Patents

Literature

81results about How to "Realize "Zero Emissions"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

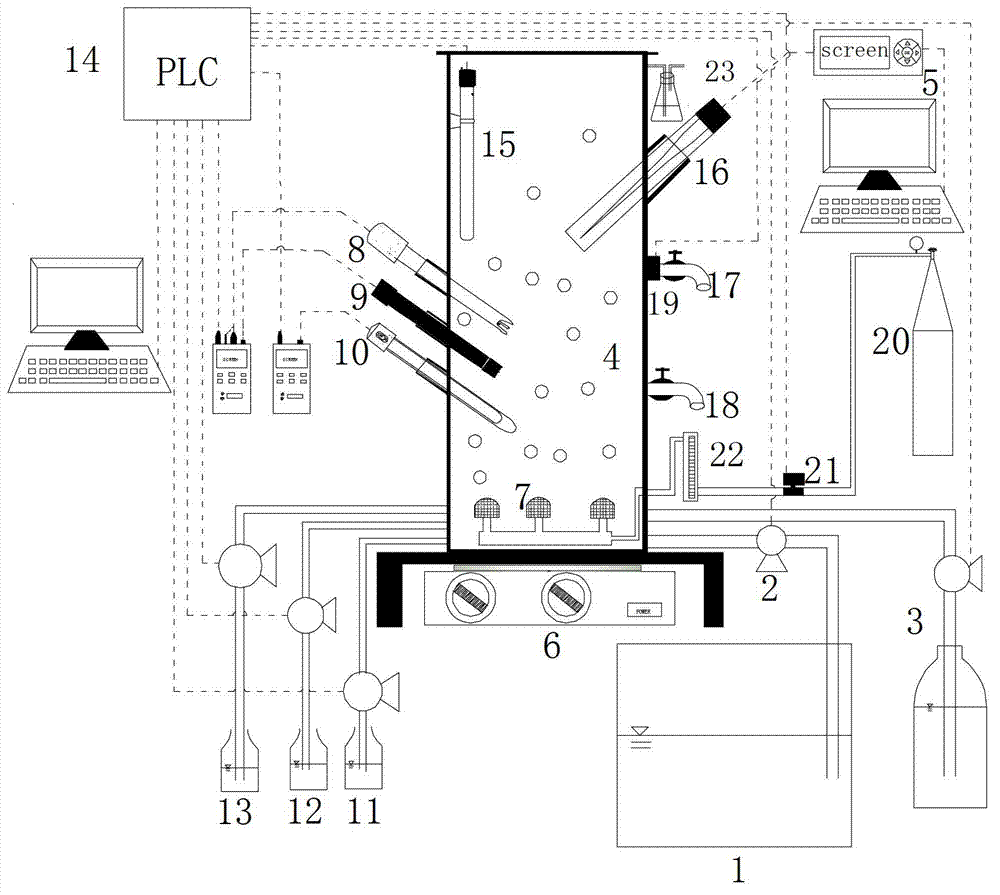

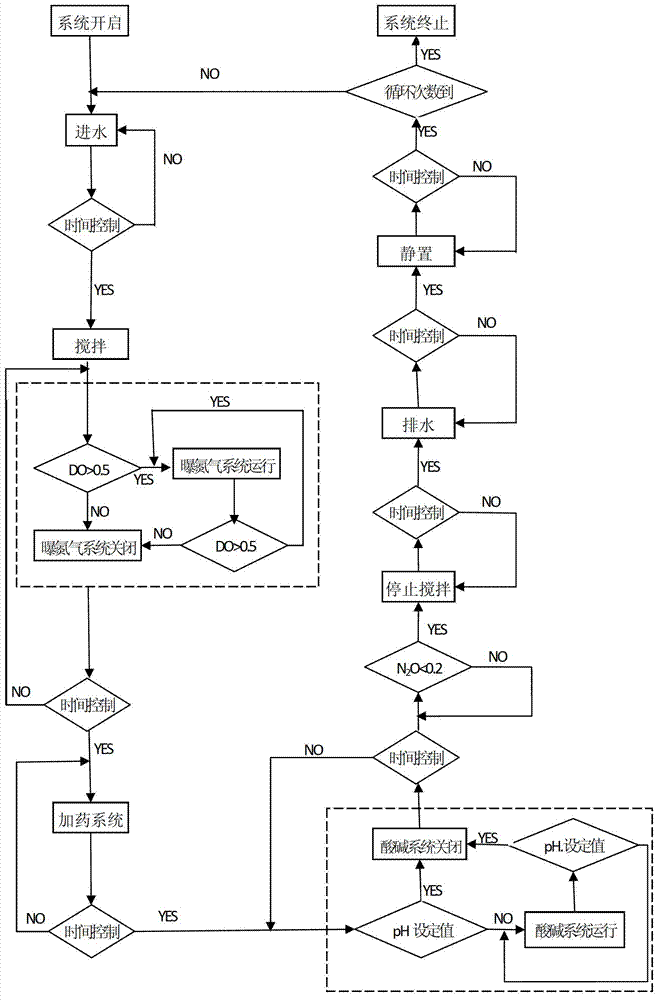

Reduction control device and method for N2O produced in denitrification dephosphorization process

ActiveCN102849850AAutomatic control of online recording dataExcellent process parametersTreatment with aerobic and anaerobic processesTotal factory controlPeristaltic pumpActivated sludge

The invention provides a reduction control device and method for N2O produced in the denitrification dephosphorization process and belongs to the technical fields of automatic control of an activated sludge process treatment system and wastewater biological denitrification dephosphorization by means of a sequencing batch reactor (SBR) process. Aiming at solving the technical problem that sodium nitrite adopted to serve as an electron acceptor produces N2O in the denitrification dephosphorization process in the existing SBR process, the device uses an SBR as a main body and comprises a water distribution tank, a peristaltic pump, a magnetic stirring apparatus, an acid adding system, an alkali adding system, an on-line control system connected with a computer and a N2O on-line detecting system. The on-line control system is connected with a water inlet peristaltic pump, a mud discharging system, the acid adding system, the alkali adding system, a temperature control device, the stirring apparatus, a drain valve, a relay on a magnetic valve of a nitrogen aerating system, an oxidation reduction potential (ORP) sensor, a pH sensor and a dissolved oxygen sensor. The N2O on-line detecting system is connected with a N2O microelectrode. The whole process is automatically finished through a programmable logic controller (PLC) of the computer, and the N2O on-line detecting system performs quantitative analysis to the nitrogen conversion condition to confirm dominant mechanism and influencing factors for the N2O production in the denitrification dephosphorization process.

Owner:SDIC XINKAI WATER ENVIRONMENT INVESTMENT CO LTD

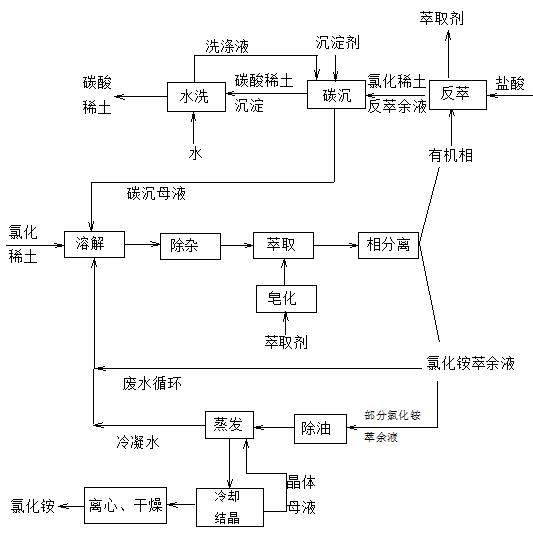

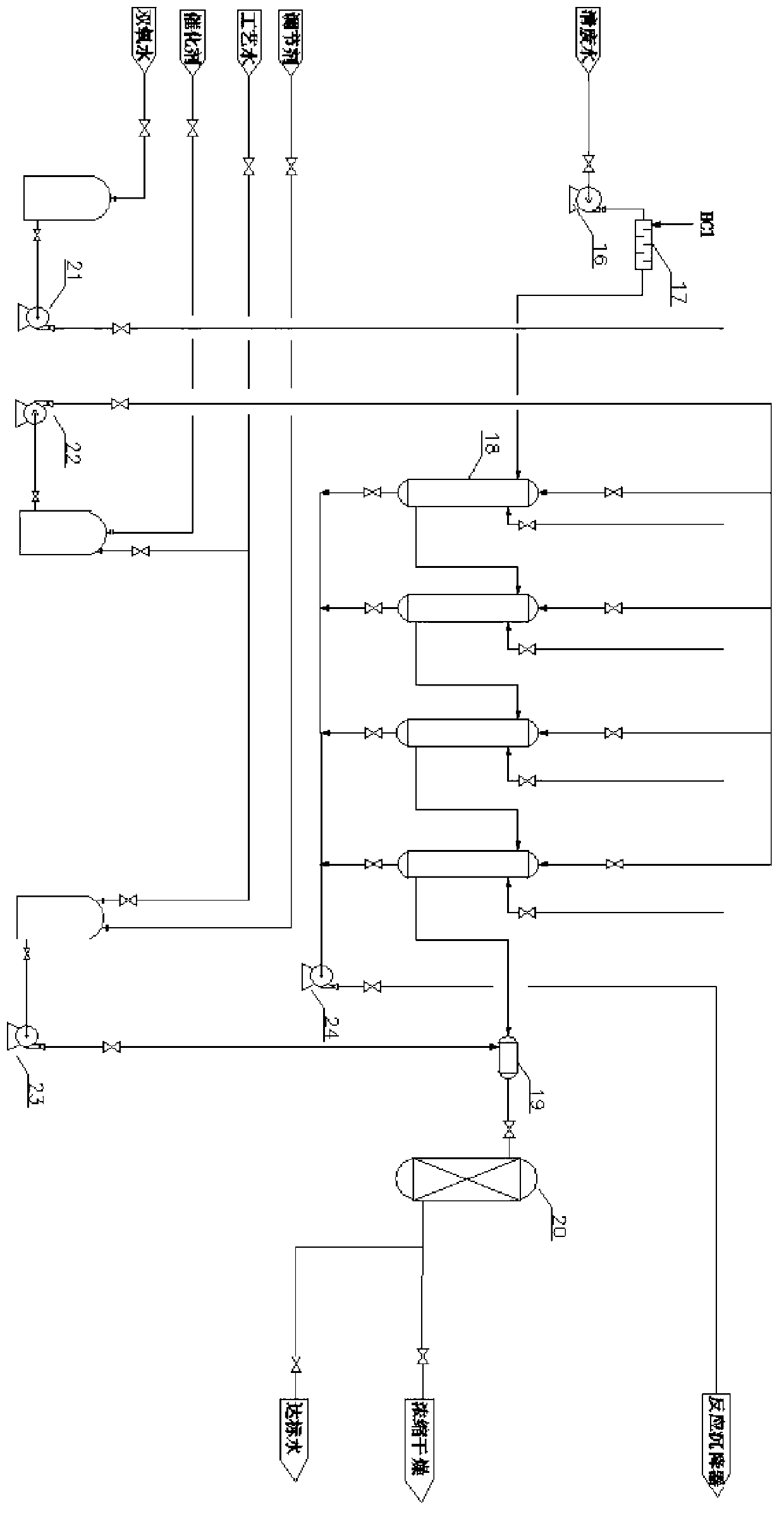

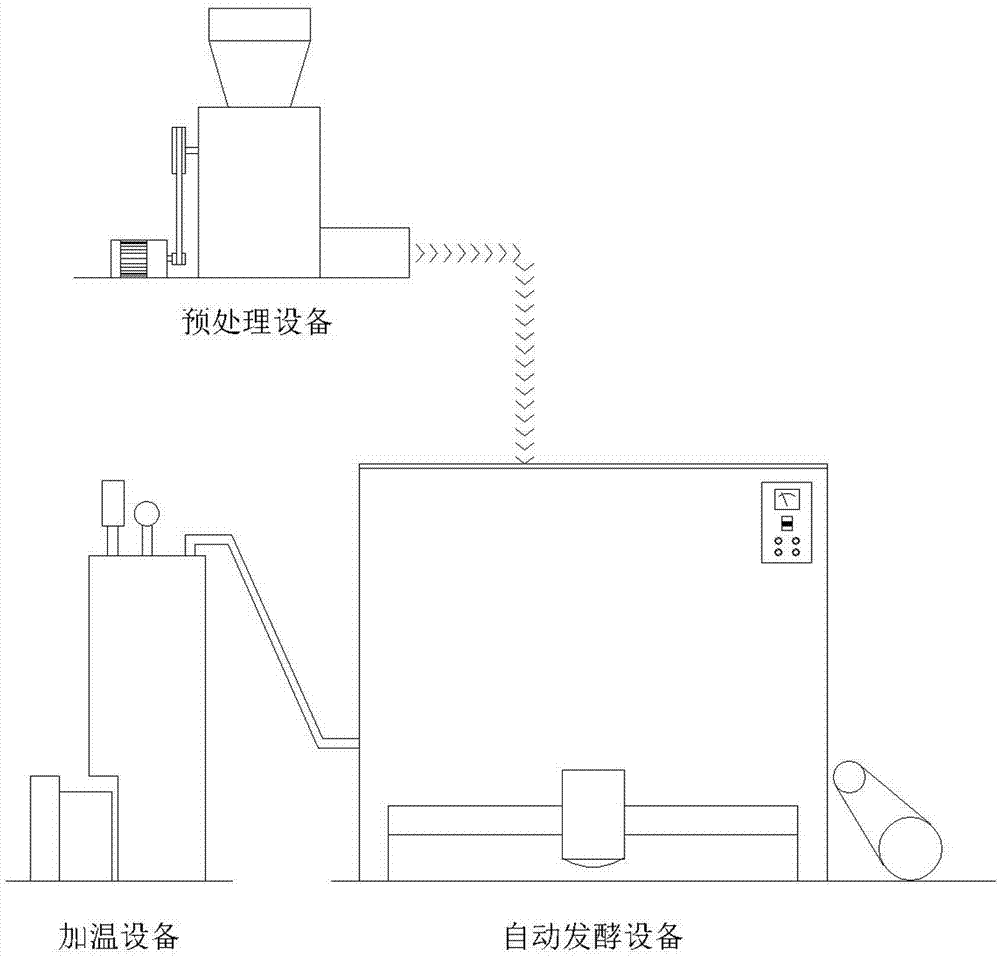

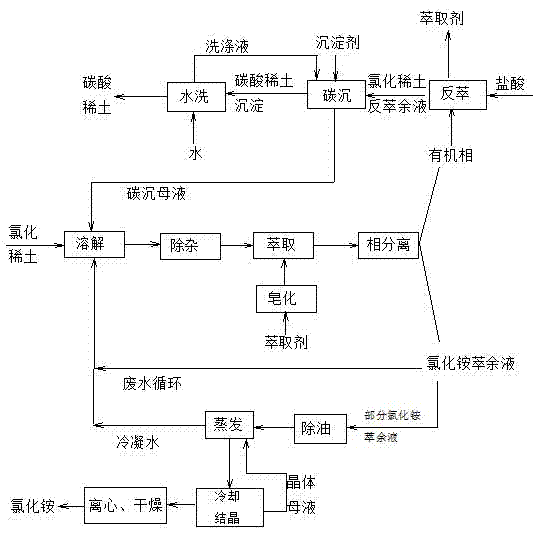

Method for treating rare earth ammonium chloride wastewater

InactiveCN102531025ASimple processHigh recovery rateMultistage water/sewage treatmentRare earth metal compoundsCarbon sinkRare earth

The invention discloses a method for treating rare earth ammonium chloride wastewater, belonging to the field of wastewater treatment. The method for treating the rare earth ammonium chloride wastewater comprises the steps of: dissolving ammonium chloride rare earth, carrying out organic phase saponification, carrying out extraction separation, recycling wastewater, stripping, carbon-sinking, washing, evaporating, cooling and crystallizing. According to the method, ammonium chloride raffinate and carbon sink mother liquor which are generated by extraction separation on the rare earth are used as the solvents of the ammonium chloride rare earth for recycling so that the ammonium chloride in the wastewater is increased, the ammonium chloride is favorably evaporated and condensed, and energy resource consumption is reduced. Meanwhile, washing liquor of rare earth carbonate precipitates is recycled for preparing a precipitating agent, thus water resources are saved. The mass percent of the ammonium chloride in the recycled finished product is 91.7-96.5 percent in the terms of dry basis; and the economic benefit is remarkable, the wastewater is recycled, and zero emission of the rare earth wastewater is recycled.

Owner:江西德盛精细化学品有限公司

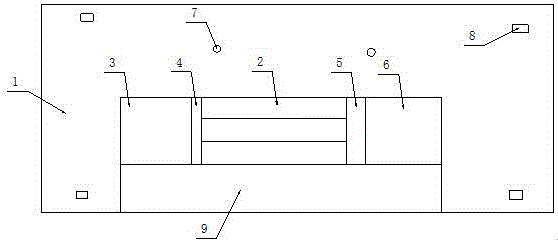

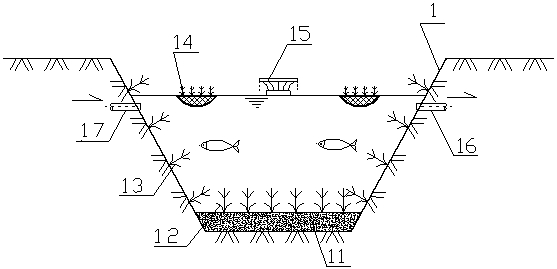

Ecological cycling freshwater aquaculture method

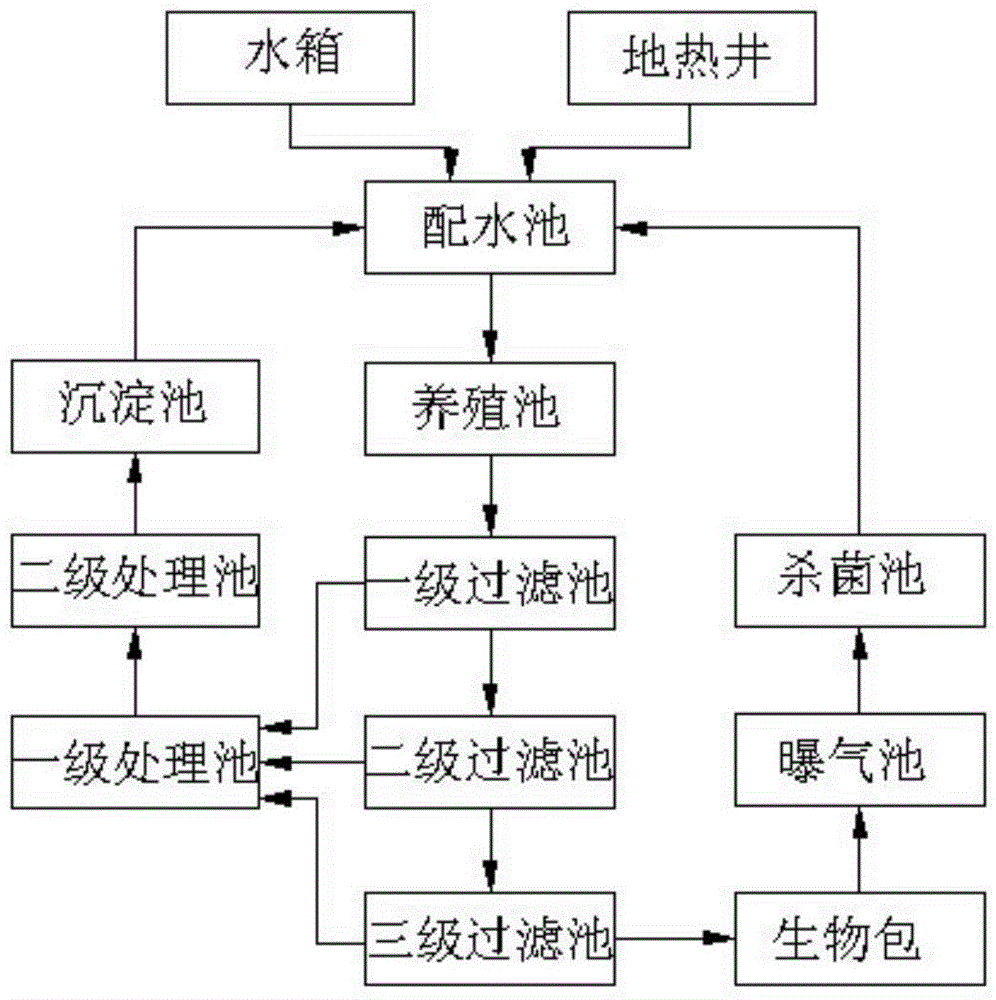

InactiveCN105638515ACompact structureEasy to manageClimate change adaptationPisciculture and aquariaEcological environmentWater source

The invention provides an ecological cycling freshwater aquaculture method. The method comprises: preparing a culture water source, supplying water to culture ponds, filtering water, and treating sewage. The plurality of culture ponds are arranged from left to right in sequence to form a culture pond group. The culture ponds in the culture pond group are connected in parallel, and form a recirculating aquaculture system with a filter tank, a treating pond, a settling pond, a biological package, an aeration tank, and a sterilization pond. Using the ecological cycling freshwater aquaculture method, water of the whole system forms virtuous cycle, and is suitable for growth of freshwater fishes and shrimps, and zero discharge of aquaculture wastewater is realized, and water resource is saved. The ecological cycling freshwater aquaculture method has obvious ecological environment benefits, and meets the sustainable development strategy of the country.

Owner:天津市滨海新区塘沽金岛养殖有限公司

Treatment method of wastewater generated in cyclization step in production process of epoxy chloropropane from glycerol

ActiveCN103342434ARealize "Zero Emissions"Realize resourcesMultistage water/sewage treatmentNature of treatment waterDecompositionSnow melting

The invention relates to a treatment method for high-salinity organic wastewater generated in a production process of epoxy chloropropane from glycerol. The treatment method comprises the steps of: performing hydrolysis reaction on the high-salinity organic wastewater; performing advanced oxidization or wet oxidization; and concentrating and drying. The method is simple and convenient in process flow, easy to operate and control, and environment-friendly; inorganic precipitates in the wastewater can be recovered for producing building materials; organic chlorine-containing compounds in the wastewater are decomposed into glycerol, and the decomposition rate is up to more than 95%; two major pollutants in the wastewater, namely, calcium chloride and glycerol, are utilized for generating an environment-friendly snow-melting agent, so that the pollutant resource recovery is realized. Organic pollutants in the wastewater generated in the advanced oxidization or wet oxidization can be mineralized; calcium chloride in the wastewater is utilized for producing industrial calcium chloride. The treatment method has the beneficial effect that 'zero release' of the wastewater generated in a cyclization step in the production process of epoxy chloropropane from glycerol can be realized.

Owner:NINGBO HUANYANG CHEM

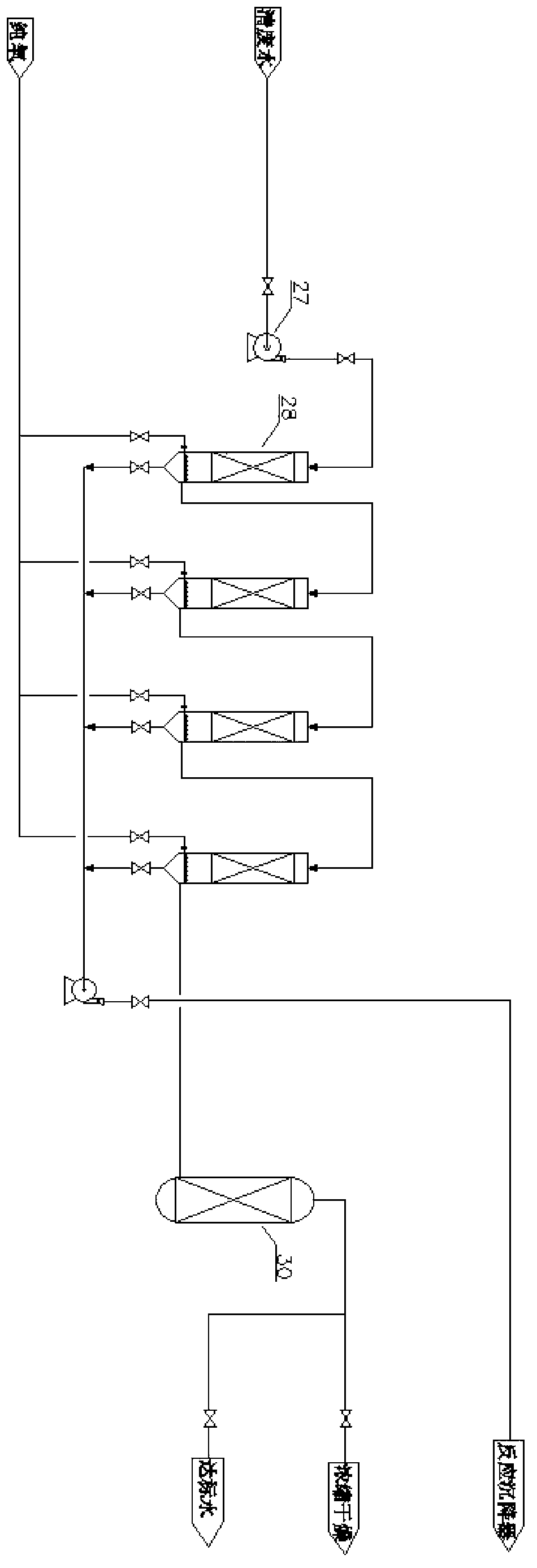

Coking waste water zero discharge treatment process

InactiveCN1948188AAchieving "Zero Emissions"Realize "Zero Emissions"Multistage water/sewage treatmentWater/sewage treatment by degassingDistillationWater quality

The present invention relates to a pyrogenic waste water zero discharge treatment process. It is characterized by that said process includes the following steps: making the pyrogenic waste water undergo the process of primary ammonia distillation treatment, then making biochemical treatment, and making the treated waste water be directly returned into the dust-removing system of steel-smelting converter, utilizing converter smoke dust and flue gas to further degrade the pollutants of amino nitrogen, phenol, cyanogens and COD in the pyrogenic waste water under the high temperature condition, and making the discharged water undergo the processes of flocculating settling, filtering and water quality stabilization so as to attain the discharge requirement.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

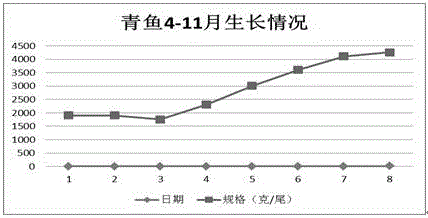

Aquaculture method of high-quality and high-yield clear water grass carp

InactiveCN106069953AImprove meat qualityHigher fiberFood processingClimate change adaptationFiberWater quality

The invention provides an aquaculture method of a high-quality and high-yield clear water grass carp. The aquaculture method comprises the following concrete steps: (1) building a pond; (2) carrying out pre-treatment on the pond; (3) stocking fries; (4) feeding feed; (5) regulating and controlling water quality; (6) preventing and treating diseases; and (7) fishing in good time. By adopting the aquaculture method provided by the invention, fish flesh quality of the grass carp is improved after the grass carp is cultured for two years, content of fibers and proteins in the fish flesh is greatly increased, the fish flesh is tender and crisp, and the fish flesh is boilproof and does not break and taste is delicious and refreshing, so that high-quality grass carp with crisp flesh is obtained; besides, by virtue of reasonable distribution of feed, on one hand, the fish flesh quality of the grass carp is hard, crisp and tasty and the fish flesh is delicious and refreshing in taste, and on the other hand, the feed adopts Se-enriched feed, organic selenium content of a feedstuff fish is increased, digestive absorption of the grass carp to selenium is promoted. Compared with common grass carp, selenium content of the grass carp cultured by adopting the method is 10 times that of the common grass carp, health function is obviously enhanced, and immunity of a human body can be enhanced.

Owner:兴业县葵峰双江原生态草鱼养殖场(微型企业)

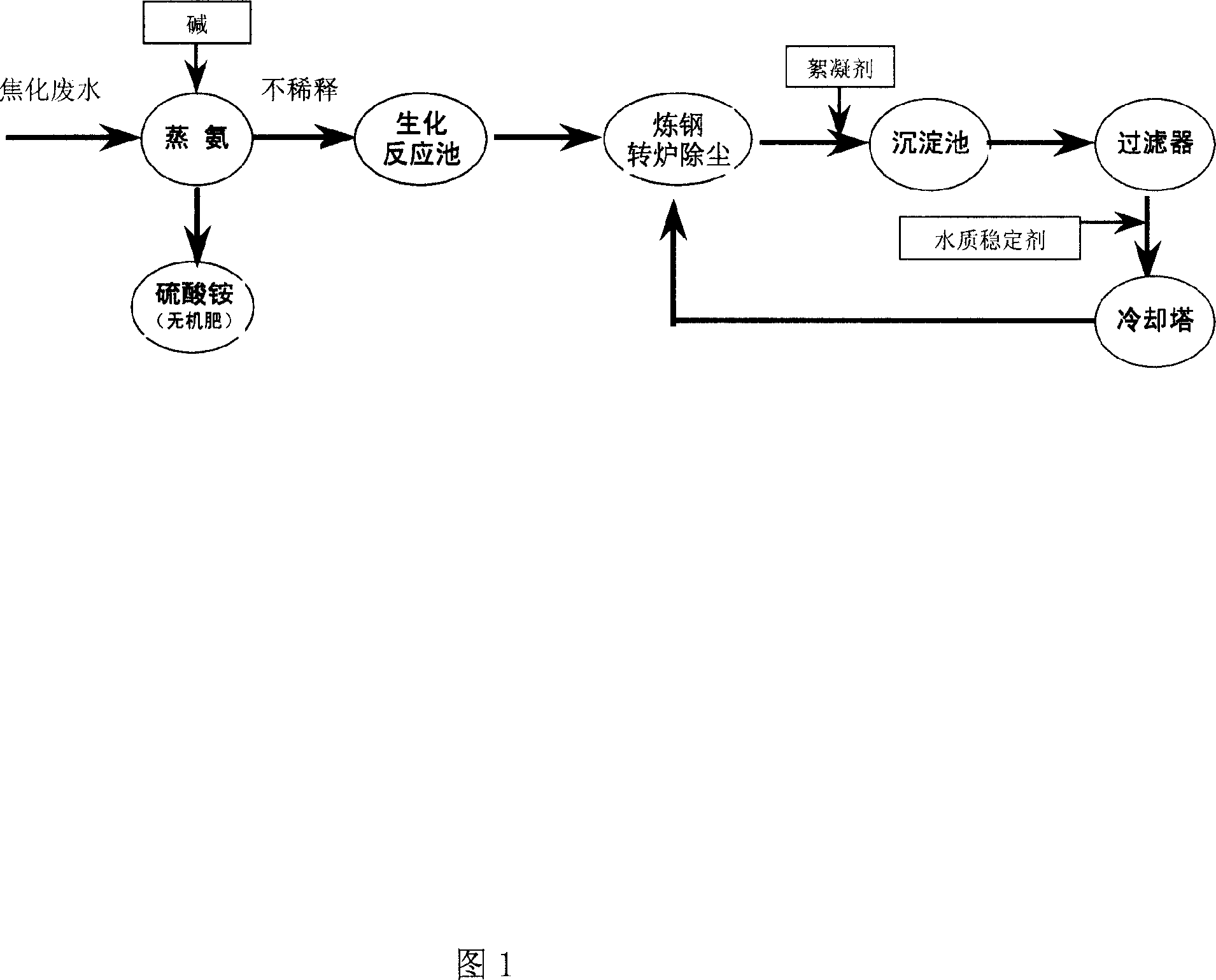

High-ammonia nitrogen low C/N ratio waste water treatment process and use thereof

InactiveCN101139134ASimple processGood denitrification effectWaste based fuelSustainable biological treatmentChemistryNitrogen fertilizer

The present invention provides a treatment technics and application to wastewater with high ammonian and low C / N ratio. The technics adopts a compound technics of ''pretreatment plus immobilized microorganism-biological aerated filter''. Firstly, the wastewater enters the S section of the compound technics and most of the suspended substances and part of the COD are removed to prevent the suspended substances in the wastewater from plugging the filter materials in IBAF and guarantee the stable operation of the subsequent IBAF technics. The yielding water of the S section enters the IBAF biological treatment technics to remove most ammonian and COD in the wastewater and the yielding water can be discharged out directly or recycled after a proper depth treatment. Compared with the prior art, the present invention has the advantages of simple S-IBAF technics, good denitriding effect, small area occupancy, low operation cost, low mud output and convenient operation and management. The present invention has the applications that the present invention not only has specific effects on compounding the industrial wastewater of ammonia and nitrogenous fertilizer, the industrial wastewater of the coal combined methanol, the wastewater of leather, the corn deep processing of the food industry, the wastewater treatment and alteration in the monosodium glutamate industry, but is also suitable for other treatment technics and application to wastewater with high ammonian and low C / N ratio.

Owner:北京盖雅技术中心有限公司

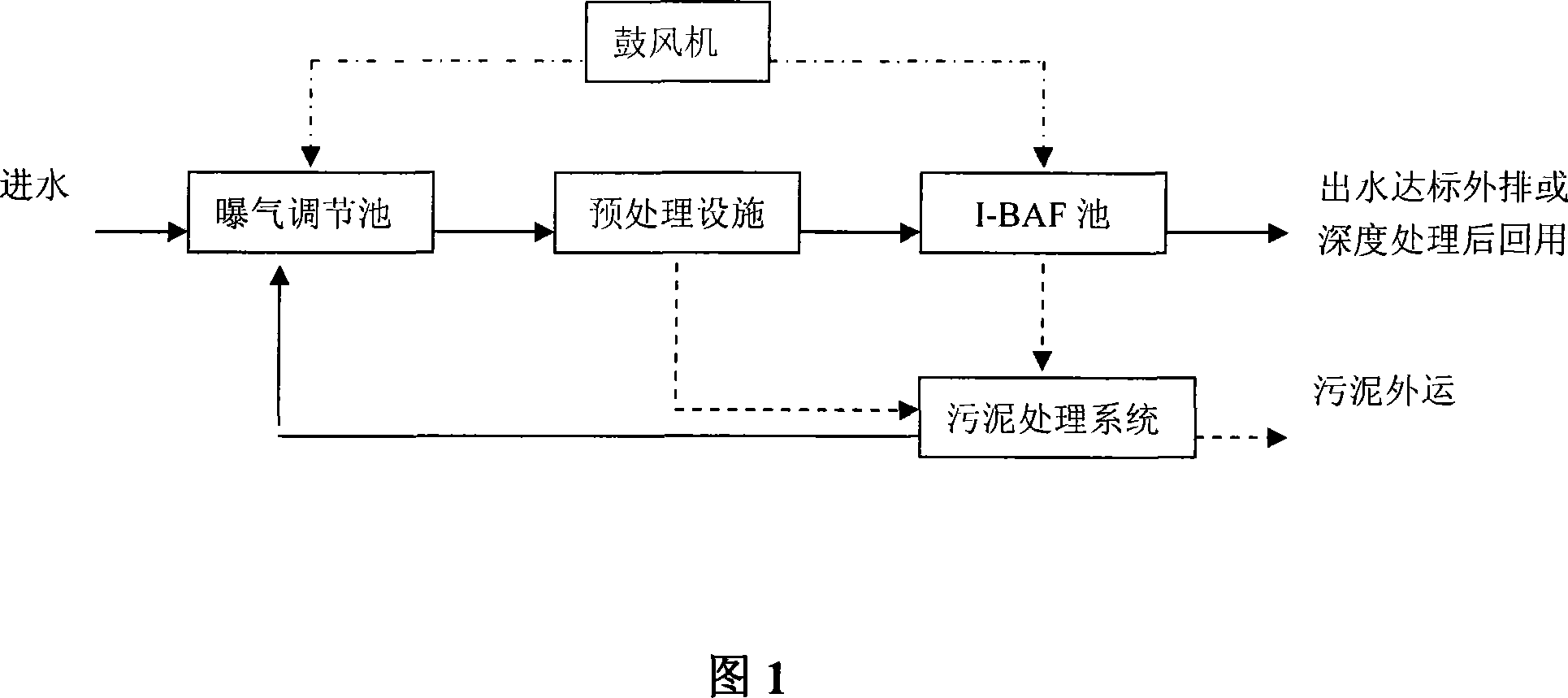

Rapid harmless plant organic residue treatment and fertilizer utilization process and equipment thereof

ActiveCN102951939ASolve pollutionAchieving "Zero Emissions"Bio-organic fraction processingOrganic fertiliser preparationBiotechnologyActive state

The invention provides a rapid harmless plant organic residue treatment and fertilizer utilization process and equipment thereof, and relates to a harmless and efficient treatment technology for vegetable depot vegetable residues, and equipment thereof. According to the present invention, processes of an automated machinery treatment and a rapid fermentation treatment are adopted, and vegetable residue treatment equipment is adopted to treat vegetable residues, wherein the vegetable residue treatment equipment comprises parts such as a pre-treatment device, a heating device and an automatic fermentation device, and the vegetable residue treatment process comprises steps such as material pre-treatment, ratio performing, fermentation and post-treatment. With the present invention, high quality active organic fertilizer can be rapidly produced, a vegetable depot pollution problem can be completely solved, zero emission of organic waste in the vegetable depot can be really achieved, and high quality organic fertilizers with characteristics of excellent color, excellent odor and excellent nutrient, and nutrition organic matrixes can be produced, wherein beneficial bacteria in the organic fertilizer is at an active state, and can continuously produce beneficial biological effects after the bacterial is applied into soil.

Owner:湖南回龙湖现代农业科技有限公司 +1

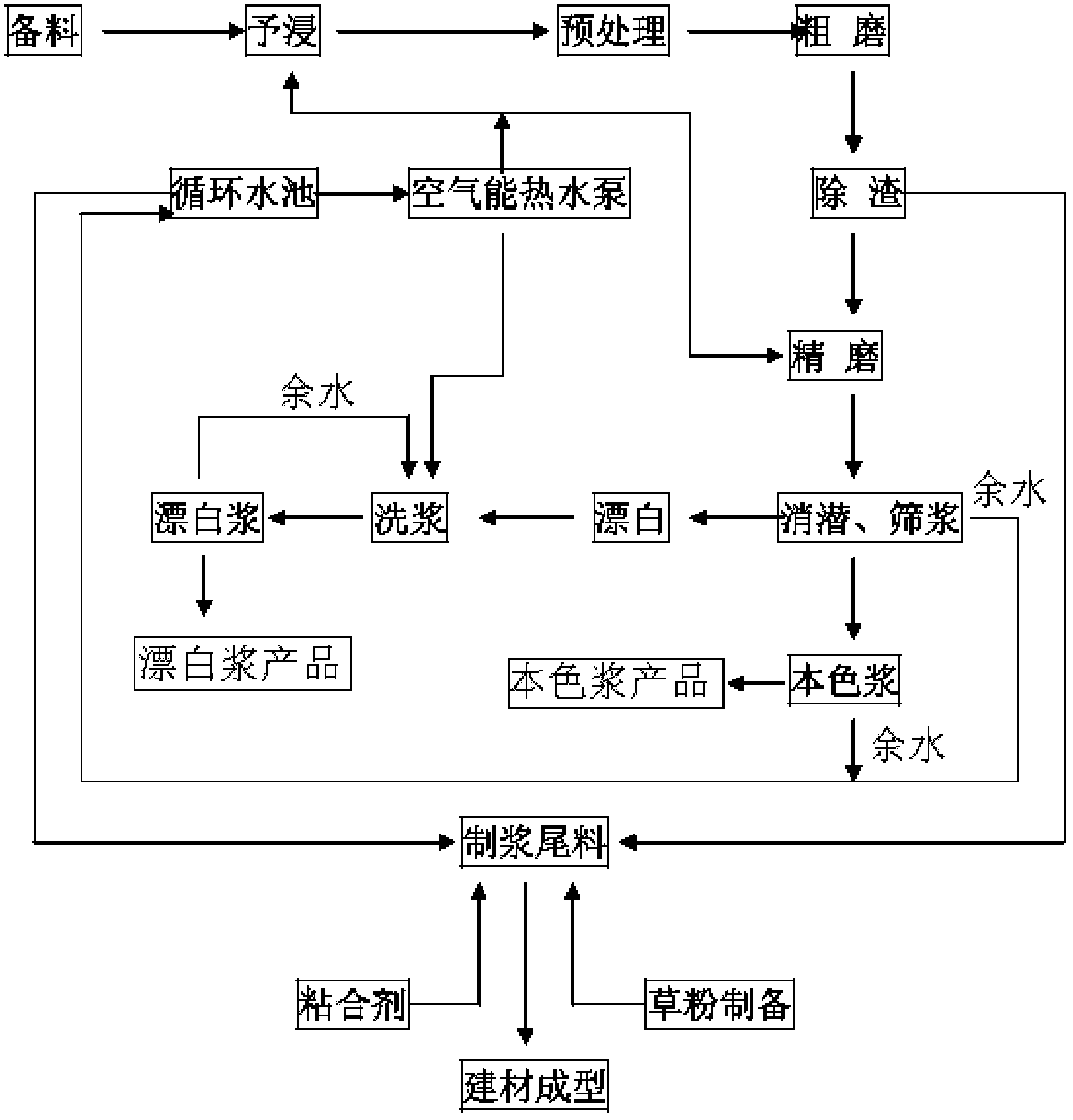

Environment-friendly clean pulping process

ActiveCN102587181AAchieving "Zero Emissions"Realize "Zero Emissions"Washing/displacing pulp-treating liquorsPulp bleachingWater circulationPulp and paper industry

The invention belongs to the field of paper-making pulping and particularly relates to an environment-friendly clean pulping process. The pulping process comprises four steps of: mechanical grinding, bleaching by using active hyperoxide, cyclic utilization of pulping residual water and comprehensive utilization of pulping tailing. According to the method, the mechanical grinding is used to replace chemical cooking for the pulping; environment-friendly chemicals are used for replacing conventional chemicals; the pulping process is changed; an air-source hot water pump is used to replace a boiler to provide hot-water circulation; and the purpose of environment-friendly clean pulping is achieved.

Owner:谢明文

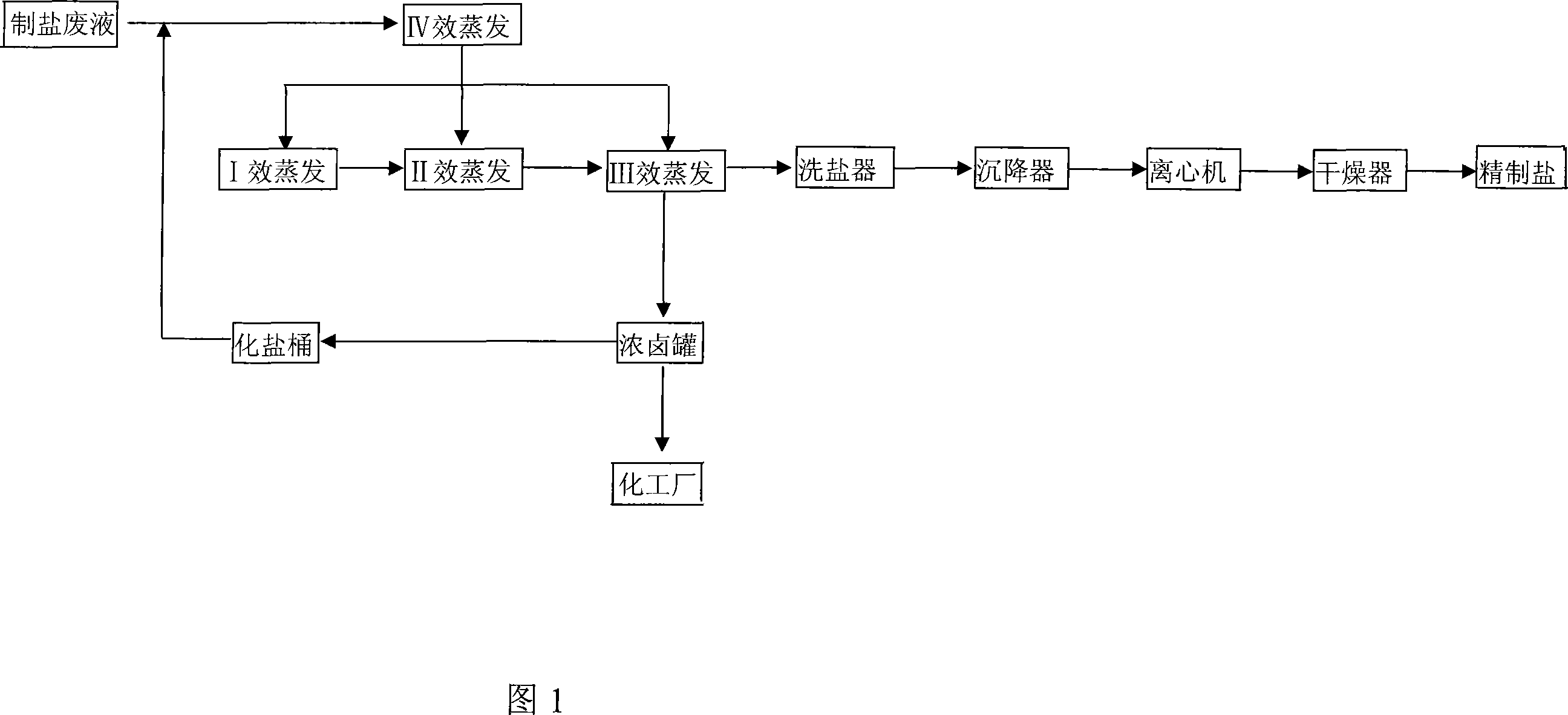

Technique for producing refined salt from salt production waste liquid

ActiveCN101104532AIncrease productionQuality improvementGeneral water supply conservationSeawater treatmentWater desalinationLiquid waste

The present invention provides a refined salt preparation technology by using salt-making liquid waste. The technology comprises the following five steps: evaporation and concentration, mother liquor thickening, bitter salt recovery, washing and dehydration, as well as drying and packaging, and the refined salt will be finally sent to the salt storehouse. The effect of the invention is that the advanced vacuum salt-making technology and salt washing process are adopted in stead of alternative drying to produce high-quality industrial salt so as to improve the yield and quality of industrial salt. Meanwhile, the invention can also help improve the concentration of bittern that enters into the potassium-making work section to reduce the salinity and provide high-quality raw materials for the production of chemical plants; the application of the invention can save the alternative drying area, raise resource utilization rate, increase product yield and reduce the loss of chemical resources to provide a model road for comprehensive utilization of the seawater salt industry as well as the concentrated seawater salt-making after the desalination. The invention achieves organic combination between the new-type salt-making industry and the ocean chemical engineering and realizes zero-discharge of the salt-making waste liquid to make the brine resources be scientifically protected and rationally used. The invention can also protect the marine environment and gradually realize factory salt production.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

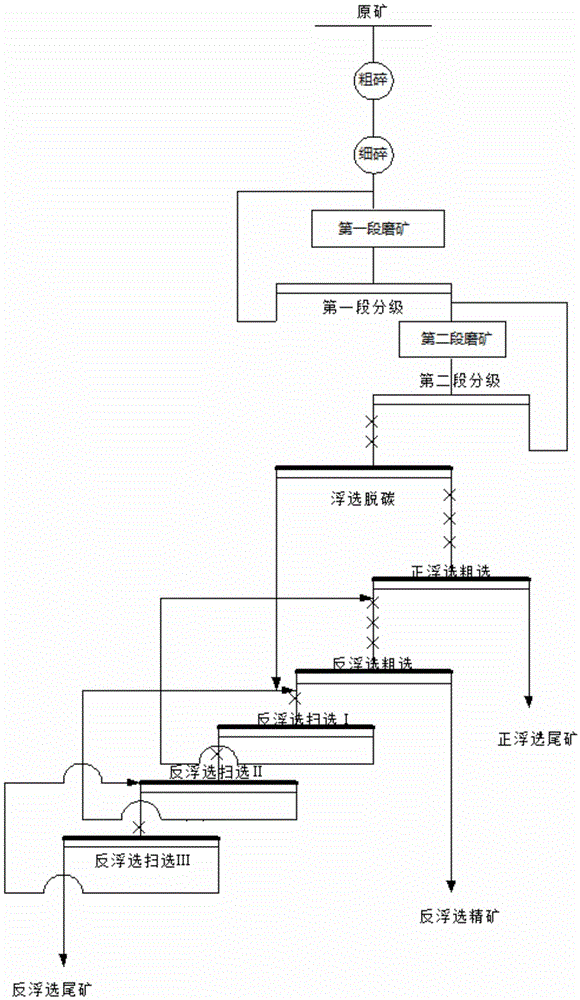

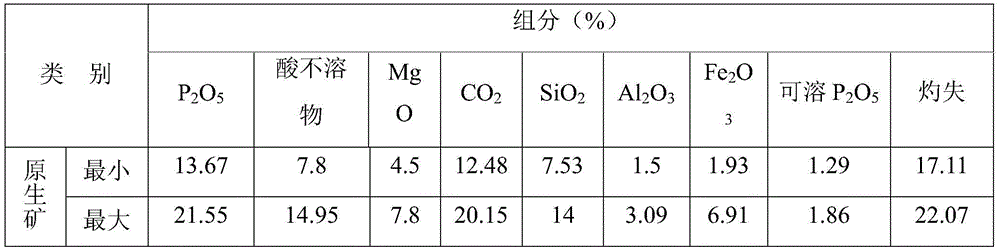

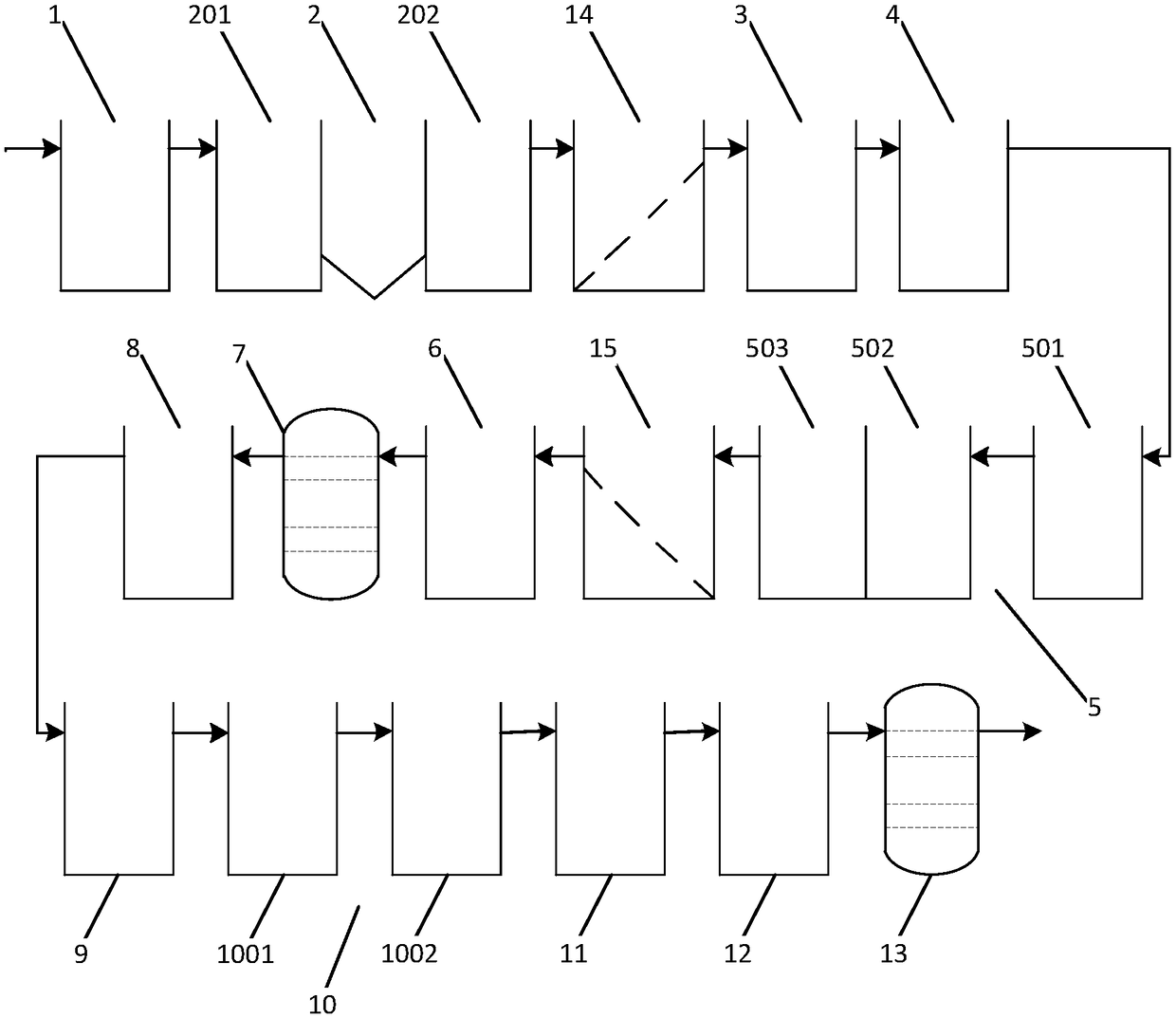

Process for mineral processing of low-grade silicon calcium collophanite

The invention discloses a process for mineral processing of low-grade silicon calcium collophanite. The process sequentially comprises smashing, ball milling, flotation decarburization, positive flotation roughing, reverse flotation roughing and reverse flotation scavenging. A specific collecting agent and a foaming agent are added into silicon calcium collophanite pulp in the flotation process. The process has the advantages that 1) high-grade phosphate concentrate can be obtained from low-grade phosphorite raw material, the influence of organic carbon on positive and reverse flotation is reduced, the effect of agent adsorption by organic carbon is eliminated, the production cost is reduced, and the grade of phosphate concentrate is improved; 2) the collecting agent is improved, so that the flotation efficiency is improved, the normal temperature flotation is achieved, and the flotation temperature is reduced from 35 DEG C to 17-25 DEG C; 3) due to the adoption of nonhazardous and efficient agent, concentrate water and tailing water are not treated, are subjected to closed cycle and are not discharged, and zero emission is achieved.

Owner:XIANGXI XINHUI EL CHRONIUM CO LTD

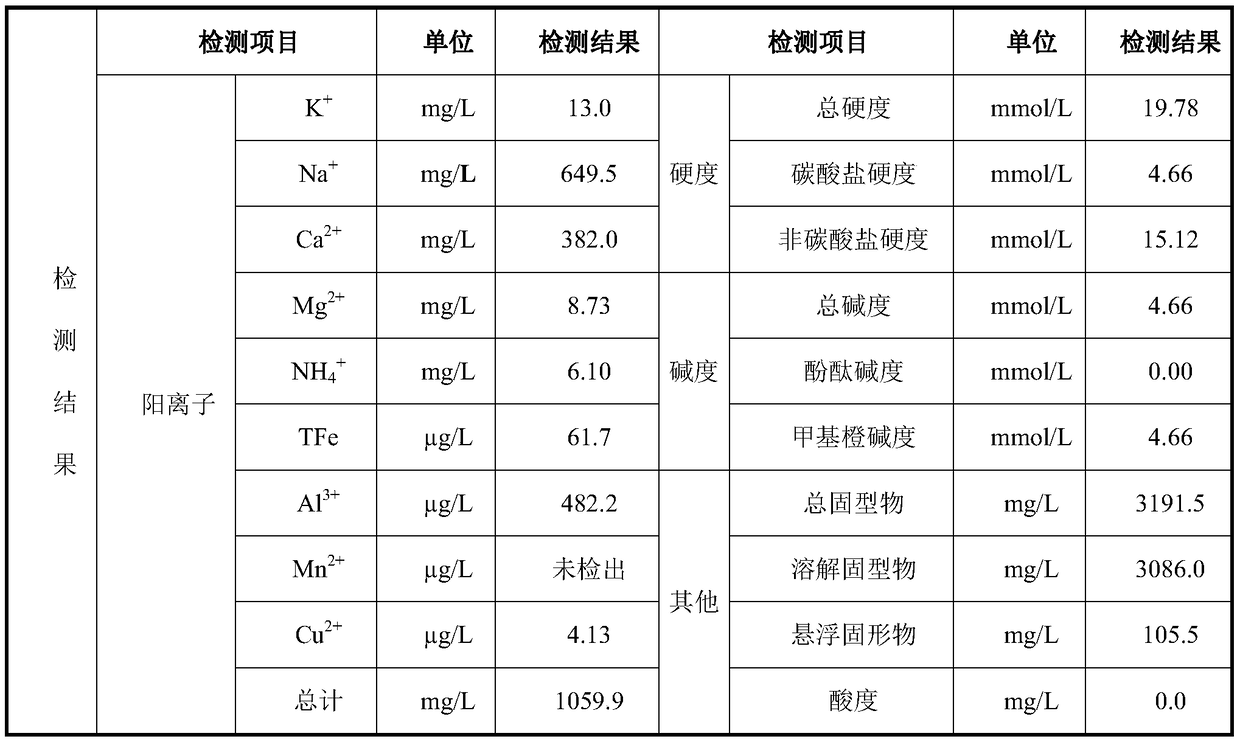

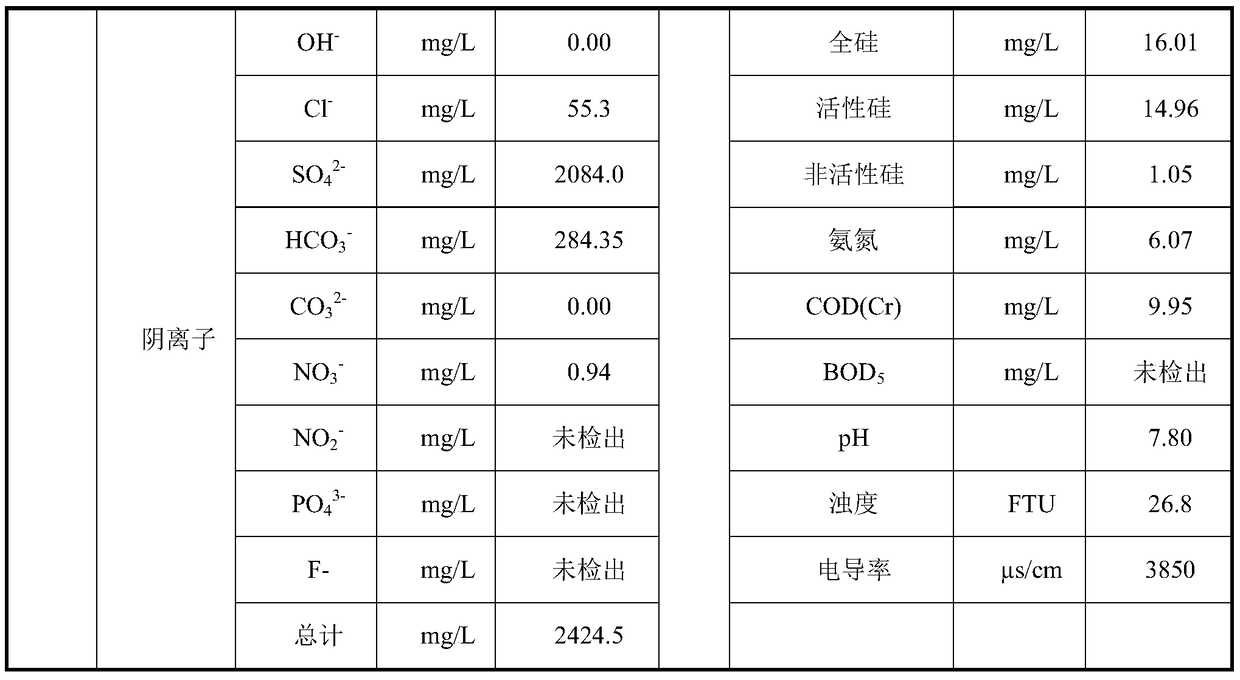

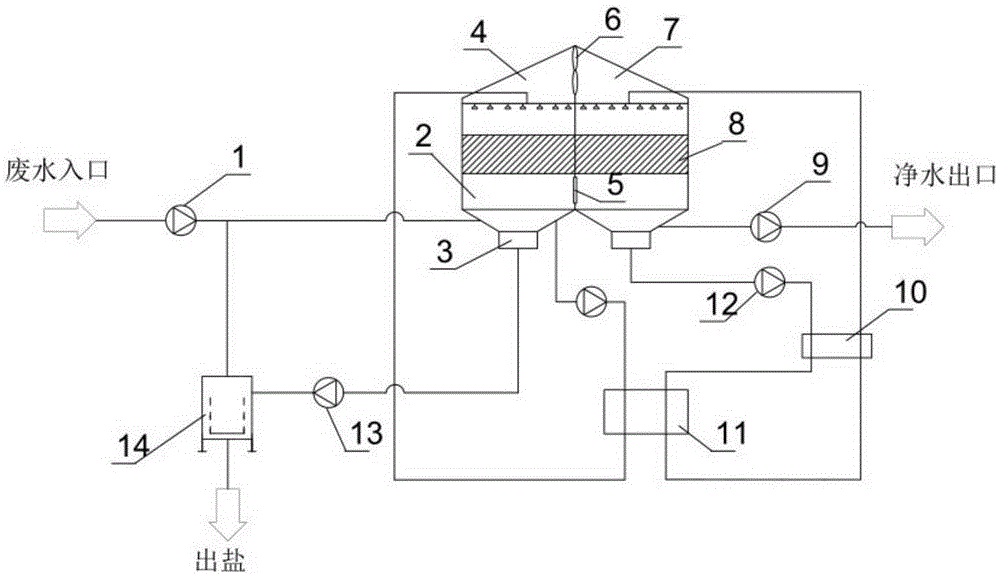

Treatment method and system for reutilization and resource utilization of high-mineralization mine water

PendingCN109231632AImprove processing efficiencyAchieving "Zero Emissions"Scale removal and water softeningWater/sewage treatment by ion-exchangeResource utilizationEvaporation

The invention provides a treatment method and system for reutilization and resource utilization of high-mineralization mine water. The treatment method comprises the following steps: firstly, pre-treating to effectively reduce the rigidity and form calcium carbonate sediment; recycling the calcium carbonate and carrying out first-time desalting; secondly, concentrating and carrying out second-timedesalting; finally, carrying out evaporation and crystallization treatment to really realize zero emission of wastewater. The treatment technology and system, provided by the invention adopt a reasonable flow design; the system is operated stably, the treatment efficiency of the wastewater is high, energy sources are saved, and the treatment cost is effectively reduced.

Owner:华电水务工程有限公司

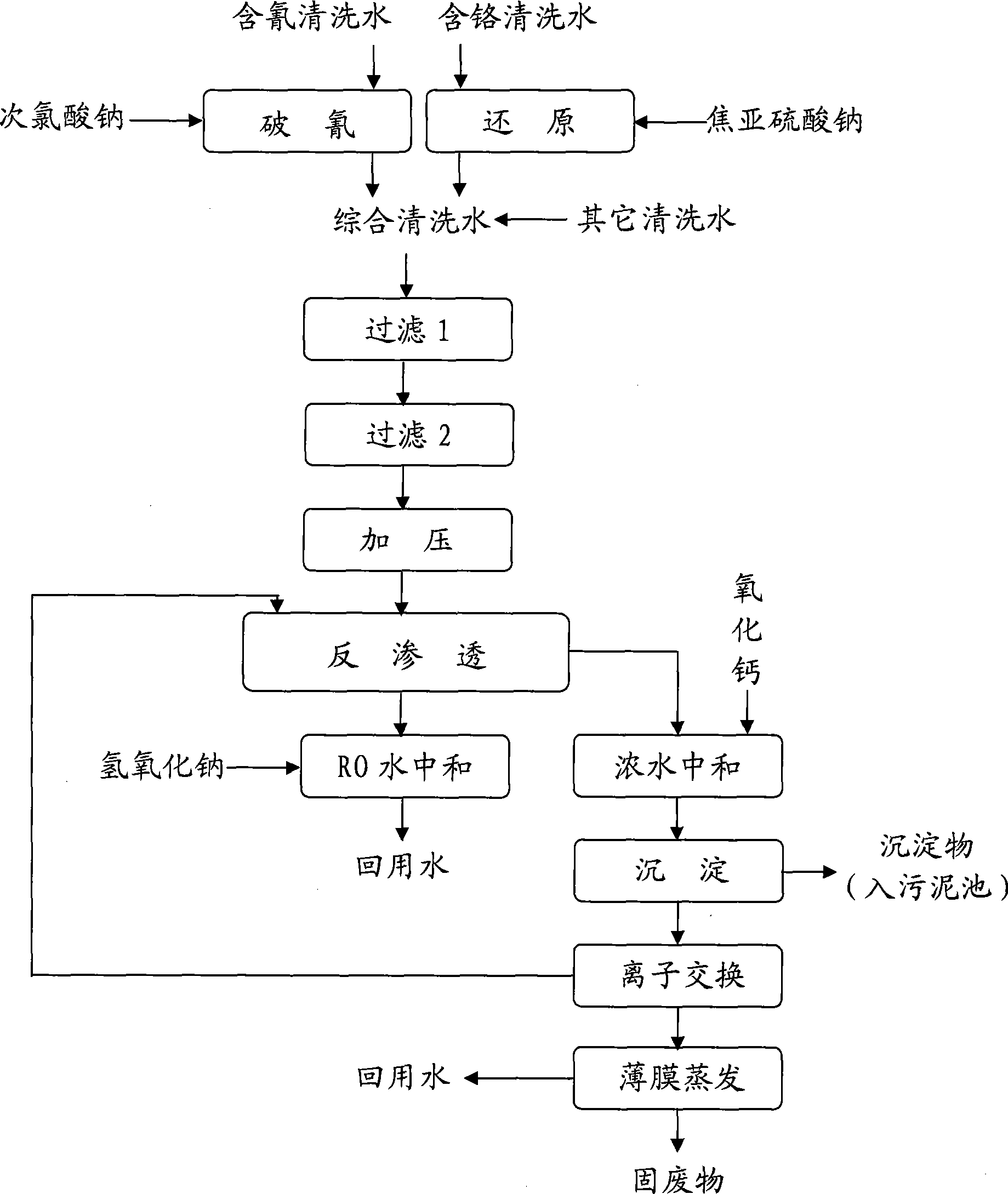

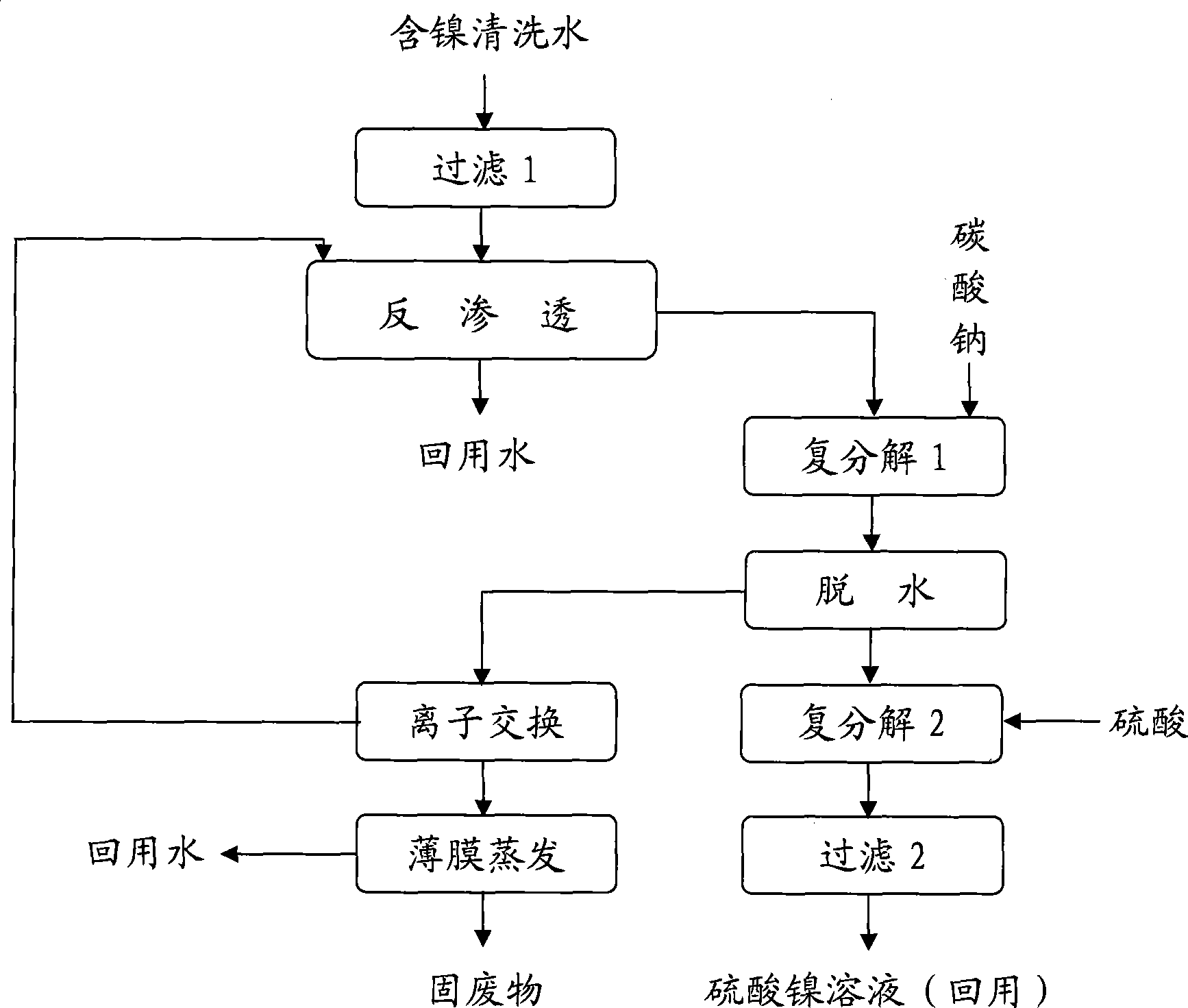

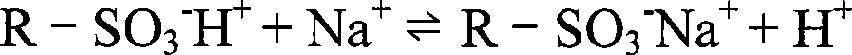

Electroplating washing water zero discharge method

InactiveCN101392402ASolve the waste of resourcesAchieving "Zero Emissions"CellsIon exchangeZero emission

The invention relates to a method for realizing zero emission of electro-plating cleaning water; the recovery rate of the treatment of electro-plating cleaning water in the prior art is about 75 percent. The invention proposes a zero emission technique for electro-plating cyanide, chromium compound and / or nickel cleaning water, which adds an ion exchange process to the original discharged concentrate water on the basis of the recovery of RO (reserve osmosis) water through reverse osmosis concentration method, so as to transfer the soluble impurity ions to resins, thus reducing the content of impurity ions in the concentrated water and returning to the RO system for purification; the wastewater generated by the regeneration of resins is membrane vaporized and recycled, thus realizing 'zero emission'. The technical process is scientific and reasonable, which not only avoids dirt blocking and short service life of membrane processing, but also overcomes the problem of too large vaporization energy consumption of direct heating.

Owner:海宁市海整整流器有限公司

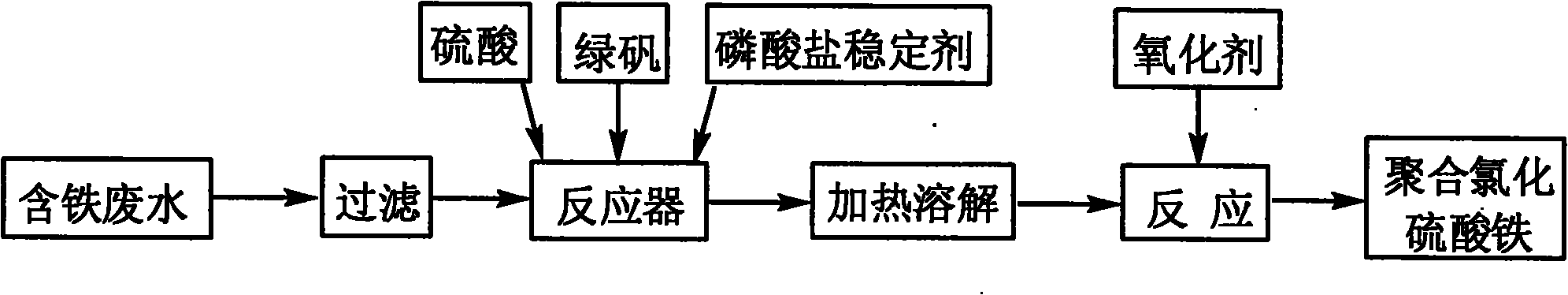

Method for preparing water purifying agent poly-ferric sulfate chloride by utilizing iron-containing wastewater in potassium fluotitanate production

InactiveCN101786707ASimple processReliable workmanshipWater contaminantsMultistage water/sewage treatmentPhosphatePotassium

The invention relates to a method for preparing a water purifying agent poly-ferric sulfate chloride by utilizing iron-containing wastewater in potassium fluotitanate production. The invention adopts a technical scheme that: the iron-containing wastewater discharged in the potassium fluotitanate production is directly utilized as a raw material; copperas and industrial sulphuric acid are added to regulate the total iron concentration and the acidity; a phosphate-tartrate composite stabilizer is added into the raw material; and at normal pressure, Fe2+ in the mixture is oxidized into Fe3+ through an oxidizer at the temperature of between 60 and 90 DEG C and the mixture is hydrolyzed to generate the poly-ferric sulfate chloride. In the method, the iron-containing wastewater in the potassium fluotitanate production is fully utilized to prepare the high-efficient poly-ferric sulfate chloride, and defects of poor process effect on the iron-containing wastewater and severe secondary pollution in the prior art are overcome; and the zero emission of the wastewater in the potassium fluotitanate production is realized, and new pollution is not caused so as to achieve the aim of changing the waste into the treasure. The method has the advantages of simple process flow, mild conditions, easy operation and control, no need of special or complicated equipment, small investment, quick effect, obvious economic and environmental benefits, and convenient promotion and industrial production. The product of the invention is suitable to be used as a treatment agent for multiple kinds of industrial wastewater and domestic sewage, particularly for heavy sewage.

Owner:HUNAN UNIV OF SCI & TECH

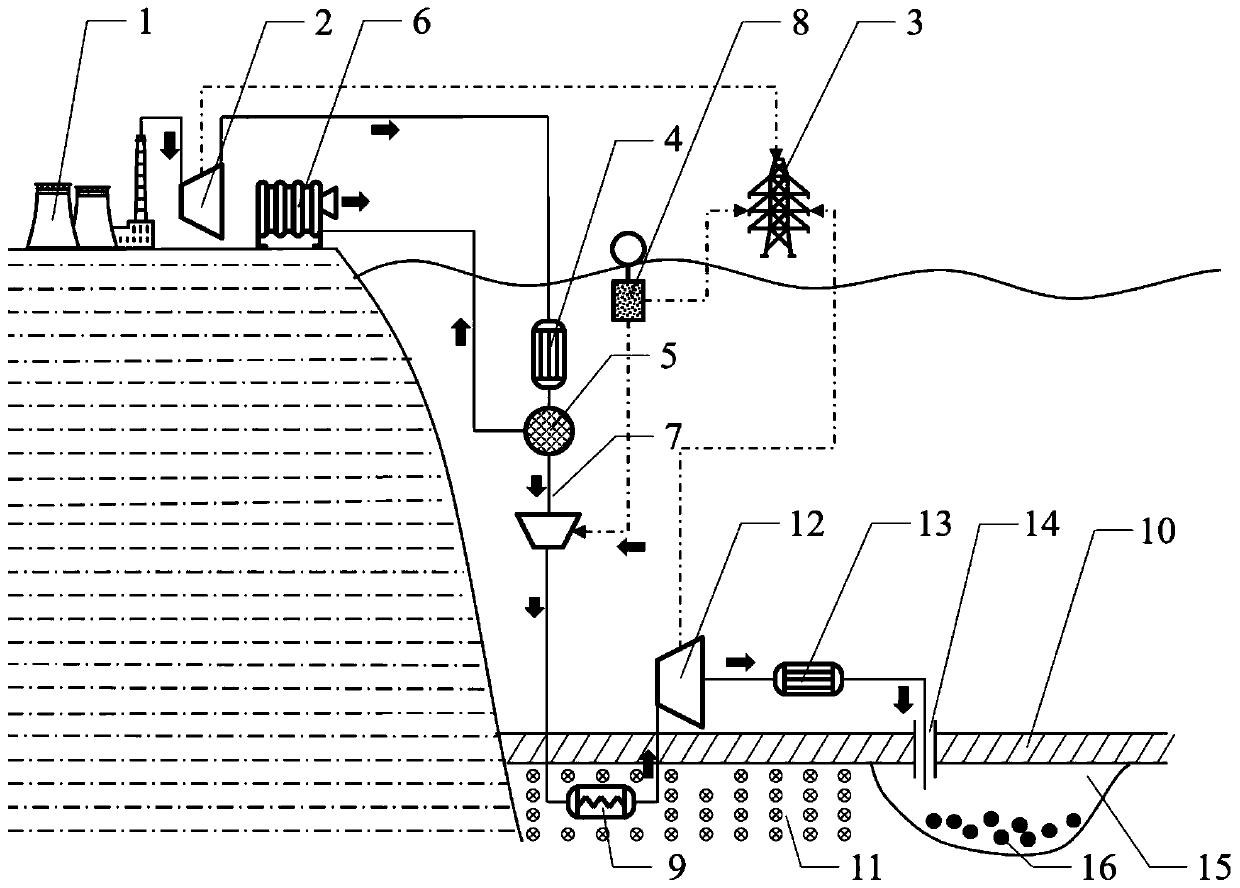

Deep-sea carbon storage and power generation system

The invention discloses a deep-sea carbon storage and power generation system. The deep-sea carbon storage and power generation system comprises a waste heat turbine, a waste gas heat exchanger, a gasstripping device, a waste gas treatment device, a supercritical carbon dioxide compressor, wave energy power generation equipment, a geothermal heat exchanger, a supercritical carbon dioxide turbineand a seabed cooler. According to the deep-sea carbon storage and power generation system disclosed by the invention, waste heat power generation and carbon dioxide stripping are performed on power plant waste gas, and the stripped carbon dioxide is applied to a seabed geothermal Brayton cycle, and is finally stored in deep-sea storage holes. The system is compact in structure, is small in size and is high in efficiency. Rich seabed geothermal energy is used as a heat source, is free of pollution and is low in cost; carbon dioxide is stored in the form of carbon dioxide hydrate, is relativelylow in cost, is environmentally-friendly and is good in leakproofness; and a dried oilfield, gas field or natural hole with a good storage cover in a seabed geologic body is utilized as a carbon storage site, so that the storage effect is good, and later-period maintaining and monitoring cost is reduced, and therefore, the system has a wide application prospect.

Owner:XI AN JIAOTONG UNIV

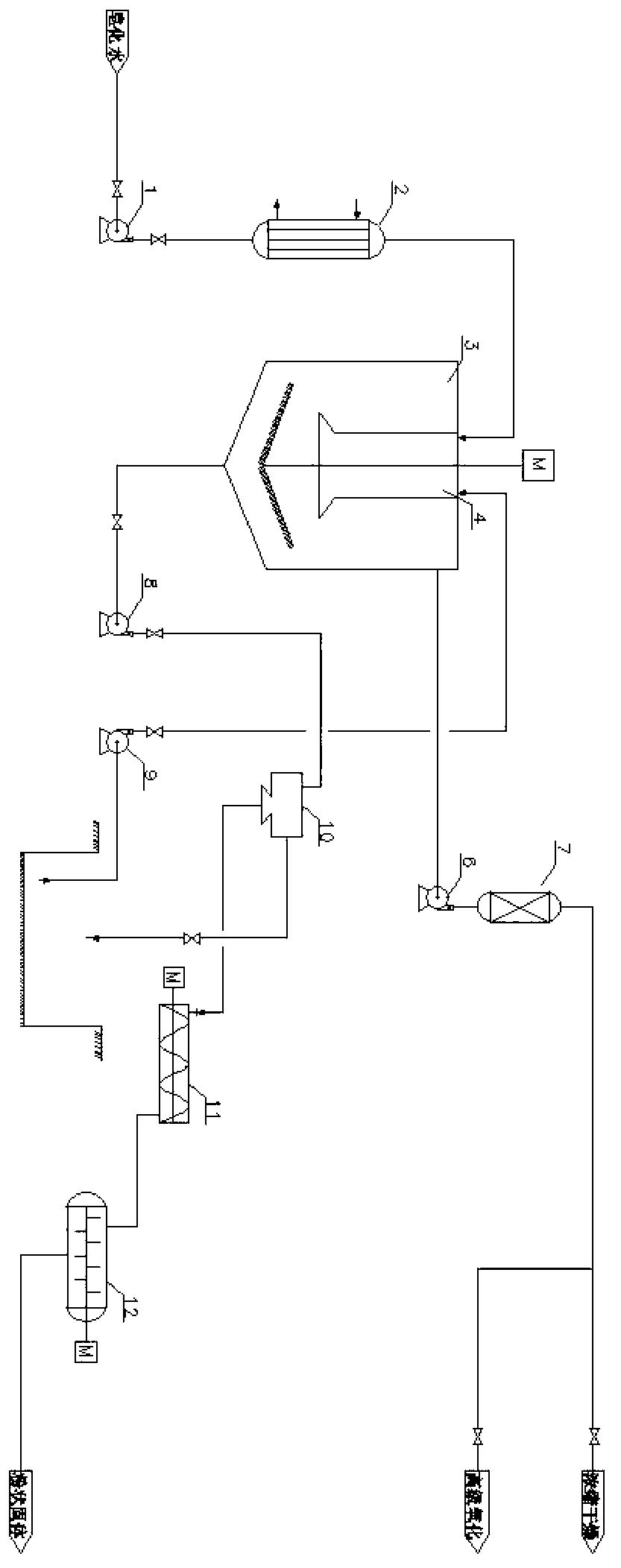

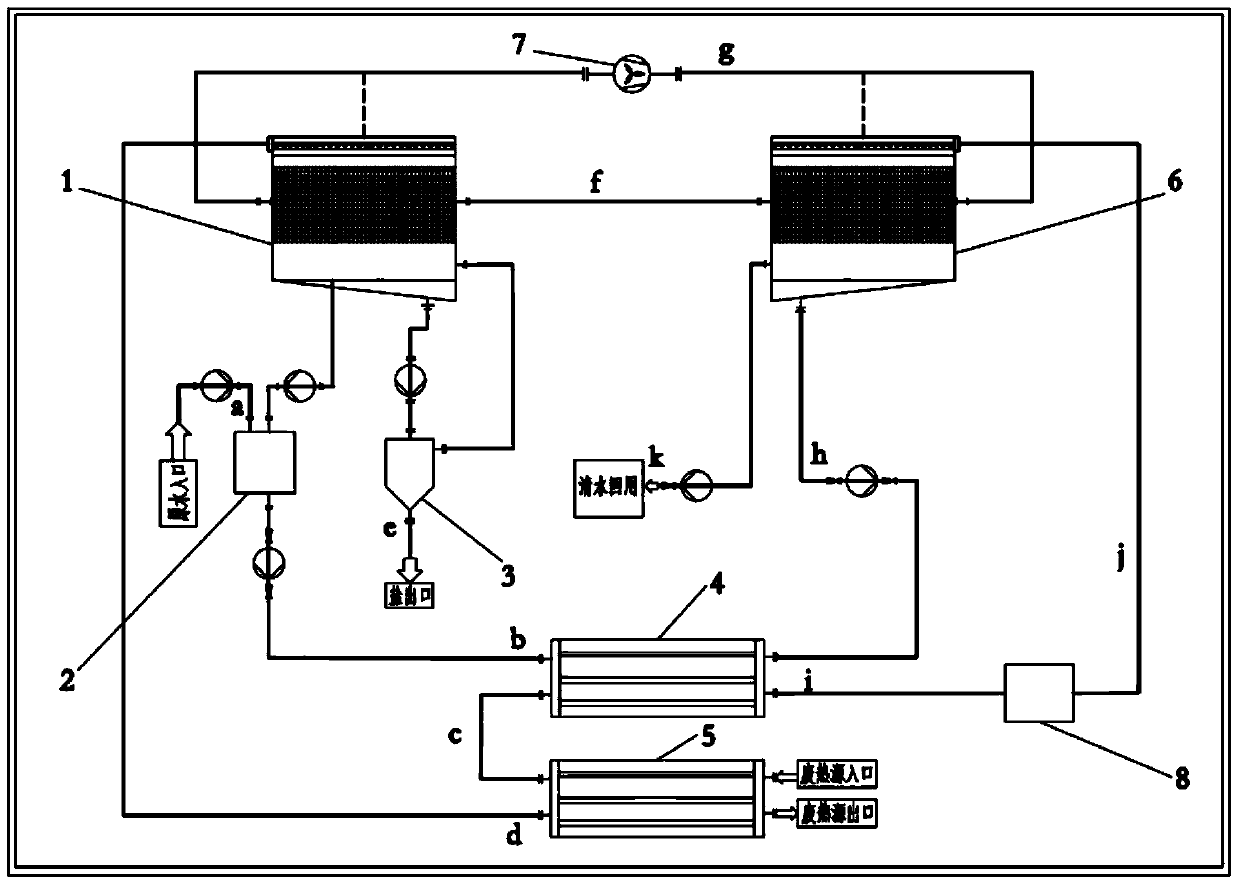

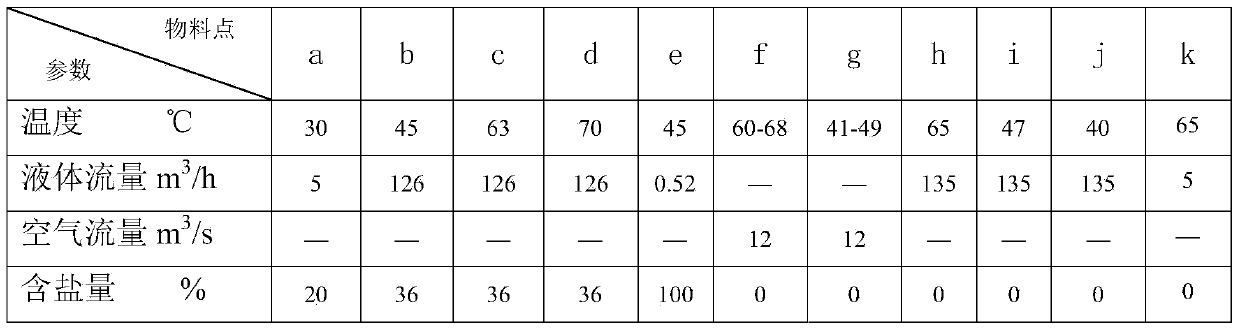

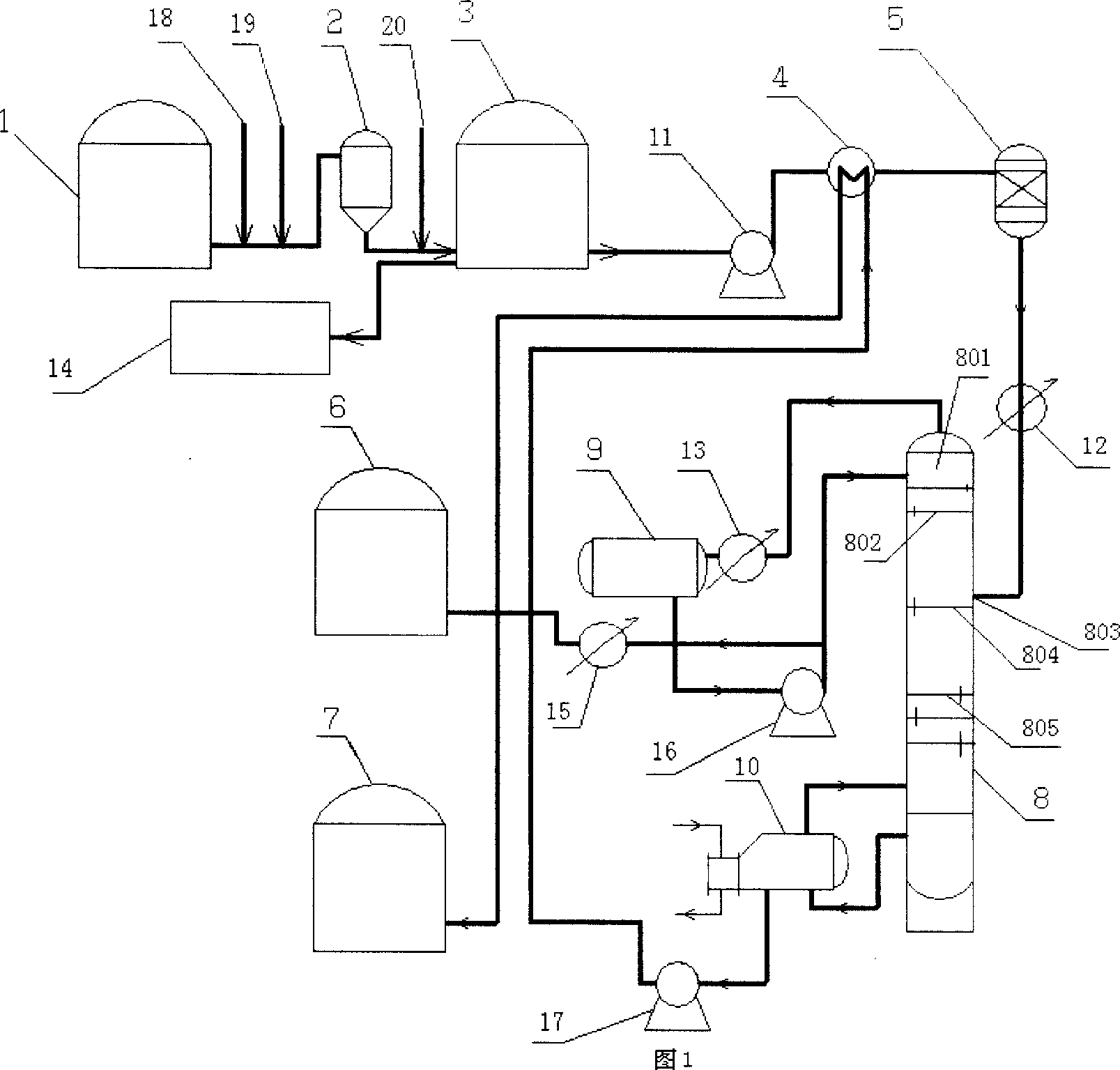

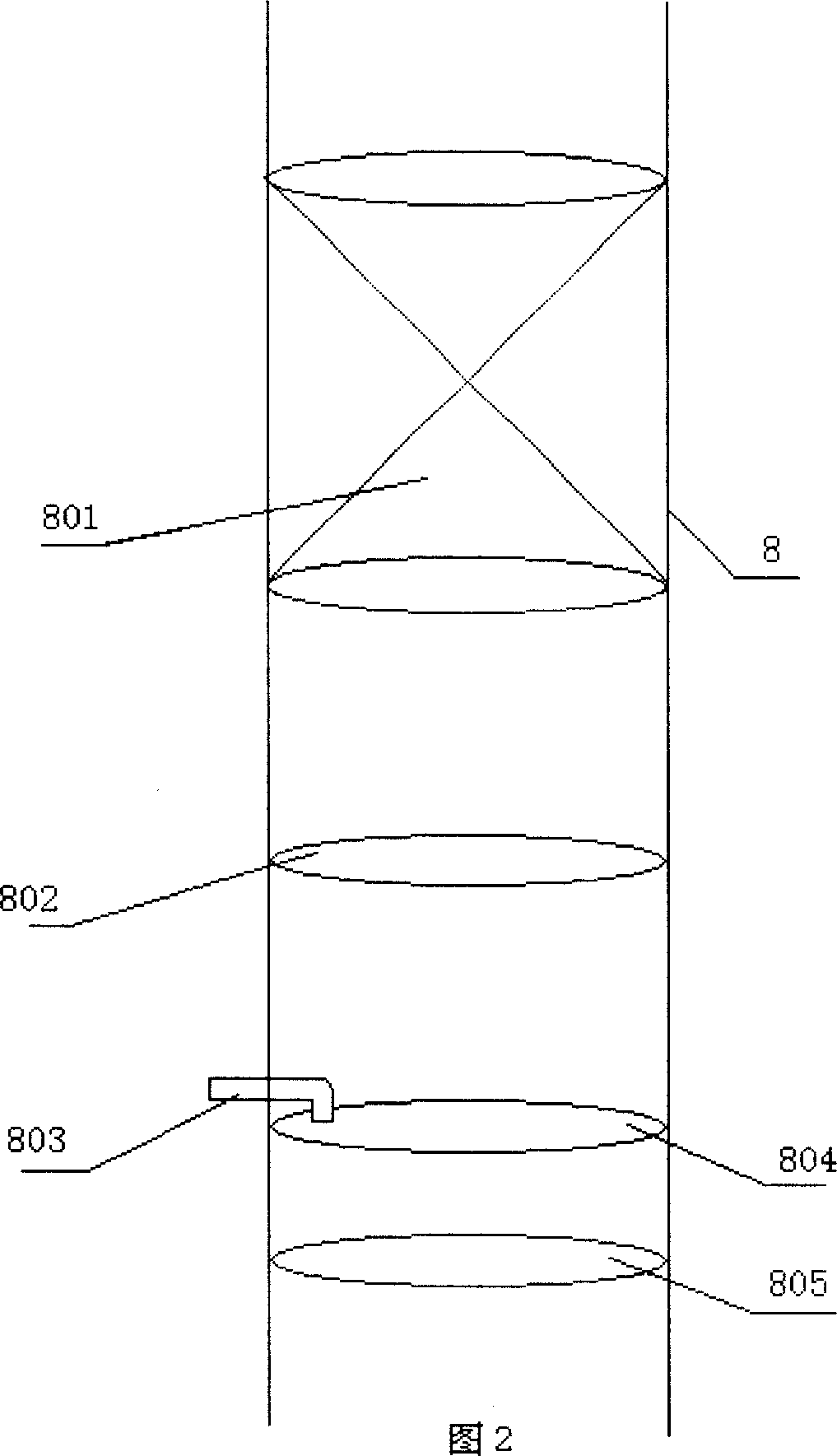

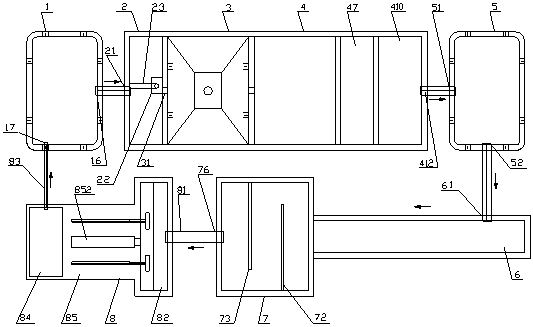

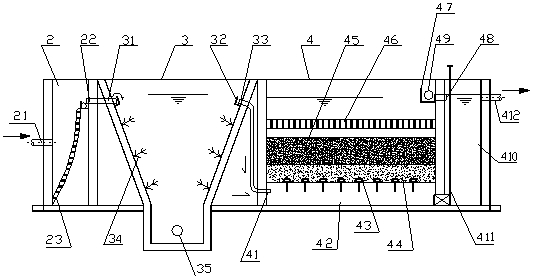

Low-temperature evaporation, concentration and crystallization system and method using waste heat

ActiveCN104211130ARealize \"Zero Emissions\"Implement resourcesWater/sewage treatmentEnergy based wastewater treatmentIndustrial wasteEvaporator

The invention discloses a low-temperature evaporation, concentration and crystallization system using waste heat. The low-temperature evaporation, concentration and crystallization system comprises an evaporation chamber, a heat exchanger set containing at least one heat exchanger, a cooler, a condensation chamber and a draught fan, wherein the evaporation chamber, the draught fan and the condensation chamber are connected with one another to form a closed circulation loop; a water inlet and a water outlet of the heat exchanger set are connected with a raw water opening and an evaporator respectively; a heat-exchanging medium inlet of the heat exchanger set is connected with a heat-exchanging medium outlet of the condensation chamber and a waste heat source; a heat-exchanging medium outlet of the heat exchanger set is connected with a refrigerating medium inlet of the condensation chamber by the cooler; the system further comprises a solid-liquid separator connected with a crystallized salt outlet of the evaporation chamber; and the waste heat source comprises each type of industrial waste heat, residual heat or waste gas, such as low-temperature exhausted gas, low-temperature circulating water, cinder flushing water, terrestrial heat tail water, solar hot water and the like. By adopting the system and the method disclosed by the invention, recycling and harmless treatment can be carried out on high-concentration salt-containing wastewater under a relatively low temperature so that the energy consumption is low, and the repeated utilization rate of energy is high.

Owner:KMD BEIJING ENERGY & ENVIRONMENT TECH CO LTD

Gas field methanol sewage disposal process

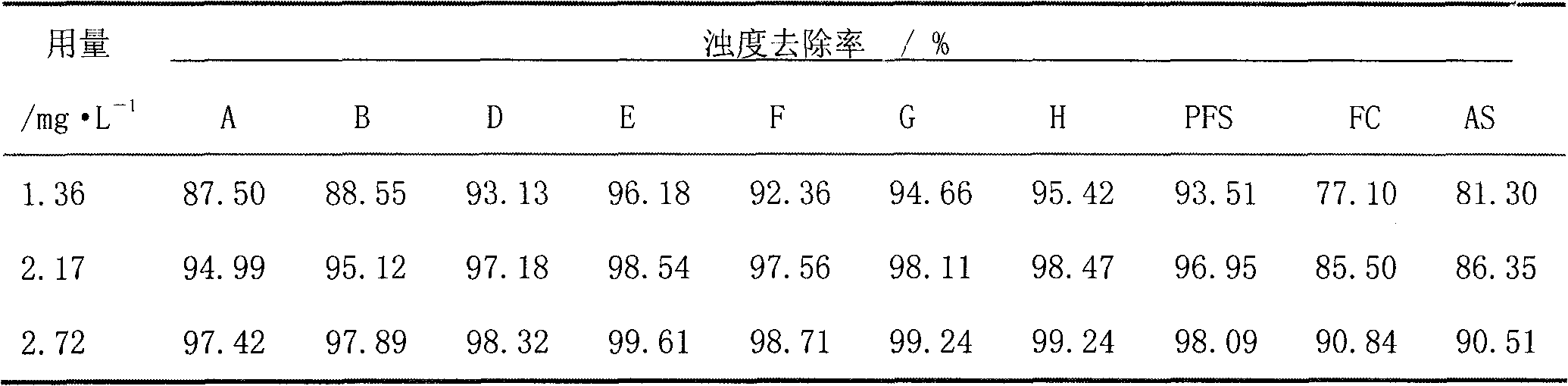

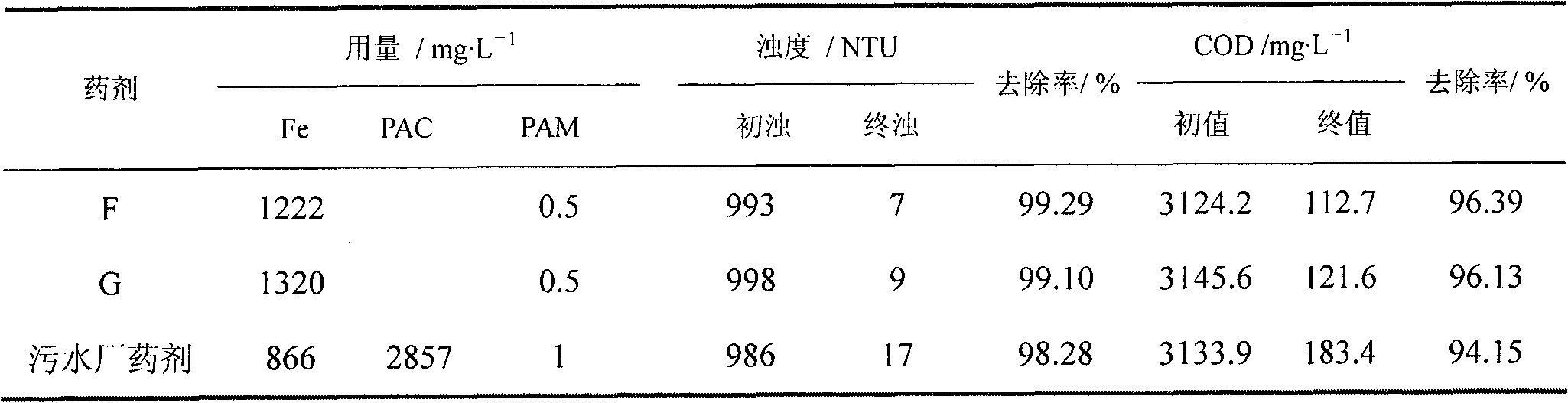

InactiveCN1966428AIncrease turbidityHigh salinityOrganic chemistryMultistage water/sewage treatmentSewageTower

The invention relates to the water treatment technology, especially a gas field methanol sewage treatment technology which at least includes pretreating technology, methanol reclaiming technology and sewage back-flowing technology. The characteristic of the invention: after removing oil, adjusting Ph value, oxidizing to remove iron and flocculating / precipitating, separate the methanol from the sewage in the methanol-reclaiming device the core of which is dephlegmation tower, the treated water goes back to stratum. The invention finally managed to reclaim the methanol with zero release of waste liquids. The methanol-reclaiming dephlegmation tower adopts ''filling material + sieve pore (or oblique aperture)'' and ''floating valve + sieve pore (or oblique aperture)'' complex tower model to solve many problems such as obstructing and the adaptability of the dephlegmation tower to the large change of methanol content in different sewages.

Owner:XIAN CHANGQING TECH ENG

Technology for biochemical treatment and fertilizer use of tobacco invalidism body

ActiveCN103373867AReduce volumeNo spreadBio-organic fraction processingOrganic fertiliser preparationBiotechnologyNicotiana tabacum

The invention relates to a technology for biochemical treatment and fertilizer use of a tobacco invalidism body. The technology realizes availability of the tobacco through a microbial decomposition and fermentation method, and realizes recycling and fertilizer use of the tobacco invalidism body through steps of pretreatment, sterilization, degradation of nicotine tar, fermentation and postripeness. According to the technology, the problem of recycling the tobacco invalidism body is solved, high quality active organic fertilizer can be produced rapidly, and the contamination problem caused by the tobacco invalidism body in production of tobacco is completely solved.

Owner:湖南碧野农业科技开发有限责任公司

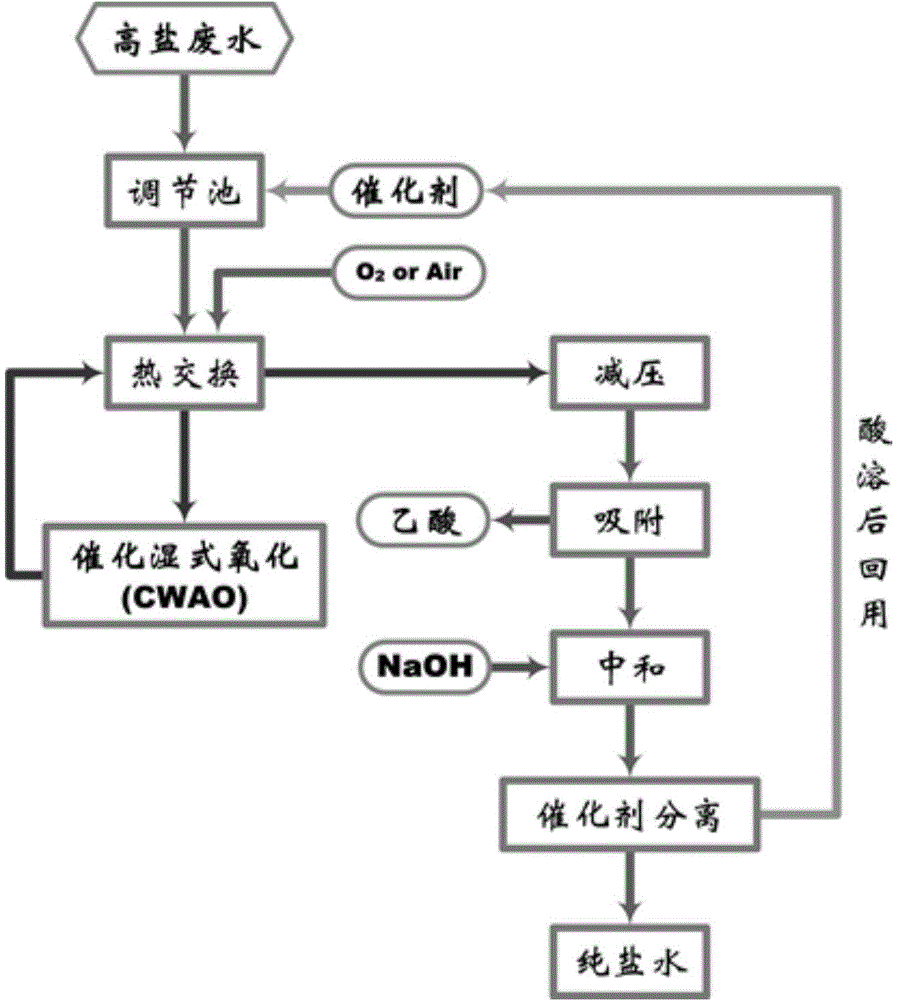

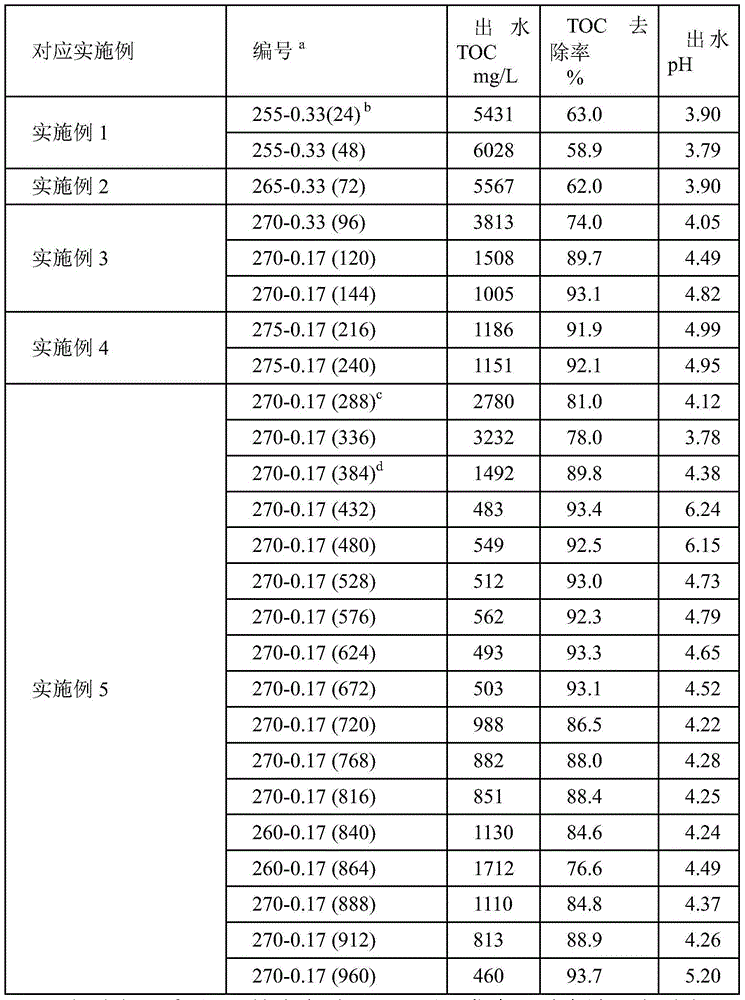

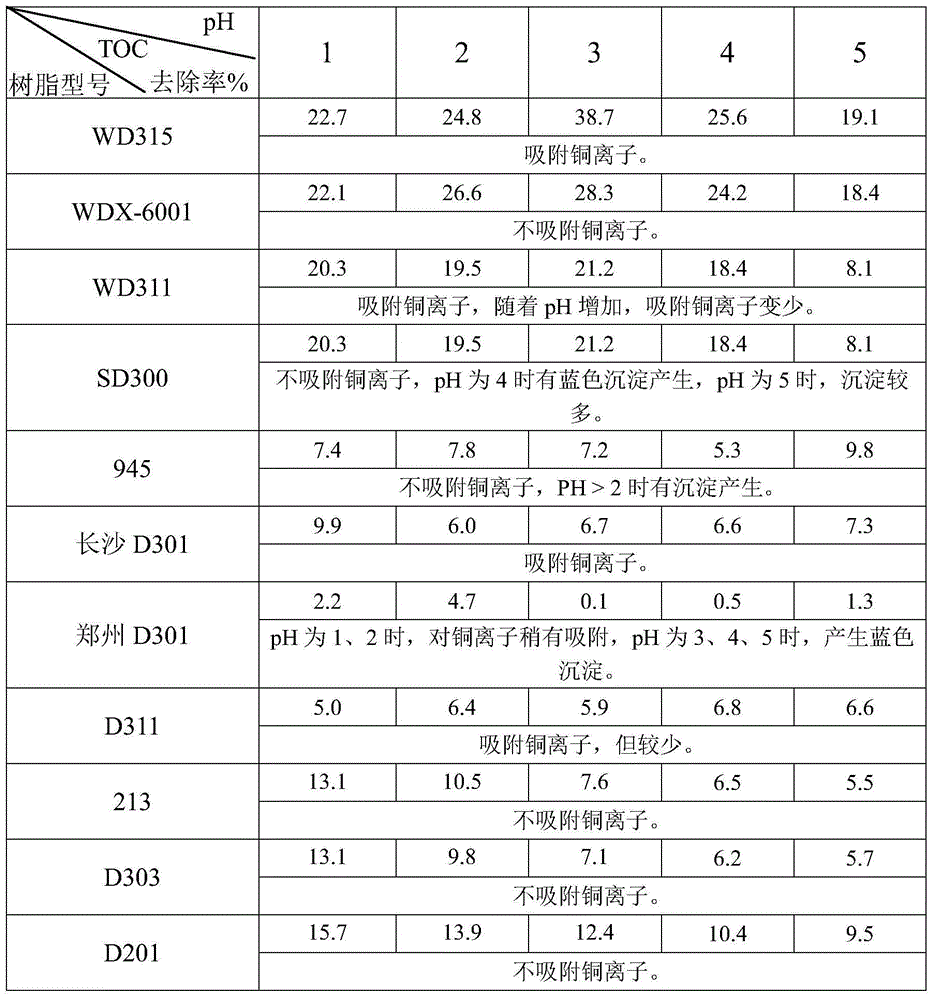

Resource utilization method for high-salt wastewater from epichlorohydrin preparation through glycerol method

InactiveCN105645624AAchieving "Zero Emissions"Realize "Zero Emissions"Multistage water/sewage treatmentNature of treatment waterIonChemistry

The present invention relates to a resource utilization technology for high-salt wastewater from epichlorohydrin preparation through a glycerol method, and belongs to the high-salt difficultly-degraded organic wastewater treatment. The technology comprises three operation units such as catalytic wet oxidation, acetic acid recovery and catalyst recovery. According to the present invention, the high-salt wastewater resource utilization technology has advantages of simple process, high treatment efficiency, small occupation area, resource recycling, low secondary pollution and the like; the sodium acetate recovered through the technology can be adopted as the raw material of the environmentally friendly snow melting agent, the TOC of the generated purified NaCl solution is less than 10 mg / L, and the generated purified NaCl solution can be adopted as the ion membrane caustic soda production raw material; and with the use of the technology, the economical and cyclically-developable green epichlorohydrin production process can be formed for enterprises.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

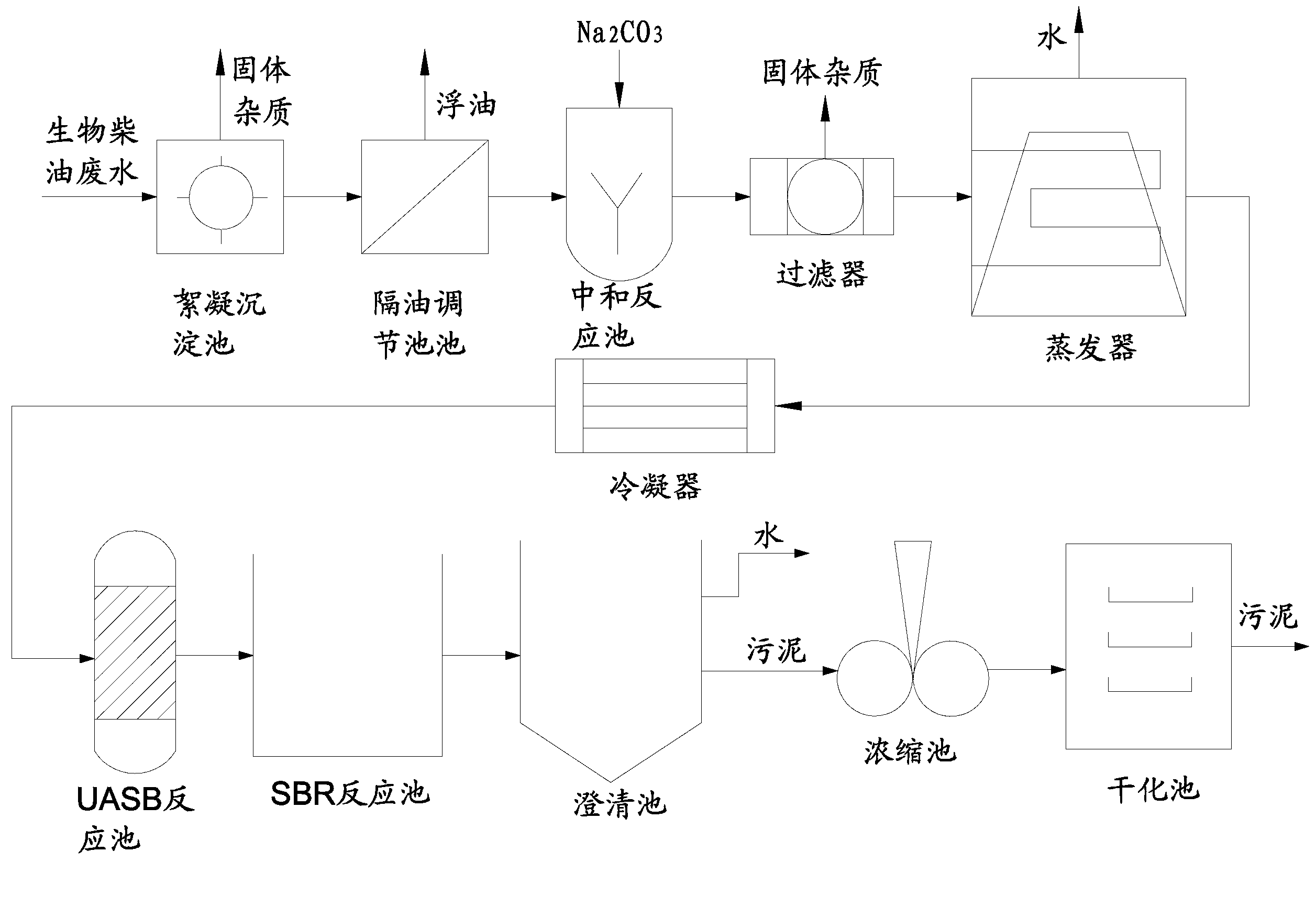

Multi-stage treatment process for biodiesel wastewater

InactiveCN103232140AThorough treatmentGood degreasing effectMultistage water/sewage treatmentBiodieselWater quality

The invention provides a multi-stage treatment process for biodiesel wastewater, which comprises the following specific operation steps: introducing biodiesel wastewater into a flocculation precipitation tank, and adding flocculant to perform flocculation precipitation reaction so as to remove part of solid impurities; transferring the biodiesel wastewater into an oil separation conditioning tank, and performing oil separation treatment to remove floating oil in the wastewater; transferring the wastewater subjected to the oil separation treatment into a neutralization reaction tank, and adding Na2CO3 to remove hydrochloric acid in the wastewater; filtering the wastewater, introducing into an evaporator, and performing single-effect evaporation; performing condensation treatment on the wastewater subjected to the evaporation, and sequentially performing anaerobic treatment and aerobic treatment on the wastewater subjected to the condensation treatment; introducing the wastewater into a clarification tank, precipitating to remove biomass in the wastewater; and finally, discharging the wastewater treated in the clarification tank, and concentrating, drying and discharging the sludge precipitate in the clarification tank. According to the invention, better oil removal effect can be achieved; and the effluent water quality of the treated wastewater meets the wastewater emission standard.

Owner:QUANZHOU NORMAL UNIV

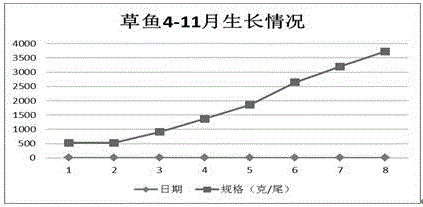

Method for cultivating Litopenaeus vannamei through circulating water fish-farming system

ActiveCN106234270ADelay or reduce useReduce usageClimate change adaptationPisciculture and aquariaSocial benefitsZoology

The invention relates to the field of aquaculture, in particular to a method for cultivating Litopenaeus vannamei through a circulating water fish-farming system. According to the method, Mylopharyngodon piceus, Ctenopharyngodon idella and Lateolabrax japonicus are farmed in a running water cultivating unit, and Litopenaeus vannamei are cultivated in a large pond. For a test pond having an area of 32.9 mu, fishes and shrimps of 49.18 tons in total can be produced by two crops in one year, the production goes to the yield per mu of 1494.8 kg, total output value is 969600 yuan, average output value per mu is 29470 yuan, total materialized cost is 555000 yuan, total profit is 414600 yuan, and average profit per mu is 12602 yuan; the whole cultivating process is free of emission of cultivation wastewater, zero emission of cultivation tail water is achieved, and ecological, economic and social benefits are good.

Owner:HANGZHOU AQUATIC PROD TECH PROMOTION GENERAL STATION

Low-temperature spray evaporation waste water treatment device and waste water treatment method

InactiveCN105344119AReduce energy consumptionLow running costEvaporator accessoriesWater/sewage treatment by heatingRecuperatorEngineering

The invention discloses a low-temperature spray evaporation waste water treatment device and a waste water treatment method. The waste water treatment device comprises an evaporation concentrator and a heat exchange system, and the evaporation concentrator comprises an evaporation chamber with a waste water inlet and a condensation chamber with a pure water outlet; the evaporation chamber is communicated with the condensation chamber through a top channel and a bottom channel to form an air circulation channel, and a fan used for blowing air in the evaporation chamber into the condensation chamber is arranged in the top channel; a cold medium inlet of a heat recycling heat exchanger is connected with the evaporation chamber, and a cold medium outlet of a heat recycling heat exchanger is connected with a water distribution pipe of a water distribution layer of the evaporation chamber; a cold medium inlet of a heat release heat exchanger is connected with a pure water circulation water outlet of the condensation chamber, and a cold medium outlet of the heat release heat exchanger is connected with a hot medium inlet of the heat recycling heat exchanger; a hot medium outlet of the heat recycling heat exchanger is connected with a hot medium inlet of a heat absorption heat exchanger, and a hot medium outlet of the heat absorption heat exchanger is connected with the water distribution pipe of the water distribution layer of the condensation chamber. According to the low-temperature spray evaporation waste water treatment device and the waste water treatment method, the energy consumption is low, and the application range is wide.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Full steel slag roller compacted concrete and preparation method thereof

The invention discloses a full steel slag roller compacted concrete and a preparation method thereof. The full steel slag roller compacted concrete comprises the following raw materials by weight: 24-37 portions of a steel slag composite powder, 45-65 portions of a steel slag aggregate, 11-18 portions of steel slag water washing mud and 3-5 portions of water. The method is as below: weighing the steel slag composite powder, steel slag aggregate, steel slag water washing mud and water according to the weight ratio; and uniformly mixing to obtain the full steel slag roller compacted concrete. The invention can play the recycling value of metallurgical wastes, reduce the cost of roller compacted concrete, and obtain great economic benefits. More important, application of the invention can economize natural gravel and cement, thereby saving natural resources and energy and protecting the ecological environment.

Owner:宝武环科武汉金属资源有限责任公司

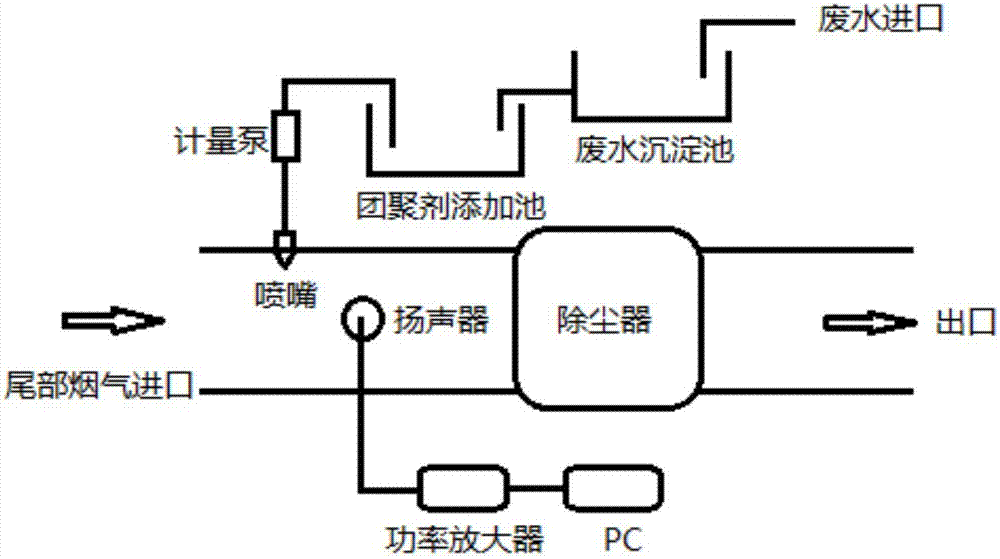

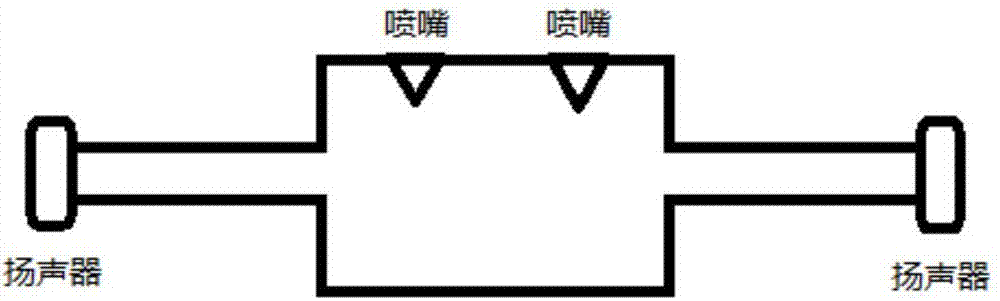

Method of removing small particulate matters in coal-fired flue gas by combining chemical agglomeration with acoustic agglomeration

The invention discloses a method of removing small particulate matters in coal-fired flue gas by combining chemical agglomeration with acoustic agglomeration to solve the problem that conventional dedusting equipment is hard to remove small particulate matters in flue gas for zero emission of desulfurization and denitrification wastewater in a coal-fired power plant. The method comprises the following steps: taking the supernate after the desulfurization and denitrification wastewater of the power plant is treated; adding a high polymer adhesive and a surfactant to prepare a chemical agglomerant; spraying the chemical agglomerant into a flue in front of a dedustor through an atomizing nozzle; adding a low-frequency sound field, wherein the small particulate matters of the coal-fired power plant are agglomerated under the combined action of chemistry and sound waves; and finally, removing the agglomerated particulate matters through a conventional dedustor. In a proper condition, 70% of the small particular matters which are smaller than 10 [mu]m can grow to 10[mu] or above through agglomeration. Therefore, the problem of zero emission of the wastewater is solved, and the problem of removal of small particulate matters in coal-fired flue gas is solved. The method has a wide application prospect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Aquaculture pollution biological ecological purification and cyclic utilization system and method

ActiveCN111727926AEffective controlEfficient removalHops/wine cultivationWaste water treatment from animal husbandryEnvironmental resource managementBiological filter

The invention provides an aquaculture pollution biological ecological purification and cyclic utilization system and method. The system comprises an aquaculture ecological culture pond, a biological sedimentation tank, a double-medium biological filter tank, a deep ecological purification pond, an internal circulation ecological ditch, a water purification activation tank and a disinfection tank which sequentially communicate with one another, wherein the disinfection tank communicates with the aquaculture ecological culture pond. Through physical, chemical and biological ecological purification methods, culture water is purified, so that the culture water is recycled, and residual baits, excrement, nitrogen, phosphorus, organic matters and residual fish drugs in the culture water are effectively controlled and removed; and bottom mud discharged by the biological sedimentation tank is restored and then is utilized in farmlands or orchards. Zero emission of pollutants is realized, the aquaculture pollution biological ecological purification and cyclic utilization system and method are environmentally friendly, ecological and healthy aquaculture is realized, and the aquaculture pollution biological ecological purification and cyclic utilization system and method cause little or even no pollution to the environment, and are environmentally friendly and safe.

Owner:HUNAN AIRBLUER ENVIRONMENTAL PROTECTION TECH

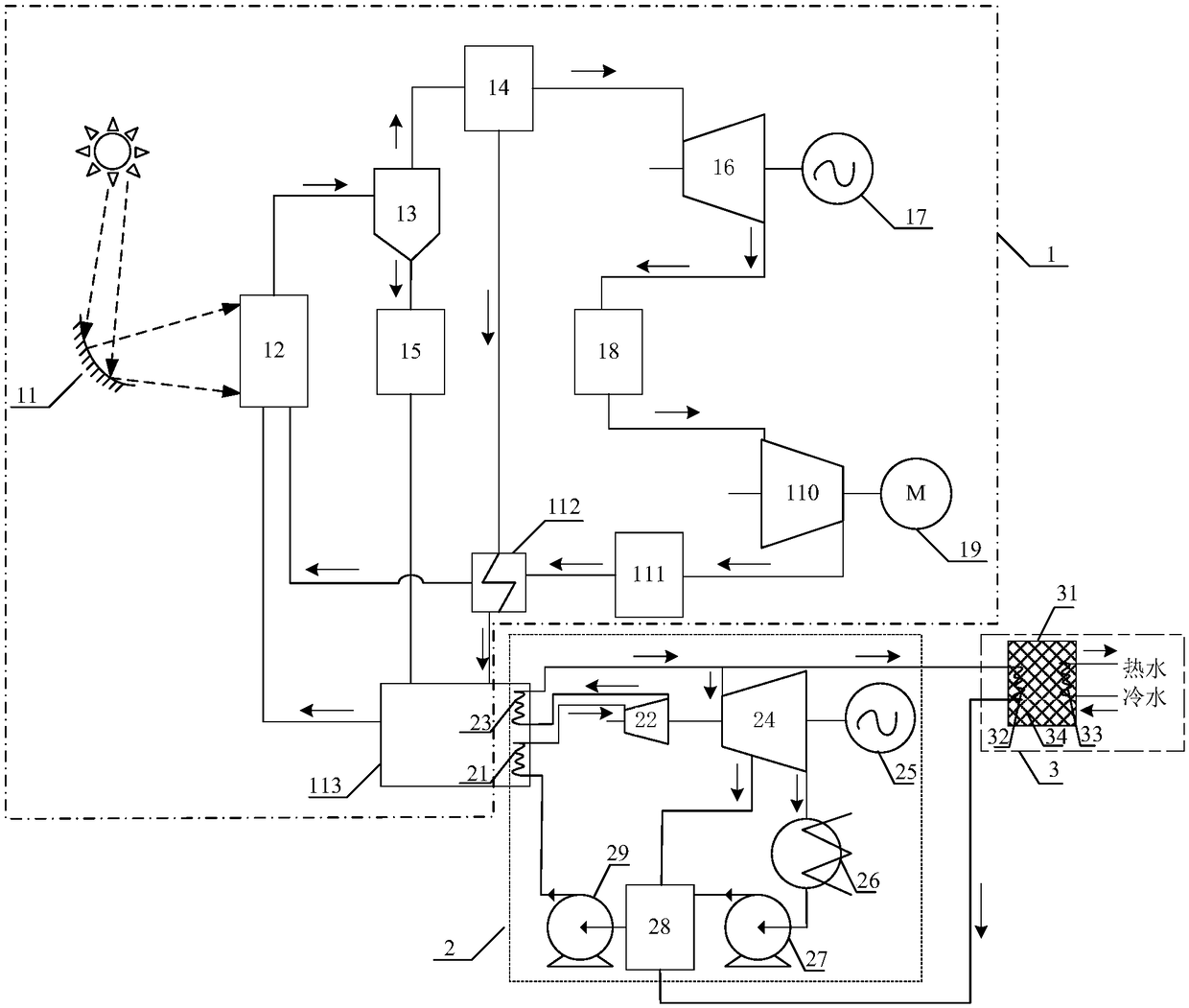

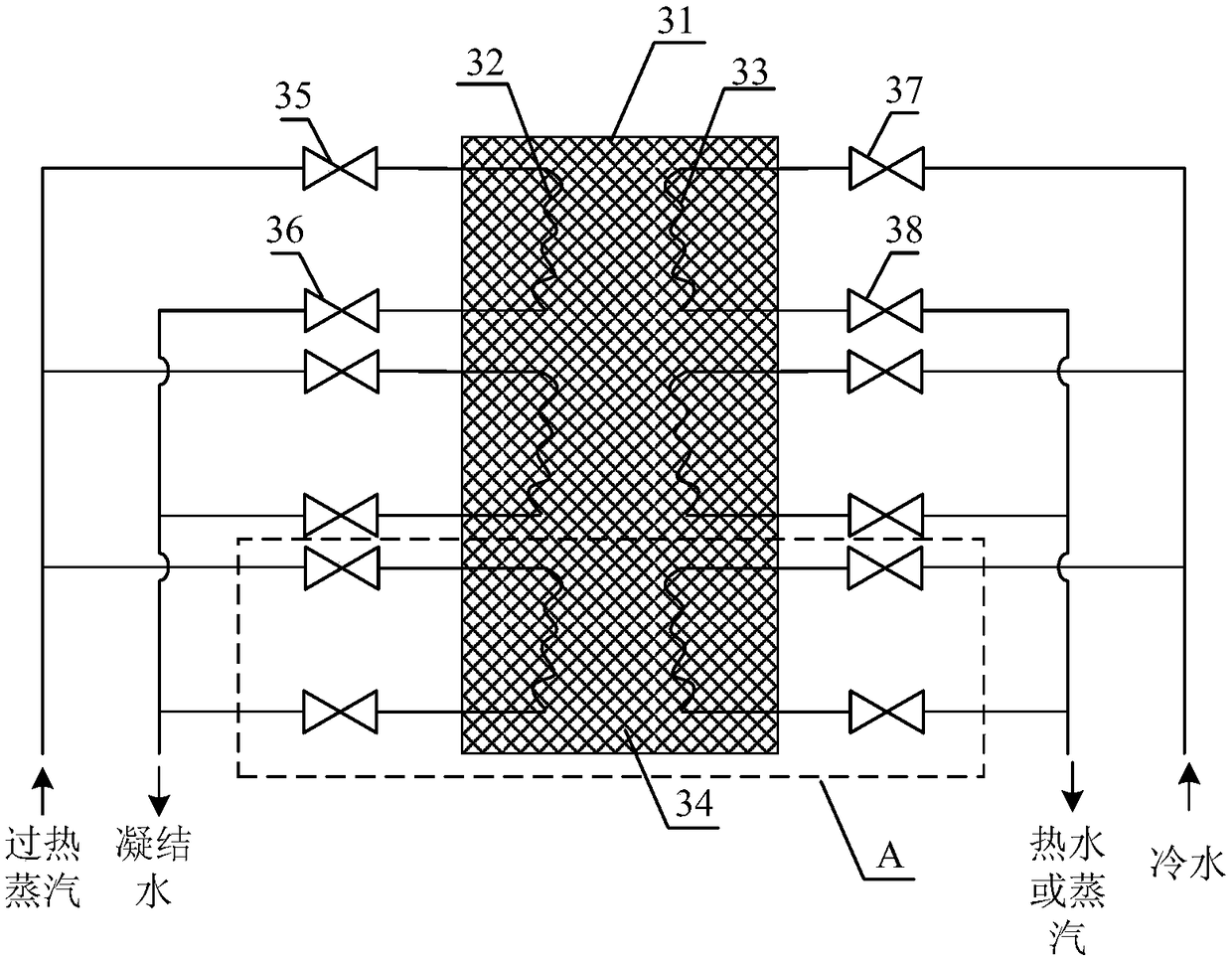

Heat and power combined supply system based on solar thermochemical energy storage

ActiveCN108800628AStable heat supplyRealize "Zero Emissions"Solar heating energySteam generation heating methodsClean energyElectric power

The embodiment of the invention discloses a heat and power combined supply system based on solar thermochemical energy storage. The system comprises a solar thermochemical circulating sub system, a steam turbine power generation circulating sub system and a heat storage heat exchange sub system. The solar thermochemical circulating sub system, the steam turbine power generation circulating sub system and the heat storage heat exchange sub system are arranged in a coupled manner. A binding mode of ordering power by heat in the prior art is changed by guaranteeing stable electric output of the steam turbine power generation circulating sub system and stable heat power supply of the heat storage heat exchange sub system as the solar thermochemical circulating sub system provides energy to thesteam turbine power generation circulating sub system and the heat storage heat exchange sub system, separately. Meanwhile, the solar thermochemical circulating sub system in closed circulation achieves zero emission of carbon dioxide. Compared with a conventional thermal power generation system, the heat and power combined supply system based on solar thermochemical energy storage provided by the invention is only driven by clean energy sources such as solar energy and wind energy, so that not only is the cost of fuels saved, but also is the environmental pollution avoided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

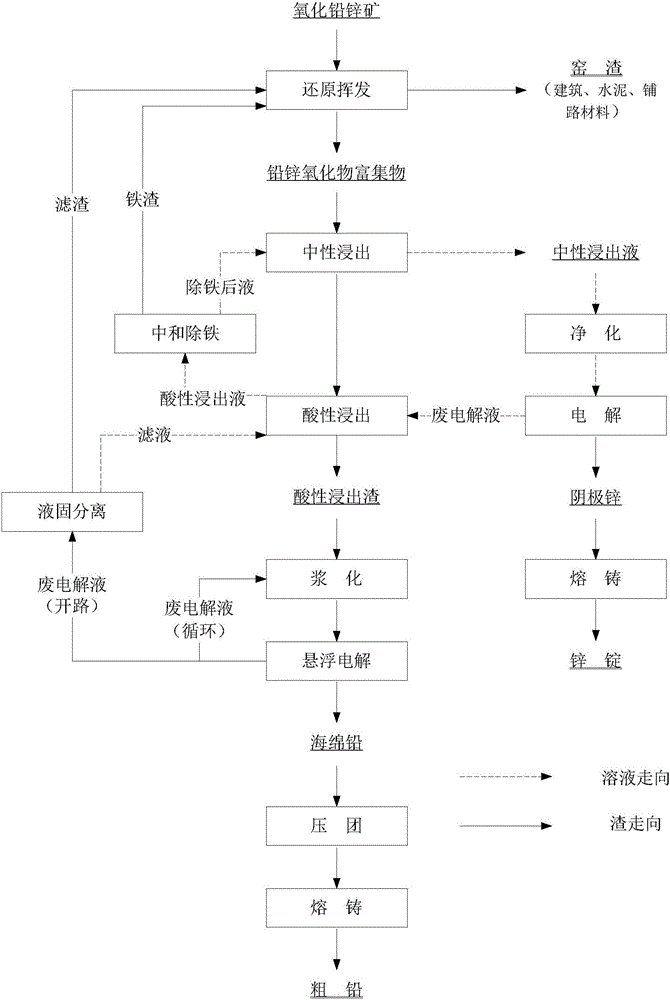

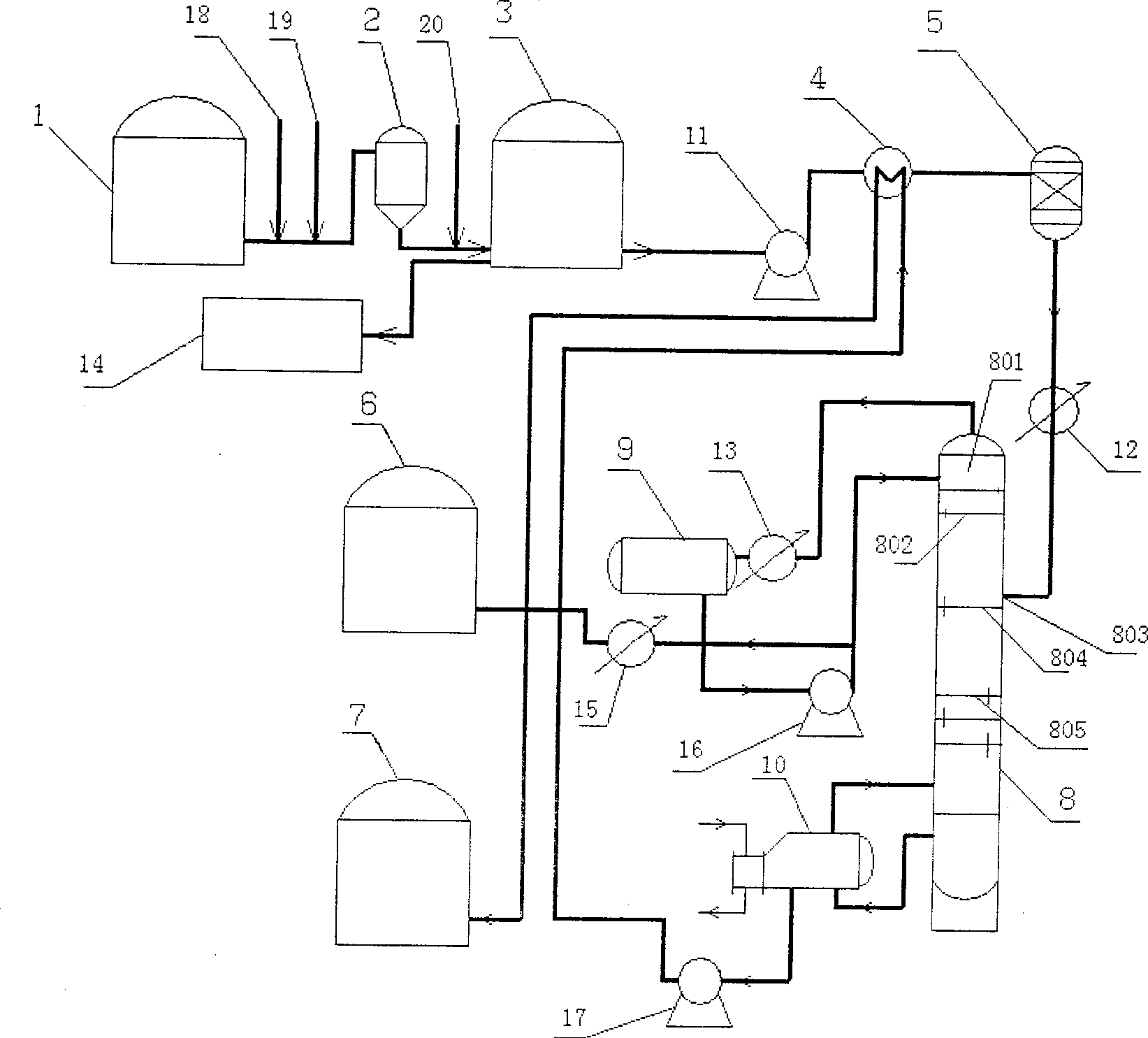

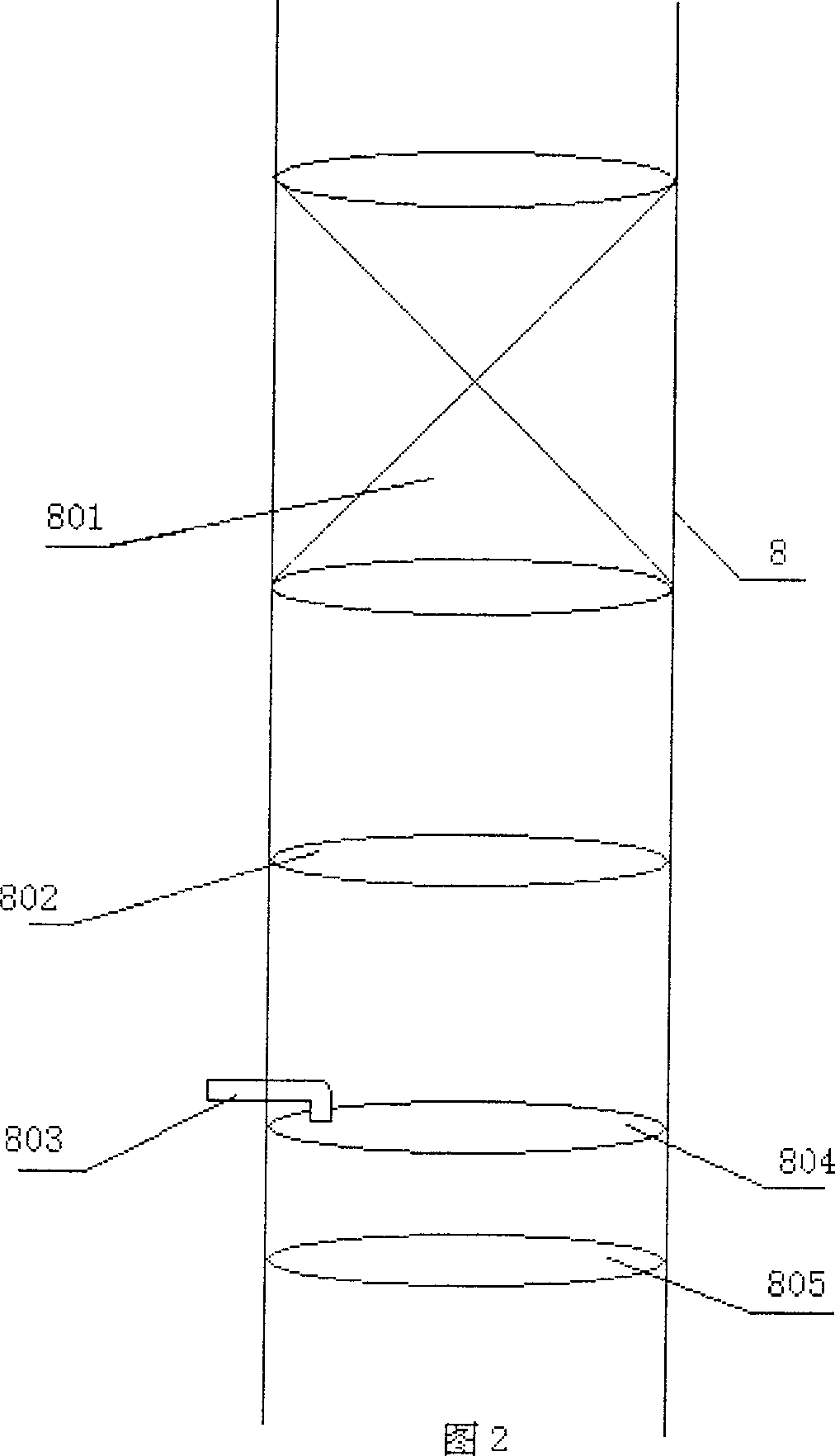

Environment-friendly metallurgy extracting method for lead-zinc oxide ores

InactiveCN106498181AStable in natureQuality improvementPhotography auxillary processesProcess efficiency improvementElectrolysisImpurity

The invention discloses an environment-friendly metallurgy extracting method for lead-zinc oxide ores, and belongs to the field of lead zinc ore metallurgy. The method comprises the following steps: reducing and volatilizing the lead-zinc oxide ores to obtain high-quality lead-zinc oxide enrichment, and separating lead and zinc from other impurities in raw ores; carrying out sulfuric acid leaching-purifying-electrodeposition on the lead-zinc oxide enrichment to obtain cathode zinc, and casting to obtain zinc ingot products; and after slurrying zinc leaching residues, continuously adding in a suspension electrolytic bath for producing lead powder by electrodeposition, and after washing, filtering and briquetting the lead powder, smelting into lead bullion. The lead and the zinc are highly enriched effectively by pyrogenic-process reduction and volatilization, and influence of impurities such as Fe, Si, Ca, Mg and Al to a smelting process is greatly reduced; and the zinc and the lead are effectively extracted in a sulfuric acid system to directly obtain the cathode zinc and the lead bullion, organic circulation of lead and zinc smelting systems is realized, consumption of energy and materials is greatly reduced, meanwhile, 'zero' consumption of sulfuric acid, 'zero emission' of waste water and 'zero' emission of smelting wastes are realized simultaneously, and the environment-friendly metallurgy extracting method for the lead-zinc oxide ores is environment-friendly.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Gas field methanol sewage disposal process

InactiveCN100486920CIncrease turbidityHigh salinityOrganic chemistryMultistage water/sewage treatmentSewageTower

The invention relates to the water treatment technology, especially a gas field methanol sewage treatment technology which at least includes pretreating technology, methanol reclaiming technology and sewage back-flowing technology. The characteristic of the invention: after removing oil, adjusting Ph value, oxidizing to remove iron and flocculating / precipitating, separate the methanol from the sewage in the methanol-reclaiming device the core of which is dephlegmation tower, the treated water goes back to stratum. The invention finally managed to reclaim the methanol with zero release of waste liquids. The methanol-reclaiming dephlegmation tower adopts ''filling material + sieve pore (or oblique aperture)'' and ''floating valve + sieve pore (or oblique aperture)'' complex tower model to solve many problems such as obstructing and the adaptability of the dephlegmation tower to the large change of methanol content in different sewages.

Owner:XIAN CHANGQING TECH ENG

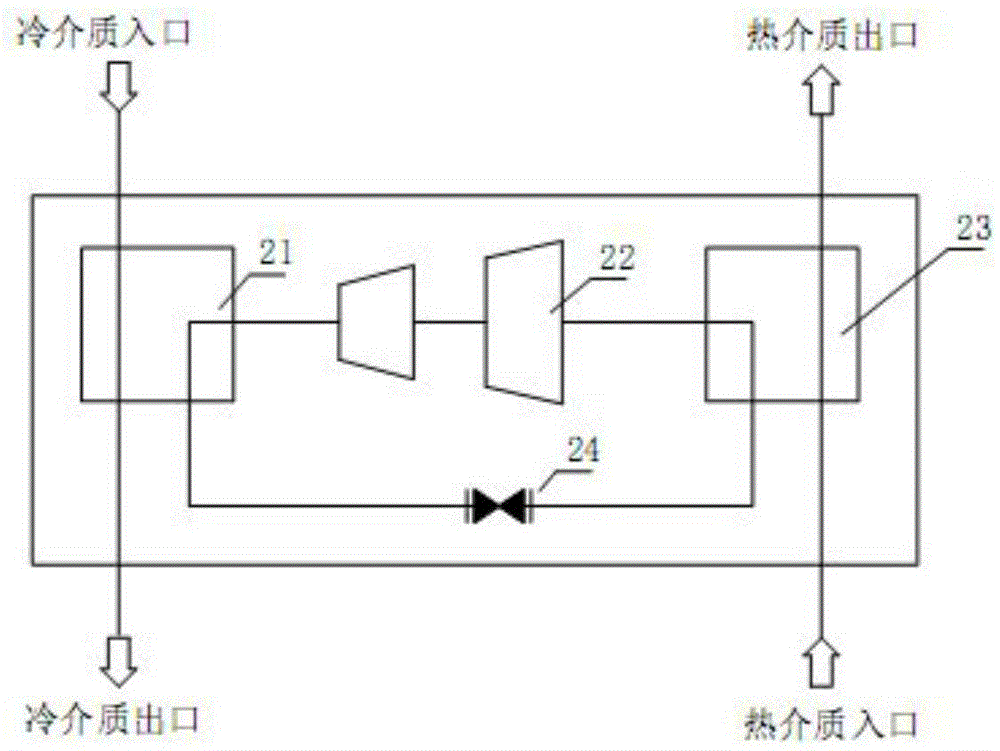

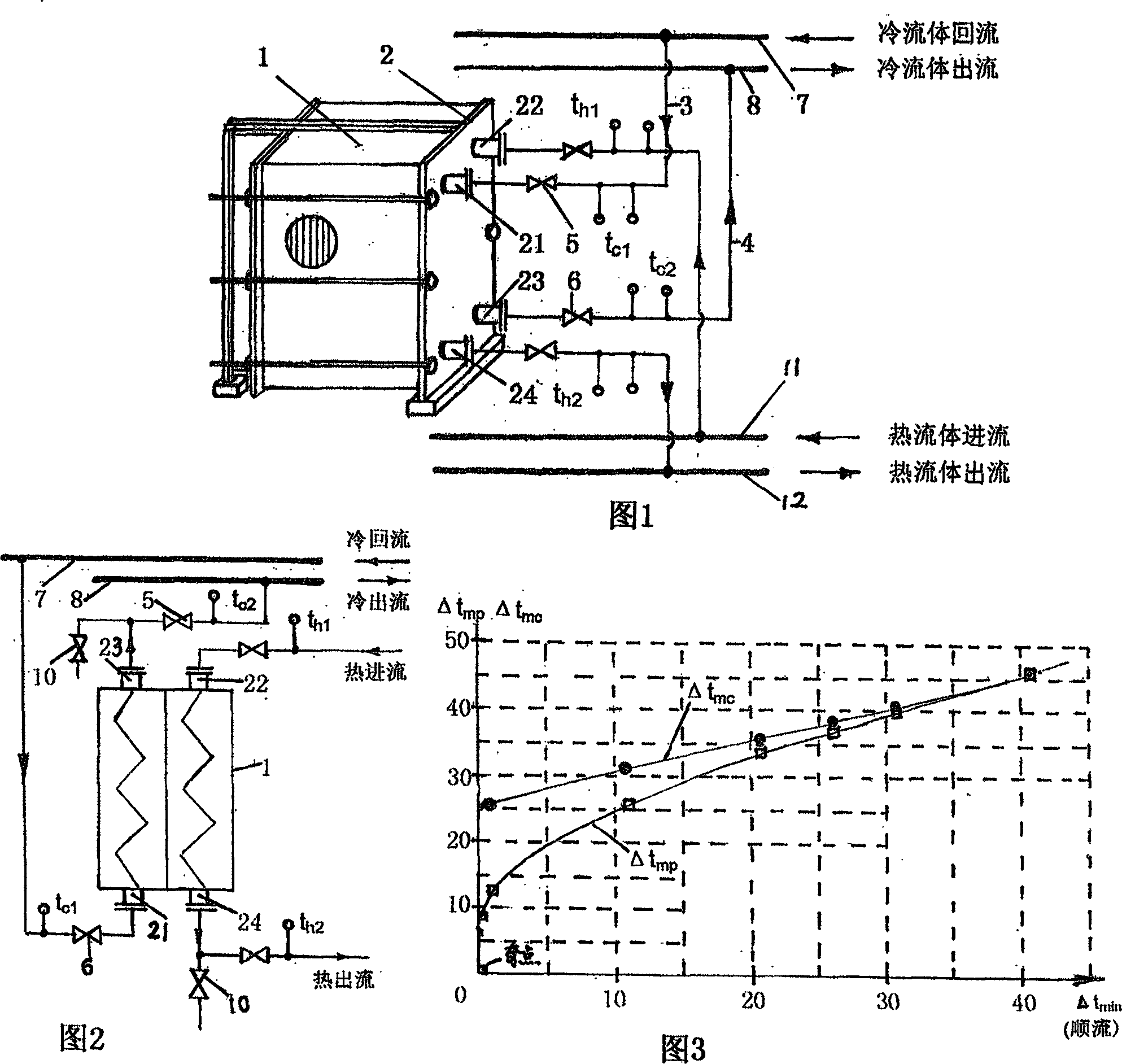

Plate heat exchanger with no deposited scale, and heat exchange mode

InactiveCN1873362ARealize \"Zero Emissions\"Realize functionCorrosion preventionHeat exchange apparatusEngineeringProduced water

The present invention relates to an improvement technique of heat exchanger, in the concrete, it is a plate type heat exchanger which does not produce water scale deposit and its water exchange mode. It is characterized by that in fixed tight-pressing plate side of general plate-type heat exchanger, the cold fluid inlet of upper portion of said fixed tight-pressing plate is connected with cold fluid backflow manifold by means of pipeline, the cold fluid outlet of lower portion of said fixed tight-pressing plate is connected with cold fluid discharge manifold by means of pipeline. Said invention adopts a downflow heat exchange mode, can make cold fluid and hot fluid be flowed from top to bottom in the plate-type heat exchanger, so that said invention utilizes the impact action of downwards-flowing fluid and gravity action of water scale granules self-body so as to implement the 'zero discharge' of said plate-type heat exchanger and on-tine 'automatic blowdown' function.

Owner:王正方 +1

Method for treating rare earth ammonium chloride wastewater

InactiveCN102531025BSimple processHigh recovery rateMultistage water/sewage treatmentRare earth metal compoundsCarbon sinkRare earth

The invention discloses a method for treating rare earth ammonium chloride wastewater, belonging to the field of wastewater treatment. The method for treating the rare earth ammonium chloride wastewater comprises the steps of: dissolving ammonium chloride rare earth, carrying out organic phase saponification, carrying out extraction separation, recycling wastewater, stripping, carbon-sinking, washing, evaporating, cooling and crystallizing. According to the method, ammonium chloride raffinate and carbon sink mother liquor which are generated by extraction separation on the rare earth are used as the solvents of the ammonium chloride rare earth for recycling so that the ammonium chloride in the wastewater is increased, the ammonium chloride is favorably evaporated and condensed, and energy resource consumption is reduced. Meanwhile, washing liquor of rare earth carbonate precipitates is recycled for preparing a precipitating agent, thus water resources are saved. The mass percent of the ammonium chloride in the recycled finished product is 91.7-96.5 percent in the terms of dry basis; and the economic benefit is remarkable, the wastewater is recycled, and zero emission of the rare earth wastewater is recycled.

Owner:江西德盛精细化学品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com