Plate heat exchanger with no deposited scale, and heat exchange mode

A plate heat exchanger, scale deposition technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problem of not correctly reflecting the physical process of heat transfer along the flow of plate heat exchangers, to achieve Save fuel and power resources, improve heat exchange efficiency, and improve the effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

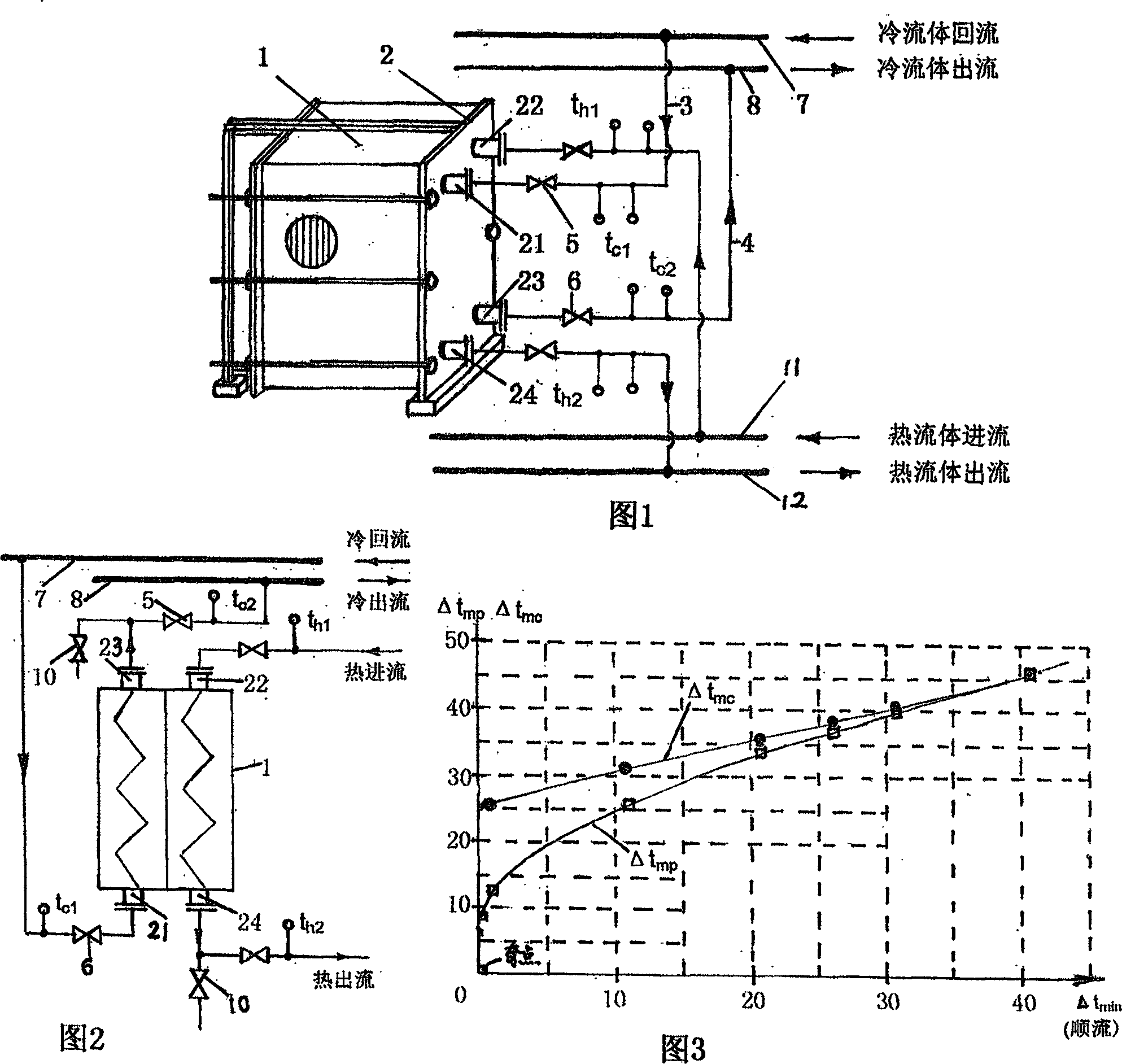

[0053] As shown in Figure 1, on the side of the fixed compression plate 2 of the ordinary plate heat exchanger 1, the cold fluid inlet 21 on the upper part of the fixed compression plate 2 is connected to the cold fluid return main pipeline 7 with the pipeline 3 equipped with the valve 5 With the pipeline 4 that valve 6 is installed, the cold fluid outlet 23 on the bottom of the fixed compression plate 2 is connected with the cold fluid outflow main pipeline 8, the hot fluid inlet 22 communicates with the hot fluid inlet main pipeline 11, and the hot fluid outlet 24 It communicates with the thermal fluid outflow main pipeline 12. The feature of this pipeline connection is that when the valve 5 and the valve 6 are in an open state, the cold fluid in the return main pipeline 7 can flow into the plate heat exchanger 1 from the cold fluid inlet 21 on the upper part of the fixed pressing plate 2, and the cold fluid can flow into the plate heat exchanger 1. The fluid flows from top ...

Embodiment 2

[0055] Such as Figure 9 As shown, on the basis of the heat exchange between the cold and hot fluids described in Embodiment 1, a high-frequency anti-scaling and descaling system such as that provided by the utility model patent ZL96 2 38603.0 is installed on the cold fluid return main pipeline 7 The water treatment device 9, even if the cold fluid is ground water with relatively high hardness, the heat exchange plate will not be hard scaled, and the purpose of neither depositing scale nor hard scale can be achieved. Figure 9 It is a parallel structure of multiple plate heat exchangers. The cold fluid inlets 21 communicate with the cold fluid return main pipeline 7 respectively, the hot fluid inlets 22 communicate with the hot fluid inlet main pipeline 11 respectively, and the cold fluid outlets 23 communicate with the cold fluid outlet respectively. The main pipeline 8 communicates, and the thermal fluid outlets 24 communicate with the thermal fluid outflow main pipeline 12 re...

Embodiment 3

[0057] On the basis of installing a high-frequency anti-scaling and descaling water treatment device on the cold fluid return main pipeline 7 described in Example 2, and then install a water treatment device on the hot fluid inflow main pipeline 11 as provided by the utility model patent ZL96 2 38603.0 High-frequency anti-scaling and descaling water treatment device, so that both cold and hot fluids can use non-demineralized water, and it can realize that there is no deposited scale and mud in the plate heat exchanger, and no hard scale chemically adsorbed.

[0058] The present invention proposes a method for forming a plate heat exchanger without scale deposits, by changing the conventional connection mode of the cold fluid inlet and outlet pipes of the common plate heat exchanger, that is, by exchanging the positions of the conventionally connected inlet and outlet pipes , change the normal flow direction of the cold fluid in the heat exchanger, so that the original cold and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com