Resource utilization method for high-salt wastewater from epichlorohydrin preparation through glycerol method

A technology for epichlorohydrin and high-salt wastewater, applied in chemical instruments and methods, separation/purification of alkali metal chlorides and carboxylic acid compounds, etc. , to achieve the effect of simple process flow, low recyclable resources and low secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

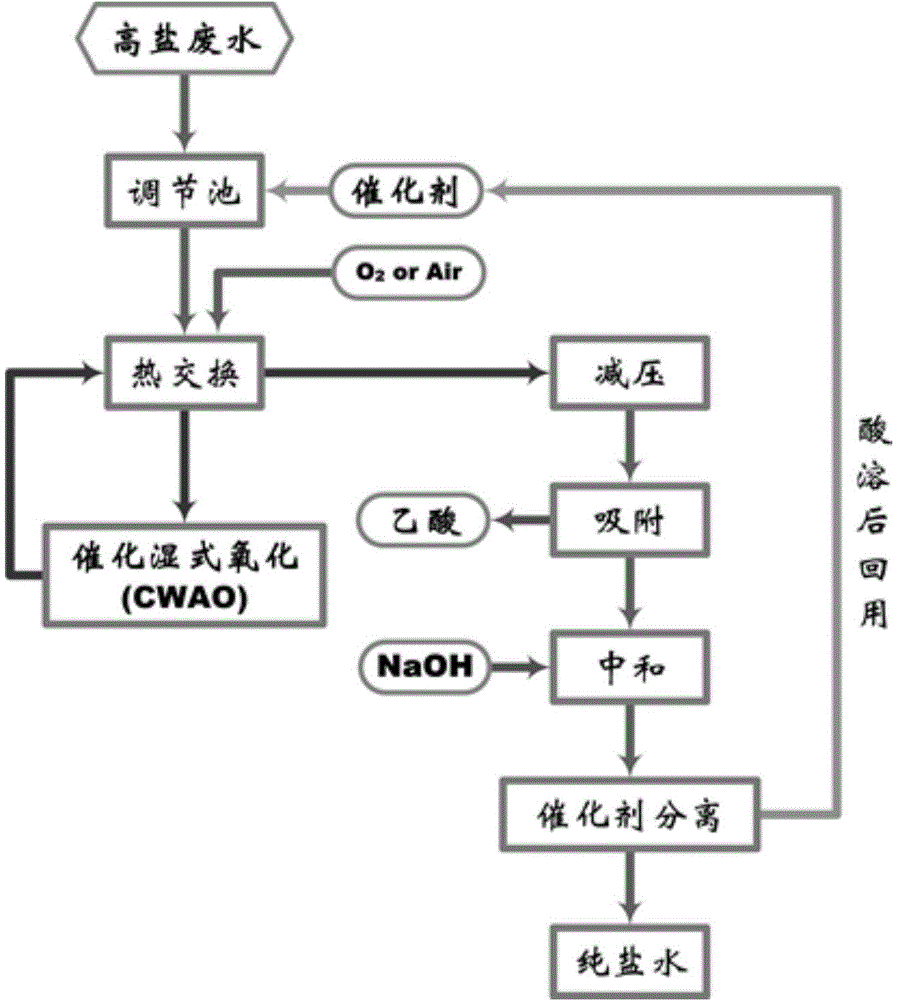

Method used

Image

Examples

Embodiment 1

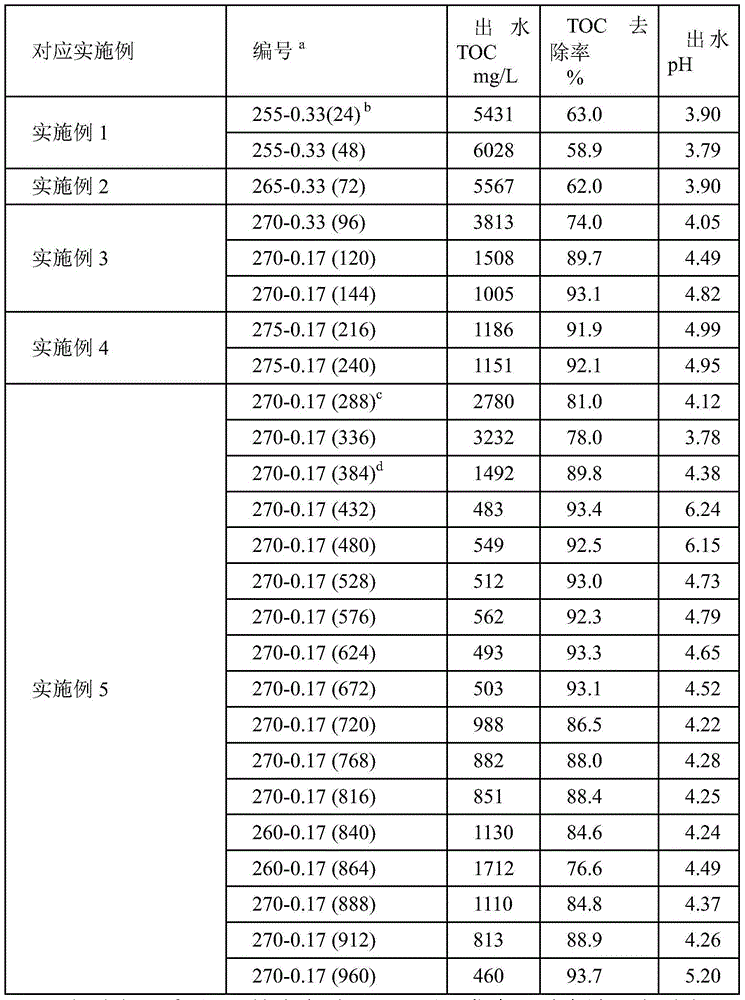

[0035] Take 1L of glycerol method epichlorohydrin high-salt wastewater, add 48g of 37wt% concentrated hydrochloric acid to the adjustment tank to adjust to pH = 3, dilute the wastewater by 4 times with deionized water, add CuCl 2 As a catalyst, its dosage is 0.5wt.% of the high-salt wastewater. Then it is mixed with air through the pipeline and then enters the heat exchanger to be heated to 220°C, and finally enters the catalytic wet oxidation reaction tower for reaction. The catalytic wet oxidation reaction temperature is 255°C, the reaction pressure is 5.5MPa, and the waste water space velocity is 2h -1 , the gas flow rate is 80mL / min. The effluent is cooled to 60°C in the heat exchanger. The reaction results are shown in Table 1.

Embodiment 2

[0037] Take 1L of glycerol method epichlorohydrin high-salt wastewater, add 48g of 38wt% concentrated hydrochloric acid to the adjustment tank to adjust to pH=2, dilute the wastewater by 4 times with deionized water, add NiCl 2 and ZnCl 2 (Molar ratio 1:1) as a catalyst, its dosage is 0.4wt.% of high-salt wastewater. Then it is mixed with air through the pipeline and then enters the heat exchanger to be heated to 240°C, and finally enters the catalytic wet oxidation reaction tower for reaction. The catalytic wet oxidation reaction temperature is 265°C, the reaction pressure is 6.0MPa, and the waste water space velocity is 2h -1 , the gas flow rate is 80mL / min. The effluent is cooled to 50°C in a heat exchanger. The reaction results are shown in Table 1.

Embodiment 3

[0039] Take 1L of glycerol method epichlorohydrin high-salt wastewater, add 48g of 37wt% concentrated hydrochloric acid to the adjustment tank to adjust to pH=3, dilute the wastewater by 3 times with deionized water, add FeCl 3 As a catalyst, its dosage is 0.3wt.% of the high-salt wastewater. Then it is mixed with air through the pipeline and then enters the heat exchanger to be heated to 240°C, and finally enters the catalytic wet oxidation reaction tower for reaction. The catalytic wet oxidation reaction temperature is 270°C, the reaction pressure is 6.5MPa, and the waste water space velocity is 1~2h -1 , The gas flow rate is 40-80mL / min. The effluent is cooled to 40°C in a heat exchanger. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com