Multi-stage treatment process for biodiesel wastewater

A technology of biodiesel and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficult to achieve good oil removal effect and influent water quality requirements High, high operating costs, etc., to achieve good degreasing effect, complete treatment, and prevent sewage pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

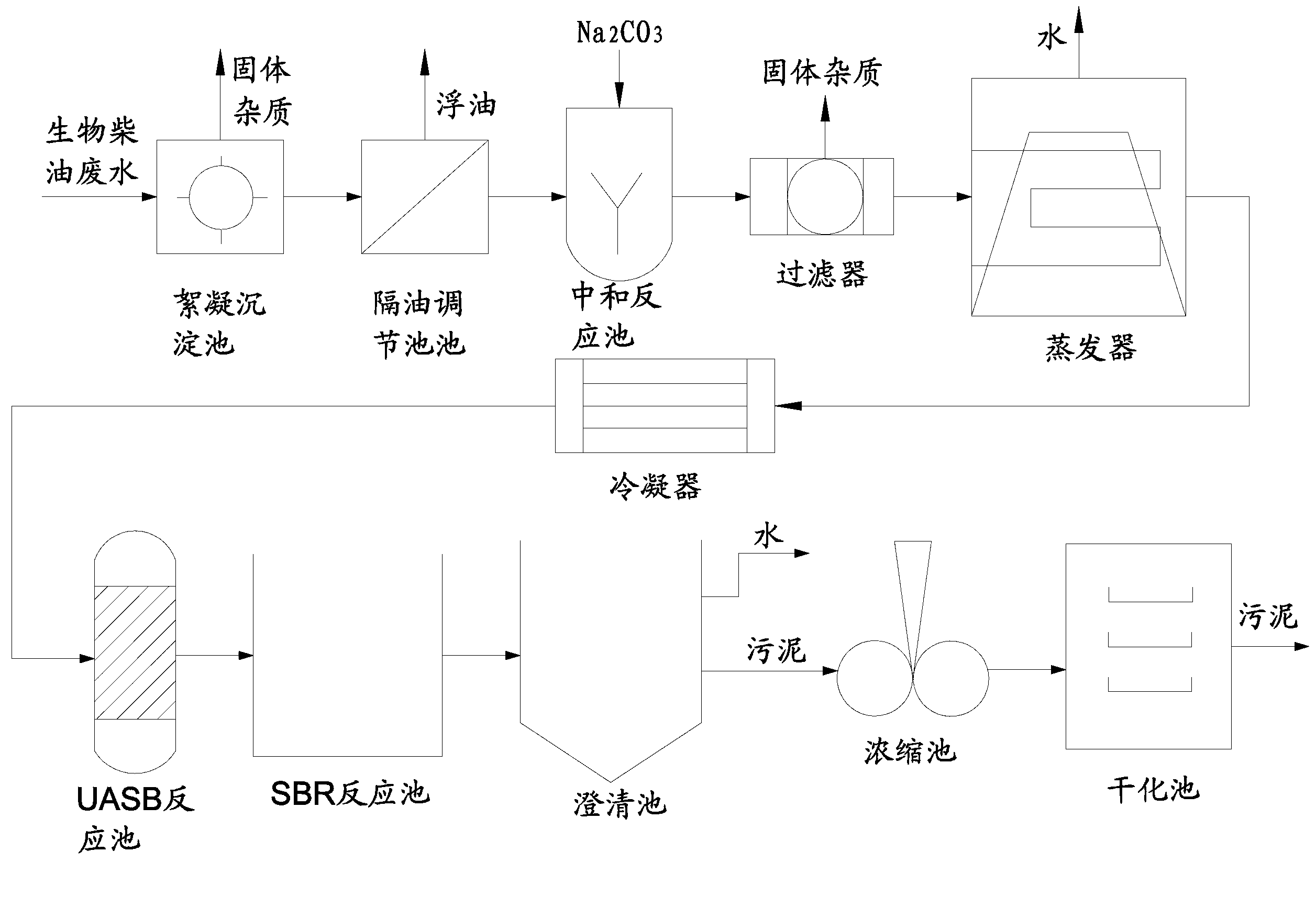

[0020] see figure 1 , the specific operation of the multi-stage treatment process of biodiesel wastewater of the present invention is as follows: the wastewater produced in the biodiesel production process, i.e. biodiesel wastewater, is led to the flocculation and sedimentation tank, and flocculant is added to carry out flocculation and precipitation reaction to remove insoluble substances in biodiesel wastewater. Organic matter and suspended impurities, and demulsification of biodiesel and slick oil, so that the oil droplets gather into large oil droplets and float on the water surface; then the biodiesel wastewater is transferred from the flocculation sedimentation tank to the oil separation adjustment tank, and heated to make the biodiesel The temperature of the wastewater is kept at 40-50°C, and then the oil floating on the water surface after the demulsification is recovered by using the oil slick recovery machine, and then most of the biodiesel and slick oil in the wastew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com