Treatment method of wastewater generated in cyclization step in production process of epoxy chloropropane from glycerol

A technology of epichlorohydrin and treatment methods, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve problems affecting the application of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

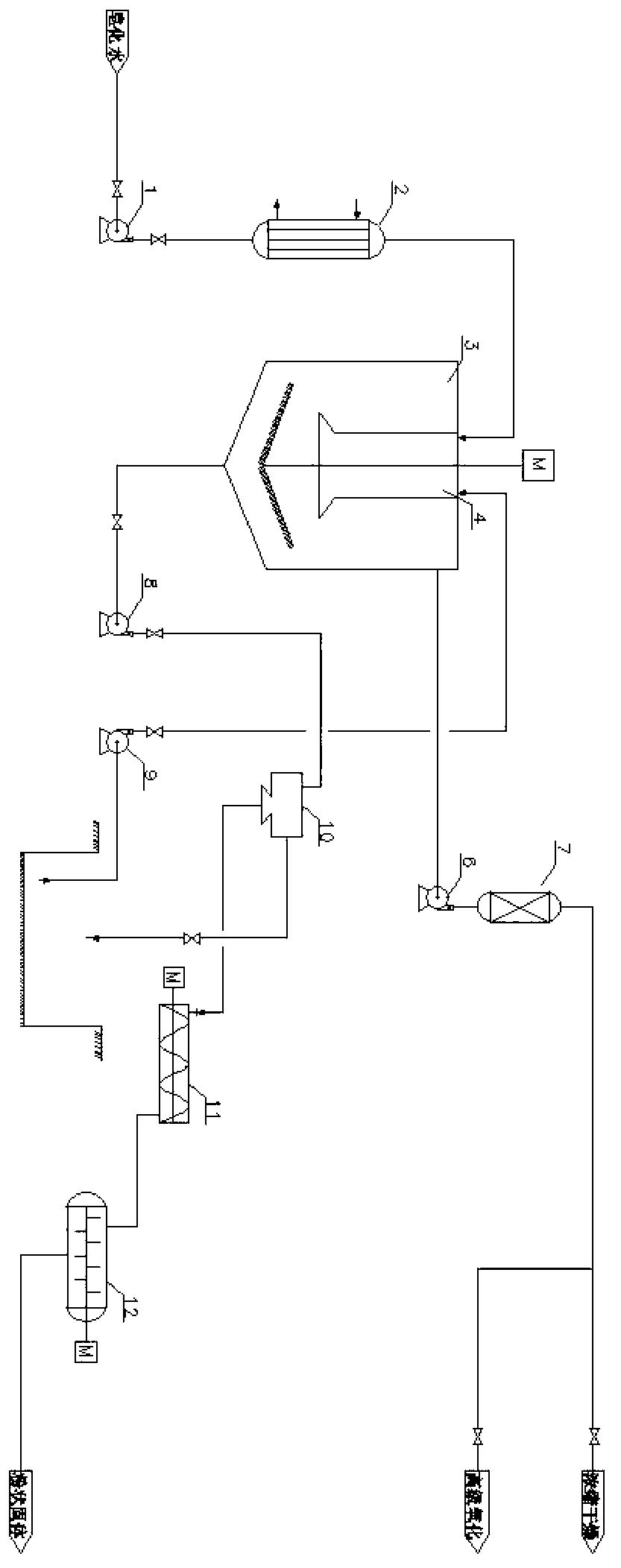

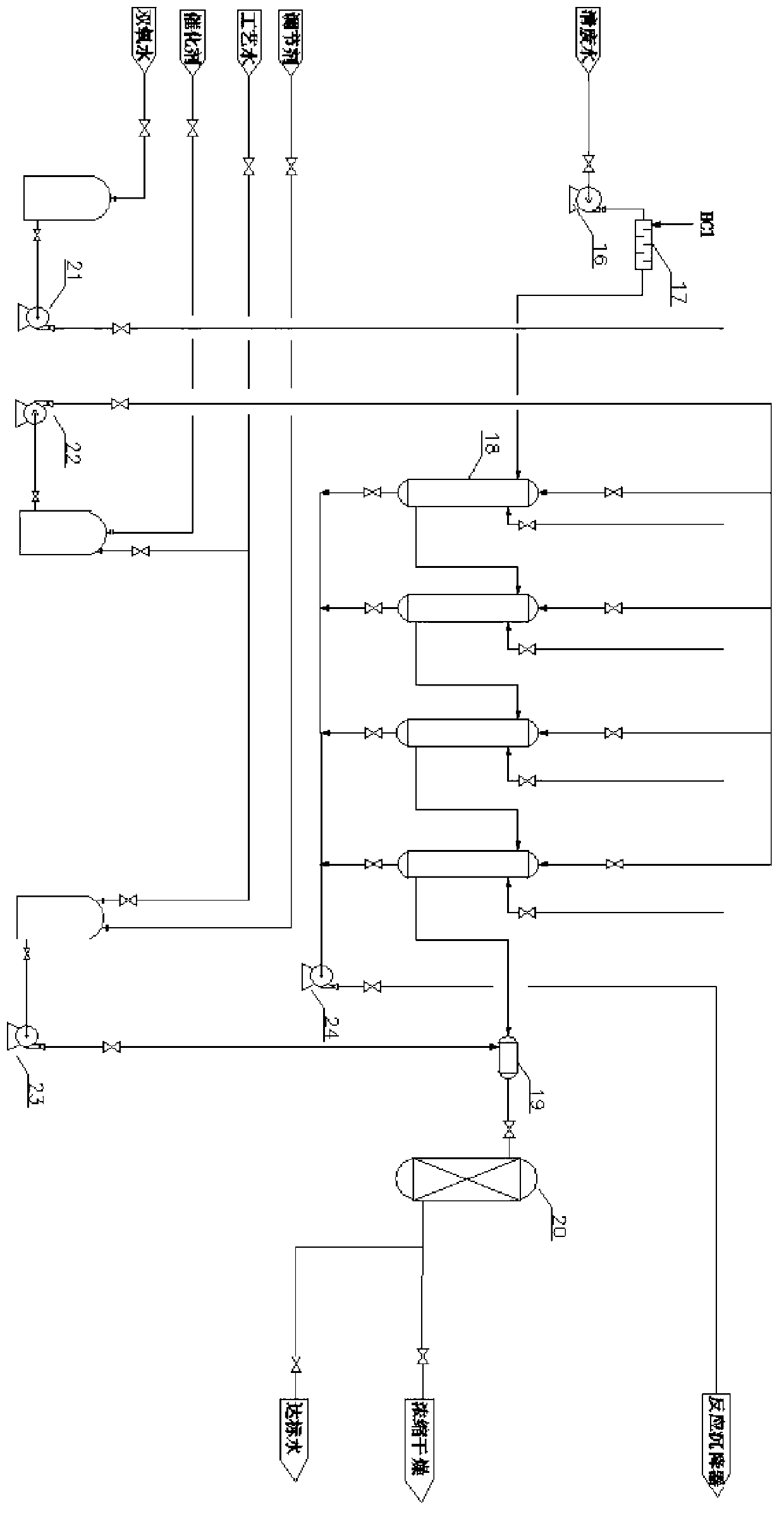

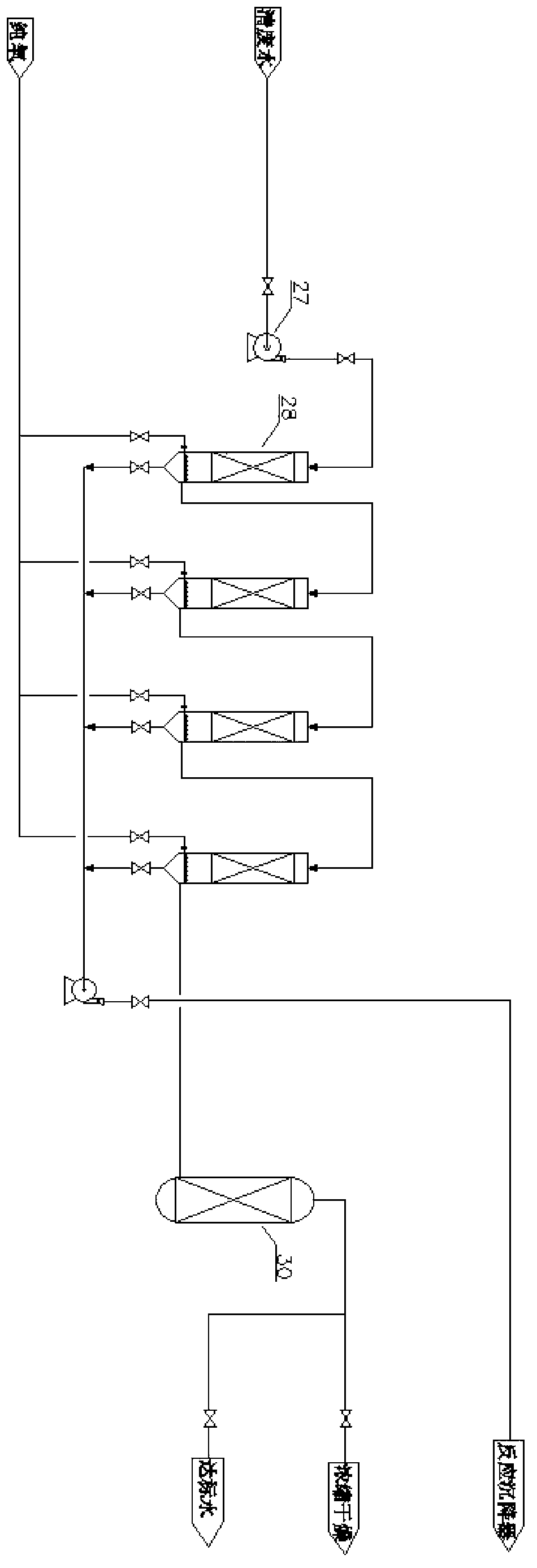

Image

Examples

Embodiment 1

[0097] Embodiment 1: the treatment of the waste water produced in the cyclization step in the glycerol method epichlorohydrin production method

[0098] The waste water that this embodiment handles contains 10.64%CaCl by described waste water weight 2 , 0.52%Ca(OH) 2 , the contents of glycerin and organic chlorine-containing compounds are listed in Table 1, wherein the total amount of organic chlorine-containing compounds is 50mg / L.

[0099] The equipment used in this embodiment is as follows: the reaction settler 3 is a non-standard container; the ceramic membrane filter 7 is a product sold by Zibo Dongqiang Environmental Protection Equipment Co., Ltd. under the trade name ceramic filter for water treatment; plate and frame filter press Or filter centrifuge 10 is a product sold by Zhangjiagang Baobao Centrifuge Manufacturing Company under the trade name PAUT type full-automatic scraper unloading centrifuge; the vacuum rake dryer is produced by Changzhou Yutong Drying Equipme...

Embodiment 2

[0120] Embodiment 2: the treatment of the waste water produced in the cyclization step in the glycerol method epichlorohydrin production method

[0121] The wastewater treated by this embodiment contains 12.0% CaCl by weight of the wastewater 2 , 0.3%Ca(OH) 2 , the contents of glycerol and organic chlorine-containing compounds are listed in Table 2.

[0122] The equipment used in this example is the same as that used in Example 1.

[0123] The implementation steps of this embodiment are as follows:

[0124] A. Hydrolysis reaction

[0125] The waste water is sent to the heater 2 by the former waste water delivery pump 1, and then sent to the reaction chamber 4 of the reaction settler 3 after being heated to 102° C., and 10 ppm of chlorine by the total weight of the waste water is added at the entrance of the reaction chamber 4 at the same time. Ferrous coagulant. In the reaction chamber, the hydrolysis reaction was carried out for 90min to convert the organic chlorine-cont...

Embodiment 3

[0138] Embodiment 3: the treatment of the wastewater produced in the cyclization step in the glycerol method epichlorohydrin production method

[0139] The wastewater treated by this embodiment contains 9.0% CaCl by weight of the wastewater 2 , 1.0%Ca(OH) 2 , the contents of organic chlorine-containing compounds are listed in Table 3.

[0140] The equipment used in this example is the same as that used in Example 1.

[0141] The implementation steps of this embodiment are as follows:

[0142] A. Hydrolysis reaction

[0143] The waste water is sent to the heater 2 by the former waste water delivery pump 1, and then sent to the reaction chamber 4 of the reaction settler 3 after being heated to 98° C., and 10 ppm of chlorine by the total weight of the waste water is added at the entrance of the reaction chamber 4 at the same time. Ferrous coagulant. Carry out hydrolysis reaction 60min in described reaction chamber, organic chlorine-containing compound is converted into glyce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com