Production system of aqueous urea solution for motor vehicles

A production system, the technology of urea for vehicles, applied in the directions of dissolving, dissolving, driving agitator dissolving, etc., can solve the problems of high price and high cost, and achieve the effects of reduced production cost, low operating cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

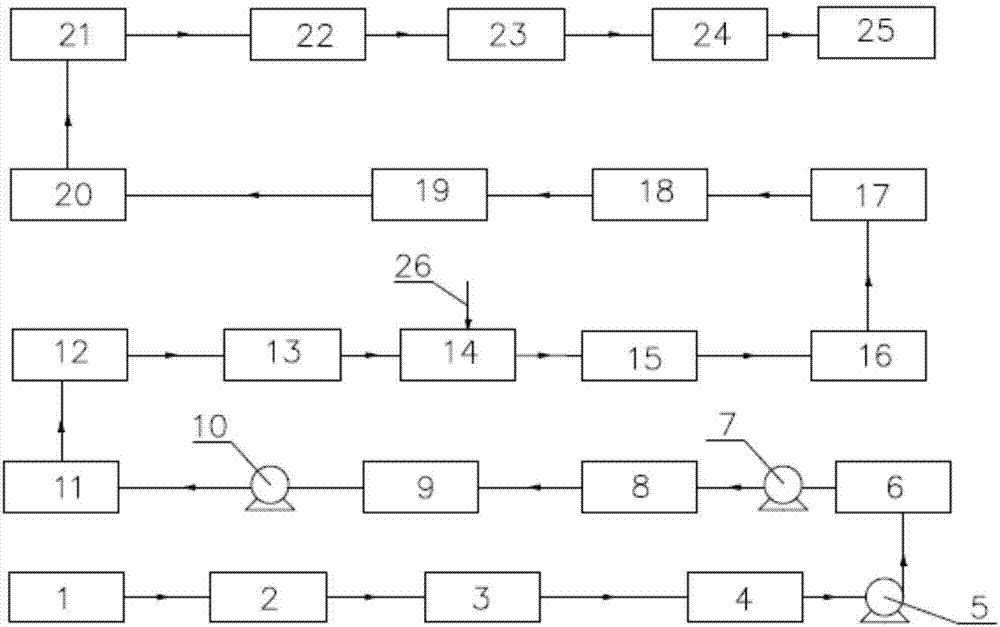

[0022] See figure 1 As shown, the vehicle urea solution production system provided in this embodiment includes a raw water tank 1, and after the raw water tank 1, a multi-media filter 2, an activated carbon filter 3 and a security filter 4 are arranged in sequence, and the security filter 4 passes through a first-stage The RO reverse osmosis high-pressure pump 5 is connected to the first-stage RO reverse osmosis membrane filter 6, and the first-stage RO reverse osmosis membrane filter 6 is connected to the second-stage RO reverse osmosis membrane filter 8 through the second-stage RO reverse osmosis high-pressure pump 7, and the second-stage RO reverse osmosis membrane filter 8 is connected. A reverse osmosis water tank 9 is arranged after the RO reverse osmosis membrane filter 8, and the reverse osmosis water tank 9 is connected with the UV sterilizer 11 through the EDI water delivery pump 10, and the EDI pure water machine 12 and the high-purity water tank 13 are arranged succ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com