Patents

Literature

101results about How to "Reduce process production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn process of nanometer mesoporous TiO2 powder

InactiveCN1636879AEffective generationReduce process production costsTitanium dioxideSolventTitanium dioxide

The preparation process of nanometer mesoporous TiO2 powder includes TiO2 gel particle with titanyl sulfate and sodium hydroxide as main material, water as solvent and surfactant; and subsequent filtering, drying, heat treatment and grinding to prepare nanometer anatase type mesoporous TiO2 powder with pore diameter of 2-15 nm, particle size of 8-15 nm and specific surface area of 80-150 sq m / g. The preparation process has low cost is suitable for industrial production. The prepared nanometer mesoporous TiO2 has wall of nanometer anatase type crystal, may be ultraviolet excited to generate photoelectron and photohole and is suitable for use as catalyst.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

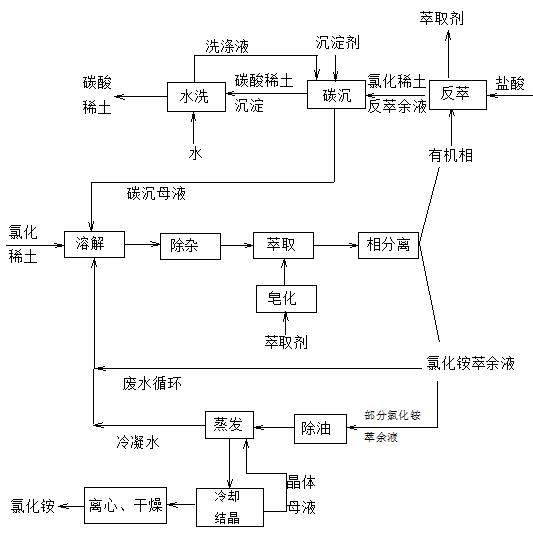

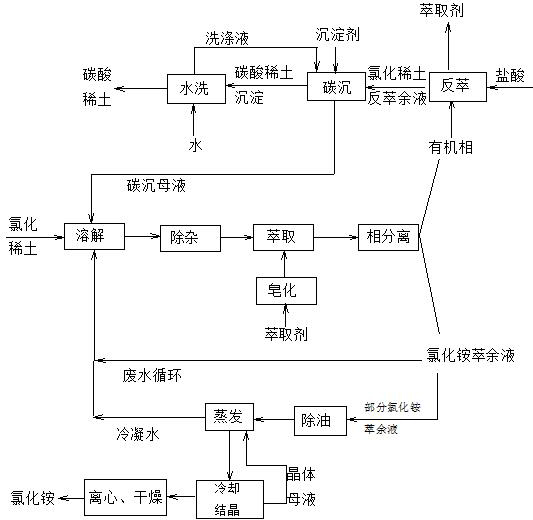

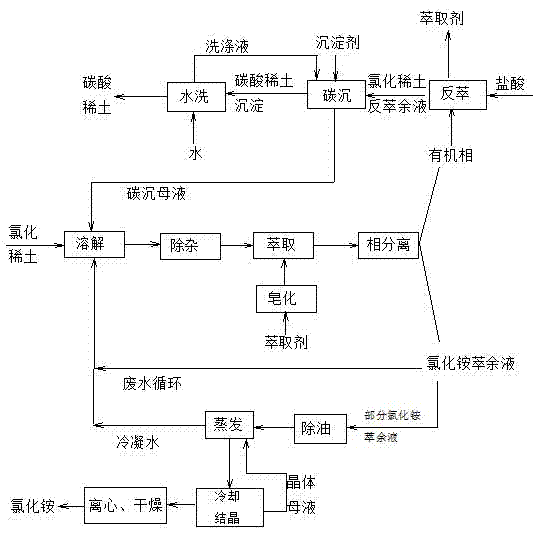

Method for treating rare earth ammonium chloride wastewater

InactiveCN102531025ASimple processHigh recovery rateMultistage water/sewage treatmentRare earth metal compoundsCarbon sinkRare earth

The invention discloses a method for treating rare earth ammonium chloride wastewater, belonging to the field of wastewater treatment. The method for treating the rare earth ammonium chloride wastewater comprises the steps of: dissolving ammonium chloride rare earth, carrying out organic phase saponification, carrying out extraction separation, recycling wastewater, stripping, carbon-sinking, washing, evaporating, cooling and crystallizing. According to the method, ammonium chloride raffinate and carbon sink mother liquor which are generated by extraction separation on the rare earth are used as the solvents of the ammonium chloride rare earth for recycling so that the ammonium chloride in the wastewater is increased, the ammonium chloride is favorably evaporated and condensed, and energy resource consumption is reduced. Meanwhile, washing liquor of rare earth carbonate precipitates is recycled for preparing a precipitating agent, thus water resources are saved. The mass percent of the ammonium chloride in the recycled finished product is 91.7-96.5 percent in the terms of dry basis; and the economic benefit is remarkable, the wastewater is recycled, and zero emission of the rare earth wastewater is recycled.

Owner:江西德盛精细化学品有限公司

Technology for extracting bran dietary fibers by combining ultrasonic-assisted enzymolysis and microbial fermentation

ActiveCN104921149AImprove functionalityHigh nutritional valueFood ingredientsFood ultrasonic treatmentBiotechnologyCellulose

The invention discloses a technology for extracting bran dietary fibers by combining ultrasonic-assisted enzymolysis and microbial fermentation. The gloss of a dietary fiber product is ivory, the function index of the dietary fiber product is far higher than the standard of dietary fibers commonly used in the western countries, and the dietary fiber product can serve as high-quality dietary fibers and an ideal food additive. The technology has the advantages that the dietary fibers in bran are extracted through the technology of combining ultrasonic-assisted enzymolysis protein starch removal, microbial fermentation and ultrasonic-assisted enzymolysis, the product yield and the function are obviously improved; the bran dietary fibers obtained after ultrasonic-assisted enzymolysis and microbial fermentation are carried out and the lignin degradation rate reach 70% or higher, part of thallus dietary fibers are included, and the nutrient value of the bran dietary fibers is obviously improved; the production cost of the technology is low, industrialization production is facilitated, and a set of bran dietary fiber developing and utilizing approach which is high in efficiency, low in cost, safe and feasible is established.

Owner:HENAN KUANGHUA FOOD CO LTD

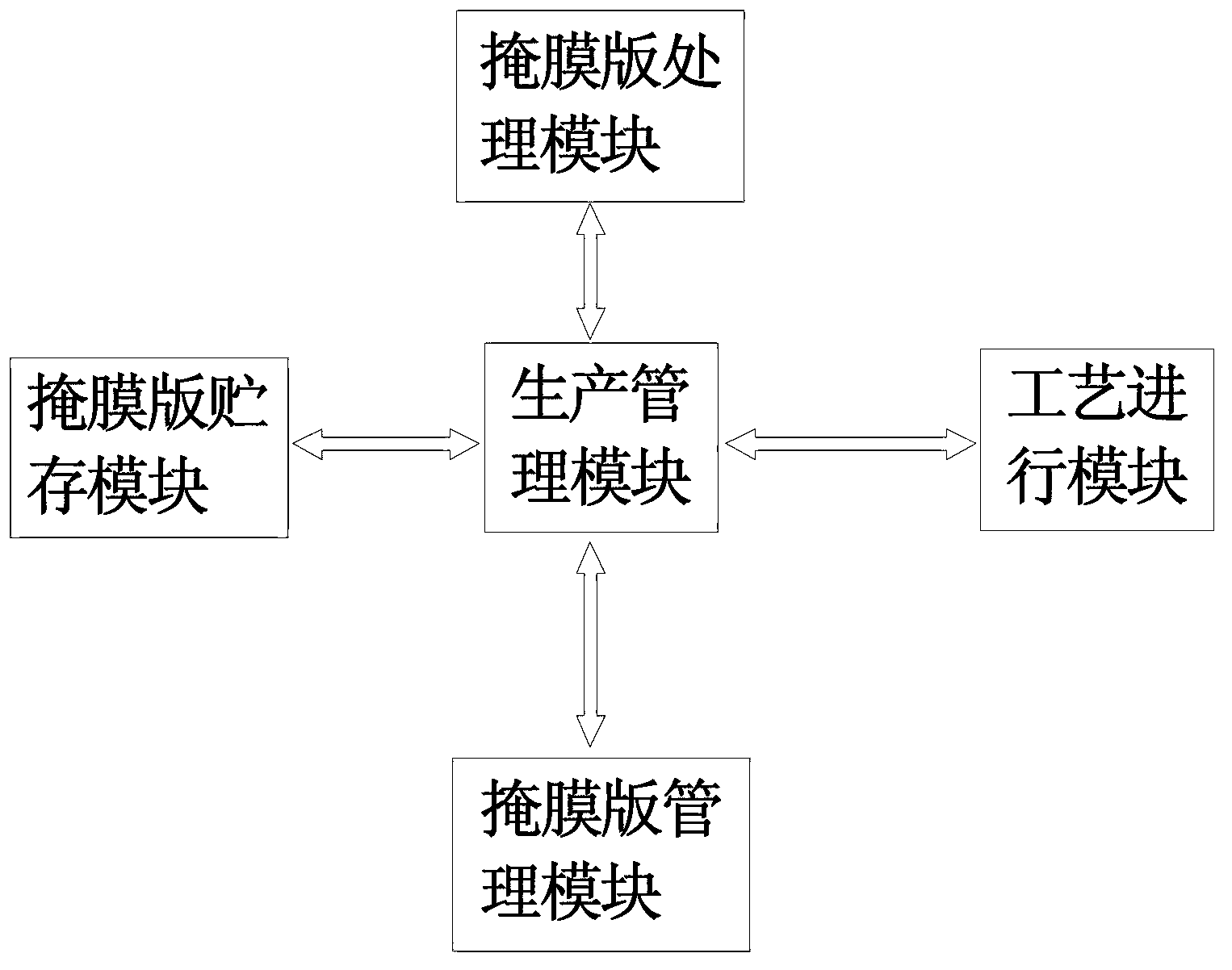

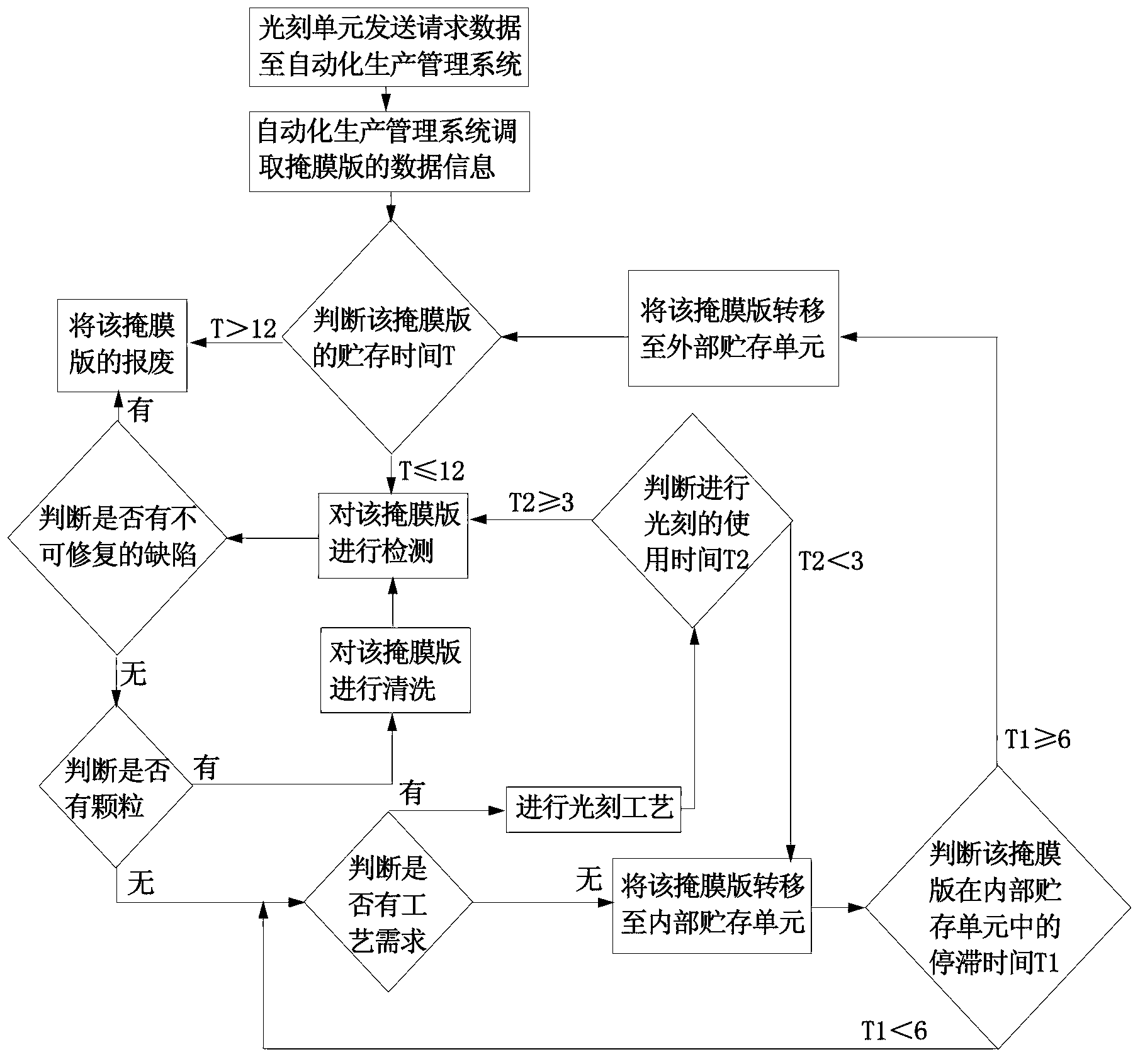

Automated mask management system and method

ActiveCN103176371AMonitor usageEasy to trackPhotomechanical exposure apparatusMicrolithography exposure apparatusProcess moduleHuman error

The invention discloses an automated mask management system and method. The system comprises a production management module, a mask management module, a process execution module, a mask processing module and a mask storage module, wherein the production management module can be in data interaction with the mask management module, the process execution module, the mask processing module and the mask storage module respectively through an EAP (Equipment Automatic Program) and a server. According to the system and the method, disclosed by the invention, a mask can be accurately applied to a corresponding photoetching machine, a corresponding photoetching process and a corresponding photoetching product, so that the error ratio caused by human factors is reduced, the range of influence caused after problems occur is reduced, the use conditions of the mask can be effectively monitored, and the mask trace tracking is facilitated; and thus, the subsequent data analysis is facilitated, the feedback speed is accelerated, and then, the management is timesaving and laborsaving, so that the process production cost is reduced, and the problem of yield caused by human errors is solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

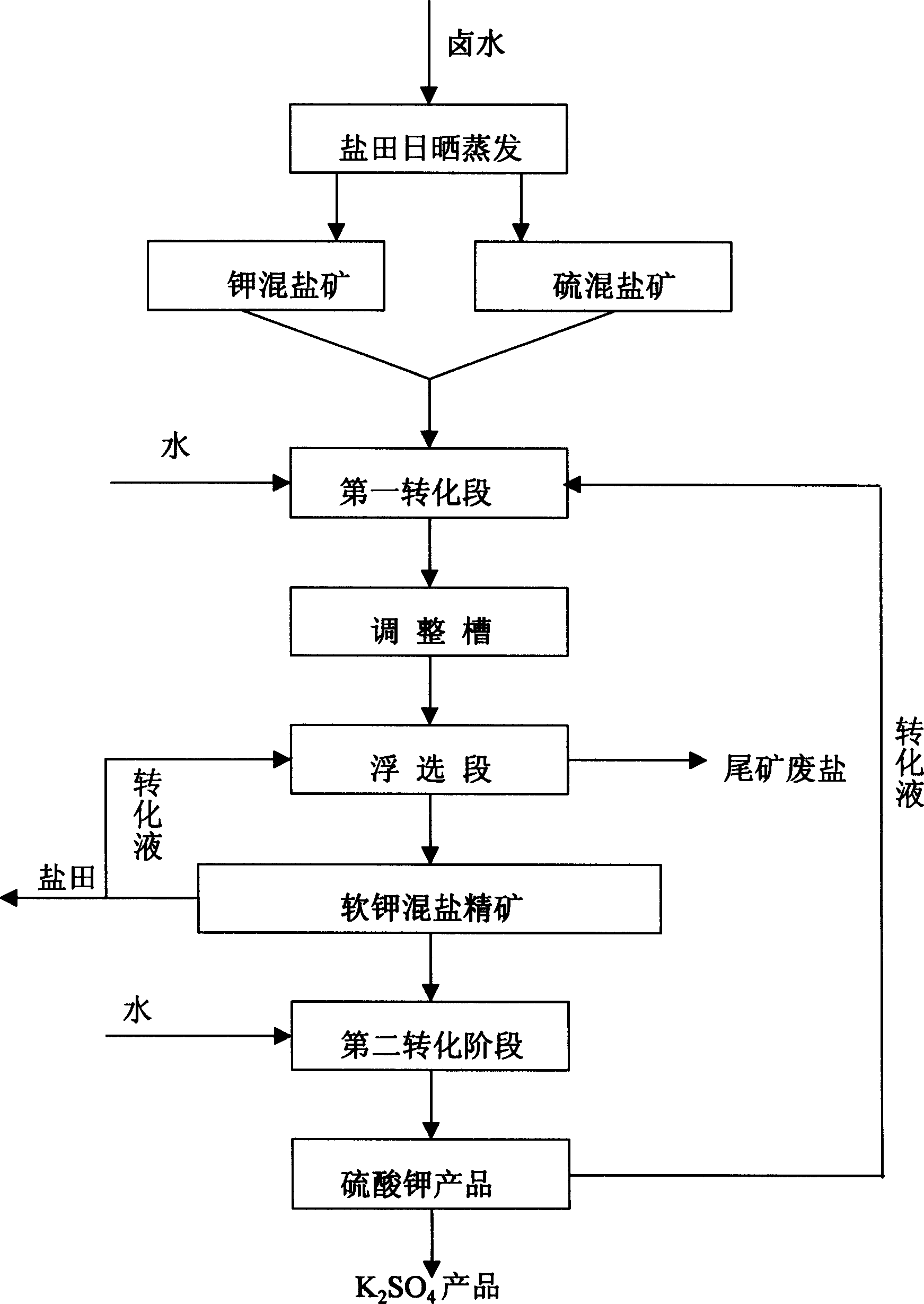

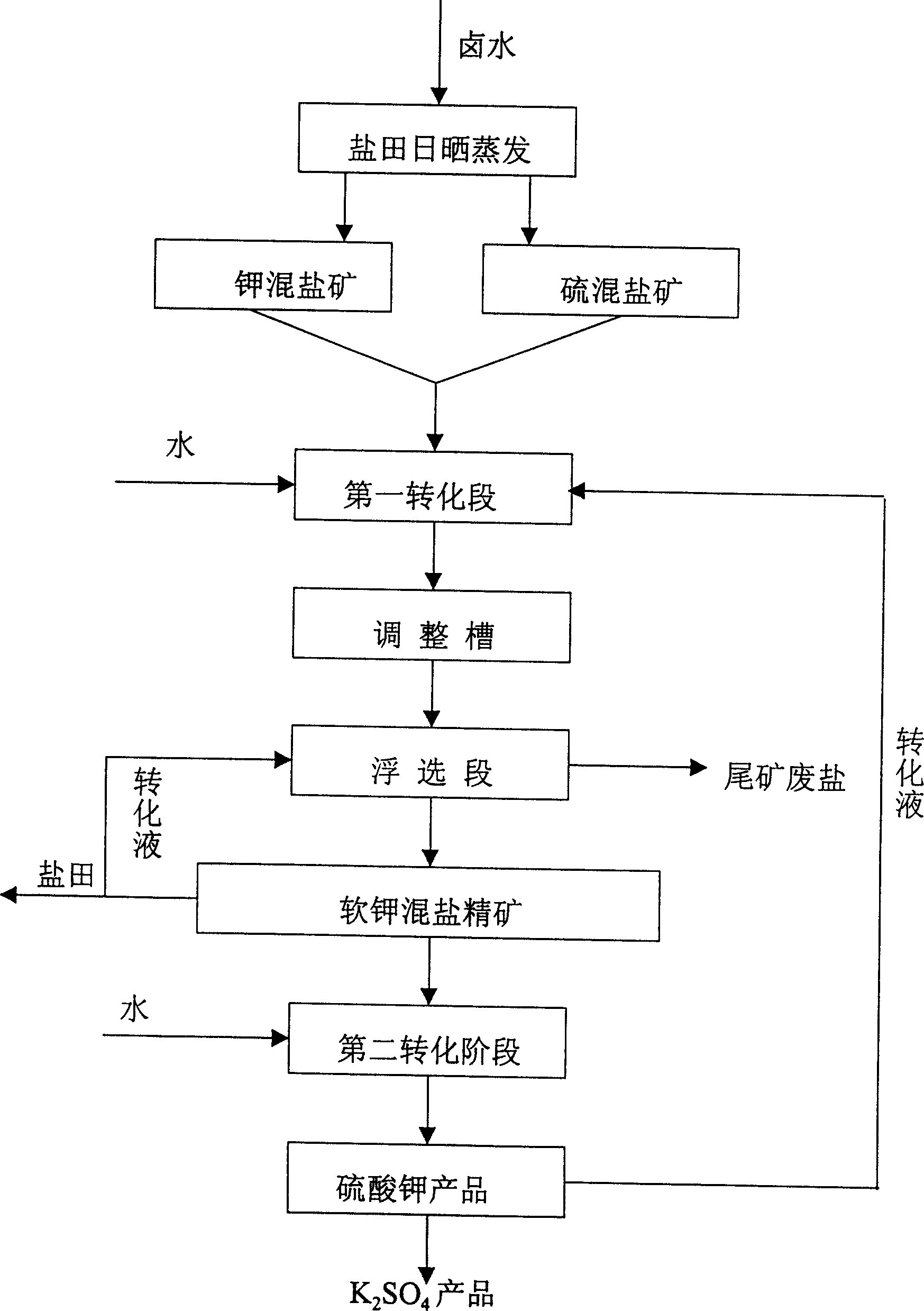

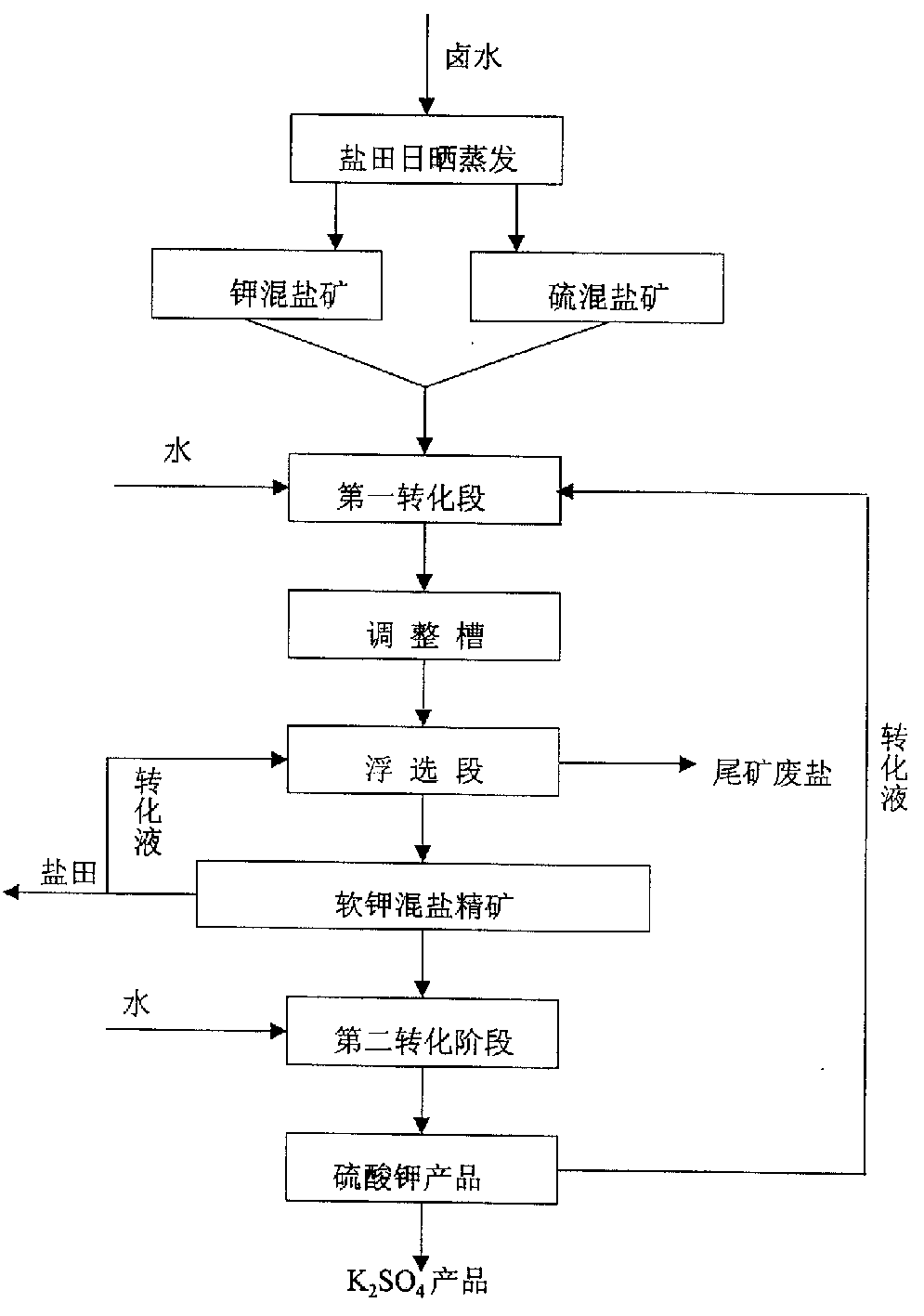

Potassium sulfate preparing process from sulfate-type salt lake bittern

InactiveCN1548372AAdaptable to changeWhite colorDouble sulfate preparationFlotationSalt lakeChloride

The present invention is one method of preparing potassium sulfate with sulfate type lake bittern resource. The preparation process includes the following steps: shining bittern to obtain mixed sulfate mineral with sodium chloride, schoenite, magnesium sulfate and potassium chloride as main components and mixed potassium salt mineral with sodium chloride, potassium chloride, magnesium sulfate and carnallite as main components; mixing these two kinds of mineral and converting with water at normal temperature to obtain coarse mixed schoenite mineral; floating the mixed schoenite mineral to obtain concentrated mixed schoenite mineral; adding water to the high-grade concentrated mixed schoenite mineral and decomposing directly to obtain potassium sulfate product; water washing the tailing to obtain industrial salt. The technological process is power saving and low in cost, and has other advantages.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

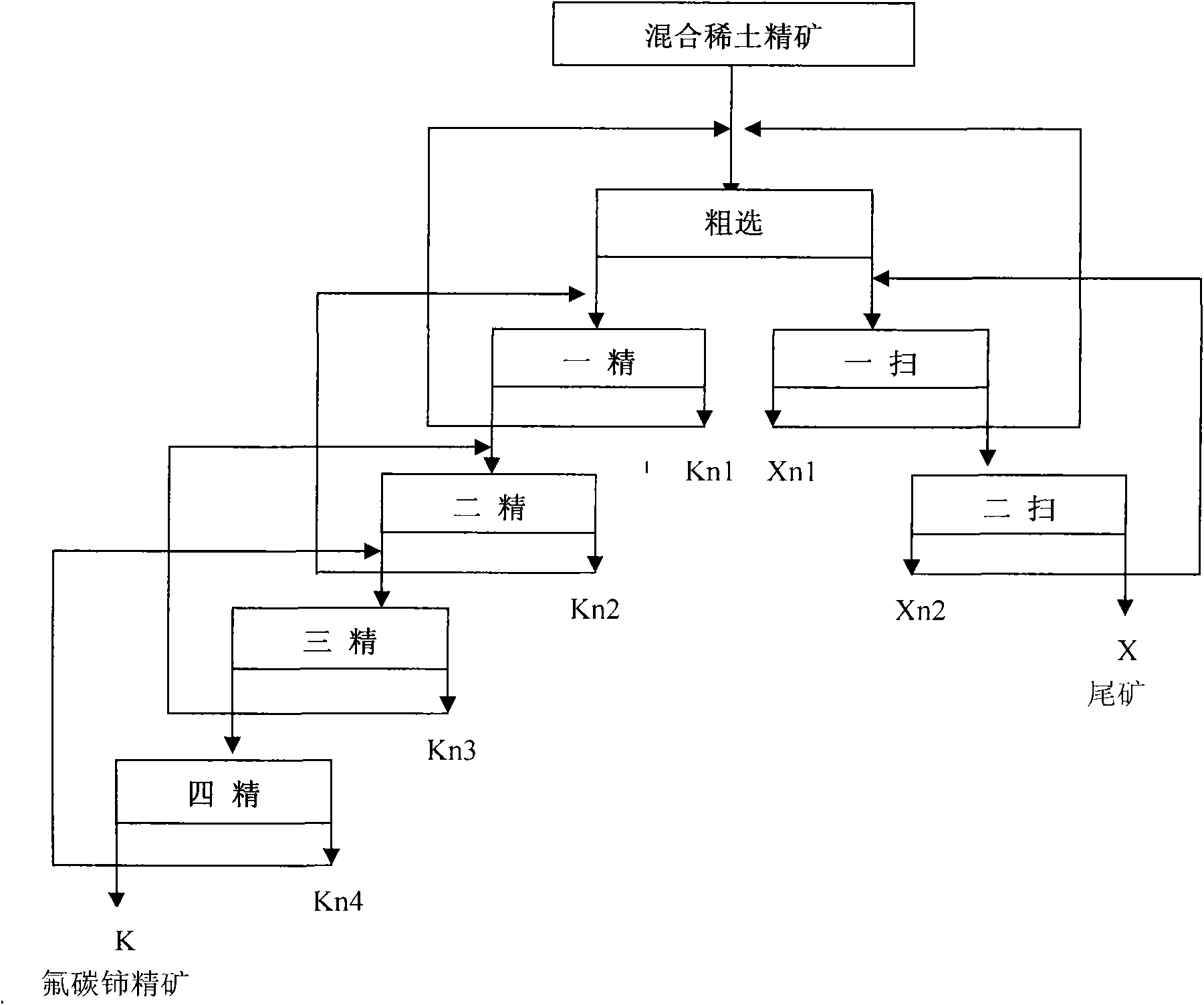

A kind of beneficiation method of purifying bastnaesite concentrate

InactiveCN102274796AReduce process production costsNo pollution in the processFlotationScavengerFoaming agent

The invention relates to a beneficiation method for purifying bastnaesite concentrate, which belongs to the technical field of rare earth beneficiation. The present invention is a new mineral processing process for purifying bastnaesite concentrate from mixed rare earth concentrate mainly composed of bastnaesite in Baotou Baiyun Obo. Phthalic acid is used as a collector, alum is used as a regulator, and No. 2 oil is used as a foaming agent. After a flotation process of primary roughing, fourth stage selection, and secondary sweeping, the purity of the bastnaesite concentrate obtained is ≥98%, bastnaesite recovery rate ≥95%, thus providing high-quality raw materials for the reform of the mixed rare earth concentrate smelting process.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

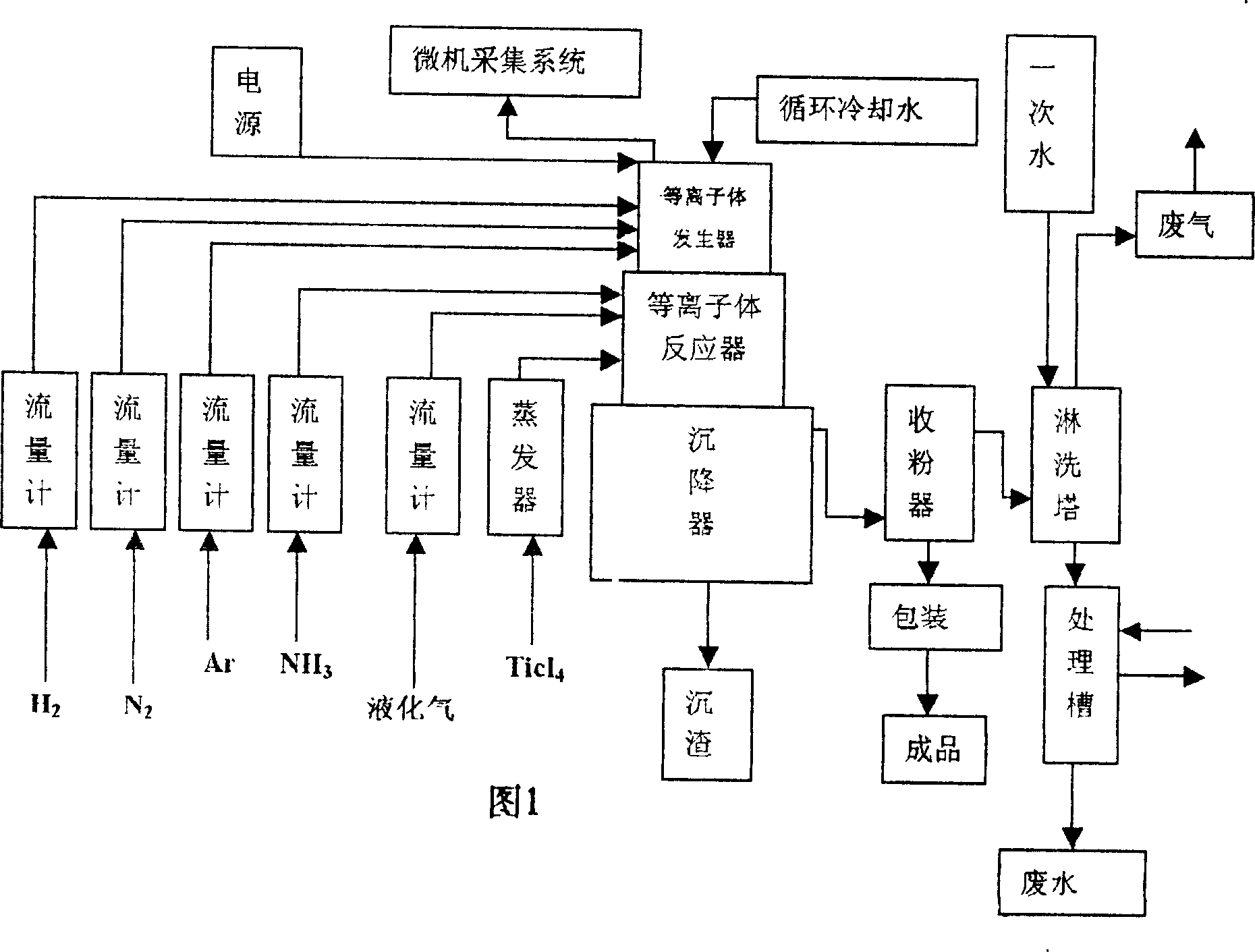

Process for preparing titanium carbonitride ceramic powder body by utilizing plasma chemial gas phase synthesis method

The process for preparing titanium carbonitride ceramic powder body by using plasma chemical gas-phase synthesis method is characterized by utilizing the D.C. electric arc plasma as heat source, heating the gas N2-H2-Ar flowing through electric arc to high temp. of 4800-5200 deg.C and feeding said gas and liquefied gas heating-evaporated by evaporator, TiCl4 and NH3 gases into plasma reactor together to make them quickly produced decomposition and synthesis reaction of titanium carbonitride, and making the TiCN formed at 1200-1300 deg.c in reactor undergo the processes of crystallization, growth, cooling and gas-solid separation so as to obtain the invented nano-grade titanium carbonitride ceramic powder body.

Owner:白万杰

Method for producing steel for low-nitrogen stranded wire by use of non-vacuum process of converter

The invention discloses a method for producing steel for a low-nitrogen stranded wire by use of the non-vacuum process of a converter, belonging to the technical field of steel for prestressed steel strand. The method comprises the steps of molten iron desulphurization and slagging off, converter smelting, slag blocking and tapping, steel ladle deoxidization and alloying, steel ladle slag modification, LF steel ladle refining, Si-Ca wire feeding, steel ladle bottom soft argon blowing, full-protection casting of 160mm*160mm small square billet and terminal electromagnetic stirring matched with a crystallizer; the technical parameters of control are as follows: the converter adopts double-slag operation, the end point carbon is under 0.20-0.30% control, the tapping temperature is 1,600-1,630 DEG C, and the thickness of roughing slag is 0-50mm; a micro-nitrogen carburant (N: 0.005-0.025%) is matched with 5kg of carbon per ton of steel, 1.5kg of Si-Ca-Ba per ton of steel is added for deoxidization, and 4kg of synthetic slag per ton of steel is added; the oxygen activity outside the LF refining station is controlled to be less than or equal to 10ppm, and the content of FeO and MnO in final slag is less than or equal to 3%; and 1m Ca-Si wire per ton of steel is fed, and the soft argon blowing time is 12-30 minutes. The method disclosed by the invention remarkably lowers the production cost and reaches the nitrogen quality control level of steel for producing a stranded wire in a vacuum degassing process.

Owner:SHOUGANG CORPORATION

Novel process for preparing dietary fiber by high-value comprehensive utilization of wheat bran

InactiveCN106173877AImprovement of dietary fiber extraction rate and water-soluble dietary fiber yield and product functionalityHigh nutritional valueLactobacillusFood dryingNutrientWater soluble

The invention discloses a novel process for preparing a dietary fiber by high-value comprehensive utilization of wheat bran. A dietary fiber product is creamy white in color, functional indexes are far higher than dietary fiber standards commonly used by western countries, and the dietary fiber product can serve as a high-quality dietary fiber and an ideal food additive. The novel process has the advantages that firstly, dietary fibers in the bran are extracted by ultrasonic-assisted enzymolysis protein removal starch, compound microorganism liquid fermentation, ultrasonic-assisted enzymatic hydrolysis with cellulase and lactic acid bacteria solid fermentation processes, secondly, bran cellulose and lignin subjected to ultrasonic-assisted enzymatic hydrolysis and microbial fermentation are high in degradation rate, nutrient values of the dietary fibers in the bran are remarkably improved, thirdly, the production cost of the process is low, industrial production is facilitated, and a high-efficiency, low-cost, safe and feasible bran dietary fiber development and utilization method is established.

Owner:BINZHOU ZHONGYU FOOD

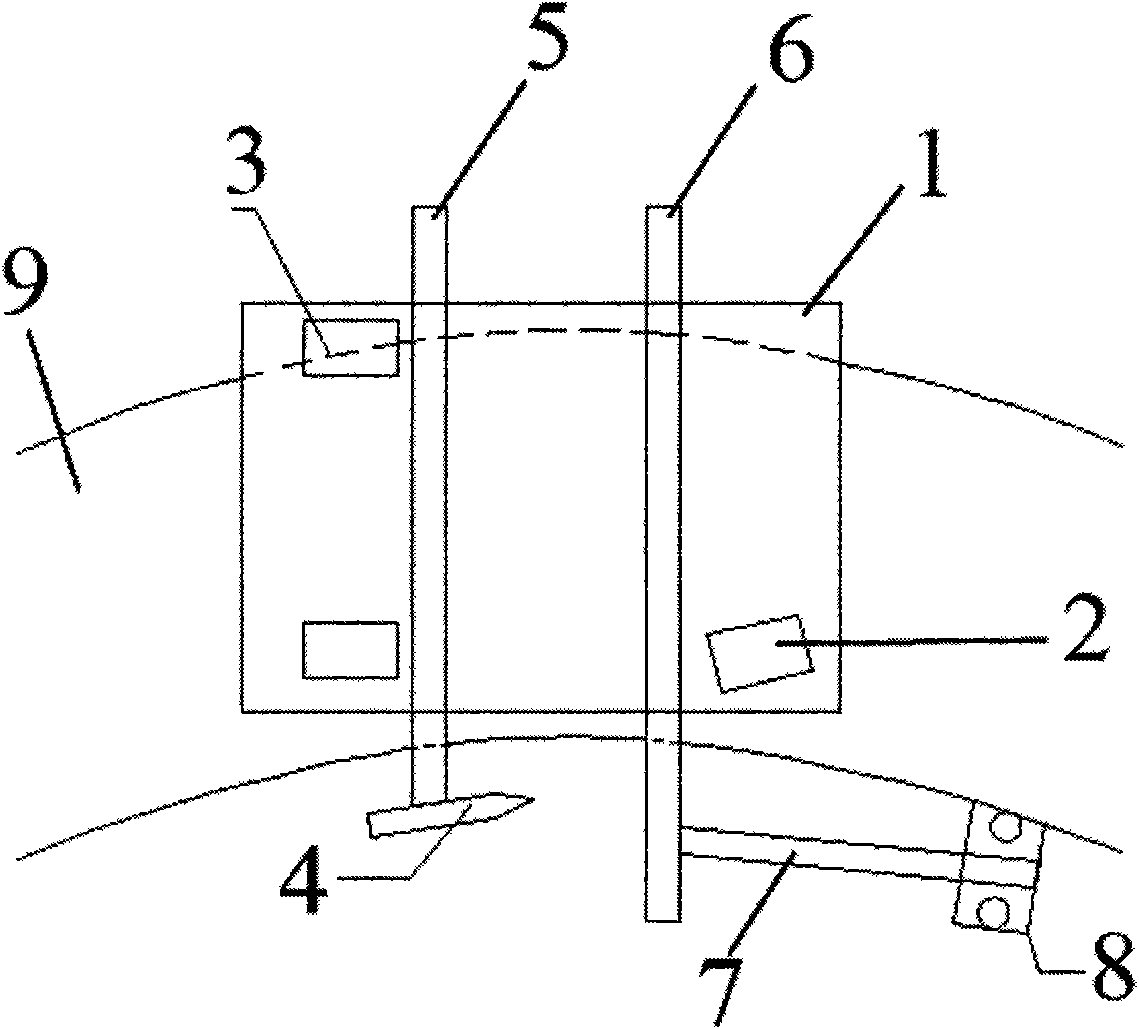

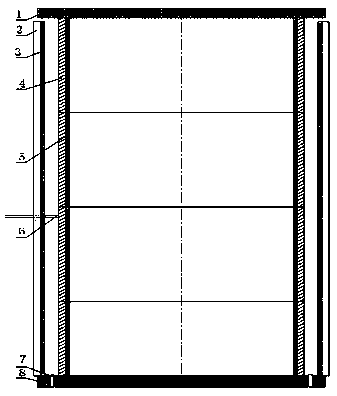

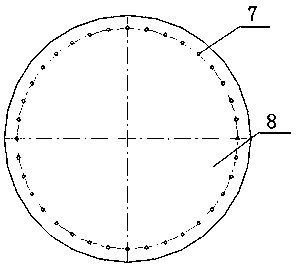

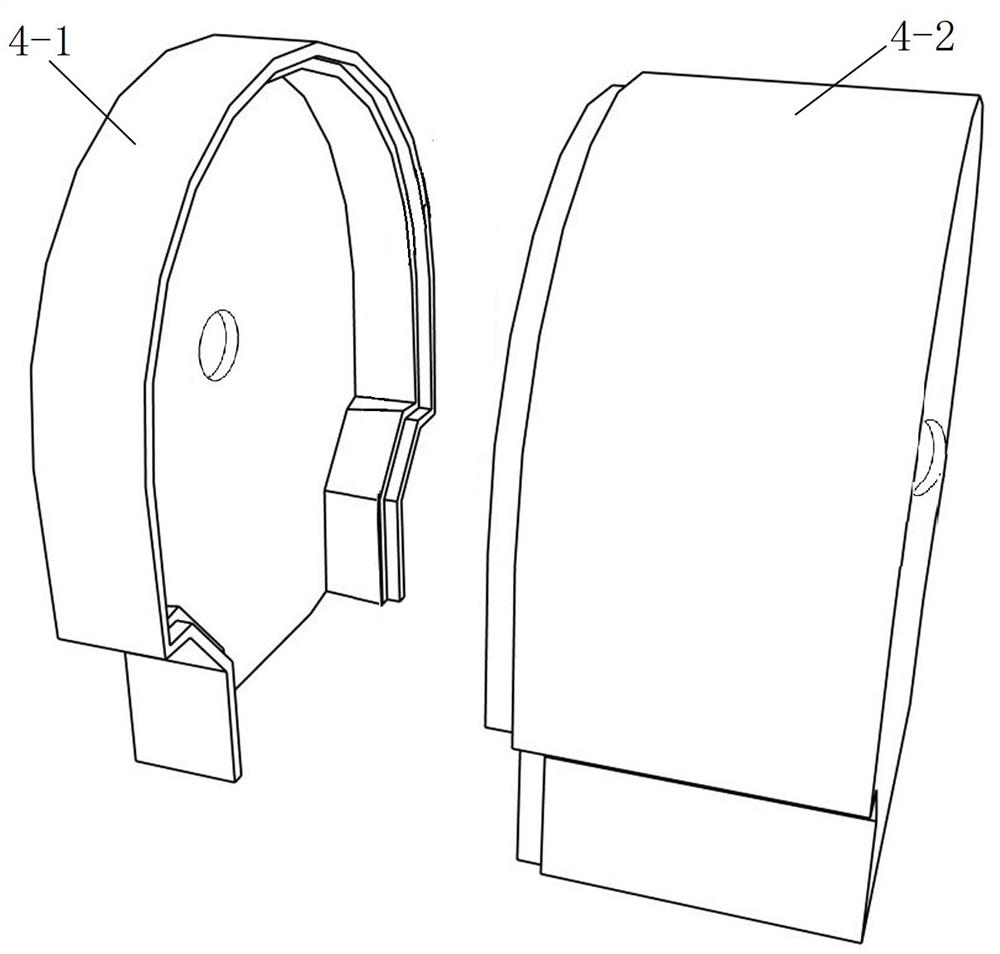

Railess automatic guiding flame cutter

InactiveCN101954521AReduce process production costsSimple structureGas flame welding apparatusVehicle frameDrive wheel

The invention provides a railess automatic guiding flame cutter. The cutter is formed by a frame, two travelling wheels, a driven wheel and a cutting torch, wherein a regulating rod is arranged in the frame; the cutting torch is arranged at one end of the regulating rod and positioned outside the frame; the travelling wheels are arranged at the front part of the bottom of the frame; the driven wheel is arranged at the rear part of the bottom of the frame; a regulating lead screw is arranged in the frame; one end of the regulating lead screw extends out of the frame to be connected with a backup arm; the backup arm and the cutting torch are positioned at the same side of the frame; and the front end of the backup arm is provided with a backup wheel. When a beveling is performed on the steel plate with an arc-shaped edge, the backup arm extends inside the lateral side of the plate, and the backup wheel is closely attached to the lateral side of the plate. When the frame moves forward, the driven wheel faces to the internal side of the steel plate, the travelling direction of the driven wheel is controlled by the machine-shaping appearance of the plate in the previous process and the backup arm, and the cutting torch is used for cutting the beveling for the plate. The distance between the backup wheel and the frame can be changed by adjusting the screw rod so as to adapt to the curve radius of the steel plate.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

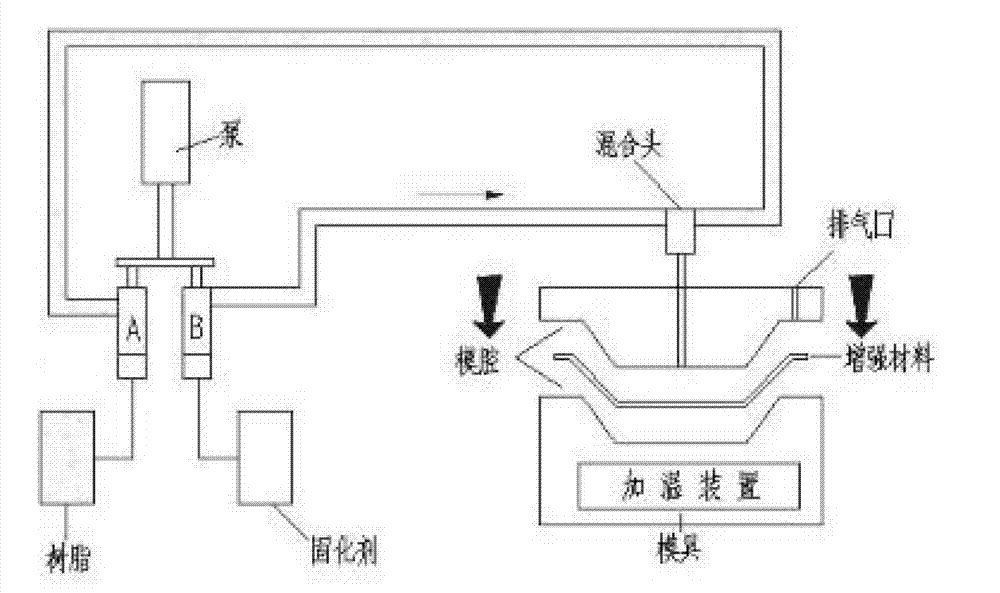

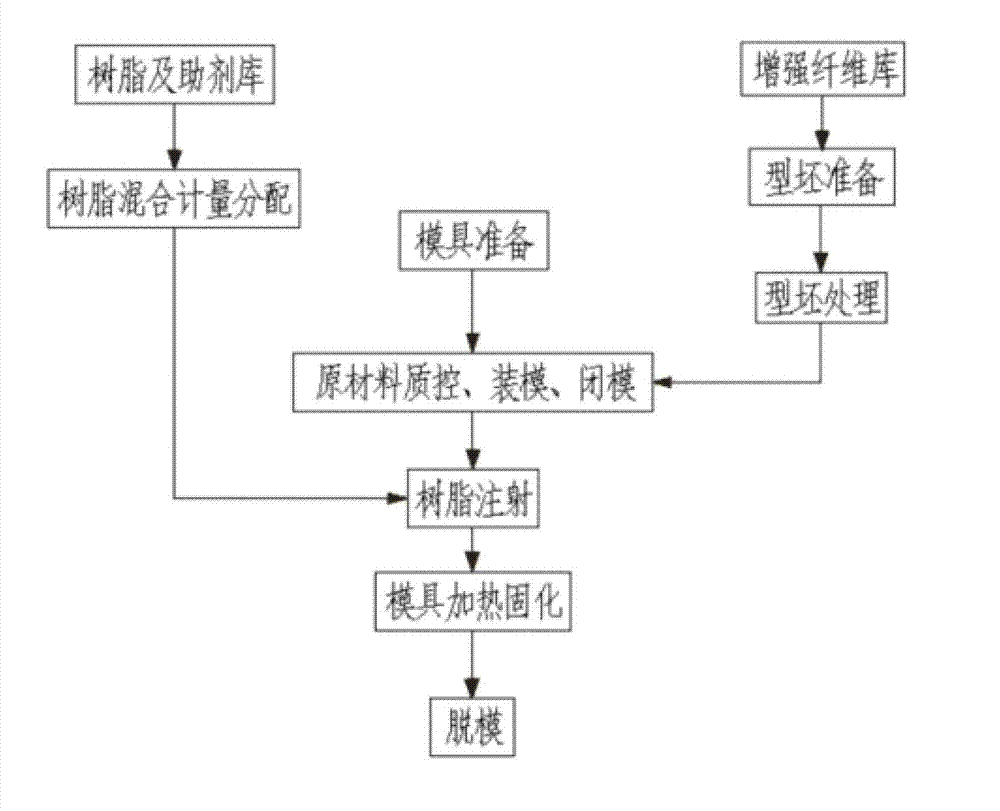

RTM (Resin transfer molding) technology for composite material molding

InactiveCN103240893AResolution timeSolve the problem of large product deformationGlass fiberState of art

The invention discloses an RTM (resin transfer molding) technology for composite material molding. The RTM technology for composite material molding comprises the following steps of: step one, placing glass fiber reinforcing materials in advance in a mold cavity of a mold; step 2, injecting a prepared resin glue solution into the mold cavity from an injection hole after a mold is closed and locked at certain temperature and pressure, and soaking the glass fiber reinforcing materials; and step 3, controlling the temperature and curing through a heating device in the mold, starting up the mold, and demolding. The RTM technology for composite material molding disclosed by the invention can effectively solve the problems of longer molding time as well as great product deformation in the prior art, and the technology is low in production cost, and is beneficial to popularization.

Owner:JIANGSU AOXIN NEW ENERGY AUTOMOBILE

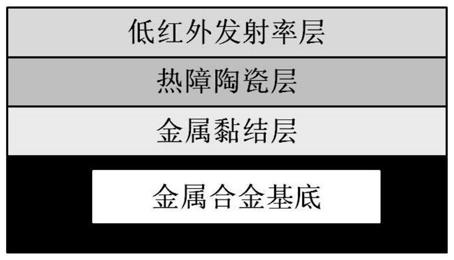

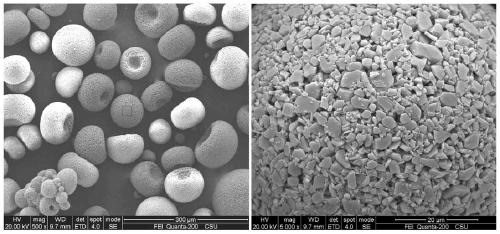

Thermal barrier/high-temperature low infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110117764AImprove temperature resistanceImprove thermal insulation performance and bond strengthMolten spray coatingBonding strengthMetal

The invention discloses a thermal barrier / high-temperature low infrared emissivity integrated coating. The coating is of a multilayer stacked structure. The multilayer stacked structure successively comprises a metal bonding layer, a thermal barrier ceramic layer and a low infrared emissivity layer from inside to outside. The thermal barrier ceramic layer is a rare earth hexaaluminate layer, and the low infrared emissivity layer is a Bi2O3-MgO-Al2O3-Li2O-SiO2 serial glass coating containing a conductive phase Pd powder. The integrated coating has the advantages of heat-insulating property, high-temperature low infrared emissivity, high bonding strength and the like. The metal composite material with the coating is simple and manure in process, relatively low in cost and easy for scaled production and application.

Owner:NAT UNIV OF DEFENSE TECH

Process for making anti-counterfeiting printed release paper

ActiveCN103818134AImprove performanceStrong adhesionSynthetic resin layered productsPattern printingBiochemical engineeringSecurity printing

The invention relates to a process for making anti-counterfeiting printed release paper. The process is characterized by sequentially comprising the following steps of a, preparing anti-counterfeiting ink; b, printing anti-counterfeiting marks; c, film-coating; d, exhausting on film-coated surfaces; e, coating release layers. The process solves the problem that the anti-counterfeiting marks cannot be printed on release paper in the prior art, the production cost of the process is low, and the made release paper has good performance.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

Preparation method for anti-oxidation anti-ultraviolet active yeast extract based on low temperature plasma

The invention provides a preparation method for an anti-oxidation anti-ultraviolet active yeast extract by using an atmospheric pressure low temperature plasma generating device, belonging to the field of application of low temperature plasma technology. The preparation method is characterized by comprising the following successive steps: culturing yeast cells; selecting a type of an atmospheric pressure low temperature plasma generating device and setting working parameters; treating a suspension of the yeast cells by using atmospheric pressure low temperature plasma; and extracting active substances of the yeast cells having undergone plasma treatment. The preparation method provided by the invention has the advantage of capacity of highly efficiently and conveniently changing the activity of an enzyme in the yeast cells. The prepared active yeast extract can be used as an additive for articles of everyday use and has anti-ultraviolet, anti-oxidation, anti-ageing, fresh-keeping, sterilization and anti-inflammation effects and the like. According to the invention, since the active yeast extract is produced by using microbial fermentation, the environment and natural resources pose no influence, industrialization and automation can be easily realized, and the method has the advantages of low production cost, easiness, stability, easy regulation and control and a high success rate. Enterprises of various scales can invest on the preparation method provided by the invention.

Owner:PEKING UNIV

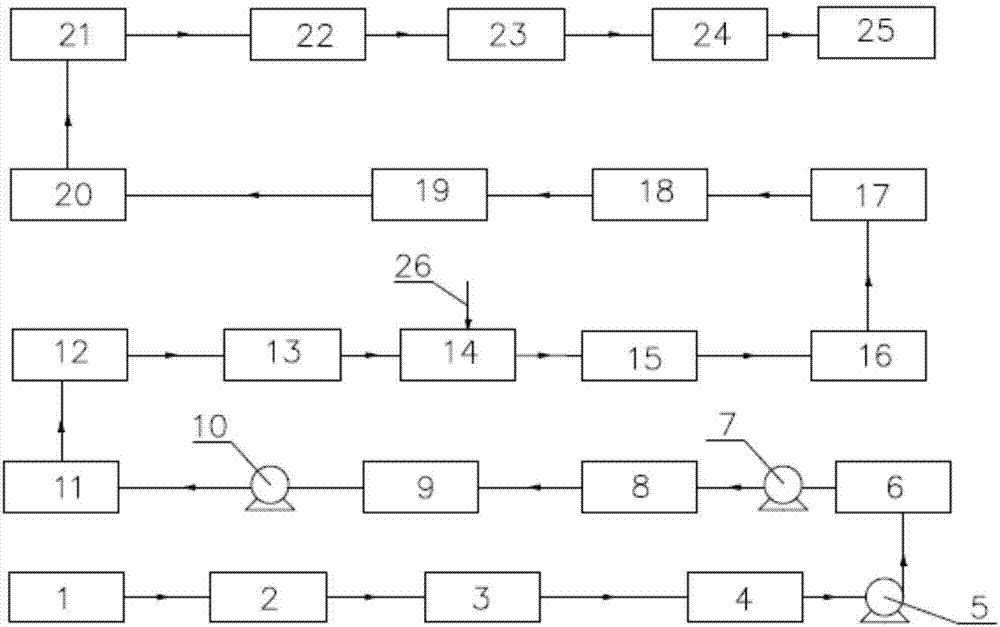

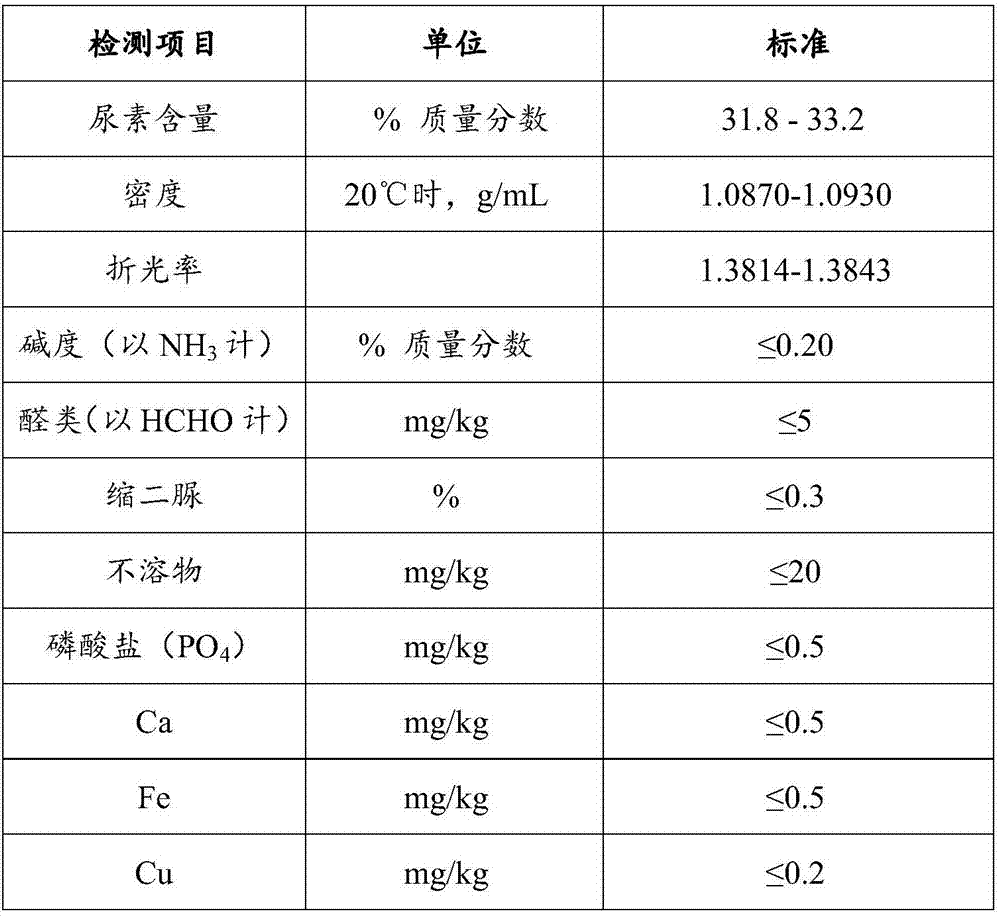

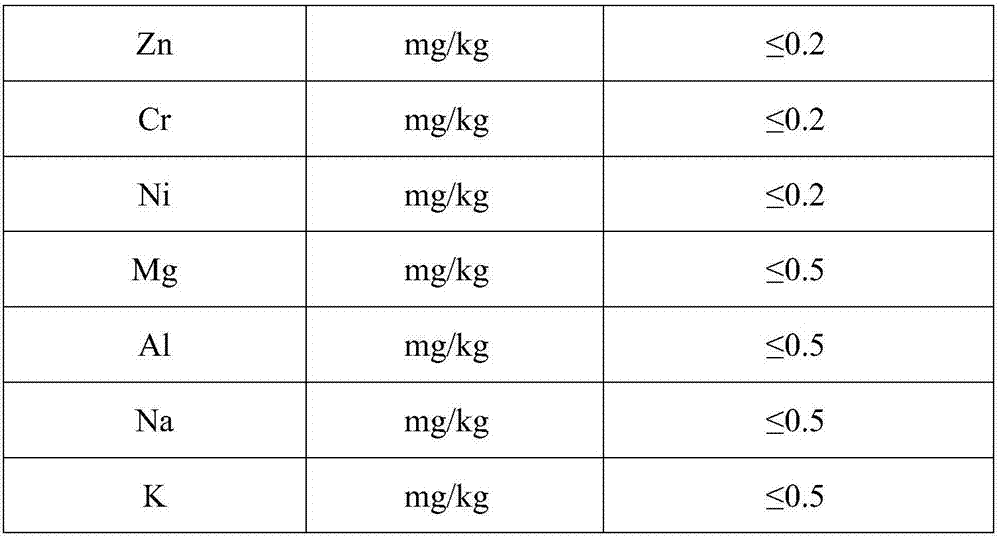

Production system of aqueous urea solution for motor vehicles

InactiveCN107261872ALow costReduce manufacturing costWater/sewage treatment by irradiationTransportation and packagingAqueous solutionGroundwater

The invention belongs to the technical field of urea production, and concretely discloses a production system of an aqueous urea solution for motor vehicles. The production system of the aqueous urea solution for motor vehicles is characterized in that raw water adopts municipal tap water or underground water, urea adopts generally agricultural or industrial urea, and the aqueous urea solution for motor vehicles is prepared through preparing highly pure water, dissolving common urea and purifying a urea solution. The commercial price of the common industrial and agricultural urea is 1500 yuan / t, and the is remarkably lower than that pure urea having a high price, so the cost taken in the production of every ton of the aqueous urea solution for motor vehicles by using the production system of the aqueous urea solution for motor vehicles is 500 yuan or above lower than the cost taken in the production of every ton of the aqueous urea solution for motor vehicles by using a traditional highly-pure urea preparation technology, the production cost is remarkably reduced, and the running cost of every ton of the aqueous urea solution for motor vehicles is 550 yuan or below.

Owner:XISHUI COUNTY FURUIDE CHEM ENG

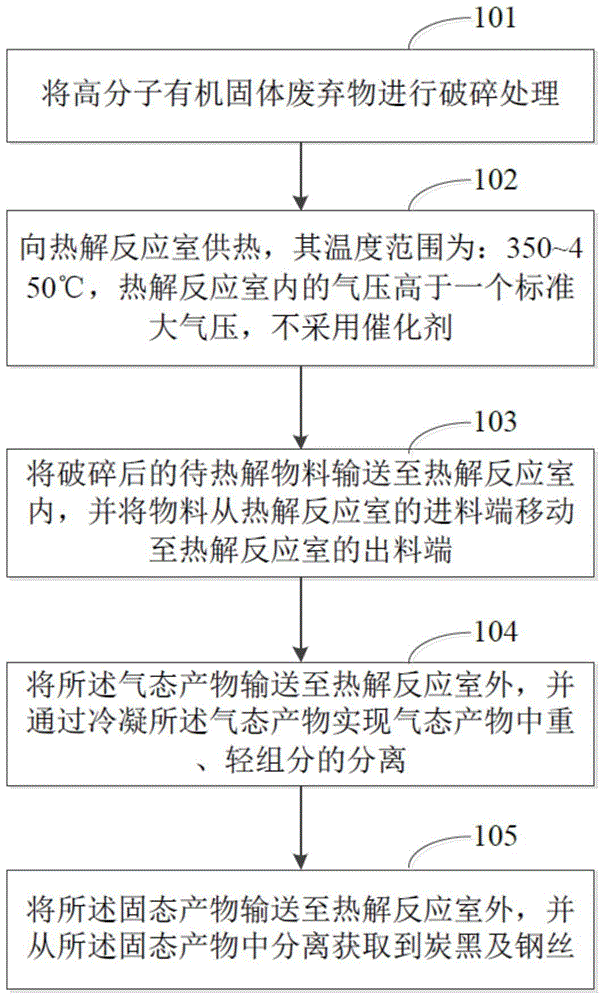

Thermal pyrolysis treatment method for organic wastes

InactiveCN105670675ARealize secondary useImprove protectionPigmenting treatmentSolid waste disposalMolecular solidGas phase

The invention relates to a thermal pyrolysis treatment method for organic wastes, which includes the following steps: (1) crushing high-molecular solid organic wastes; (2) melting the crushed high-molecular solid organic wastes at certain temperature to obtain a liquid to-be-pyrolyzed material; and (3) feeding the liquid to-be-pyrolyzed material to a pyrolytic reaction chamber and moving the material from a feeding end of the pyrolytic reaction chamber to a discharge end of the pyrolytic reaction chamber, so that the material is continuously subjected to a pyrolysis reaction during the moving process for converting the liquid to-be-pyrolyzed material into a gas-phase product and a solid-phase product through the pyrolysis reaction, wherein the pyrolysis reaction is 370-410 DEG C in temperature range and is carried out without a catalyst. The pyrolysis reaction effectively improves device safety performance and service life and reduces production cost on the basis of ensuring pyrolysis reaction efficiency and process yield.

Owner:ZHANGJIAGANG HUACHENG LOCOMOTIVE PRECISION PIPE MFG

Potassium sulfate preparing process from sulfate-type salt lake bittern

InactiveCN1255320CAdaptable to changeWhite colorDouble sulfate preparationFlotationDecompositionEnergy analysis

The invention provides a method for producing potassium sulfate by using sulfate-type salt lake brine resources. The method comprises the following steps: drying the sulfate-type salt lake brine in a salt field to obtain sodium chloride, soft potassium and magnesium Sulfate mixed salt ore of vanadium, magnesium sulfate and potassium chloride and potassium salt mixed salt ore mainly containing sodium chloride, potassium chloride, magnesium sulfate and carnallite; after mixing these two kinds of ores, they are mixed with The water is converted to produce coarse langbeinite mixed ore. The mixed ore is selected through the flotation process to select the langbeinite mixed salt concentrate, and then add water to the high-grade langbeinite mixed salt concentrate to decompose directly. Potassium sulfate product can be obtained; its tailings can be used as industrial salt after being washed with water; compared with the existing similar process, the present invention removes the grinding process with large power consumption, and the whole process does not add potassium chloride, saving Energy saving, cost reduction, simple process, normal temperature and pressure operation, strong adaptability to different grades of raw material ores, and good product purity and whiteness.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Molding technology for composite material product

InactiveCN103213289AResolution timeSolve the problem of large product deformationGlass fiberTemperature control

The invention discloses a molding technology for a composite material product. The molding technology comprises the following steps of: (1) placing a glass fiber reinforcement material in a mold cavity of a metal mold in advance; (2) after closing the mold and locking, injecting prepared resin adhesive liquid into the mold cavity from an injection hole at a certain temperature and pressure, and soaking the glass fiber reinforcement material; and (3) carrying out temperature control solidification through a heating device in the metal mold, opening the mold and demolding. The molding technology for the composite material product, disclosed by the invention, can effectively solve the problem of incapability of rapid solidification existing in the mold scheme for composite material product and mold materials in the prior art, and the molding technology is low in production cost and is beneficial to popularization.

Owner:JIANGSU AOXIN NEW ENERGY AUTOMOBILE

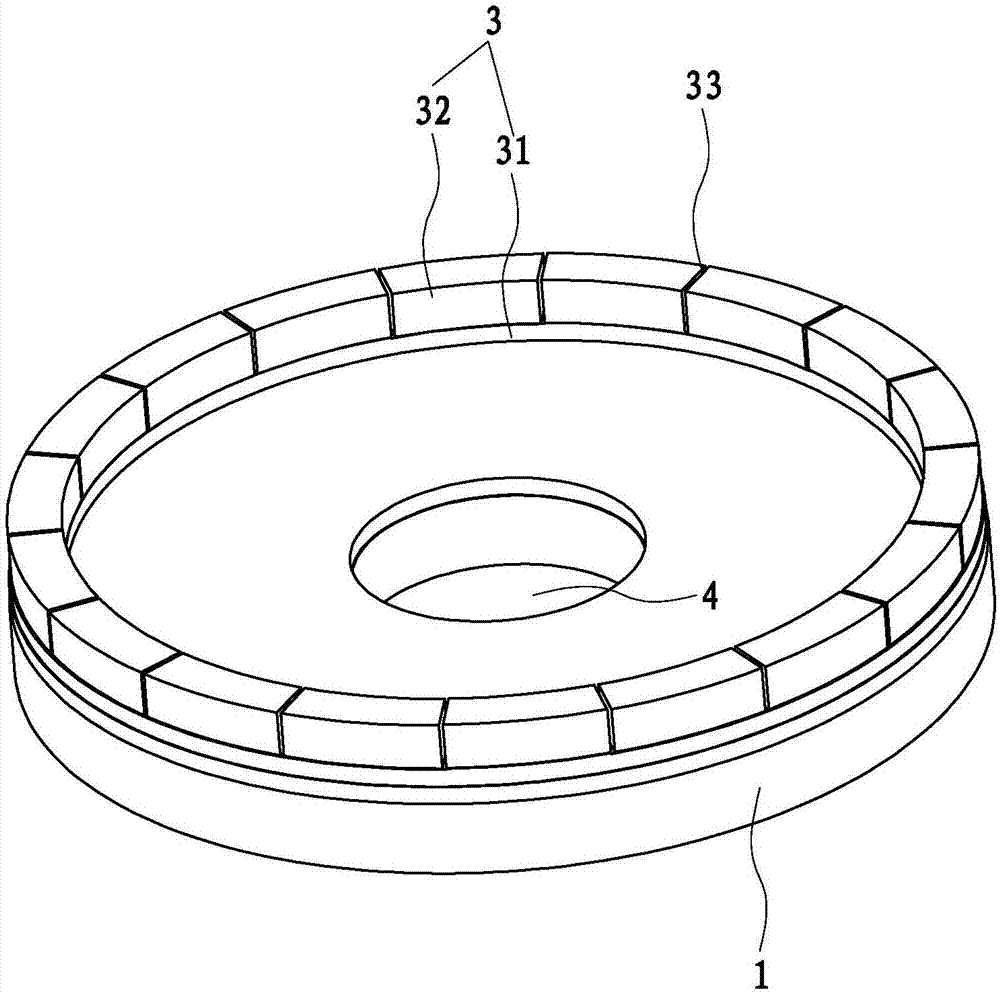

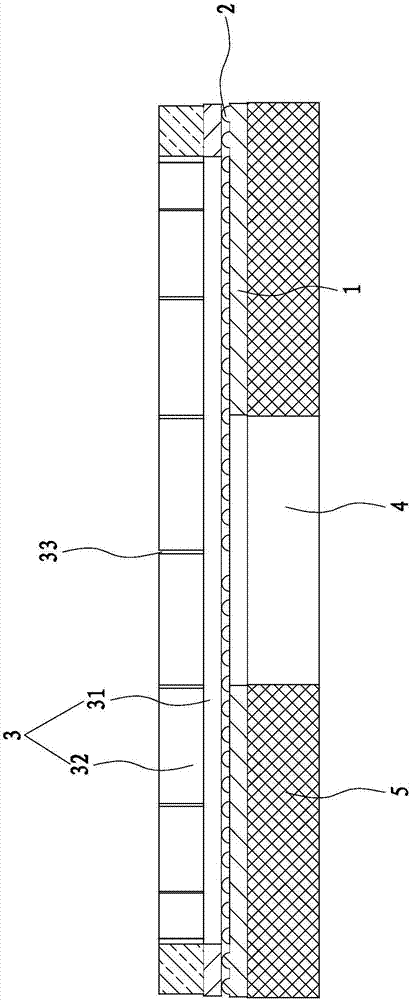

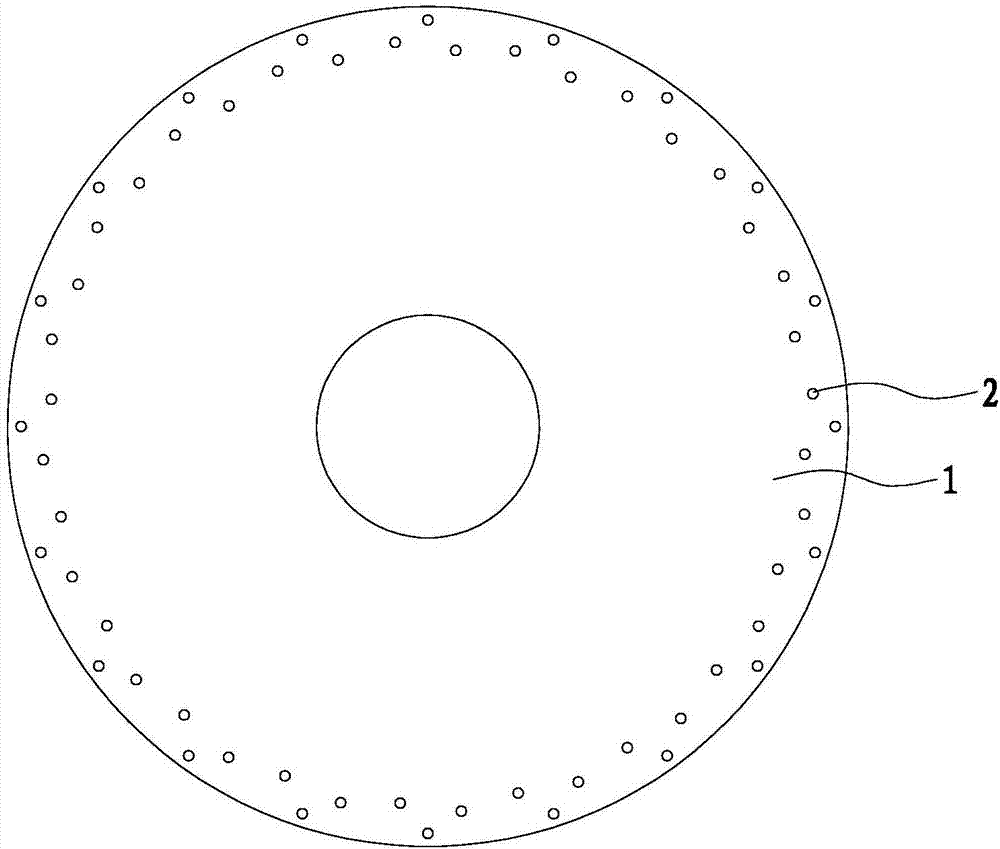

Manufacturing technique of grinding disc

The invention relates to a manufacturing technique of a grinding disc. The manufacturing technique comprises the following steps that firstly, an annular iron base is manufactured; secondly, an iron tool bit bottom sheet is manufactured, an alloy powder mixture forms a grinding tool bit agglomerated block in a cold pressing mode, the grinding tool bit agglomerated block is put on the tool bit bottom sheet and tightly bonded to the tool bit bottom sheet through hot smelting and sintering under certain pressure, and thus, tool bits are formed; thirdly, a plurality of convex points are formed on the base in a stamping mode, and every two or more adjacent convex points form an installation seat for installing each tool bit; and fourthly, the tool bits are put on the installation seats, and the tool bits are fastened and connected to the installation seats in a butt-weld mode. The technical problems that in the prior art, the production cost is high, the manufacturing efficiency is low, and the firmness is poor are solved.

Owner:南安市友和五金制品有限公司

A liquid-phase synthesis method of tuftsin

InactiveCN101550180ALow pricePrevention is cheapPeptide preparation methodsBulk chemical productionSynthesis methodsSide chain

The invention relates to a synthetic method of tuftsin (L-Thr-L-Lys-L-Pro-L-Arg-OH). Each alpha-amino group of tuftsin the constituent amino acids is proceeded Z protection, the side chain amino groups uses BOC and pbf protection strategy, condensing by DCC, applying ester activating method to connect peptide from C terminal to N terminal in turns, and at last stripping protecting group from products Z-Thr-Lys(BOC)-Pro_arg(pbf)-OH to obtain the tuftsin Thr-Lys-Pro-Arg-OH. The invention can synthesize numerous tuftsin of high purity with simple processing steps, high yield, low cost and important application value.

Owner:HANGZHOU HUAJIN PHARMA

Selenium-enriched microbial fertilizer and preparation method thereof

InactiveCN108558484AGrowth-promotingIncrease contentBio-organic fraction processingBacteriaDipotassium phosphateSodium arsenite

The invention discloses selenium-enriched microbial fertilizer and a preparation method thereof. The method includes the steps of adjusting the COD concentration of red date processing wastewater to 30-60 g / L, adding ammonium sulfate, dipotassium phosphate and sodium arsenite, adjusting the pH value to 7.2-8.0 after heating, and then obtaining a plant growth-promoting bacteria liquid culture medium; inoculating bacillus amyloliquefaciens into the liquid culture medium, and obtaining bacillus amyloliquefaciens liquid seeds after cultivation; inoculating the bacillus amyloliquefaciens liquid seeds into a new liquid culture medium, introducing sterile air for cultivation, and then obtaining a bacillus amyloliquefaciens liquid; adopting excrement of livestock and poultry, mushroom shreds and smashed straw as raw materials of a solid culture medium, adding the bacillus amyloliquefaciens liquid into the raw materials of the solid culture medium, conducting standing and stacking, introducingair for cultivation, and then obtaining a solid fermented product; drying the solid fermented product to obtain the selenium-enriched microbial fertilizer. The production cost is reduced from two aspects including the production raw materials and the production process, and meanwhile, the selenium-enriched microbial fertilizer has the reinforced functions of promoting growth of plants and preventing and treating plant diseases.

Owner:河北丰禾绿光农业科技有限公司 +1

Method for treating rare earth ammonium chloride wastewater

InactiveCN102531025BSimple processHigh recovery rateMultistage water/sewage treatmentRare earth metal compoundsCarbon sinkRare earth

The invention discloses a method for treating rare earth ammonium chloride wastewater, belonging to the field of wastewater treatment. The method for treating the rare earth ammonium chloride wastewater comprises the steps of: dissolving ammonium chloride rare earth, carrying out organic phase saponification, carrying out extraction separation, recycling wastewater, stripping, carbon-sinking, washing, evaporating, cooling and crystallizing. According to the method, ammonium chloride raffinate and carbon sink mother liquor which are generated by extraction separation on the rare earth are used as the solvents of the ammonium chloride rare earth for recycling so that the ammonium chloride in the wastewater is increased, the ammonium chloride is favorably evaporated and condensed, and energy resource consumption is reduced. Meanwhile, washing liquor of rare earth carbonate precipitates is recycled for preparing a precipitating agent, thus water resources are saved. The mass percent of the ammonium chloride in the recycled finished product is 91.7-96.5 percent in the terms of dry basis; and the economic benefit is remarkable, the wastewater is recycled, and zero emission of the rare earth wastewater is recycled.

Owner:江西德盛精细化学品有限公司

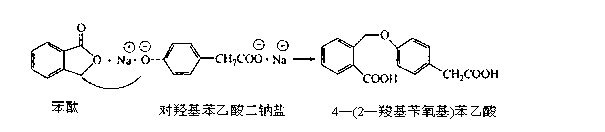

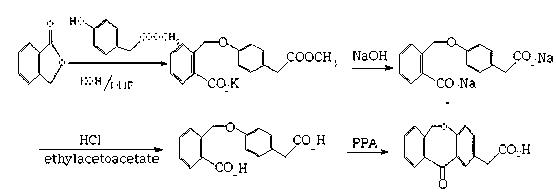

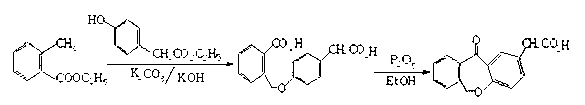

Preparation method of isoxepac

The invention relates to a preparation method of isoxepac, belonging to the field of organic matter synthesis. The preparation method sequentially comprises following steps of: 1) condensation: preparing 8-12 parts of p-hydoxyphenylactic acid by weight, 6-12 parts of phthalide by weight and 8-12 parts of sodium methylate, dissolving the p-hydoxyphenylactic acid and the phthalide by using DMAC (dimethylacetamide), adding the sodium methylate, heating the solution to 80-170 DEG C for reaction for 3-10h under pressure of 0.1-10Pa, regulating pH (potential of hydrogen) to 1-5, and conducting crystallization to precipitate 4-(2-carboxybenzyloxy) phenylacetic acid; 2) cyclization: dissolving the 4-(2-carboxybenzyloxy) phenylacetic acid obtained in the step 1 by using glacial acetic acid, adding 3-52 parts of polyphosphoric acid by weight, heating the solution to 30-100 DEG C for reaction for 3-12h under pressure of 0.1-10Pa, and then conducting cooling crystallization to obtain crude isoxepac products; and 3) purification: dissolving the crude isoxepac products by using ethyl acetate and then conducting refining and decolorization to obtain isoxepac products. The preparation method provided by the invention has the advantages of environmental-friendly production, low production cost, high product yield and purity, and short production cycle.

Owner:HUZHOU HENGYUAN BIOCHEM TECH

Quick low-cost CVD compacting method for carbon/carbon composite material

InactiveCN108220913AUniform and denseRapid densificationChemical vapor deposition coatingCarbon compositesOperability

The invention discloses a quick low-cost CVD compacting method for a carbon / carbon composite material. The method comprises the following steps: assembling a preform and an inner core mold tougher forhigh-temperature pre-treatment; placing the treated perform and inner core mold between upper and lower graphite electrodes of a deposition chamber of CVD equipment; and carrying out heating and introducing carbon source gas for 40-200h to prepare a carbon / carbon composite material product at one time. The method disclosed by the invention has the advantages and characteristics that 1, the methodintegrates advantages of a temperature differential method, a gas limiting method and a spontaneous heating characterized deposition process, so that influence of crusting of pyrolytic carbon on thesurface layer on deposition and compaction can be prevented effectively, the ability of the carbon source gas diffused to the perform is enhanced, and the deposition efficiency can be improved greatly; 2, the problem that density is not uniformly increased is solved, and the product quality is consistent; 3, the production energy consumption is low and the process and production cost is relativelylow; 4, the control degree of an air flow is high, and the utilization ratio of gas is high; 5, the perform and the graphite inner core mold are easily demolded, so that the operability is good; and6, the density state of the product can be controlled precisely, so that an accurate product effect is obtained.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

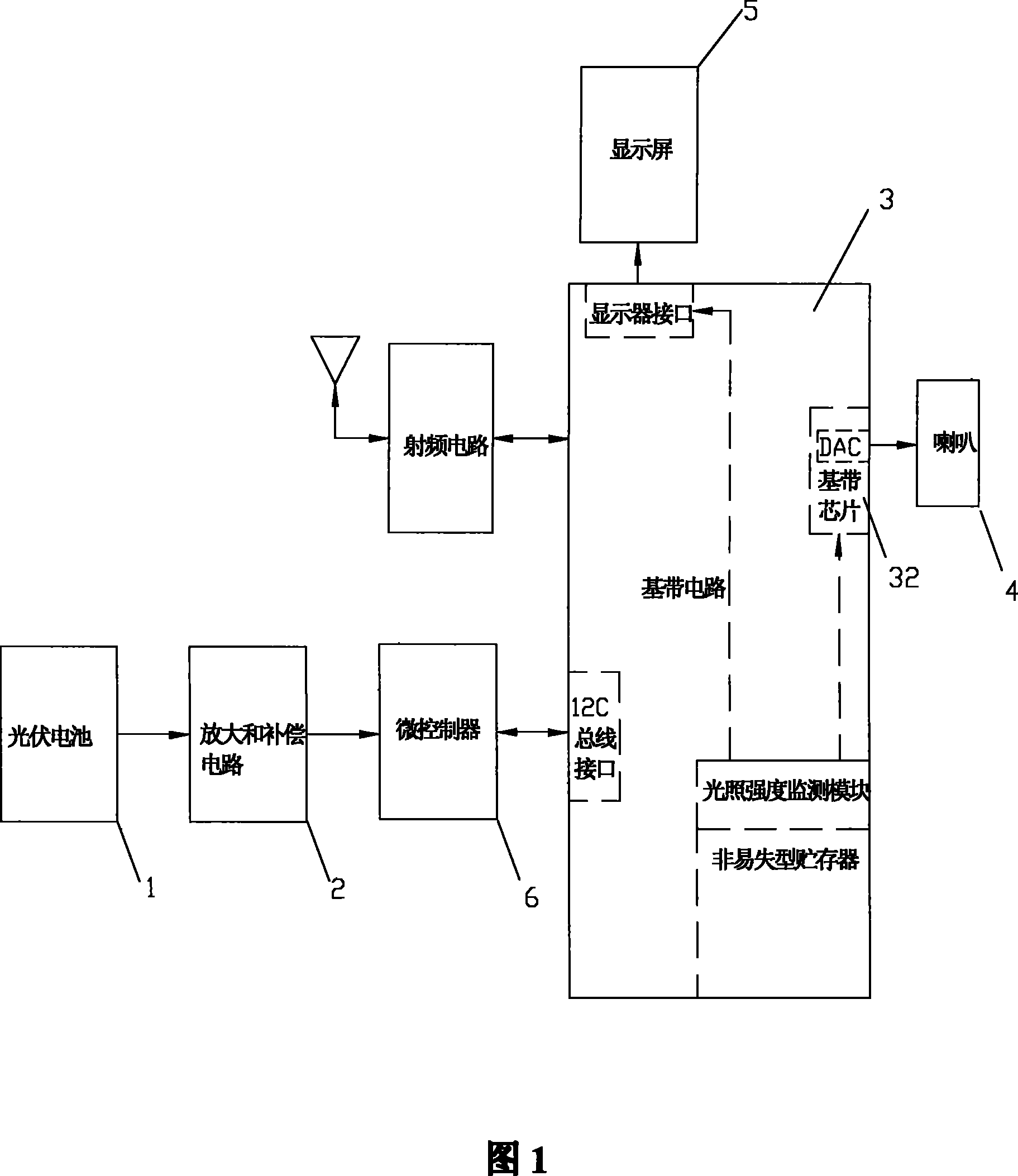

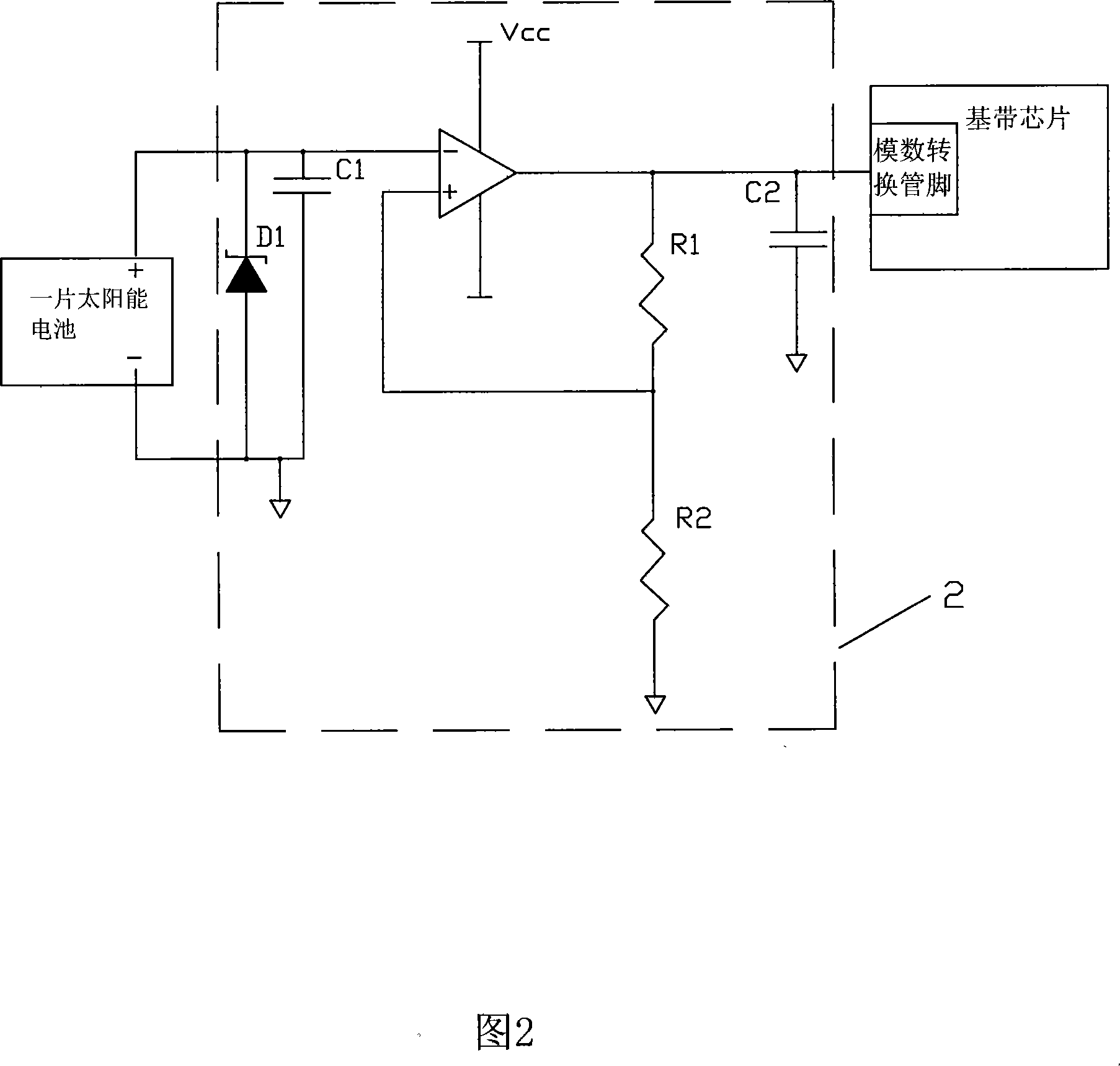

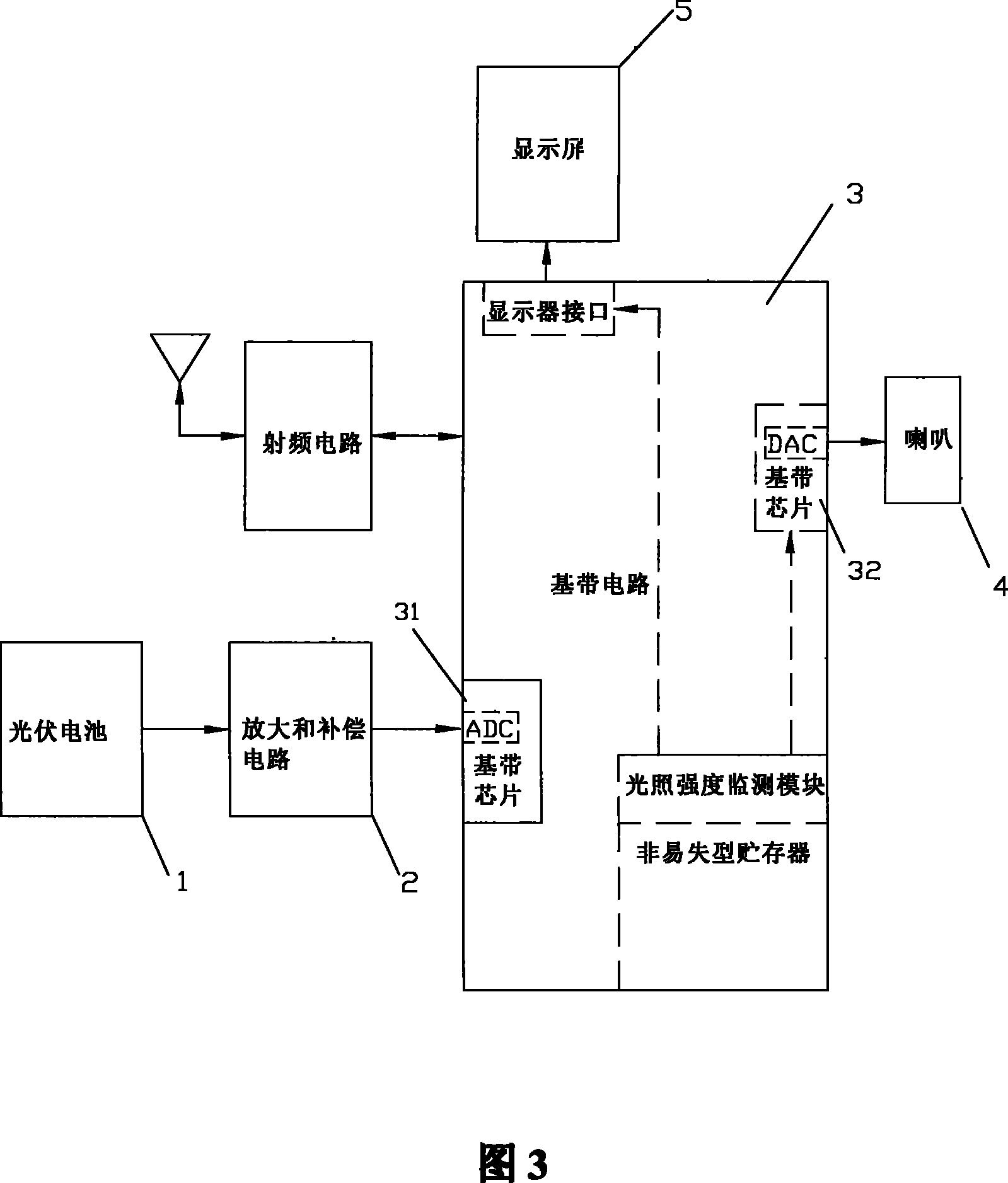

Mobile phone with function for measuring illumination intensity and its method

InactiveCN101169338BEasy to carryReduce process production costsPhotometry electrical circuitsTelephone set constructionsMobile phoneAtmosphere

The invention relates to a mobile phone which has the function of measuring the intensity of illumination, and belongs to the technical filed of mobile phone intensity of illumination measuring. The illumination is sampled, compensated and amplified by arranging an intensity of illumination measuring device which comprises an intensity of illumination sensor, a compensating and an amplifying circuit center processor; and the intensity of illumination is accounted through an intensity of illumination measuring module. The invention fully utilizes the character that the mobile phone is carried around, thereby solving the technical problem of inconvenience in measuring the intensity of illumination outdoors. The invention is in particular suitable to be used as an assistant measuring device for scientific research, thereby being beneficial for the physical research on atmosphere and the instruction on agricultural production.

Owner:BEIJING HI TECH WEALTH INVESTMENT DEV

Anti-corrosion treatment process for model surface

InactiveCN108048832AReduce sheddingEasy to removePretreated surfacesMetallic material coating processesWater basedTemperature resistance

The invention relates to the technical field of model production, in particular to an anti-corrosion treatment process for a model surface. The anti-corrosion process for the metal is divided into three types, namely metal anode protection, metal cathode protection and non-metal coating protection on the metal surface at present, but the effect of a method in the prior art is not ideal. For nylonproducts, large-effect and thin-walled nylon products need to be formed by injection molding, and large-effect and thick-walled nylon products need to be formed by casting; and the nylon products areadhered to a forming mold and not prone to demoulding during forming, so that the products are easily deformed or broken. The anti-corrosion treatment process for the model surface has the advantagesof being water-based and environment-friendly, non-sticky, high in adhesive force, high in high temperature resistance, high in hardness and high in corrosion resistance. The preparation method of graphene-based or graphite oxide-based anti-rust paint is low in process production cost, flexible and controllable, and suitable for modification of anti-corrosion coatings of many varieties and metal corrosion prevention in a larger range; and the anti-corrosion coating with high performance and high quality can be prepared and widely applied to corrosion prevention of metal surfaces.

Owner:CHUNAN COUNTY QIANDAO LAKE YAOSHAN HANDICRAFT FACTORY

Process for preparing Si-Al-Ba alloy using 5000KVA ore furnace

The invention discloses a smelting silicon aluminum barium alloy preparation method, this method take the certain granularity silica, the bauxite, the barite, the steel filings and the coke as a raw material, after the certain ingredient compared to the mix, invests in the ore hot stove to carry on smelting, smelting temperature 1800-2500deg.C, the smelting time is in turn 2-3 hour is an end product. The method smelting silicon aluminum barium alloy output high, the electricity consumes lowly, economic efficiency considerable, the operation is simpler.

Owner:刘长福

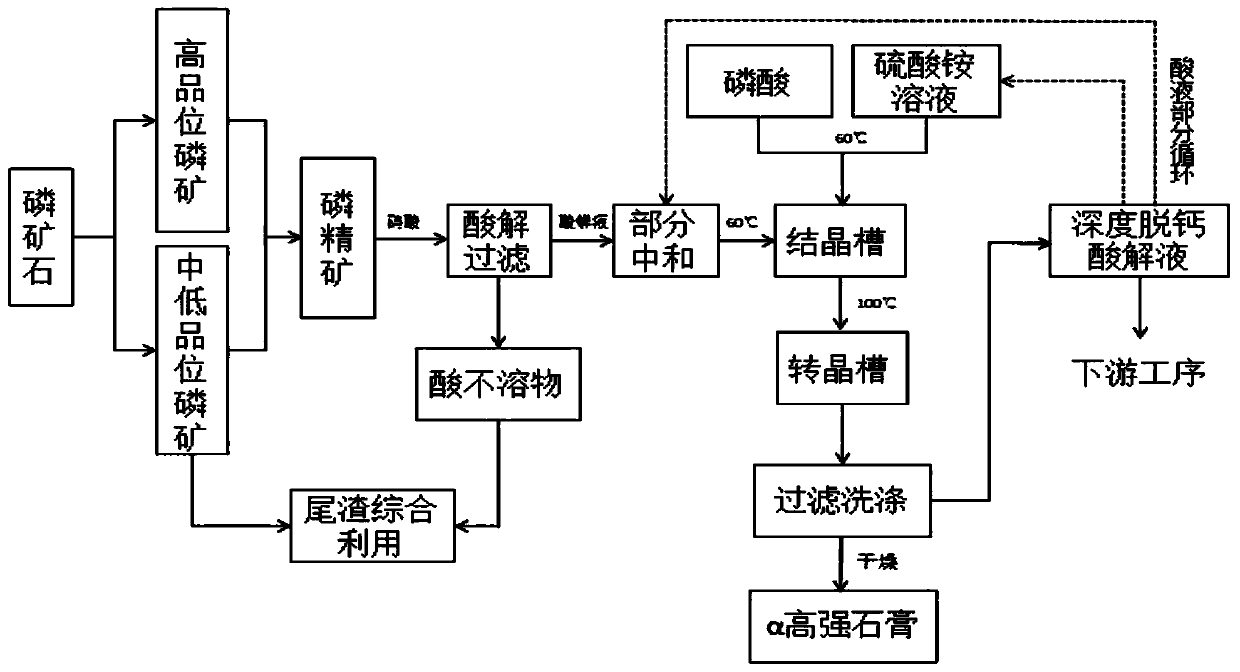

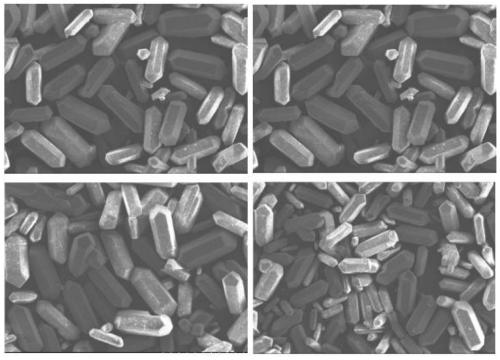

Method for decomposing phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum

ActiveCN111533154AReduce manufacturing costTake advantage ofCalcium/strontium/barium sulfatesPhosphoric acidChemical industryO-Phosphoric Acid

The invention discloses a method for decomposing a phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum. The method comprises: decomposing phosphoriteby nitric acid, filtering out acid insoluble substances, partially neutralizing the acidolysis liquid, regulating and controlling the concentration of calcium ions in the acidolysis liquid, adding the acidolysis liquid into a crystallization tank containing a mixed solution of additional phosphoric acid and ammonium sulfate, controlling the reaction temperature to be 50-70 DEG C and the reactiontime to be 0.5-2 hours to firstly generate dihydrate gypsum, then, making the reaction slurry flow into a crystal transformation tank, and raising the temperature to 95 to 110 DEG C for reacting for aperiod of time so that an alpha-type high-strength gypsum product can be produced as a byproduct. According to the invention, the acidolysis liquid can be used for producing products such as fine phosphate, high-water-solubility phosphate fertilizer and the like, meanwhile, calcium resources in the acidolysis liquid are converted into an alpha high-strength gypsum product, solid waste phosphogypsum is changed into product phosphogypsum, environmental risks caused by the fact that a large amount of solid waste phosphogypsum is produced as a byproduct in the ammonium phosphate industry are eliminated, the phosphorus compound fertilizer industry is promoted to adjust the product structure, solid waste emission is reduced, and sustainable development of the phosphorus chemical industry is promoted.

Owner:GUIZHOU UNIV

SPHC low-carbon type steel production technology

ActiveCN109880972APromote full buoyancyReduce temperature dropMelt-holding vesselsManufacturing convertersSlagMolten steel

The invention discloses an SPHC low-carbon type steel production technology. A following control method is adopted and comprises the steps that converter end point content low-level control is guaranteed on the premise that it is guaranteed that the converter end point temperature meets the requirements; the CAS refining effect is improved, slag inclusion adsorption is conducted, and meanwhile theRH station inlet oxygen content is decreased to ensure the pouring property of molten steel; a CAS argon blowing model is optimized, argon gas stirring pressure models in the different stages are made, therefore, full floating of inclusions is effectively promoted, and meanwhile the process temperature drop is reduced; RH low oxygen level control is achieved, the RH station inlet oxygen content is decreased, the RH residual oxygen content is precisely controlled, the aluminum consumption is reduced, and the production yield is indirectly decreased; and the continuous casting machine protective pouring argon gas flow is optimized, and the condition that the pouring property is influenced due to water port inclusion concentration is avoided. According to the SPHC low-carbon type steel production technology, the purposes that on the basis that a water port is not displaced in the pouring process, the continuous pouring number is increased, and meanwhile the production cost of the processes is reduced are achieved.

Owner:SD STEEL RIZHAO CO LTD

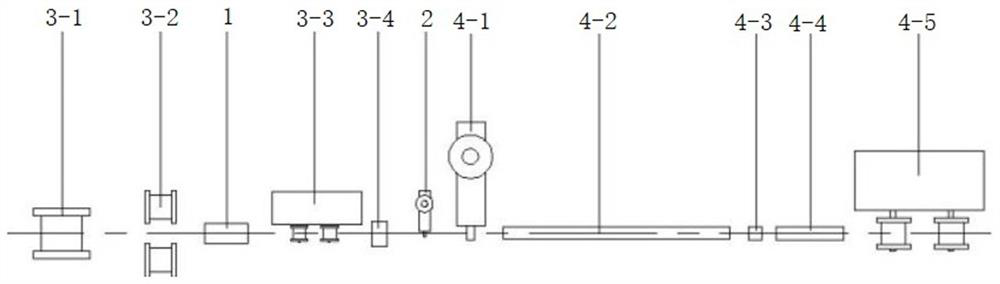

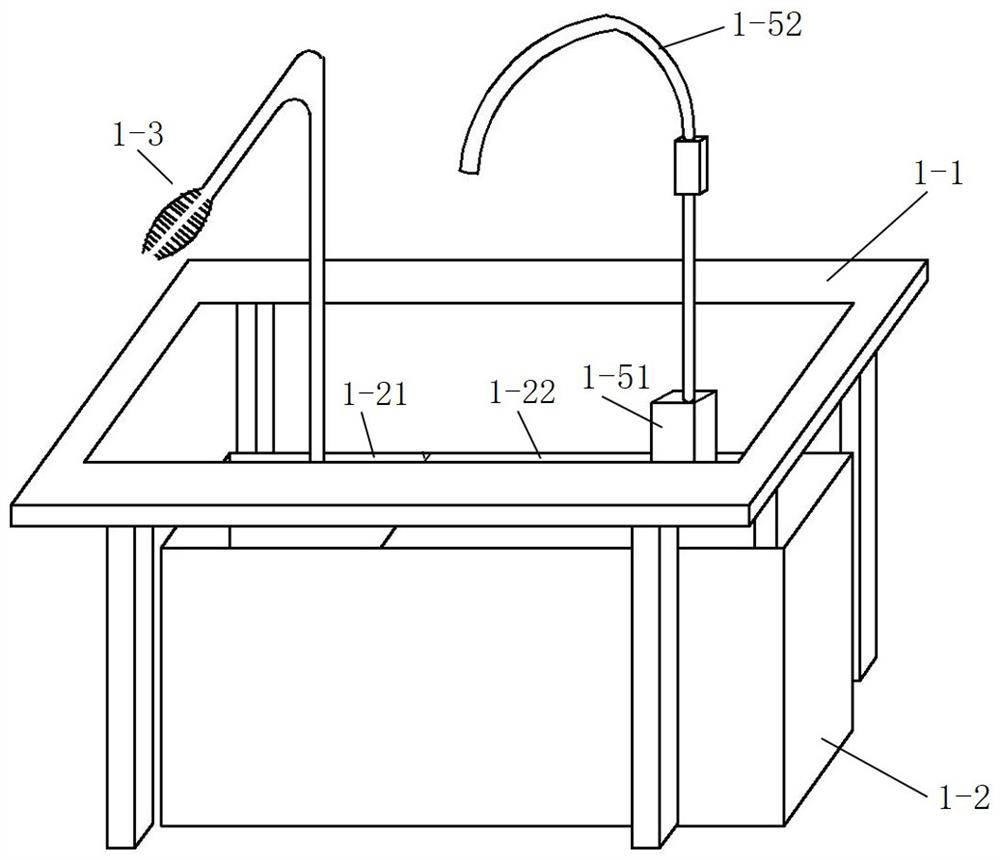

Steel wire coating and optical cable processing integrated device

PendingCN112415688AReduce the phenomenon of attenuation increaseIncrease productionLiquid surface applicatorsFibre mechanical structuresProduction lineBond coat

The invention discloses a steel wire coating and optical cable processing integrated device, which comprises a cabling device, a sheath shaping device, a steel wire cleaning device and a steel wire coating device; the steel wire cleaning device and the steel wire coating device are connected in series between the cabling device and the sheath shaping device; the device is used for cleaning the surface of a steel wire and coating a bonding layer on the surface of the steel wire in sequence, and the cable core coated with the bonding layer is conveyed to the sheath shaping device for sheath processing. The steel wire cleaning device and the steel wire coating device are connected to a traditional optical cable production line in series, so that the products are produced in one time; whereinthe gaps between steel wires and a sheath layer of a butterfly-shaped optical cable finished product are filled with a coating bonding material, so that an optical cable sheath and the steel wires arebonded firmly, and the twisting phenomenon of the steel wires and the sheath layer in the construction process can be reduced; therefore, the prepared optical cable product is reliable, high in stability and suitable for batch large-scale production.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com