Heat exchanger with 2-20 flow paths

A heat exchanger and process technology, applied in the field of heat exchange, can solve the problems of long installation, high cost, insufficient heat exchange, etc., and achieve the effect of small temperature difference at the hot end, long overall length, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

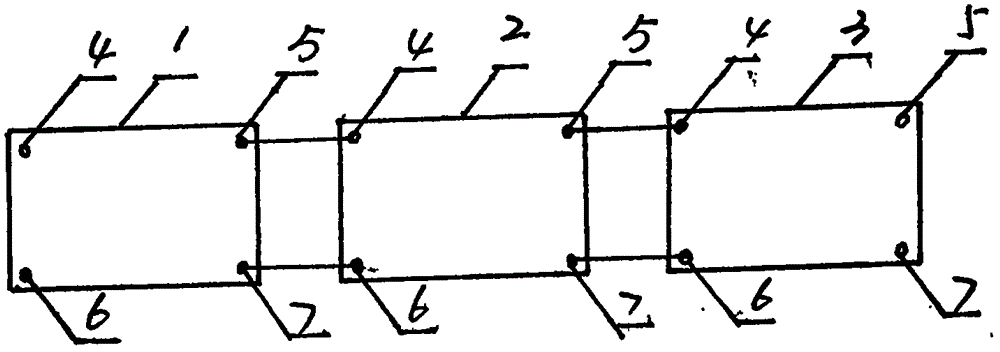

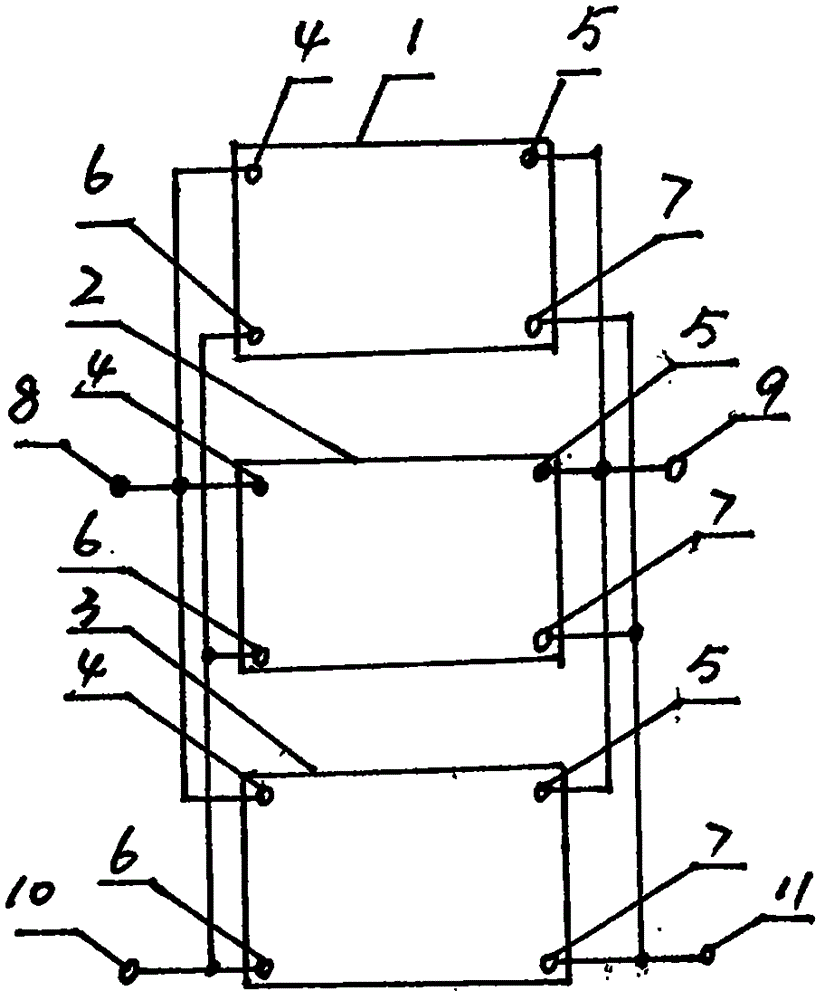

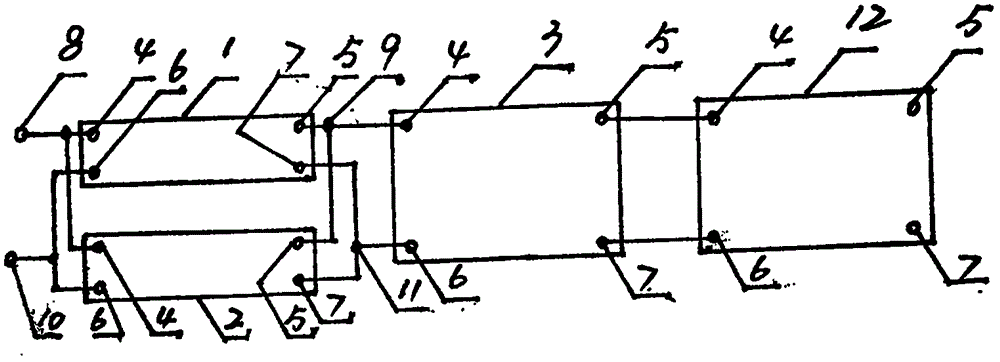

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] A heat exchanger with 2-20 processes according to the present invention, including 1-20 heat exchangers, is characterized in that: the method of increasing the number of processes is adopted to increase the total length of the first medium flow channel of the heat exchanger and the total length of the second medium flow channel, so that the total length of the first medium flow channel reaches 0.3-20 meters, and the total length of the second medium flow channel reaches 0.3-20 meters, and finally realizes reducing the temperature difference at the hot end of the heat exchanger; The method to increase the number of processes is: construct 2-20 processes in the internal structure of 1 heat exchanger or use 2-20 heat exchangers to form 2-20 processes in series or use 2-20 heat exchangers 2-20 processes are composed of parallel and serial connections; the heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com