Patents

Literature

1134results about "Mixture aftertreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microemulsion process and composition

ActiveUS20060057168A1Quality improvementCosmetic preparationsOrganic active ingredientsVegetable oilSilanes

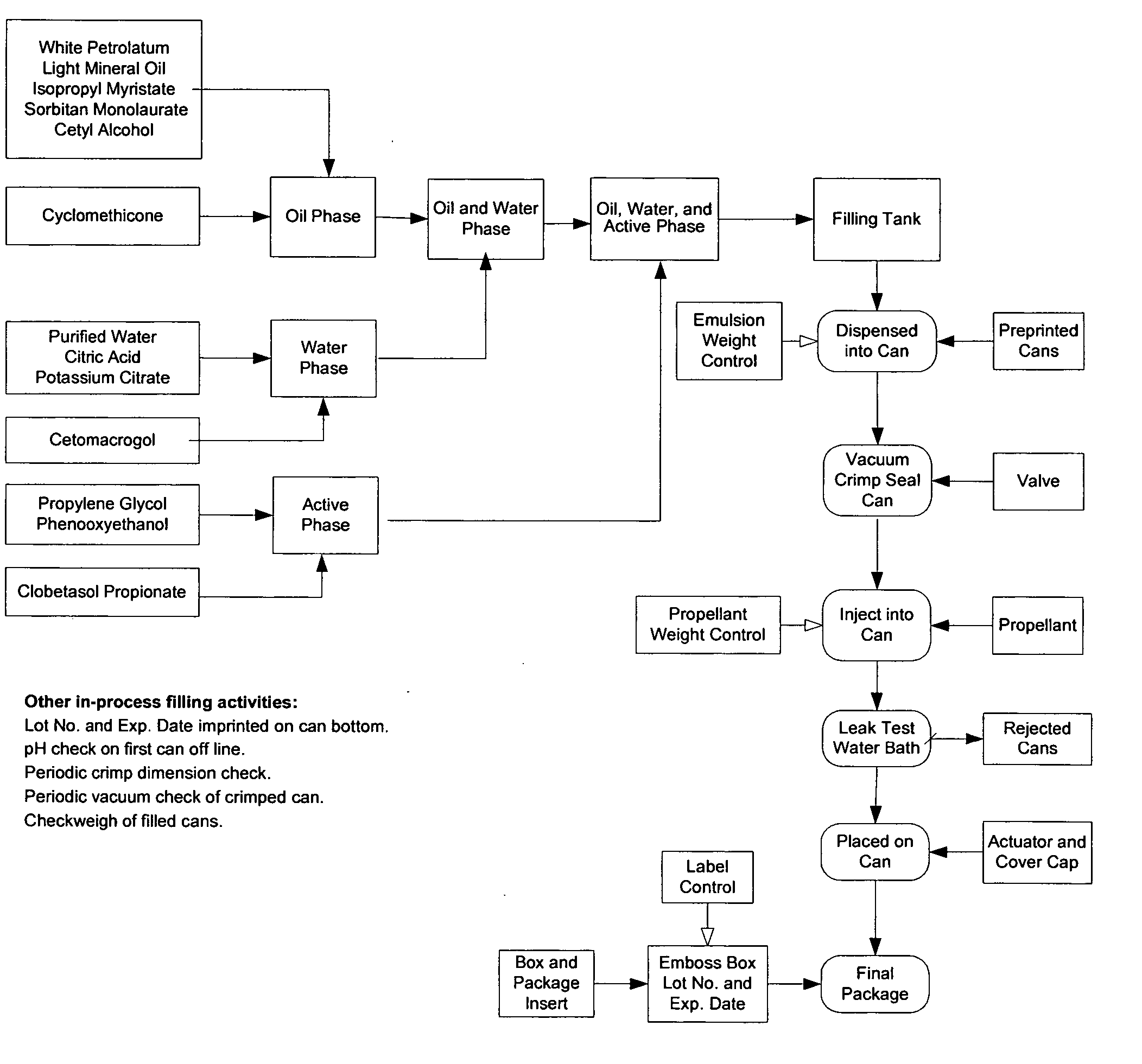

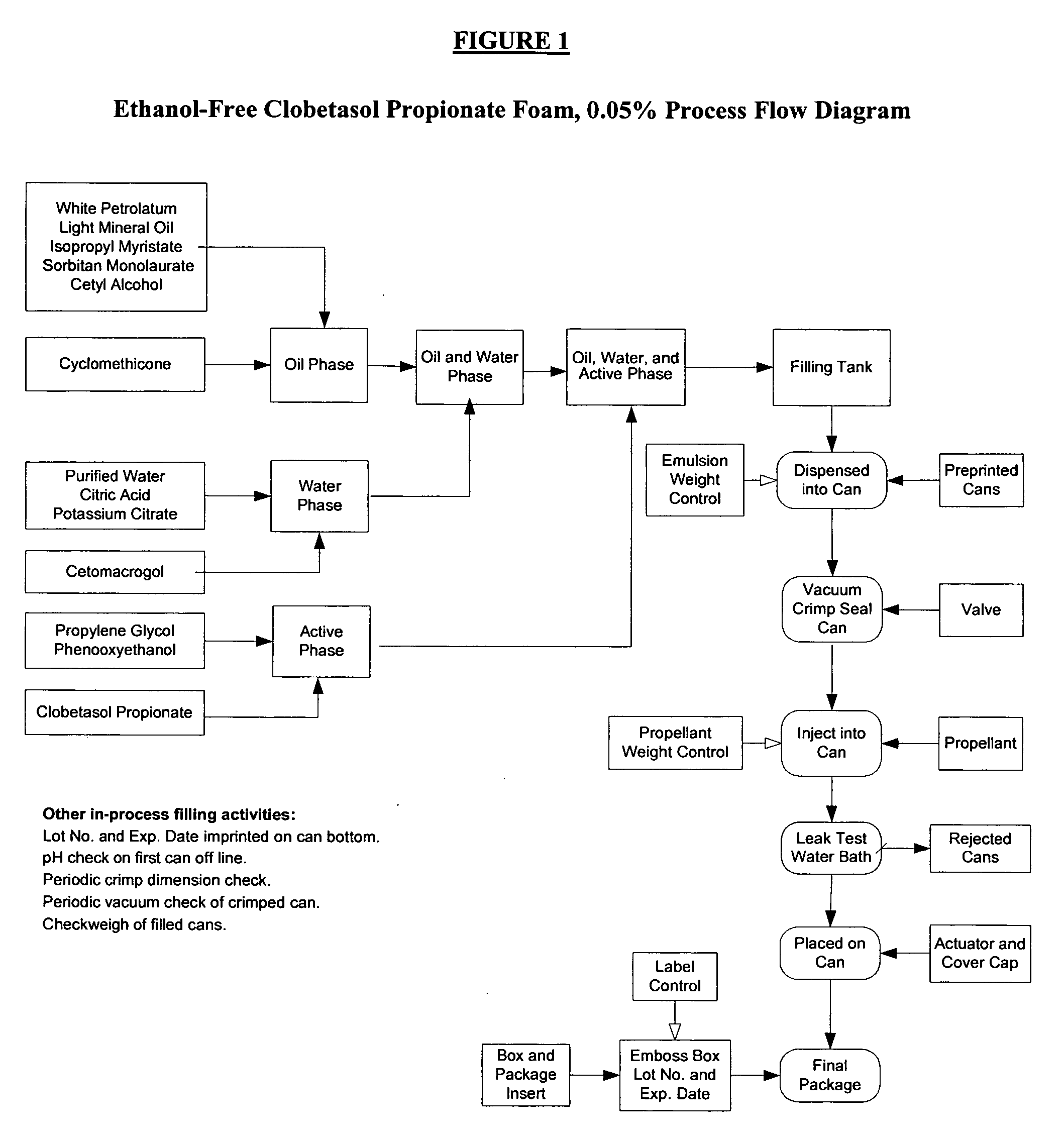

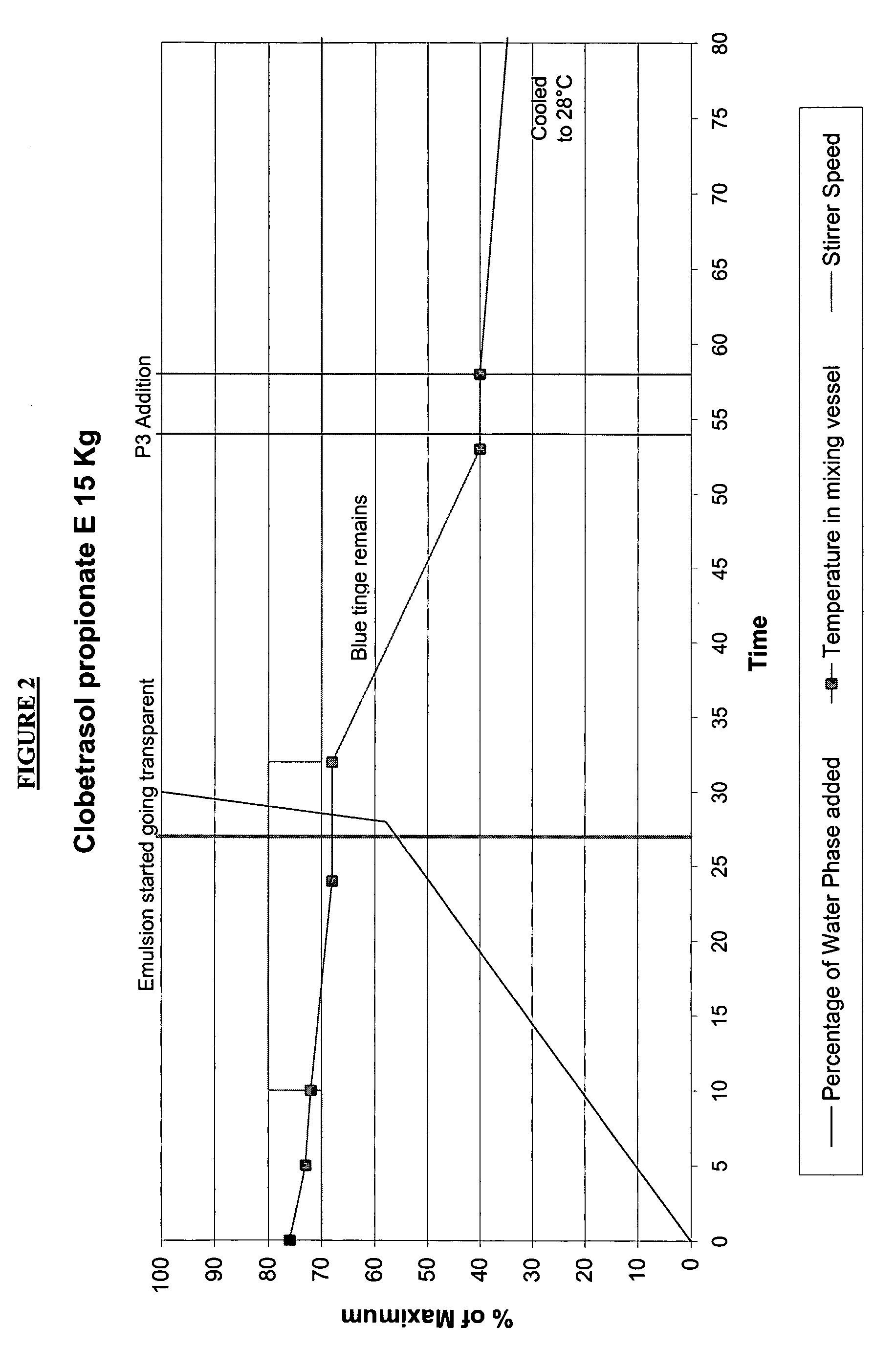

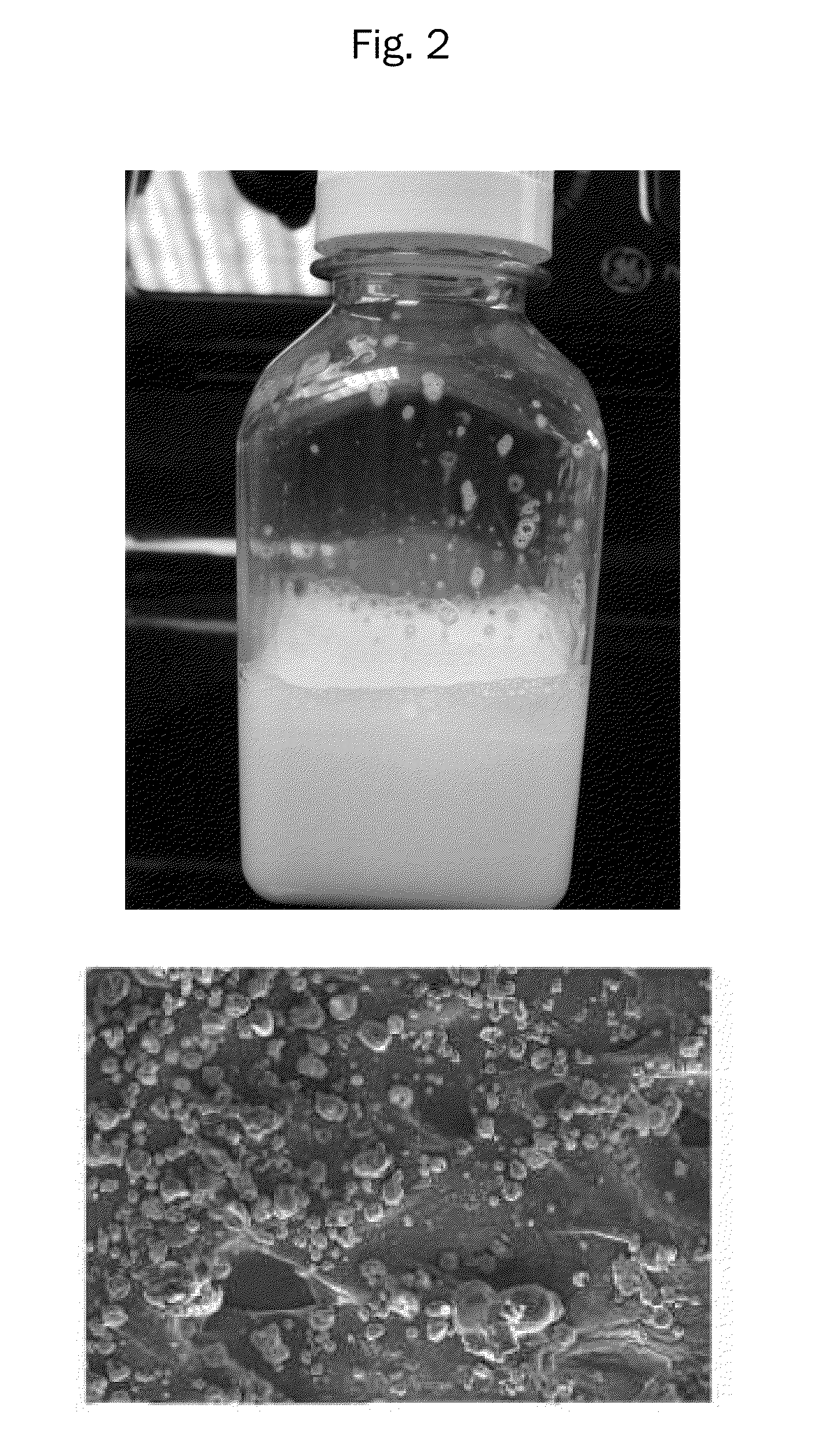

There is provided a process for the preparation of an oil in water (O / W) microemulsion or sub-micron emulsion composition for dermal delivery of at least one pharmaceutically active ingredient, the method including the steps of a) Admixing a first part including at least one of the group consisting of animal, mineral or vegetable oils, silanes, siloxanes, esters, fatty acids, fats, halogen compounds or alkoxylated alcohols; and one or more lipophilic surfactants, and a second part including water and at least one hydrophilic surfactant to achieve homogeneity, b) heating the mix of step a) to a phase assembly temperature in the range of 40-99° C., preferably 45-95° C., more preferably 65-85° C. with continuous mixing to obtain a microemulsion or sub-micron emulsion, c) allowing said microemulsion or sub-micron emulsion to cool, and d) adding a third part to said microemulsion or sub-micron emulsion at a temperature between 2° C. and said phase assembly temperature, said third part if necessary being premixed and heated until the components are dissolved and including at least one component selected from the group consisting of non-surfactant amphiphilic type compound, surfactant and water with the proviso that when the third part includes water it also includes a non-surfactant amphiphilic type compound and / or surfactant. The phase assembly temperature can be determined visually by the achievement of translucence in the composition or by measures such as conductivity which peaks and then is maintained at a plateau whilst phase assembly occurs. It has been found that whilst if a non-surfactant amphiphilic type compound such as the polyol is added together with the second part as would conventionally be the case, a microemulsion or sub-micron emulsion is not formed, by adding the so called third part, phase assembly occurs at a lower temperature than would be expected and moreover, this phase appears to assist in maintaining the microemulsion or sub-micron emulsion characteristics of the formulation during storage at normal temperatures.

Owner:STIEFEL WEST COAST

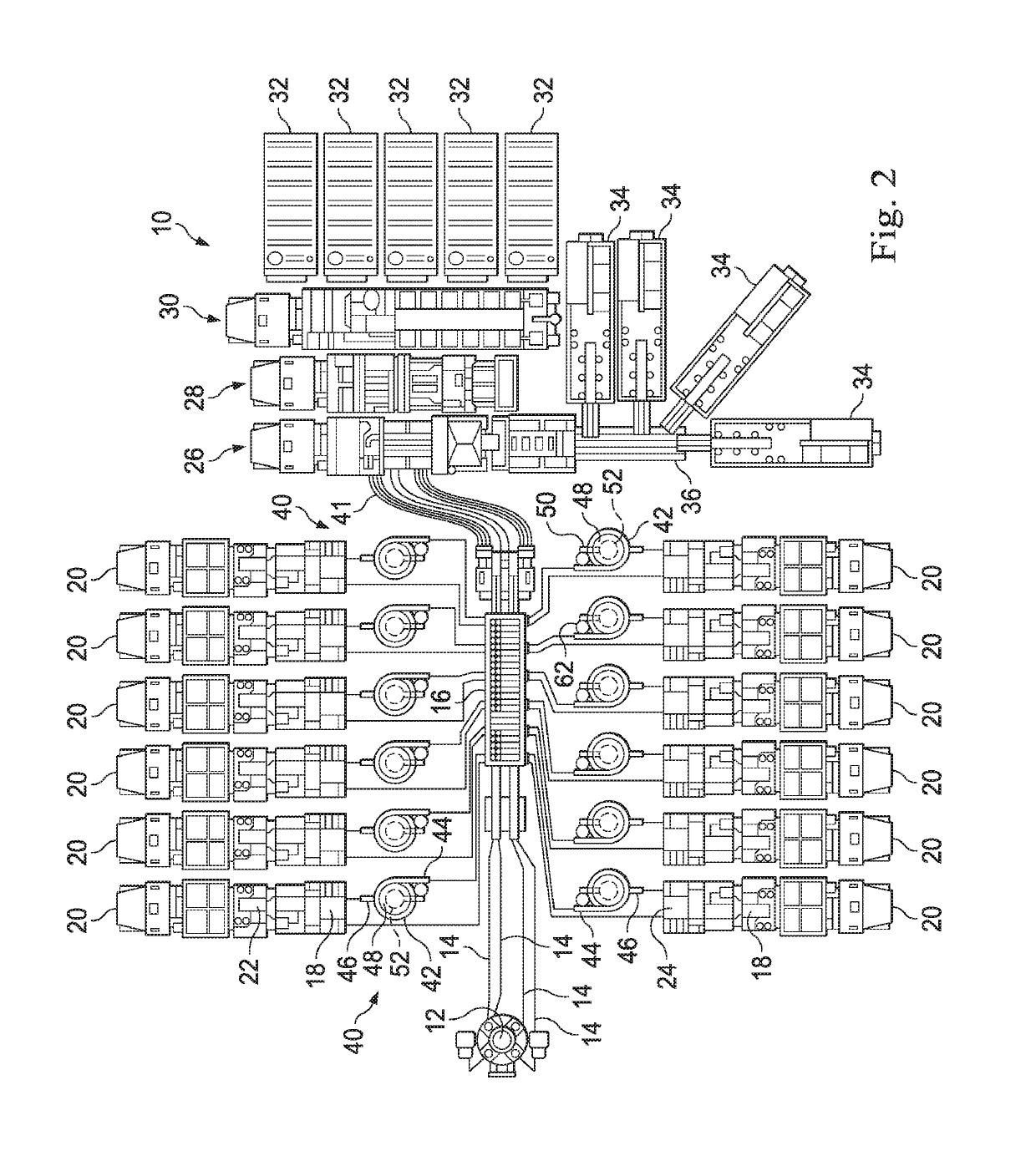

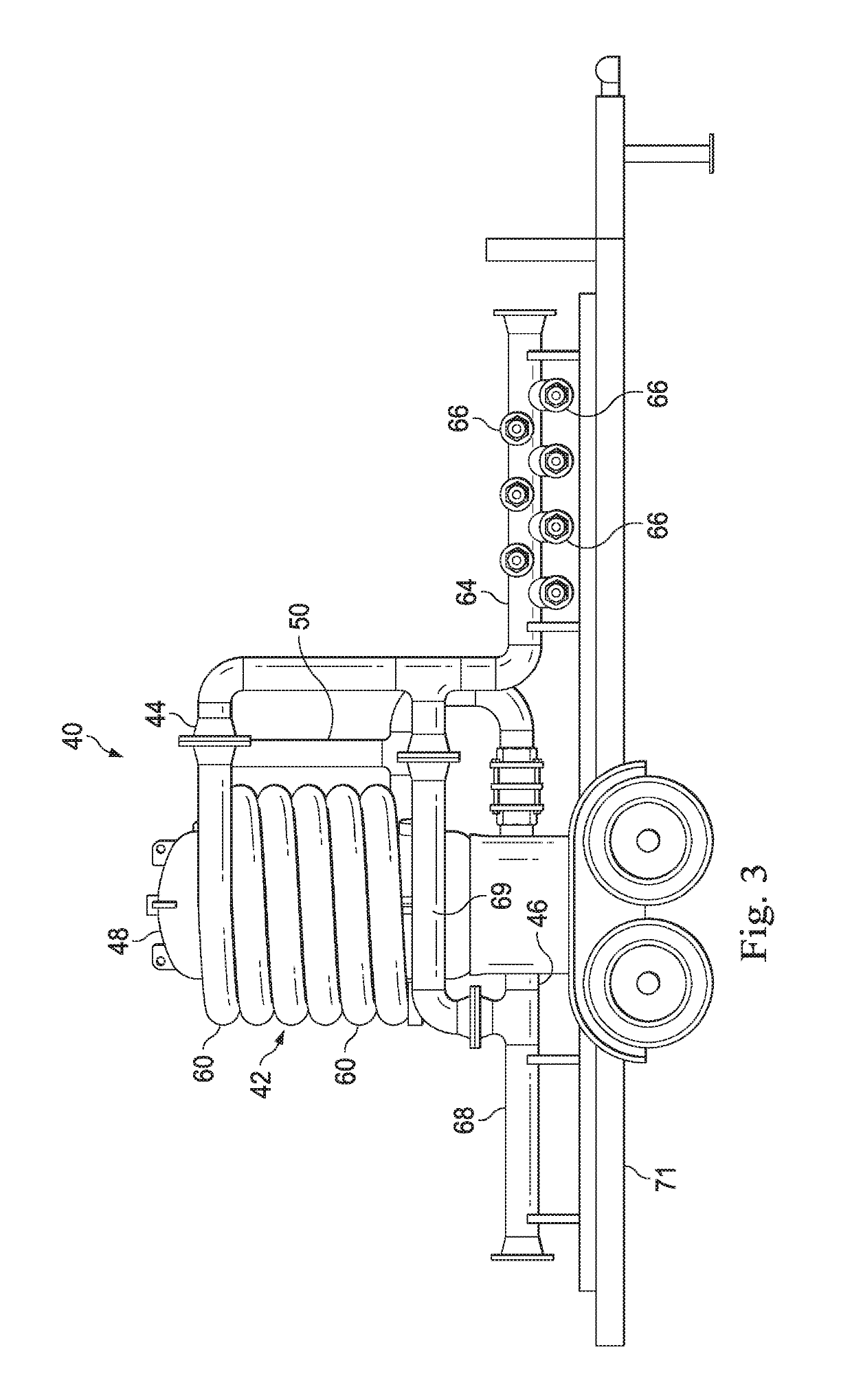

Apparatus and method for treatment of hydraulic fracturing fluid during hydraulic fracturing

A hydraulic fracturing system utilizes a multi-phase separation apparatus to separate gas entrained in hydraulic fracturing fluids during the blending process prior to introduction of hydraulic fracturing fluid into high pressure fracturing pumps by directing hydraulic fracturing fluids from a blender through a plurality of loops and thereafter, directing a portion of the separated fluid into a vortex cluster system.

Owner:CH INT EQUIP LTD +1

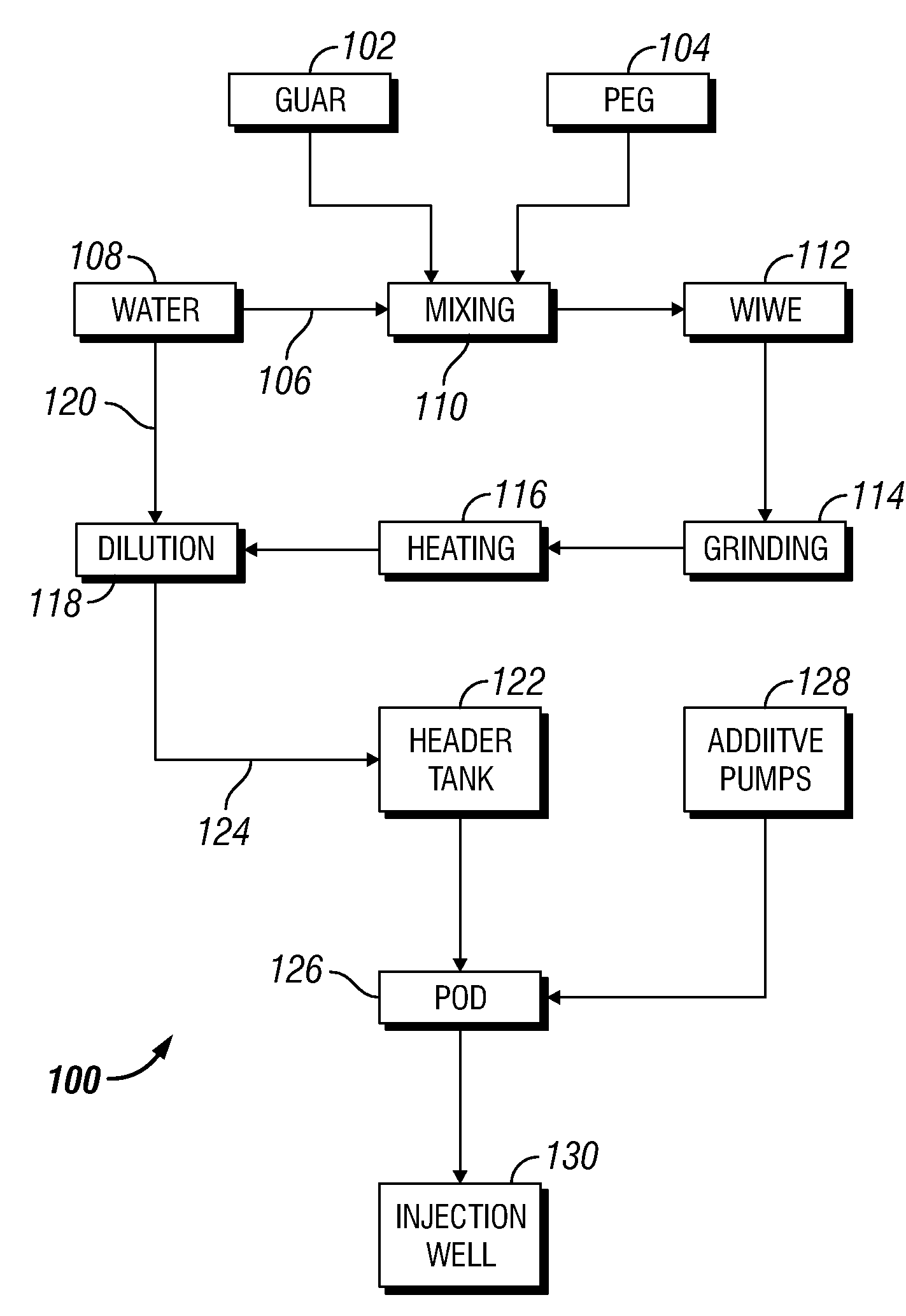

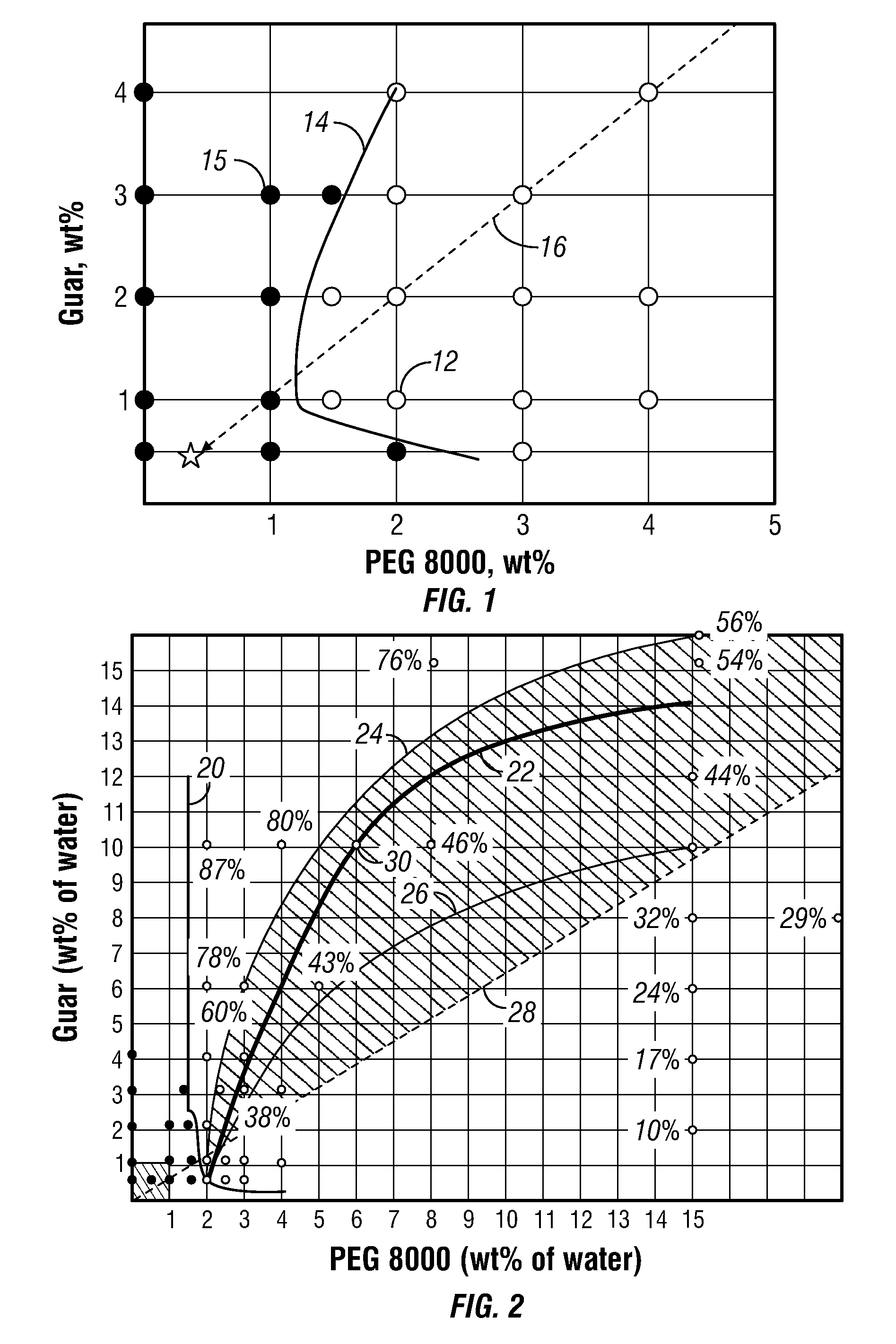

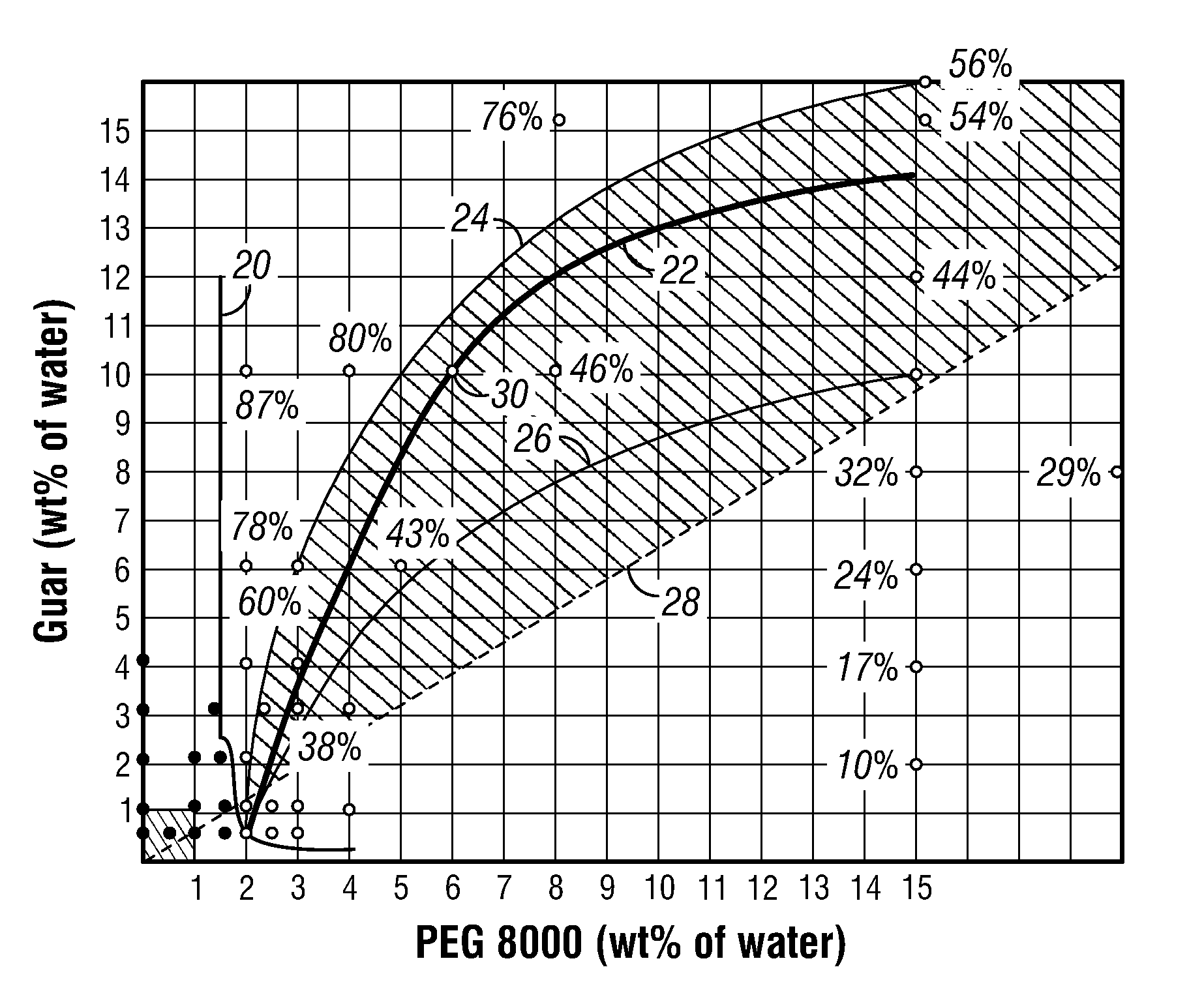

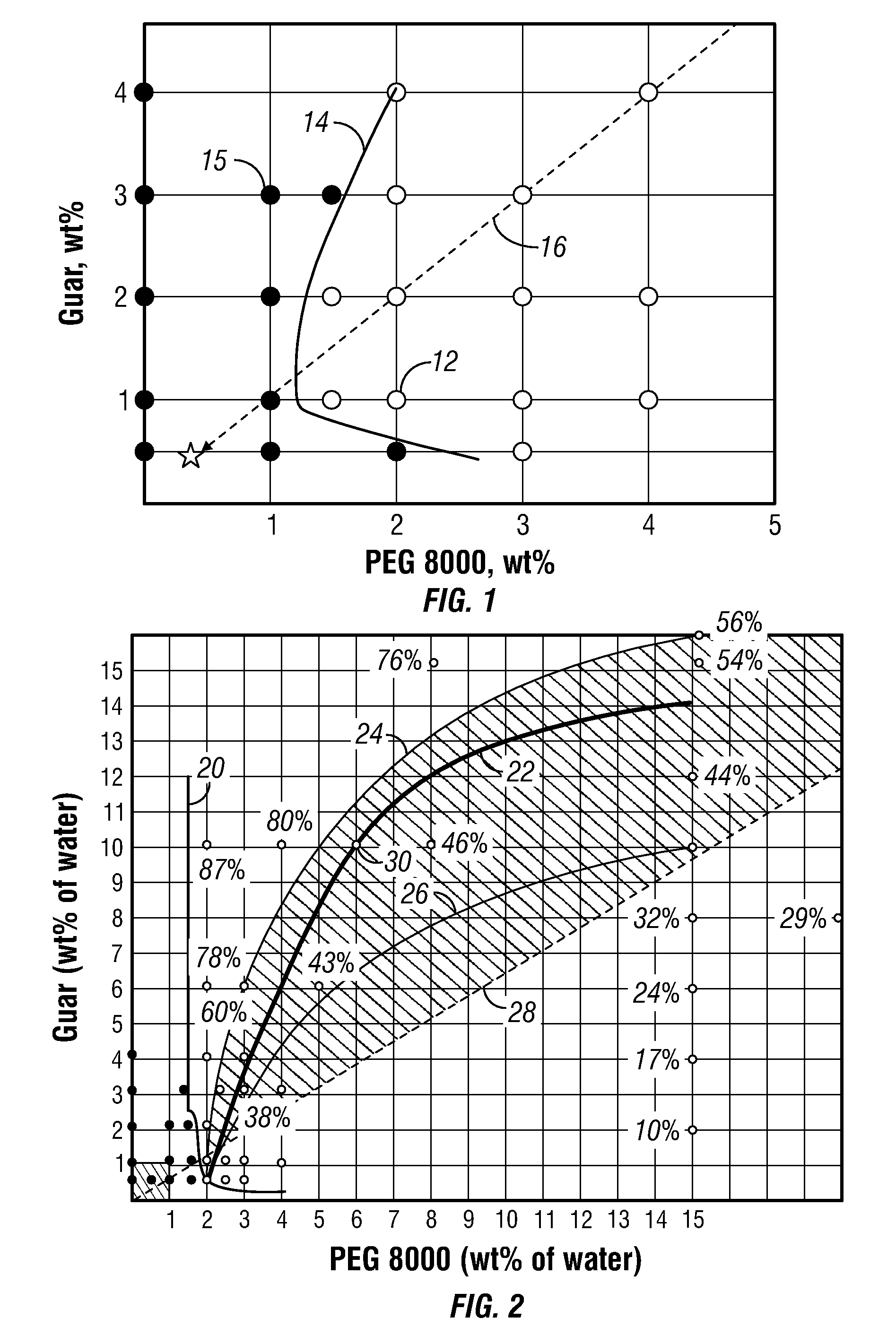

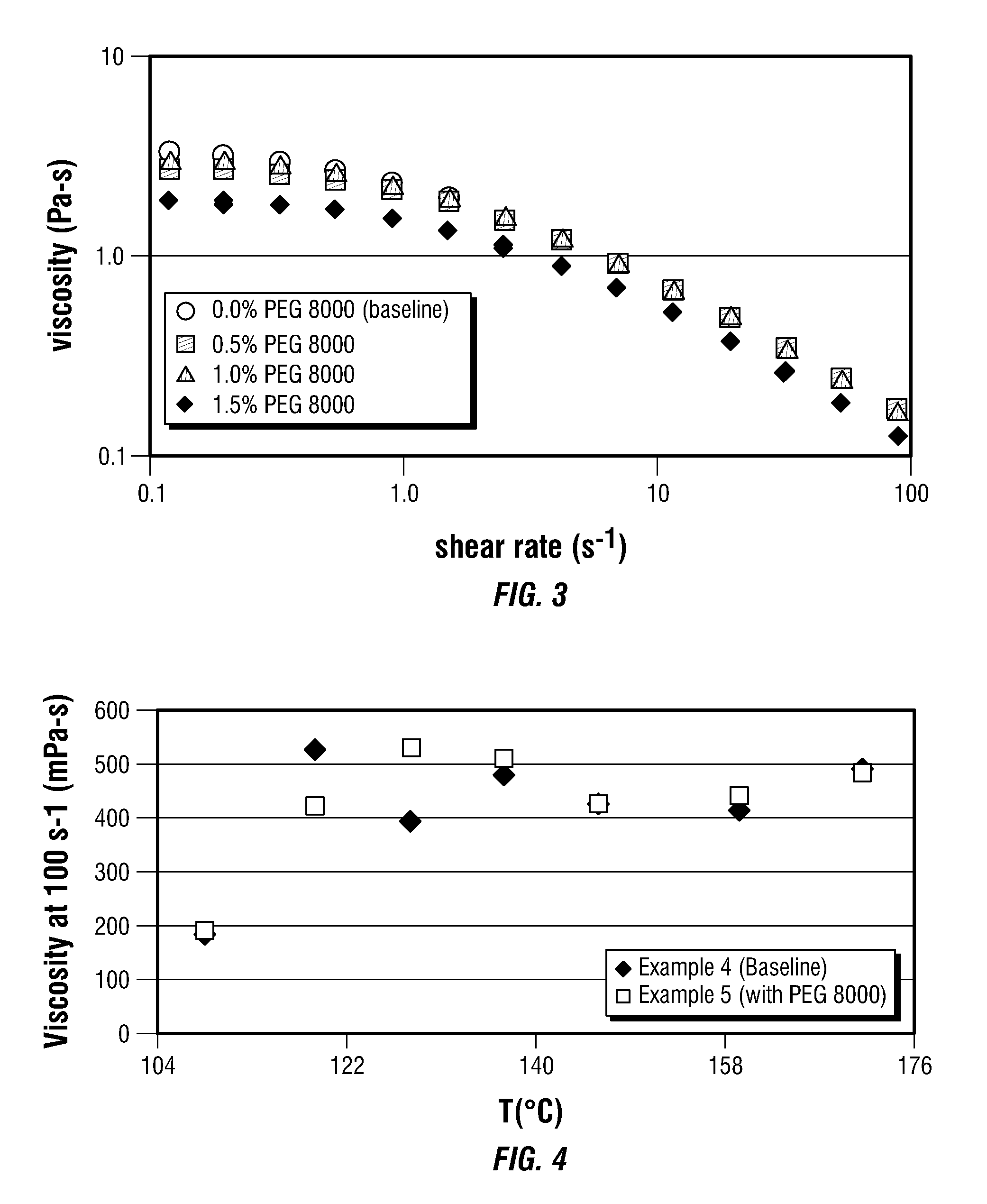

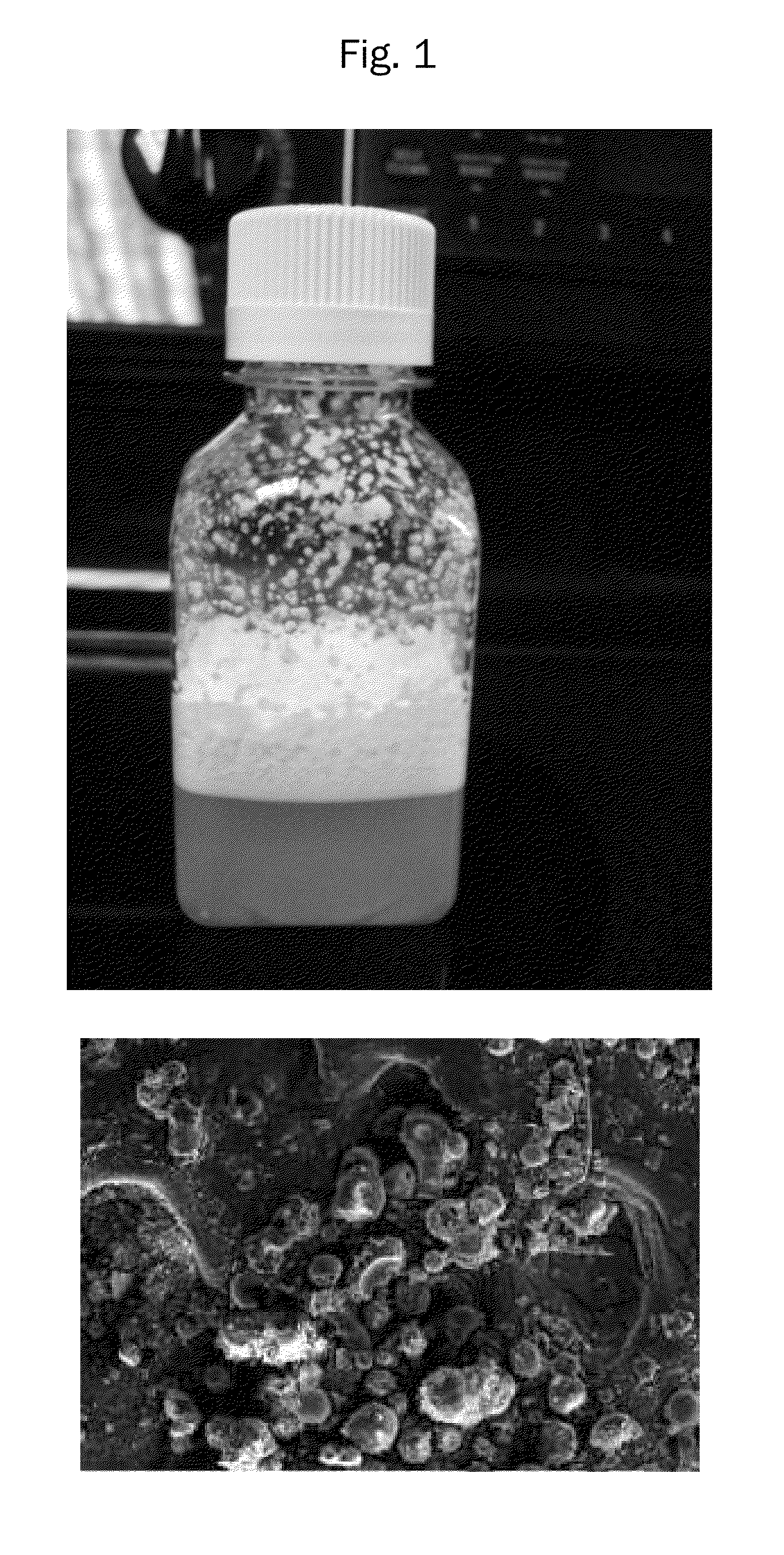

Polymer Delivery in Well Treatment Applications

InactiveUS20090023614A1Reduce solubilityEasy to pumpTransportation and packagingFluid removalActive polymerEmulsion

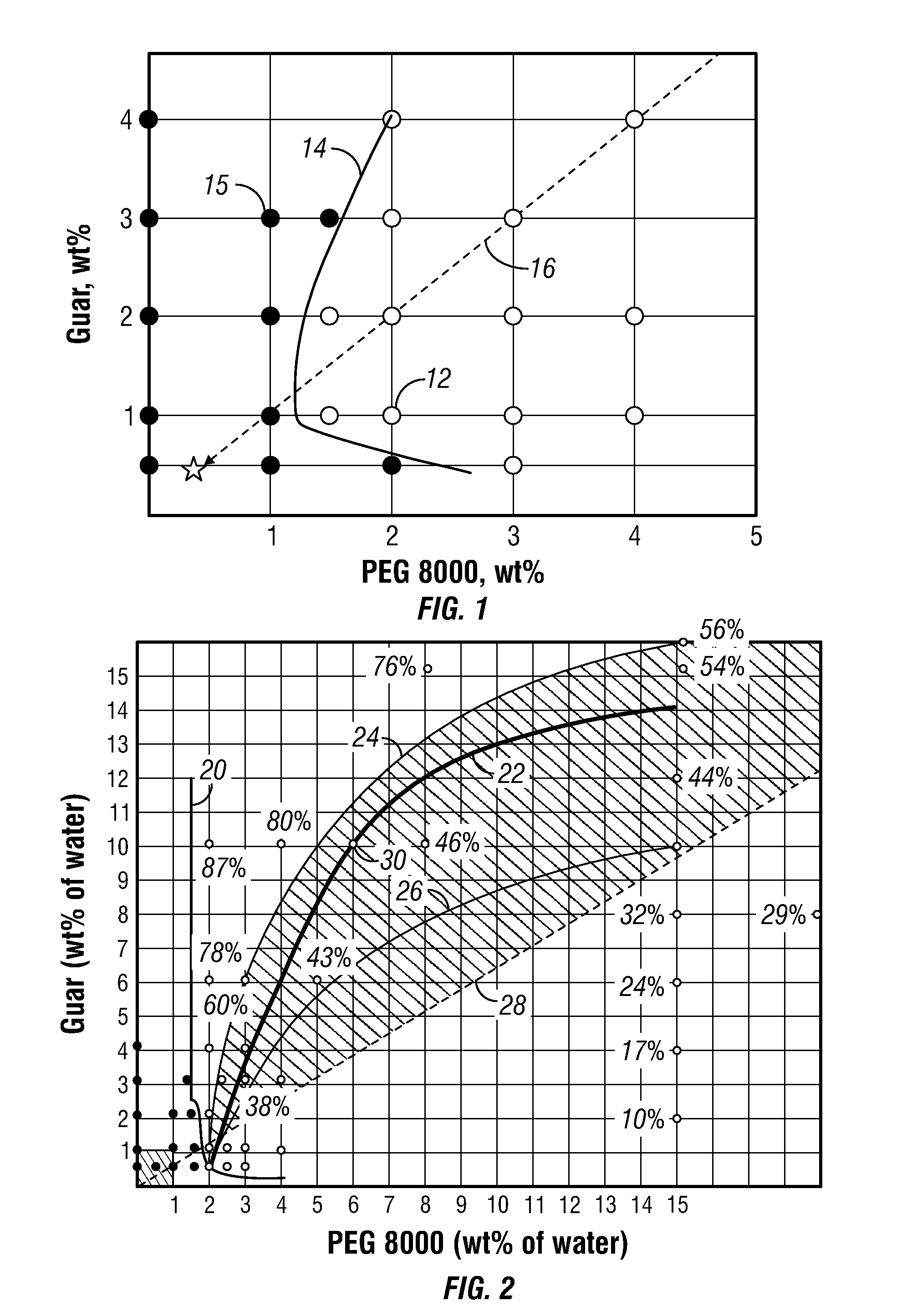

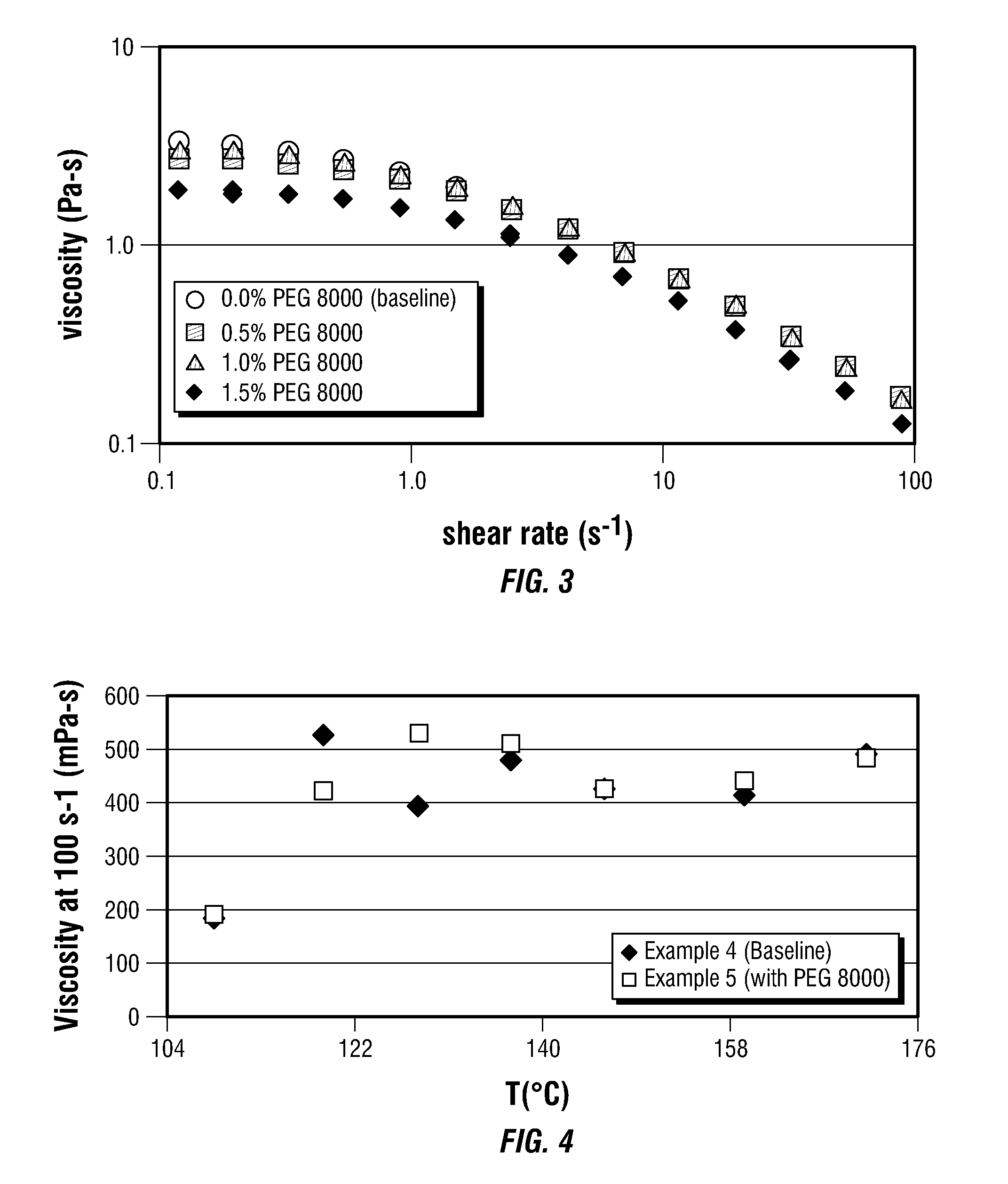

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

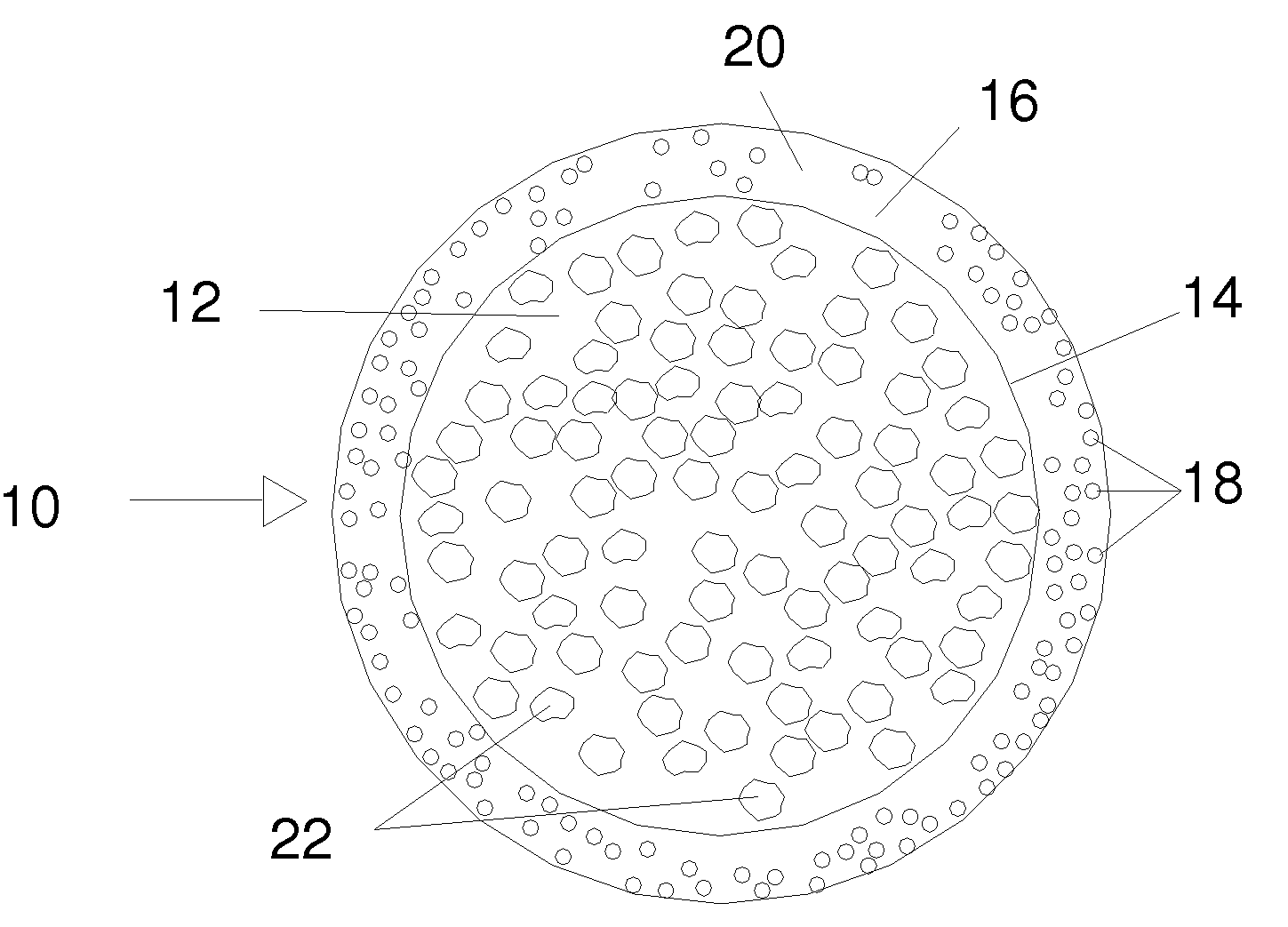

Roofing granules with high solar reflectance, roofing materials with high solar reflectance, and the process of making the same

ActiveUS20100151199A1Uniform applicationHigh opacityLiquid surface applicatorsRoof improvementNear infrared reflectanceTransmittance

Roofing granules include a core having an average ultraviolet transmission of greater than sixty percent and an average near infrared reflectance of greater than sixty percent and a UV coating layer on the exterior surface. The coating provides UV opacity, while the core provides near infrared reflectance.

Owner:CERTAINTEED CORP

Polymer Delivery In Well Treatment Applications

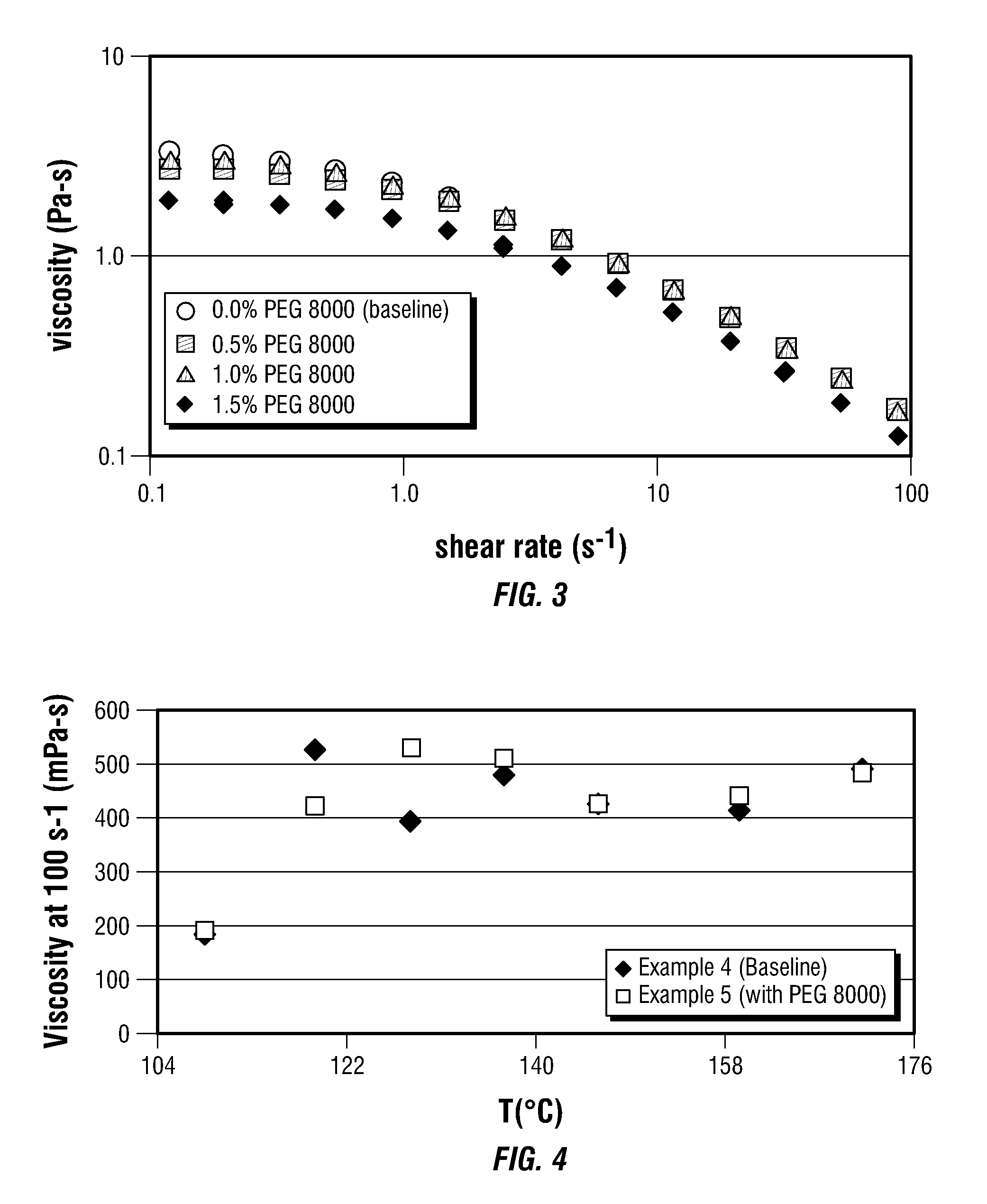

InactiveUS20090023615A1Reduce solubilityLow viscosityTransportation and packagingMixer accessoriesActive polymerEmulsion

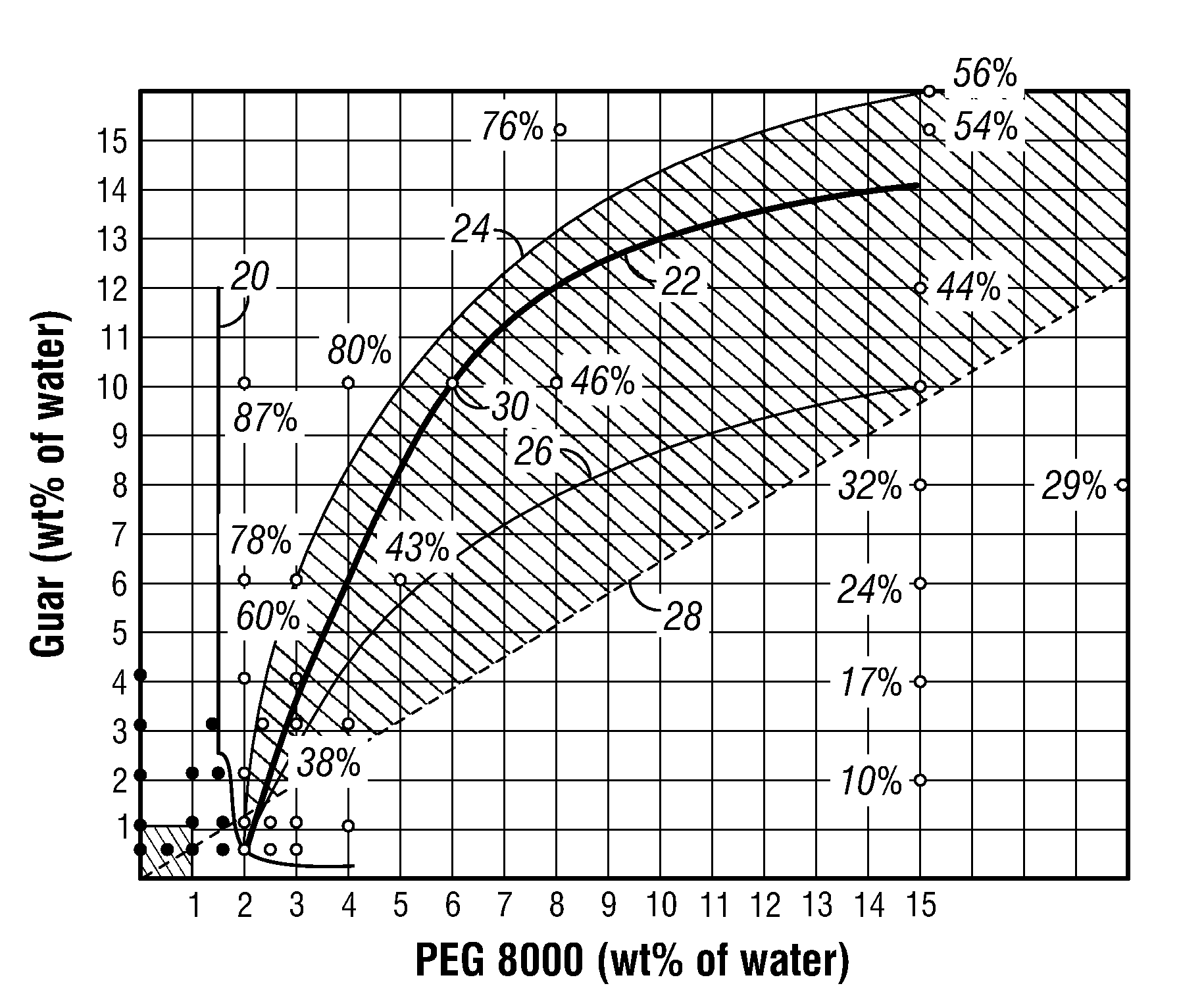

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

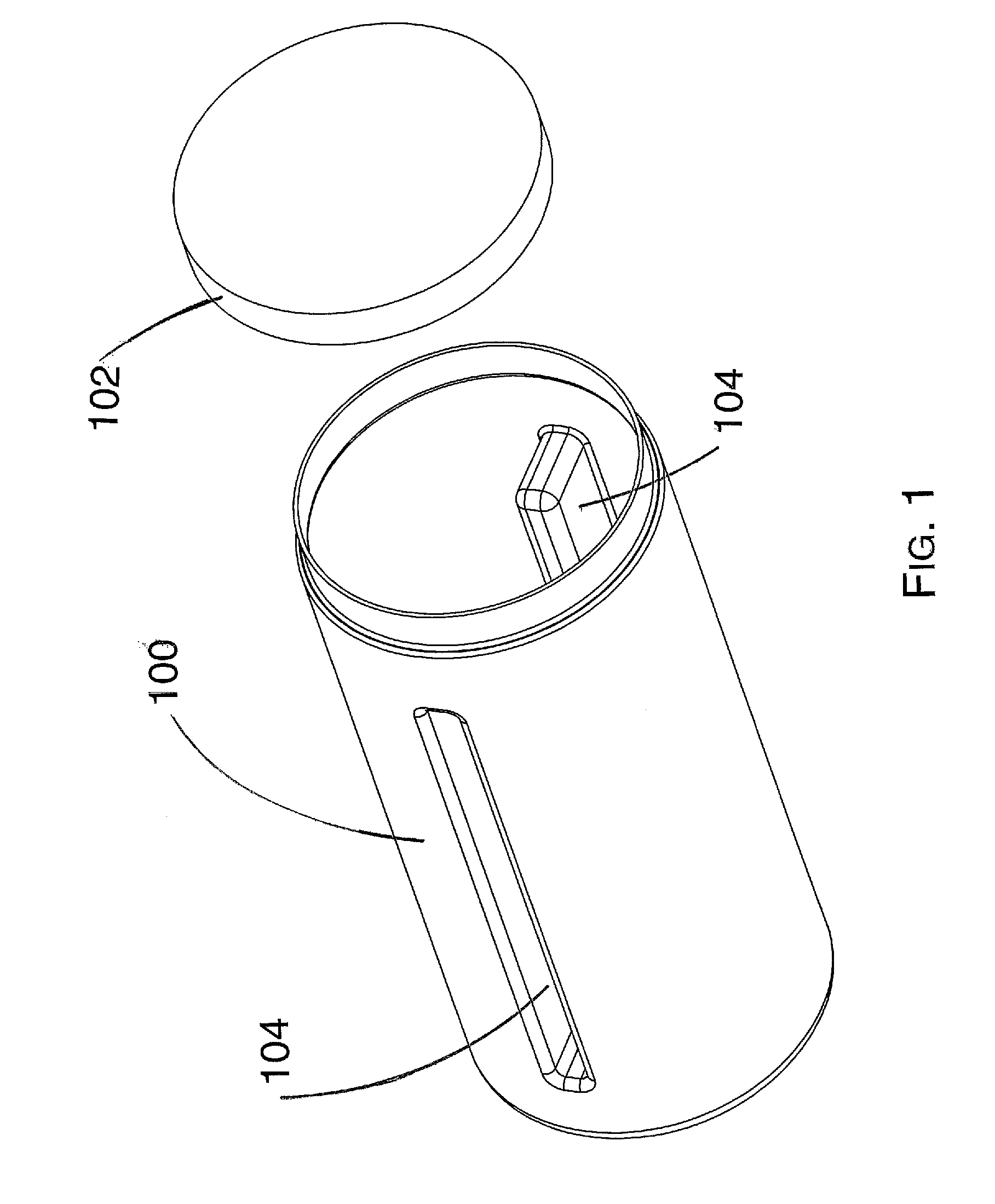

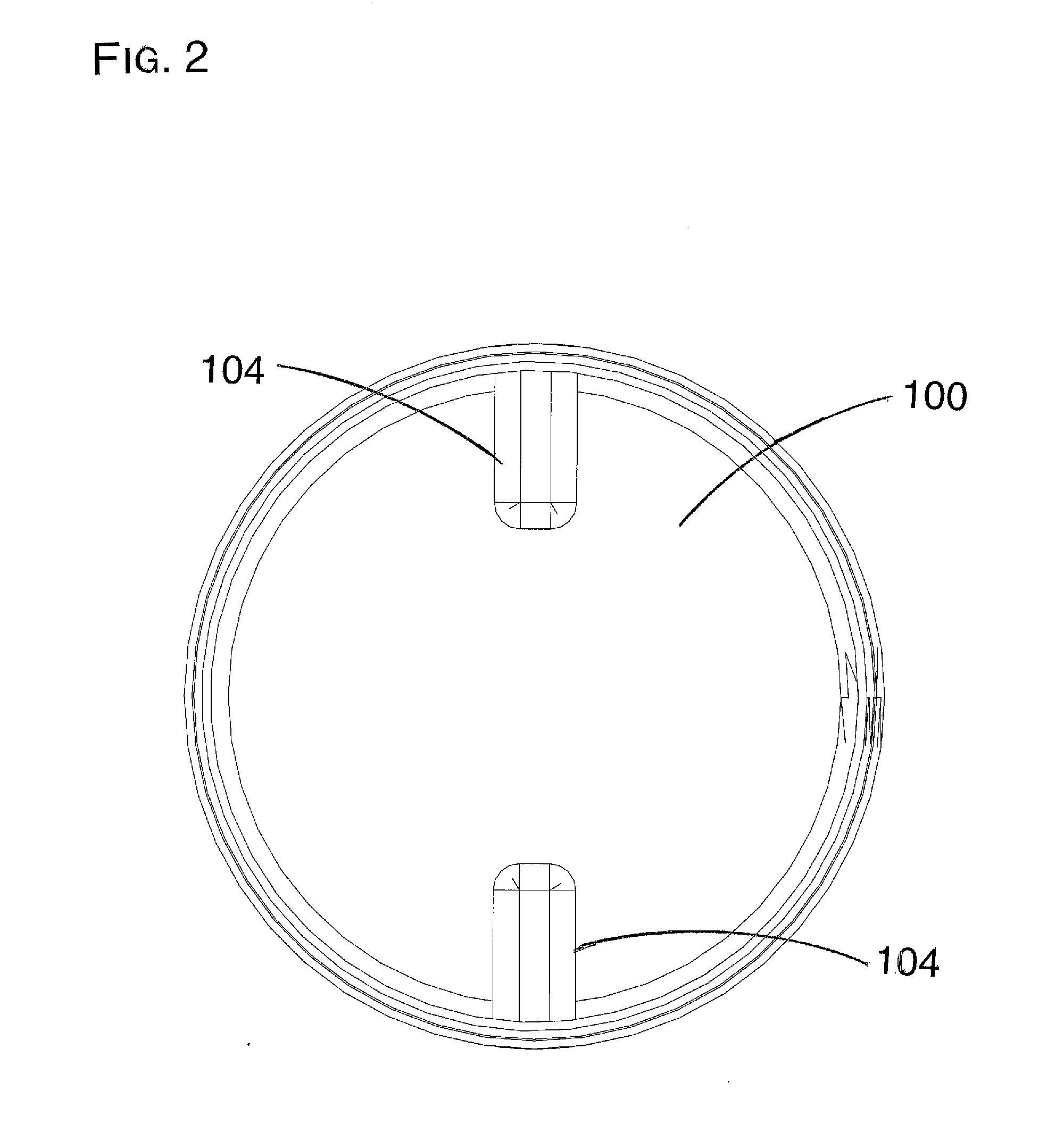

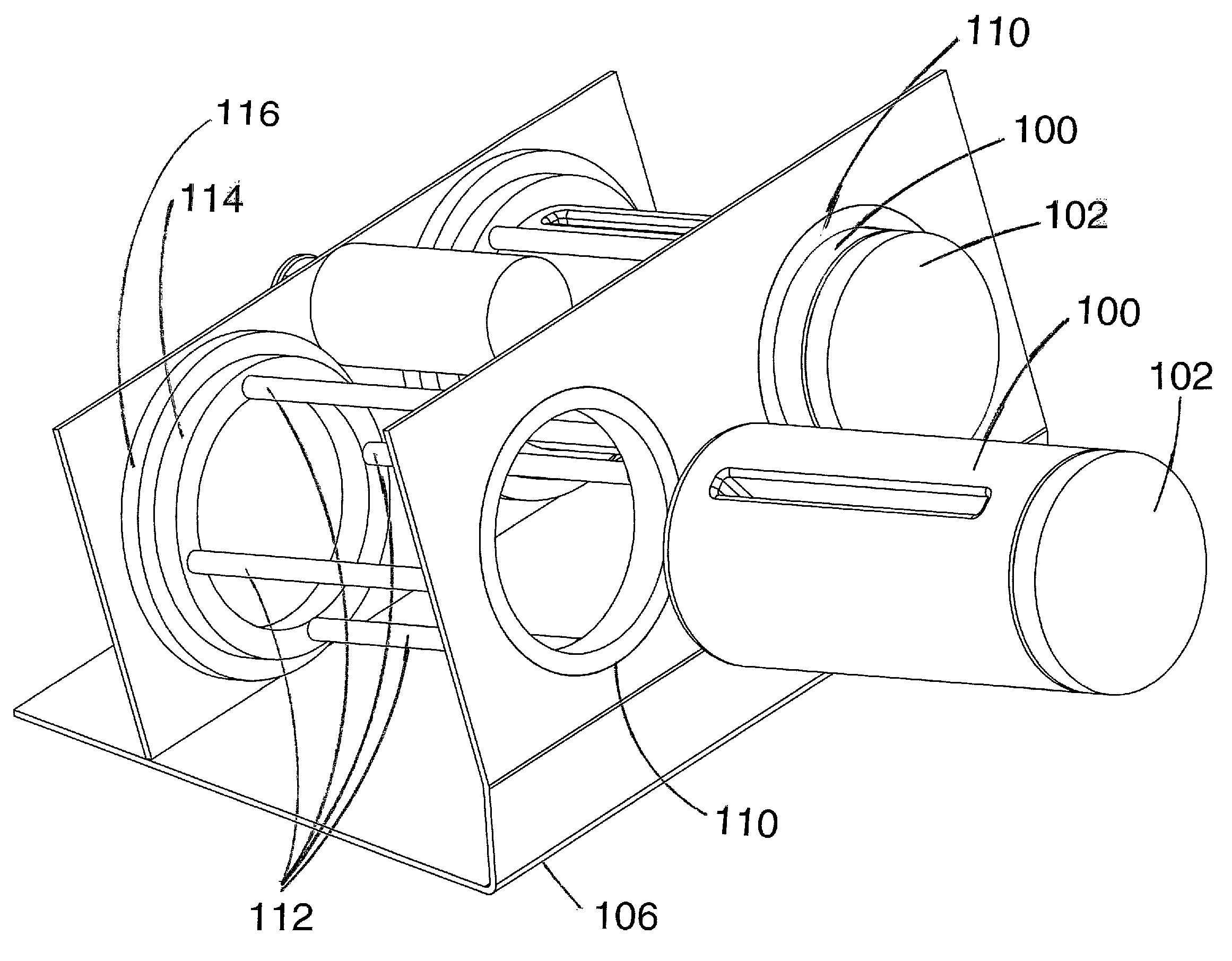

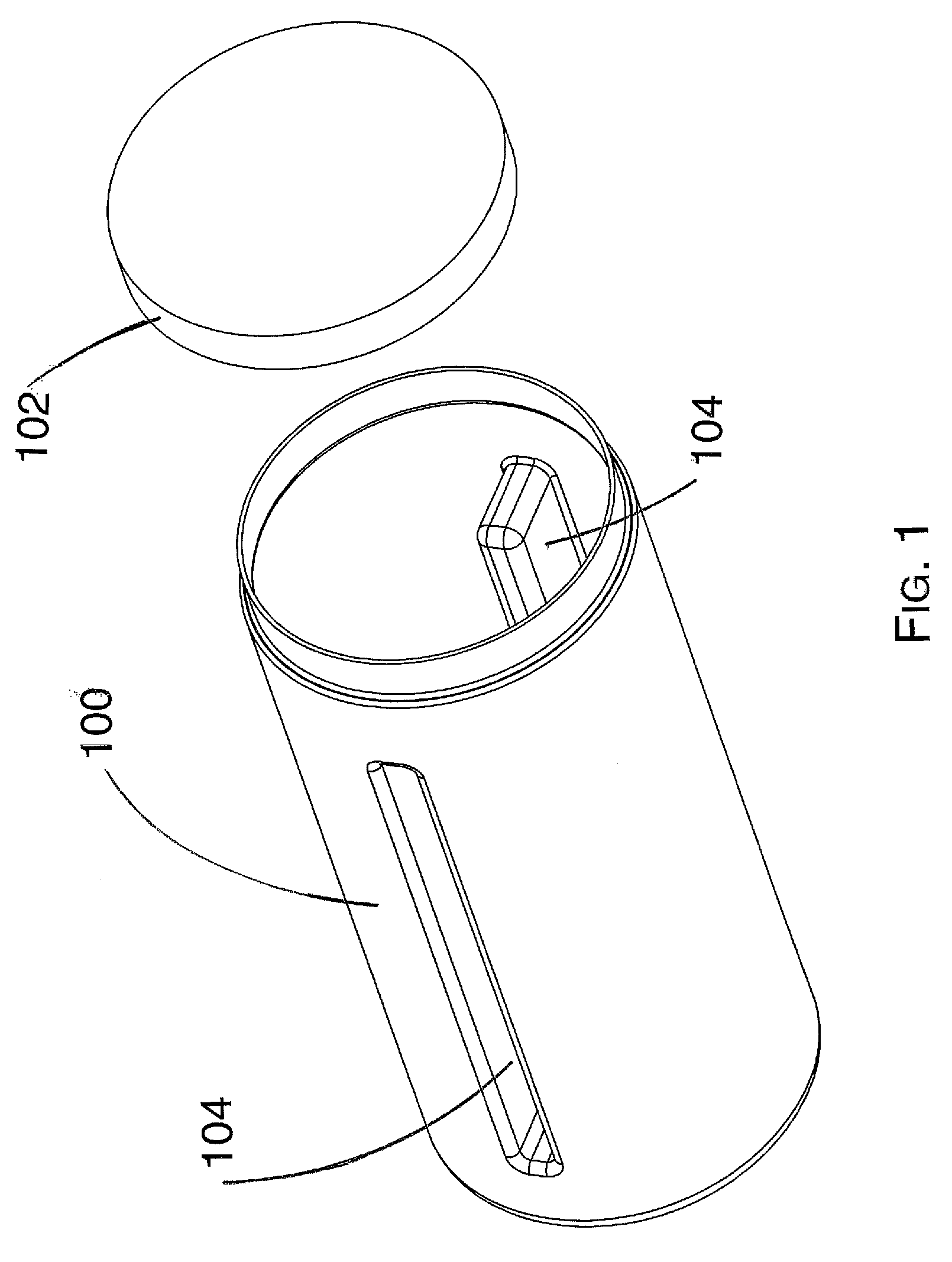

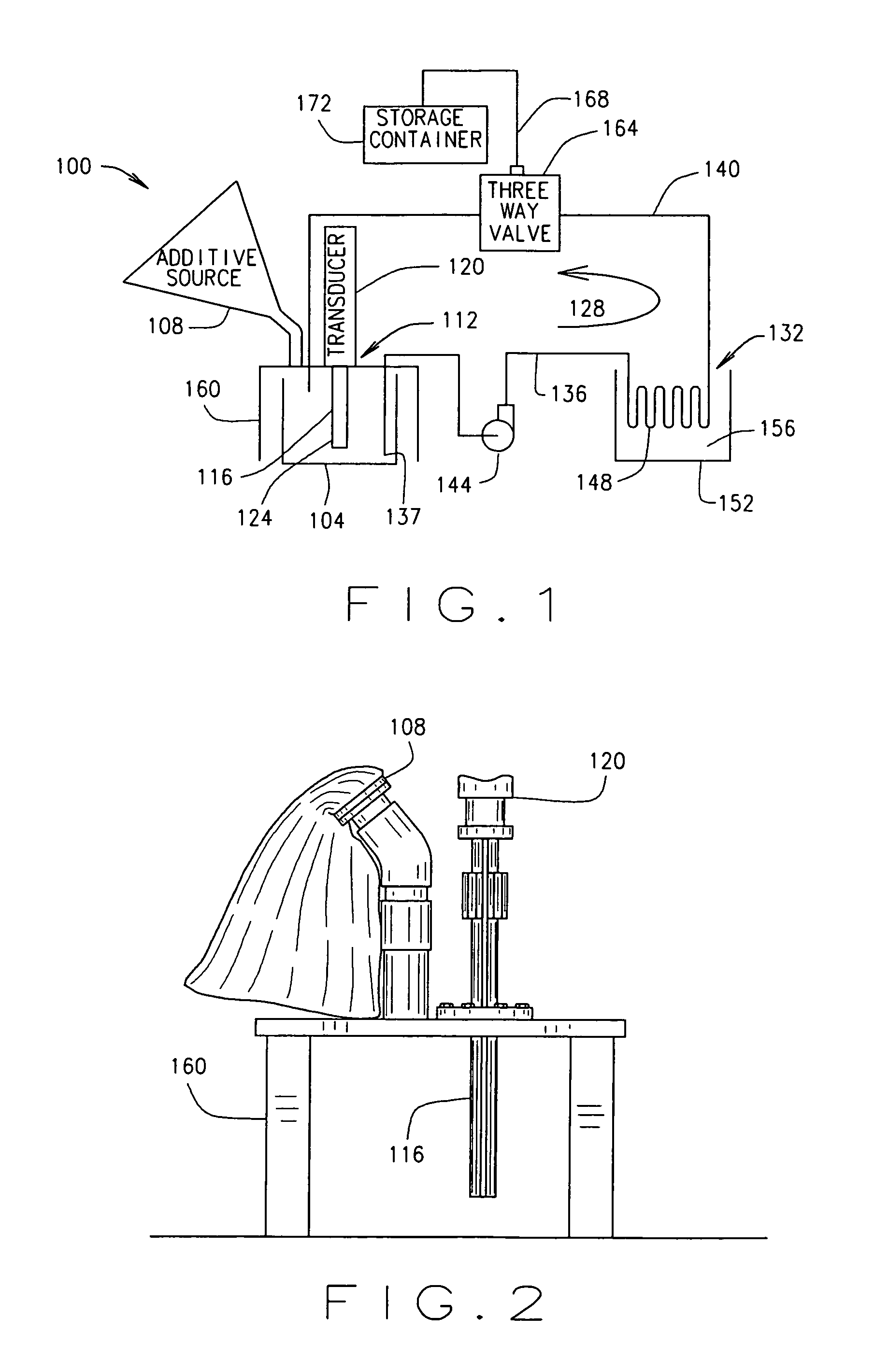

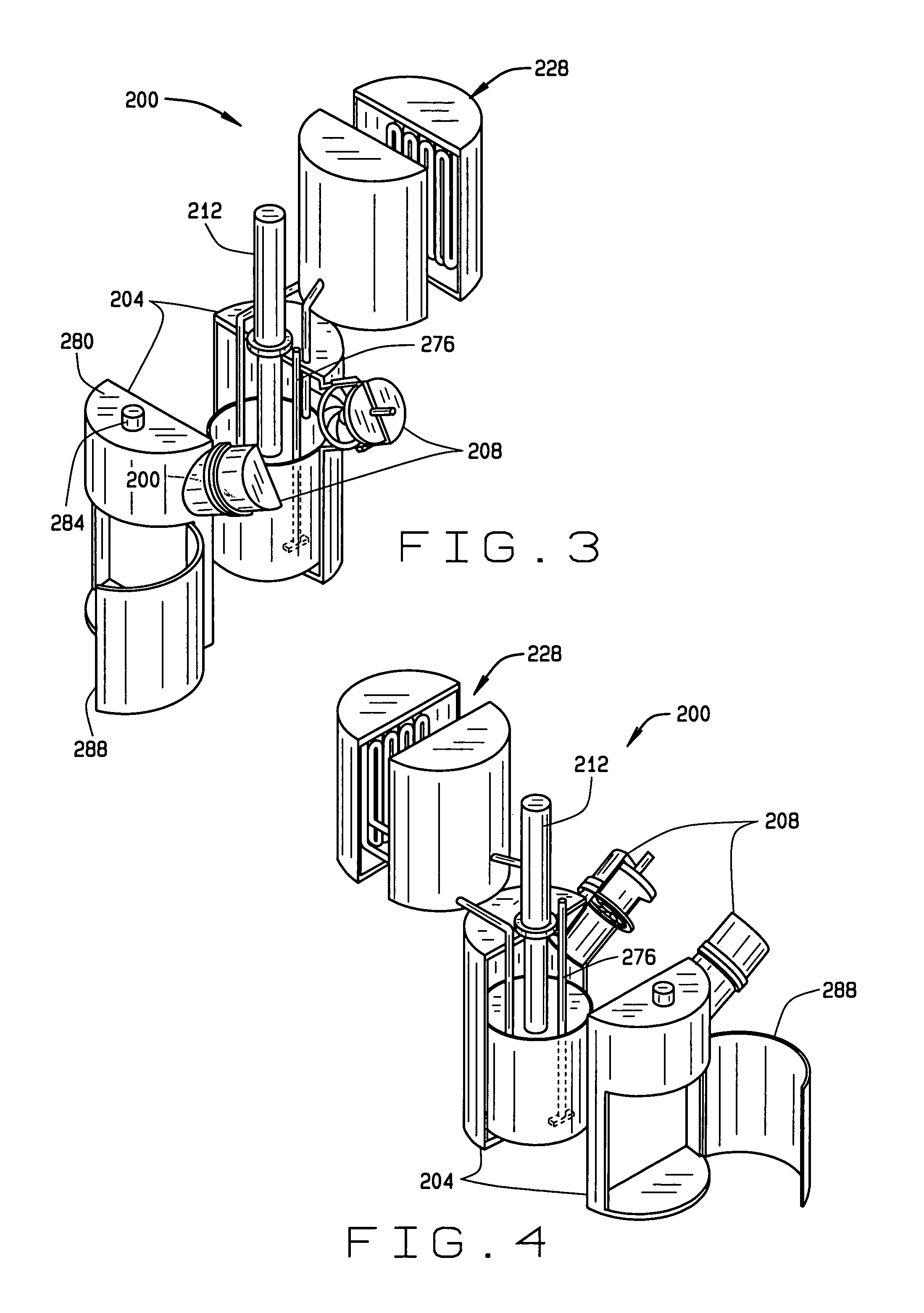

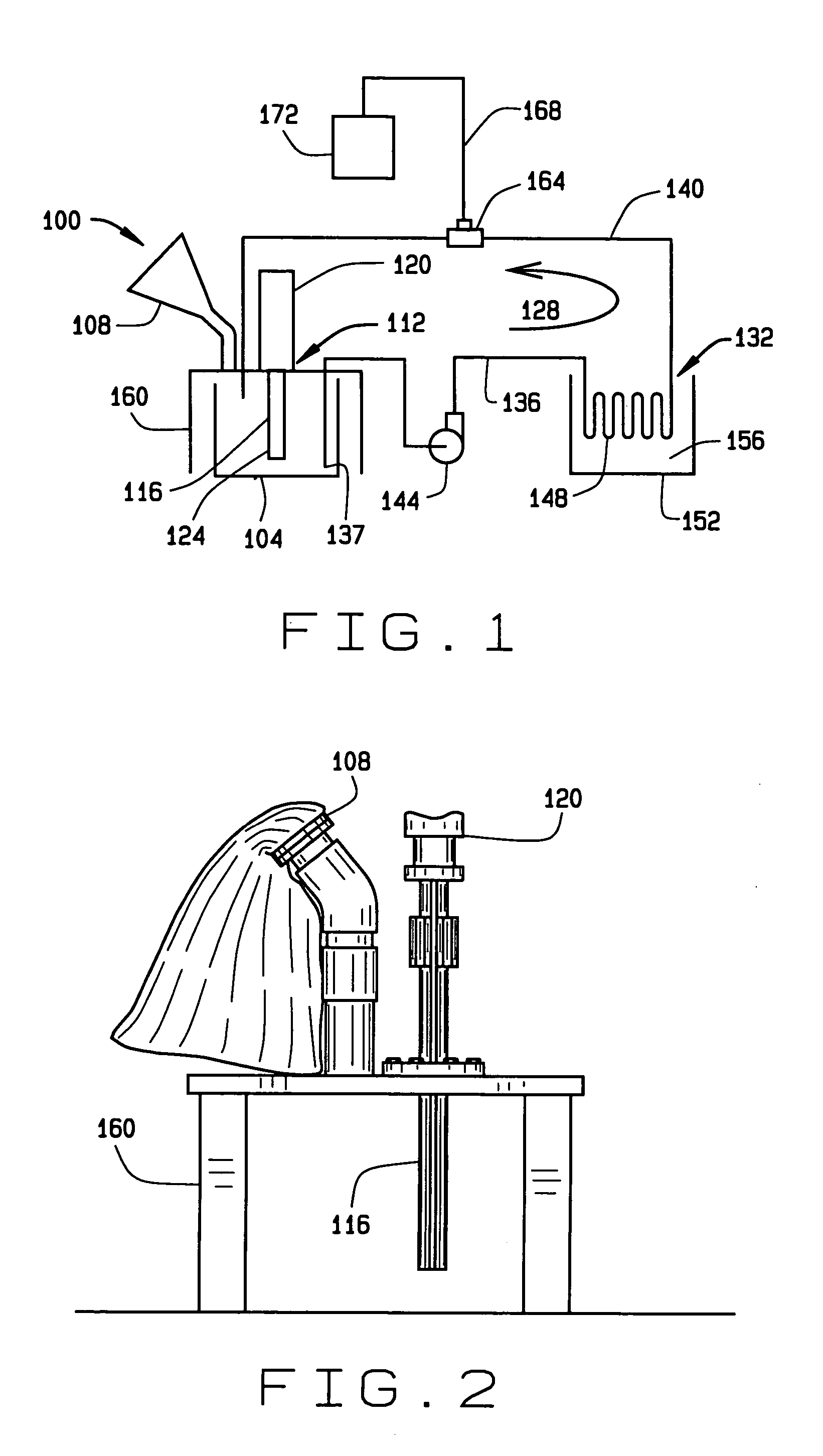

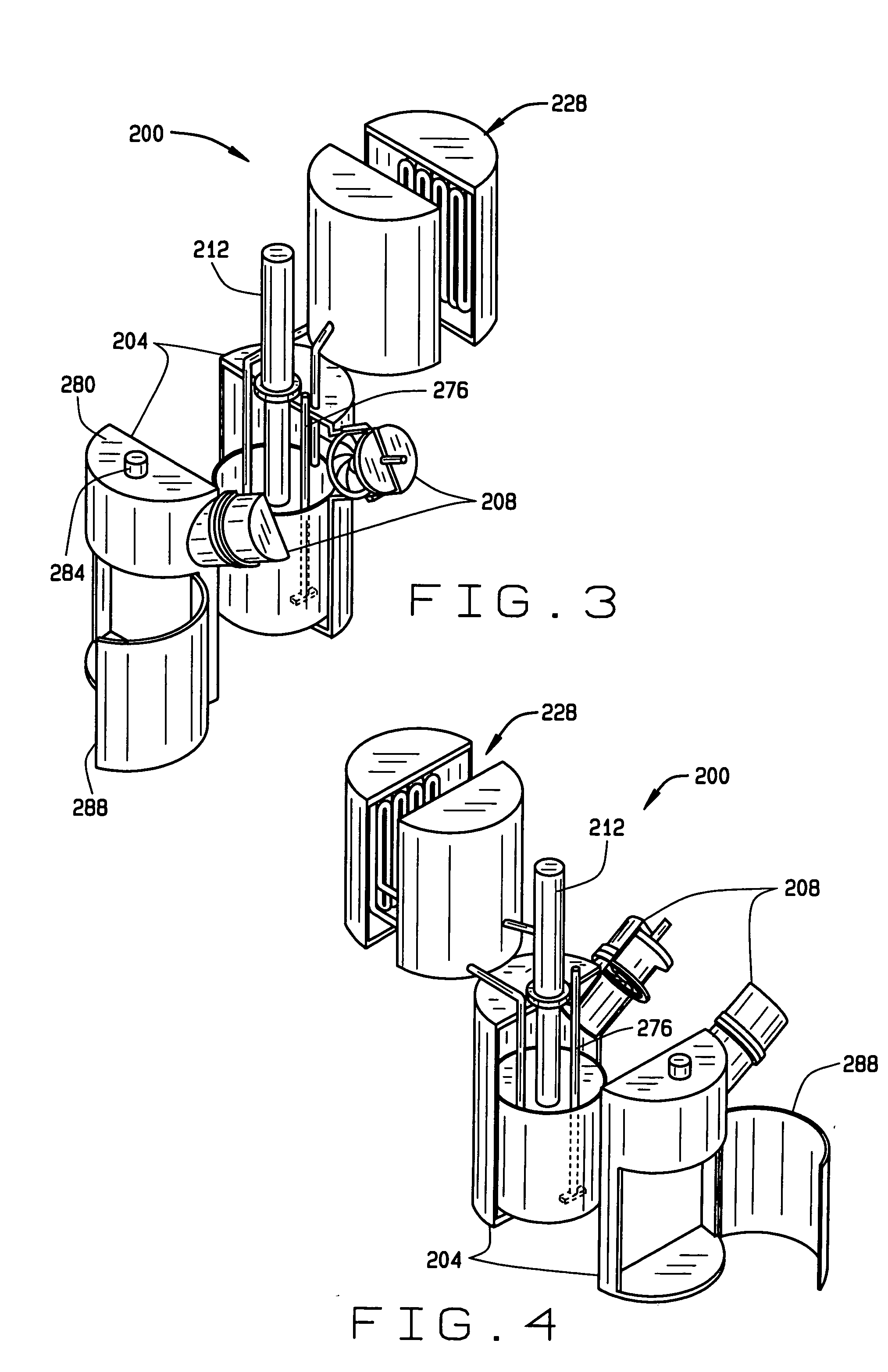

Method and apparatus for producing slush for surgical use

ActiveUS20090301107A1Rotating receptacle mixersShaking/oscillating/vibrating mixersSaline waterHigh integrity

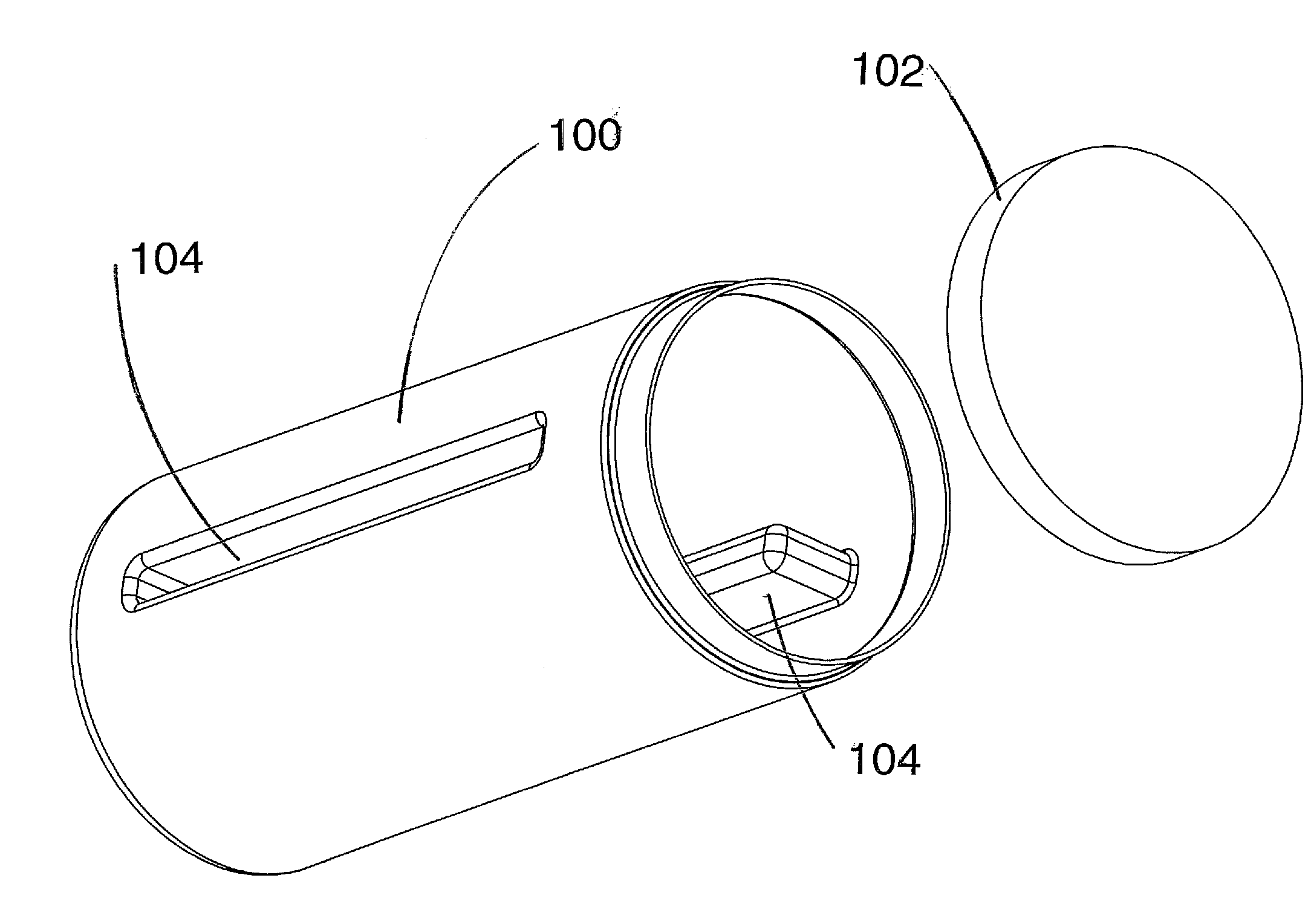

Methods and apparatus for producing saline slush for surgical applications. Producing surgical saline slush in a slush bottle that is a rigid or semi-rigid, high integrity, sturdy container that resists punctures and leaks to better maintain a sterile barrier and does not rely on having an external object placed in the fluid to mix the slush. Slush is agitated by rotating the slush bottle within a slush bottle carriage around an axis of rotation. Agitation of the slush may be increased by including an agitation feature such as at least one fin in one or more sidewalls of the slush bottle. The rotating slush bottle is chilled. One variation is to keep the sterile saline in a flexible container and tumble the flexible container in a rotating slush bottle. Other variations are suggested.

Owner:C CHANGE SURGICAL

Method and apparatus for producing slush for surgical use

ActiveUS7874167B2Rotating receptacle mixersShaking/oscillating/vibrating mixersSaline waterEngineering

Methods and apparatus for producing saline slush for surgical applications. Producing surgical saline slush in a slush bottle that is a rigid or semi-rigid, high integrity, sturdy container that resists punctures and leaks to better maintain a sterile barrier and does not rely on having an external object placed in the fluid to mix the slush. Slush is agitated by rotating the slush bottle within a slush bottle carriage around an axis of rotation. Agitation of the slush may be increased by including an agitation feature such as at least one fin in one or more sidewalls of the slush bottle. The rotating slush bottle is chilled. One variation is to keep the sterile saline in a flexible container and tumble the flexible container in a rotating slush bottle. Other variations are suggested.

Owner:C CHANGE SURGICAL

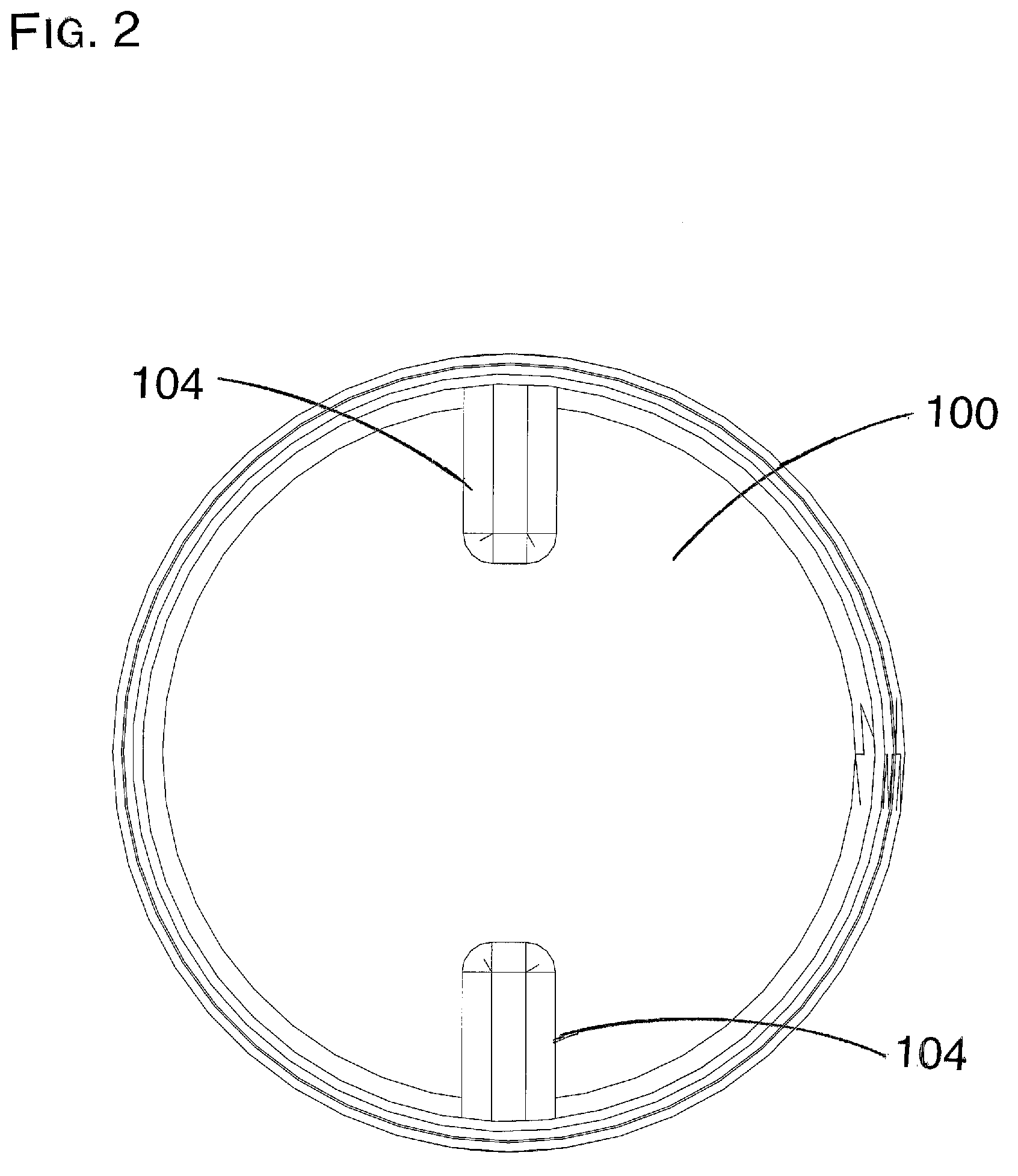

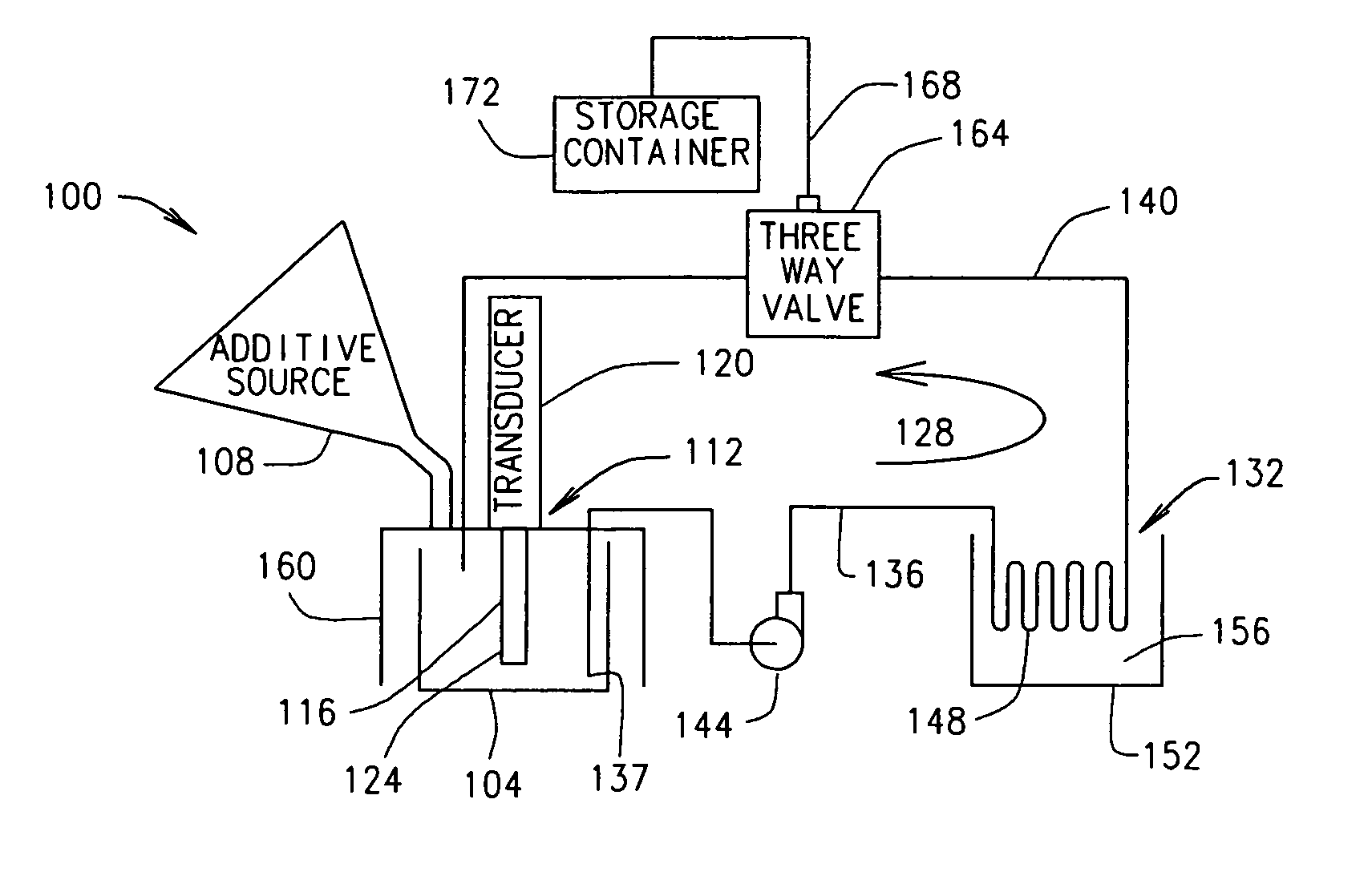

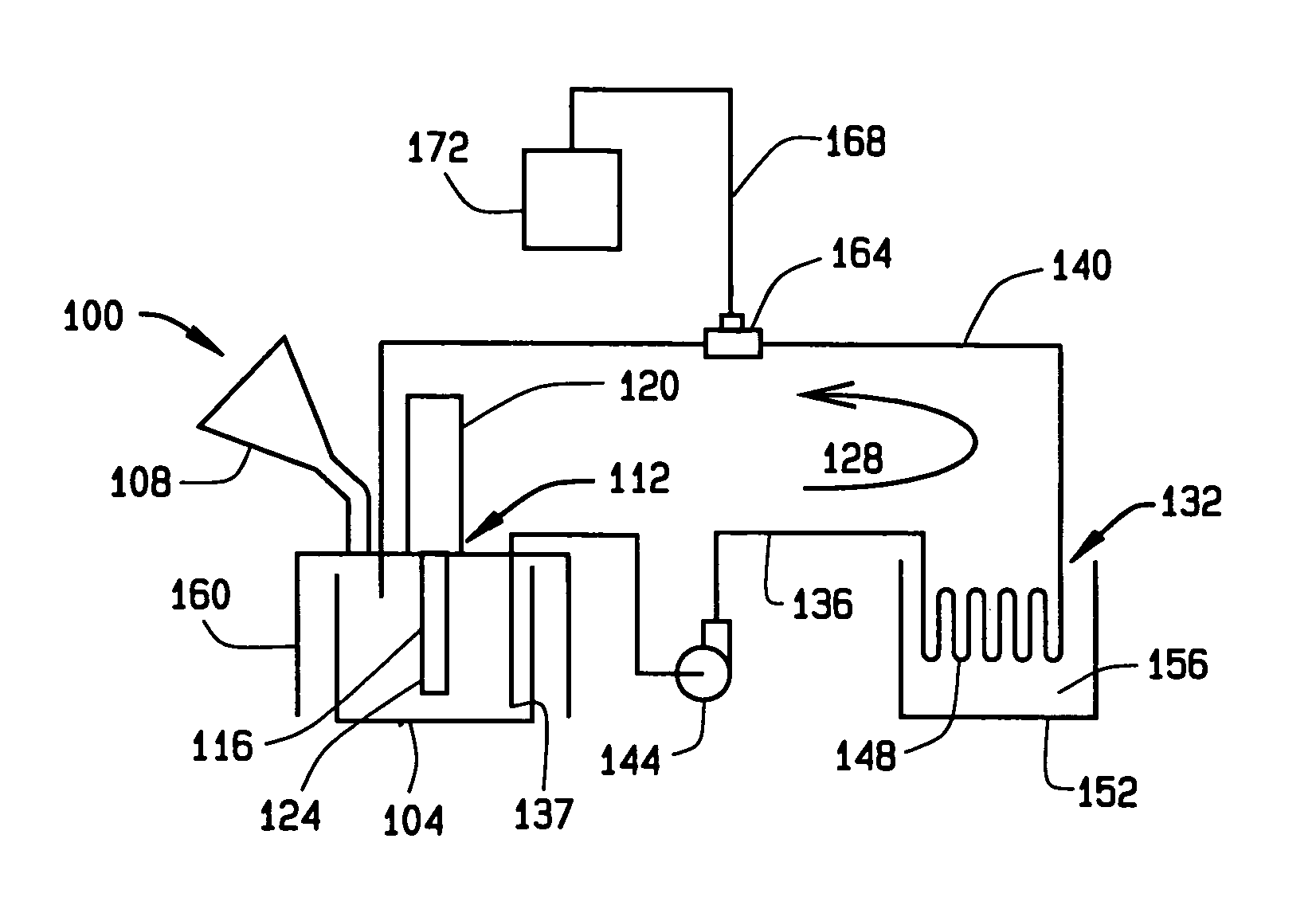

Coating production systems and methods with ultrasonic dispersion and active cooling

Coating production systems and methods which include ultrasonic dispersion and active cooling. The system includes a mixing reservoir and an ultrasonic disperser for ultrasonically dispersing an additive with another coating component within the mixing reservoir. The system also includes a heat exchanger in communication with the mixing reservoir to receive a mixture of the additive and another coating component from the mixing reservoir. The mixture is cooled by thermal energy transfer from the mixture to the heat exchanger. The cooled mixture is returned to the mixing reservoir.

Owner:THE BOEING CO

Polymer delivery in well treatment applications

InactiveUS8044000B2Reduce solubilityLow viscosityTransportation and packagingFluid removalActive polymerEmulsion

This invention relates to compositions and methods for treating subterranean formations, in particular, oilfield stimulation compositions and methods using water-in-water polymer emulsions to uniformly dissolve a rheologically active polymer, such as a thickener or friction reducer, in the treatment fluid. The emulsions have a low viscosity and are easily pumped for mixing into a treatment fluid, where upon dilution with an aqueous medium, the polymer is easily hydrated without forming fish-eyes. The partitioning agent in the water-in-water emulsion does not generally affect the rheology of the treatment fluid. The invention also relates to further processing of the emulsion by wet grinding, high shear mixing and / or heating to enhance the hydration rate in the preparation of the well treatment fluid.

Owner:SCHLUMBERGER TECH CORP

Leucine/Peptide Composition and Method of Formulation

InactiveUS20110233469A1Low viscosityMore amenable to heat-treatmentPeptide/protein ingredientsOther chemical processesAmino acid compositionViscosity

Disclosed is a method for providing amino acids in a form having improved solubility and / or improved suspension properties, and a product made by the method. The method also provides protein and amino acid compositions having decreased viscosity following heat treatment.

Owner:GLANBIA NUTRITIONALS IRELAND

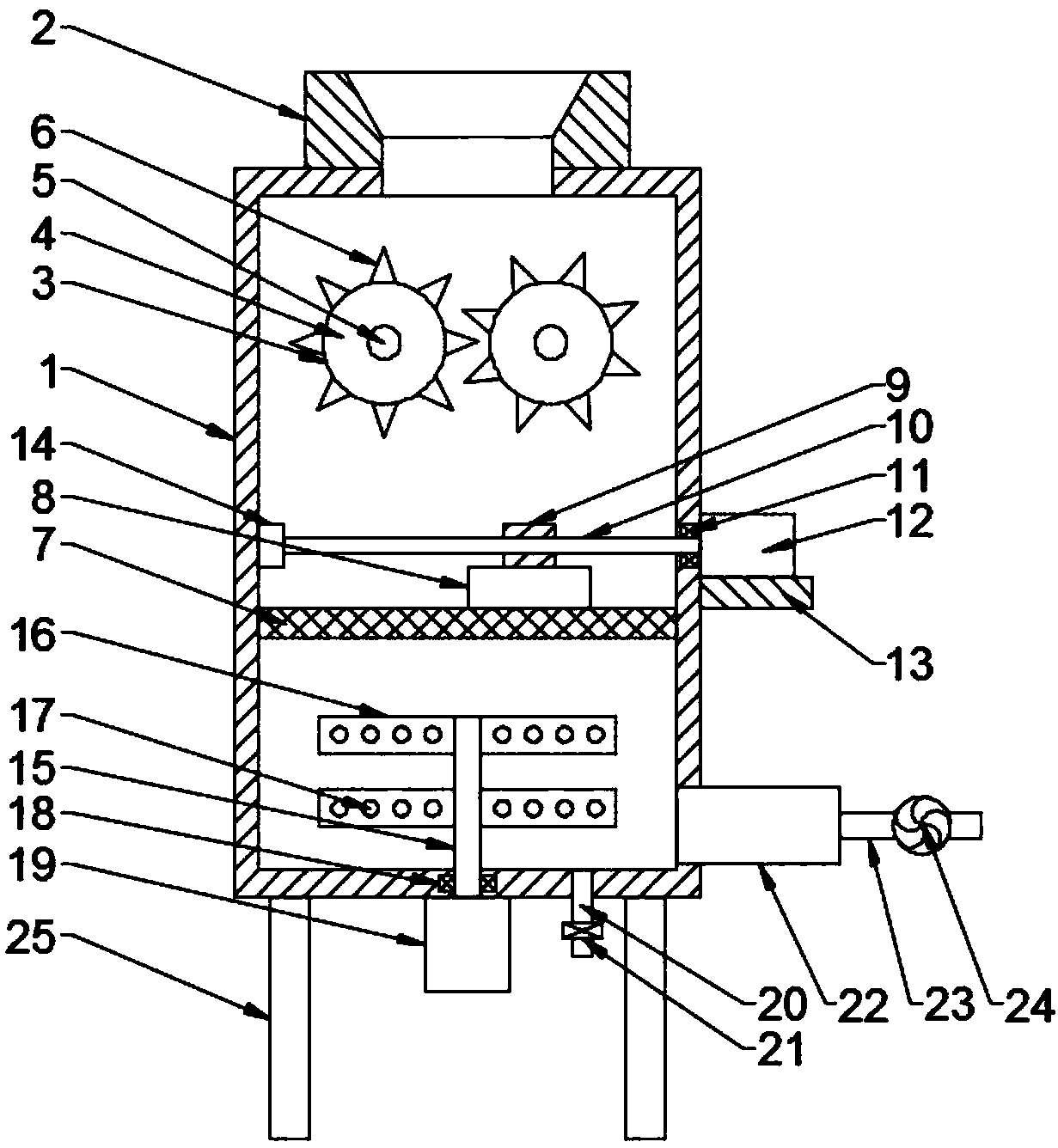

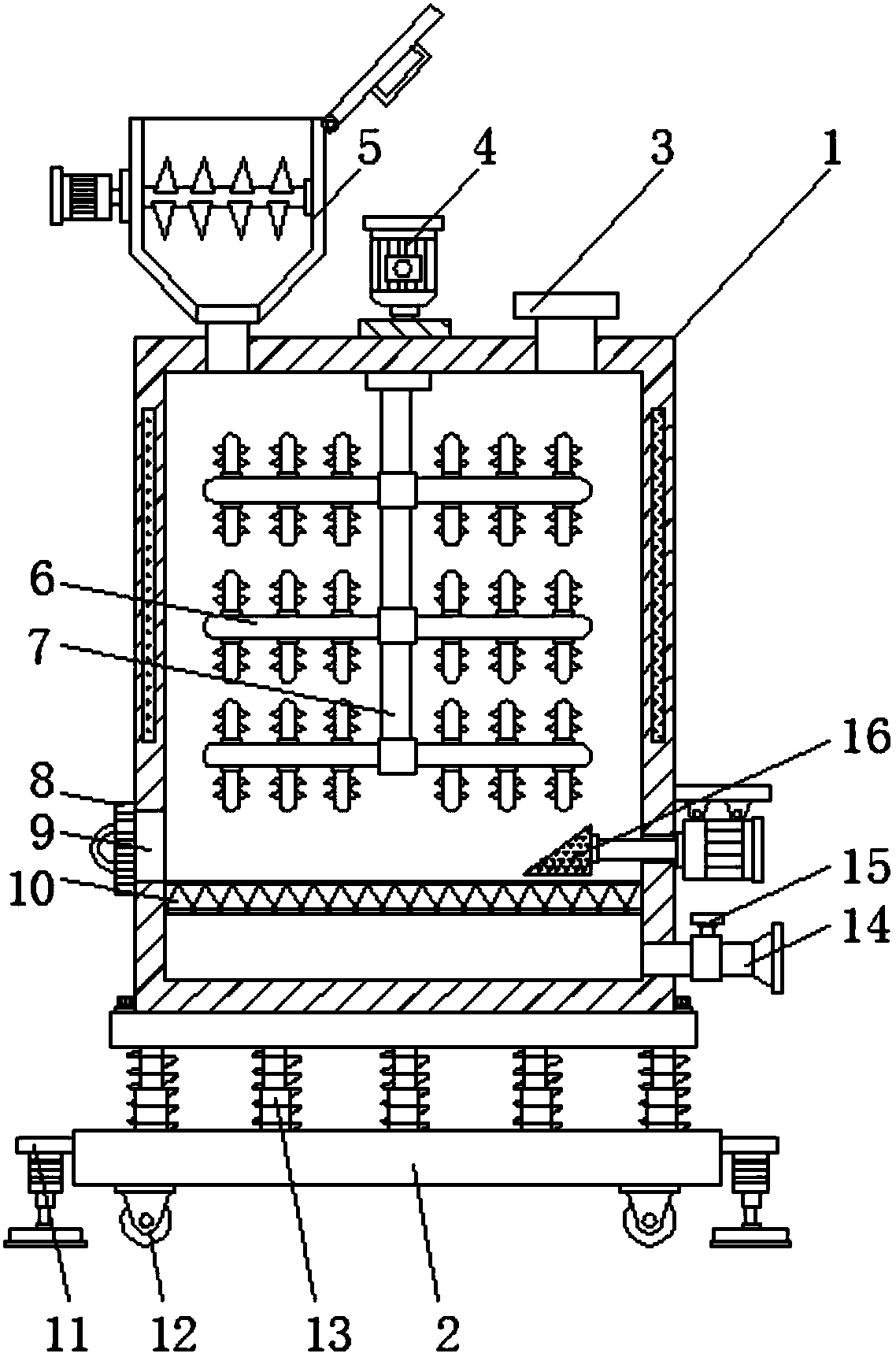

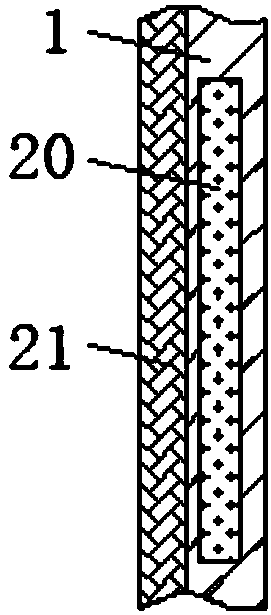

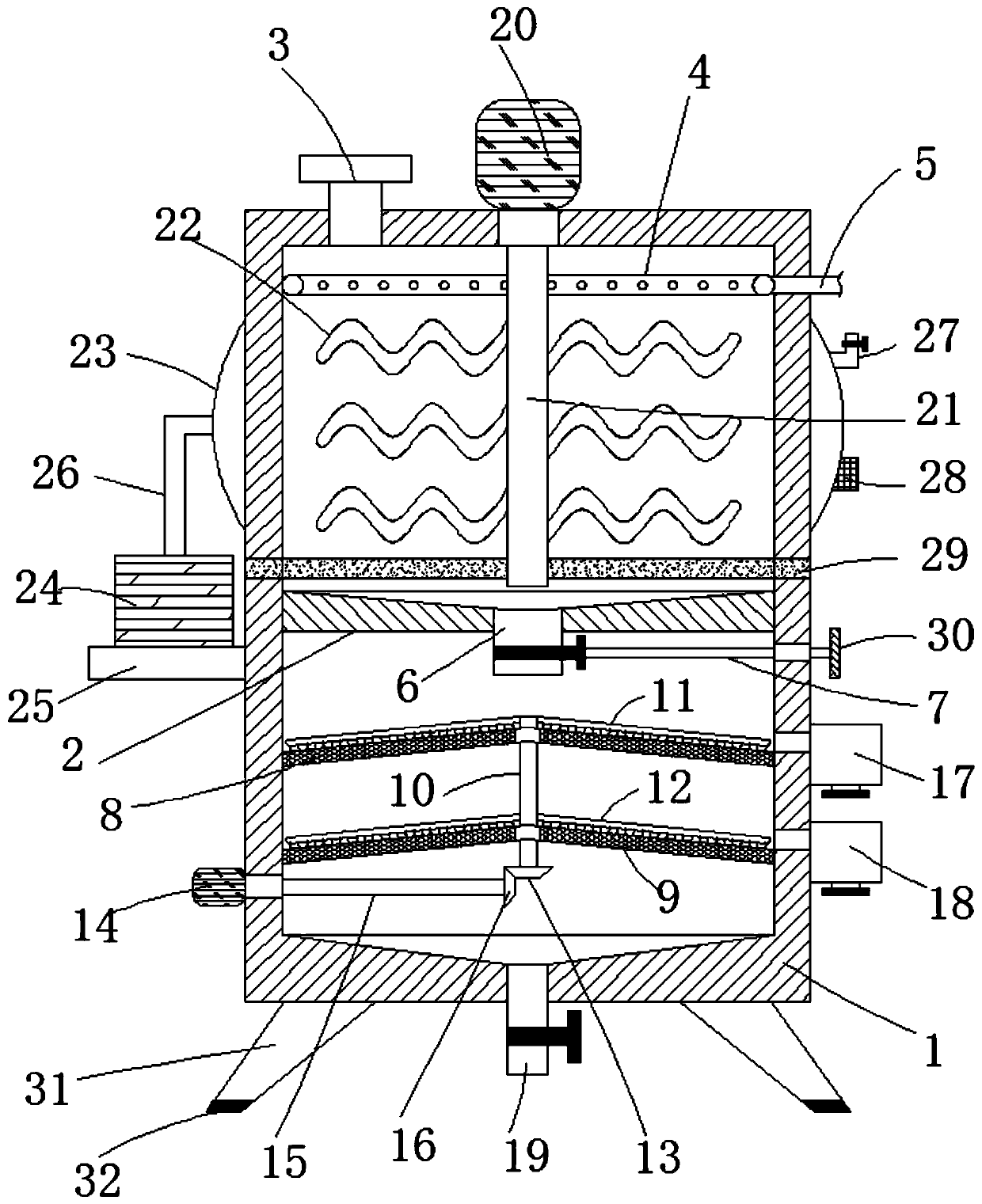

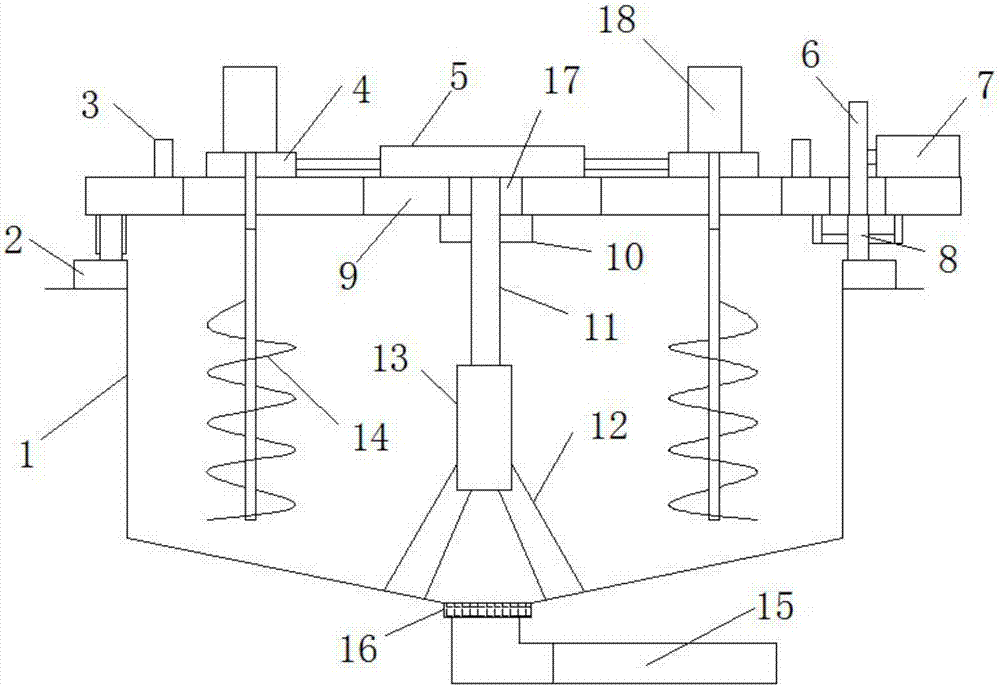

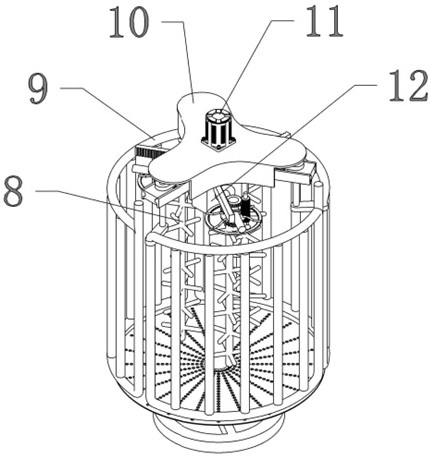

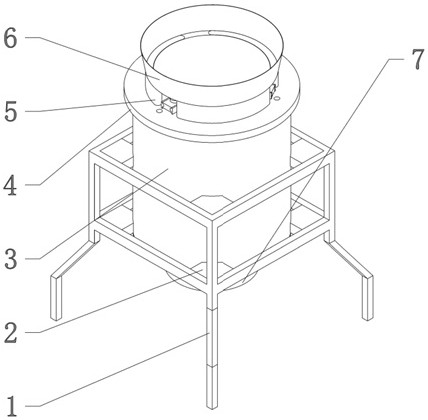

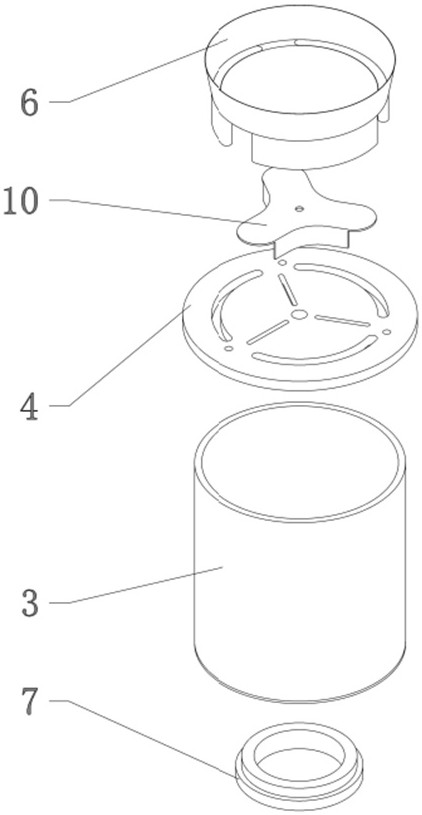

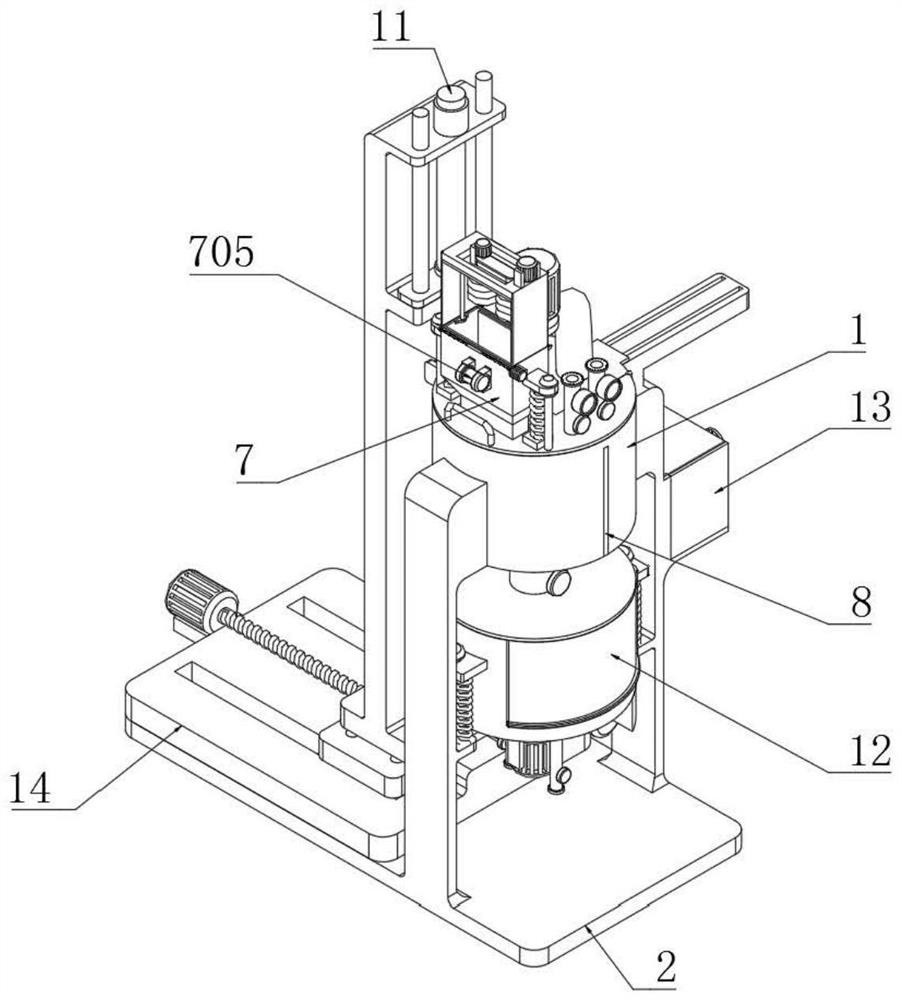

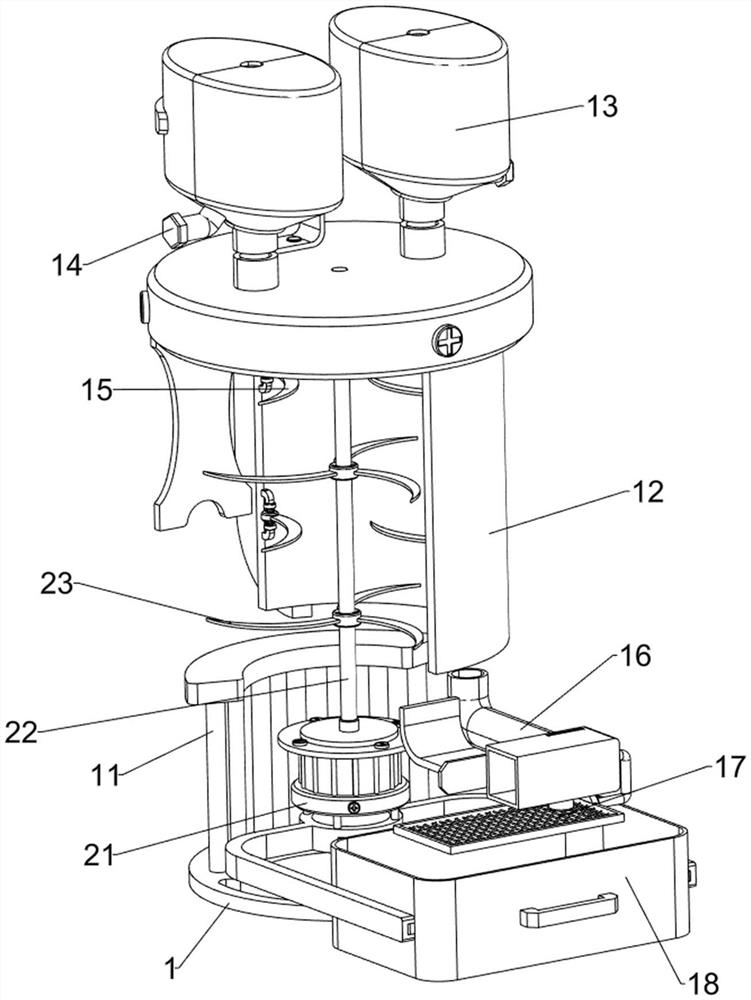

Flocculation stirring device for sewage treatment

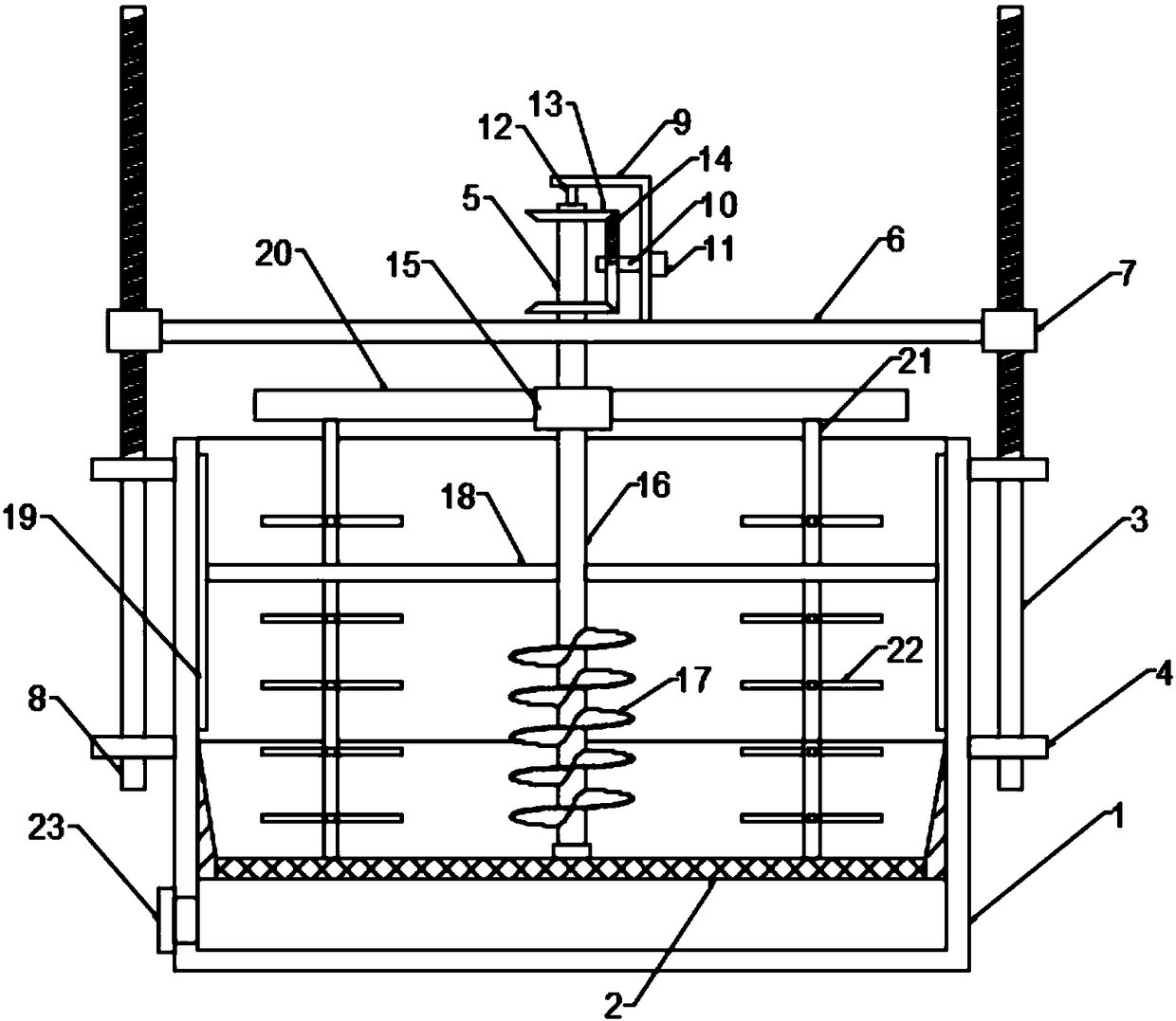

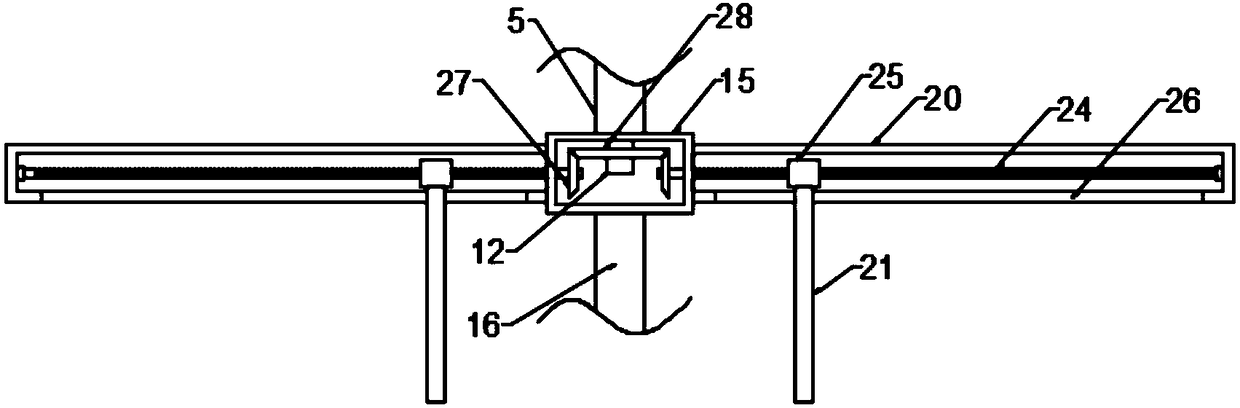

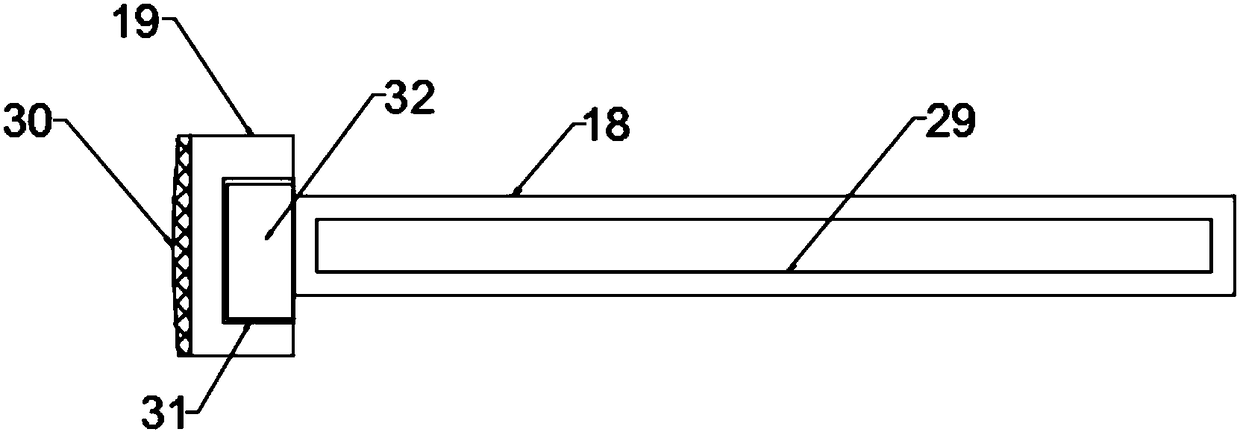

InactiveCN108585152AEasy to handleAvoid it happening againRotary stirring mixersTransportation and packagingFlocculationDrive shaft

The invention discloses a flocculation stirring device for sewage treatment. The flocculation stirring device for sewage treatment comprises a stirring cylinder body, the inner part of the stirring cylinder body is provided with a filter mesh frame, the outer side of the filter mesh frame is slidably connected with the up side and lower side of the inner side wall of the stirring cylinder body, the outer side of the stirring cylinder is provided with two lifting screw rods which are symmetrical with the axis of stirring cylinder body, and the mounting frame is provided with a driving shaft, and the driving shaft is connected to the rotating sleeve through a positive and negative transmission mechanism, the side wall of the stirring rod shaft is also provided with a spiral blade and a plurality of connecting cross bars, the lower end of the adjusting cross bar is extended into the inner part of the connecting frame body, and the lower end of the adjusting cross bar is provided with a bevel gear disc, and the end of the two adjusting screw rods which extends into the connecting frame body is provided with a driving bevel gear, and the two driving bevel gears are meshed with the bevelgear disc. The device has simple structure, the position of the stirring rod is variable, the stirring effect is improved, the sewage treatment effect is improved, the inner wall of the treatment cylinder can be cleaned, the operation is convenient, and the practicability is strong.

Owner:郭兵兵

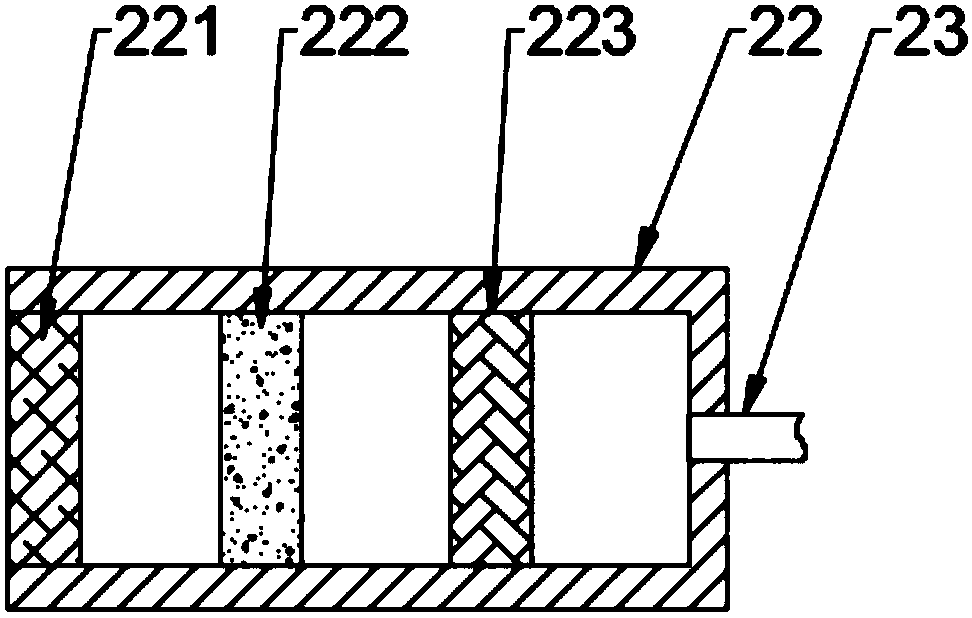

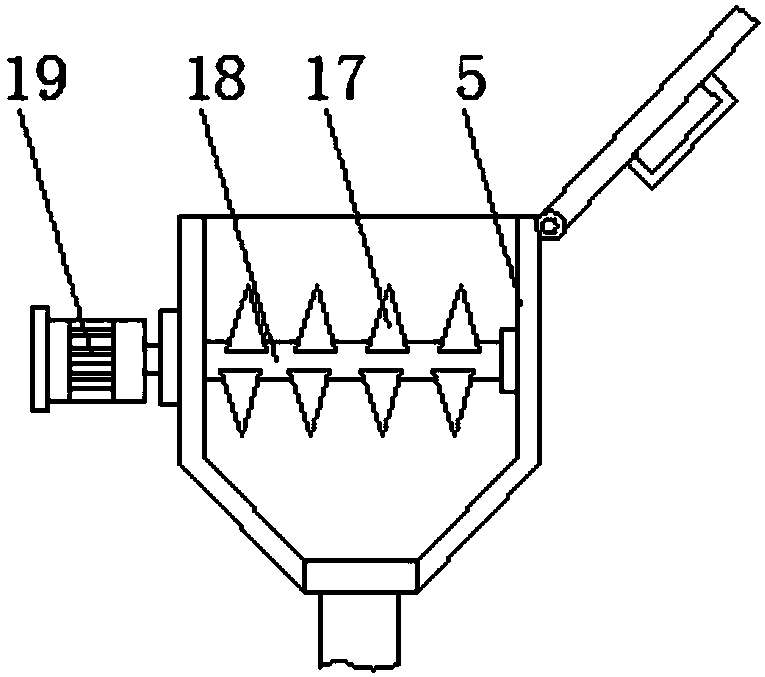

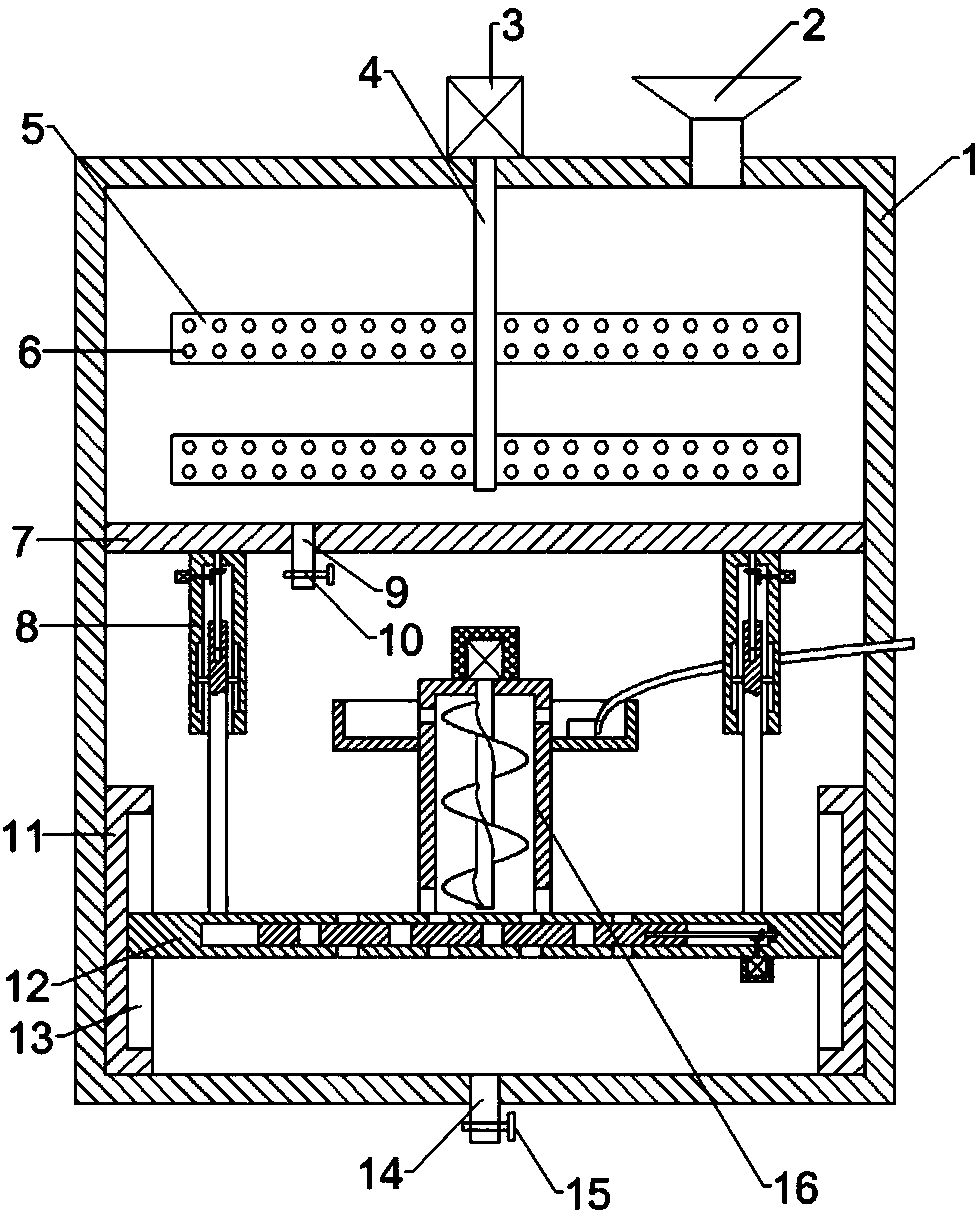

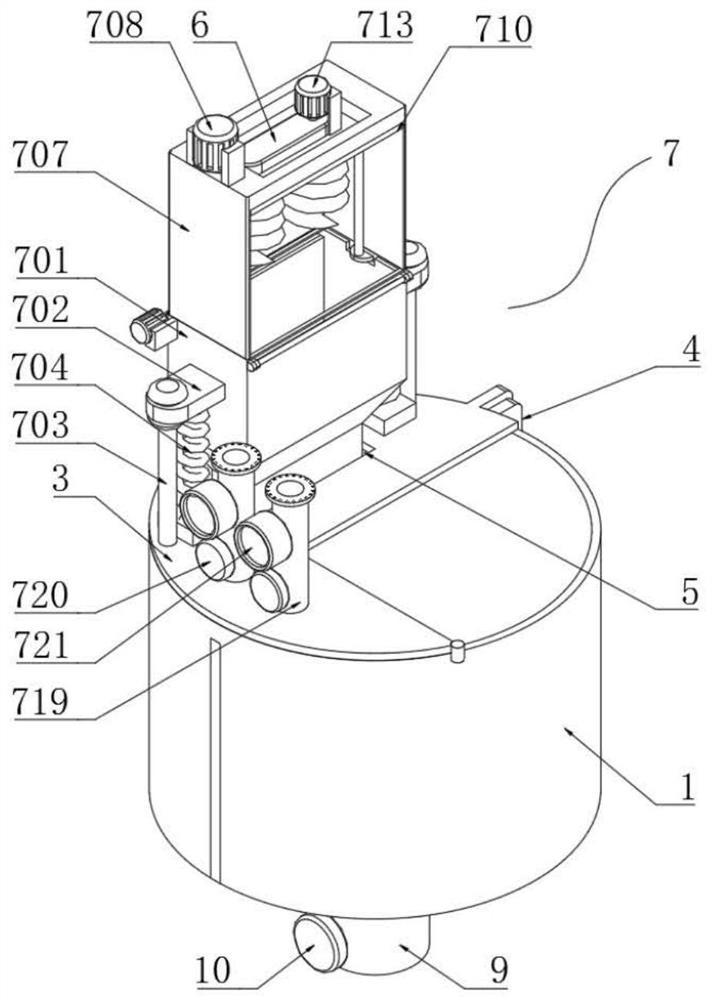

Shower gel production device based on natural tea and ginger raw material production technology

InactiveCN107551600AEasy extractionEasy to completeCosmetic preparationsRotary stirring mixersShower gelPulp and paper industry

The invention discloses a shower gel production device based on a natural tea and ginger raw material production technology. The shower gel production device comprises a kettle body, wherein the top end of the kettle body is connected with a feeding hopper in a penetrating way, a crushing roller group is arranged at the upper part of an inner cavity of the kettle body, a filter screen is arrangedin the middle of the inner cavity of the kettle body, a grinding disc is arranged at the top end of the filter screen, the top end of the grinding disc is fixedly connected with a moving block, a screw rod is embedded in the moving block, a stirring rod is arranged at the bottom of the inner cavity of the kettle body, a plurality of stirring blades are uniformly arranged at the stirring rod, a plurality of supporting legs are uniformly arranged at the bottom end of the kettle body, the bottom of one side end of the kettle body is connected with a filter cartridge in the penetrating way, the other end of the filter cartridge is connected with a drug discharging pipe in the penetrating way, and a water pump is arranged on the drug discharging pipe; according to the shower gel production device, through arranging the crushing roller group and the grinding disc, tea leaves and ginger blocks are respectively crushed and ground, so that the beneficial components in the tea leaves and the ginger blocks can be conveniently and fully extracted to improve the raw material utilization rate; the filter cartridge can completely remove fixed particles in a solution, so that the quality of the extracting solution is guaranteed, and the completion of subsequent procedures of the shower gel is facilitated.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

Roofing granules with high solar reflectance, roofing materials with high solar reflectance, and the process of making the same

ActiveUS8394498B2High opacityLow transparencyLiquid surface applicatorsRoof improvementTransmittanceNear infrared reflectance

Roofing granules include a core having an average ultraviolet transmission of greater than sixty percent and an average near infrared reflectance of greater than sixty percent and a UV coating layer on the exterior surface. The coating provides UV opacity, while the core provides near infrared reflectance.

Owner:CERTAINTEED CORP

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

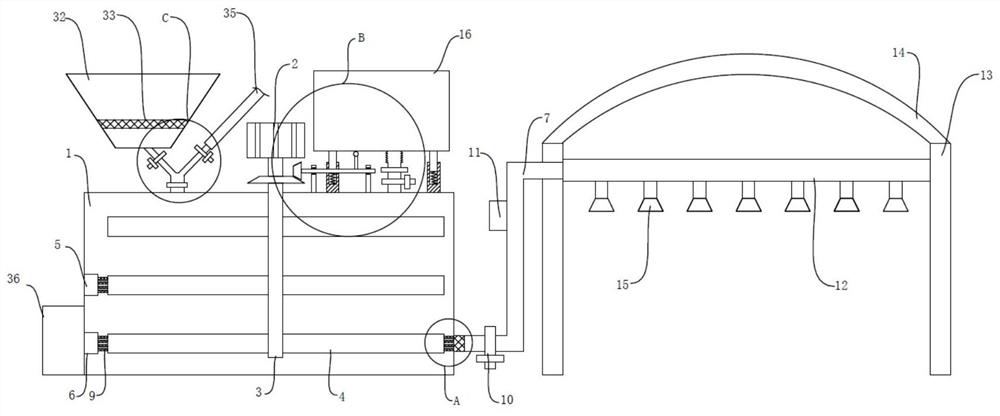

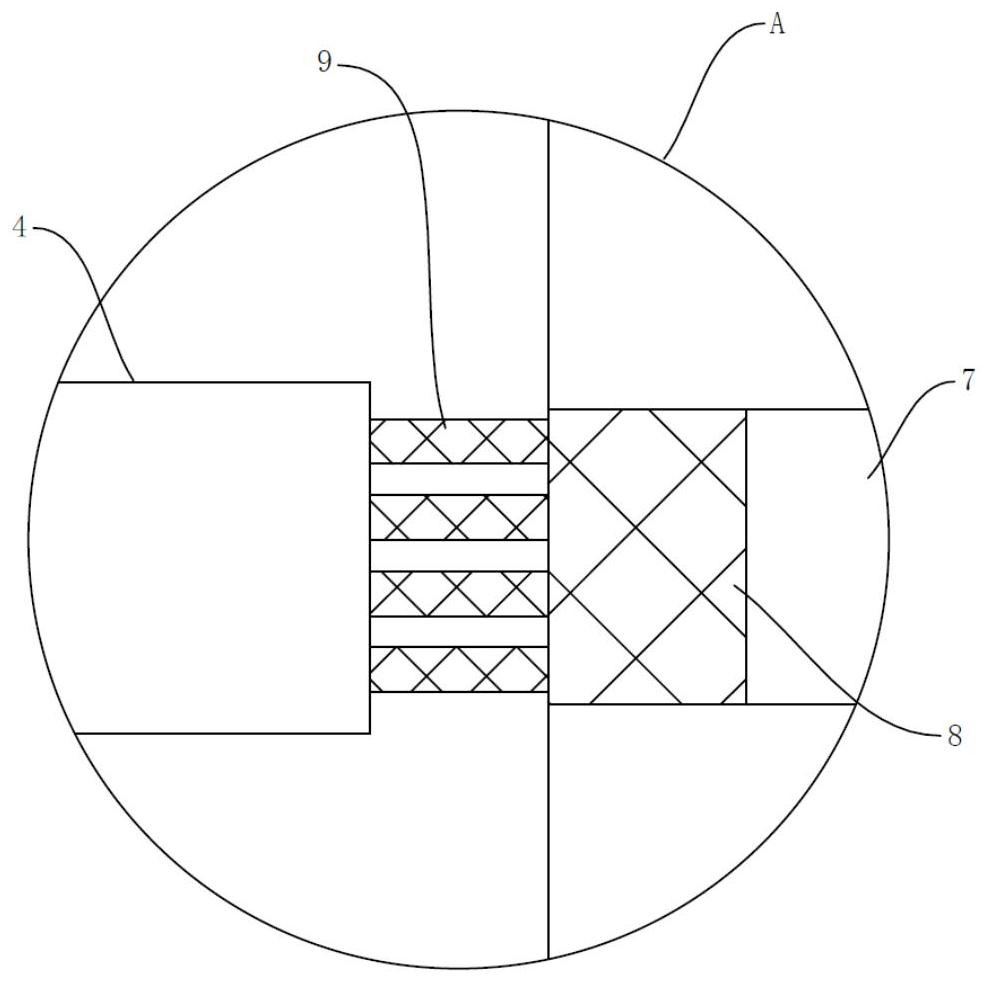

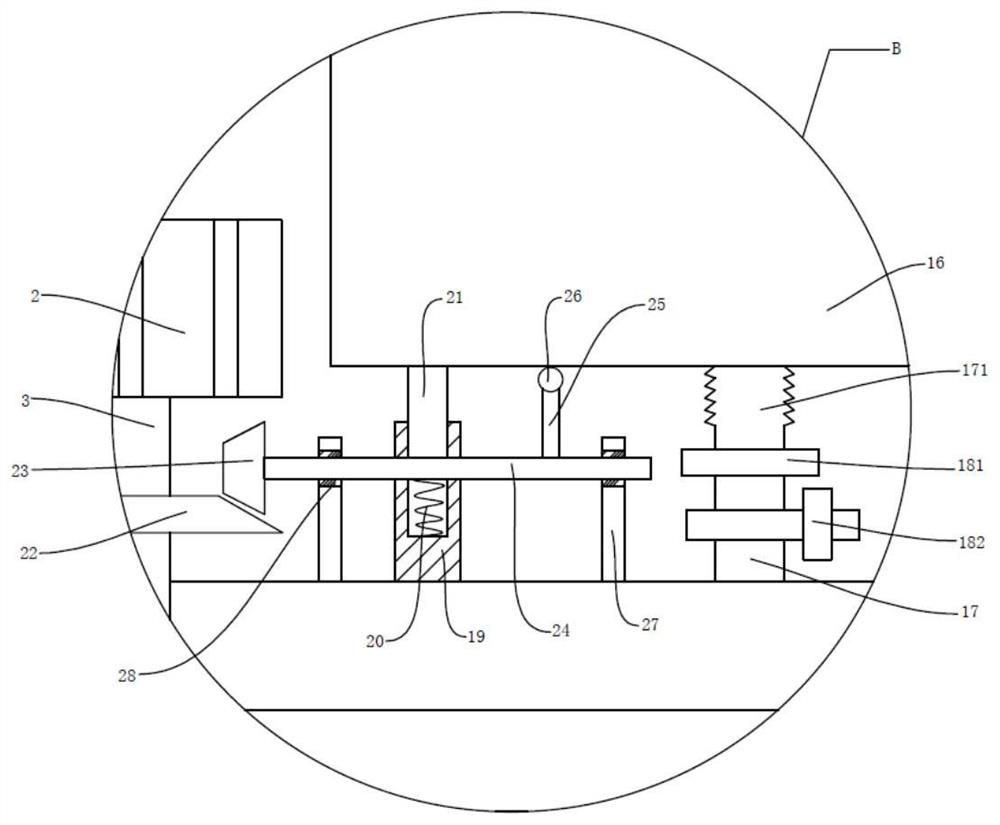

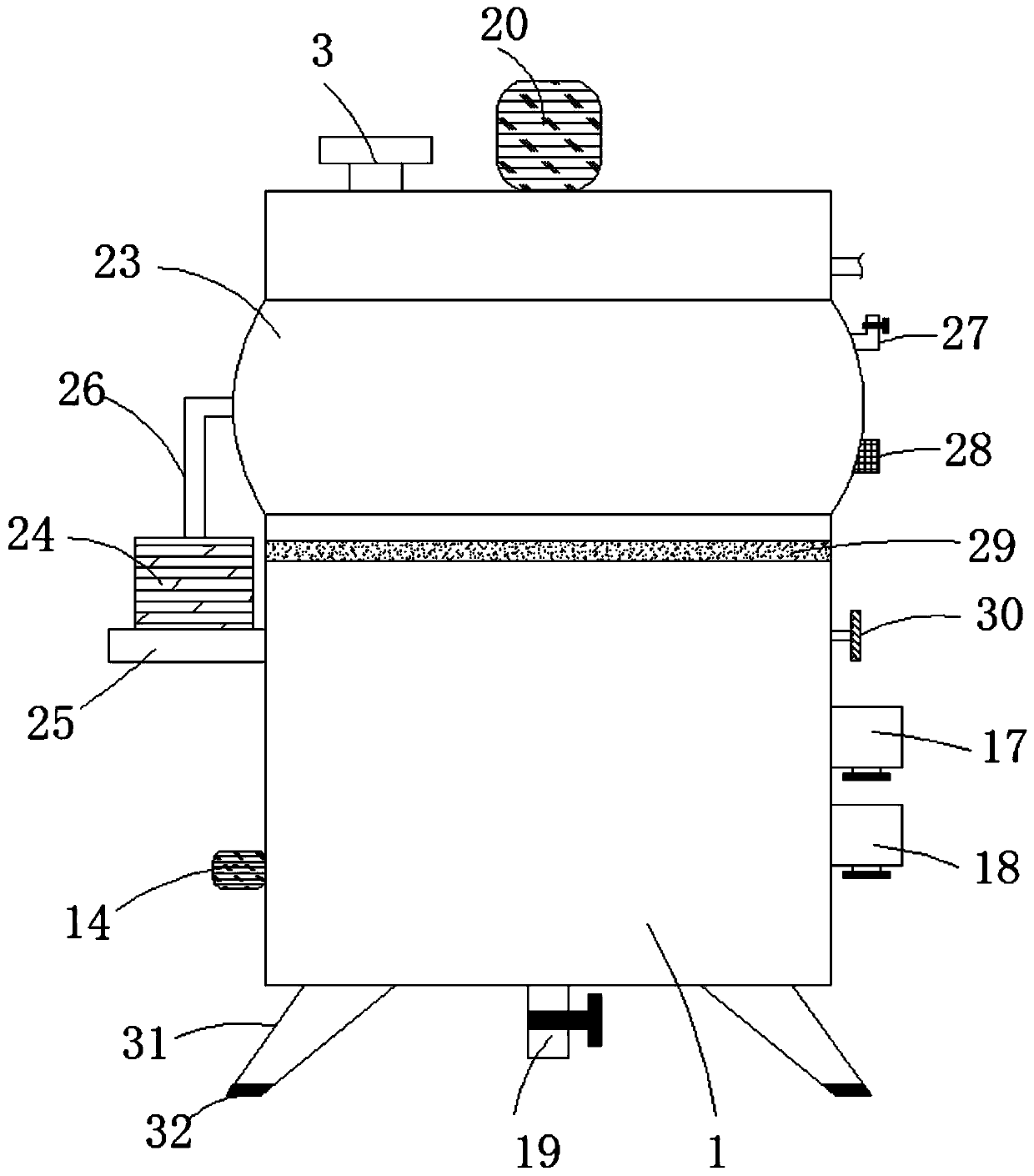

Irrigation system for greenhouse water and fertilizer integration

InactiveCN111617669ADissolve completelyAvoid damageTransportation and packagingRotary stirring mixersGreenhouseAgricultural engineering

The invention discloses an irrigation system for greenhouse water and fertilizer integration. The system comprises a blending box, a rotating rod is fixedly arranged at the output end of a rotating motor, an EC sensor and a PH sensor are fixedly arranged on the side wall of an inner cavity of the blending box, a water and fertilizer filter screen is fixedly arranged at the joint of a communicatingpipe and the blending box, and brushes are arranged on stirring blades close to the EC sensor, the PH sensor and the water and fertilizer filter screen. A fertilizer box is arranged above the blending box, and an impact ball is fixedly arranged at the end part of an extension rod. A three-way pipe is arranged on the blending box in a communicating mode, a first branch pipe is communicated with aninner cavity of the blending box, a second branch pipe is communicated with a rainwater collecting box, and a third branch pipe is communicated with a water inlet pipe. According to the irrigation system for greenhouse water and fertilizer integration, the rotating rod in the irrigation system can clean the EC sensor, the PH sensor and the water and fertilizer filter screen while stirring water and fertilizer mixed liquid, measurement is accurate, blockage is avoided, and the use is convenient.

Owner:安徽省益丰生态农业科技有限公司

Water reducing agent production equipment capable of carrying out multi-stage filtration

InactiveCN110876901AFacilitates multiple filteringEasy to mix and produceRotary stirring mixersTransportation and packagingFiltrationProcess engineering

The invention relates to the technical field of water reducing agent production, and discloses water reducing agent production equipment capable of performing multi-stage filtration. The water reducing agent production equipment comprises a production tank; a transversely-arranged partition plate is fixedly arranged in the middle in the production tank, and the production tank is divided into a stirring cavity and a filtering cavity through the partition plate; a stirring mechanism is arranged in the stirring cavity, a feeding pipe is fixedly connected to one side of the upper side wall of thestirring cavity, an annular water pipe is fixedly connected to the upper portion in the stirring cavity, multiple evenly-distributed water spraying holes are formed in the inner annular side wall theannular water pipe, and a water inlet pipe is fixedly connected to one side of the outer annular side wall of the annular water pipe. The water reducing agent production equipment capable of performing multi-stage filtration can realize uniform water spraying, uniform heating, and stirring on water reducing agent raw materials to produce water reducing agents, and realize multi-stage filtration on produced water reducing agents, avoid discharge of residual particles of the raw materials in the produced water reducing agents, improve water reducing agent production quality, avoid raw materialwaste, and is convenient to use by people.

Owner:徐州巨龙新材料科技有限公司

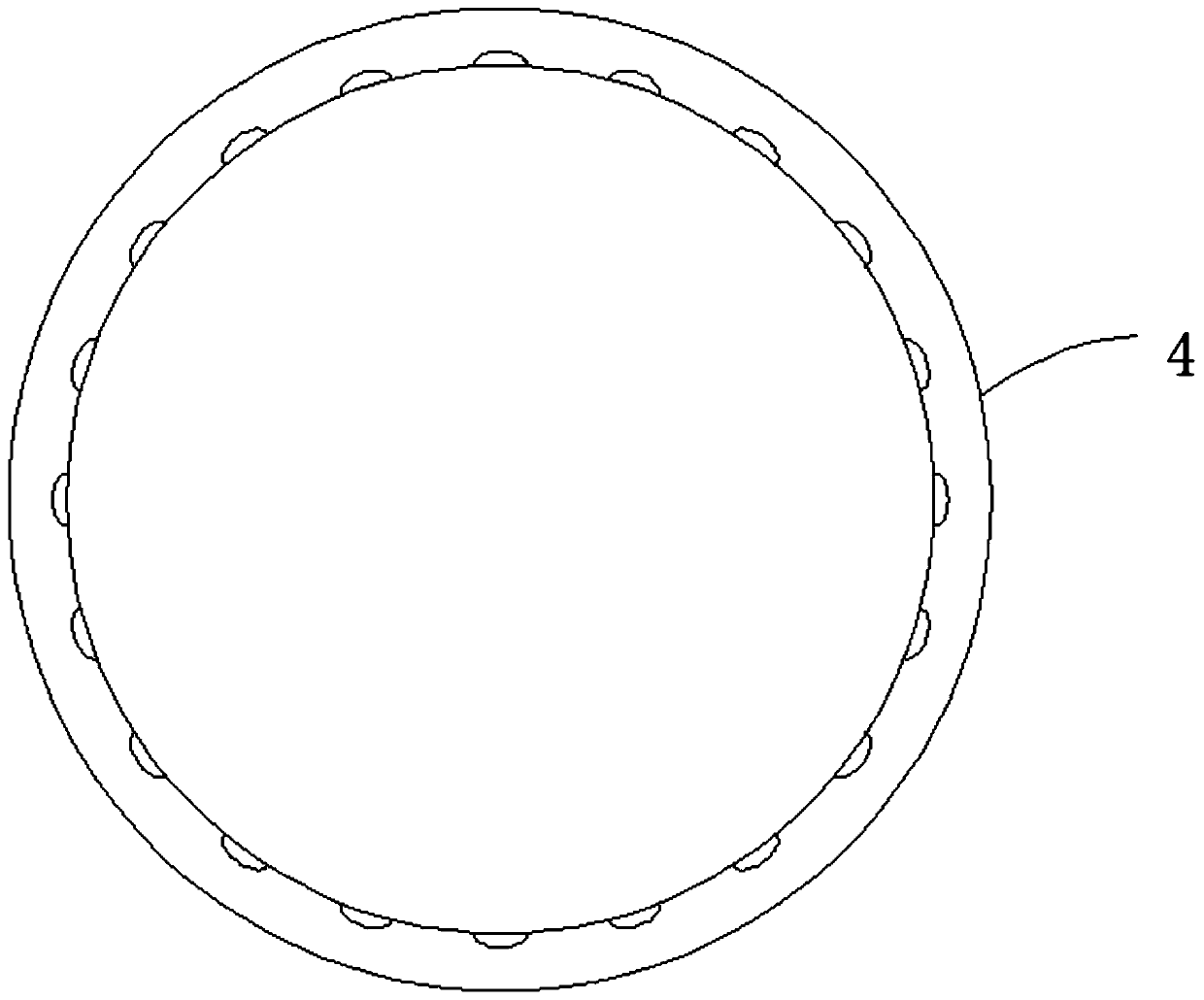

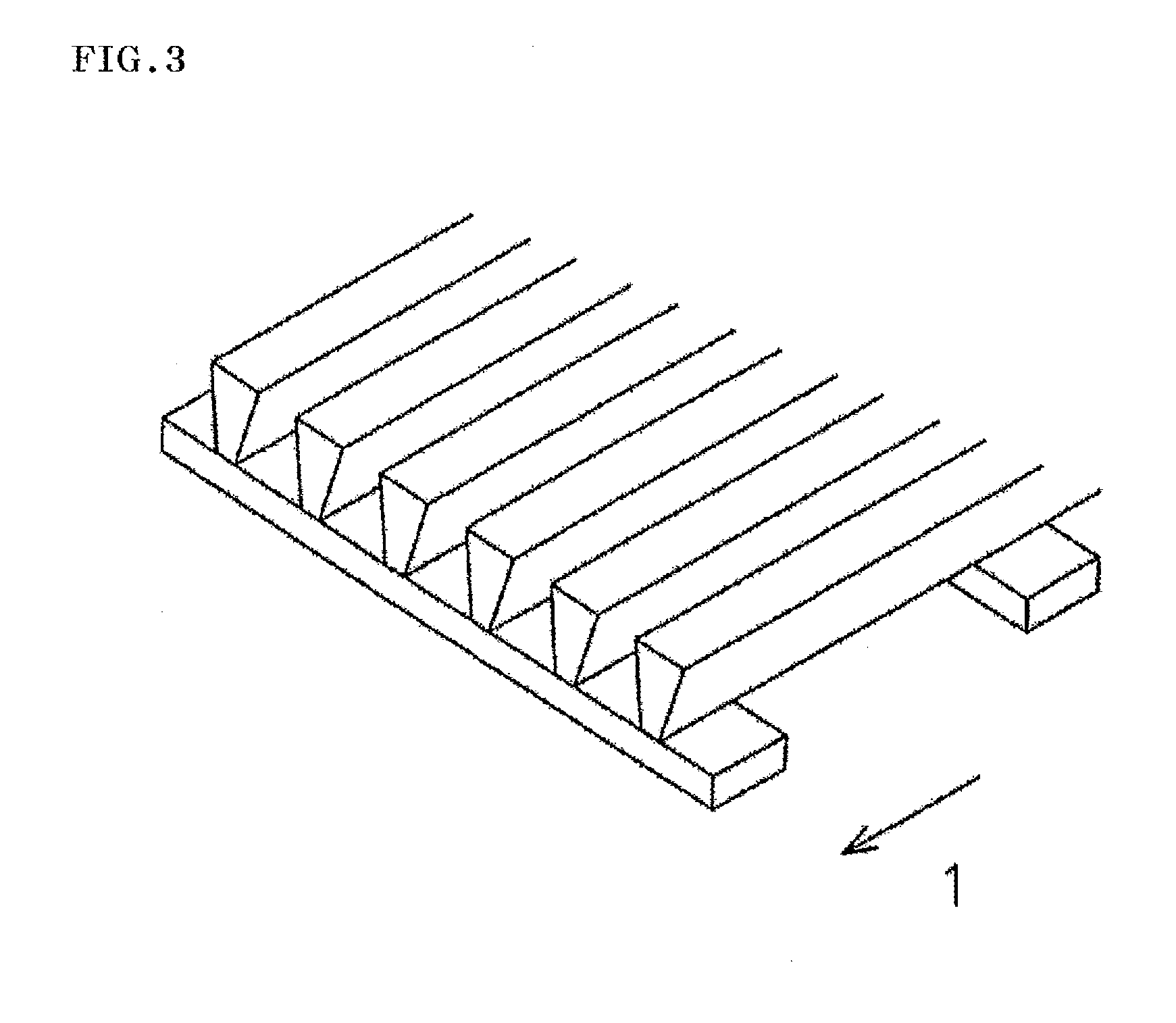

Rubber wet master batch producing method, rubber wet master batch, and rubber composition containing rubber wet master batch

ActiveUS20150247011A1High strengthPrevent degradationRotary stirring mixersSpecial tyresMasterbatchPolymer science

A method for producing a rubber wet master batch contains a coagulating step of mixing a slurry solution containing the filler and the dispersing solvent with the rubber latex solution, and coagulating the mixture, thereby producing a filler-containing rubber coagulation, and a heating step of using a uniaxial extruder to heat the filler-containing rubber coagulation to a temperature of 180 to 200 C, thereby dehydrating, drying and plasticizing the filler-containing rubber coagulation through a single step. The uniaxial extruder is an extruder having a screw, and an outer cylinder having an inner wall surface in which a slit is formed to be extended along the longitudinal direction of the outer cylinder (screw axial direction); and at least one portion of the inner wall surface of the outer cylinder is subjected to blasting treatment.

Owner:TOYO TIRE & RUBBER CO LTD

Sludge stirring tank

InactiveCN107983200AEasy to operateThe principle is simpleSludge treatmentTransportation and packagingHydraulic cylinderSludge

The invention discloses a sludge stirring tank. The sludge stirring tank comprises a cross beam, wherein a sludge tank is arranged below the cross beam; two stirring devices are symmetrically arrangedat the lower end of the cross beam; sliding blocks corresponding to the two stirring devices are arranged at the upper end of the cross beam in a sliding manner; a second motor is fixedly connected to one side, far away from each stirring device, of each of the two sliding blocks; output shafts of the two second motors are fixedly connected to the upper ends of the two stirring devices; a double-head hydraulic cylinder is arranged between the two sliding blocks and is fixedly connected to the upper end of the cross beam; a telescoping rod of the double-head hydraulic cylinder is fixedly connected to the two sliding blocks; and a limiting block which is fixed to the upper end of the cross beam is arranged at one side, far away from the double-head hydraulic cylinder, of each of the two sliding blocks. The sludge stirring tank is novel in structure; the two stirring devices can revolute in the sludge tank while rotating, and the stirring radius can be adjusted, so that the stirring canbe completely performed; and the sludge stirring tank is easy to popularize.

Owner:合肥挺泰环保科技有限公司

Environment-friendly sewage treatment equipment with separating function

InactiveCN107555562AFull mixing effectGood flocculation effectRotary stirring mixersMixer accessoriesFlocculationEngineering

The invention discloses environment-friendly sewage treatment equipment with a separating function, which comprises a treating shell, a partition board is fixedly connected to the internal of the treating shell, a first rotating shaft is arranged, above the partition board, in the treating shell, the first rotating shaft is vertically arranged, and the top end of the first rotating shaft extends upward, the top end of the first rotating shaft is fixedly connected with an output shaft of a first motor located on the upper side of the treating shell, a plurality of disturbing plates are fixedlyconnected onto the first rotating shaft, and a plurality of disturbing holes are uniformly formed in each disturbing plate. The environment-friendly sewage treatment equipment with the separating function has the beneficial effects that the disturbing holes in the disturbing plates are used for performing disturbing on sewage and a flocculating agent, so as to enable the sewage and the flocculating agent to be sufficiently mixed to improve the flocculation effect; after the flocculation is finished, a height adjusting device is used for declining a separating device, a second separating plate,matched with a horizontal threaded rod, moves leftward, so as to stagger a first through hole and a second through hole, and then the separating device separates the sewage from the flocculating agent, thus realizing the separation.

Owner:苏州雨谦工品科技有限公司

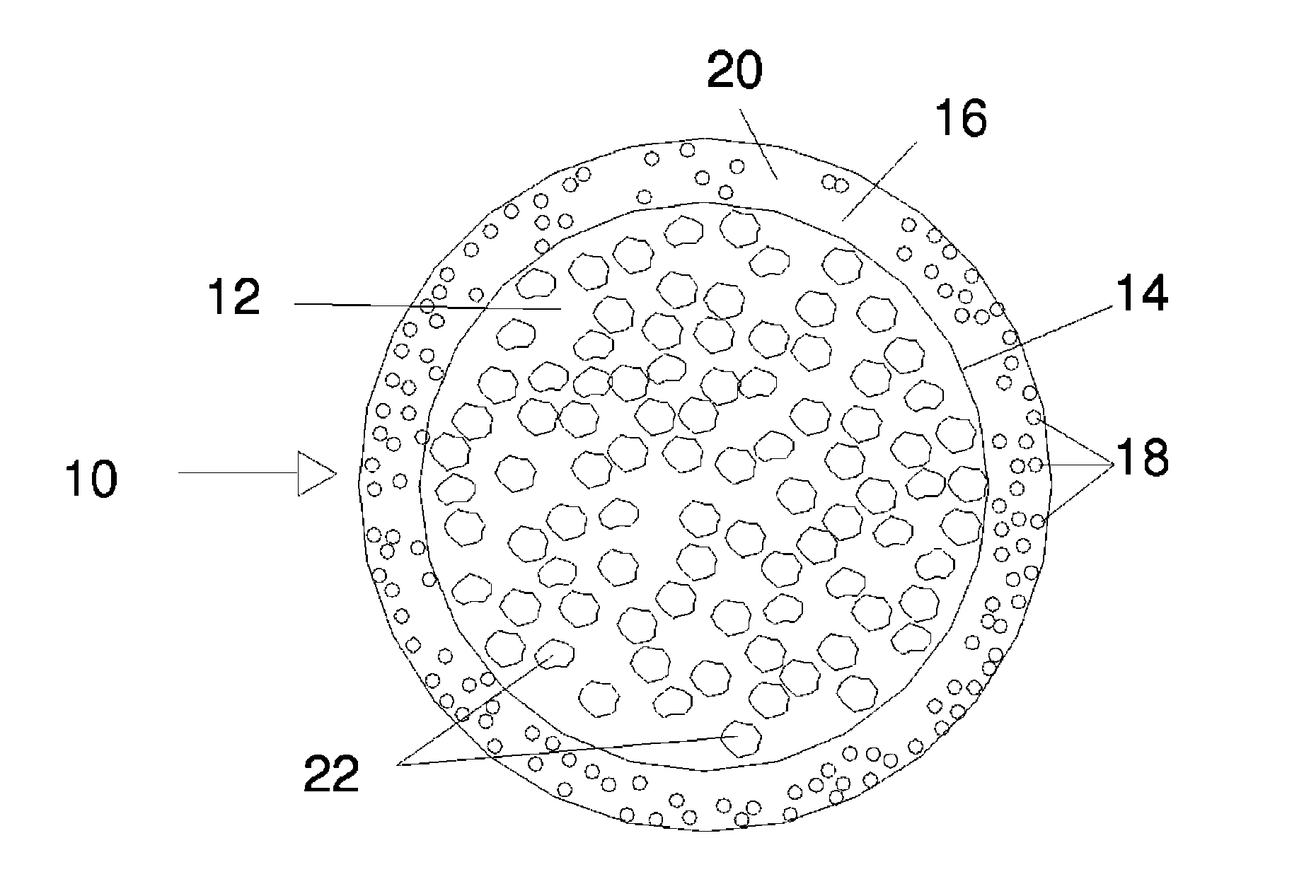

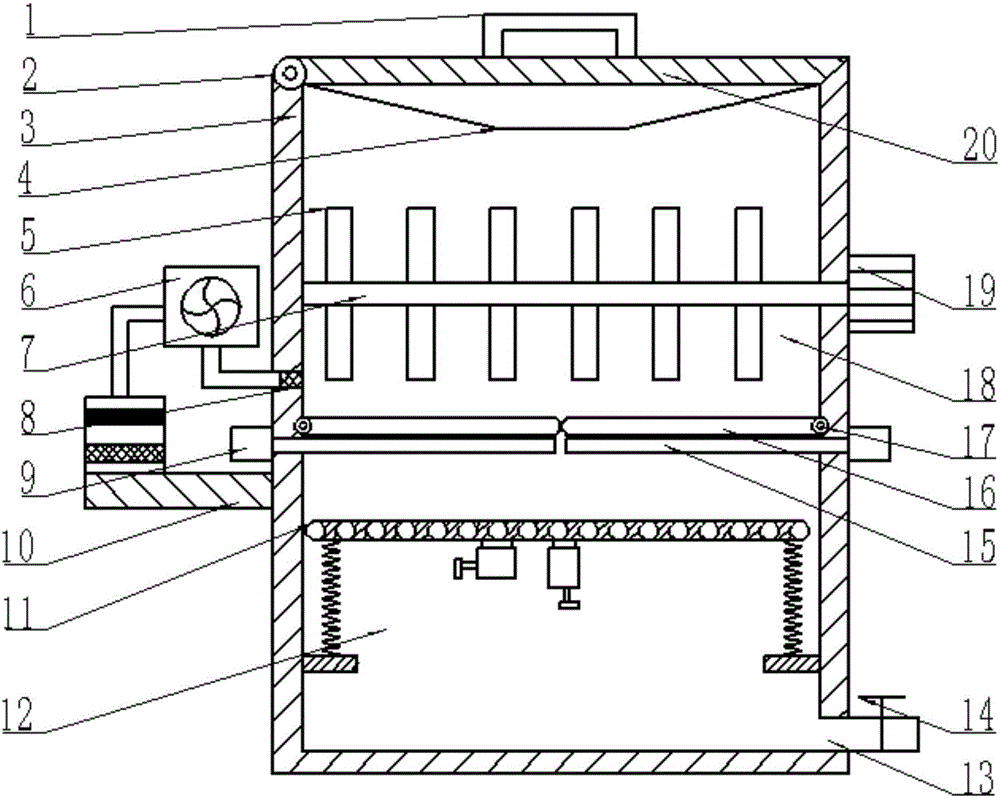

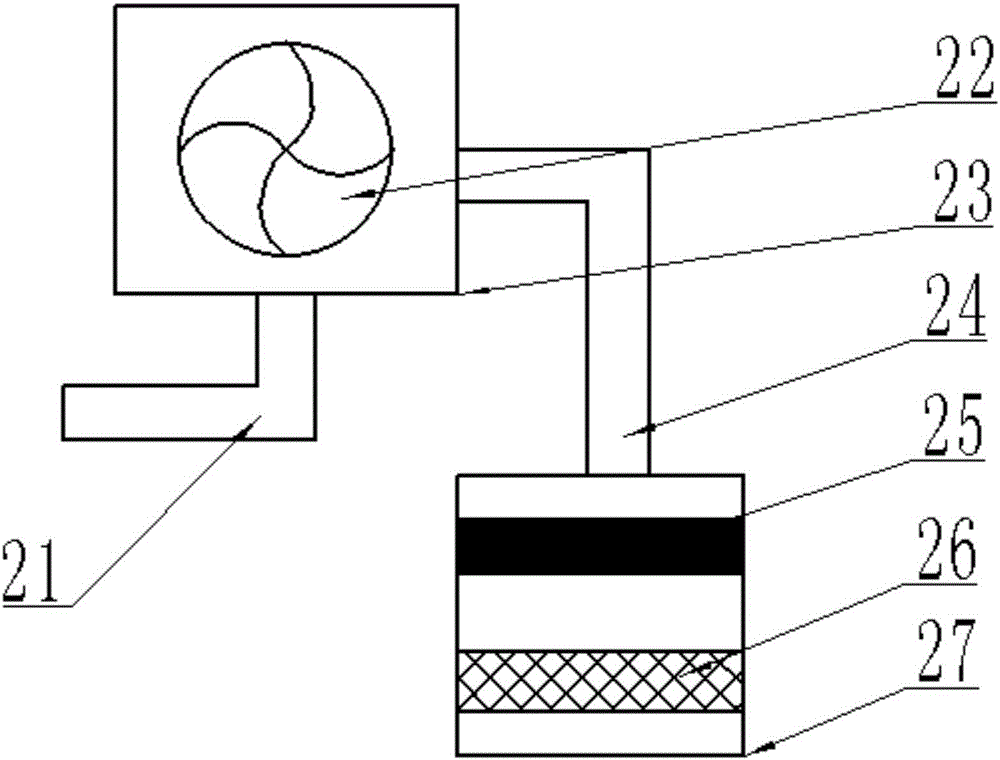

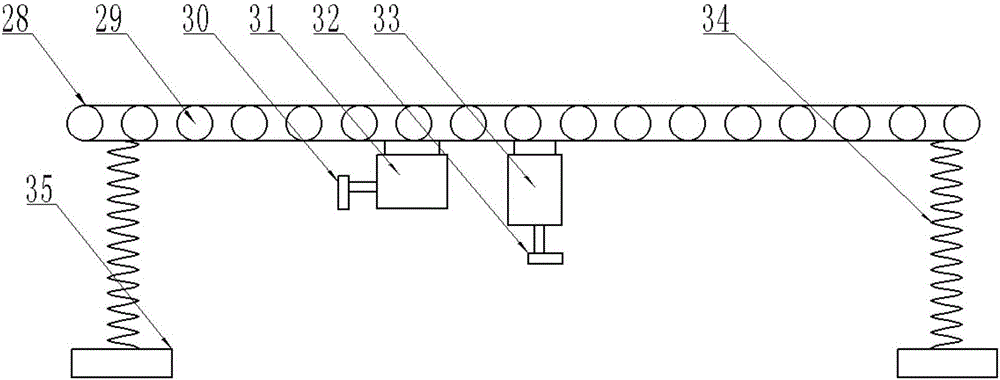

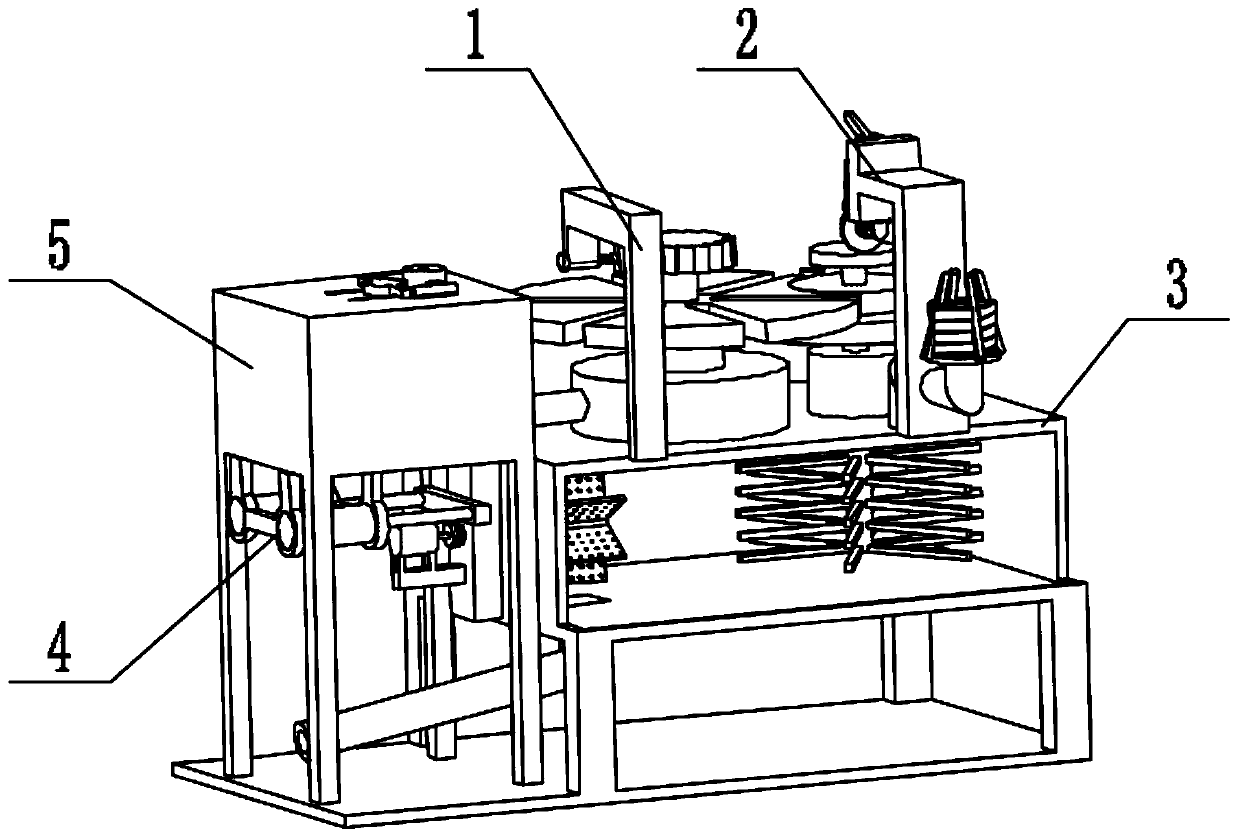

Medicine mixing and screening device capable of achieving dehumidification and iron removal

InactiveCN106513308AAvoid collision damageEasy to openSievingTransportation and packagingIron removalEngineering

The invention provides a medicine mixing and screening device capable of achieving dehumidification and iron removal. The medicine mixing and screening device comprises a box body and a box cover, wherein a stirring chamber, a storage chamber, a feed inlet, a stirring and mixing device, a dehumidification device, an iron removal plate and a vibration screening device are arranged on the box body; the stirring and mixing device comprises stirring rods, a stirring shaft and a stirring motor; a placing plate is arranged at the lower end of the dehumidification device; the dehumidification device is placed on the placing plate; the dehumidification device comprises an air inlet pipe, an air blower, an air blowing channel and a filter box; the iron removal plate is arranged at the lower end of the stirring and mixing device; second hinges are arranged at the two ends of the iron removal plate; the iron removal plate is fixed to the box body through the second hinges; a telescopic shaft is arranged at the lower end of the iron removal plate; the vibration screening device comprises fixed plates, a vibration screen, a first motor, a second motor and springs; a handle and a first hinge are arranged on the box cover; and the box cover is connected on the box body through the first hinge. According to the medicine mixing and screening device, the maintenance is facilitated, the mixing is thorough, dehumidification and iron removal can be achieved, and medicine particles can be screened.

Owner:郑州吉音动漫科技有限公司

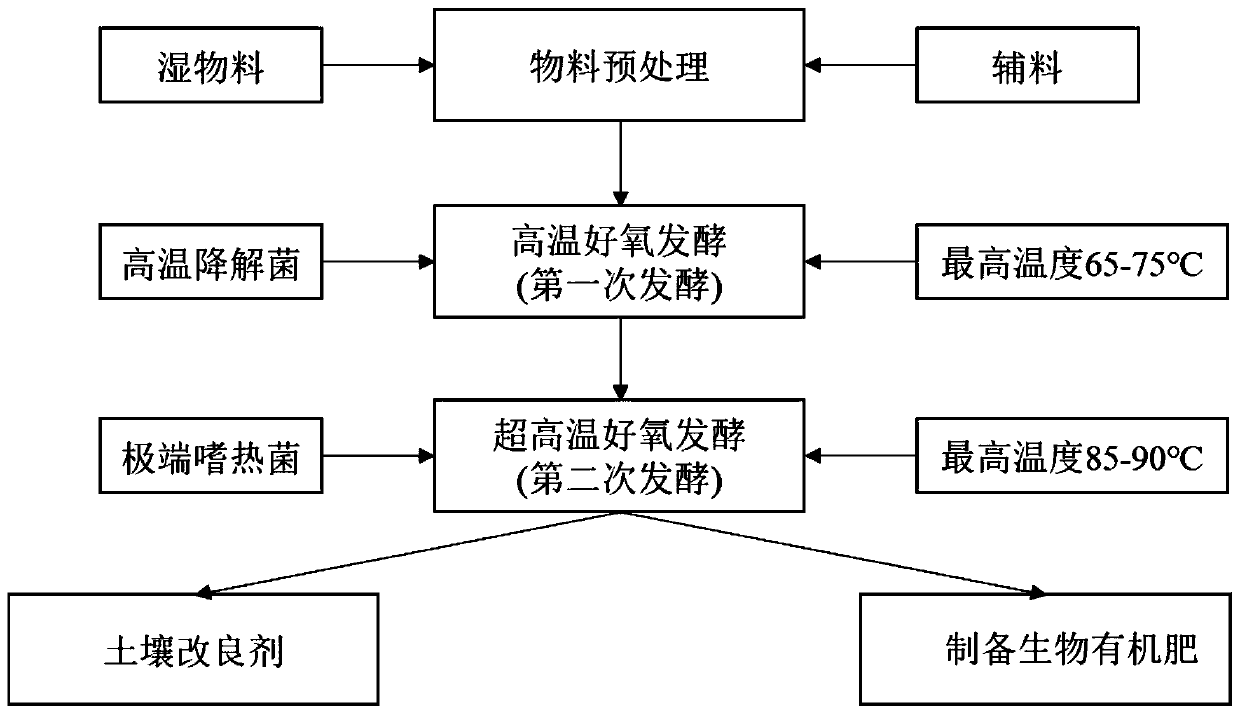

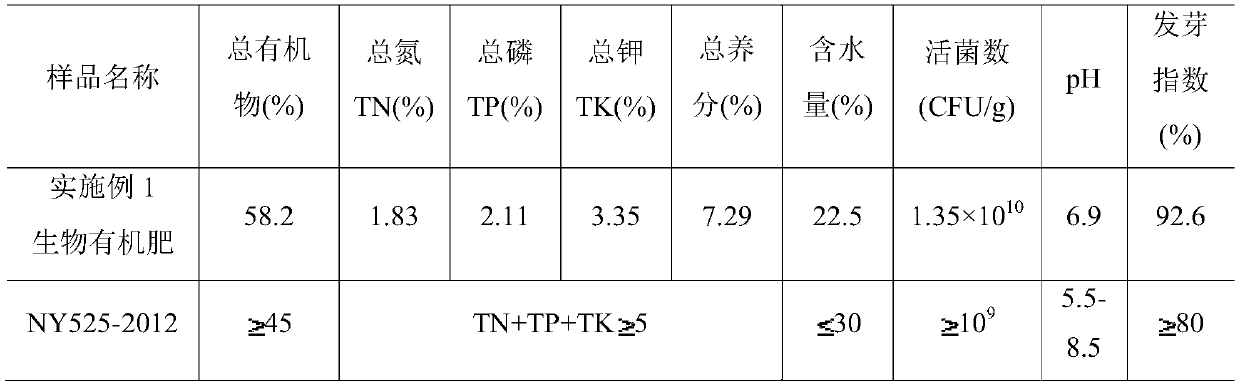

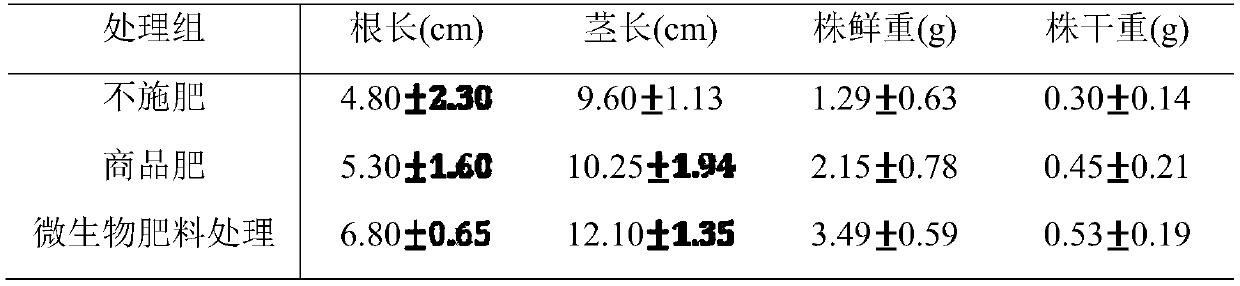

Method for treating organic solid waste and bio-organic fertilizer prepared by using method

InactiveCN110550987AHigh feasibilityIncrease productionBio-organic fraction processingSewage/sludge fertilisersExtreme thermophileEconomic benefits

The invention relates to a method for treating organic solid waste and bio-organic fertilizer prepared by using the method. The method comprises the steps: (1) mixing the wet material of the organic solid waste with crushed auxiliary materials so as to obtain a mixture with a water content of 45-55%; (2) inoculating high-temperature degrading bacteria to the mixture obtained in the step (1), performing ventilation on the mixture so as to ensure a fully aerobic environment of the mixture, performing intermittent turning-mixing treatment, and maintaining the temperature of the mixture at 65-75 DEG C for high-temperature fermentation for 2-6 days so as to obtain an intermediate material; and (3) inoculating extreme thermophiles to the intermediate material obtained in the step (2), performingeven turning, performing ventilation on the intermediate material so as to ensure a fully aerobic environment of the material, maintaining the highest temperature of the intermediate material at 85-90 DEG C continuously for 2-6 days, and performing static fermentation on the material for 18-21 days. Compared with the prior art, the method has the advantages of high feasibility, simple operation,a short production cycle, high output and stable product quality, and a win-win situation of environmental protection and economic benefits is achieved.

Owner:TONGJI UNIV

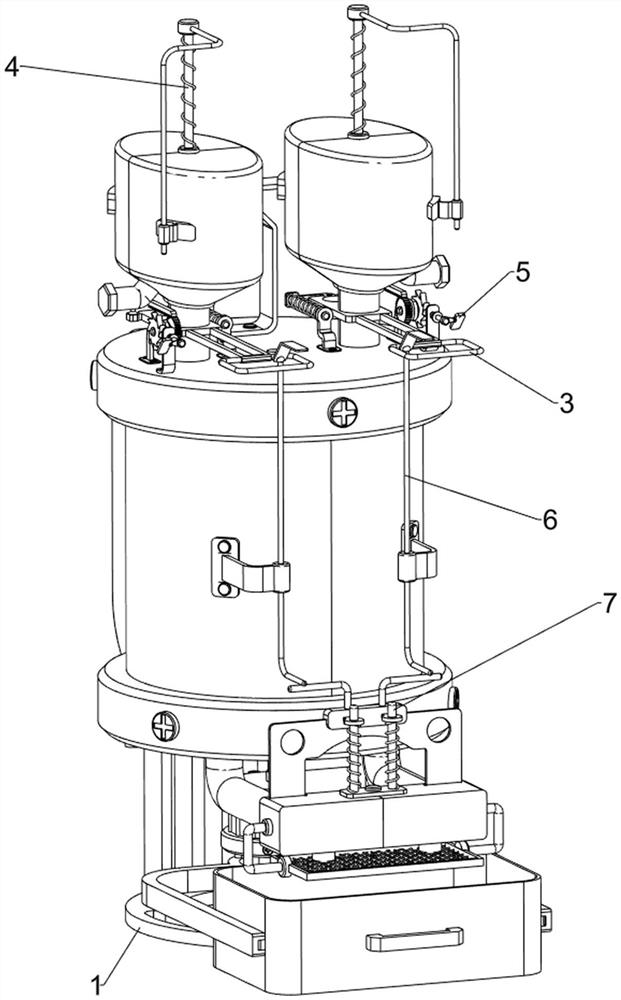

Pig feed stirring and mixing device

InactiveCN112191129AStir wellSimple structureFeeding-stuffTransportation and packagingControl engineeringElectric machinery

The invention provides a pig feed stirring and mixing device, which comprises a box body, a lifting clamping mechanism, a roll cutting mechanism, a first butt joint pipe, a second butt joint pipe anda sewer trap, wherein stabilizing blocks are fixedly installed at the positions, close to the top and the bottom, of the four corners of the inner wall of a stabilizing frame, the stabilizing frame fixes a mixing barrel into the stabilizing frame through the multiple stabilizing blocks, a barrel cover is fixedly installed at the top of the mixing barrel, a plurality of feeding pipes are evenly andfixedly installed at the bottom of a feeding hopper, the feeding hopper is fixed to the barrel cover through the feeding pipes and communicates with the mixing barrel, and a rotary stirring mechanismand a sweeping gathering mechanism for feed are arranged in the mixing barrel. According to the invention, a main shaft drives a rotary stirring mechanism and a sweeping gathering mechanism to operate at the same time, and clockwise and anticlockwise stirring is achieved through forward and reverse rotation of a motor, so that stirring is more sufficient; and all procedures are completed throughoperation of only one three-phase motor, so that the structure is simple, the manufacturing cost is low, and noise generated when equipment operates is reduced.

Owner:成都有一说一科技有限公司

Coating proportioning and stirring equipment

InactiveCN110787671AAdjust stirring speedEnsure safetyTransportation and packagingRotary stirring mixersProcess engineeringMachine

The invention relates to stirring equipment, in particular to coating proportioning and stirring equipment. The coating proportioning and stirring equipment comprises a proportioning and stirring mechanism, a safe driving mechanism, a machine body mechanism, a filtering mechanism and a coating supplementing mechanism; the coating proportioning and stirring equipment can be used for proportioning and stirring coating; the coating proportioning and stirring equipment is capable of adjusting stirring speed, can ensure safe operation of the stirring process, can be used for filtering while discharging, and can control whether coating is supplemented or not; the proportioning and stirring mechanism is connected with the machine body mechanism, the proportioning and stirring mechanism is connected with the safe driving mechanism, the safe driving mechanism is connected with the machine body mechanism, the machine body mechanism is connected with the filtering mechanism, the filtering mechanism is connected with the coating supplementing mechanism, and the coating supplementing mechanism is connected with the machine body mechanism.

Owner:李春艳

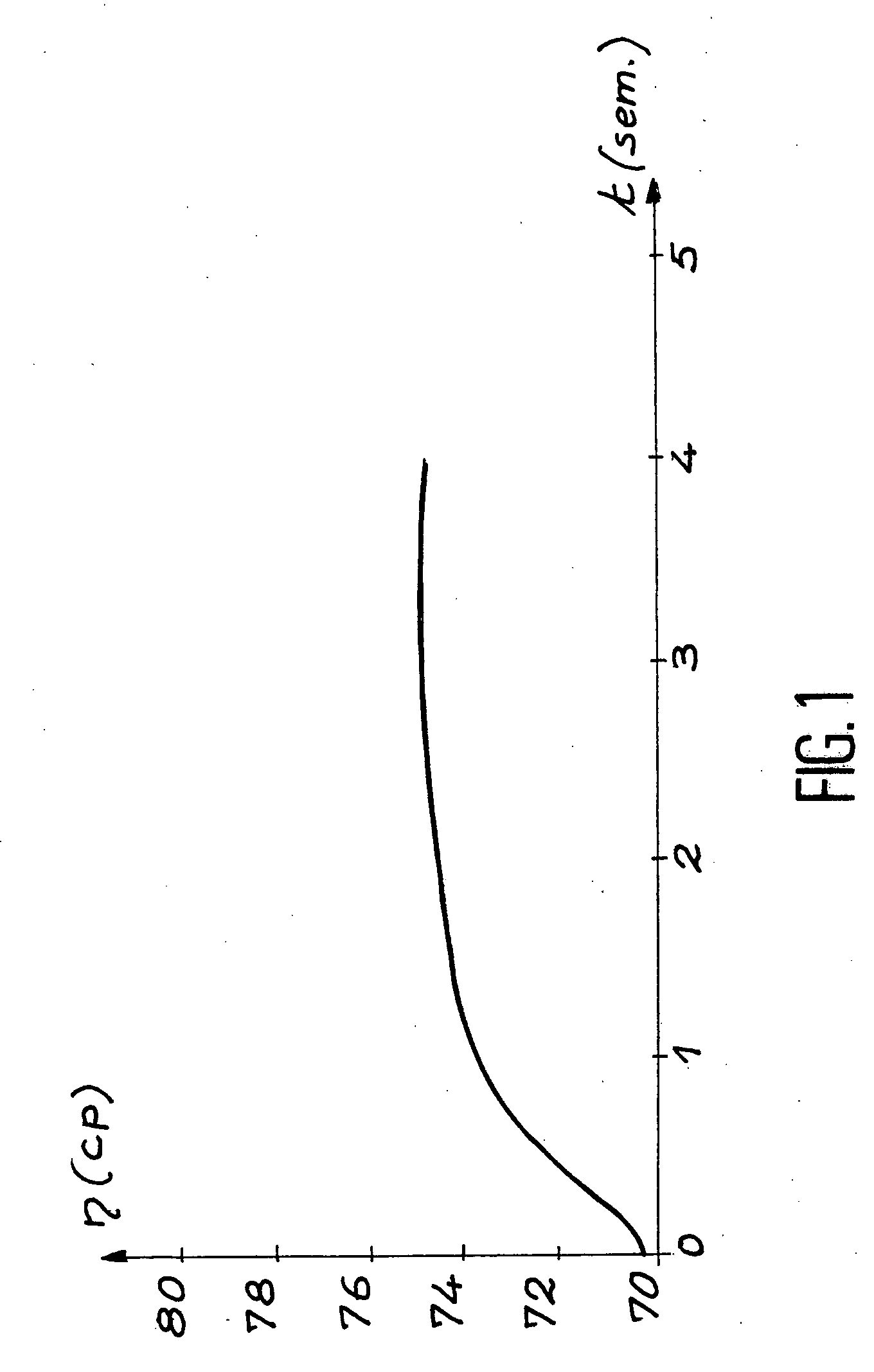

Method of preparing a stable lead zircon-titanate sol and method for preparing films based on same

InactiveUS20040014820A1Shorten the construction periodOther chemical processesZirconium compoundsLead zirconate titanateFilm base

The invention relates to a method of preparing a sol of lead zirconium titanate, known as PZT, of formula PbZrxTi(1-x)O3 with 0.45<=x<=0.7, comprising the following successive steps: (a) preparing a concentrated sol in a diol, the said sol comprising a titanium-based precursor, a zirconium-based precursor, and a lead-based precursor; (b) placing the said concentrated sol at ambient temperature without agitation, until a sol is obtained having a constant viscosity as a function of time; (c) diluting the sol obtained in (b) with a solvent compatible with the diol used in step (a). The invention likewise relates to a method of preparing PZT-based films from the said stable sol. Application of the films to the electronics field.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

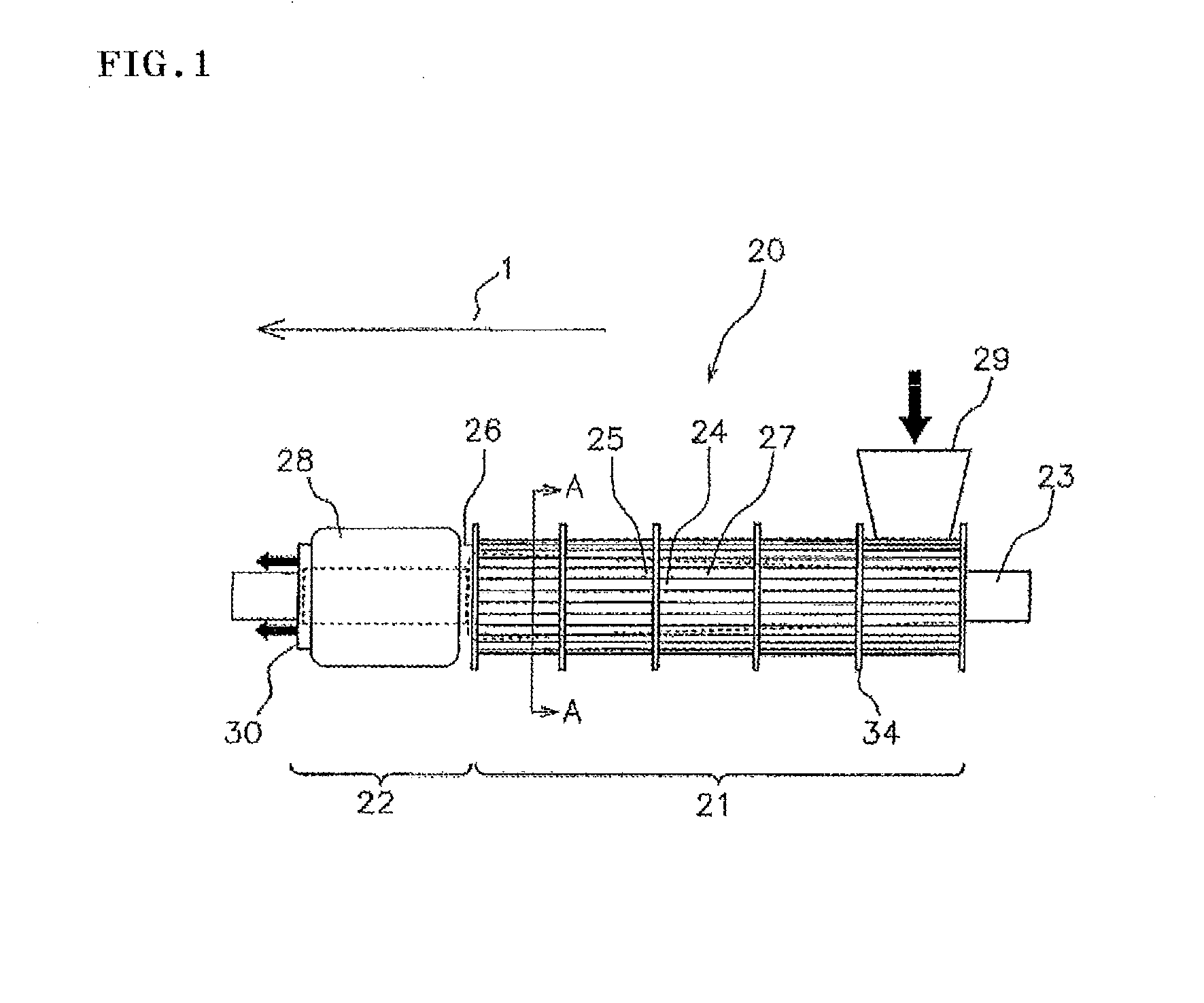

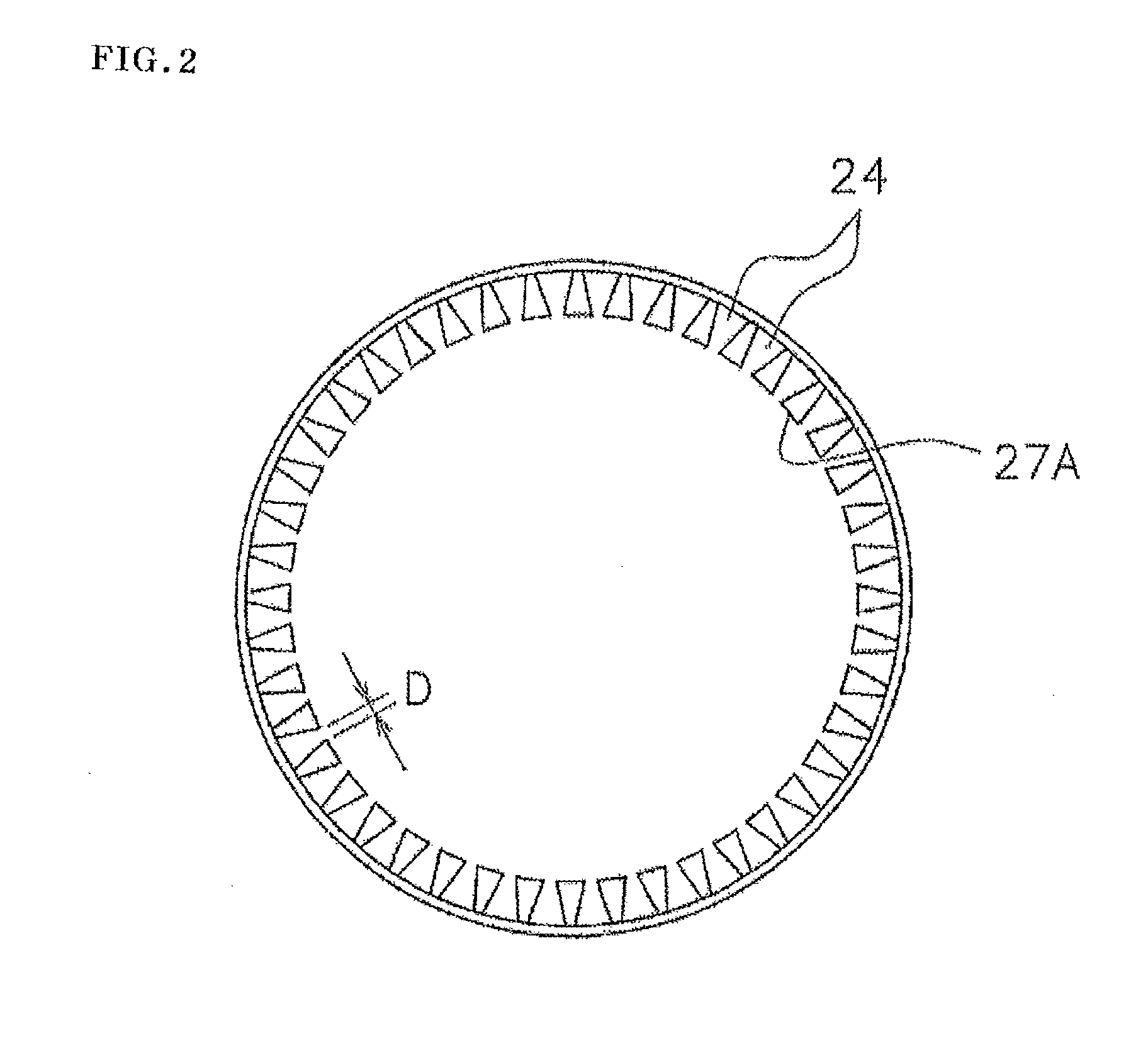

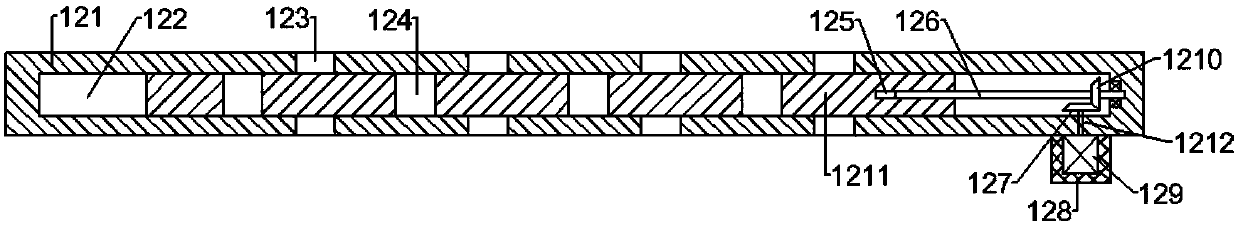

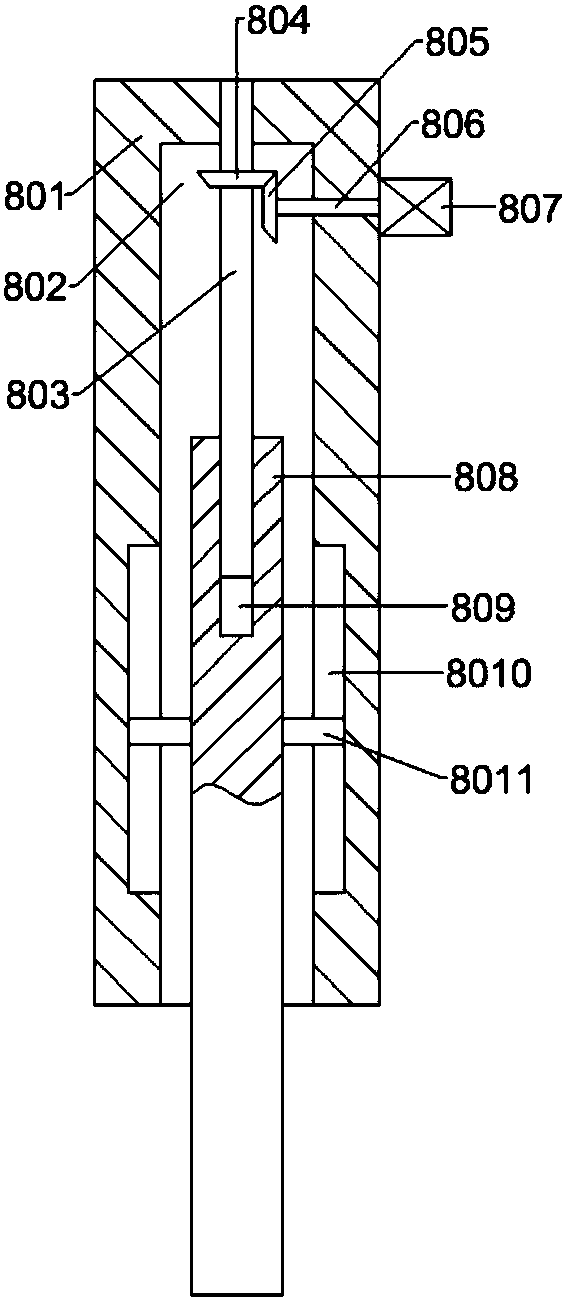

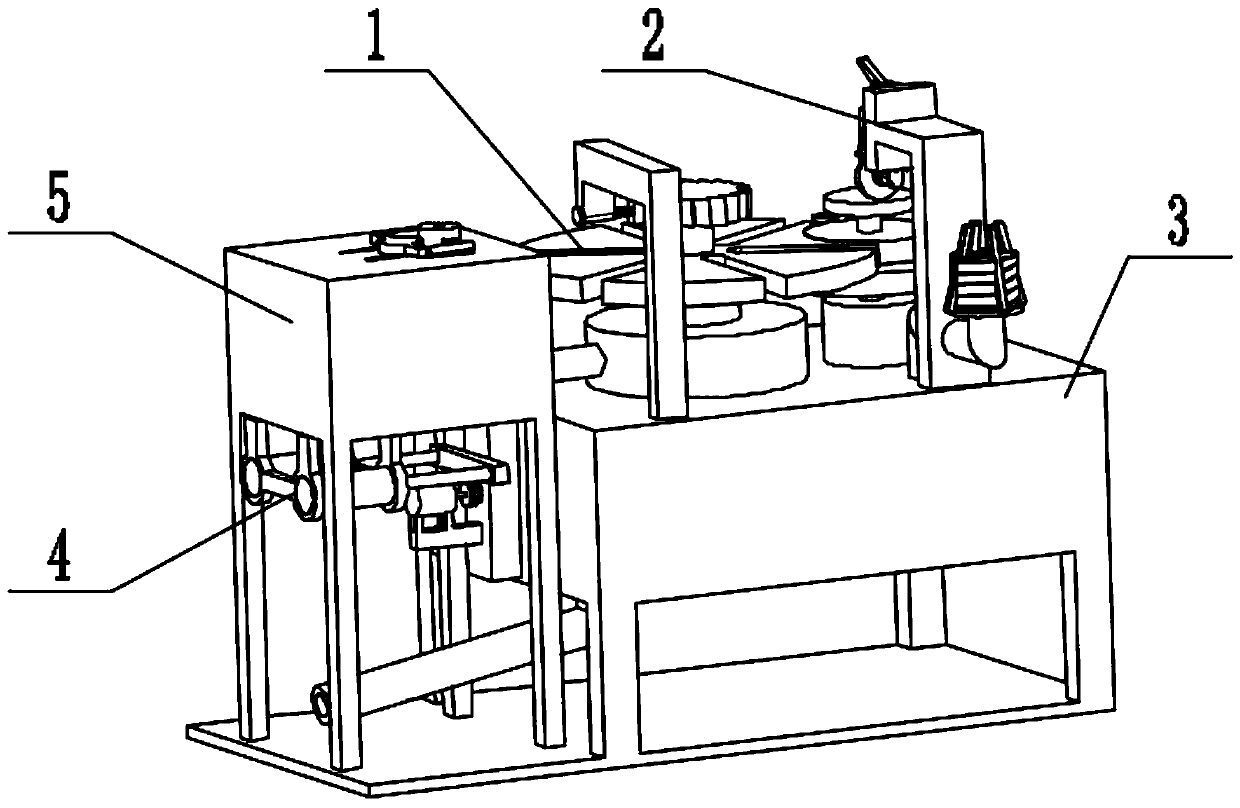

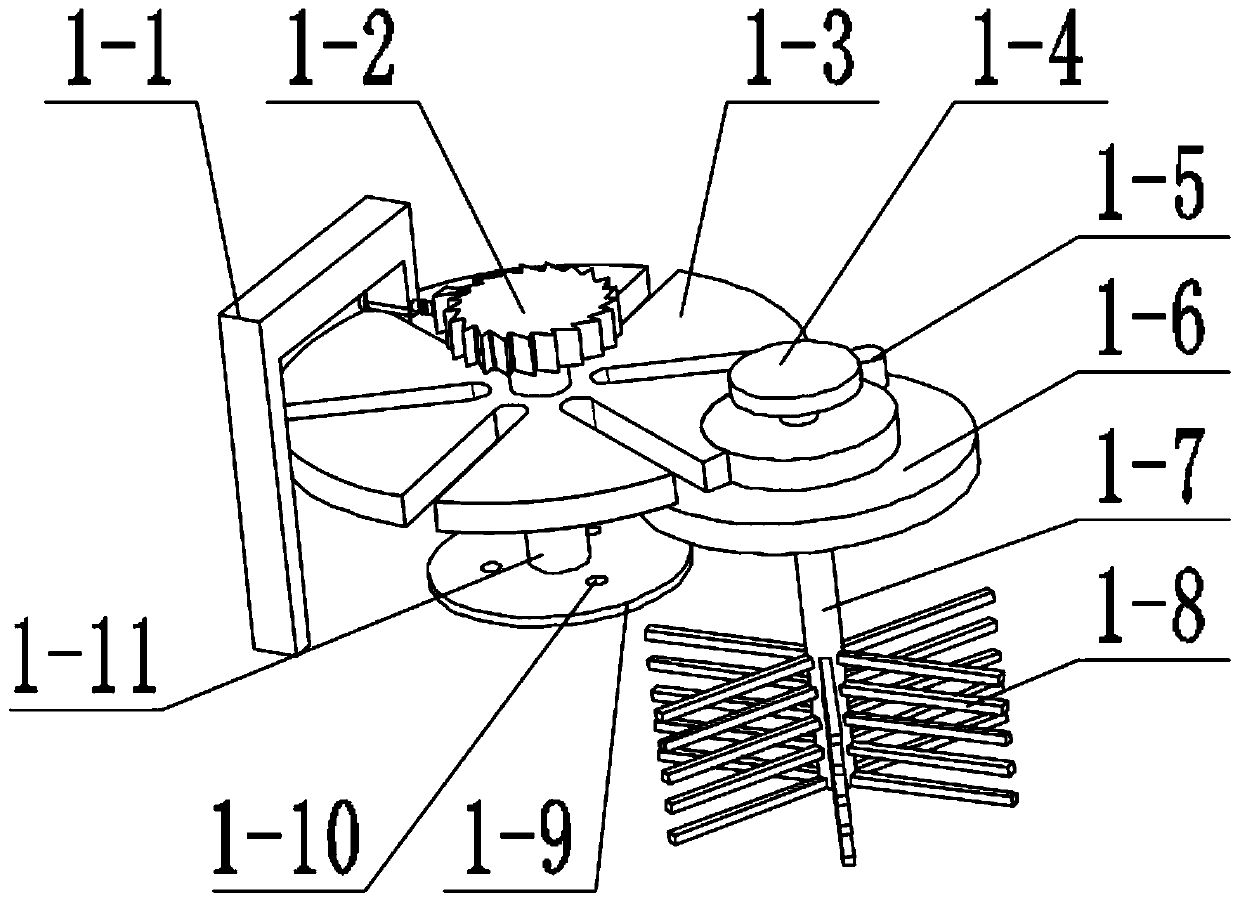

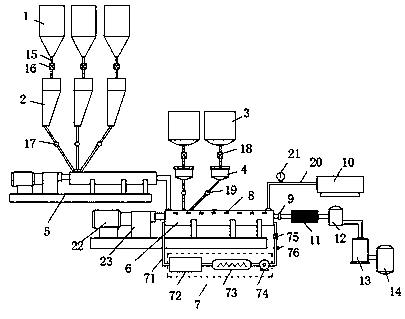

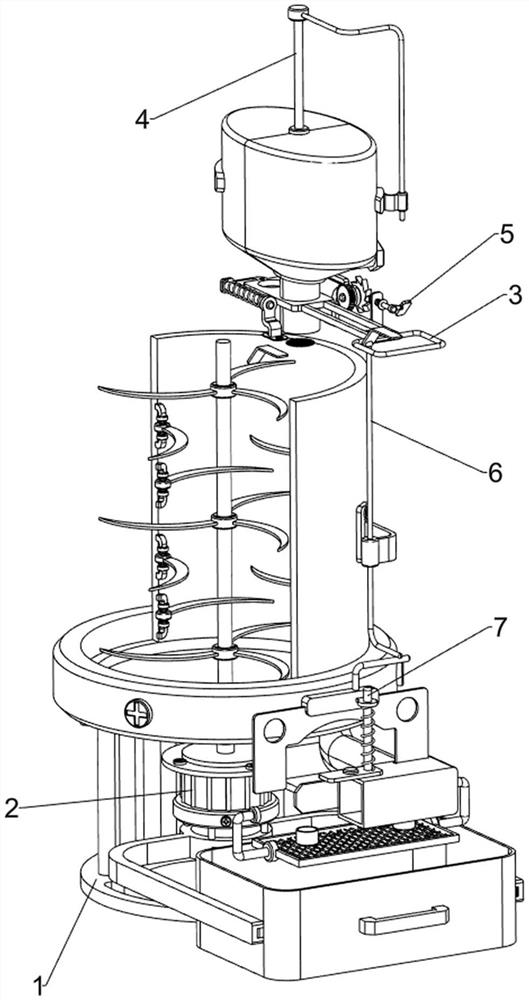

Double-spiral-shaft continuous homogenization system for lithium battery slurry material

PendingCN110052209AReduce the difficulty of mixingEasy to adjust pulping temperatureLiquid degasificationElectrode manufacturing processesFiltrationLiquid storage tank

The invention discloses a double-spiral-shaft continuous homogenization system for a lithium battery slurry material in the technical field of lithium battery slurry material production. The system comprises powder material storage bins, liquid storage tanks, powder material weight loss feeders, liquid metering feeding devices, a premixing conveyor, a double-spiral mixer, a slurry material iron-removal filter, a homogenizer and a slurry material defoaming treatment tank, wherein an auxiliary material feeding port and an exhaust port are formed in the double-spiral mixer; a cooling unit is connected to the outside of the double-spiral mixer; thermocouples are uniformly arranged inside the double-spiral mixer; the thermocouples are controlled by a controller; an outlet of the buffer tank isconnected with the homogenizer; and an outlet of the homogenizer is connected with the slurry material defoaming treatment tank, so that the slurry material mixing difficulty is low, and the service life of the equipment is effectively prolonged; and after iron removal by filtration and the slurry material reaches the buffer tank, slurry material vacuum defoaming and further sol are carried out, so that a binder which cannot be completely dissolved can continue to be fully dissolved, and the required fineness, solid content and viscosity of the slurry material are achieved.

Owner:WUXI LINGOOD MACHINERY TECH

Coating production systems and methods with ultrasonic dispersion and active cooling

ActiveUS20050117447A1Shaking/oscillating/vibrating mixersOther chemical processesThermal energyActive cooling

Coating production systems and methods which include ultrasonic dispersion and active cooling. The system includes a mixing reservoir and an ultrasonic disperser for ultrasonically dispersing an additive with another coating component within the mixing reservoir. The system also includes a heat exchanger in communication with the mixing reservoir to receive a mixture of the additive and another coating component from the mixing reservoir. The mixture is cooled by thermal energy transfer from the mixture to the heat exchanger. The cooled mixture is returned to the mixing reservoir.

Owner:THE BOEING CO

Brake and clutch plate production raw material efficient mixing device

InactiveCN106861522AImprove the mixing effectEasy to take awayRotary stirring mixersTransportation and packagingEngineeringMixing effect

The invention belongs to the technical field of brake and clutch plate production and relates to a brake and clutch plate production raw material efficient mixing device. The device can be simply operated, has good mixing effects and can be used for production of low-cost brake and clutch plates. The device comprises a bottom plate, support legs, a material receiving frame, a discharge device and a first stirring device. The top of the bottom plate are provided with support legs and the material receiving frame. The support legs are located in the left side of the material receiving frame. The tops of the support legs are provided with the discharge device. The discharge device is provided with the first stirring device. Through multiple raw material stirring processes, mixing effects are very high. The device utilizes a motor for driving and saves energy consumption.

Owner:刘晓富

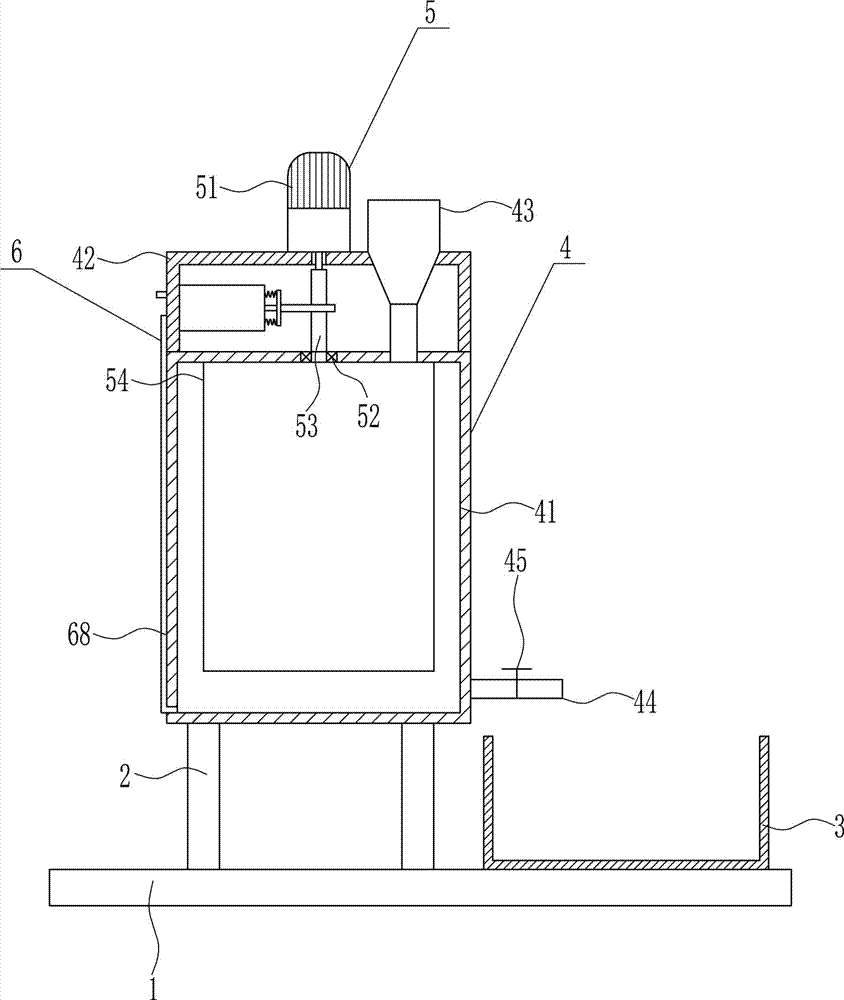

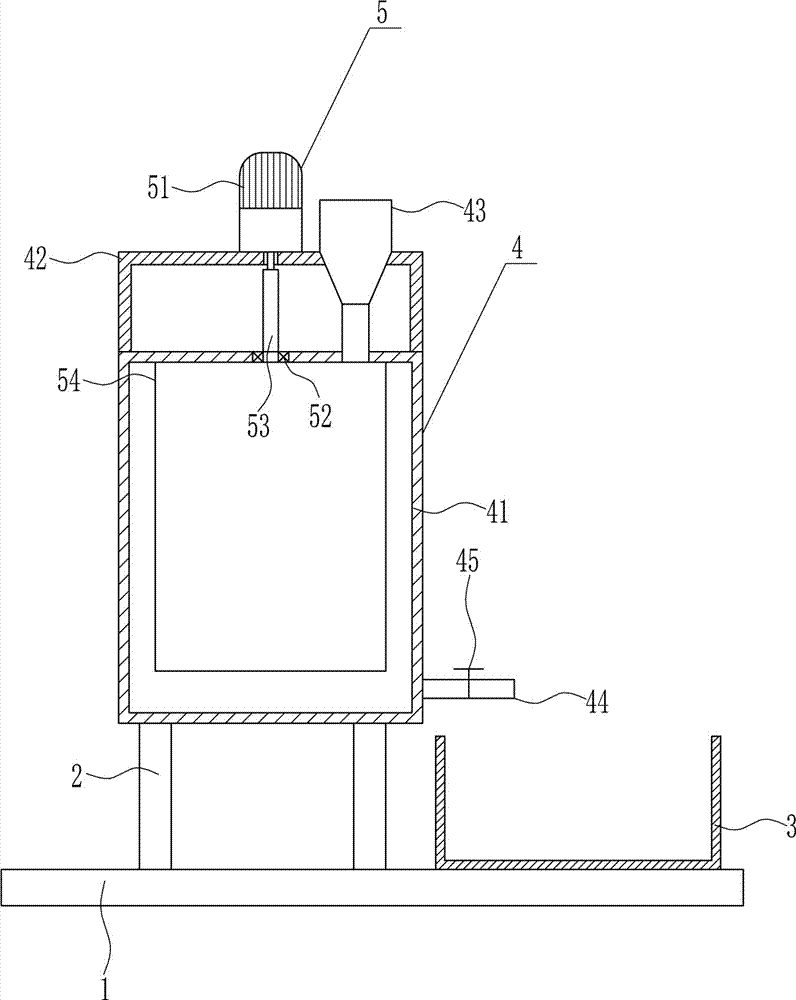

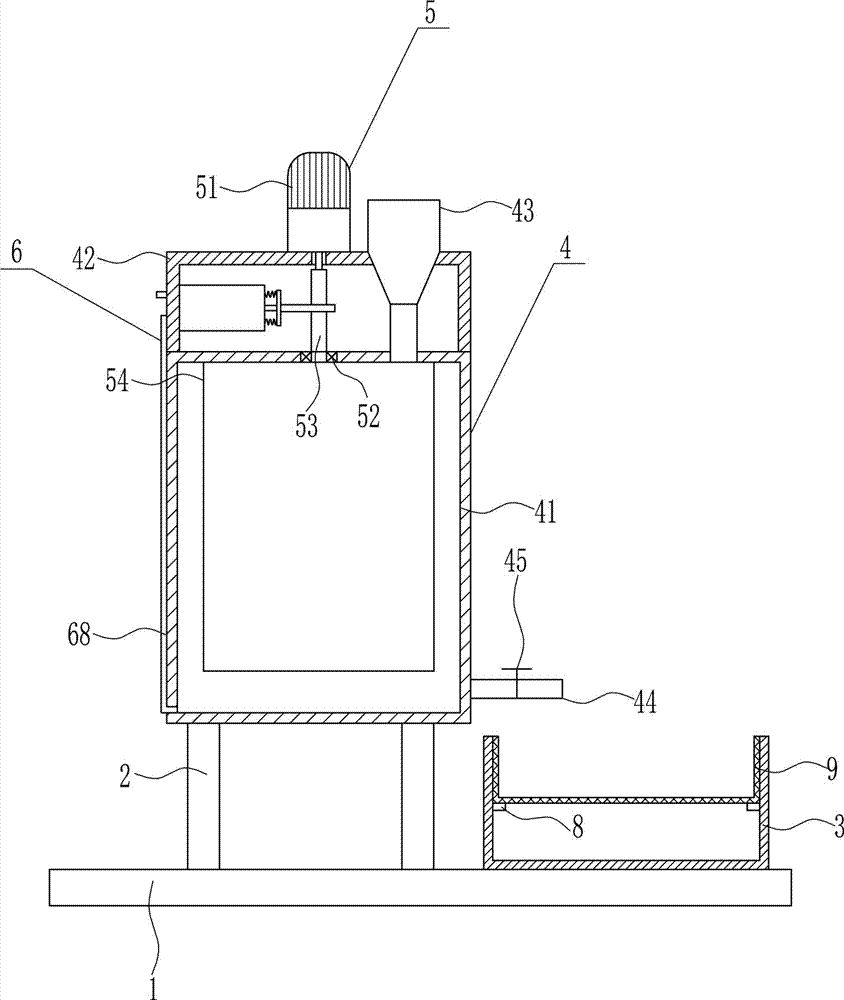

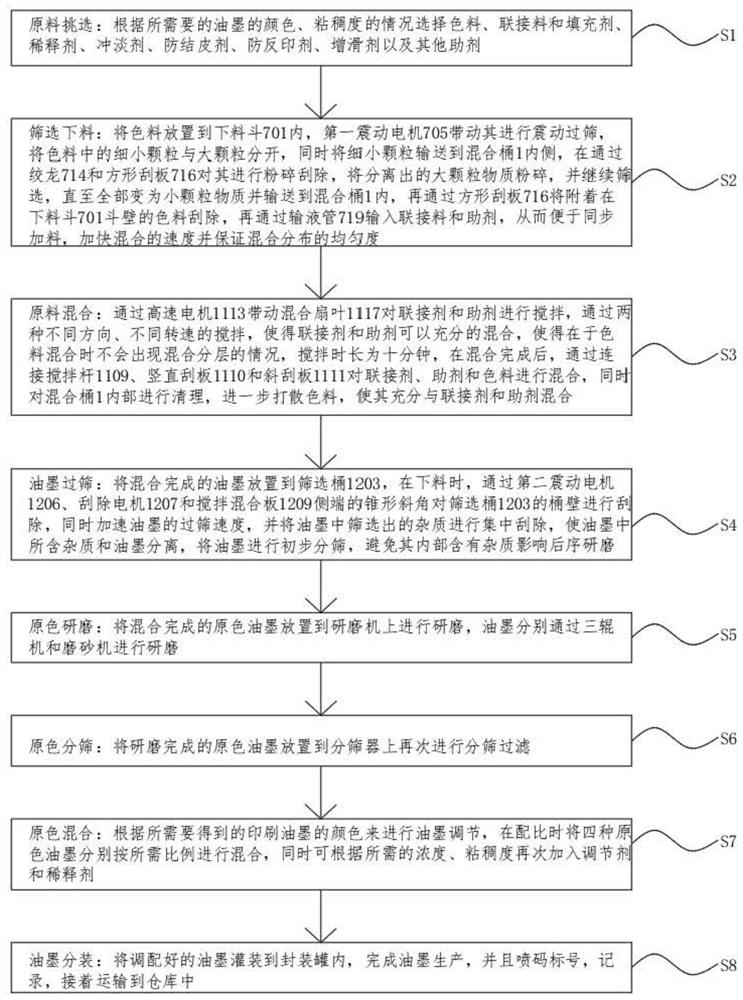

Preparation method of uniformly distributed ink for color printing

InactiveCN112473508AScientific and reasonable structureSafe and convenientRotary stirring mixersTransportation and packagingColor printingEngineering

The invention discloses a preparation method of uniformly distributed ink for color printing. A blanking hopper is placed on the inner side of a feeding port, hollow supporting blocks are welded to the two ends of the blanking hopper, first vibration springs are welded to the bottom ends of the hollow supporting blocks, one end of the blanking hopper is connected with a first vibration motor, anda fine screen is clamped to the inner side of the blanking hopper, a lifting motor is installed at the top end of a fixed installation frame, a linkage gear is connected with an auger in a welded modethrough a linkage rod, a square scraping plate is placed on the inner side of the blanking hopper, and pigment placed in the blanking hopper is screened and blanked through the vibration springs andthe vibration motor, therefore the pigment is filtered, and meanwhile lifting smashing is conducted through the auger and a lifting supporting plate, and the situation that in the blanking process, large-particle pigment blocks meshes is avoided, pigment particles become small and accordingly are more effectively mixed with a solvent, the pigment is scraped off through a scraper blade, and the situation that due to one-time large-amount blanking, uneven mixing is caused is avoided.

Owner:张钰

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com