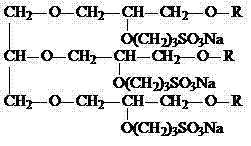

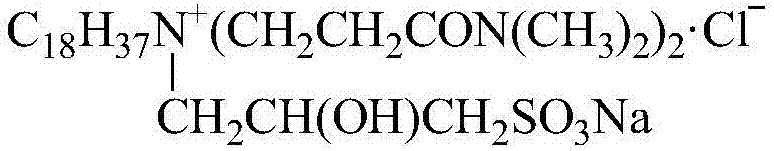

Sulfonate trimeric surfactant and preparation method thereof

InactiveCN102389746ANovel structureSimple structureTransportation and packagingMixingActive agentSurface-active agents

The invention relates to a sulfonate trimeric surfactant used for oil displacement of high-temperature and high-salinity oil reservoirs, and a preparation method thereof. The surfactant is characterized in high temperature resistance and high salt resistance. The invention adopts the technical scheme as follows: the surfactant is 1,2,3-tri (2-sodium oxopropane sulfonate-3-alkyl ether-propyl) glycerol ether (TTSS-3-n); the preparation method comprises the following steps of: dissolving glycerol in a mixed solution of phase-transfer agent and alkali, adding epoxy chloropropane, allowing reactions to occur at 50 DEG C for 5 to 10 hours, filtering and distilling to obtain glycerol-tri(propylene oxide) ether, reacting the glycerol-tri(propylene oxide) ether with a reaction product of alkyl alcohols and potassium for 8 hours, drying and distilling to obtain a light yellow solid, dissolving the solid in tetrahydrofuran, mixing with 1,3-propanesultone, adding sodium hydride, and allowing reactions to occur for 12 hours to obtain the compound TTSS-3-n. the surfactant has a novel structure and a simple preparation method; is advantageous in higher surface activity, lower critical micelle concentration and good temperature resistance and salt resistance; and can be applied to crude oil extraction in oil fields.

Owner:SOUTHWEST PETROLEUM UNIV

Process for preparing 2,3,3,3-tetrafluoropropene

ActiveUS20140121424A1Reduce contact timeHigh selectivityPreparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluoridePhysical chemistry

The present invention provides a method for efficiently preparing 2,3,3,3-tetrafluoropropene (HFO-1234yf) by a simple and economically advantageous method that is suitable for implementation on an industrial scale. The present invention provides a process for preparing 2,3,3,3-tetrafluoropropene, comprising the step of: (1) in a reactor, (1-1) reacting 1,1,1,2,3-pentachloropropane with hydrogen fluoride in an amount of 10 to 100 mol per mole of the 1,1,1,2,3-pentachloropropane 1; (1-2) in the presence of chromic oxide represented by composition formula: CrOm (1.5<m<3) or fluorinated chromic oxide obtained by fluorinating the chromic oxide; (1-3) in the presence of oxygen in an amount of 0.02 to 1 mol per mole of the 1,1,1,2,3-pentachloropropane; and (1-4) in the gas phase within a temperature range of 320 to 390 degrees centigrade, thereby obtaining a reaction product containing 2,3,3,3-tetrafluoropropene.

Owner:DAIKIN IND LTD

Process

InactiveCN107001190ARealize continuous productionRealize comprehensive utilizationPreparation by hydrogen halide split-offPreparation by halogen replacementAlkyl transferReaction zone

Disclosed is a process for preparing a highly pure 1,1,1,2,3-pentachloropropane product. The method comprises 1-a) providing a reaction mixture comprising ethylene, carbon tetrachloride and a catalyst in a principal alkylation zone to produce 1,1,1,3-tetrachloropropane in the reaction mixture; 1-b) treating the reaction mixture obtained in step 1-a) to obtain a 1,1,1,3-tetrachloropropane feedstock; 2-a) contacting the 1,1,1,3-tetrachloropropane feedstock with a catalyst in a dehydrochlorination zone to produce a reaction mixture comprising 1,1,1,3-tetrachloropropane and 1,1,3-trichloropropene; 2-b) treating the reaction mixture obtained in step 2-a) to obtain a 1,1,3-trichloropropene feedstock; 3-a) contacting the 1,1,3-trichloropropene feedstock with chlorine in a reaction zone to produce a reaction mixture containing 1,1,1,2,3-pentachloropropane and 1,1,3-trichloropropene, the reaction zone being different from the dehydrochlorination zone; and 3-b) treating the reaction mixture obtained in step 3-a) to obtain the highly pure 1,1,1,2,3-pentachloropropane product.

Owner:SPOLEK PRO CHEMICKOU A HUTNI VYROBU

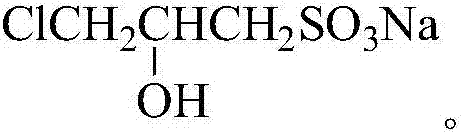

Tertiary amide quaternary ammonium salt type hydroxypropyl sodium sulfonate asphalt emulsifier and preparation method thereof

InactiveCN106977432AImprove hydrophilicityEnhanced charge strengthOrganic compound preparationTransportation and packagingEpoxySolvent

The invention discloses a tertiary amide quaternary ammonium salt type hydroxypropyl sodium sulfonate asphalt emulsifier and a preparation method thereof. The asphalt emulsifier is prepared from the following raw materials according to molar ratio: octadecylamine, an alcohol solvent, N,N-dimethylacrylamide, epoxy chloropropane and sodium hydrogen sulfite of which the molar ratio is 1mol to (4.00 to 9.00)mol to (2.00 to 2.10)mol to (1.00 to 1.15)mol to (1.05 to 1.25)mol. The alcohol solvent is ethanol, methanol or isopropyl alcohol. The asphalt emulsifier disclosed by the invention has the advantages of easily-obtained synthetic raw materials, low production cost, simple process and no need of a high temperature reaction; the asphalt emulsifier can be used for emulsifying multiple asphalts of different modes; prepared emulsified asphalt is fine, uniform and good in storage stability, and can be used for preparing cationic emulsified asphalt.

Owner:SHANDONG UNIV

Process for the manufacture of 2,3,3,3-tetrafluoropropene

InactiveUS20190127303A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystProcess engineering

The present invention provides a process of manufacture of 2,3,3,3-tetrafluoropropene by fluorination of very high purity 1,1,1,2,3-pentachloropropane (HCC-240db) into product 2,3,3,3-tetrafluoropropene (HFO-1234yf), the process comprising the following steps: —step 3 of chlorination of 1,1,3-trichloropropene to produce 1,1,1,2,3-pentachloropropane, comprising: 3-a) contacting the 1,1,3-trichloropropene feedstock with chlorine in a reaction zone to produce a reaction mixture containing 1,1,1,2,3-pentachloropropane and 1,1,3-trichloropropene, the reaction zone being different from the dehydrochlorination zone, and 3-b) treating the reaction mixture obtained in step 3-a) to obtain a 1,1,1,2,3-pentachloropropane (HCC-240db) feedstock; —step 4 of producing 2,3,3,3-tetrafluoropropene (HFO-1234yf), comprising: 4-a) reacting the 1,1,1,2,3-pentachloropropane (HCC-240db) feedstock with HF in the presence or absence of catalyst to produce a reaction mixture comprising at least one compound chosen from HCI, HF, 1,1,1,2,2-pentafluoropropane (HFC-245cb), 2-chloro-3,3,3-trifluoropropene (HCFO-1233xf) and 2,3,3,3-tetrafluoropropene (HFO-1234yf).

Owner:ARKEMA FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com