Patents

Literature

37 results about "Logarithmic mean temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

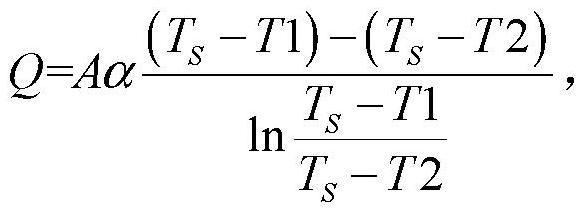

The logarithmic mean temperature difference (also known as log mean temperature difference, LMTD) is used to determine the temperature driving force for heat transfer in flow systems, most notably in heat exchangers. The LMTD is a logarithmic average of the temperature difference between the hot and cold feeds at each end of the double pipe exchanger. For a given heat exchanger with constant area and heat transfer coefficient, the larger the LMTD, the more heat is transferred. The use of the LMTD arises straightforwardly from the analysis of a heat exchanger with constant flow rate and fluid thermal properties.

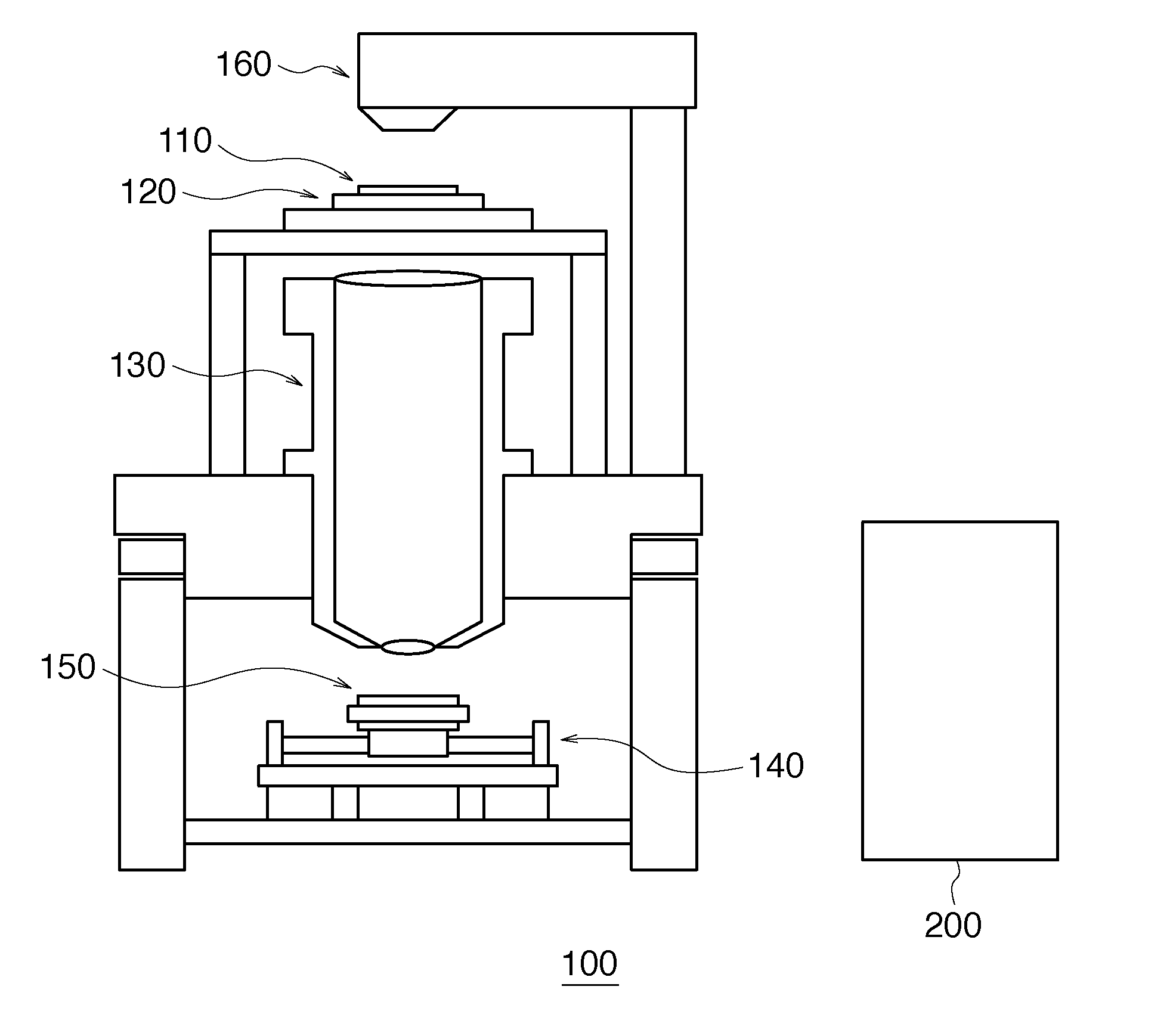

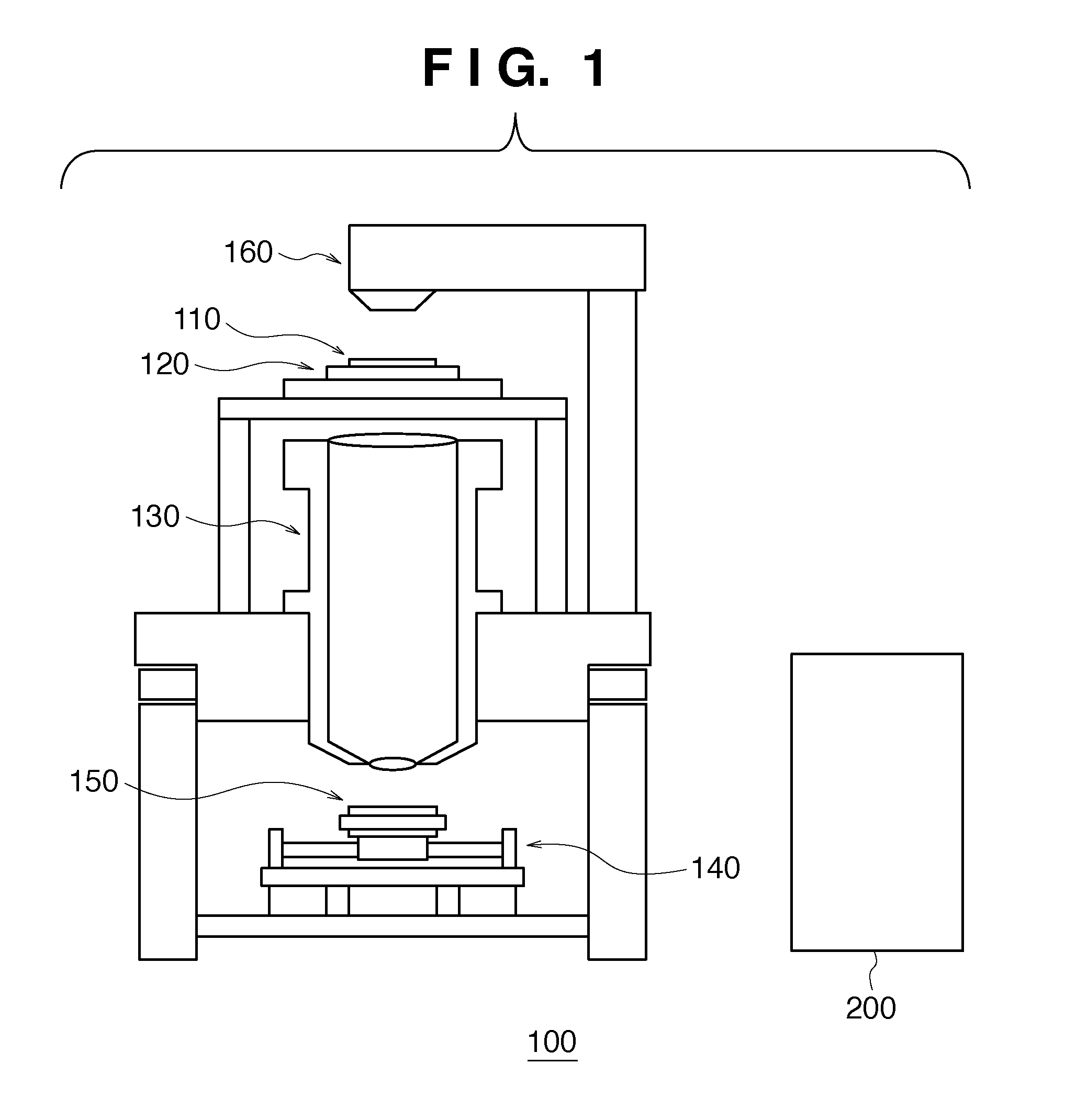

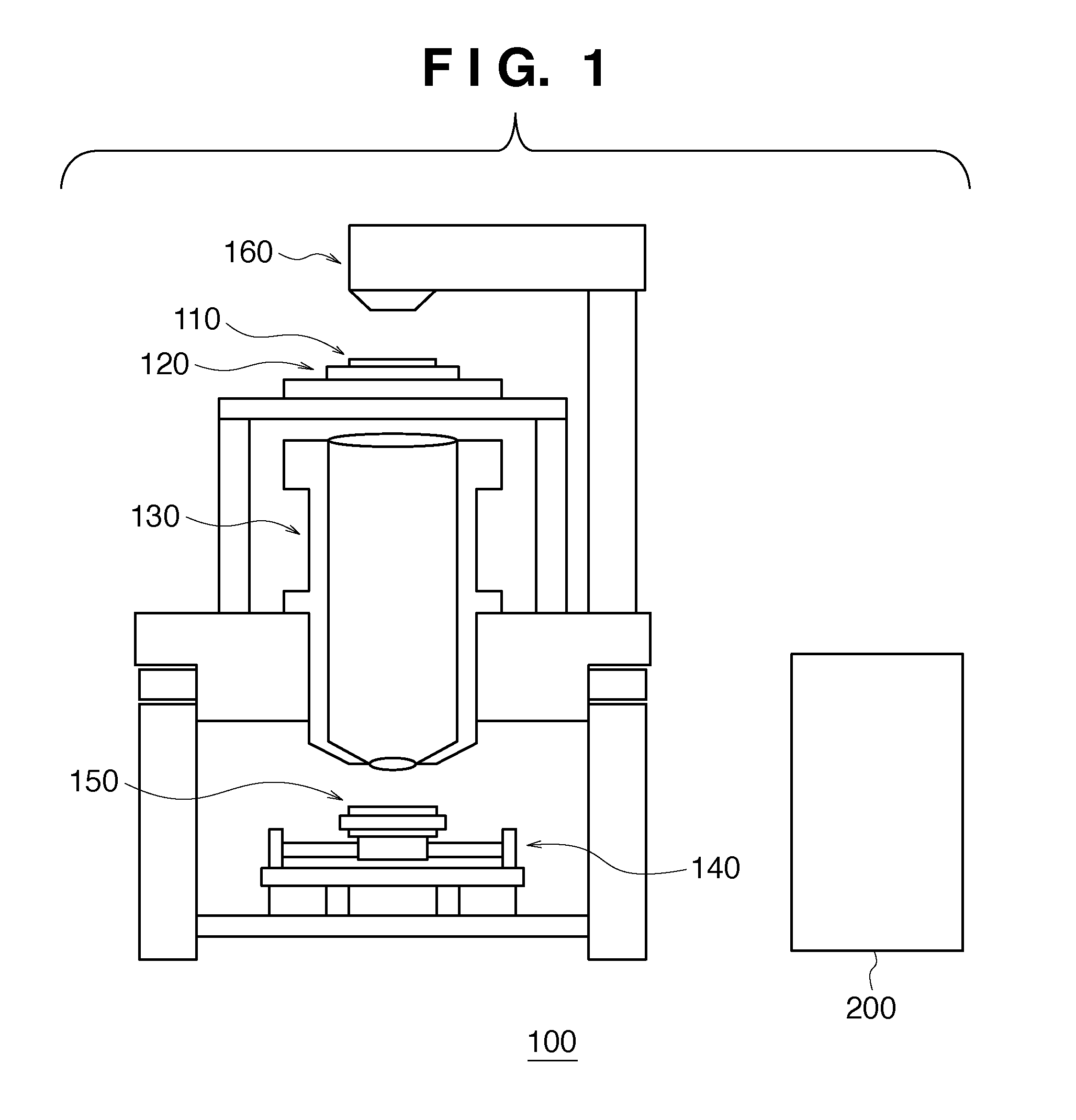

Temperature regulating apparatus, exposure apparatus, and device manufacturing method

InactiveUS20090090498A1Temperature regulationTemperatue controlPhotomechanical apparatusEngineeringHeat transfer coefficient

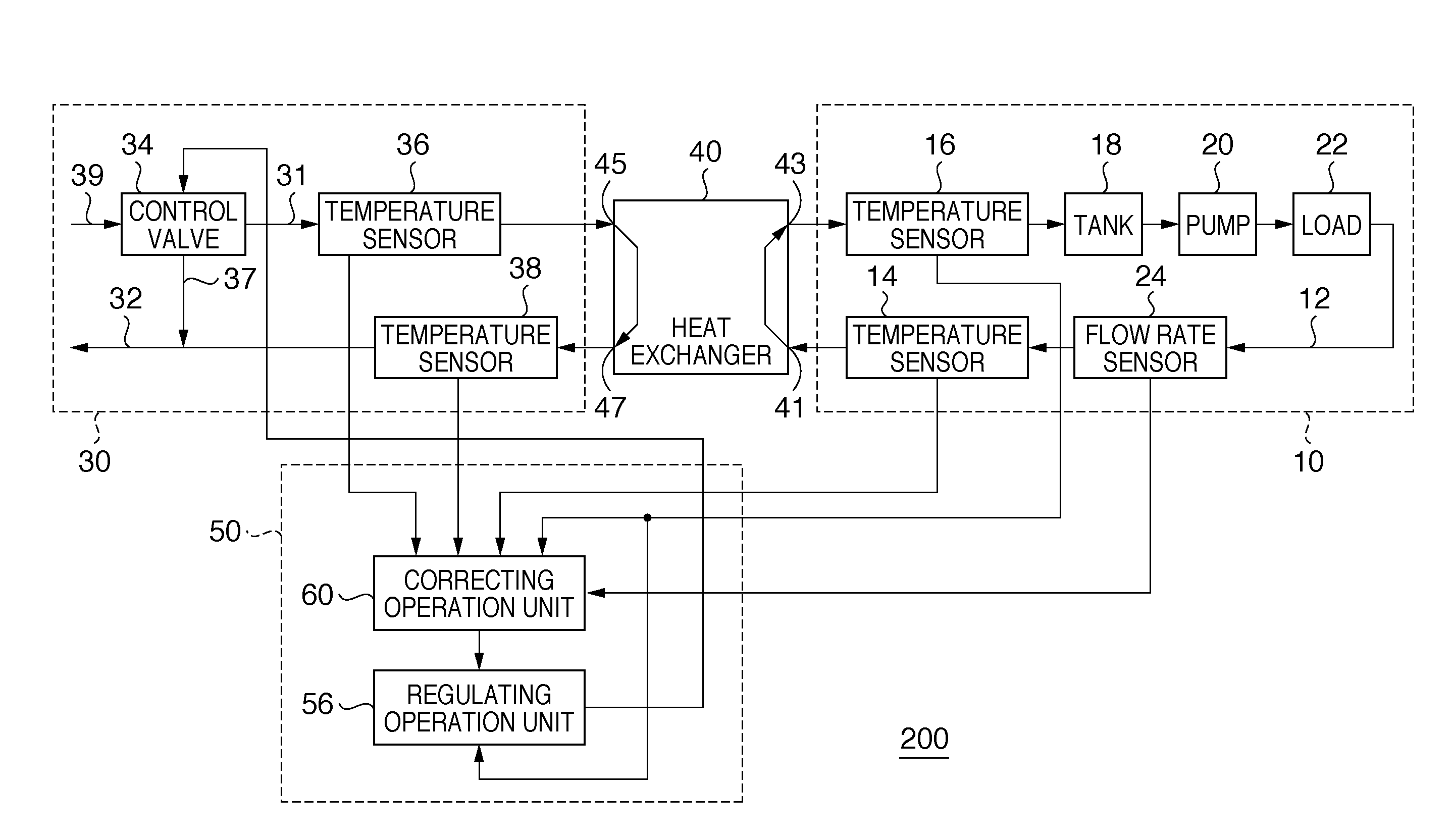

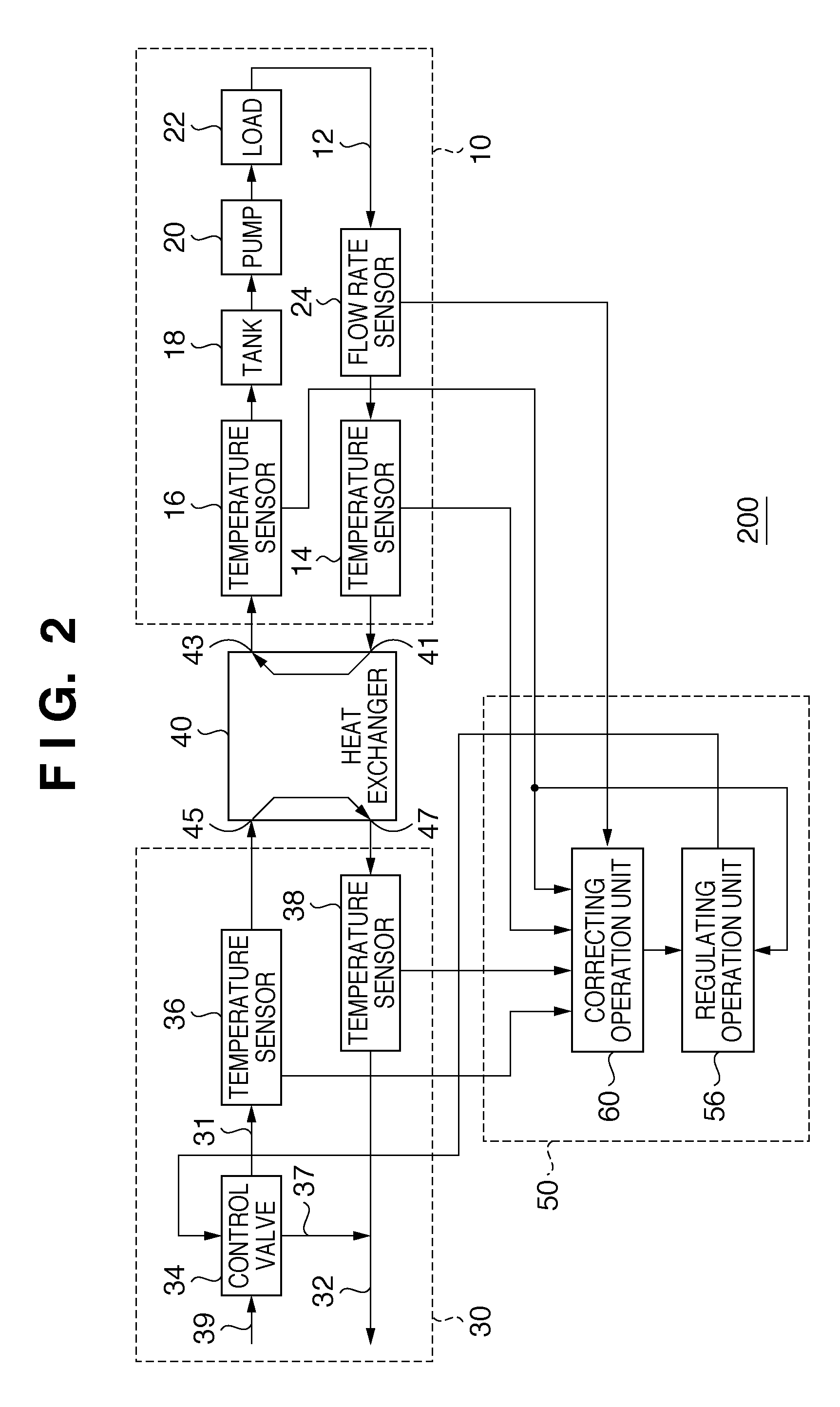

A temperature regulating apparatus includes a correcting operation unit configured a) to calculates a heat exchange amount of a heat exchanger, a logarithmic mean temperature difference or an average temperature in the heat exchanger, and a flow rate of a second medium, b) to calculate an overall heat transfer coefficient of the heat exchanger based on the heat exchange amount, the logarithmic mean temperature difference or the average temperature, and the flow rate of the second medium, and c) to correct a gain of a regulating operation unit based on a change in the heat exchange amount with a change in the flow rate of the second medium supplied to the heat exchanger.

Owner:CANON KK

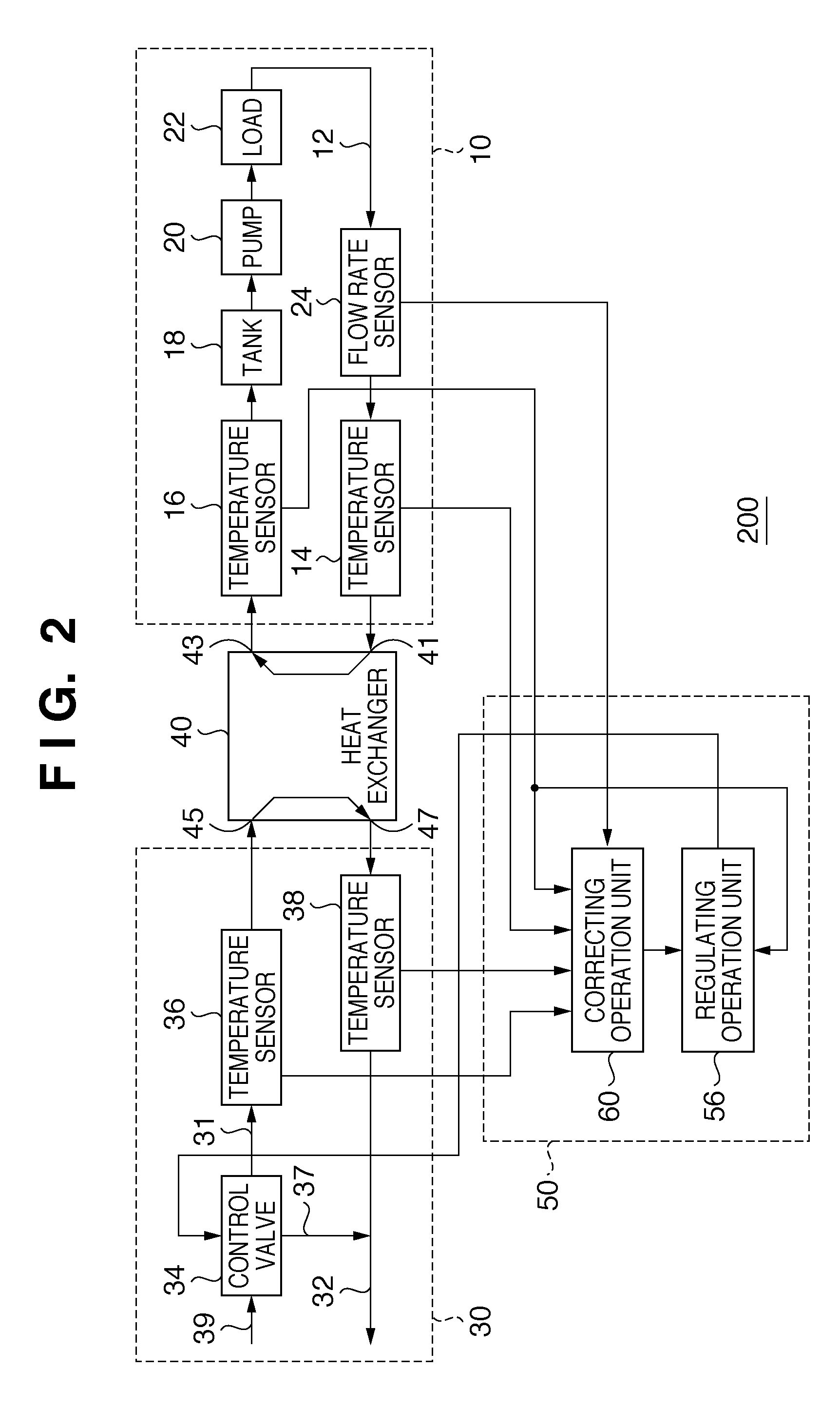

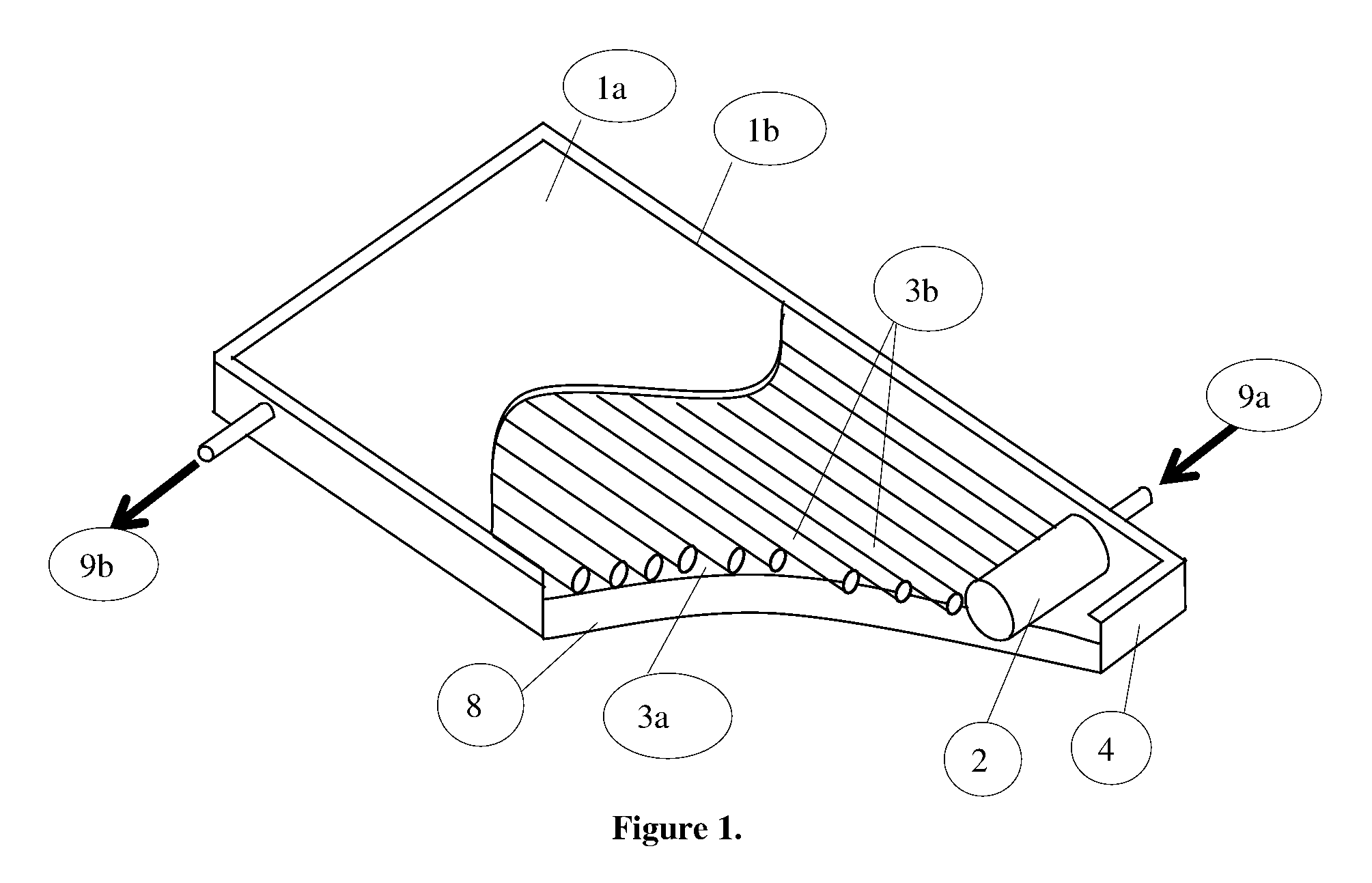

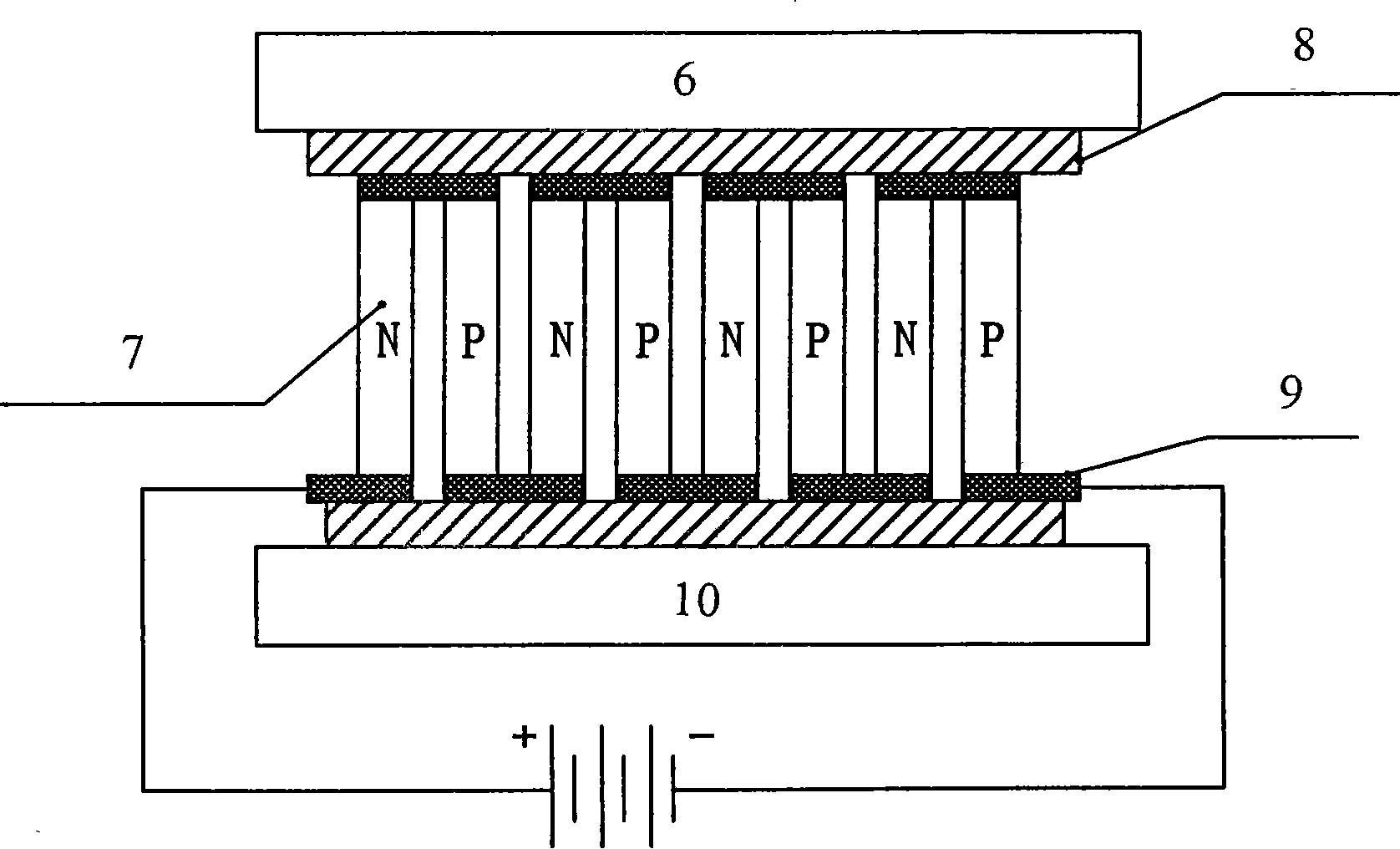

Tunnel type waste heat recovery semiconductor power generation method and device by temperature difference

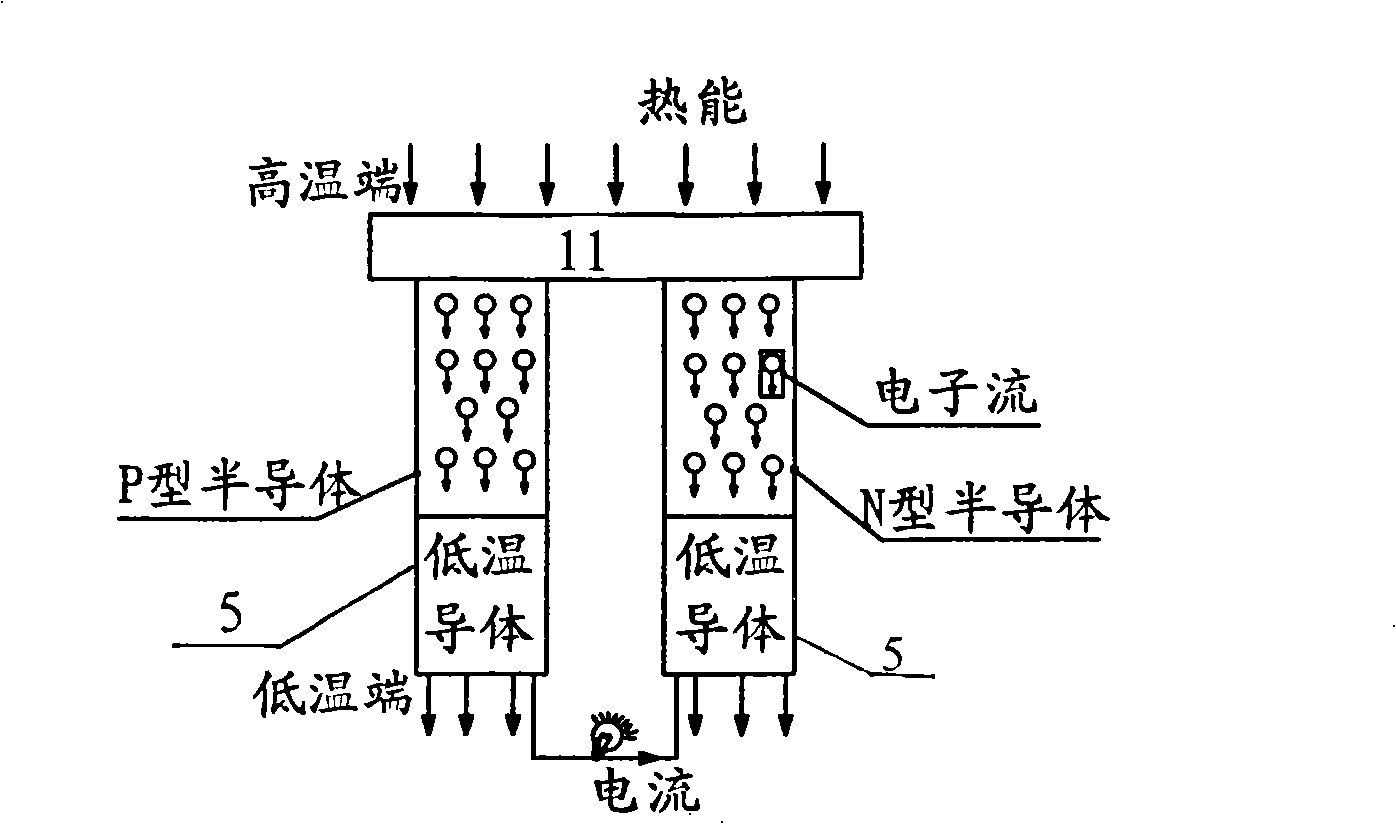

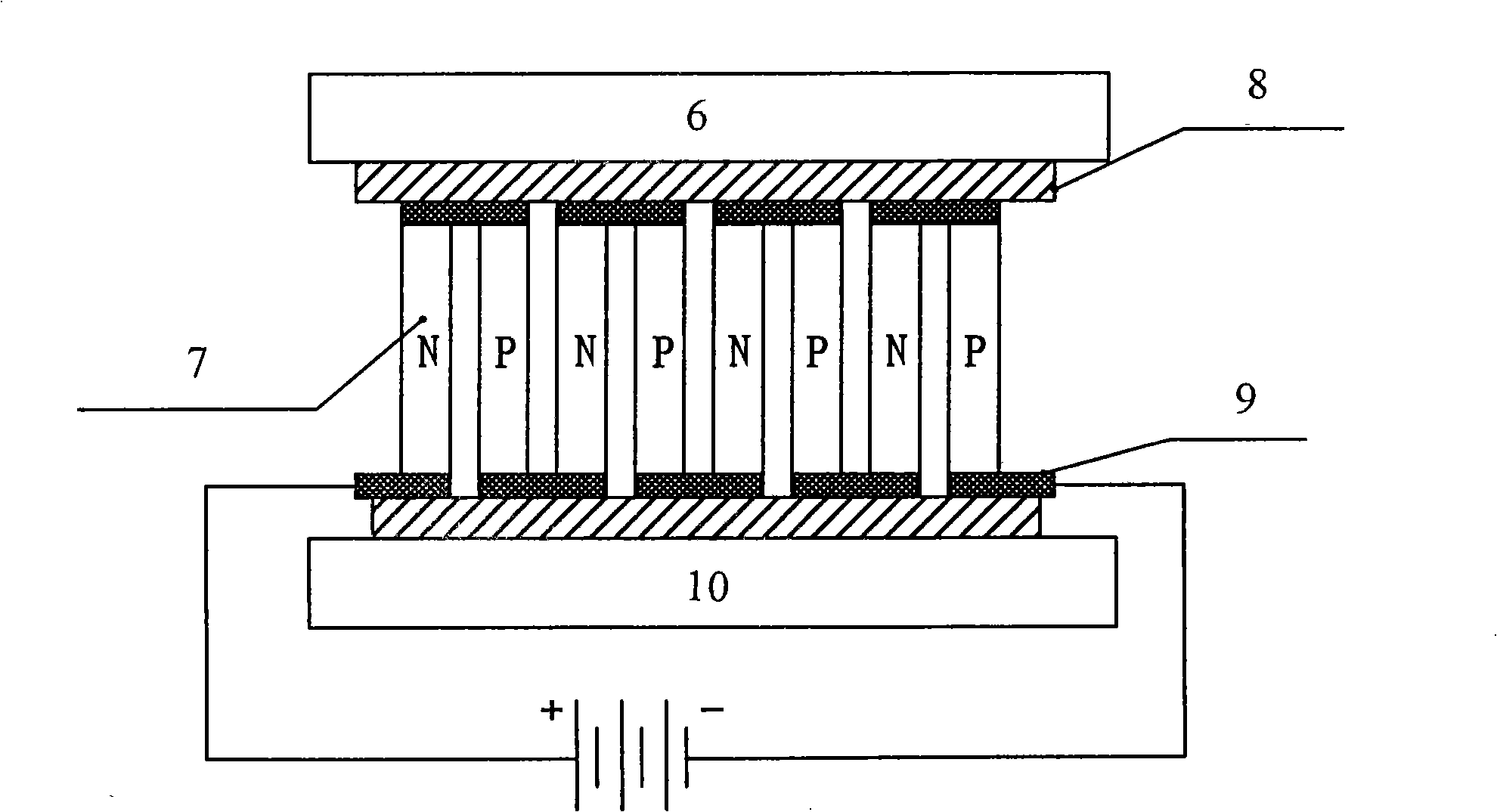

The invention provides a tunnel-typed residual-heat recovery semiconductor temperature difference generation method and a device. The generation method is characterized in that a movable heat source which emits residual heat runs pass a tunnel-typed heat collector which receives the heat emitted by the movable heat source and transmits the collected heat to a heat surface of a semiconductor temperature difference generation module; a radiator is arranged at one side of a cooling surface of the semiconductor temperature difference generation module; the cooling surface is cooled to a temperature much lower than that of the heat surface by the radiator, thus generating a large temperature difference at two end surfaces of the semiconductor temperature difference generation module; the semiconductor temperature difference generation module directly converts the temperature difference into the electric potential difference which is used as a power supply after being converted by a stabilizer circuit and AC / DC. The device of the invention comprises the semiconductor temperature difference generation module, the tunnel-typed heat collector, and a radiator; the method and the device of the invention have the advantages that the recovered residual heat energy can be directly converted into electric power, the generation process has no noise, no abrasion and no medium leakage, furthermore, the generator has the small volume, light weight, convenient movement, maintenance-free and long service life, etc.

Owner:无锡明惠通科技有限公司

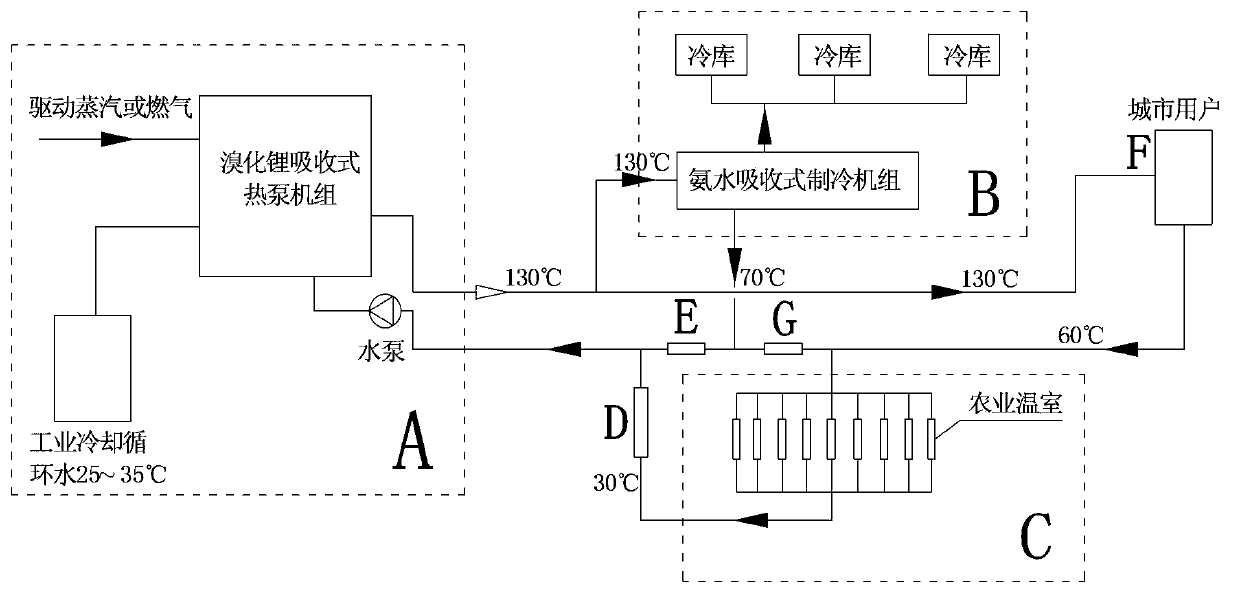

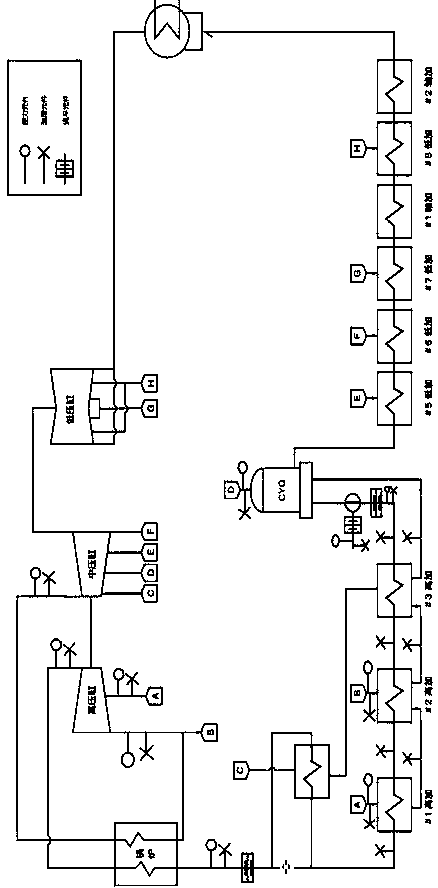

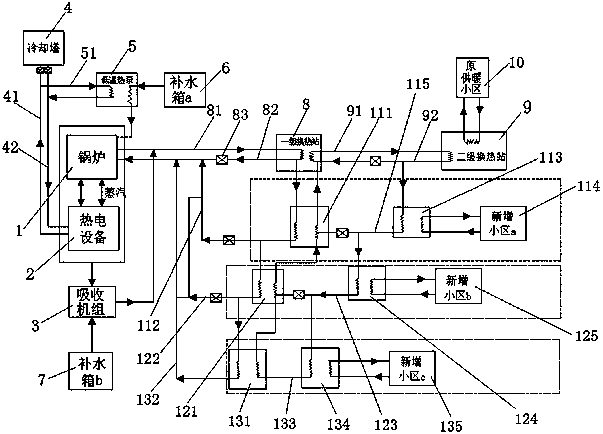

Large temperature difference centralized heating/cooling system

InactiveCN103968598ALower return water temperatureReduce power consumptionClimate change adaptationHeating and refrigeration combinationsAbsorption heat pumpElectric power

The invention discloses a large temperature difference centralized heating / cooling system. According to the large temperature difference centralized heating / cooling system, hot water output from a residual heat heating system can be divided into two ways: one way is connected with the cooling system through pipelines and the other way is connected with urban heat users through the pipelines; the cooling system is mixed with backwater of the heat supply users and then connected with heat users through the pipelines; the backwater of the heat supply users enters into an absorption heat pump in a heating system; the absorption heat pump is driven by steam or fuel gas to extract cooling circulating water residual heat; the residual heat is heated by a heater to the temperature of 130 DEG and heating water is discharged and enters into a next circulation. The large temperature difference centralized heating / cooling system has the benefits that as the back water of the system is recycled, the temperature of supply water / backwater reaches 130 / 30 DEG; as the temperature of the supply water / backwater is increased, the heat supply network delivery capacity is improved and the water pump power consumption in the system operation is reduced; moreover, an ammonium hydroxide absorption cooling unit can not only ensure cooling in winter, but also provide cold quantity for cold storages in spring, summer and autumn, power necessary for normal electric cooling is saved, the residual heat usage rate is improved and the energy conservation and emission reduction are facilitated.

Owner:DUNAN TIANJIN ENERGY SAVING SYST

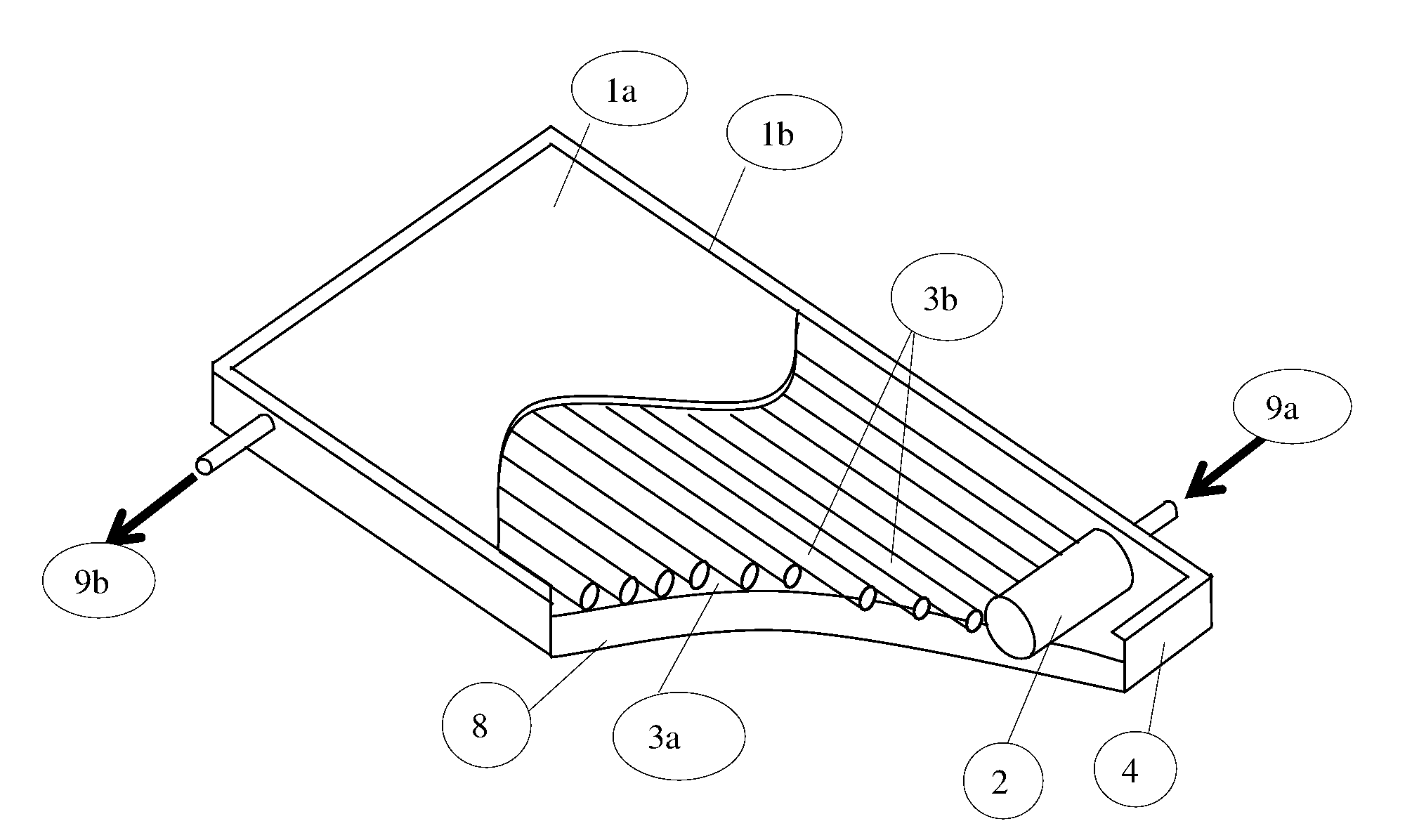

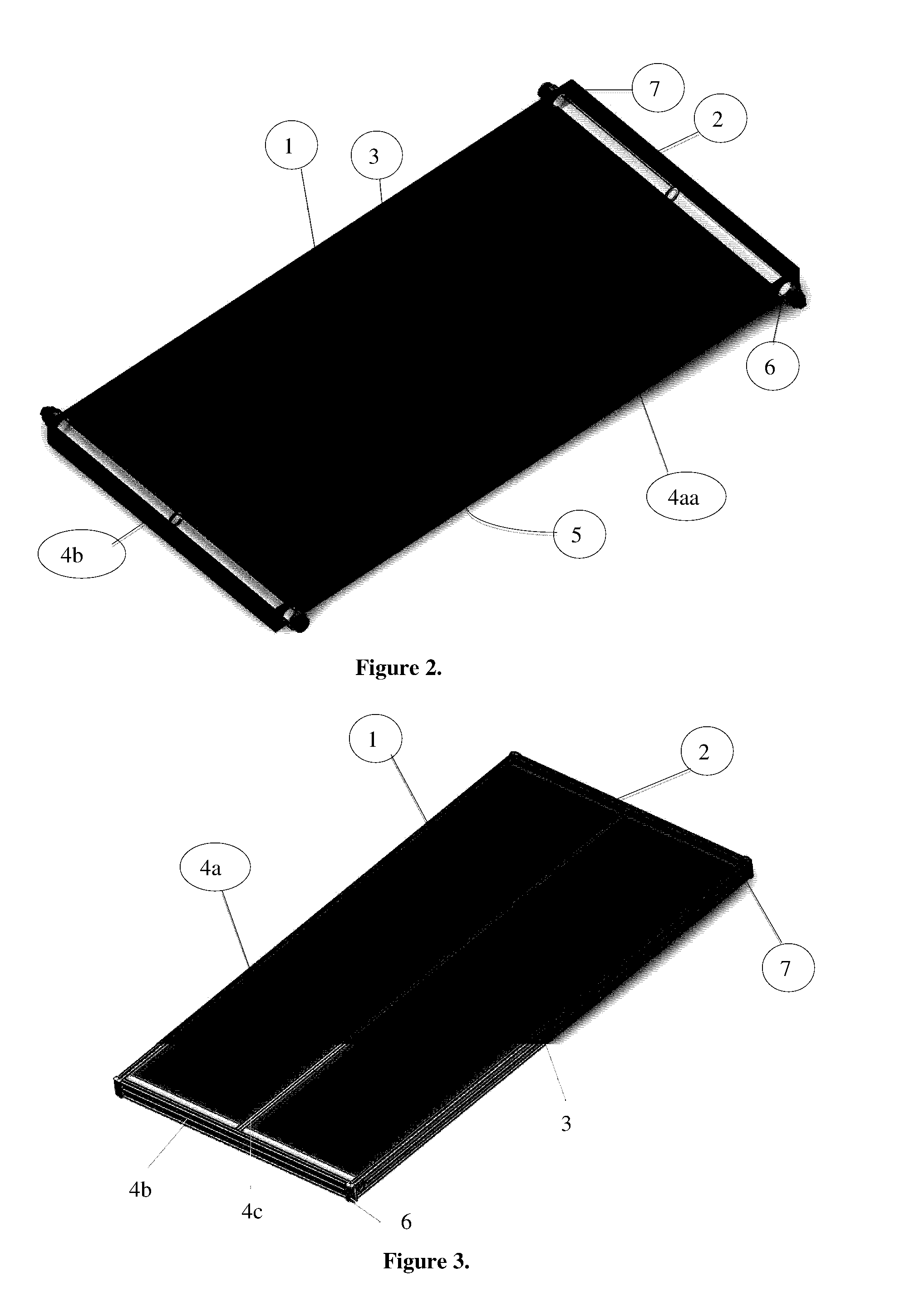

All-polymer flat plate heating solar panel with integrated controller

ActiveUS20150377515A1Provide stabilityProvide strengthSolar heating energyBatteries circuit arrangementsElectronic controllerEngineering

A flat plate heating solar panel comprised of polymer materials that can withstand relatively high temperatures. The polymer materials utilized in the panel have similar thermal expansion characteristics so that different components can by connected to each other without excessive stresses and damage during temperature changes, and with major components capable of being fabricated by molding processes, including extrusion and injection molding. An expansion joint or slot is provided in the enclosure frame to allow relative movement between the header connector and the frame in order to minimize stresses when large temperature differences exist between the absorber / header and the frame, and the slot design also provides a vent to relieve excessive air pressures inside the panel at high temperatures. An electronic controller with wireless capability, powered by a small photovoltaic solar cell with energy storage by a supercapacitor or an ultracapacitor, is integrated with the panel to operate a pump to circulate a heat transfer fluid through the panel when heating capability exists and when heat is needed to increase the temperature of the substance to be heated by the panel.

Owner:LONGVIEW GLOBAL ENTERPRISES

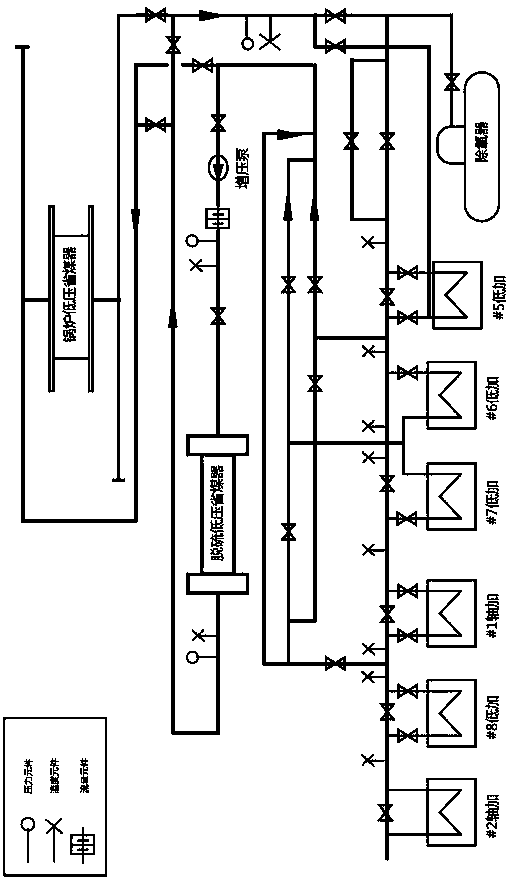

Modified calculation method for energy saving effect of low-pressure economizer

ActiveCN109388844AJudging the energy saving effectSimple methodDesign optimisation/simulationSpecial data processing applicationsFlue gasEngineering

The invention relates to a correction calculation method for energy-saving effect of a low-pressure economizer, belonging to the field of power generation. At present, there is no deep quantitative analysis of the deviation between the actual energy-saving effect and the design value. The invention comprises the following steps: 1, arranging a plurality of pressure, temperature and flow measuringpoints in the thermodynamic system of a steam turbine unit; 2, arranging a number of pressure, temperature and flow measuring points on the water side and flue gas side of the low-pressure economizer;3, carrying out thermodynamic performance tests of a steam turbine under two operating conditions of commissioning and shutdown of that low-pressure economizer, and obtain the energy-saving effect ofthe low-pressure economizer; 4. calcualting the heat transfer coefficient, logarithmic average temperature difference and heat transfer of low-pressure economizer under the test condition; 5, calculating the heat exchange of the corrected low-pressure economizer; 6, The energy-saving effect of the low-pressure economizer is obtained after the operation parameters are corrected. The invention canjudge the energy-saving effect of the low-pressure economizer, and can obtain the energy-saving effect of the corrected low-pressure economizer.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

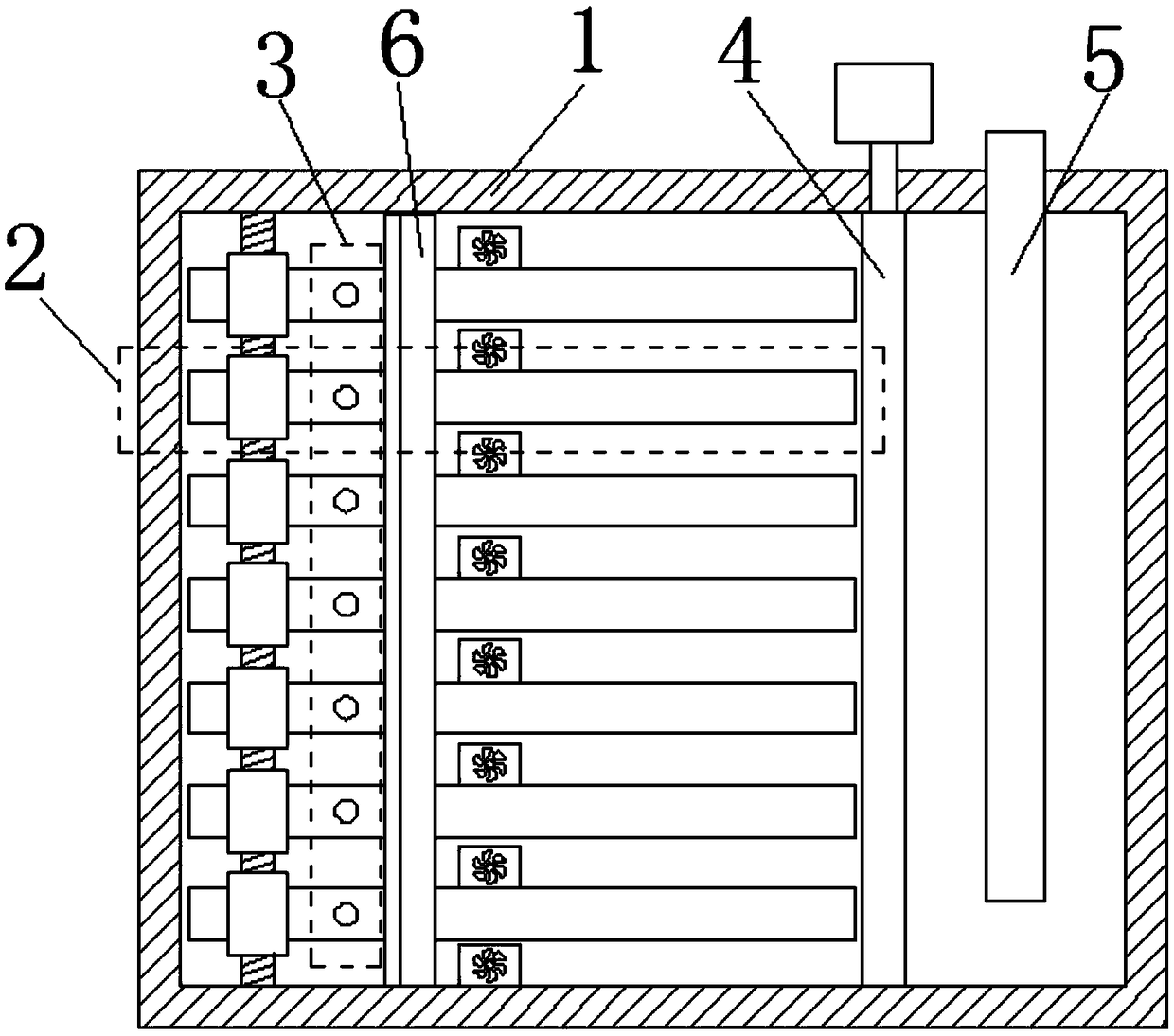

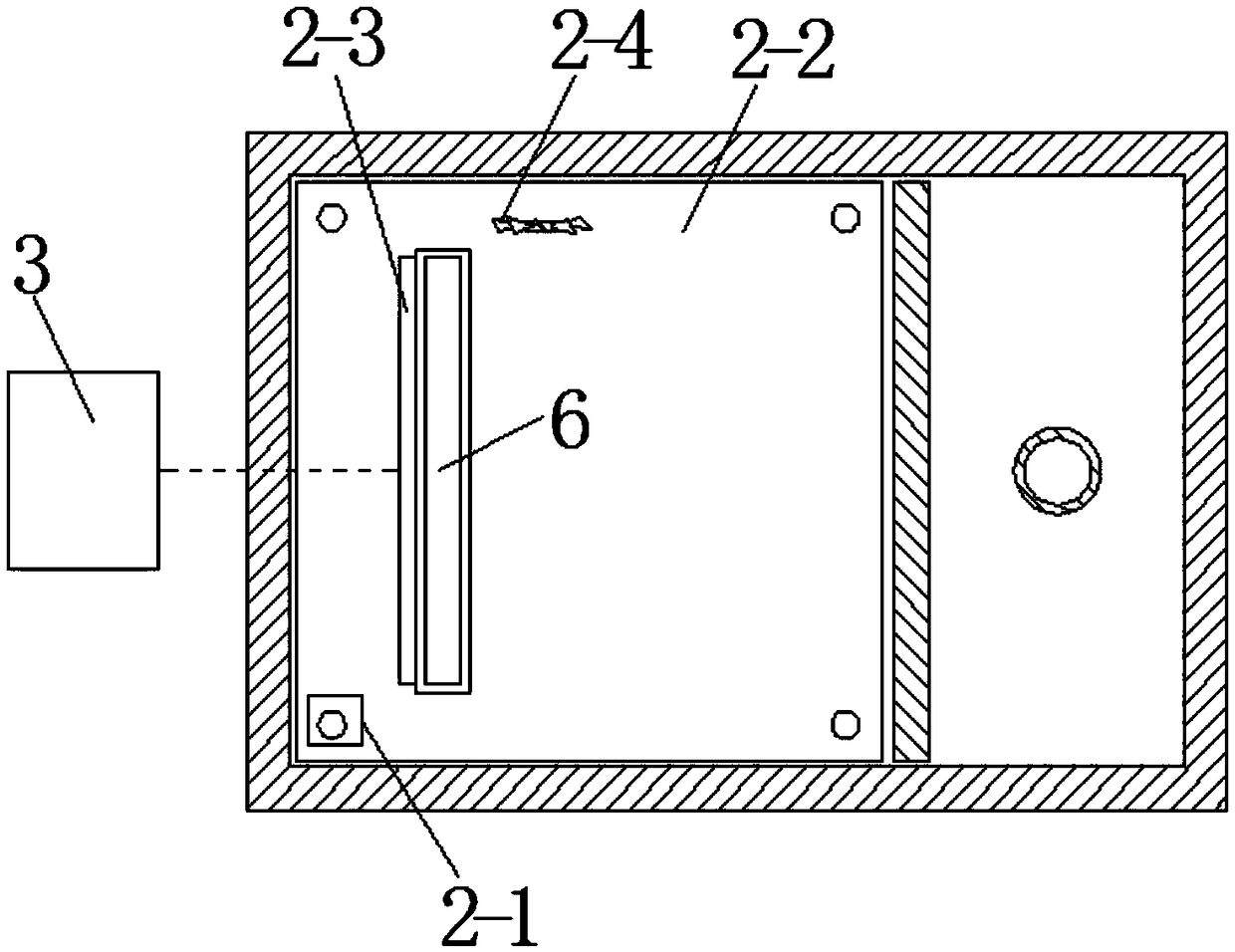

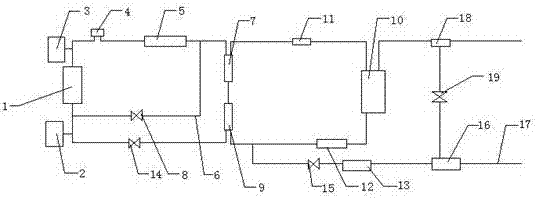

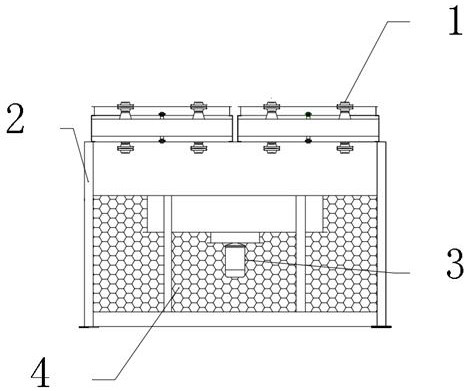

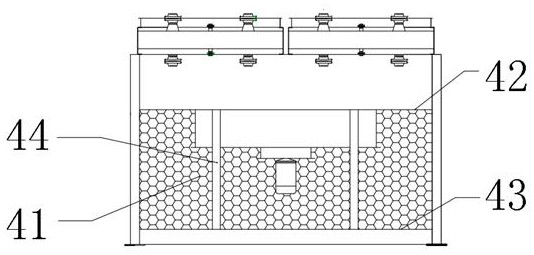

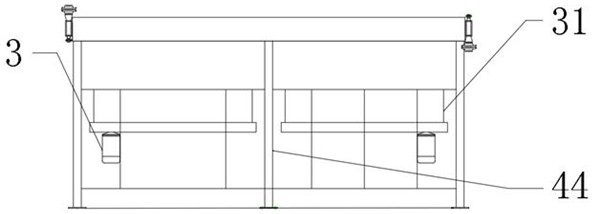

Building material volatility detection device simulating geothermal environment

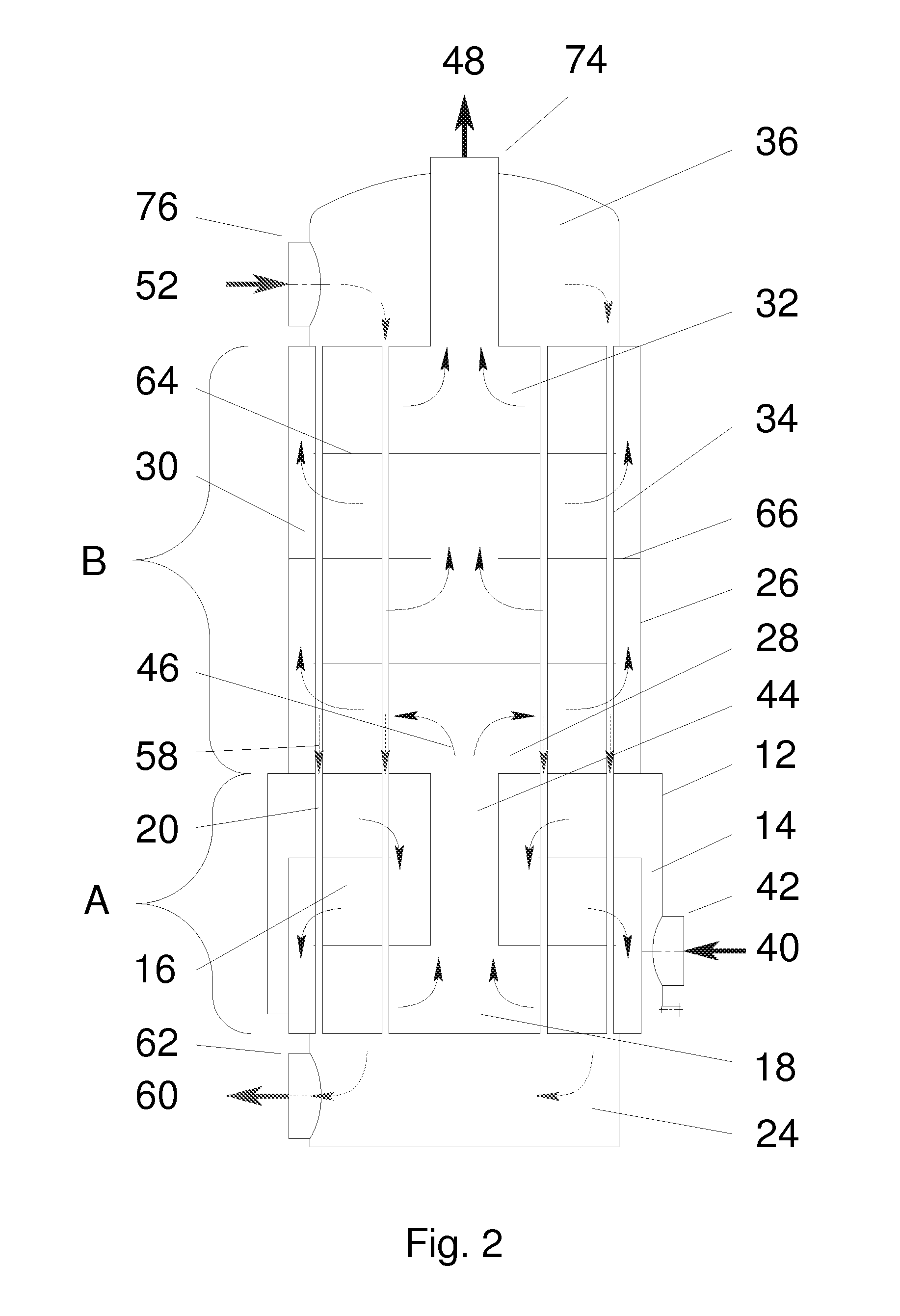

ActiveCN109270113AAchieve temperature controlStable temperatureMaterial thermal analysisEngineeringTemperature difference

The invention belongs to the technical field of volatility detection, and particularly relates to a building material volatility detection device simulating a geothermal environment. The building material volatility detection device comprises a box, layer units, a differential temperature device, an isolating valve, a sampling pipe and a building material plate, a plurality of layer units are parallelly arranged inside the box to form a plurality of differential temperature volatilization layers, the building material plate vertically penetrates the layer units, the differential temperature device comprises a plurality of differential temperature ends with different temperature, each differential temperature end is correspondingly arranged on one layer unit, detection plates are verticallyarranged in different differential temperature volatilization layers, each differential temperature volatilization layer individually controls temperature through the differential temperature device, so that the surfaces of small-sized building materials generate different-gradient temperature difference, volatilization experiments are performed under the condition of keeping the temperature difference, the actual temperature gradient of the small-sized building materials under geothermal conditions is simulated, and volatility detection experiments are performed.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

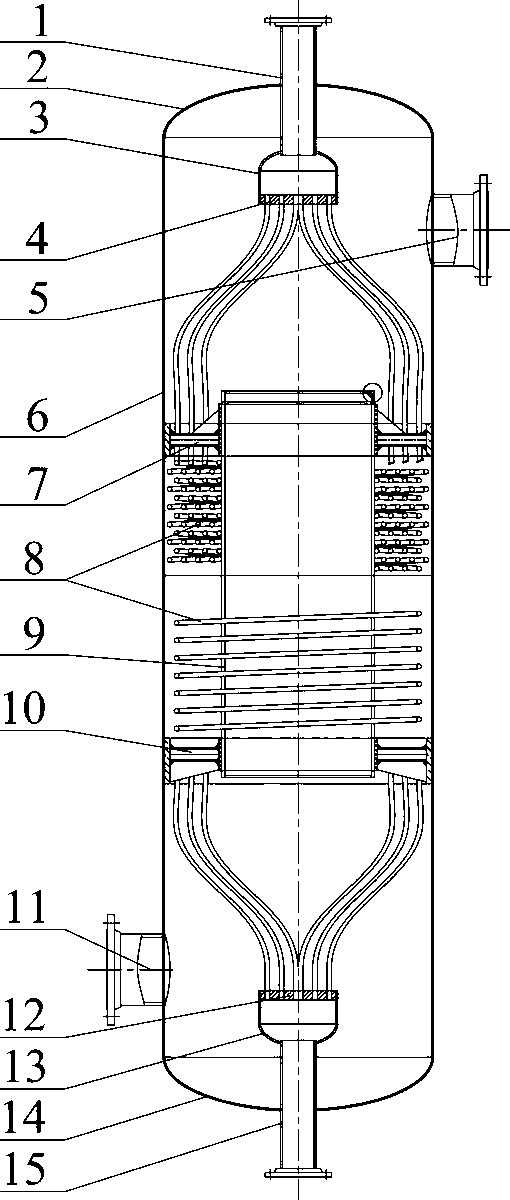

Low-temperature methanol-methanol winding tubular heat exchanger design and calculation method

InactiveCN102999707ANot easy to repairAvoid easy removalSpecial data processing applicationsMathematical modelProcess engineering

The invention provides a low-temperature methanol-methanol winding tubular heat exchanger design and calculation method and is mainly applicable to the fields of coal gas, coal methanol and other coal chemical industries comprising the fields of low-temperature gas purification and low-temperature liquefied separation for low-temperature methanol wash process at the temperature of -70 DEG C. The design and calculation process comprises basic structural design and a heat exchange process calculation process, wherein the process calculation comprises the steps of: determining qualitative temperature of a low-temperature methanol inlet / outlet, searching physical methanol parameters under the qualitative temperature and pressure, calculating logarithmic mean temperature difference, calculating a thermal load, determining the specification of a heat exchanger, determining a pipeline arrangement mode, and calculating a total heat transfer coefficient, total heat transfer area, effective heat exchange height of the heat exchanger and other main parts. According to the method, a complete mathematical model for low-temperature methanol-methanol winding tubular heat exchanger process calculation is provided, the mathematical model can be applied to the heat exchange process calculation process of winding pipe bundles, so that a whole set of methanol-methanol winding tubular heat exchanger is designed.

Owner:张周卫

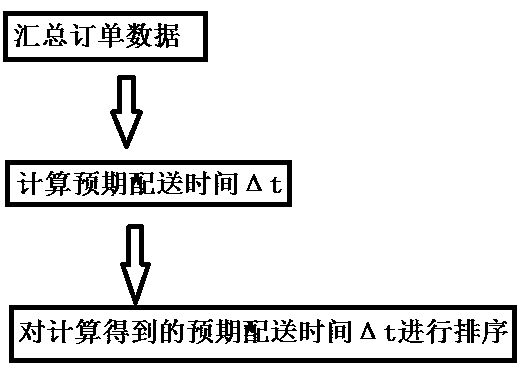

Fresh food distribution method

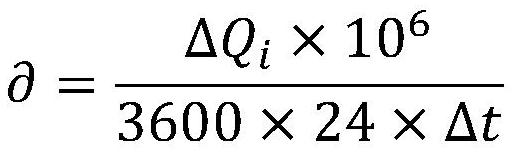

ActiveCN111445197AAvoid the same batch deliveryImprove automatic sorting efficiencyLogisticsBiotechnologyDelivery vehicle

The invention relates to a fresh food distribution method. The method comprises the following steps: 1, summarizing the types and weights of fresh foods in all online orders received on the same day into a fresh food order data table; 2, calculating the logarithm average temperature difference [delta]T and the expected delivery time [delta]t of the fresh food in the fresh food order data table; 3,sorting the calculated expected delivery time [delta]t: and selecting the fresh food of which [delta]t is greater than or equal to N into one class, and loading the fresh food of which [delta]t is greater than or equal to N into the same transport delivery vehicle, wherein N is a numerical value greater than 0 and specified by a user. According to the distribution method, fresh food with different temperature sensitivity degrees can be prevented from being distributed in the same batch, the fresh food with the minimum expected distribution time [delta]t is selected as the basis for heat preservation packaging and ice bag type selection, and more than 80% of distribution consumable cost can be saved.

Owner:BEIJING MISSFRESH ECOMMERCE CO LTD

Temperature regulating apparatus, exposure apparatus, and device manufacturing method

A temperature regulating apparatus includes a heat exchanger and regulates a temperature of a first medium by performing heat exchange between the first medium and a second medium via the heat exchanger. A regulating operation unit generates a flow rate regulating signal so that the temperature of the first medium flowing out from a primary side outlet of the heat exchanger becomes equal to a target temperature. A control valve regulates a flow rate of the second medium based on the flow rate regulating signal. A correcting operation unit (a) calculates, based on temperatures detected by first, second, third and fourth temperature sensors, a heat exchange amount of the heat exchanger, a logarithmic mean temperature difference or an average temperature in the heat exchanger, and the flow rate of the second medium, (b) calculates an overall heat transfer coefficient of the heat exchanger based on the calculated heat exchange amount and the calculated logarithmic mean temperature difference or the calculated average temperature, and the flow rate of the second medium, (c) obtains a ratio (ΔG) of a change (Q2-Q′2) in the heat exchange amount to a change (ΔF2) in the flow rate of the second medium based on the calculated flow rate (F2) of the second medium and the calculated overall heat transfer coefficient (K), and (d) corrects a gain of the regulating operation unit based on the obtained ratio.

Owner:CANON KK

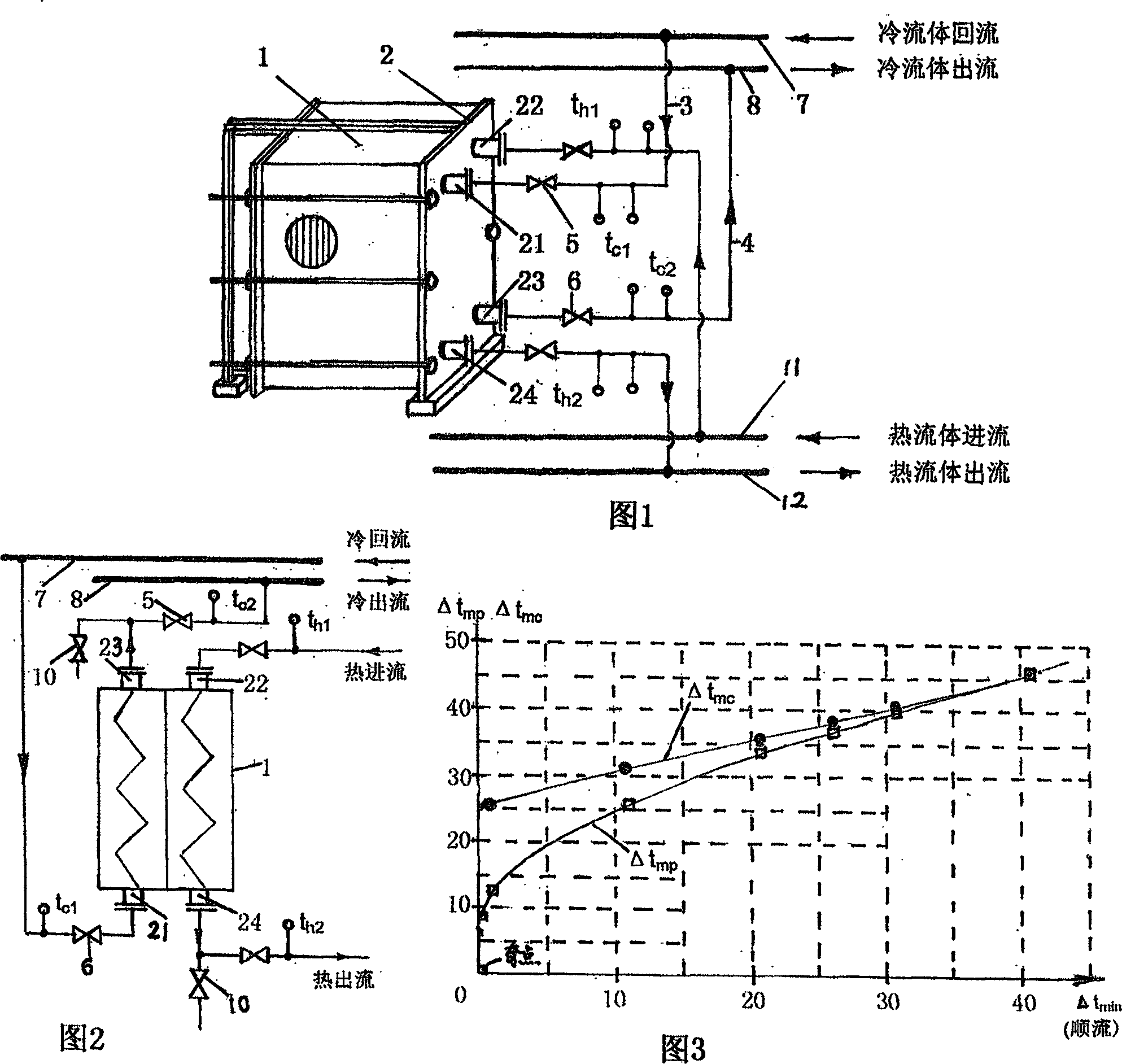

Plate heat exchanger with no deposited scale, and heat exchange mode

InactiveCN1873362ARealize \"Zero Emissions\"Realize functionCorrosion preventionHeat exchange apparatusEngineeringProduced water

The present invention relates to an improvement technique of heat exchanger, in the concrete, it is a plate type heat exchanger which does not produce water scale deposit and its water exchange mode. It is characterized by that in fixed tight-pressing plate side of general plate-type heat exchanger, the cold fluid inlet of upper portion of said fixed tight-pressing plate is connected with cold fluid backflow manifold by means of pipeline, the cold fluid outlet of lower portion of said fixed tight-pressing plate is connected with cold fluid discharge manifold by means of pipeline. Said invention adopts a downflow heat exchange mode, can make cold fluid and hot fluid be flowed from top to bottom in the plate-type heat exchanger, so that said invention utilizes the impact action of downwards-flowing fluid and gravity action of water scale granules self-body so as to implement the 'zero discharge' of said plate-type heat exchanger and on-tine 'automatic blowdown' function.

Owner:王正方 +1

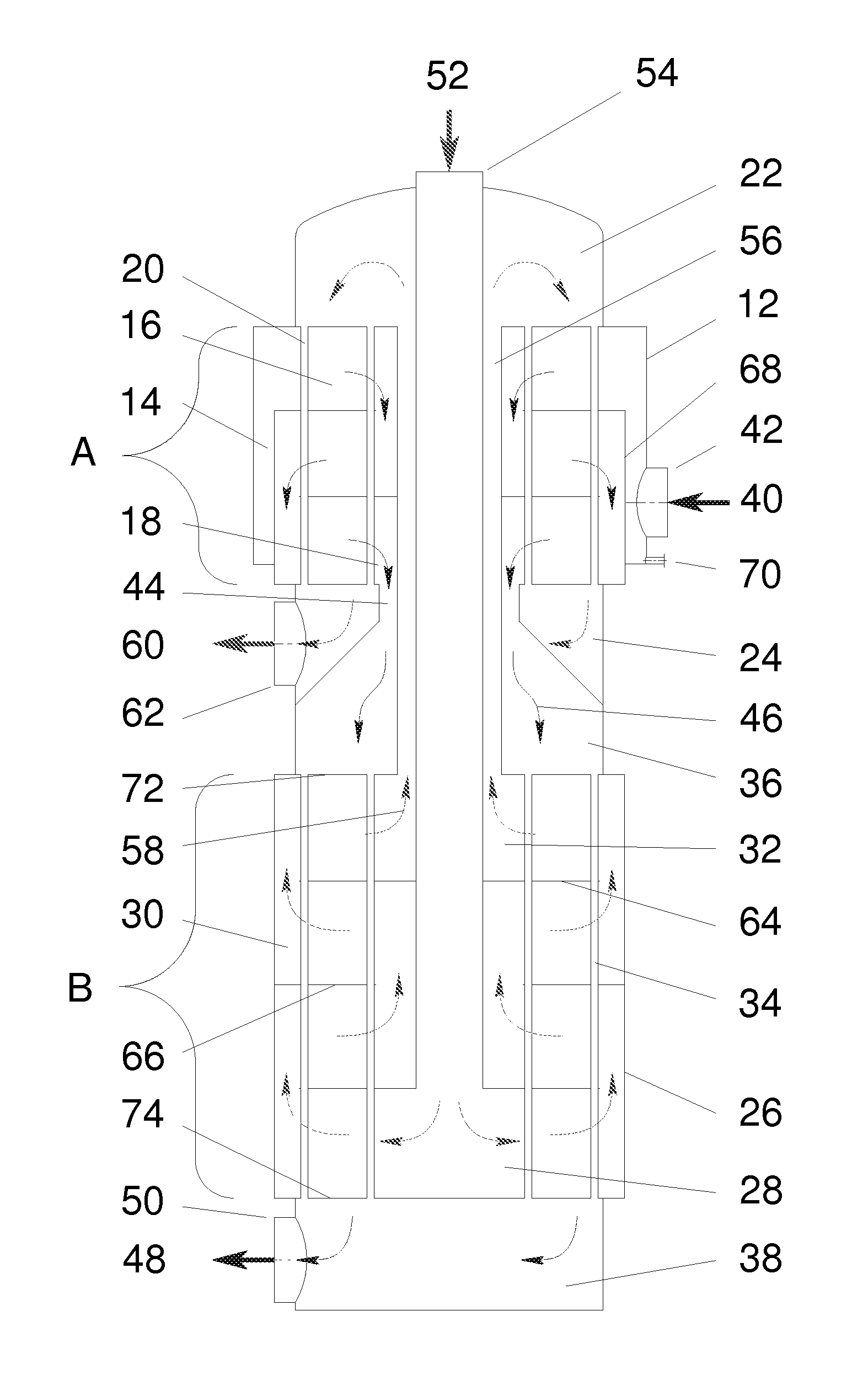

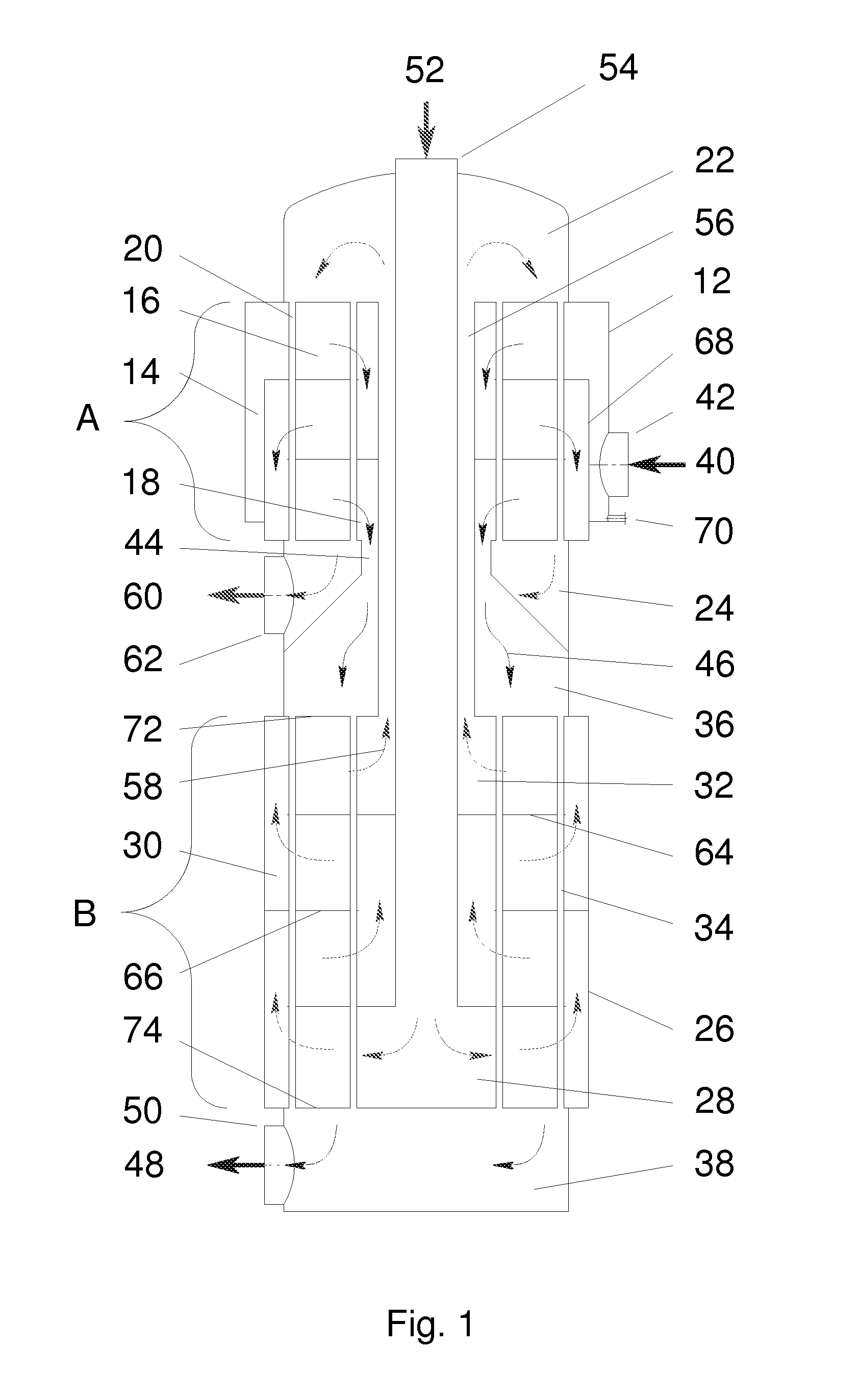

Shell And Tube Heat Exchangers

InactiveUS20110272124A1Reducing differential thermal growthReduction in differential growthCorrosion preventionHeat exchanger casingsShell and tube heat exchangerEngineering

A process for exchanging heat in a shell and tube gas-to-gas heat exchanger between a plurality of gases, said process comprising passing a cold first gas in parallel flow to a second hot gas to provide a warmer first gas; and passing said warmer first gas in counter-current flow to a hot third gas to provide a cooler said third gas. The invention provides increased minimum tube wall temperature within the exchanger for given process conditions while maintaining a high log mean temperature differential allowing for the prevention of corrosion from entrained corrosive vapours or entrained corrosive mist with a minimal increase in effective area.

Owner:CHEMETICS

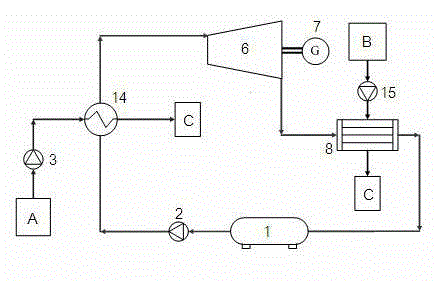

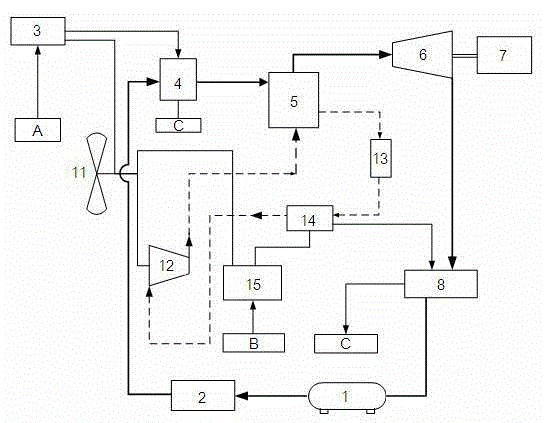

Method and device for utilizing ocean temperature difference to generate electricity

ActiveCN102213199BLarge temperature differenceIncreased efficiency of closed loopsMachines/enginesMechanical power devicesThermal energyOcean thermal energy conversion

The invention provides an ocean thermal energy conversion method and an ocean thermal energy conversion device. The method comprises the following steps of: heating a low-boiling-point working medium by using hot seawater on a surface of ocean; evaporating the low-boiling-point working medium; feeding into a turbine to push a turbo generator set to work for power generation; condensing working medium gas which is exhausted from the turbine into liquid by using cold seawater on a deep layer of the ocean; heating by using the hot seawater; feeding into the turbine to make the working medium gasevaporated; pushing the turbo generator set to work for the power generation; cyclically executing the steps; and continuously carrying out power generation. Power is generated by using ocean surfacewind power, a heat pump device is driven by the power, the temperature of the working medium is further raised by using a medium of the heat pump device, and the volume expansion ratio of the workingmedium is improved; and the temperature of the cold seawater is further reduced by using the medium of the heat pump device, the working medium exhausted gas is condensed by using the low-temperatureseawater, and a condensing effect of the working medium exhausted gas is improved. The method and the device improve the efficiency of closed cycle generation of ocean thermal energy conversion, realize the comprehensive utilization of ocean thermal energy and wind energy, have an important practical value, provide environment-friendly energy sources, and are easy to use and promote in large scale.

Owner:DONGFANG TURBINE CO LTD +2

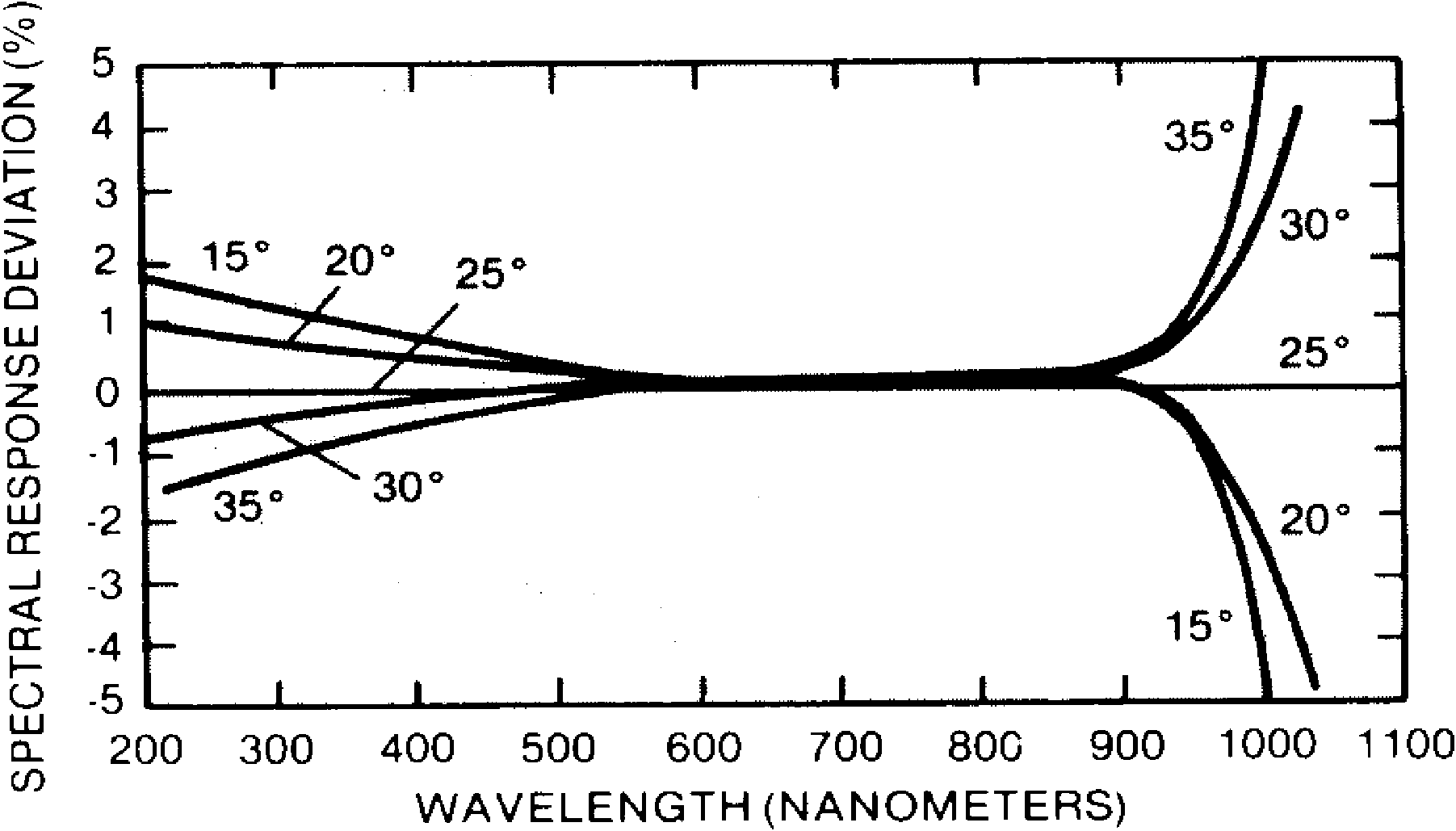

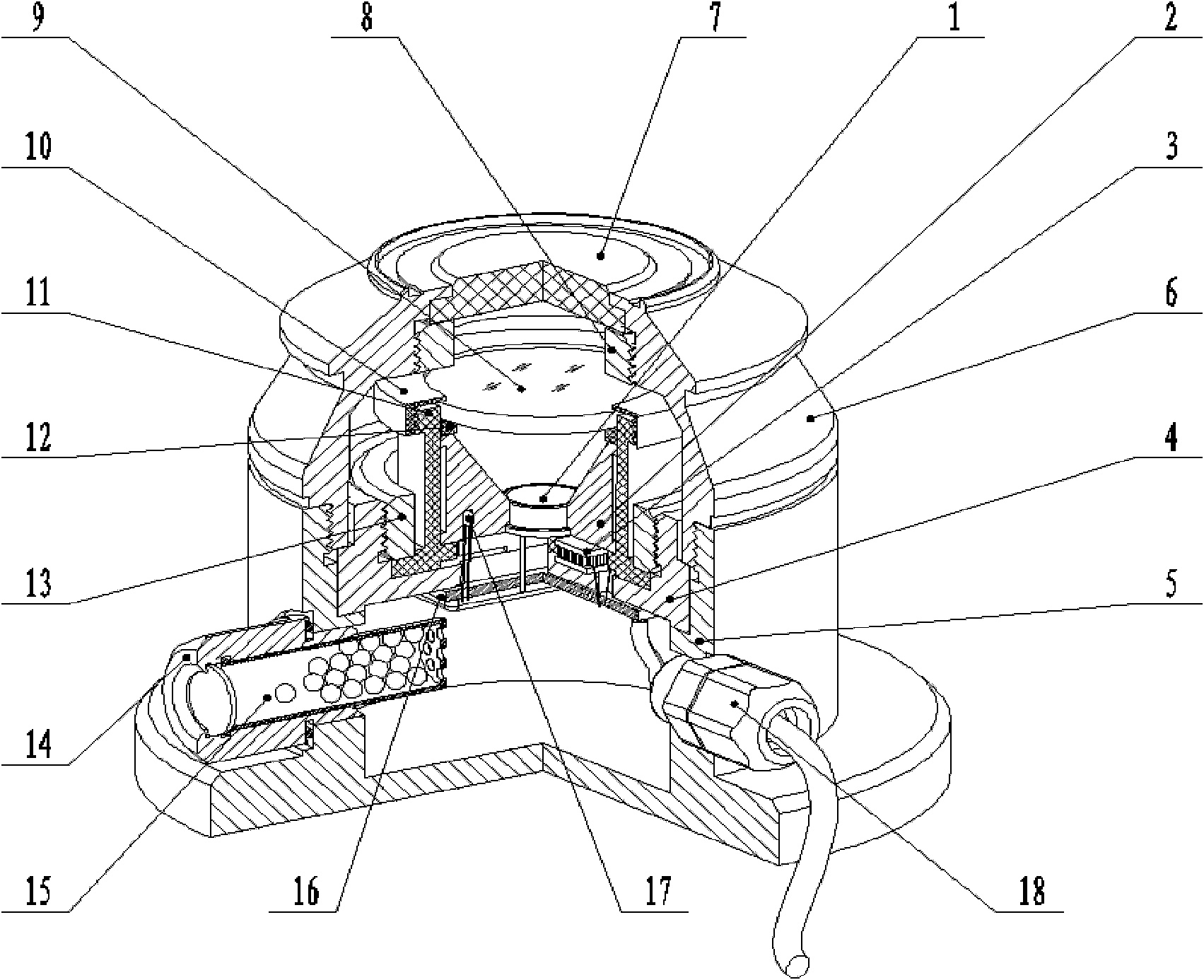

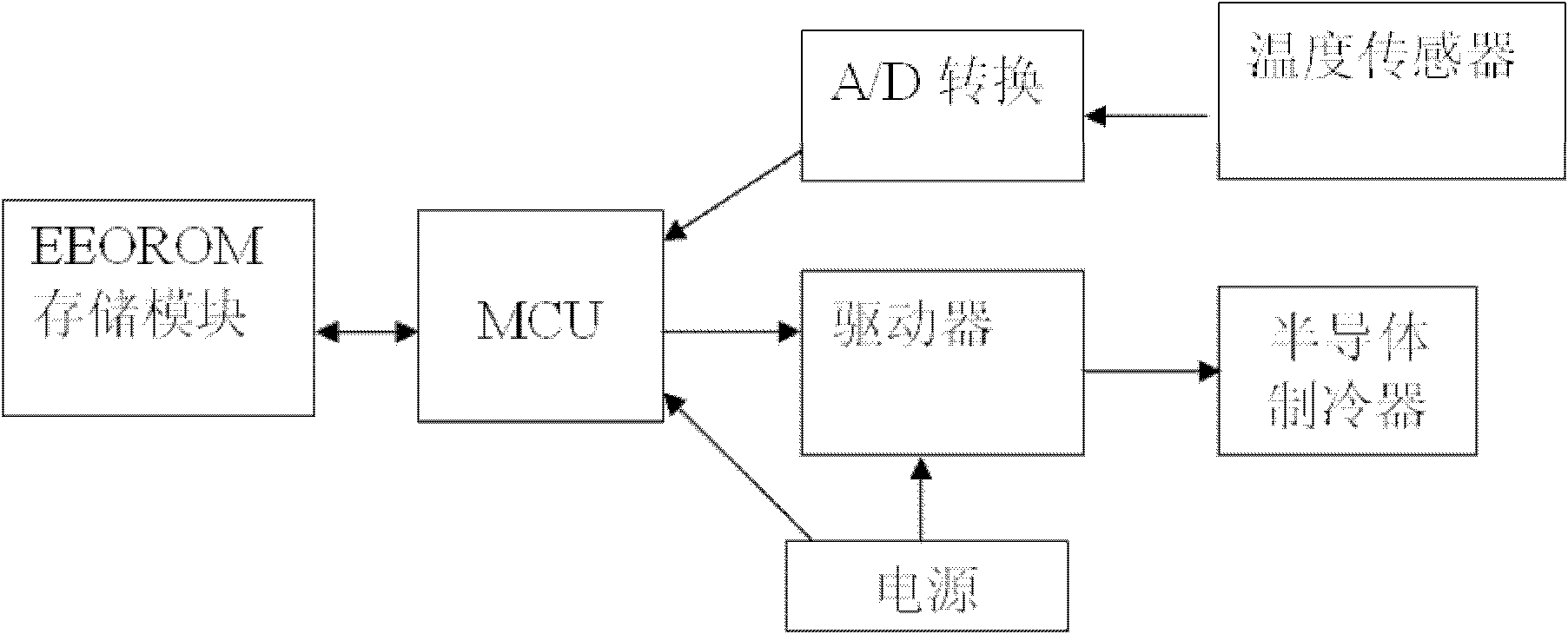

Ultraviolet sensor possessing constant temperature apparatus

InactiveCN102494766AHigh measurement accuracyReduced diffusion ratePhotometry using electric radiation detectorsWorking temperatureRadiation sensor

The invention relates to an ultraviolet sensor possessing a constant temperature apparatus. The ultraviolet sensor comprises a shell and a photoelectric inductor. The constant temperature apparatus is arranged in the shell. The photoelectric inductor is installed in the shell through the constant temperature apparatus. The constant temperature apparatus collects a working temperature of the photoelectric inductor in the shell and compares the collected working temperature with a preset temperature so that the photoelectric inductor works in a preset temperature range. According to the invention, an adverse effect of a temperature characteristic of the photoelectric inductor on radiation measurement can be radically eliminated; measuring precision of an ultraviolet radiation sensor can be greatly increased; an actual need of all-terrain, high-precision and perennial field ultraviolet radiation monitoring can be satisfied. One-end strengthened heat insulation effect can be formed through a heat insulation tube so as to reduce a constant temperature point heat flow diffusion rate. One-end strengthened heat dissipation performance is formed to reduce a general structure design scheme of a continuous increasing trend of cold and hot end temperature difference. Therefore, temperature control performance can be reinforced. Power consumption of the constant temperature control can be reduced. A structure is compact.

Owner:江苏省无线电科学研究所有限公司

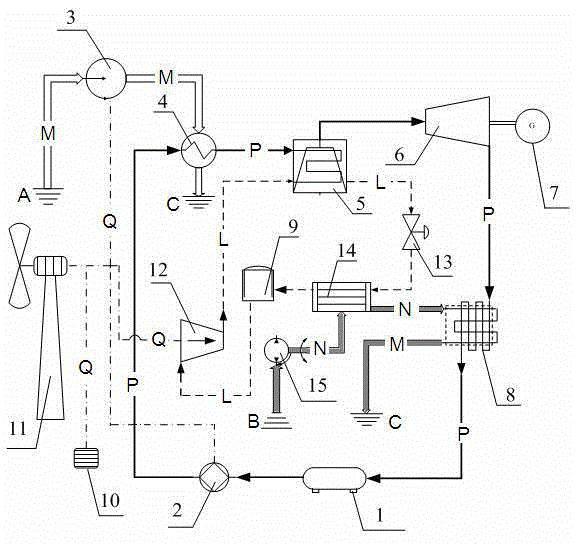

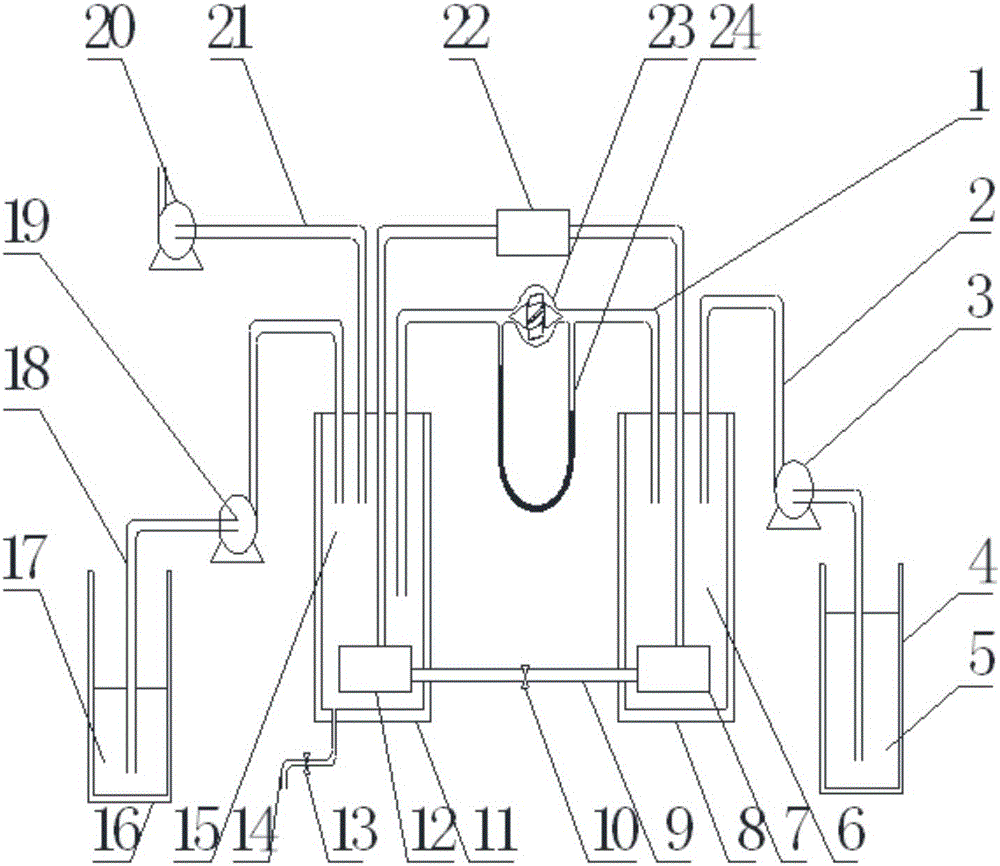

Heat pump-reinforced salt-concentration-differential electricity generation device by vapor differential pressure energy method under positive temperature difference

ActiveCN105736269AImprove energy efficiencyReduce lossMachines/enginesMechanical power devicesDifferential pressureWater vapor

The invention provides a heat pump-reinforced salt-concentration-differential electricity generation device by a vapor differential pressure energy method under positive temperature difference. The electricity generation device comprises a heat pump heating circulating device and a salt-concentration-differential electricity generation device by the vapor differential pressure energy method. The heat pump heating circulating device comprises a condenser, a heat pump pipeline, a throttle valve, an evaporator and a compressor; the salt-concentration-differential electricity generation device by the vapor differential pressure energy method comprises a low-pressure container, a high-pressure container, an expander, a differential pressure gauge and an expander pipeline; by heat pump heating circulating, heat in a concentrated solution is absorbed so as to lower the temperature of the concentrated solution, the heat is released in a dilute solution so as to increase the temperature of the dilute solution, so that temperature inversion difference generated by heat absorption through evaporation of water in the dilute solution and heat release through condensation of vapor in the concentrated solution is effectively offset, the positive temperature difference is maintained and enlarged, further positive saturated vapor differential pressure is maintained and enlarged, and the expander is promoted to do work; the energy utilization efficiency is high; the loss is small; the cost is cheap; the applicability is good; the machining is simple and convenient.

Owner:CHINA UNIV OF MINING & TECH

Heat pump water heater device

The invention relates to a heat pump water heater device, which includes an evaporator, an air inlet device and an air outlet device are respectively arranged on both sides of the evaporator, and a pipe on one side of the evaporator is connected to a gas-liquid-water separator, and the gas-liquid-water The pipeline on one side of the separator is connected to the compressor, and the compressors are respectively connected to the defrosting pipeline and the first condenser. The defrosting pipeline is provided with a bypass defrosting solenoid valve, and the other end of the defrosting pipeline is connected to the evaporator. The present invention is equipped with a water quality softening device, which softens the usual hard water and then heats it for use, so as to delay and reduce the fouling degree of the inner wall of the water tank, and improve the energy efficiency and heat exchange effect of the heat pump water heater. The condenser meets the requirements of large temperature difference and small flow rate during direct heating operation of the system and small temperature difference and large flow rate during circulating operation. It is equipped with defrosting pipelines to ensure smooth pipelines, realize energy reuse, and ensure water temperature at the same time.

Owner:安徽红叶节能电器科技有限公司

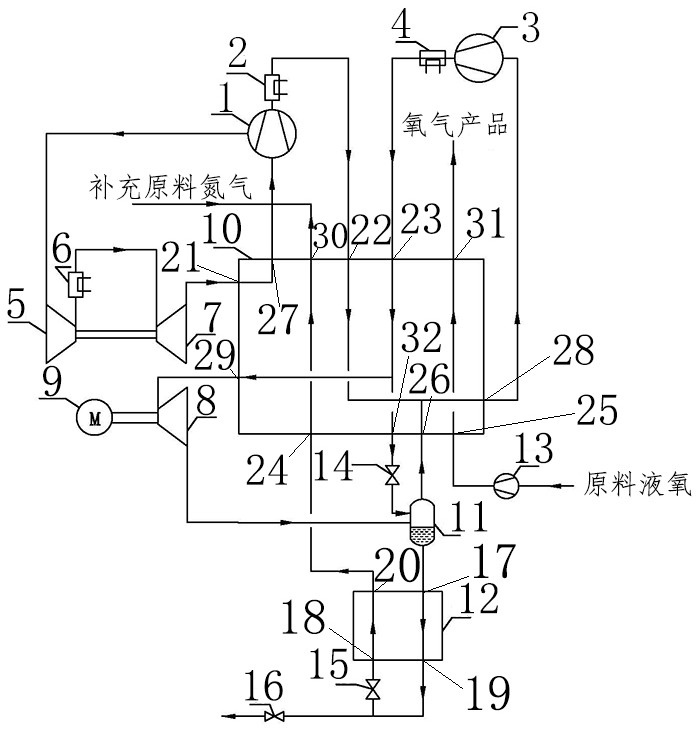

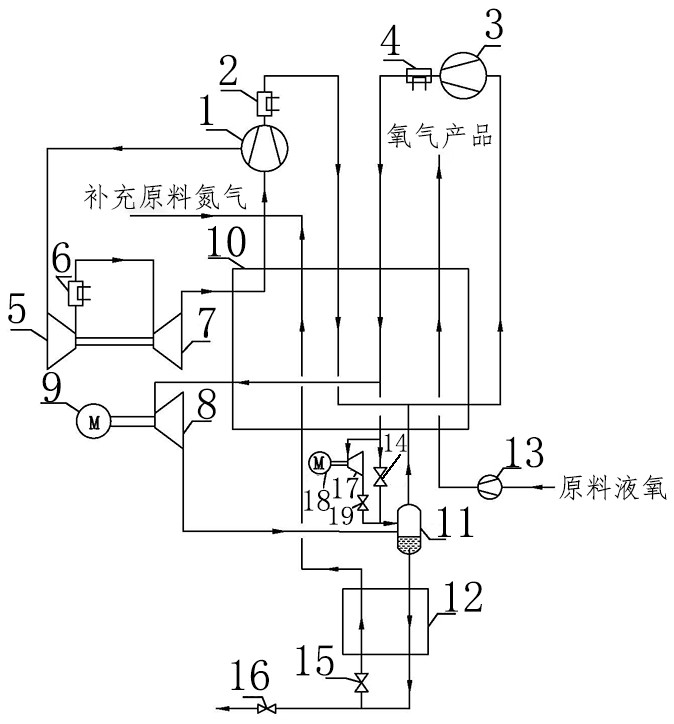

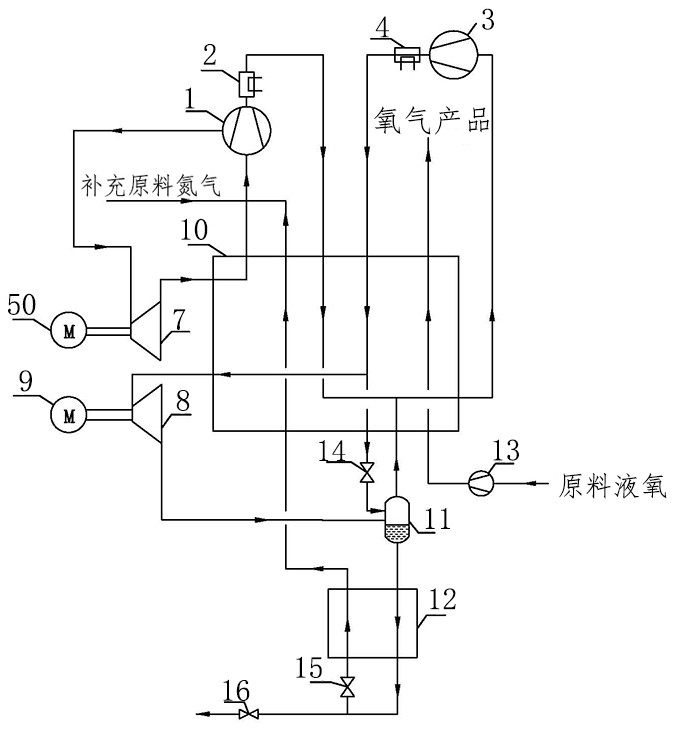

Pressurizing vaporization device for recovering liquid oxygen cold energy and using method of pressurizing vaporization device

ActiveCN114234556AReduce irreversible lossAchieve the same productionSolidificationLiquefactionProcess engineeringNitrogen gas

A boosting vaporization device for recovering liquid oxygen cold energy comprises a nitrogen compression system, an expansion refrigeration system, a liquid oxygen boosting system and a heat exchange system which are connected with one another through pipelines and valves. The nitrogen compression system consists of a first circulating nitrogen compressor, a first circulating nitrogen compressor aftercooler, a second circulating nitrogen compressor and a second circulating nitrogen compressor aftercooler; the expansion refrigeration system is composed of a nitrogen pressurization expansion machine, a nitrogen expansion machine and other auxiliary parts, nitrogen circulation and cooperation of the nitrogen circulation and the liquid oxygen vaporization reheating process are utilized, so that the overall logarithmic average temperature difference of the heat exchanger is within an extremely low range, irreversible losses of the heat exchanger are greatly reduced, and the heat exchange efficiency is improved. Therefore, recovery of high-grade cooling capacity of the liquid oxygen is realized on the basis of pressurizing and vaporizing the liquid oxygen, and the recovered cooling capacity is embodied in the form of liquid nitrogen.

Owner:HANGZHOU HANGYANG

System for concentrative warming through extracting temperature with large temperature difference via heat pump technology

InactiveCN107664314AIncrease heating capacityLess investmentHeat recovery systemsLighting and heating apparatusResidenceEngineering

A system for concentrative warming through extracting temperature with large temperature difference via a heat pump technology comprises original heating equipment. Back water in a heating back waterpipeline of the original heating equipment works as a low-temperature heat source of a heat pump system; hot water can be supplied to a residence terminal system for heating after work of the low-temperature heat pump system; if a community heating system is further increased, back water in the heating back water pipeline of the upper-stage newly-added heating system works as a low-temperature heat pump; heating performance coefficient of the heat pump is increased, so temperature of the back water can be reduced to a lower degree when a present concentrative heat-supply pipe network is remained the same; a back water temperature difference of the whole concentrative heat-supply pipe network can be increased; and heat supplying capacity can be greatly improved when the present pipe networkis remained the same. Compared with a common pipe network re-arrangement way, the scheme requires low cost and short construction period, and is flexible to arranged; huge investment for pipe networkrearrangement can be solved; and problems of traffic jam and troubles to resident life during the construction can be solved.

Owner:山东富达清洁热能科技有限公司

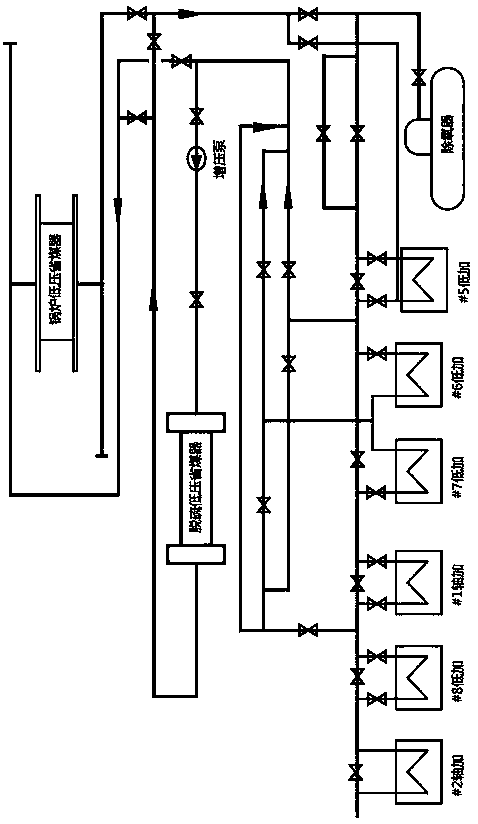

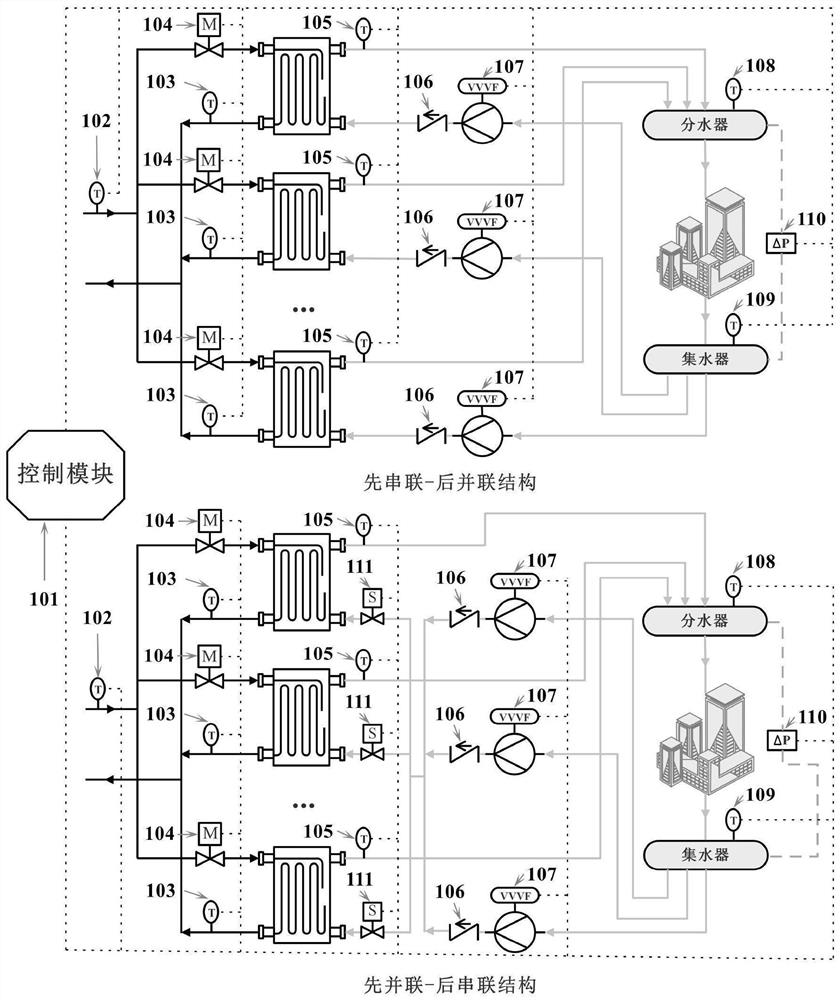

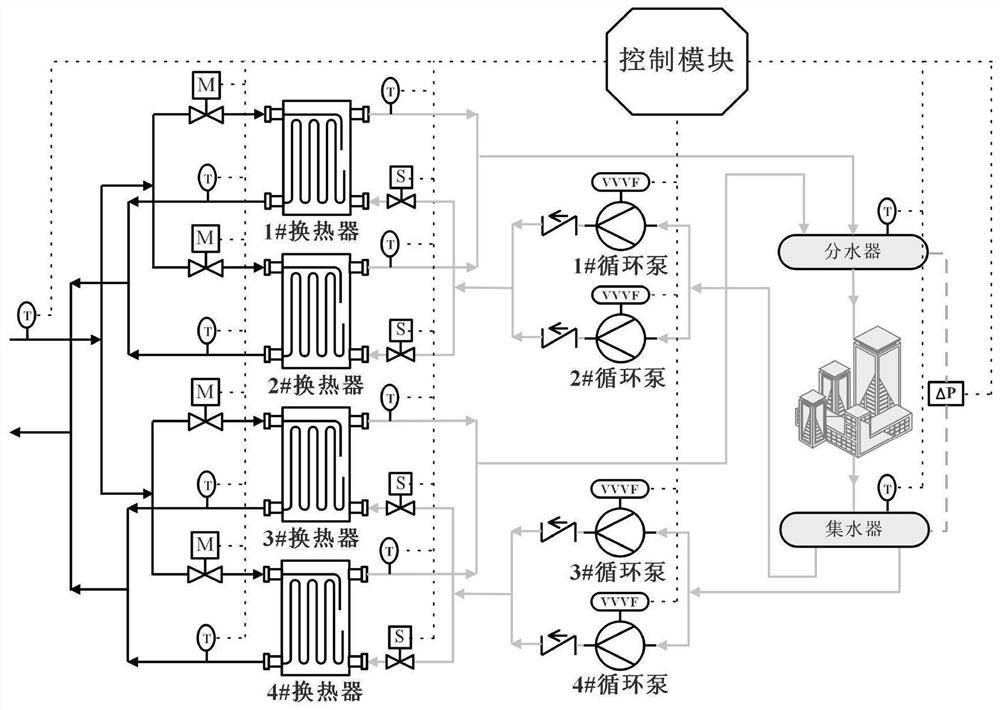

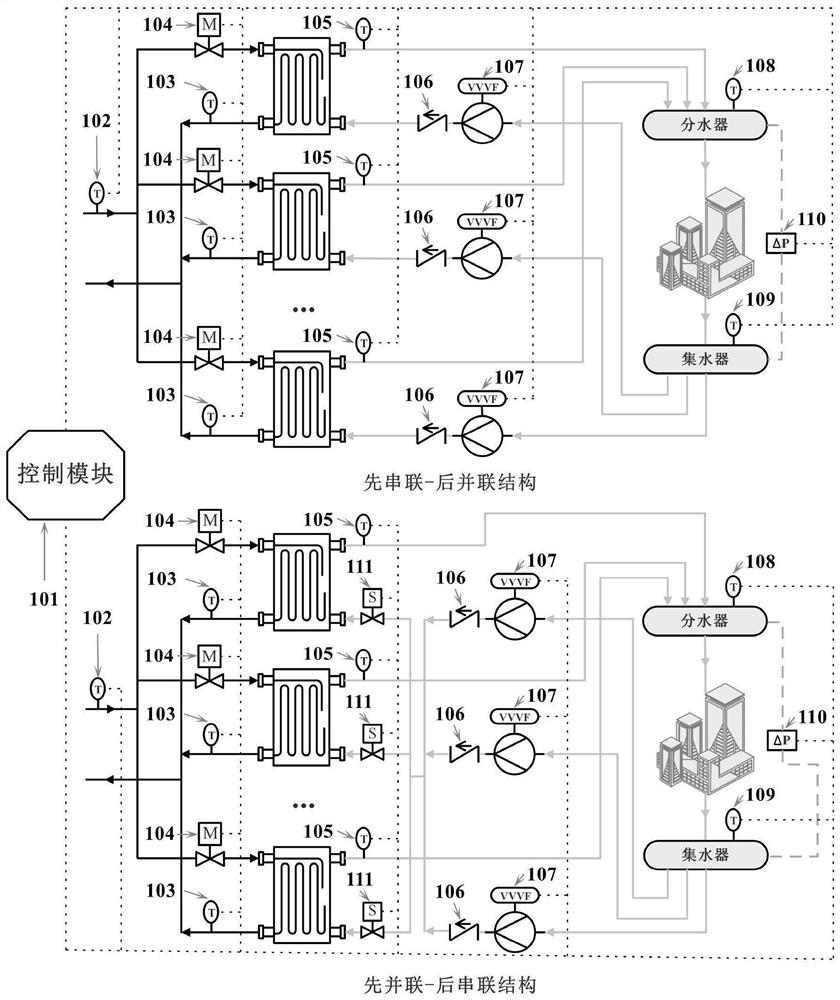

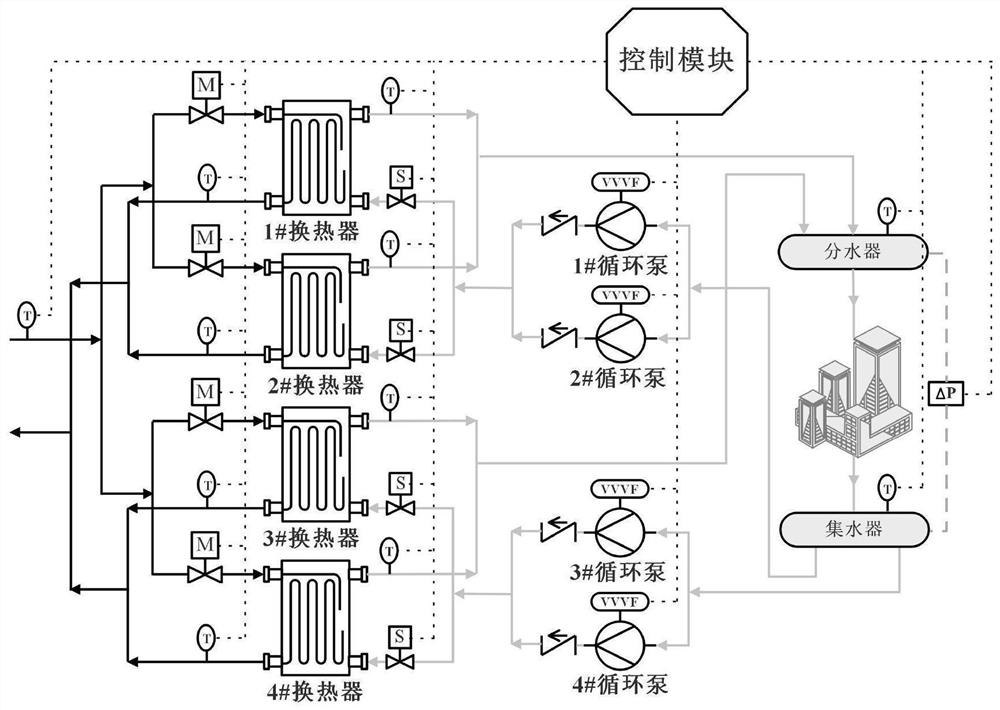

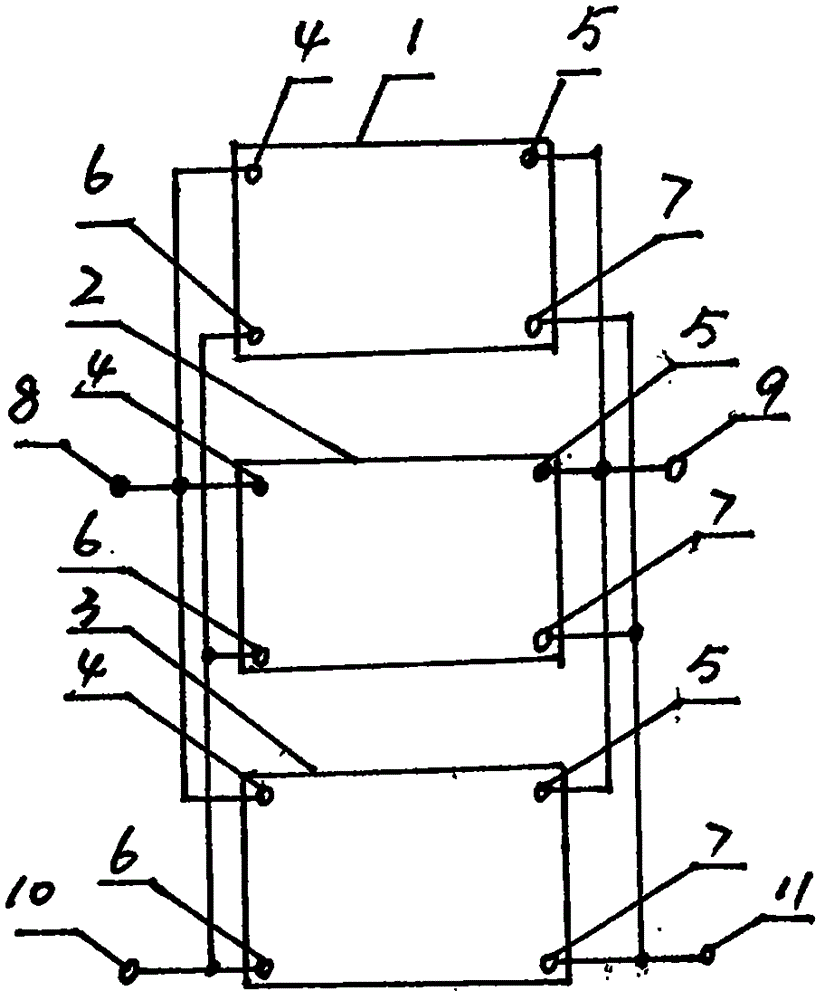

Operation switching adjusting device for heat exchangers and circulating pumps of heat exchange station and working method

ActiveCN113028492ARealize automatic increase and decrease adjustmentAvoid Ineffective Bypass PhenomenonLighting and heating apparatusCentral heating componentsSolenoid valveFrequency conversion

The invention discloses an operation switching adjusting device for heat exchangers and circulating pumps of a heat exchange station and a working method. The device comprises a control module, a heat exchange station water inlet manifold water temperature sensor, heat exchanger primary water outlet pipe water temperature sensors, heat exchanger primary water inlet pipe electric control valves, heat exchanger secondary water outlet pipe water temperature sensors, check valves, circulating pump frequency conversion speed regulators, a water distributor water temperature sensor, a water collector water temperature sensor, a water distributor and collector pressure difference sensor and heat exchanger secondary water return pipe electromagnetic valves. The logarithmic mean temperature difference is introduced to quantitatively describe the heat exchange capacity of the heat exchangers, and the logarithmic mean temperature difference of the heat exchangers is used as a criterion when the heat exchangers are increased or decreased. By taking the opening degree of an electric control valve, the frequency of the circulating pumps, the water supply temperature, the pressure difference and the keeping time of the parameters as criteria, the equipment operation switching working method of the heat exchange station with two typical structures of 'first series connection and then parallel connection' and 'first parallel connection and then series connection' of the heat exchangers and the circulating pumps is provided, and the heat supply amount adjusting range of the heat exchange station can be effectively widened.

Owner:XI AN JIAOTONG UNIV

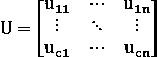

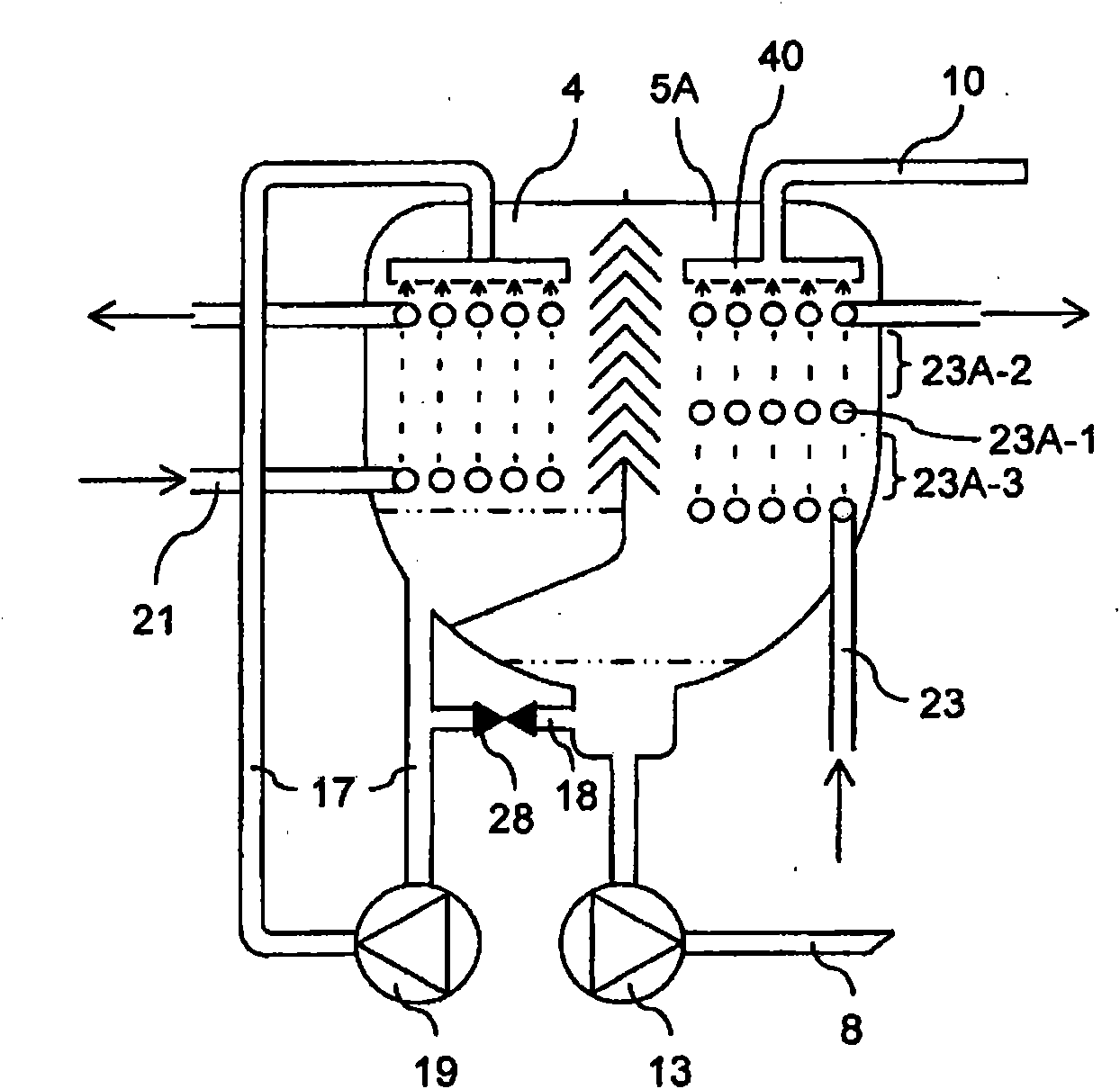

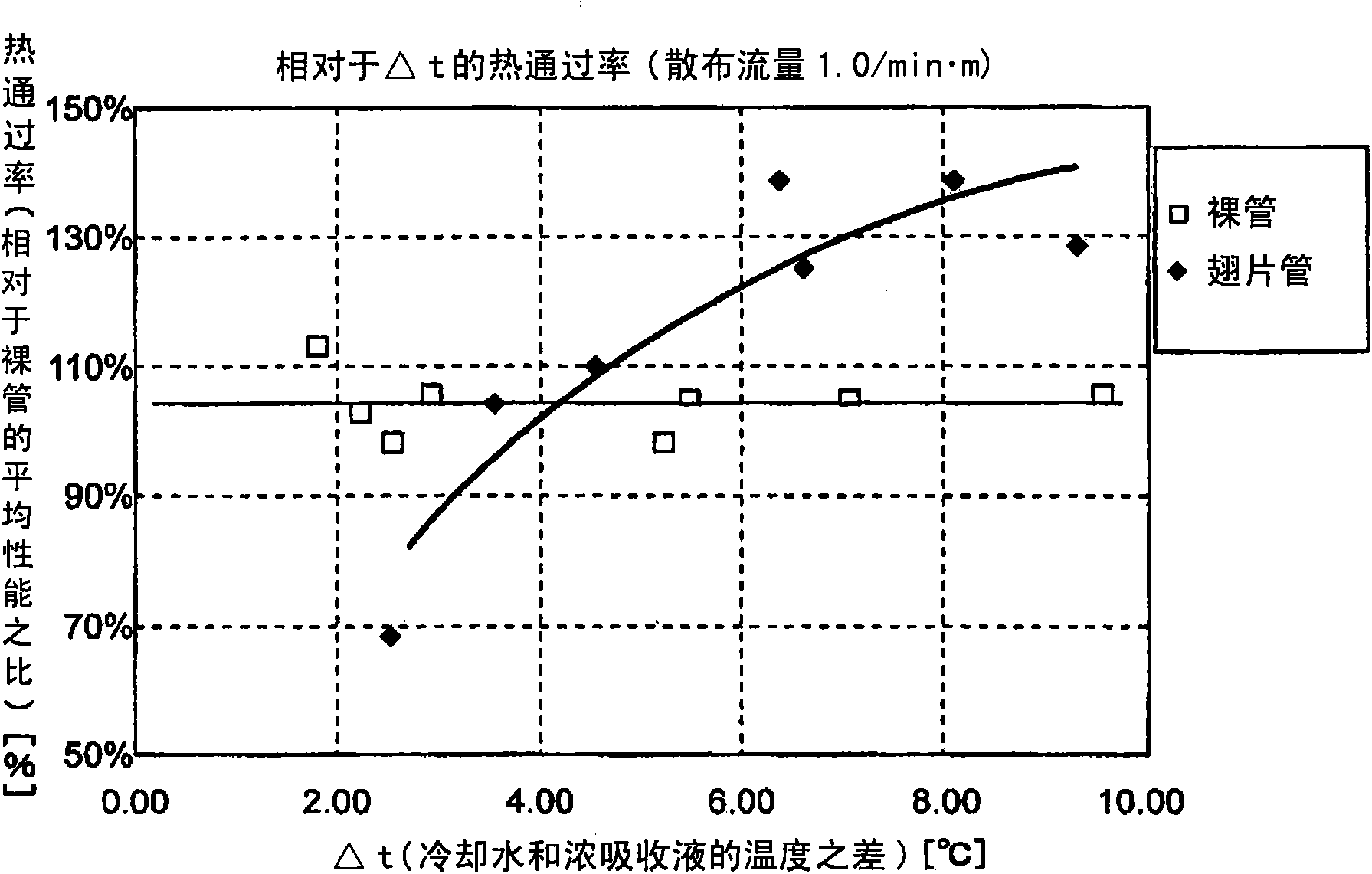

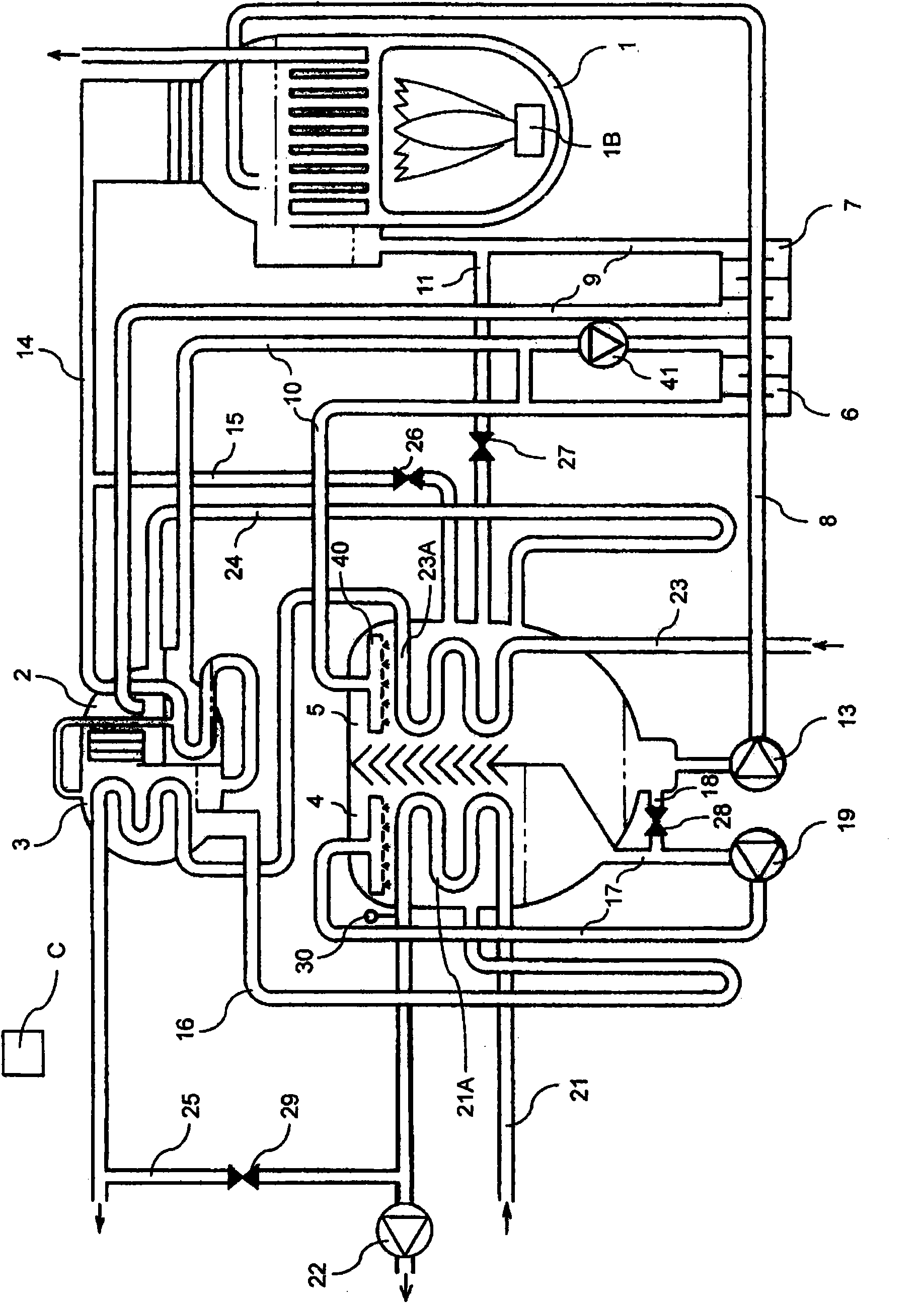

Absorber

InactiveCN101852518ADamage will notImprove absorption efficiencyEnergy efficient heating/coolingClimate change adaptationHeat conductingWater flow

The invention provides an absorber of an absorptive hot and cold water machine, which has simple and novel structure to improve the absorption efficiency and reduce the cost of an absorptive heat exchanger. The absorber has a thick absorption liquid distributing device for distributing the thick absorption liquid and an absorber type heat exchanger which is arranged under the thick absorption liquid distributing device and has a plurality of heat conducting pipes connected with cooled water pipes for driving the cooled water to circulate from the down direction to the up direction and distributing the thick adsorption liquid from the thick adsorption liquid distributing device to the outer surface of the pipe; when using a fin heat conducting pipe and a naked heat conducting pipe as the heat conducting pipe, a heat passing percent K equal in parts is calculated by following formula; the fin heat pipe is arranged on the upper layer side of the part; and the naked heat conducting pipe is arranged on the lower layer side of the part. K=Q / (AXDeltaT)(kcal / m2.DEG C.hr), wherein Q is a heat exchange capacity of the cooled water flowing in a heat conducting pipe; A is the heat conduction area of the heat conducting pipe; and Delta T is the logarithm average temperature difference of a temperature at inlet / outlet of the cooled water flowing in the heat conducting pipe and the temperature at inlet / outlet of a thick absorption liquid distributed to the outer surface of the heat conducting pipe.

Owner:SANYO ELECTRIC CO LTD

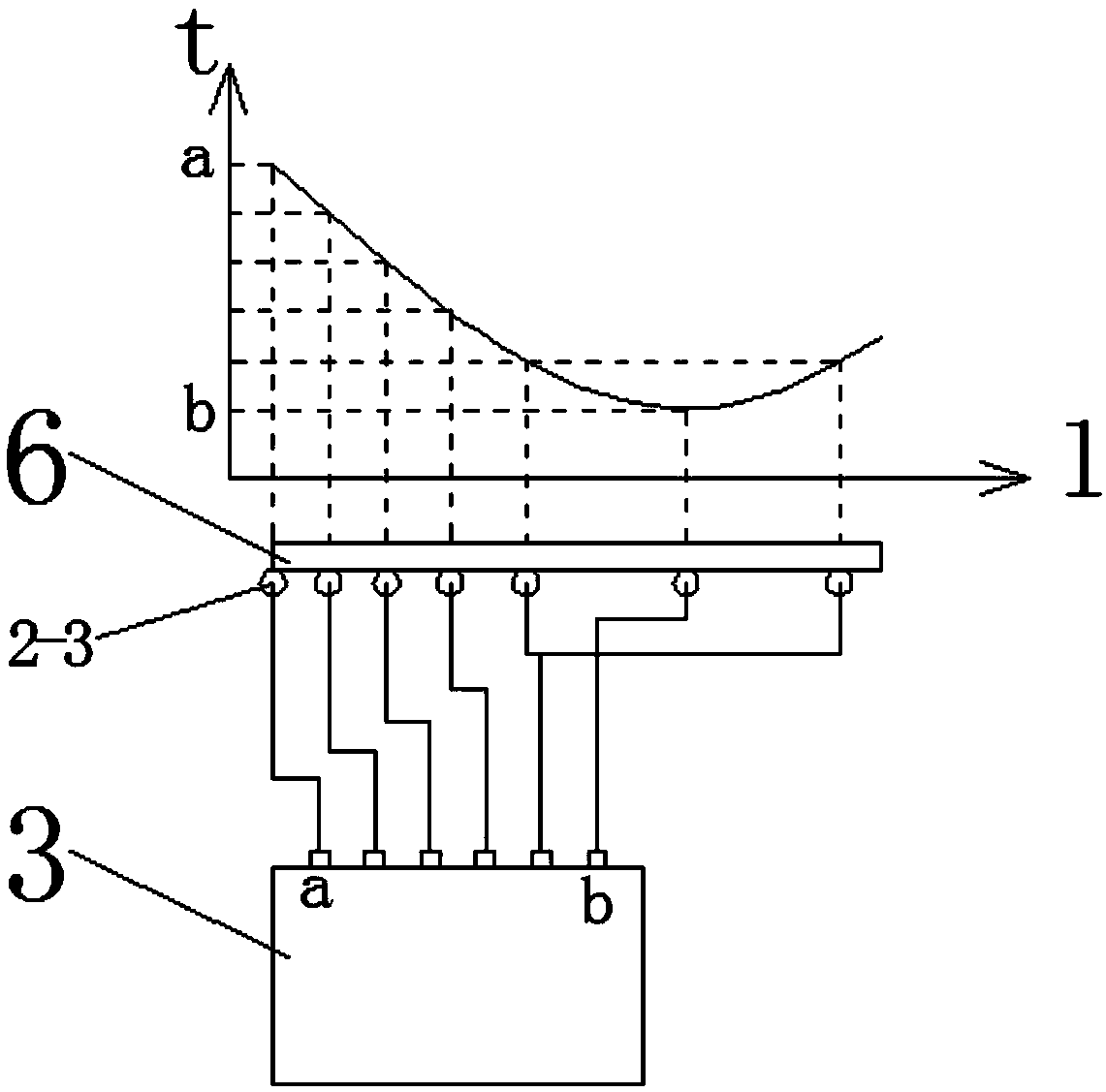

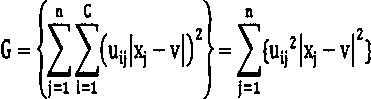

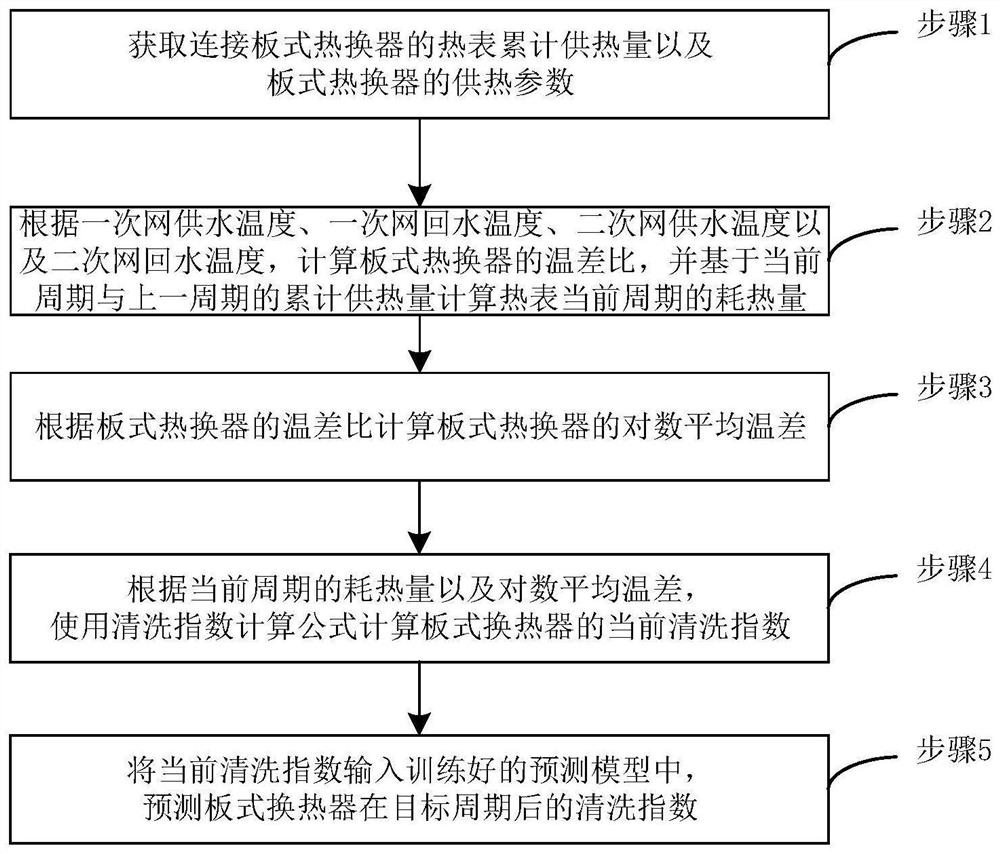

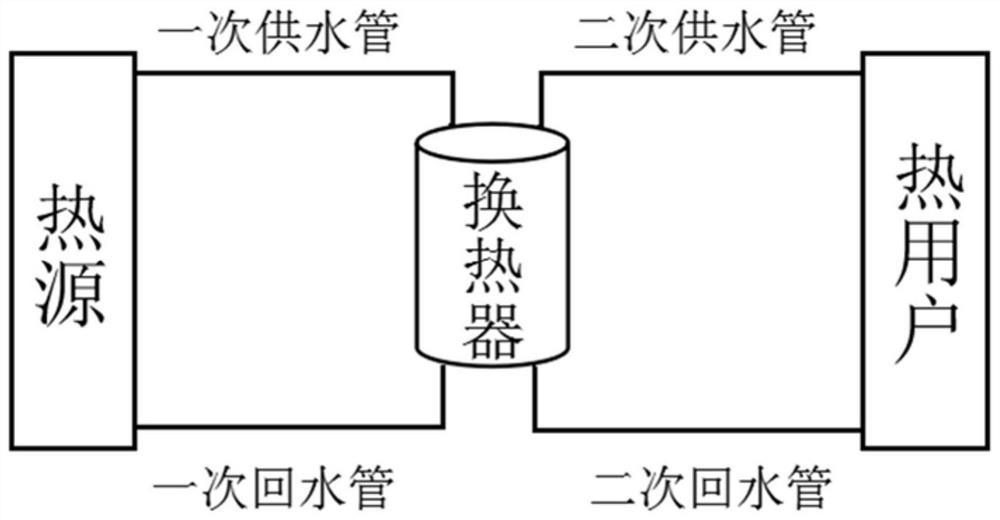

Plate heat exchanger state prediction method based on logarithmic temperature difference

PendingCN113705881AIncrease heating capacityReduce security risksForecastingCharacter and pattern recognitionPlate heat exchangerState prediction

The invention provides a plate heat exchanger cleaning index prediction method based on logarithmic temperature difference. The method comprises: obtaining the accumulated heat supply amount of a heat meter connected with the plate heat exchanger and heat supply parameters of the plate heat exchanger; calculating the temperature difference ratio of the plate heat exchanger and calculating the heat consumption of the heat meter in the current period; further obtaining the logarithmic average temperature difference of the plate type heat exchanger; calculating a current cleaning index of the plate heat exchanger by using a cleaning index calculation formula according to the heat consumption and the logarithmic average temperature difference of the current period; and inputting the current cleaning index into a trained prediction model, and predicting the cleaning index of the plate heat exchanger after the target period. Aiming at different types of plate heat exchangers, the energy efficiency parameter value of the plate heat exchanger is predicted cycle by cycle through the supply water temperature and the return water temperature on the two sides and the heat consumption of the heat meter in the current cycle, the cleaning index is predicted, the plate heat exchanger is guided to be cleaned, the heat supply capacity of a heat exchange station is improved, and potential safety hazards are reduced.

Owner:陕西启迪瑞行清洁能源研究院有限公司

High-enthalpy heat island guided air sterilizer with large temperature difference along the process and small heat transfer and temperature difference recovery type air sterilizer

The invention relates to a high-enthalpy heat island lead large on-way temperature difference and small heat transmission temperature difference back heating type air disinfector which comprises a high-enthalpy heat island and at least one atmospheric heat exchanger, wherein the atmospheric heat exchanger is connected with the high-enthalpy heat island, the outer end head of the atmospheric heat exchanger comprises an air inlet and an air outlet, the inner end head of the atmospheric heat exchanger comprises a low-temperature side air outlet and a high-temperature side air inlet, the air inlet at the outer end head is communicated with the low-temperature side air outlet of the atmospheric heat exchanger, the air outlet at the outer end head is communicated with the high-temperature side air inlet of the atmospheric heat exchanger, and the high-enthalpy heat island is positioned between the low-temperature side air outlet and the high-temperature side air inlet of the atmospheric heat exchanger. According to the invention, the high-enthalpy heat island lead is adopted, large on-way temperature difference and small heat transmission temperature difference are built inside the atmospheric heat exchanger, high-temperature air heat quantity after disinfection can be recycled, and the technical problems of incomplete disinfection, medicine residue, toxic and side effects and the like in conventional air disinfecting technology can be solved.

Owner:SHANGHAI BOHAN THERMAL ENERGY TECH CO LTD

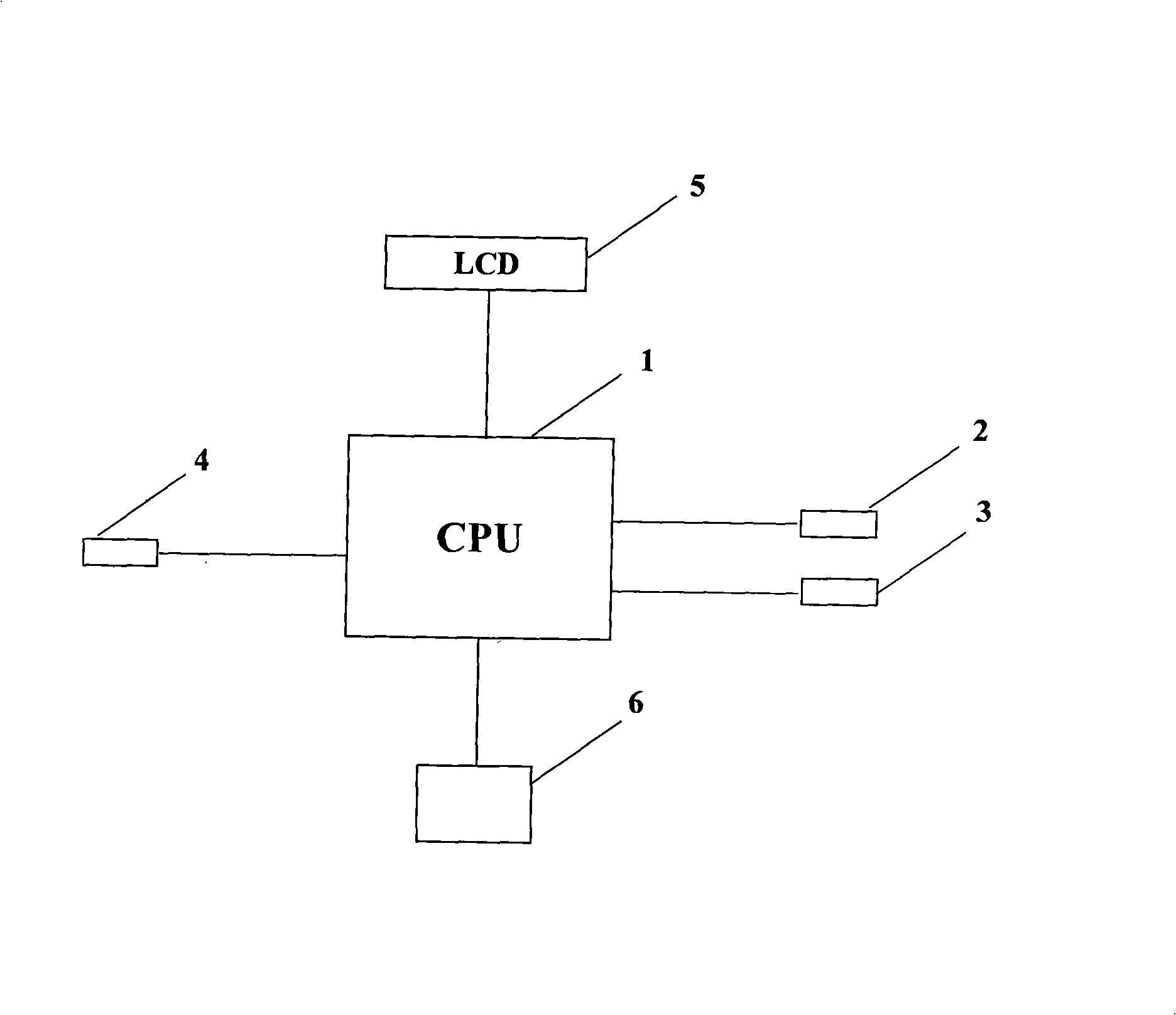

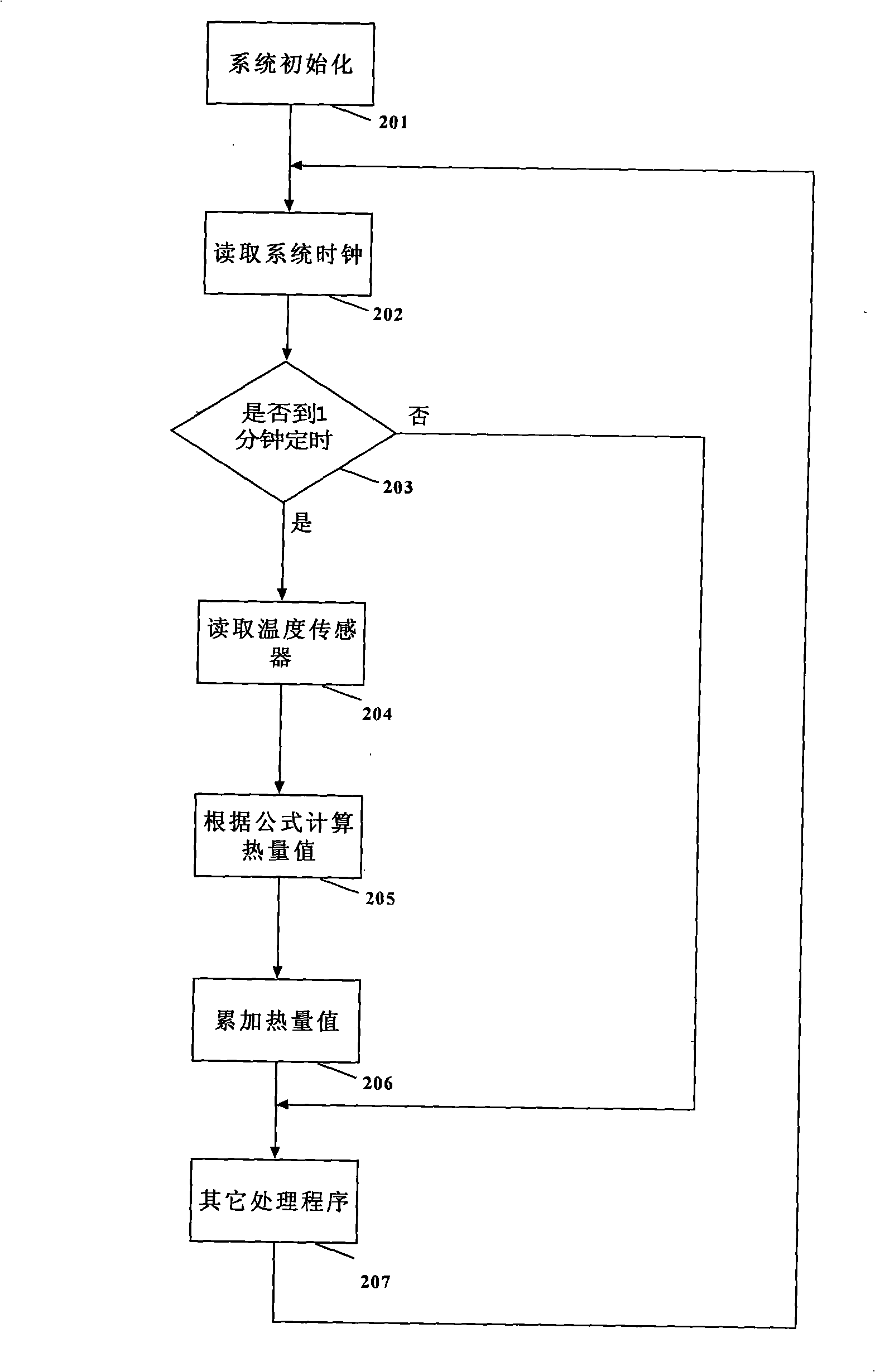

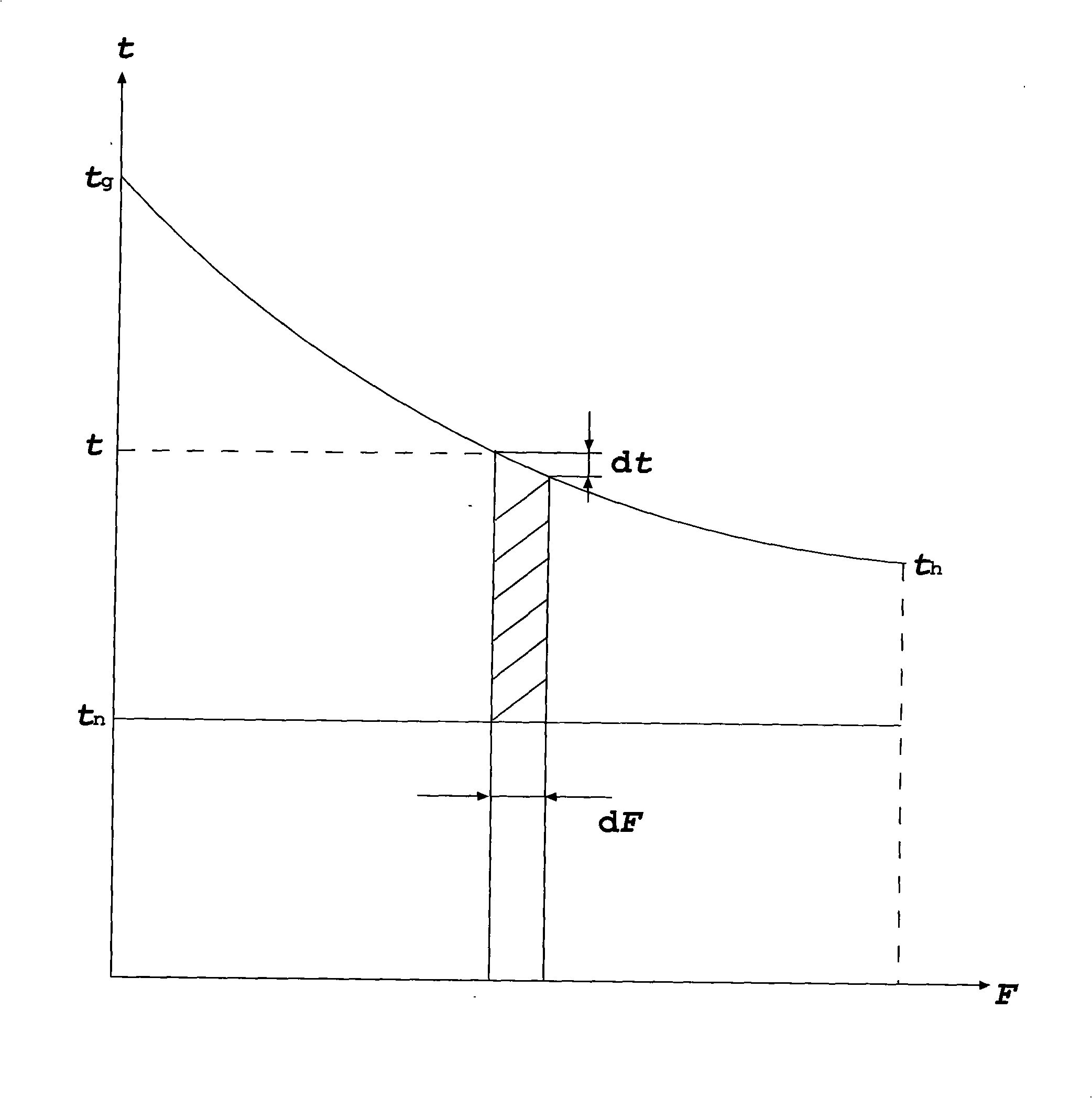

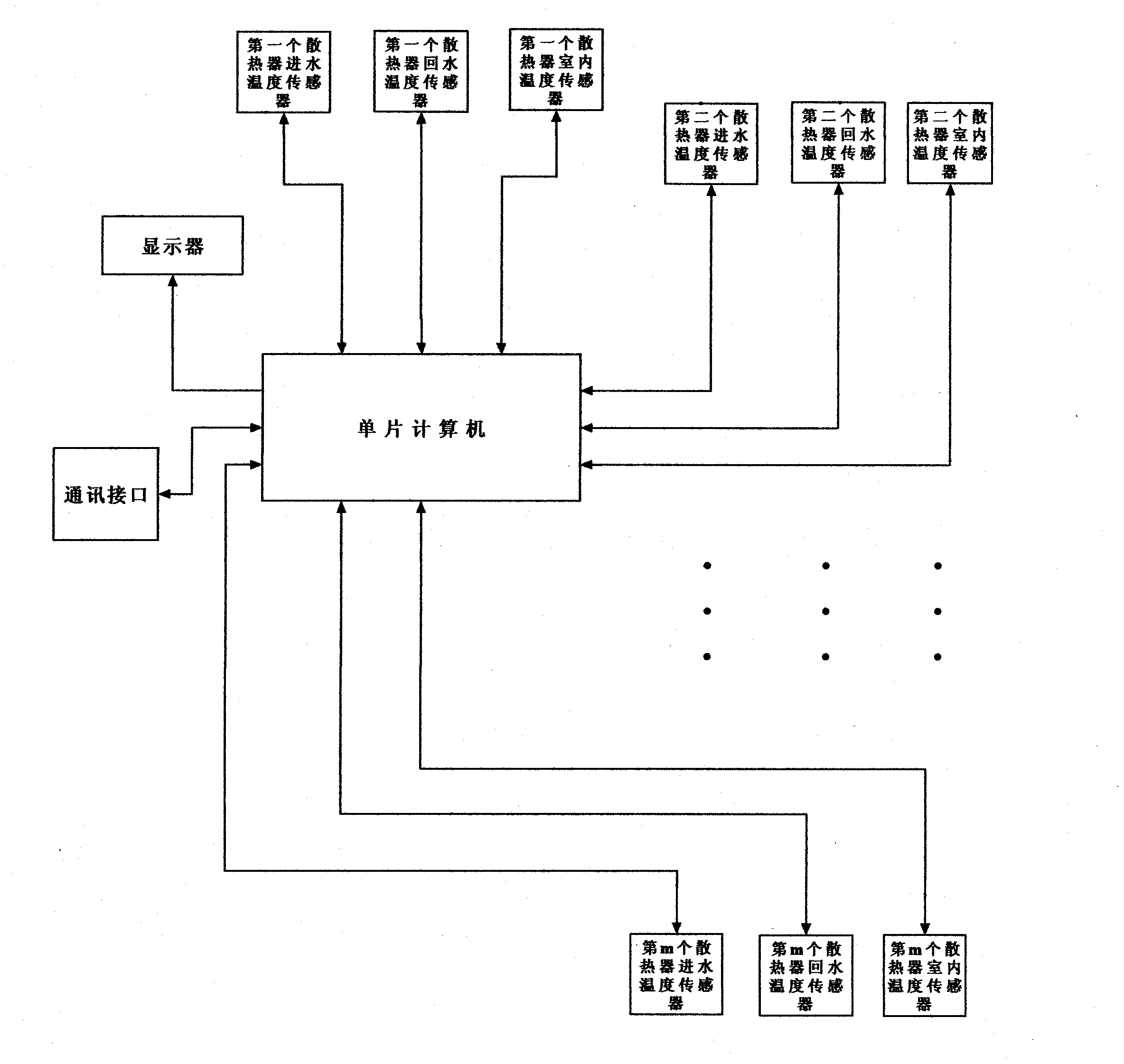

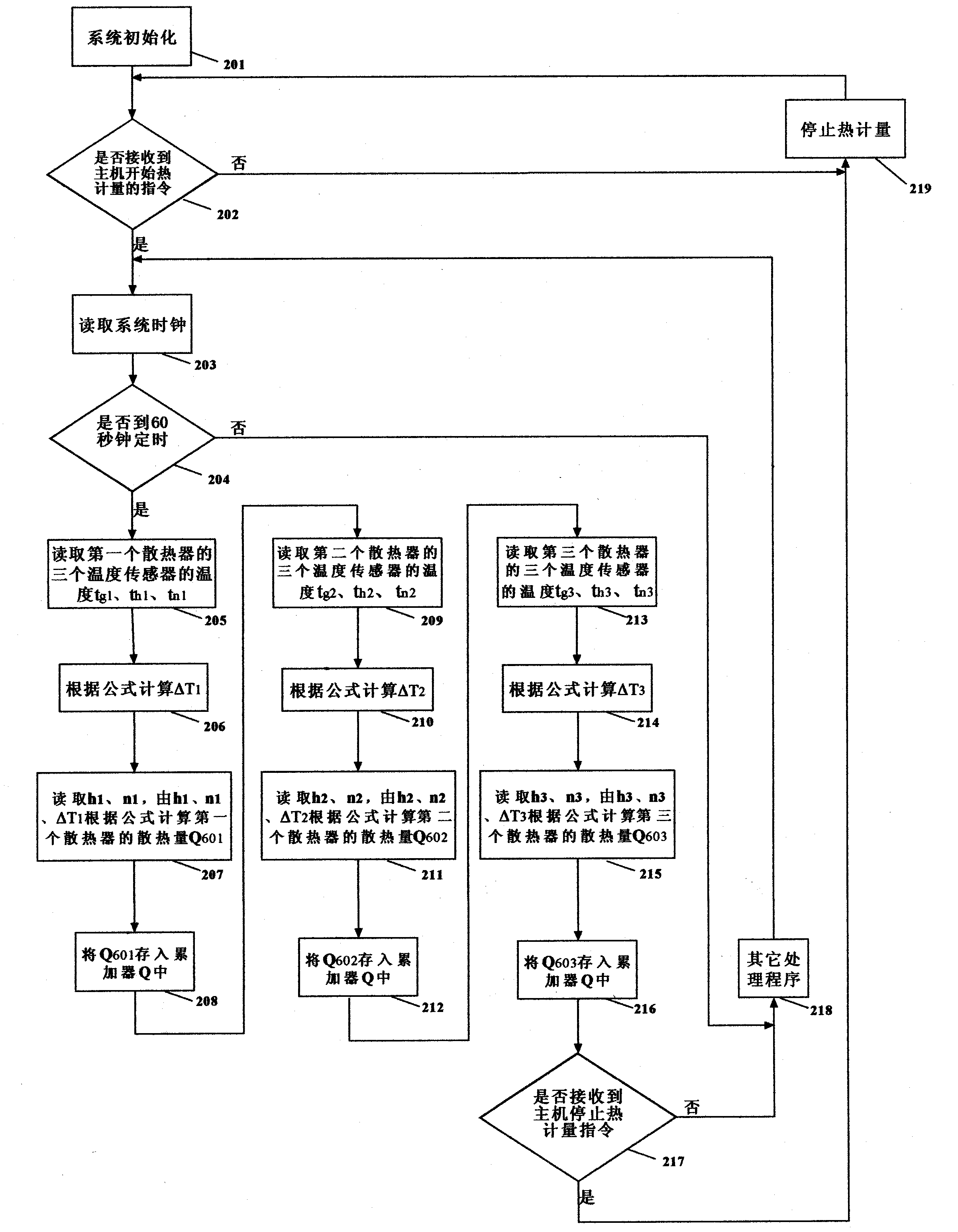

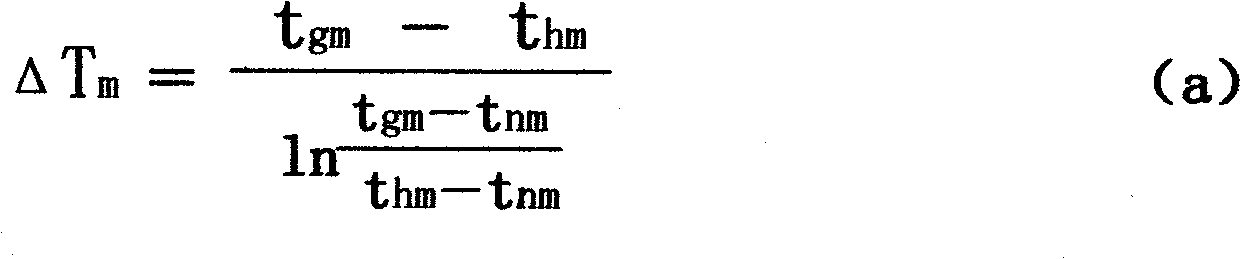

Three-temperature sensor heat distributor

InactiveCN101275760AStable jobExtended service lifeLighting and heating apparatusSpace heating and ventilation detailsDisplay deviceSingle chip

The invention discloses a heating heat metering tri-temperature sensor thermal distributor, including a single chip computer, an influent temperature sensor, a backwater temperature sensor, an indoor temperature sensor and a display, wherein the tri-temperature sensor and the display are respectively connected with the I / O port of the single chip computer storing three formulas: 1.computing the radiator characteristic coefficient A, 2.computing the logarithm average difference in temperature, 3.computing the radiating quantity of the radiator. The tri-temperature sensor thermal distributor is input with the related parameters of the radiating quantity of the radiator and the interval time into the single chip computer before the installation; the program executes the following steps when computing: reading the temperature of the temperature sensor in fixed interval, computing the logarithm average difference in temperature according to the three read temperature by the formula 2, then obtaining the radiating quantity of the radiator using the logarithm average difference in temperature and storing into the accumulator of the single chip computer. The invention is suitable for the heating heat metering of the buildings, such as the house, the enterprise and institution and the business building.

Owner:纪睿

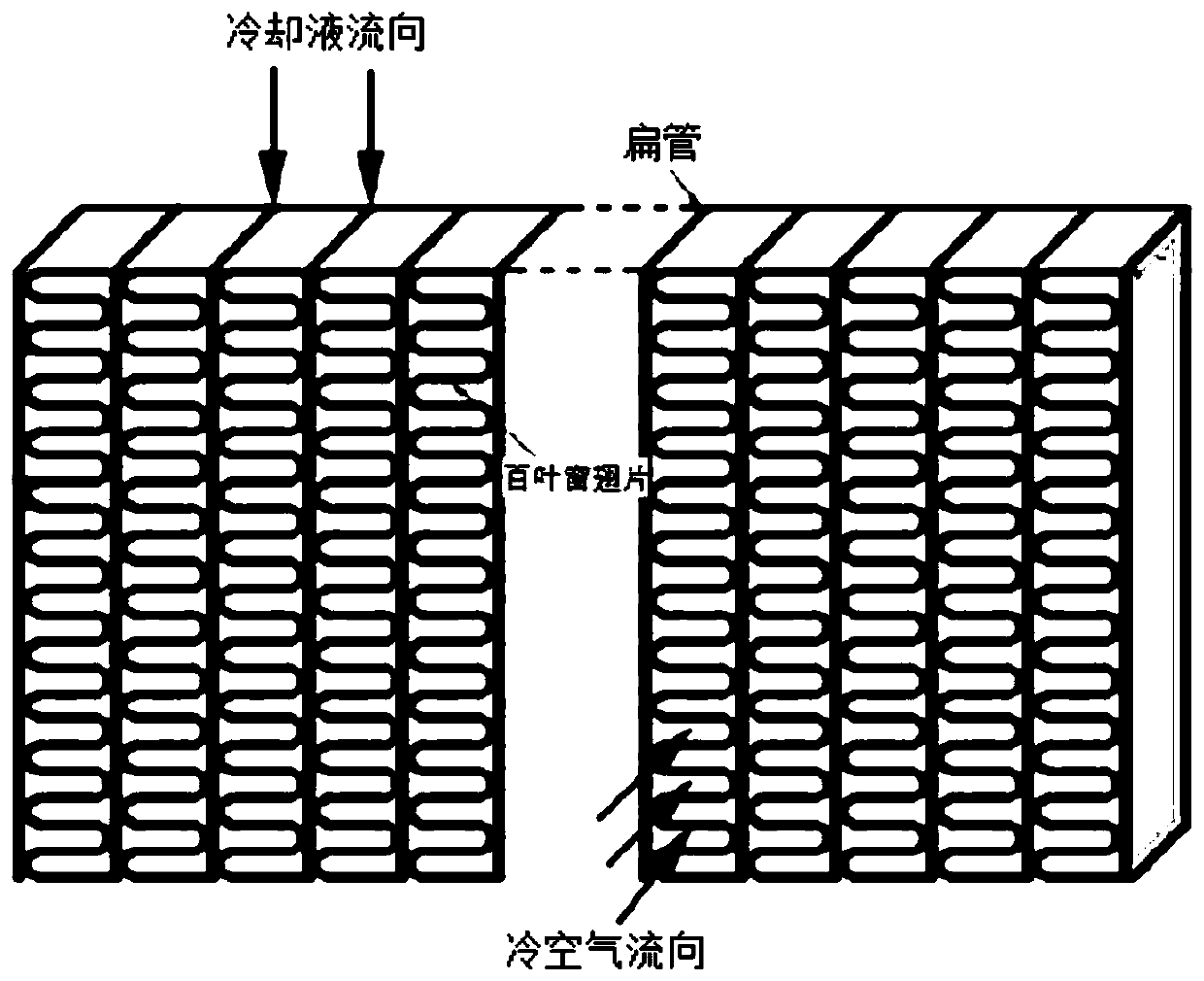

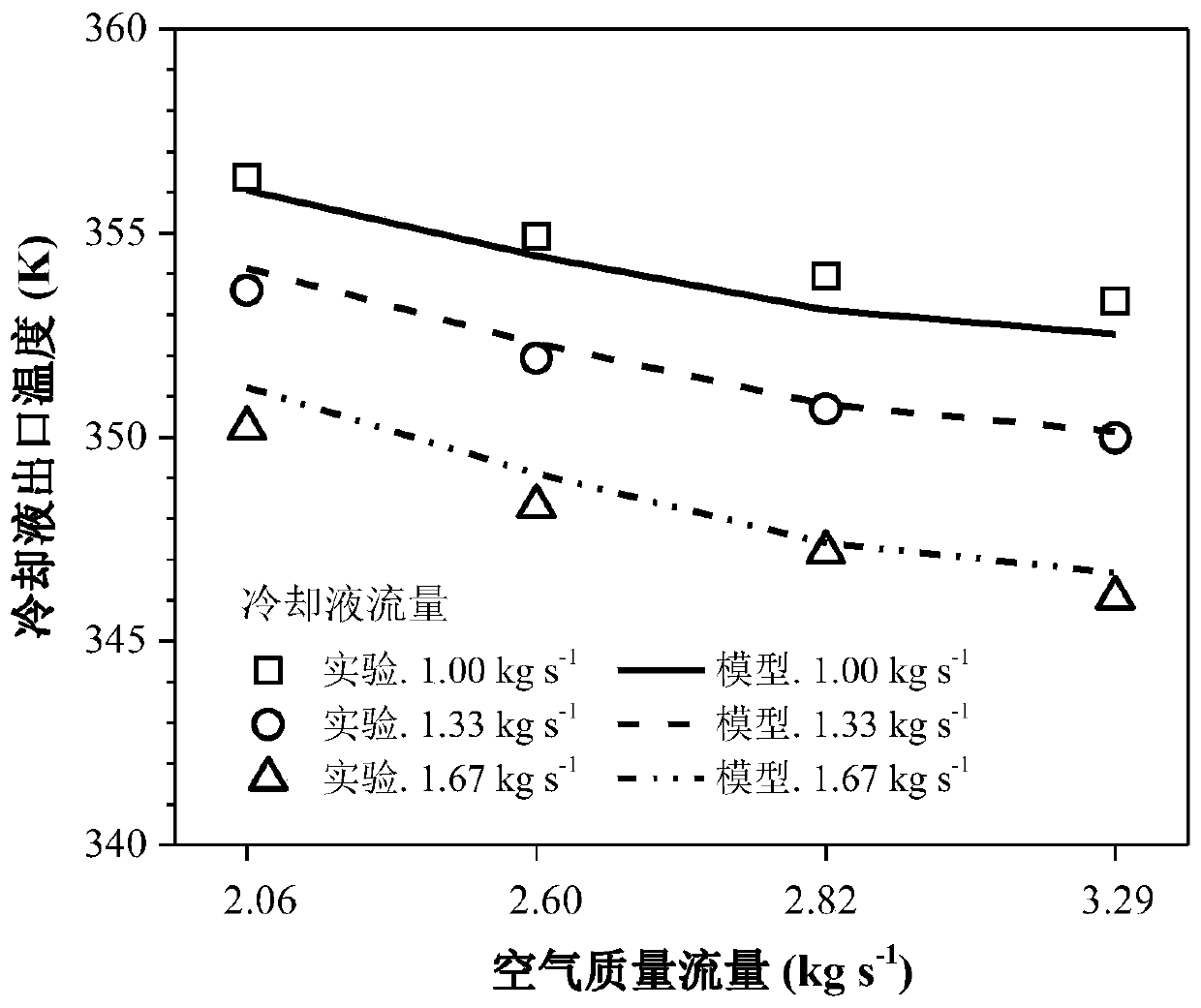

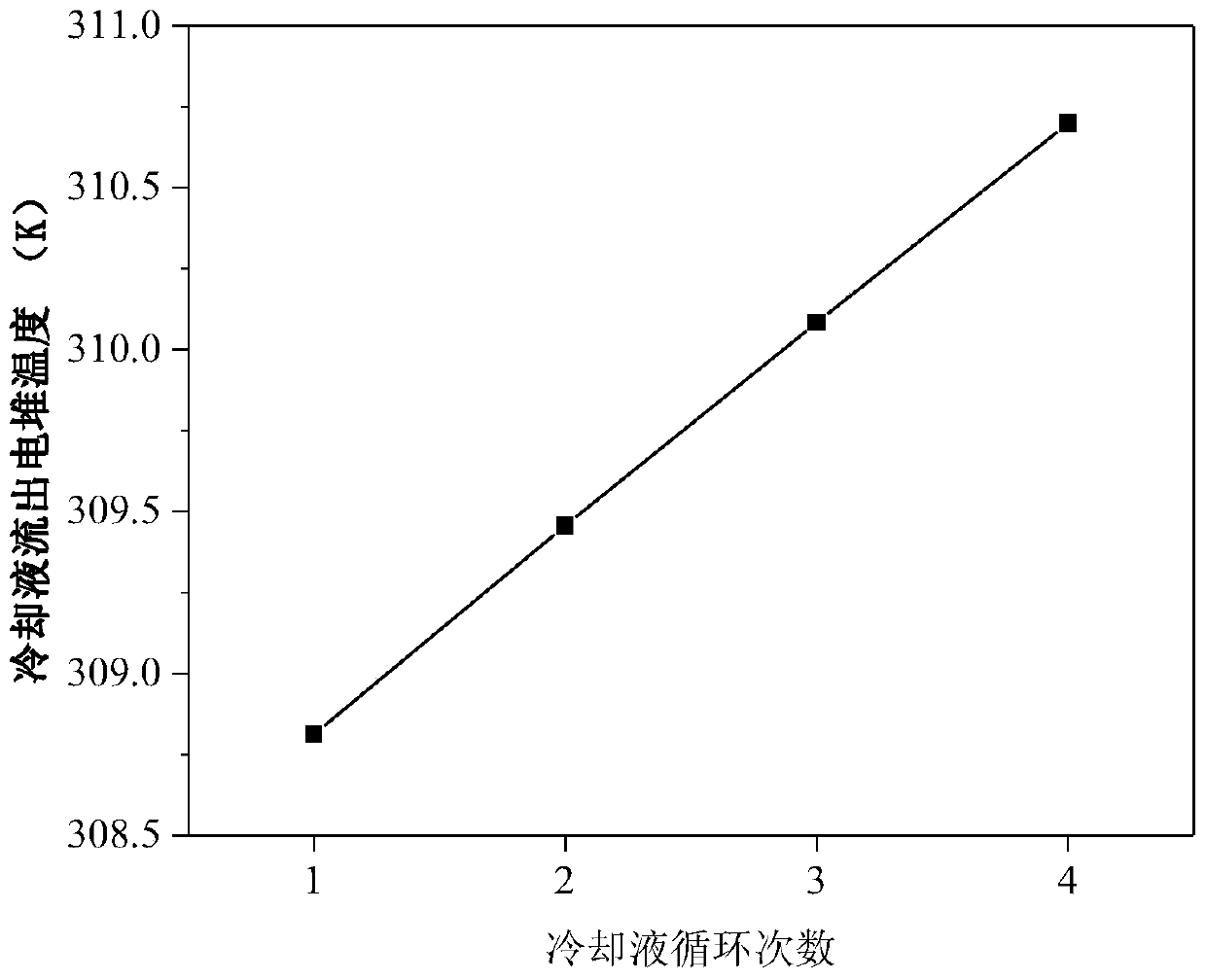

Modeling method of proton exchange membrane fuel cell cooling system

ActiveCN110134983AEnough precisionImprove computing efficiencyFuel cell controlDesign optimisation/simulationModel methodSpecific model

The invention discloses a modeling method of a proton exchange membrane fuel cell cooling system, a fuel cell is cooled by using a tubular strip-shaped finned heat exchanger, and the establishment ofa heat exchanger model is based on gas-liquid heat exchange, establishment of a specific model of the cooling system comprises seven steps of establishing an energy conservation equation, calculatingthe efficiency of a radiator, calculating the convective heat transfer between cooling liquid and a flat tube, calculating the heat conduction inside the tube wall, calculating the convective heat transfer between the outside of the flat tube and air, calculating the fin efficiency and calculating the heat transfer between the cooling liquid and an electric pile. The defects that an existing three-dimensional radiator model is low in calculation efficiency and cannot be directly used in a system model are overcome. The radiator model is based on efficiency-heat transfer unit number method, does not need an image logarithm average temperature difference method for iterative calculation, the calculation efficiency of the model is high, and enough model precision can be guaranteed.

Owner:TIANJIN UNIV

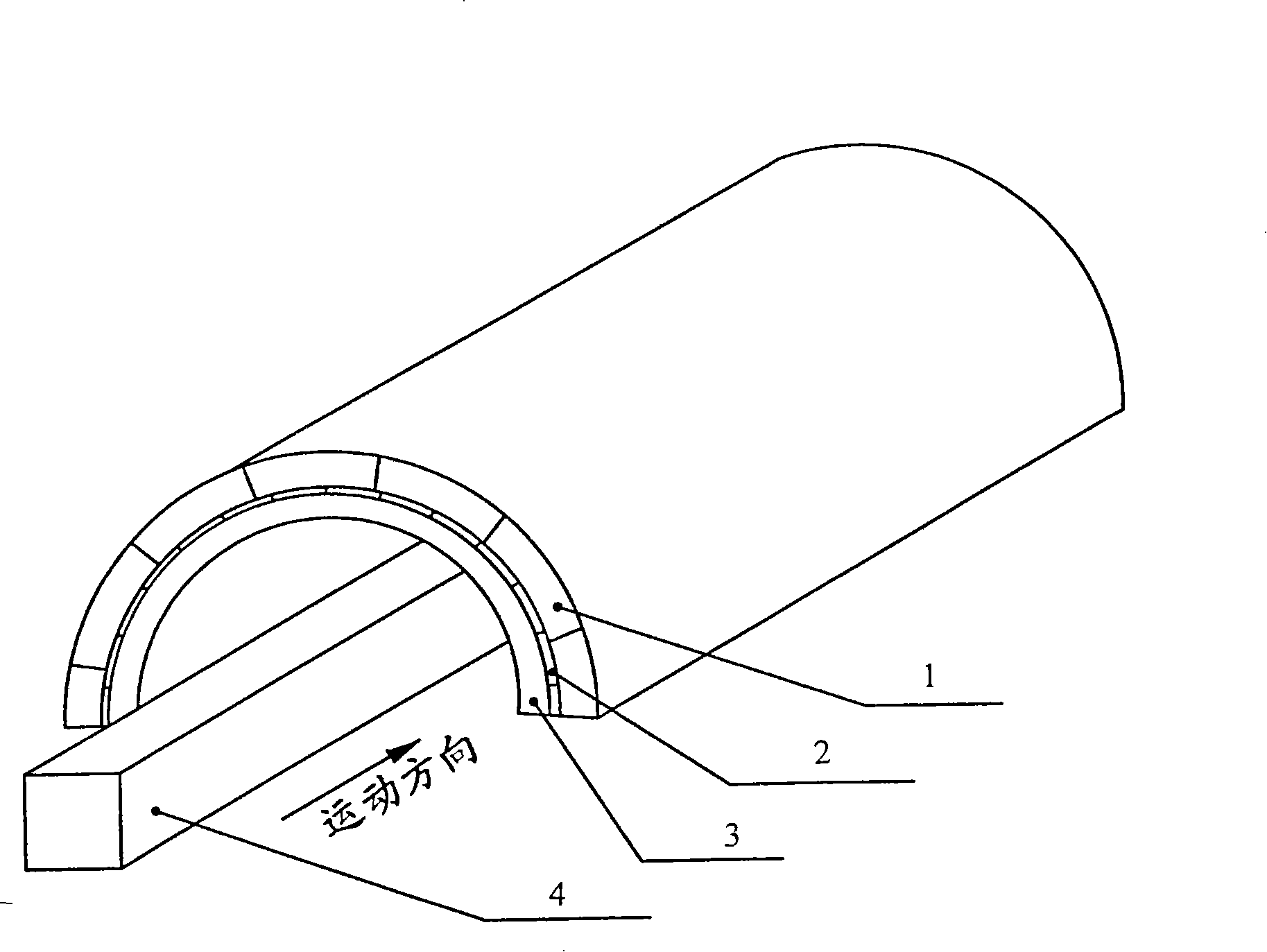

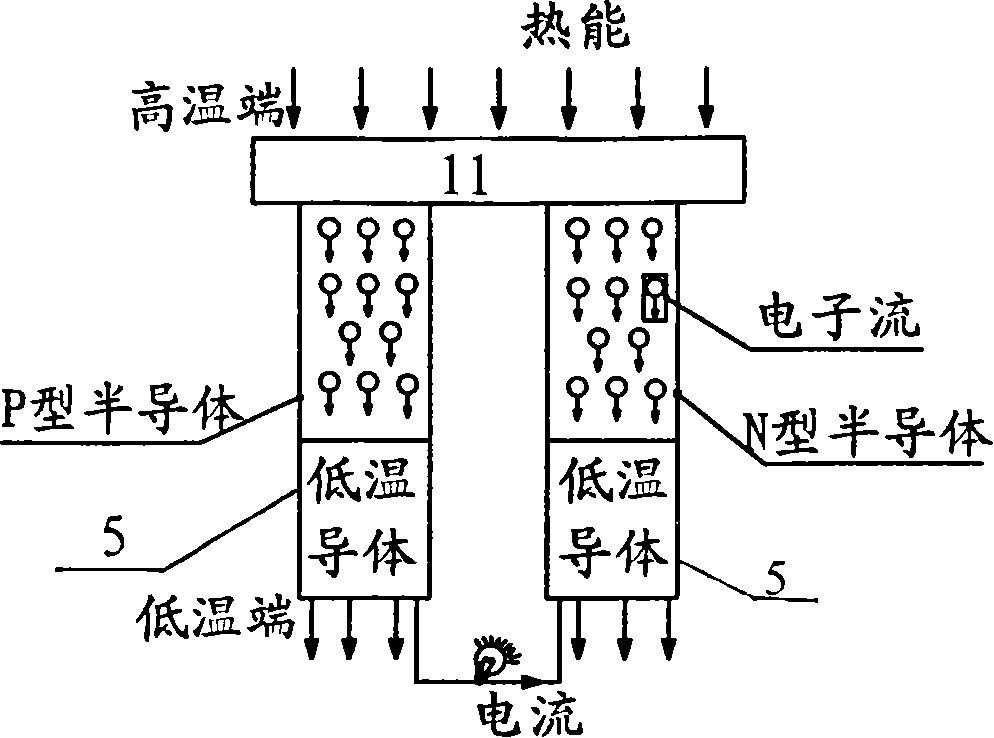

Tunnel type waste heat recovery semiconductor power generation device by temperature difference

InactiveCN101316083BReduce energy consumptionNo noiseThermoelectric device with peltier/seeback effectGenerators/motorsCollector deviceEngineering

The invention provides a tunnel-typed residual-heat recovery semiconductor temperature difference generation method and a device. The generation method is characterized in that a movable heat source which emits residual heat runs pass a tunnel-typed heat collector which receives the heat emitted by the movable heat source and transmits the collected heat to a heat surface of a semiconductor temperature difference generation module; a radiator is arranged at one side of a cooling surface of the semiconductor temperature difference generation module; the cooling surface is cooled to a temperature much lower than that of the heat surface by the radiator, thus generating a large temperature difference at two end surfaces of the semiconductor temperature difference generation module; the semiconductor temperature difference generation module directly converts the temperature difference into the electric potential difference which is used as a power supply after being converted by a stabilizer circuit and AC / DC. The device of the invention comprises the semiconductor temperature difference generation module, the tunnel-typed heat collector, and a radiator; the method and the device of the invention have the advantages that the recovered residual heat energy can be directly converted into electric power, the generation process has no noise, no abrasion and no medium leakage, furthermore, the generator has the small volume, light weight, convenient movement, maintenance-free and long service life, etc.

Owner:无锡明惠通科技有限公司

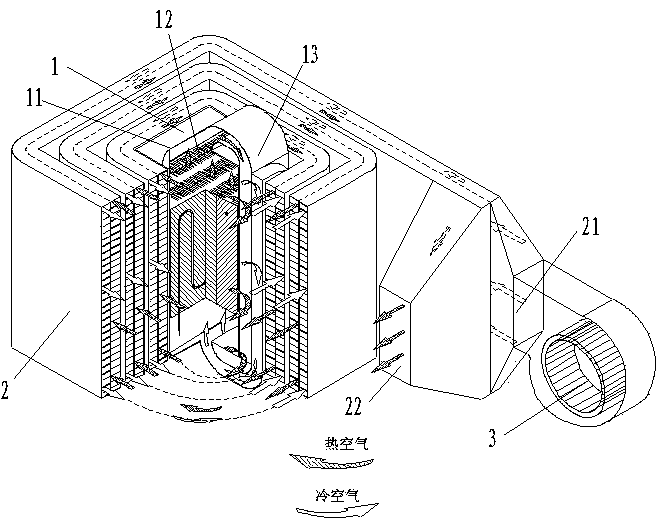

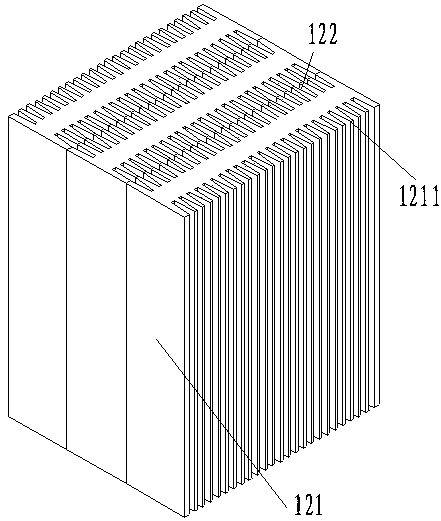

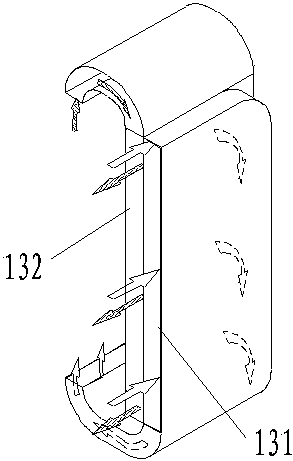

Indirect evaporation type air cooler

PendingCN111947485AAvoid wastingReduce cleaning frequencyEvaporators/condensersSpace heating and ventilation detailsElectric machineryEngineering

The invention provides an indirect evaporation type air cooler, and relates to the technical field of air cooler equipment, evaporation type air coolers and air coolers. The indirect evaporation typeair cooler comprises tube bundles, a framework, fans and an evaporation precooler, wherein the framework is a steel structural part for supporting the tube bundles, the fans and evaporation films; andthe fans are axial flow fan special for the air cooler and comprise air ducts, fan bodies, motors and transmission mechanisms, and the evaporation precooler is arranged around the axial flow fans. Byusing the evaporation precooler, air flows to finned tubes after being purified and humidified, and the humidified air takes away heat of surrounding air by evaporation of moisture in the flowing process, so that the air inlet temperature of the tube bundles is effectively reduced, the effective logarithm average temperature difference of heat transfer is increased, and the heat transfer efficiency of an air-cooled heat exchanger is improved; and meanwhile, corrosion and scaling of the finned tubes are effectively relieved, and the finned tubes are protected, so that the service life of the tube bundles of the air cooler is prolonged, and the operation safety and reliability are improved.

Owner:中冷(无锡)工程机械设备有限公司

Household heat distribution meter using three temperature sensor as measuring unit

The invention discloses a household heat distribution meter using a three temperature sensor as a measuring unit. The household heat distribution meter using the three temperature sensor as the measuring unit comprises a single chip microcomputer and a display. Each household radiator is provided with an inflow-outflow temperature sensor and an indoor temperature sensor. Formulas used for calculating logarithmic mean temperature difference and heat dissipating capacity of the radiator are stored in the single chip microcomputer. Relevant parameters used for calculating the heat dissipating capacity of each radiator are stored in the single chip microcomputer in advance. The single chip microcomputer conducts the following steps every theta times: (1) reading the inflow-outflow temperature and the indoor temperature of a first radiator; (2) calculating the logarithmic mean temperature difference; (3) putting the logarithmic mean temperature difference and other parameters of the first radiator into the formula used for calculating the heat dissipating capacity to determine the heat dissipating capacity of the first radiator at time theta; (4) storing the determined heat dissipating capacity into an accumulator Q; and then using the same steps to calculate the heat dissipating capacity of a second radiator and until the heat dissipating capacity at time theta of the last radiator is stored in the calculator Q, when the heating period expires, numerical value of the calculator Q is the heat consumption amount of the household.

Owner:纪睿

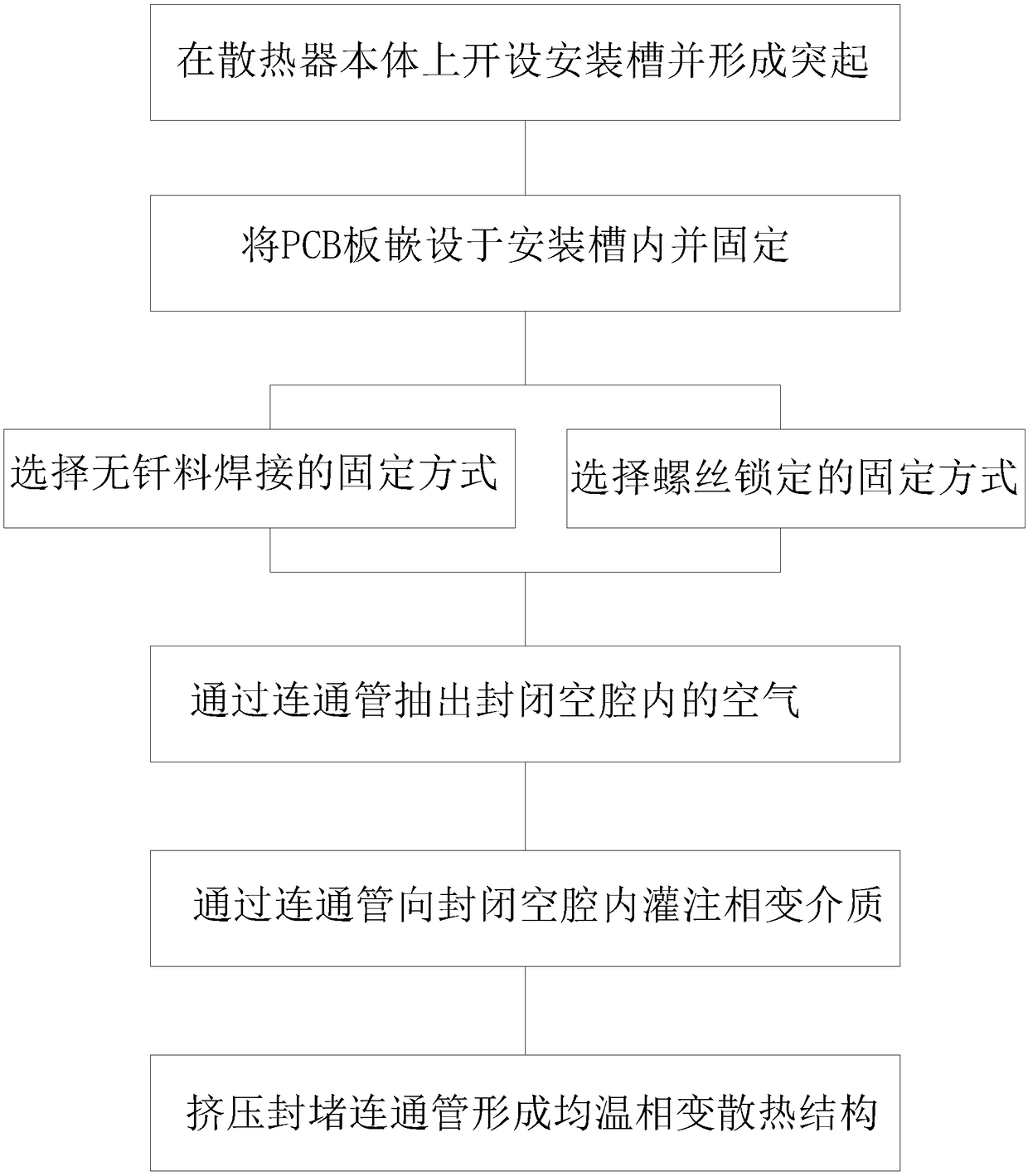

Phase change heat sink manufacturing process

InactiveCN109496108AReduce lateral temperature differenceReduce longitudinal temperature differenceModifications using liquid coolingEngineeringTemperature difference

The invention discloses a phase change heat sink manufacturing process, and relates to the technical field of heat sink bonding, comprising the following steps of S1, disposing a mounting slot on themounting surface of a heat sink body; S2, embedding and fixing a PCB in the mounting slot, wherein a closed cavity is formed between the PCB and the bottom of the mounting slot; S3, exhausting the airin the closed cavity by a communication tube preformed on the heat sink body; S4, pouring a phase change medium into the closed cavity by the communication pipe; and S5, sealing the communication tube to form a uniform temperature phase change heat dissipation structure. The uniform temperature phase change heat dissipation structure is filled with the phase change medium so as to reduce the thermal resistance between the PCB and the heat sink body. Thus, the heat on the PCB is uniformly transferred to the surface of the heat sink body, and the transverse temperature difference among variouspoints on the surface of the heat sink body and the longitudinal temperature difference of the heat sink body are reduced, thereby achieving a purpose of improving the surface utilization rate of theheat sink body and a purpose of improving a heat dissipation effect.

Owner:李洪刚

Operation Switching Adjustment Device and Working Method of Heat Exchanger and Circulation Pump in Heat Exchange Station

ActiveCN113028492BRealize automatic increase and decrease adjustmentAvoid Ineffective Bypass PhenomenonLighting and heating apparatusCentral heating componentsSolenoid valveEngineering

Owner:XI AN JIAOTONG UNIV

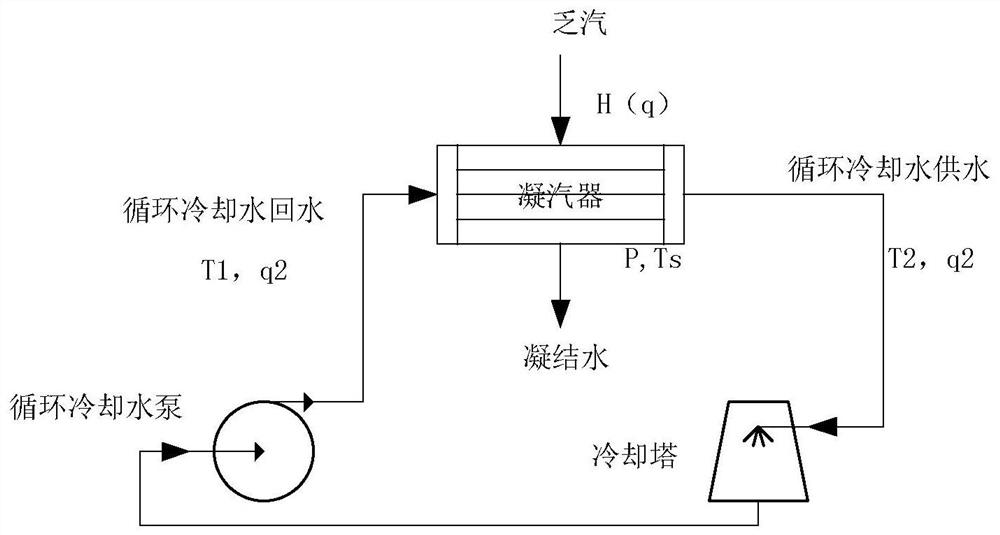

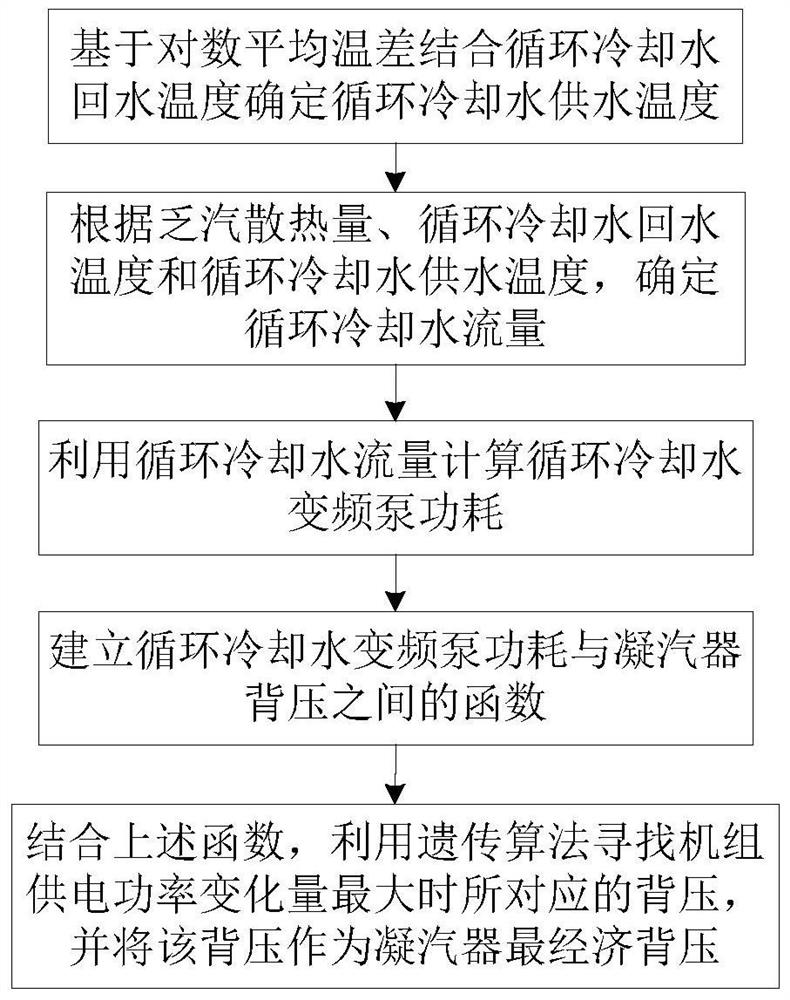

A wet cooling unit condenser economic back pressure calculation method based on logarithmic average temperature difference and a genetic algorithm

ActiveCN113221274AEasy to calculate energy saving effectGeometric CADDesign optimisation/simulationThermodynamicsGenetics algorithms

The invention discloses a wet cooling unit condenser economic back pressure calculation method based on logarithmic average temperature difference and a genetic algorithm, and relates to the field of thermal power plant cold end system economical efficiency optimization. The invention aims at calculating the most economical back pressure of the condenser of the wet cooling unit so as to calculate the energy-saving effect of the most economical back pressure. The wet cooling unit condenser economic back pressure calculation method based on logarithmic average temperature difference and a genetic algorithm comprises the following steps: firstly, establishing a function between the power consumption of a circulating cooling water variable frequency pump and the back pressure of the condenser; and then, based on the function, calculating the back pressure corresponding to the maximum power supply power variation of the unit, and taking the back pressure as the most economical back pressure of the condenser.

Owner:哈尔滨沃华智能电力技术有限公司

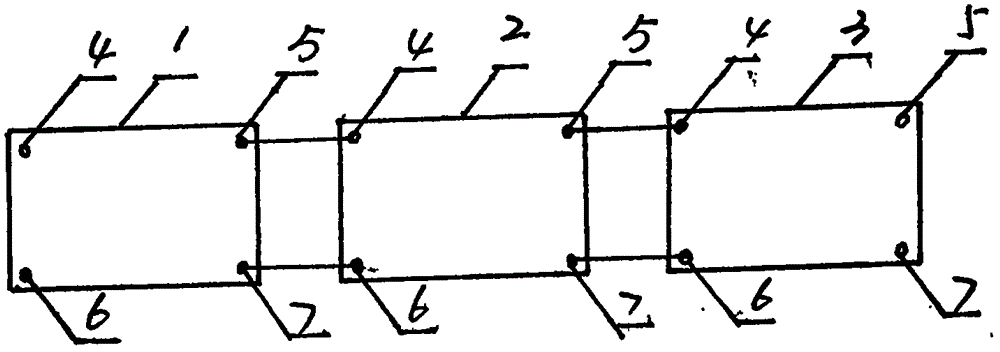

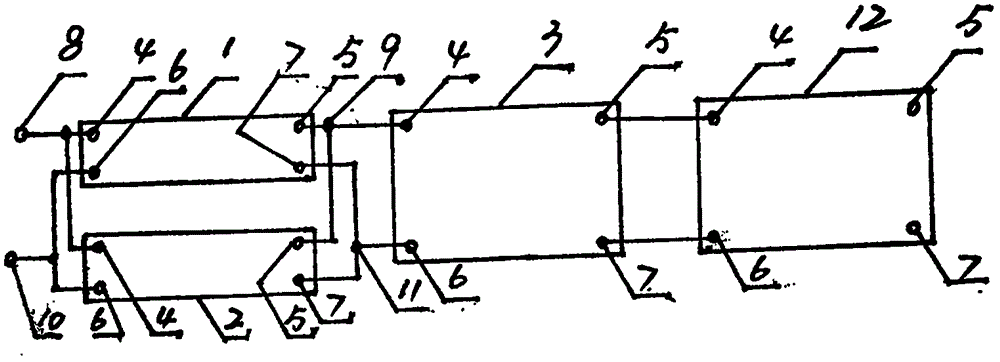

Heat exchanger with 2-20 flow paths

InactiveCN106052431AEasy to installSmall temperature difference at the hot endStationary plate conduit assembliesTemperature differenceEngineering

The invention provides a heat exchanger with 2-20 flow paths. The heat exchanger with the 2-20 flow paths comprises 1-20 heat exchanger bodies. The heat exchanger with the 2-20 flow paths is characterized in that by the adoption of a method for increasing the number of the flow paths, the total length of a first medium flow channel and the total length of a second medium flow channel of the heat exchanger are increased, the total length of the first medium flow channel is made to reach 0.3-20 meters, the total length of the second medium flow channel is made to reach 0.3-20 meters, and finally it is achieved that the hot end temperature difference of the heat exchanger is lowered; and according to the method for increasing the number of the flow paths, the 2-20 flow paths are constructed in the inner structure of the heat exchanger or the 2-20 heat exchanger bodies constitute the 2-20 flow paths through series connection or the 2-20 heat exchanger bodies constitute the 2-20 flow paths through parallel connection and series connection. The heat exchanger with the 2-20 flow paths can achieve that the hot end temperature difference of the heat exchanger is controlled to be within 1 DEG C and is convenient to apply and popularize generally on heat exchange sites.

Owner:刘洋豪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com