Method for treating organic solid waste and bio-organic fertilizer prepared by using method

A technology for organic solids and wastes, applied in the field of bio-organic fertilizers, can solve problems such as failure to function, limited degradation efficiency, and degradation efficiency of organic matter in the early stage of incomplete decomposition, so as to reduce energy consumption for heating up, and the method is efficient throughout the process and avoids mutual effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

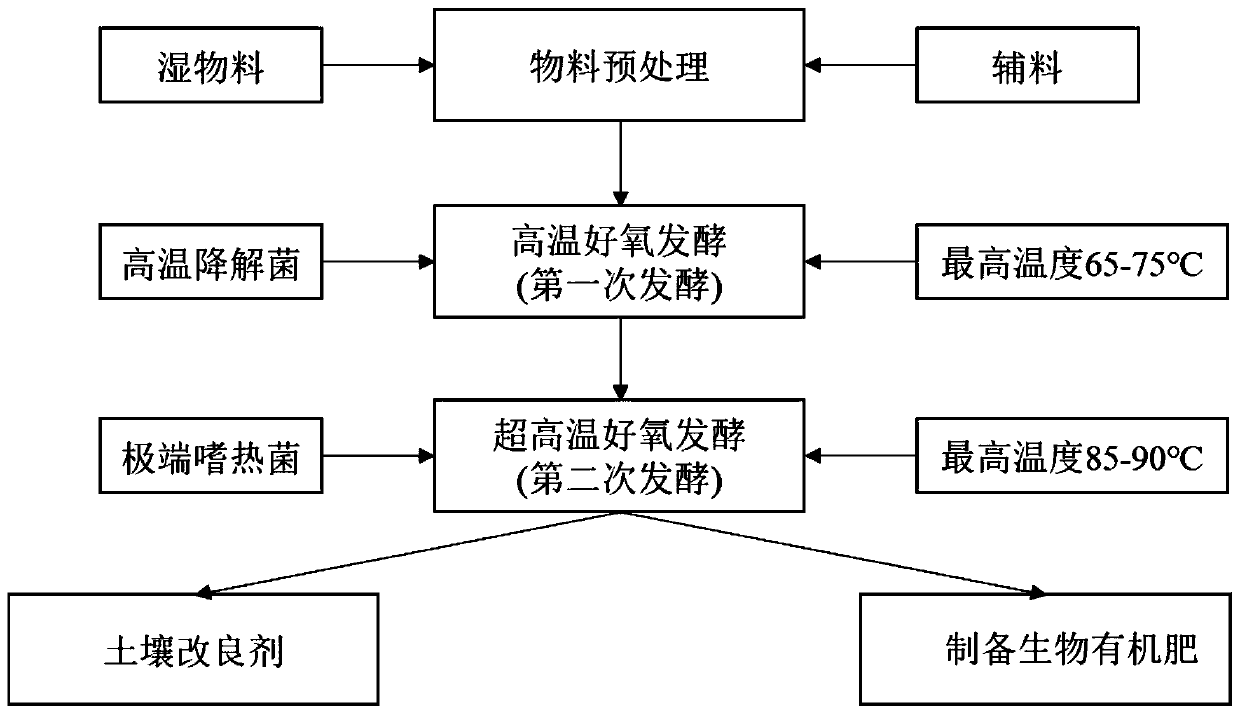

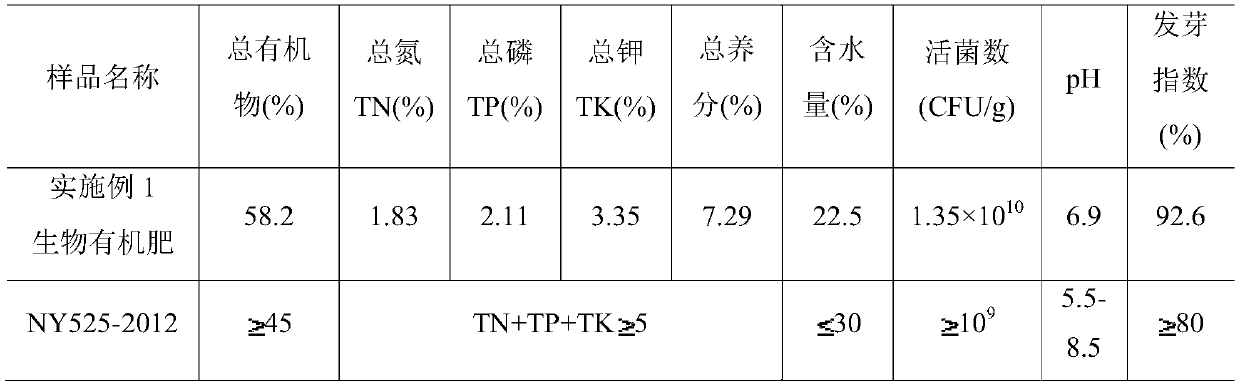

[0039] This embodiment is a method for treating organic solid waste, the process flow is as follows figure 1 As shown, Bacillus subtilis, white rot fungi, and Aspergillus niger mixed strains were used for primary high-temperature fermentation, and the extreme thermophile Thermus thermophilus was used as the inoculum for the secondary ultra-high temperature fermentation.

[0040] Specific steps are as follows:

[0041] (1) Material pretreatment:

[0042] The dry sludge (moisture content 49.7%) wet material and crushed wheat straw (30 mesh) auxiliary materials were mixed according to the weight ratio of 20:4, and the final water content of the mixed material was adjusted to 55%.

[0043] (2) High temperature aerobic fermentation (first fermentation):

[0044] The mixed material obtained in step (1) is inoculated with high-temperature degradation bacteria (Bacillus subtilis: white rot fungus: Aspergillus niger = 1:1:1, effective bacteria ratio) according to 0.5% of the weight o...

Embodiment 2

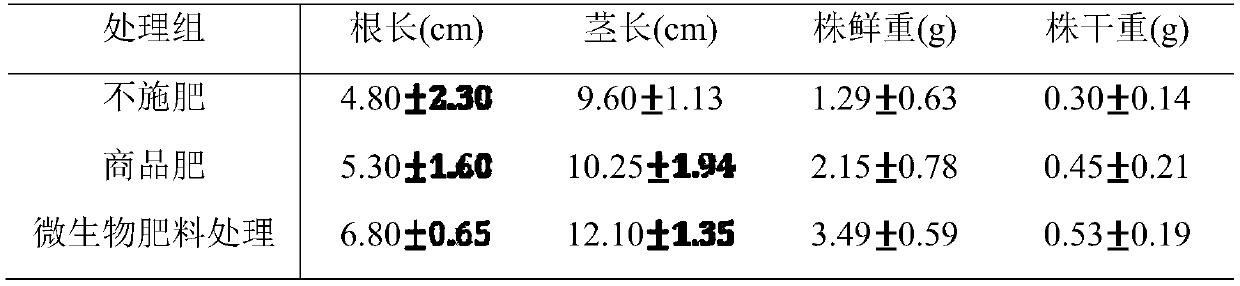

[0055] The bio-organic fertilizer prepared in Example 1 was used as a base fertilizer, mixed with soil and applied to potted planting of begonia seedlings in four seasons, and its growth-promoting effect was compared with a commercial fertilizer as a control.

[0056] See Table 2 for the application effect of the bio-organic fertilizer prepared in Example 1 on begonia seedlings in four seasons.

[0057] The growth-promoting effect of bio-organic fertilizer in the embodiment 1 of table 2 to begonia seedlings in four seasons

[0058]

[0059] Note: The values in the table are the average of 3 repeated experiments.

[0060] As can be seen from Table 2, compared with commercially available commercial fertilizers, adopt the bio-organic fertilizer in the present embodiment, the root length of plant, stem length, plant fresh weight, plant dry weight all have obvious improvement, show that this Bio-organic fertilizers have better fertilizer efficiency and are conducive to the gr...

Embodiment 3

[0063] This embodiment is a method for treating organic solid waste, the process flow is as follows figure 1 As shown, the mixed strains of Bacillus subtilis, white rot fungus and Aspergillus niger were used for the first high-temperature fermentation, and the extreme thermophile Calditerricolayamamurae was used as the inoculum for the second ultra-high temperature fermentation.

[0064] Specific steps are as follows:

[0065] (1) Material pretreatment:

[0066] Mix the dried sludge wet material with the crushed wheat straw (30 mesh) auxiliary material at a weight ratio of 20:2, and adjust the final water content of the mixed material to 45%.

[0067] (2) High temperature aerobic fermentation (first fermentation):

[0068] The mixed material obtained in step (1) is inoculated with high-temperature degradation bacteria (Bacillus subtilis: white rot fungus: Aspergillus niger = 1:1:1, effective bacteria ratio) according to 0.3% of the weight of the mixed material after adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com