Patents

Literature

74results about How to "Reduce the difficulty of mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for enhancing dry-process fermentation stability of sludge by adding kitchen waste

ActiveCN102030456AReduce heating energy consumptionSmall volumeBio-organic fraction processingClimate change adaptationGeneration rateEnergy recovery

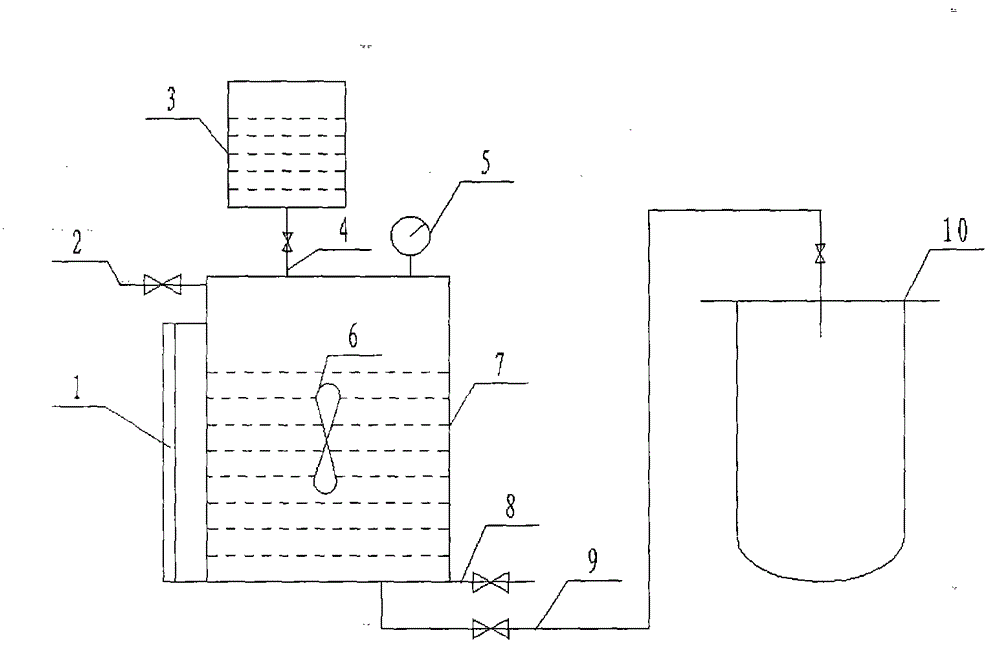

The invention relates to a method for enhancing dry-process fermentation stability of sludge by adding kitchen waste, belonging to the field of solid waste recycling. The invention can solves the problems of low acidifying degree of hydrolysis, insufficient substrates for producing methane, overhigh pH value, ammonium salt accumulation, inhibition of gas generation and the like caused by high viscosity of dewatered sludge, high TS concentration, low C / N value and the like. The method comprises the following steps: pulverizing kitchen waste, mixing the kitchen waste and dewatered sludge in the weight ratio of 1:10-15, putting the mixture in a fermentation tank to ferment, and sufficiently stirring, wherein in the fermentation process, the temperature of the materials is kept at 35+ / -1 DEG C, and the oxidation-reduction potential is smaller than or equal to -300mV; when the pH value rises to 7.5 and the methane content rises to higher than 35%, adding the kitchen waste into the fermentation tank again in batches, wherein the addition amount of the kitchen waste each time accounts for 5-10 wt% of the dewatered sludge, the pH value of the mixed materials is preferably greater than or equal to 6.6, and the preferable addition time is when the pH value of the materials rises to higher than 7.5; and when the methane content is lower than 35% and the gas generation rate obviously decreases, finishing the fermentation. The invention can be used for municipal sludge recycling and energy recovery. Compared with wet fermentation, the invention can save equipment investment and soil occupation.

Owner:TONGJI UNIV

Super-retarding concrete and preparation method thereof

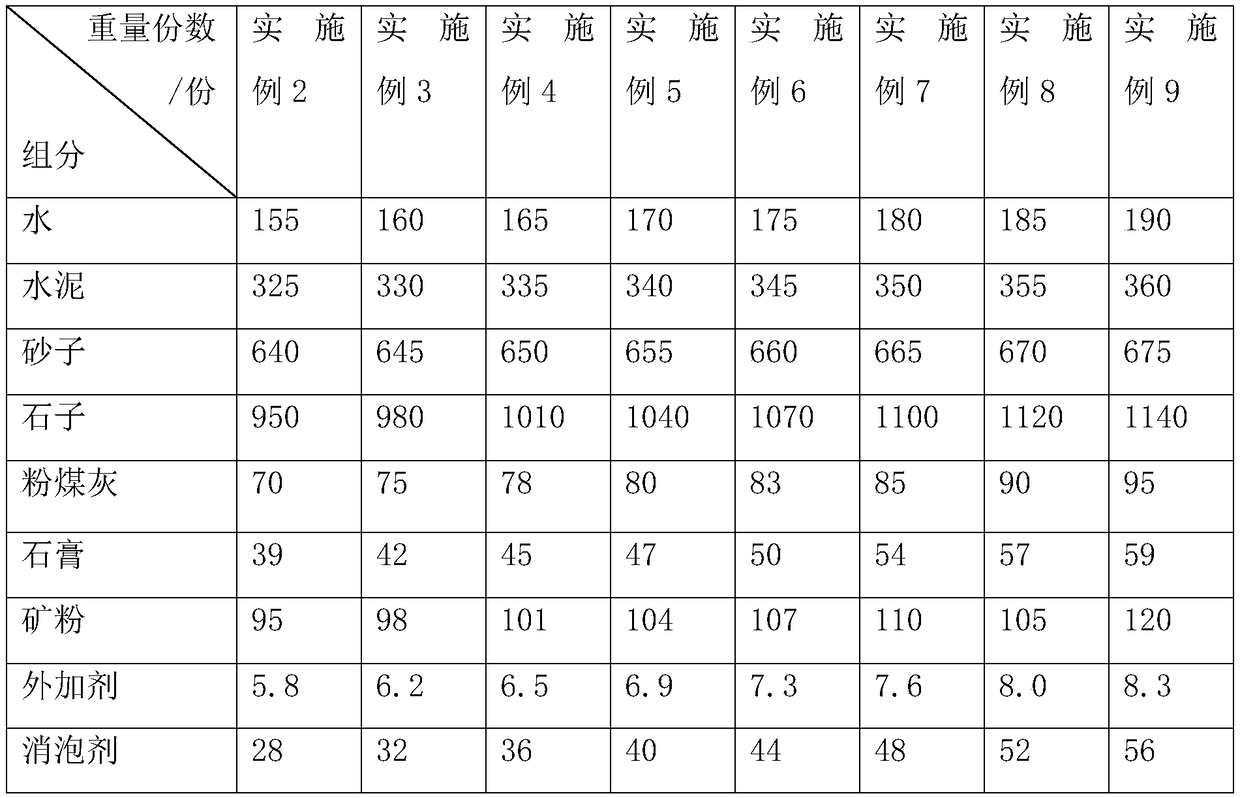

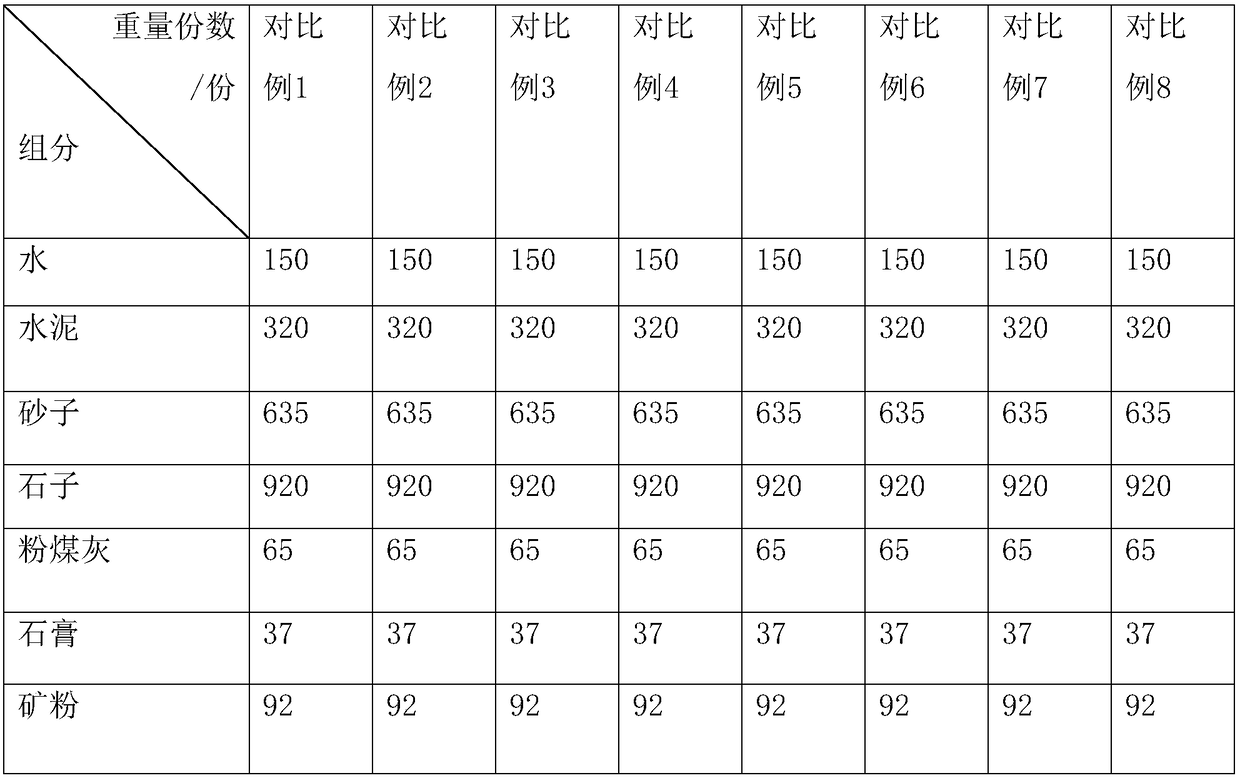

The invention discloses super-retarding concrete and relates to the technical field of building materials. According to the key pint of the technical scheme, the super-retarding concrete comprises thefollowing ingredients (by weight): 150-190 parts of water, 320-360 parts of cement, 635-675 parts of sand, 920-1140 parts of cobblestone, 65-95 parts of an admixture A, 92-120 parts of an admixture B, 37-59 parts of gypsum, and 5.5-8.3 parts of an additive. The additive comprises the following ingredients (by weight): 12-16 parts of a retarder and 38-52 parts of a polycarboxylate superplasticizer. The admixture A comprises fly ash, and the admixture B comprises mineral powder. The retarder is composed of sodium thiosulfate, glycerol and sodium tripolyphosphate according to the mass ratio of 1-3: 2.4-3.5: 2.3-3.2. The problem that concrete's short setting time and low long-term strength are hard to meet the requirement of prolonging the setting time of concrete and guaranteeing long-term strength is solved. By using the retarder and the polycarboxylate superplasticizer cooperatively, the setting time of concrete can be prolonged, and the concrete can have high long-term strength.

Owner:上海石化安东混凝土有限公司

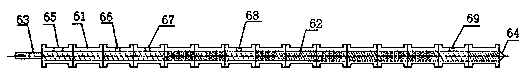

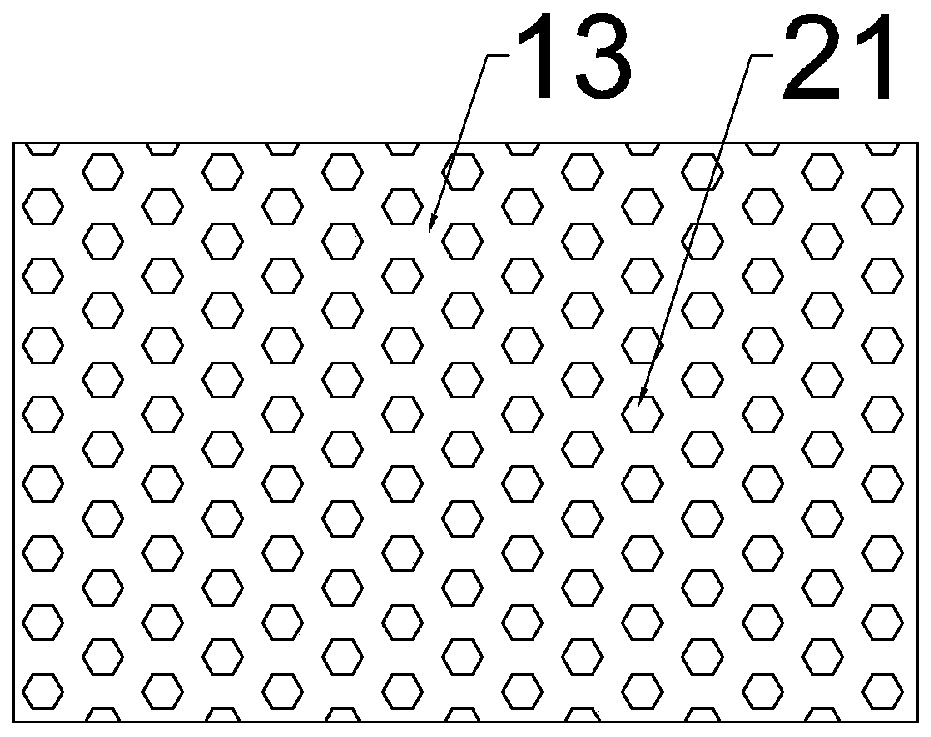

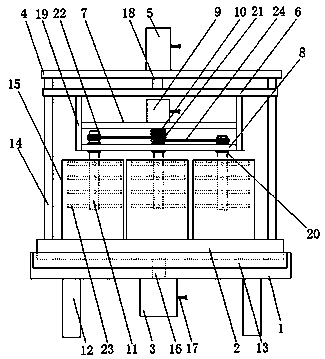

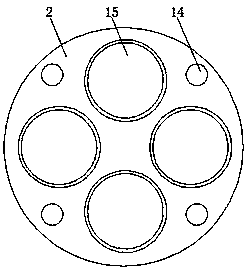

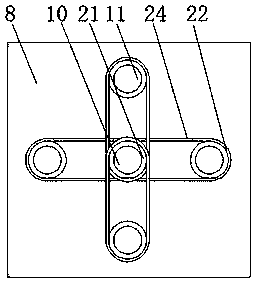

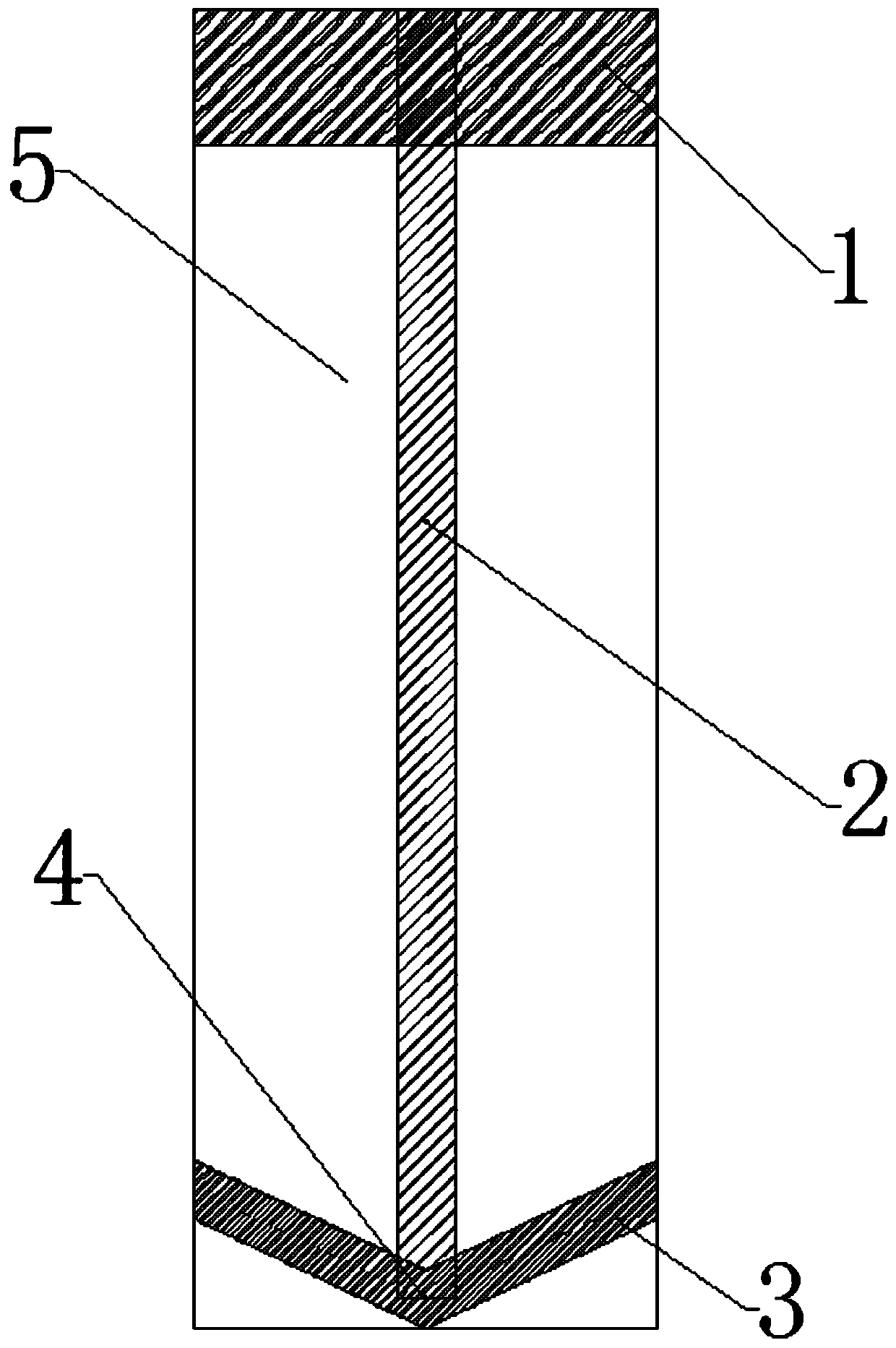

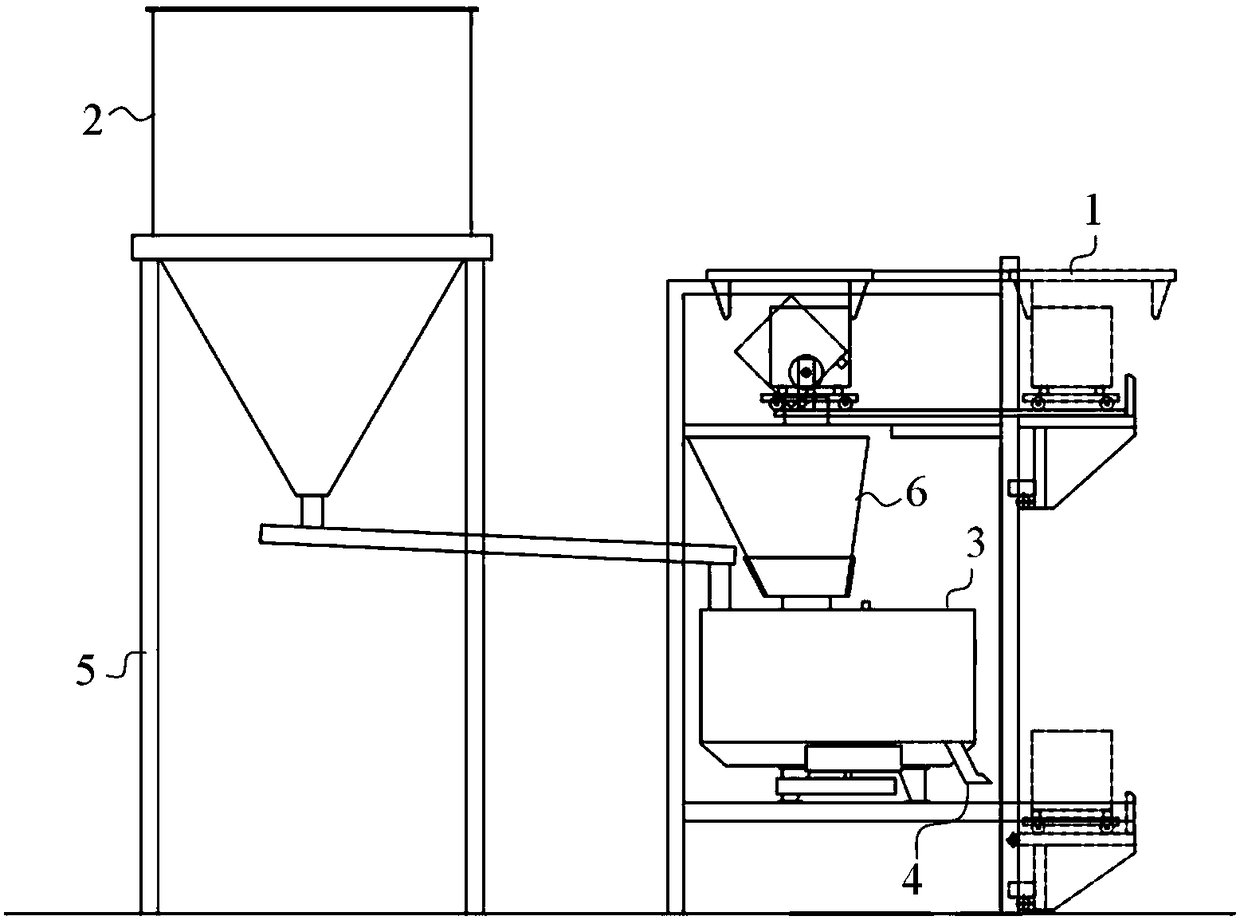

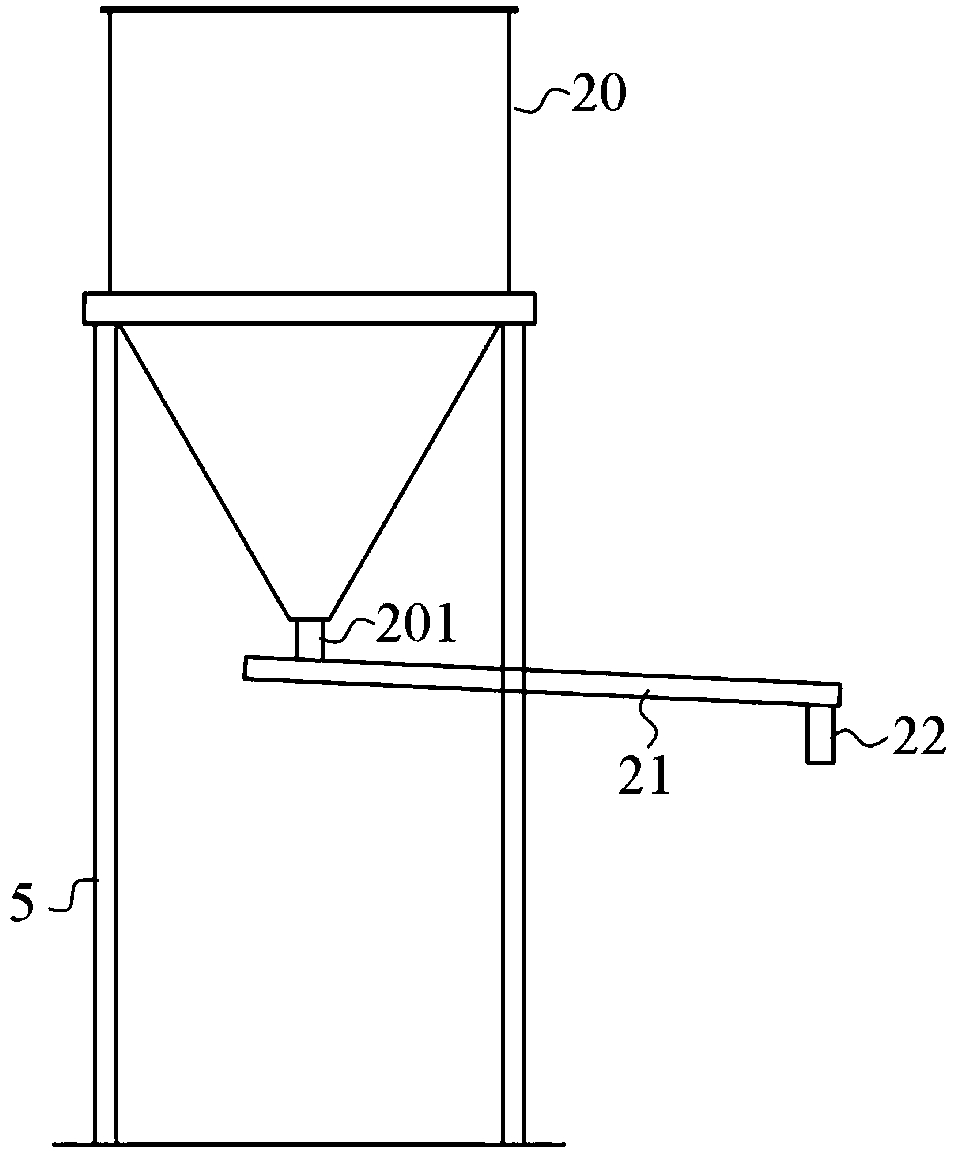

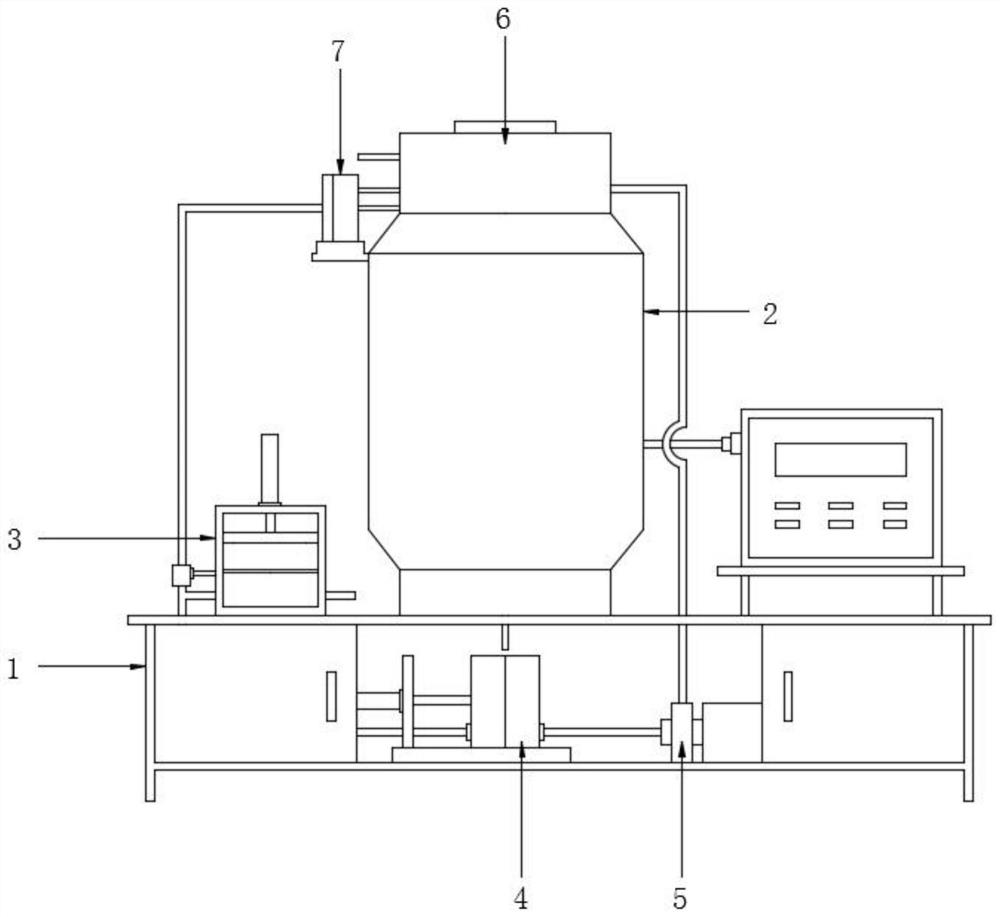

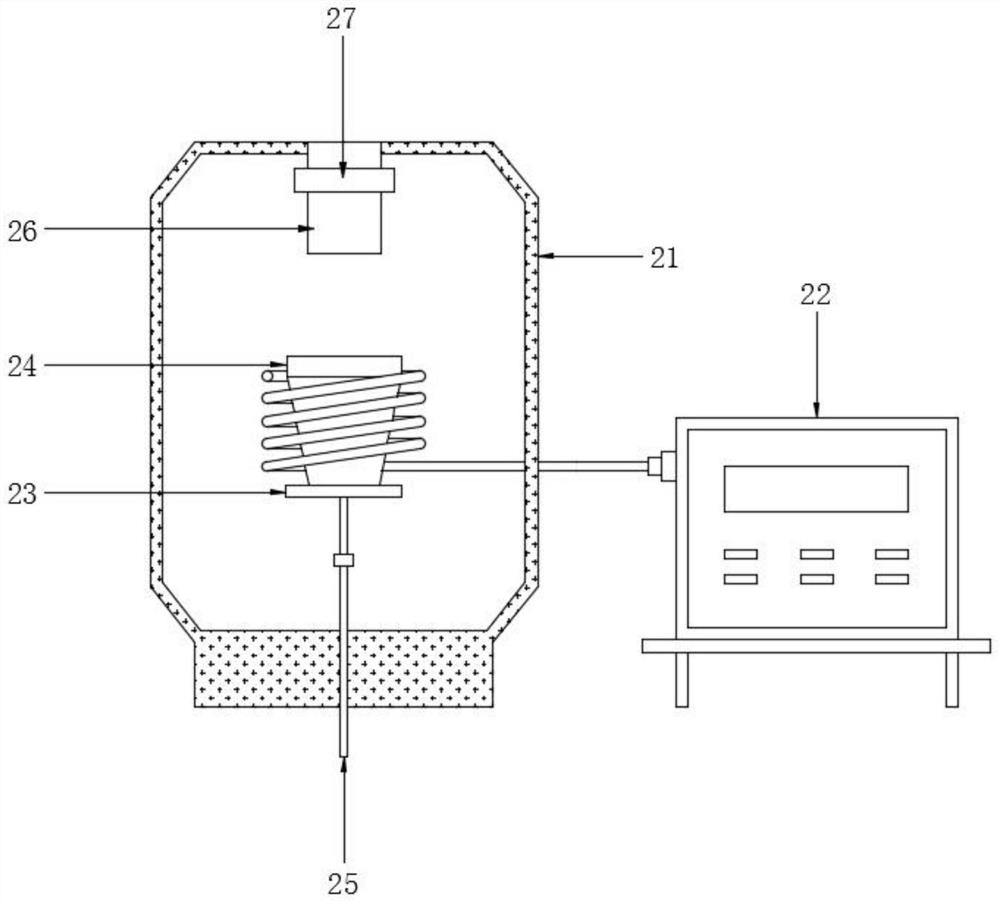

Double-spiral-shaft continuous homogenization system for lithium battery slurry material

PendingCN110052209AReduce the difficulty of mixingEasy to adjust pulping temperatureLiquid degasificationElectrode manufacturing processesFiltrationLiquid storage tank

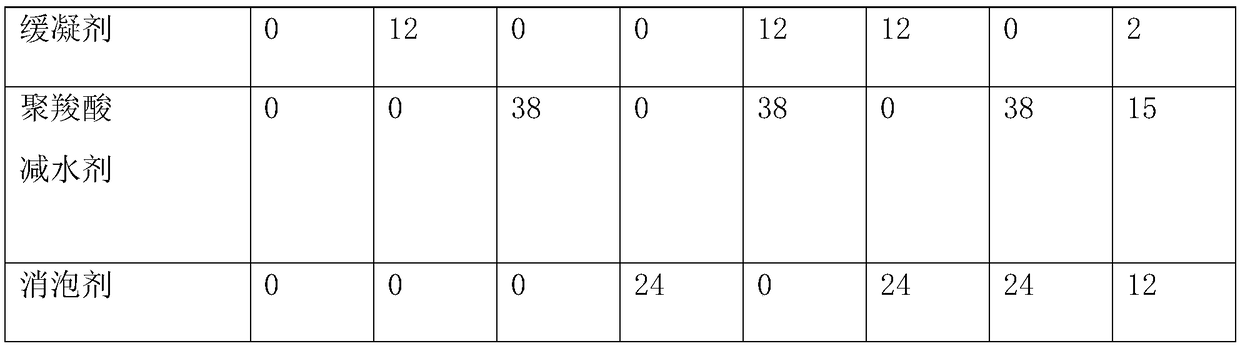

The invention discloses a double-spiral-shaft continuous homogenization system for a lithium battery slurry material in the technical field of lithium battery slurry material production. The system comprises powder material storage bins, liquid storage tanks, powder material weight loss feeders, liquid metering feeding devices, a premixing conveyor, a double-spiral mixer, a slurry material iron-removal filter, a homogenizer and a slurry material defoaming treatment tank, wherein an auxiliary material feeding port and an exhaust port are formed in the double-spiral mixer; a cooling unit is connected to the outside of the double-spiral mixer; thermocouples are uniformly arranged inside the double-spiral mixer; the thermocouples are controlled by a controller; an outlet of the buffer tank isconnected with the homogenizer; and an outlet of the homogenizer is connected with the slurry material defoaming treatment tank, so that the slurry material mixing difficulty is low, and the service life of the equipment is effectively prolonged; and after iron removal by filtration and the slurry material reaches the buffer tank, slurry material vacuum defoaming and further sol are carried out, so that a binder which cannot be completely dissolved can continue to be fully dissolved, and the required fineness, solid content and viscosity of the slurry material are achieved.

Owner:WUXI LINGOOD MACHINERY TECH

Purification method for coal tar soft pitch

InactiveCN102839008AImprove solubilityHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionPurification methodsCentrifugation

The present invention relates to a purification method for coal tar soft pitch. The method is characterized by comprising: stirring and uniformly mixing coal tar soft pitch with a softening point of 30-60 DEG C and a solvent according to a mass ratio of 1:0.5-1.5 at a temperature of 120-300 DEG C; carrying out thermal and adding the resulting material to a continuous centrifuge; carrying out continuous centrifugation separation at the same temperature to obtain a supernatant and residue; carrying out vacuum distillation on the supernatant; removing the solvent to obtain the purified pitch; and recovering the solvent to reuse. The method of the present invention has the following advantages and effects that a dissolution property of the soft pitch in the solvent and a process yield can be significantly improved, difficulties of mixing and separation are significantly decreased, and operation and maintenance are convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

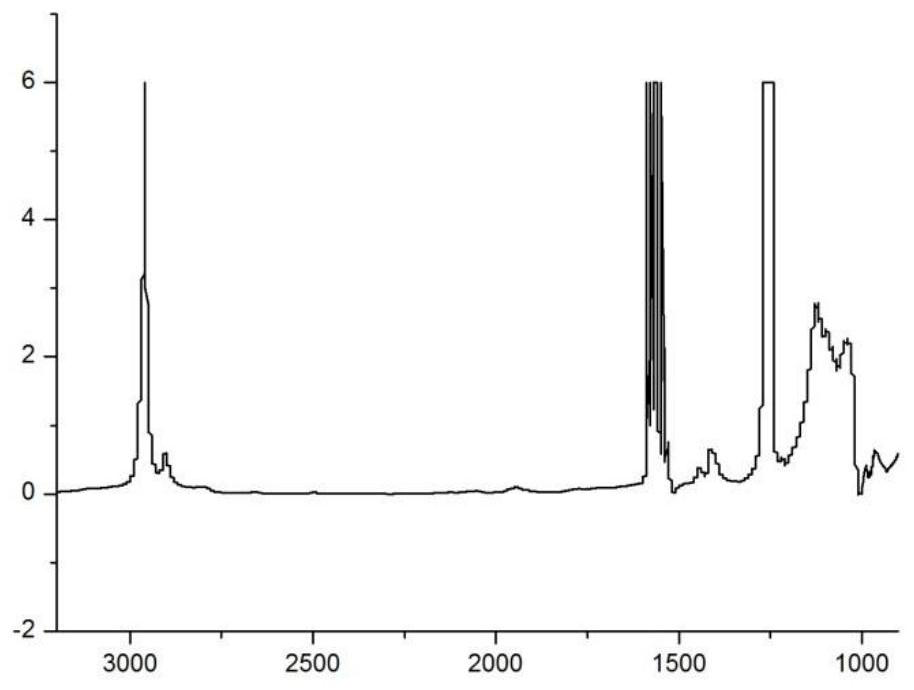

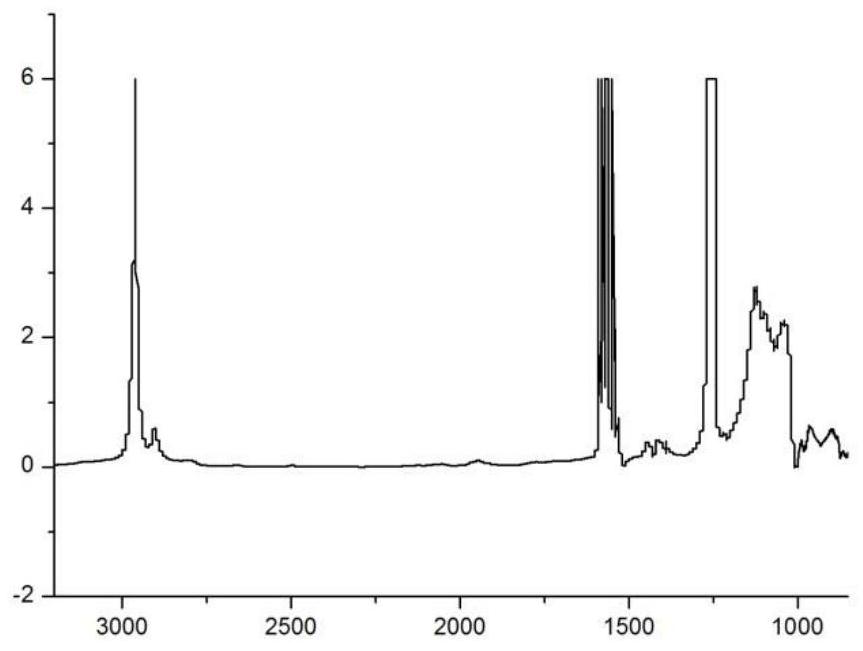

Vehicle siloxane damping elastomer

The invention discloses a vehicle siloxane damping elastomer. The vehicle siloxane damping elastomer comprises the following components: 100 parts by weight of polysiloxane matrix resin, 10-20 parts by weight of oligomeric polyester polyol with number-average molar mass of 100-150, 1-5 parts by weight of organic bentonite, 50-60 parts by weight of silicone oil, 20-30 parts by weight of silica dioxide, 20-30 parts by weight of glass beads and 2-3 parts by weight of antioxidant, wherein the weight ratio of the oligomeric polyester polyol to the organic bentonite is (4-6):1. The vehicle siloxane damping elastomer disclosed by the invention has good machinability and high system homogeneity; a product obtained by machining the vehicle siloxane damping elastomer has good quality and bright and clean surface as well as good elasticity, strong sound insulation and noise elimination capacity and good stretching and restoration performance.

Owner:LIUZHOU XINGTA IND & TRADE

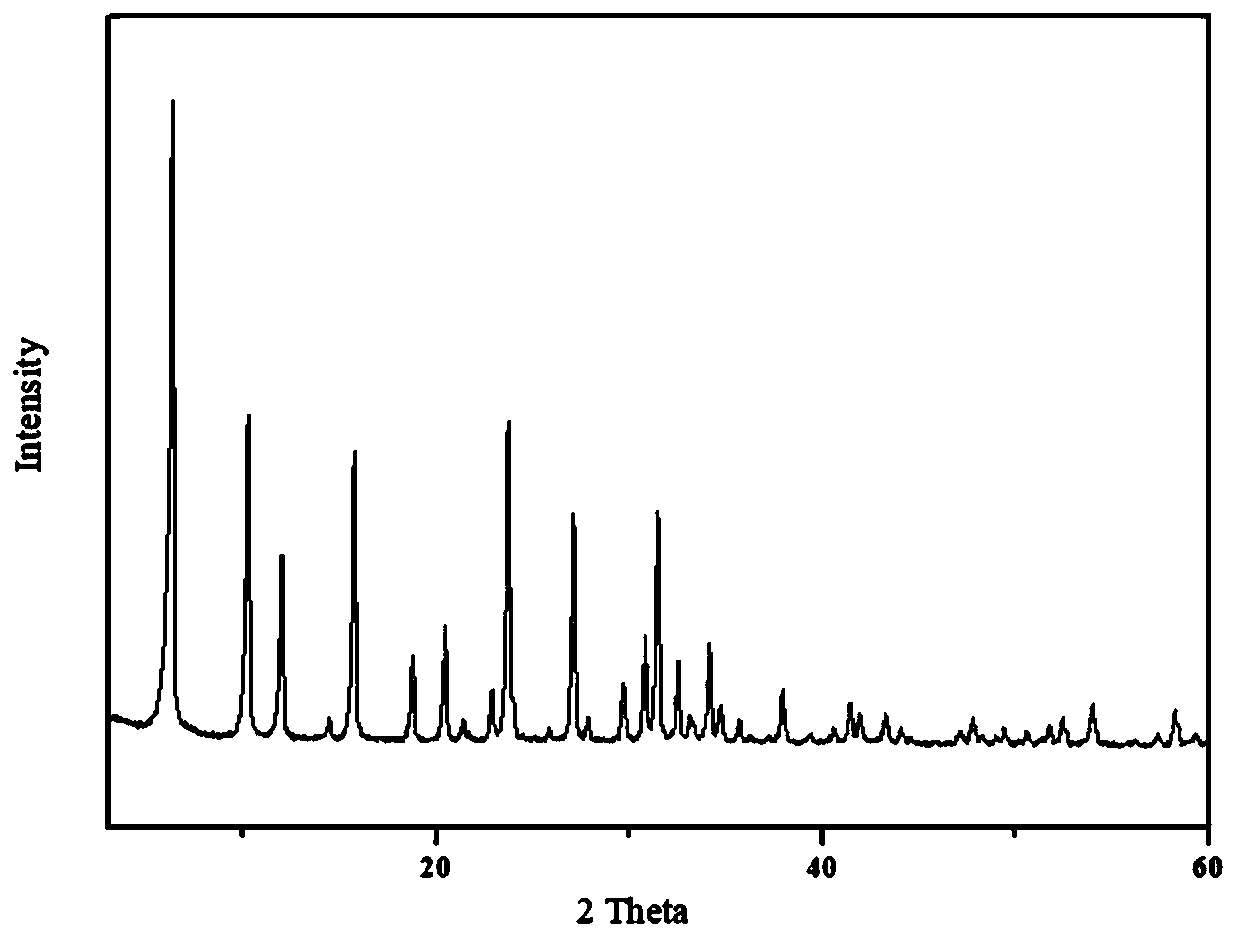

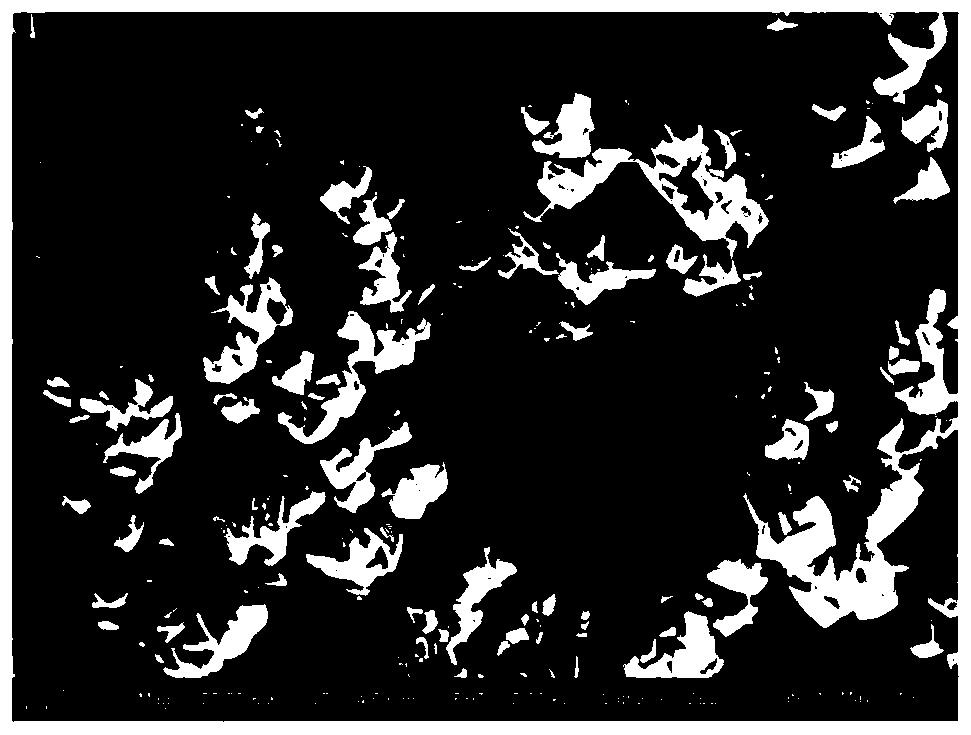

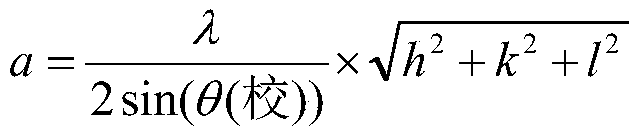

High-silicon NaY molecular sieve as well as preparation method and application thereof

PendingCN110862096AAccelerate the hydrolysis polycondensation processGood dispersionGas treatmentDispersed particle separationAluminateMolecular sieve

The invention relates to a preparation method of a high-silicon NaY molecular sieve, which comprises the following steps: S1. uniformly mixing pretreated water glass, aluminate, an alkali source and water at room temperature, standing at room temperature to 60 DEG C, and aging for 1-50 hours to obtain a guide gel; S2, adding guide gel to the pretreated water glass, then sequentially adding aluminate, aluminum salt and water, mixing the mixture to be uniform at the room temperature, obtaining a pre-reaction mixture, wherein the mass of the guide gel accounts for 1-15 wt% of the mass of the pre-reaction mixture; and S3, carrying out hydrothermal reaction on the pre-reaction mixture at 90-120 DEG C for 5-50 hours, filtering, washing and drying to obtain the NaY molecular sieve. Compared withthe prior art, the preparation method has the advantages that the water glass dispersion accelerant is added, so that the preparation of the high-silicon NaY molecular sieve and the uniform stirring of a low-alkalinity feeding system are facilitated; the prepared NaY molecular sieve is high in silica-alumina ratio, good in hydrothermal stability, large in pore diameter and high in specific surfacearea, and shows excellent performance in adsorption and removal of macromolecular VOCs.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

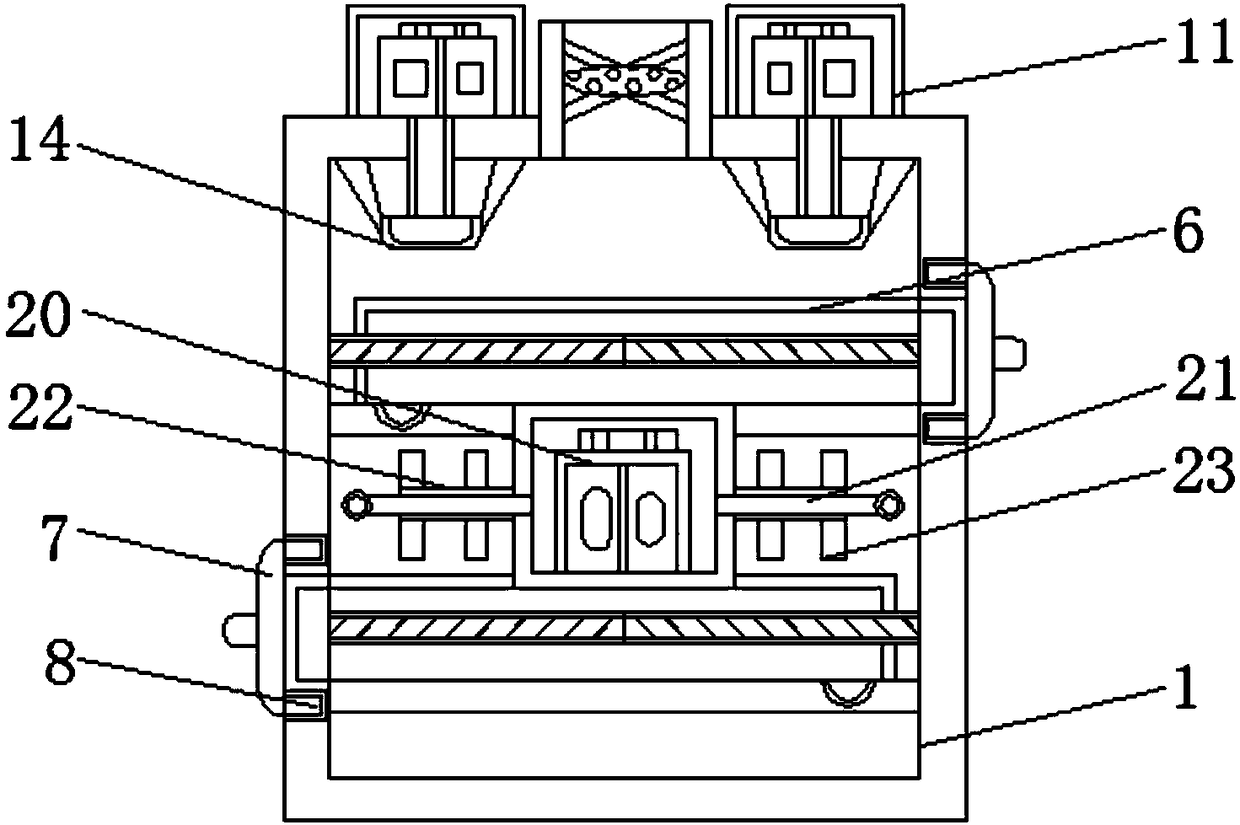

Concrete mixing device for road construction

ActiveCN111361007AStir wellReduce the difficulty of mixingCement mixing apparatusControl apparatusClassical mechanicsMechanical engineering

The invention is applicable to the field of road construction and provides a concrete mixing device for road construction. The concrete mixing device comprises a mixing chamber, a surplus storage chamber, a reciprocating mechanism, a feeding mechanism, a transmission component and a timing mechanism, wherein a mixing component is rotationally arranged in the mixing chamber, and a feeding switch isarranged between the surplus storage chamber and the mixing chamber; the reciprocating mechanism is used for driving the mixing component to perform mixing operation in a reciprocating rotating mode;the feeding mechanism is used for making a material in the surplus storage chamber enter the mixing chamber sequentially; the transmission component is used for making the material enter the mixing chamber by multiple times; and the timing mechanism is used for controlling the mixing cycle of the mixing component. According to the concrete mixing device, the uniform degree of material mixing is increased, and the mixing state of the material on each tray cannot change according to different mixing time; and meanwhile, the material is made to enter the mixing chamber by multiple times, so thatthe mixing difficulty of the mixing device is lowered.

Owner:安徽创都建设集团有限公司

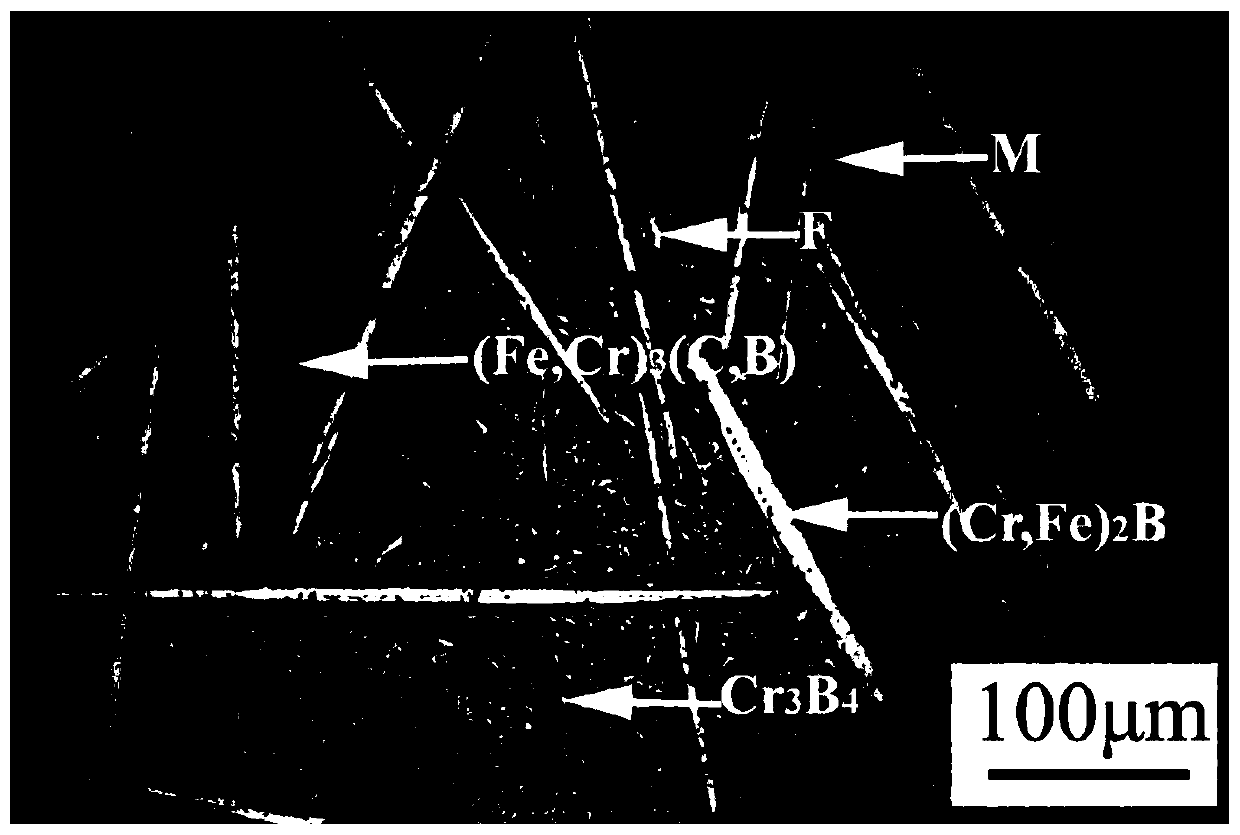

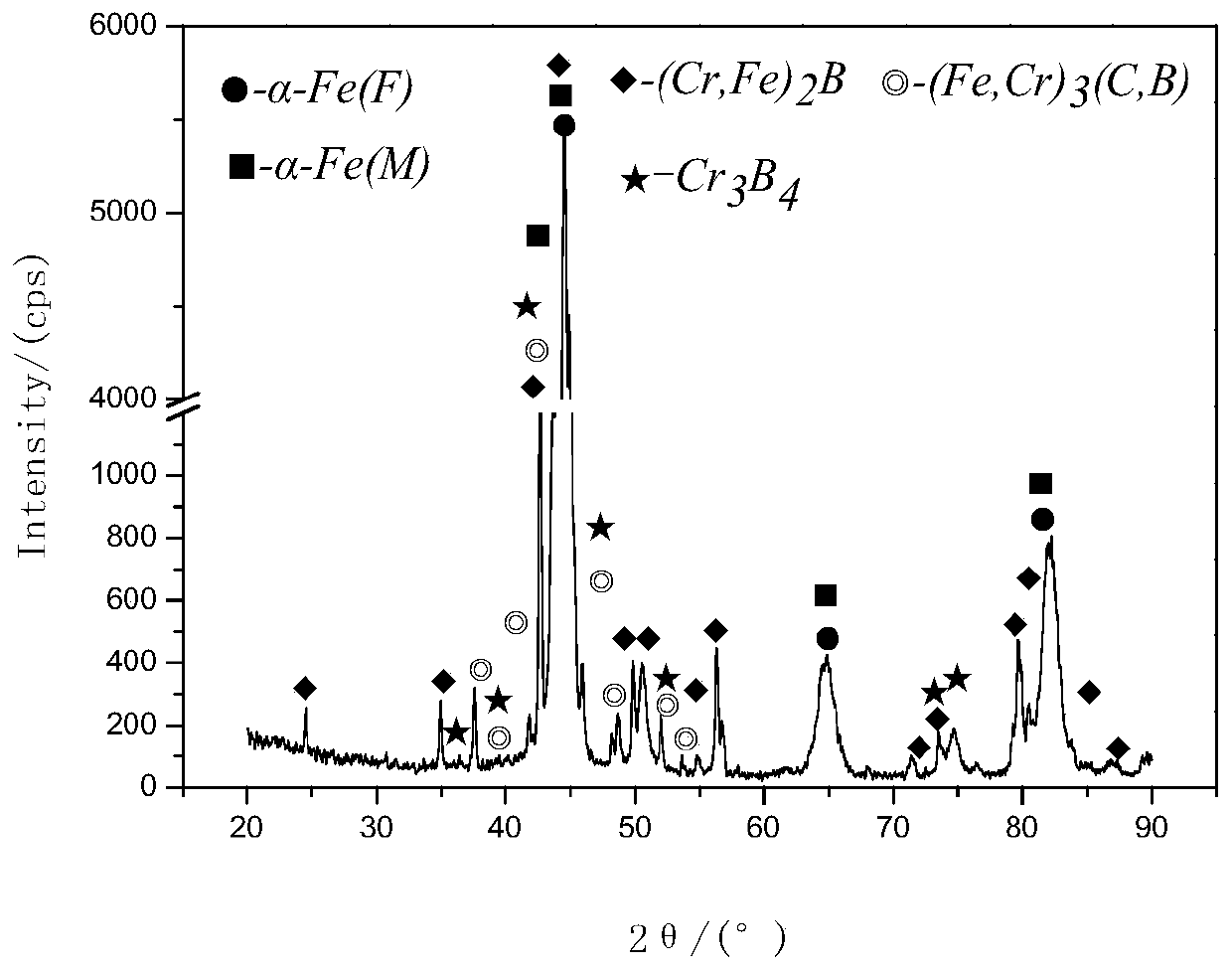

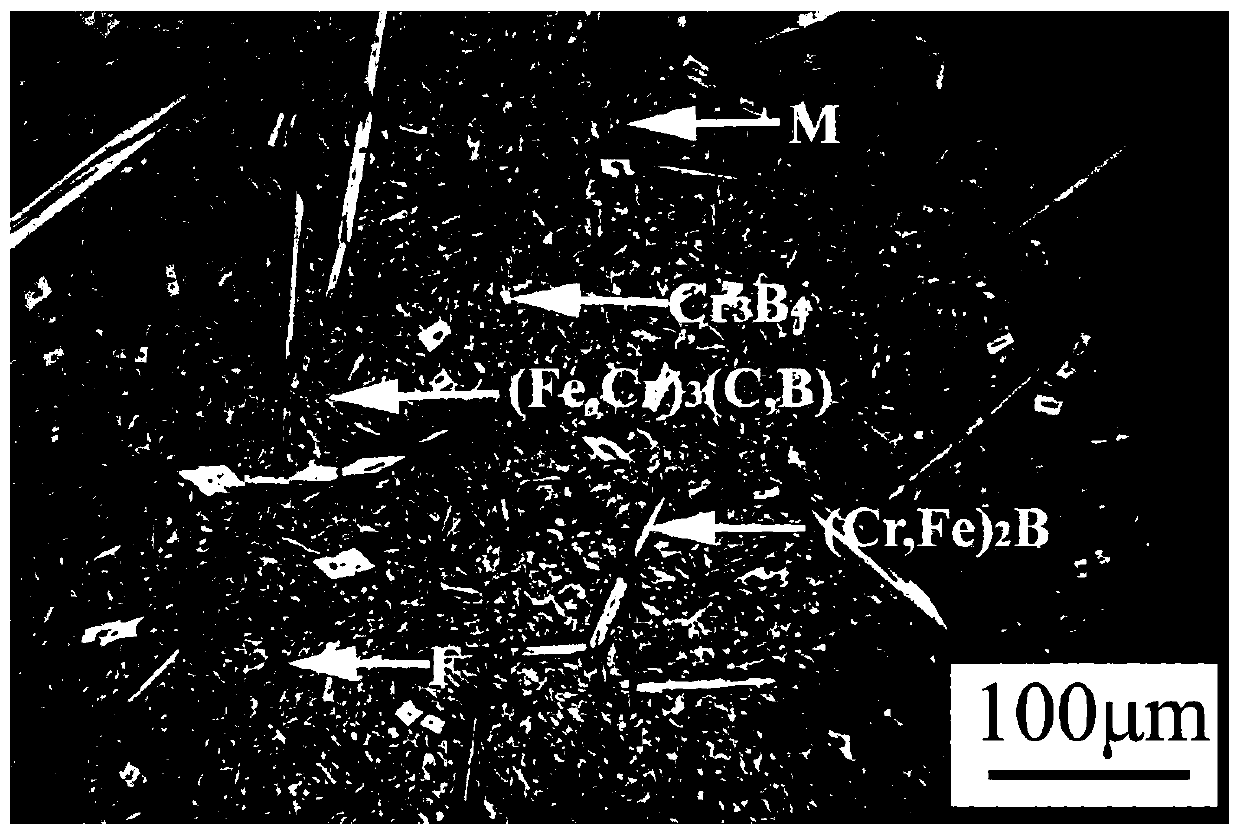

Composite powder particle of submerged arc surfacing high boron alloy and application method thereof

ActiveCN110549035AImprove wear resistanceHigh strengthArc welding apparatusWelding/cutting media/materialsWear resistantBoron carbide

The invention provides a composite powder particle of a submerged arc surfacing high boron alloy and an application method thereof, 6-14 meshes of composite powder particle made by the steps of powdercomponent dry mixing, soaking mixed powder in pure water to be mixed and wetted, rotary bonding granulation, low temperature sintering, sieving and the like is prefabricated in a weld bead, and a solid welding wire is used as an arc carrier for submerged arc surfacing, so that the composite powder melt and the solid welding wire droplet are fused into an integrated surfacing weld pool. Under theaction of arc heat, most of the boron carbide and metal chromium components contained in the composite powder particle are subjected to in-situ metallurgical reaction to form a primary M2B hypereutectic high boron alloy with a large length-width ratio and a microhardness average reaching 1622 HV. The high boron alloy prepared by the composite powder particle has excellent abrasion resistance and high toughness, and can be used for submerged arc surfacing welding wear-resistant alloy layers of parts under a low stress abrasive wear condition, and can protect the open arc welding directly.

Owner:XIANGTAN UNIV

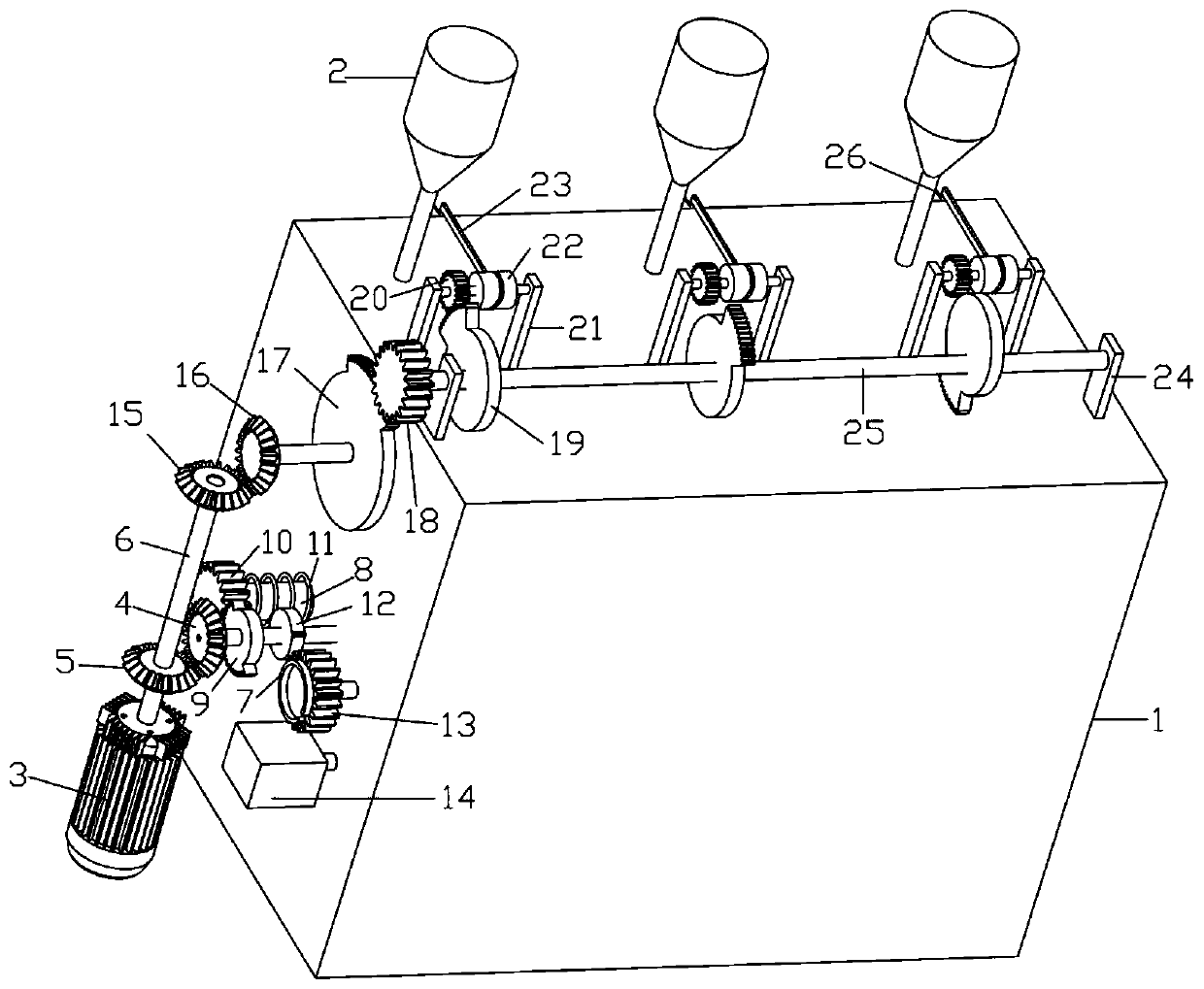

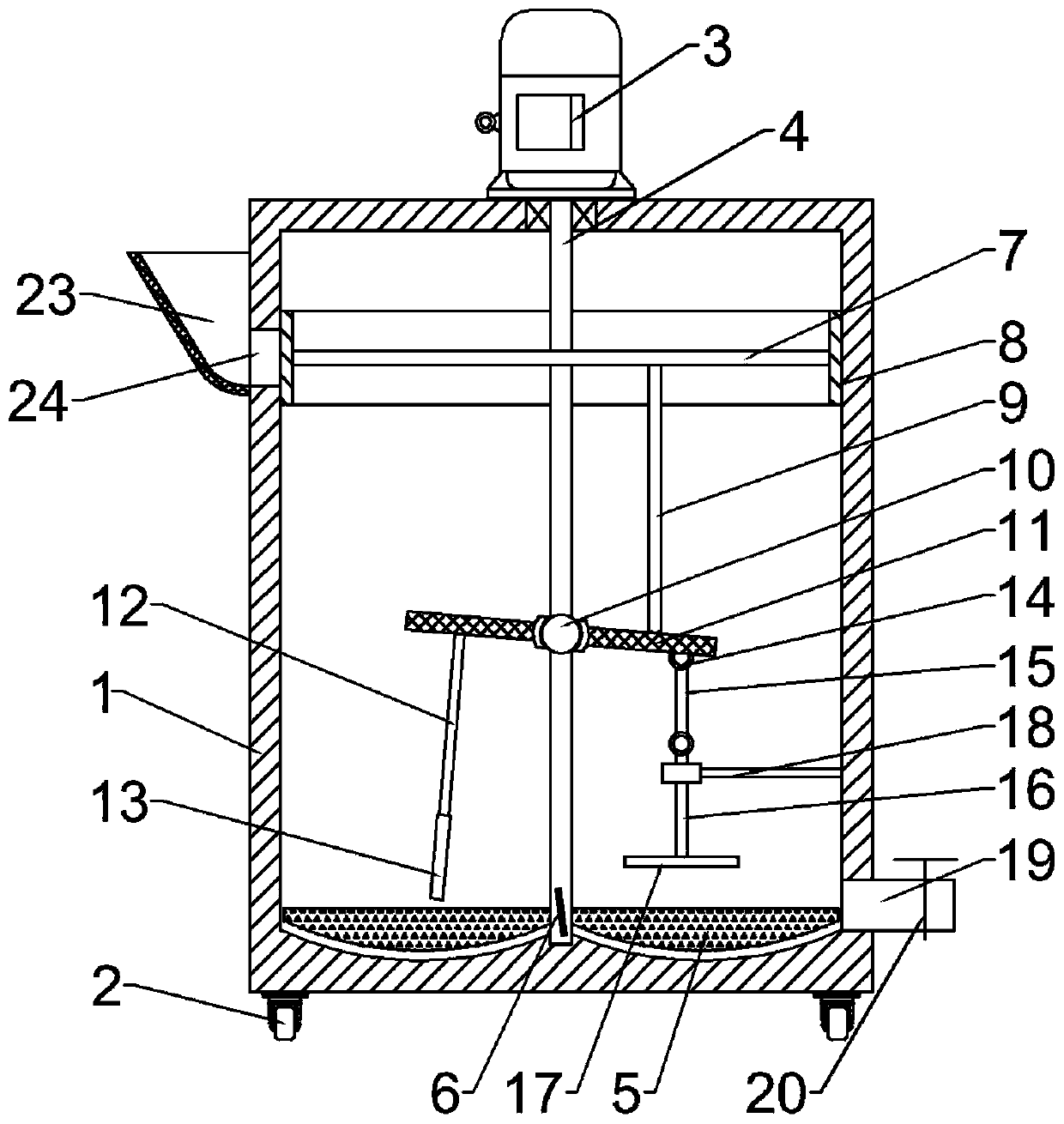

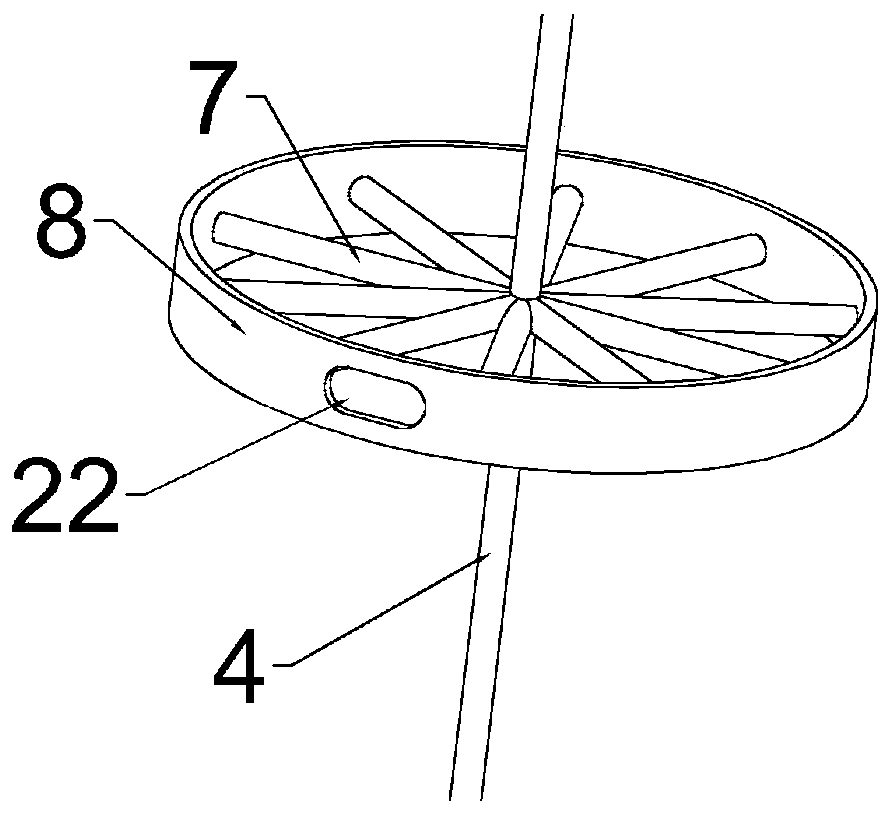

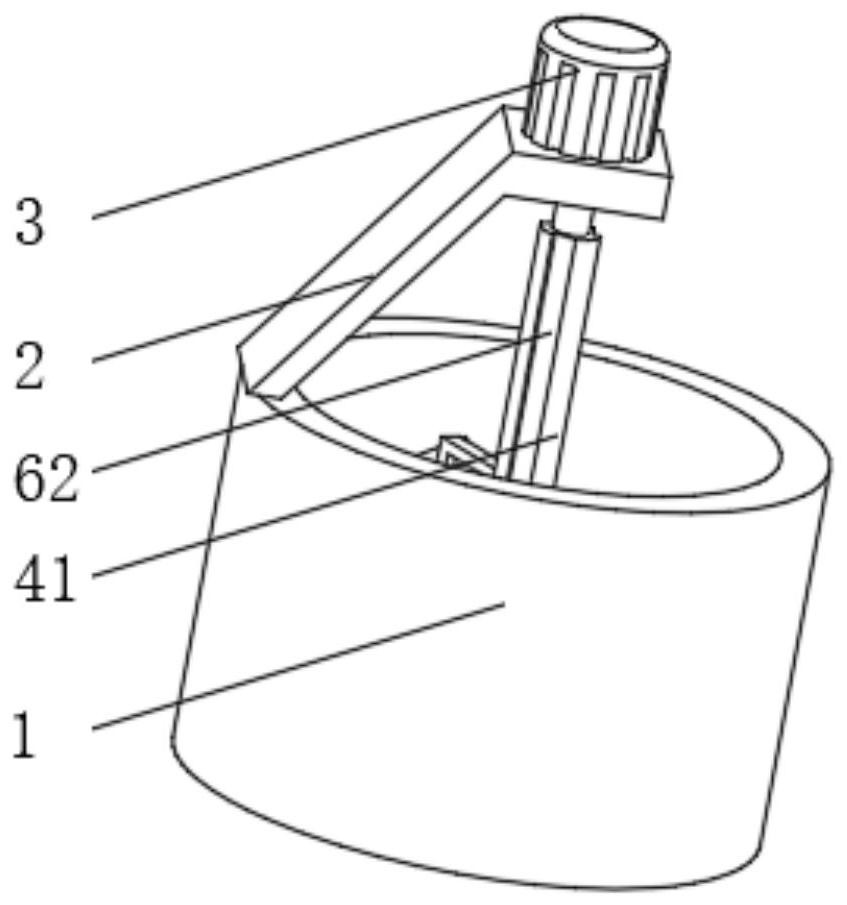

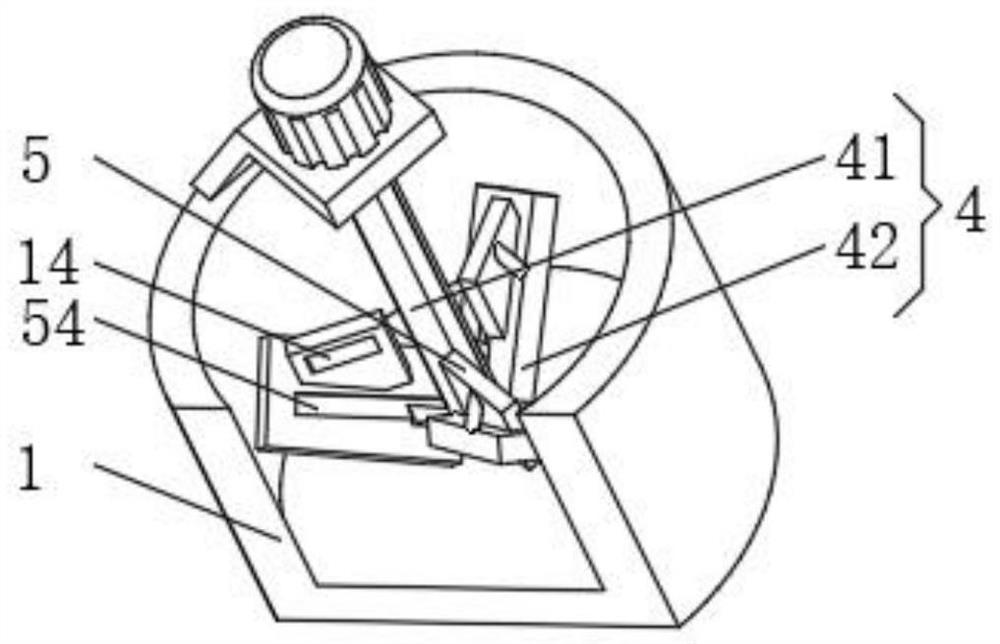

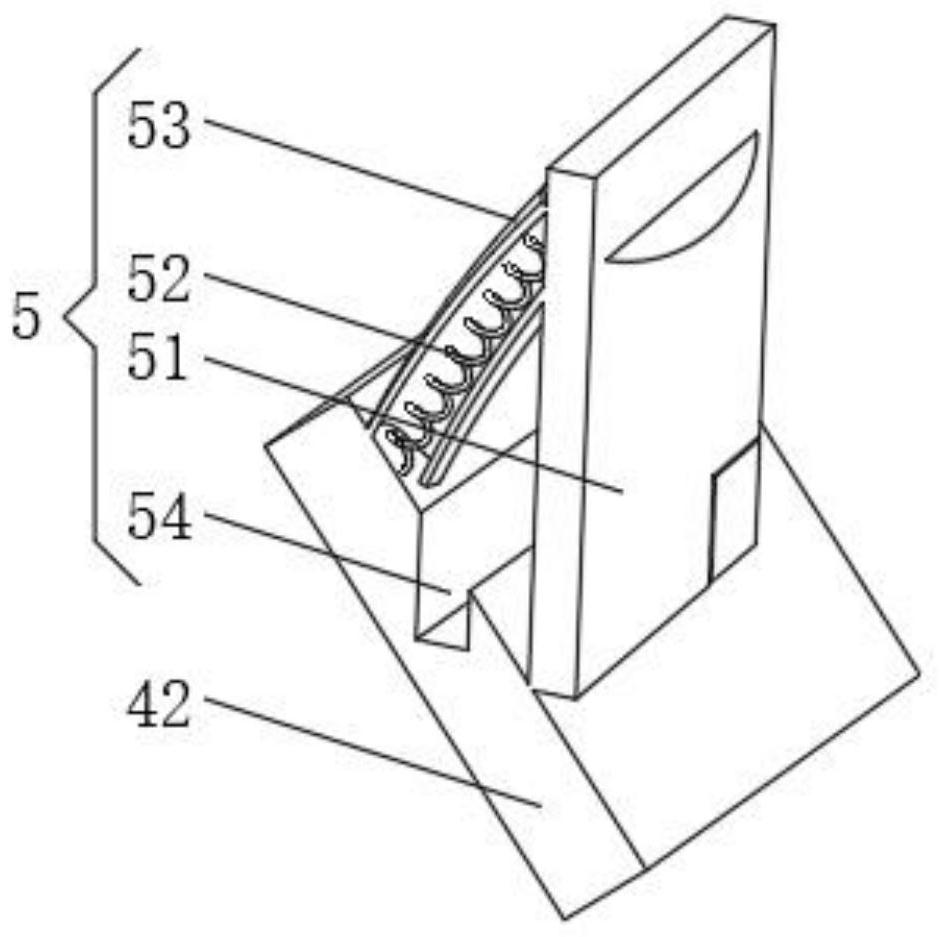

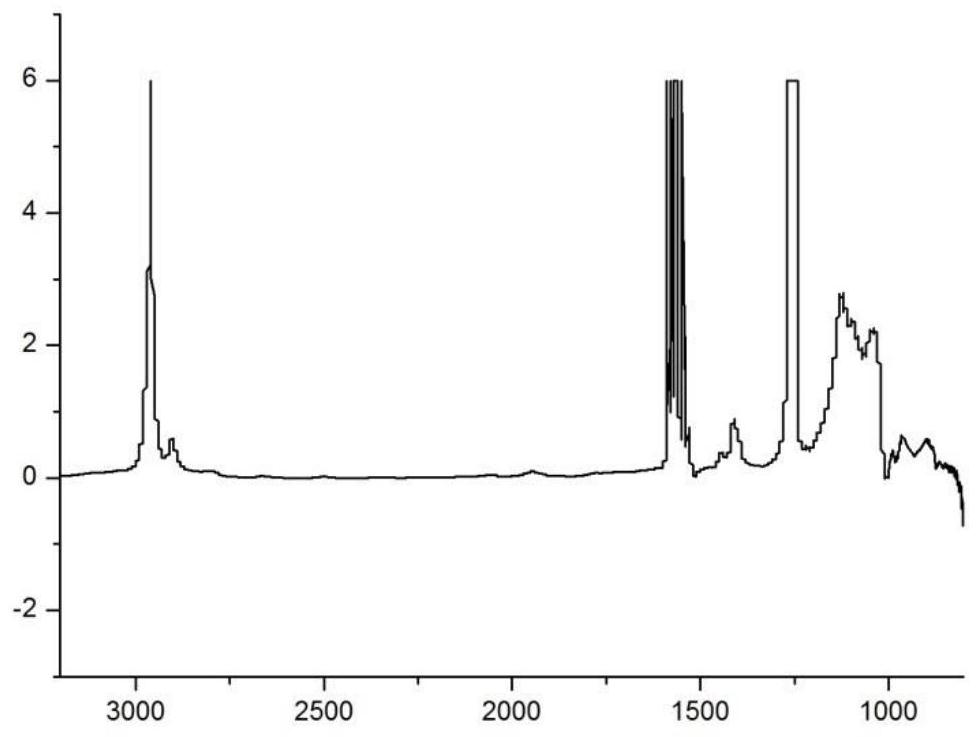

Homogenizing and dispersing equipment used for high-rate LiFePO4 soft package lithium ion power battery

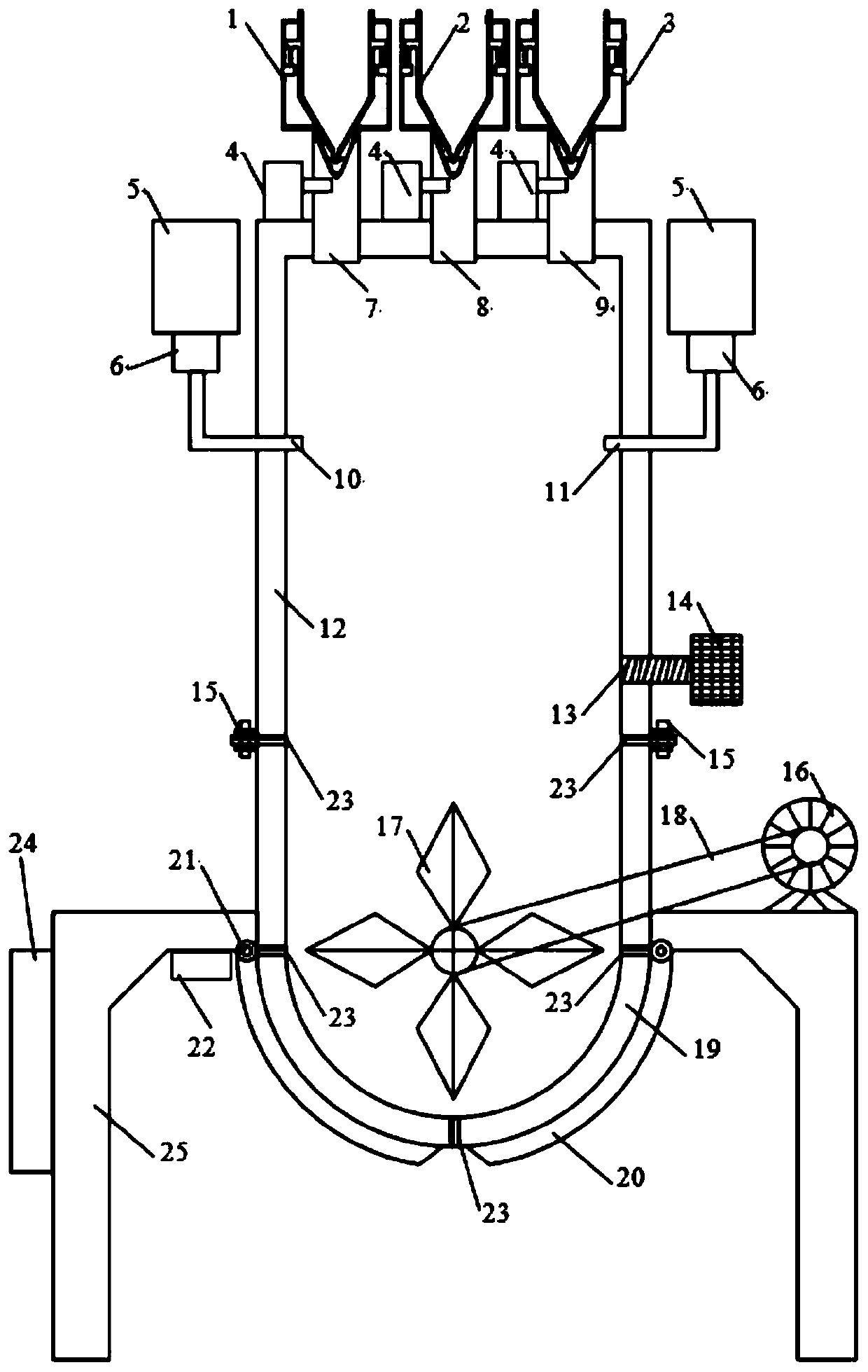

InactiveCN110270247AAchieve hybridGuaranteed uniformityShaking/oscillating/vibrating mixersElectrode manufacturing processesLithiumPower battery

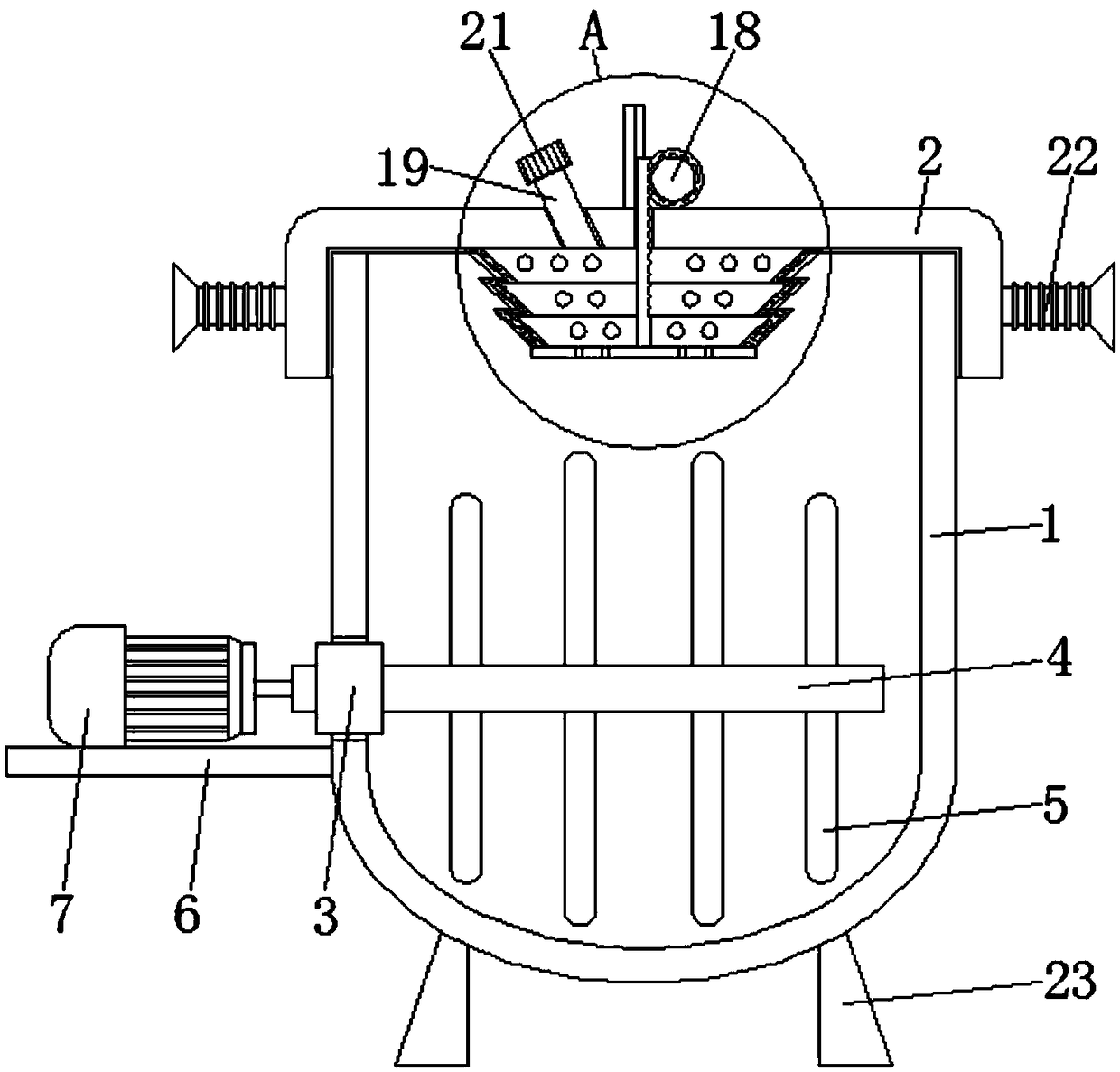

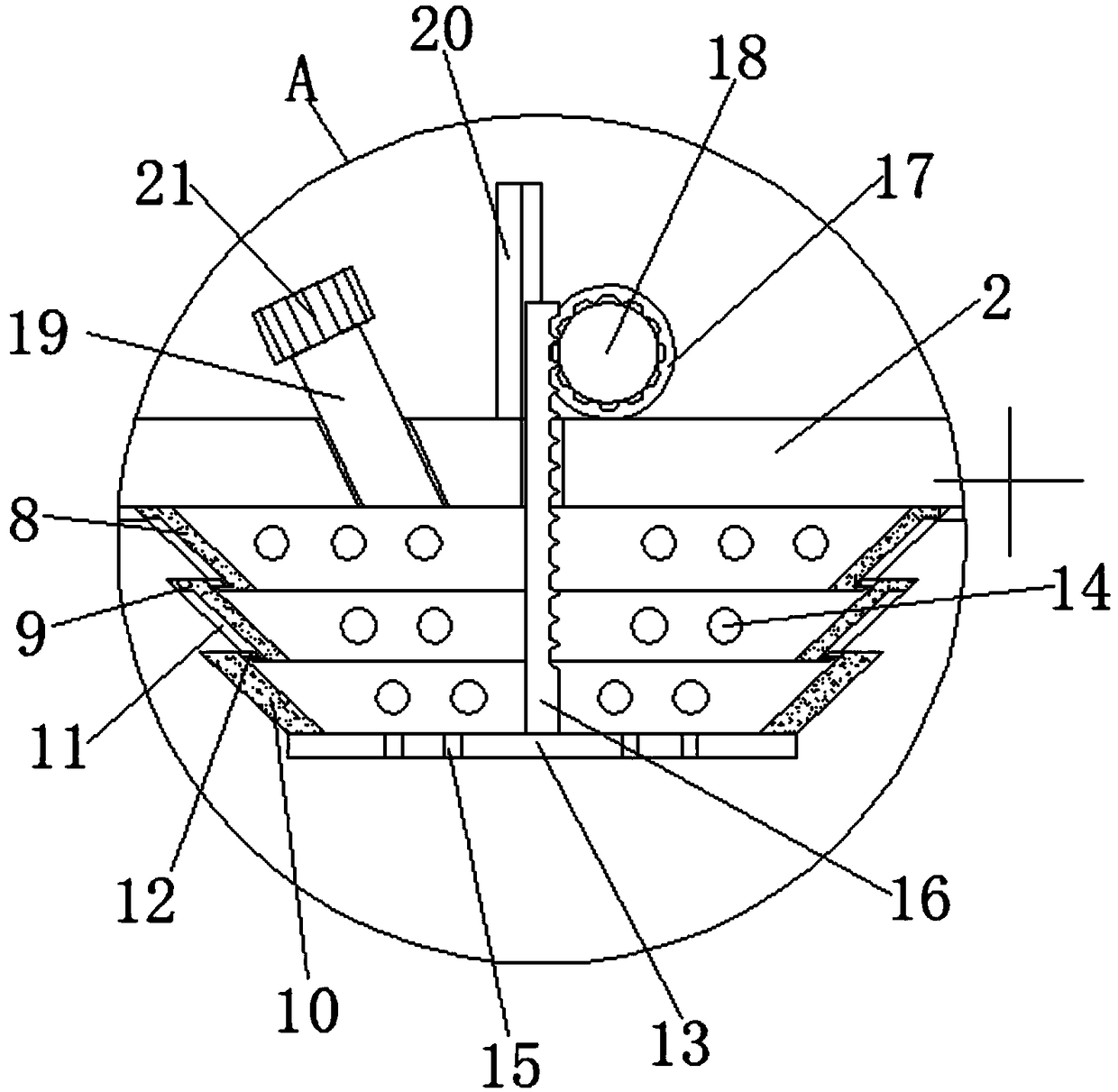

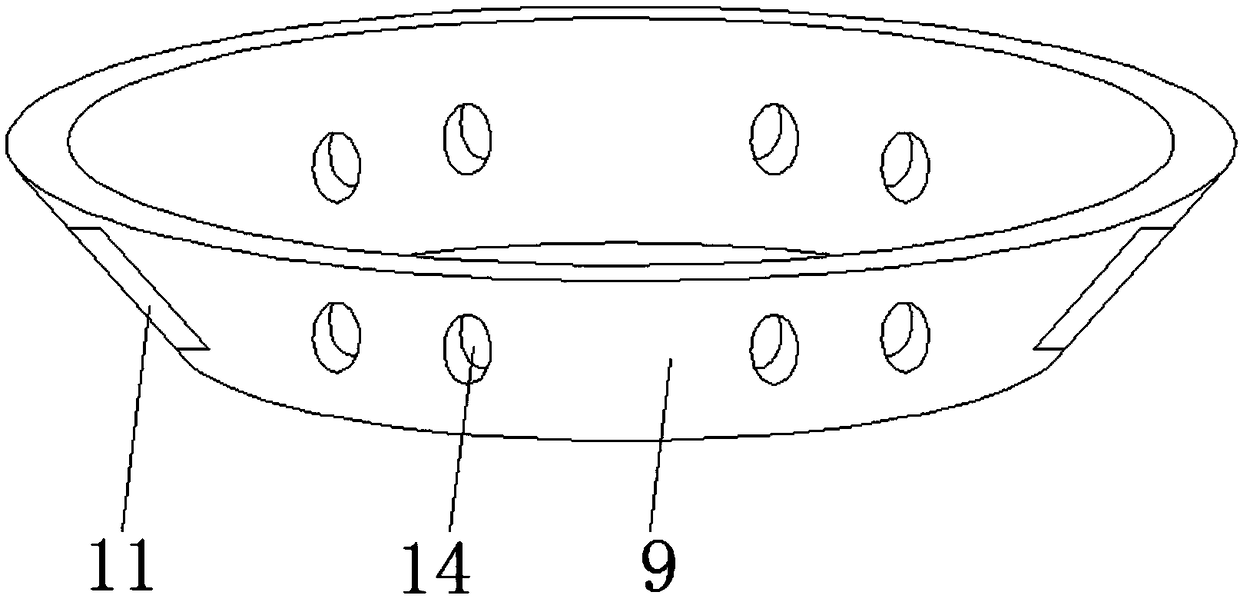

The invention discloses homogenizing and dispersing equipment used for a high-rate LiFePO4 soft package lithium ion power battery, and relates to dispersing equipment. The homogenizing and dispersing equipment used for the high-rate LiFePO4 soft package lithium ion power battery comprises a box, wherein a motor is fixedly connected with the top of the box, a longitudinal rotating shaft is fixedly connected with an output end of the motor, longitudinal stirring blades are fixedly connected with left and right sides of the bottom of the longitudinal rotating shaft, inclined stirring blades are symmetrically and fixedly connected with the front and rear of the longitudinal rotating shaft, spokes are fixedly connected with the top of the longitudinal rotating shaft, and an annular rotating board is fixedly connected with the outer sides of the spokes. The homogenizing and dispersing equipment used for the high-rate LiFePO4 soft package lithium ion power battery is simple in structure and convenient to use, during use, the longitudinal stirring blades and the inclined stirring blades are driven to rotate by the motor, thus raw slurry is mixed, the inclined stirring blades apply upward thrust force to the raw slurry, thus a mixing effect is improved, in a rotating process of the annular rotating board, intermittent blanking is achieved, thus the level of difficulty of mixing is lowered, and an inclined swing board swings to achieve movement of a first mixing board and a second mixing board, so that the evenness of raw slurry mixing is fully guaranteed.

Owner:TAIZHOU UNIV

Waste concrete recycling method with low processing cost

InactiveCN111848006ASoft natureNot easy to changeSolid waste managementGel preparationEnvironmental engineeringSorptivity

The invention discloses a waste concrete recycling method with a low processing cost. The invention belongs to the technical field of concrete processing. The method comprises: arranging hydrogel powder, drying the prepared hydrogel, preparing the hydrogel into a solidified block, crushing the waste concrete into powder with the same size as the waste concrete granular material, at the moment, adding the waste concrete granular material and the hydrogel powder into stirring equipment, and mixing. When adding waste concrete granular materials and hydrogel powder into stirring equipment, stirring equipment needs to be set, stirring directions are the same, the hydrogel is soft in property, the shape is kept, a large amount of water can be absorbed, the mixed modified concrete has certain water absorption performance, the shape of the modified concrete is not easy to change after the modified concrete absorbs water, the internal adhesiveness of the modified concrete is improved, the interior of the modified concrete is not easy to be too dry due to the fact that the hydrogel has certain water absorption performance, and cracks of the modified concrete due to the fact that the interiorof the modified concrete is too dry are reduced.

Owner:汉江城建集团有限公司

Efficient mixing equipment for paint production

InactiveCN108927055AImprove mixing efficiency and mixing qualityReduce the difficulty of mixingRotating receptacle mixersShaking/oscillating/vibrating mixersDrive shaftPiston rod

The invention discloses efficient mixing equipment for paint production, which comprises a bottom plate, a bearing platform, a motor 1, a top plate, a cylinder, a regulating plate, a connecting plate1, a connecting plate 2, a motor 2, a rotating shaft and driven shafts. The efficient mixing equipment is characterized in that the bottom plate is arranged on a bracket, the bearing platform is arranged in a bearing groove, the motor 1 is arranged on the bottom plate, the top plate is arranged on upright columns, and the connecting plate 1 and the connecting plate 2 are arranged between fixed plates. The regulating plate is arranged as a structure that can rise or fall along the upright columns, the regulating plate rises or falls along the upright columns under the action of the cylinder anda piston rod, so as to drive the connecting plate 1 and the connecting plate 2 between the fixed plates to rise or fall, and then drive the motor 2, the rotating shaft and the driven shafts to rise or fall, so that mixing rods on the driven shafts can perform mixing on paint in a mixing barrel at different heights, thereby improving the mixing efficiency of the paint.

Owner:周兆平

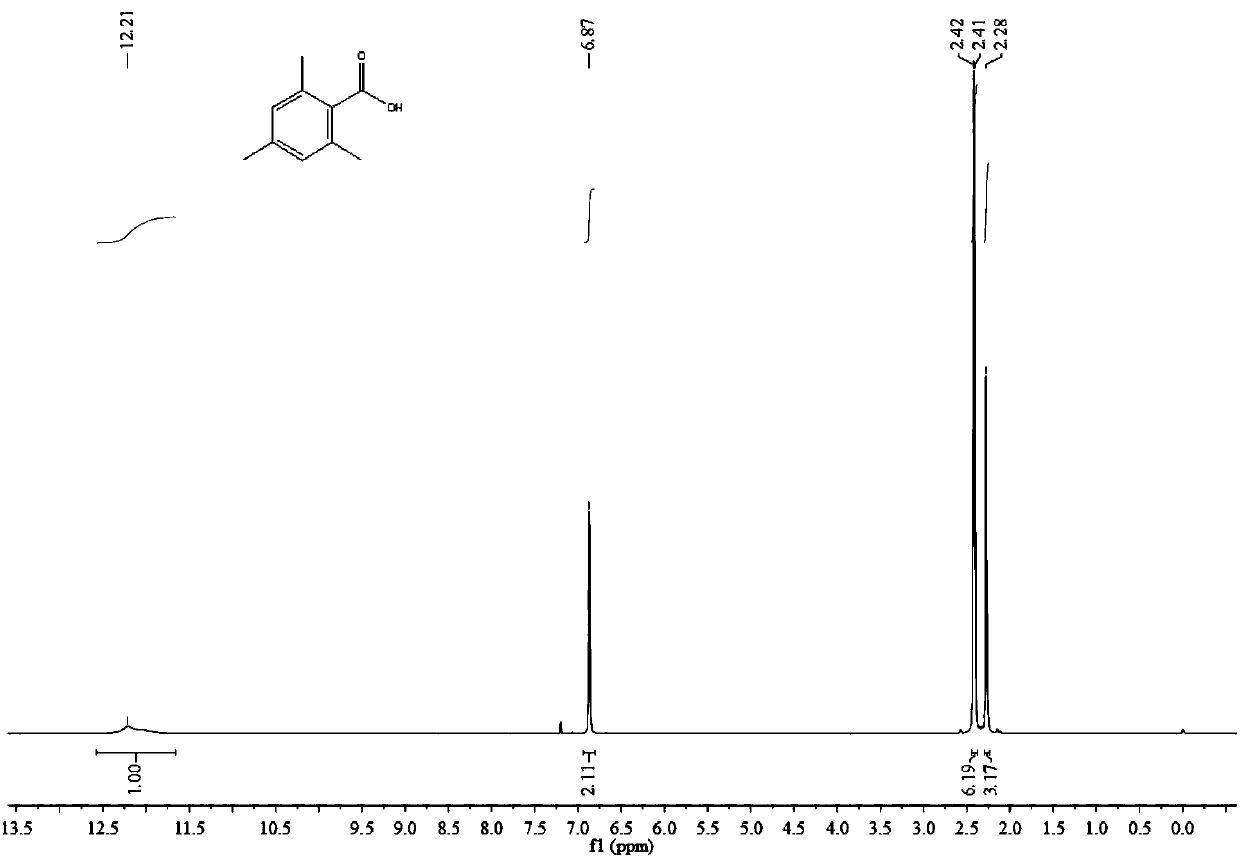

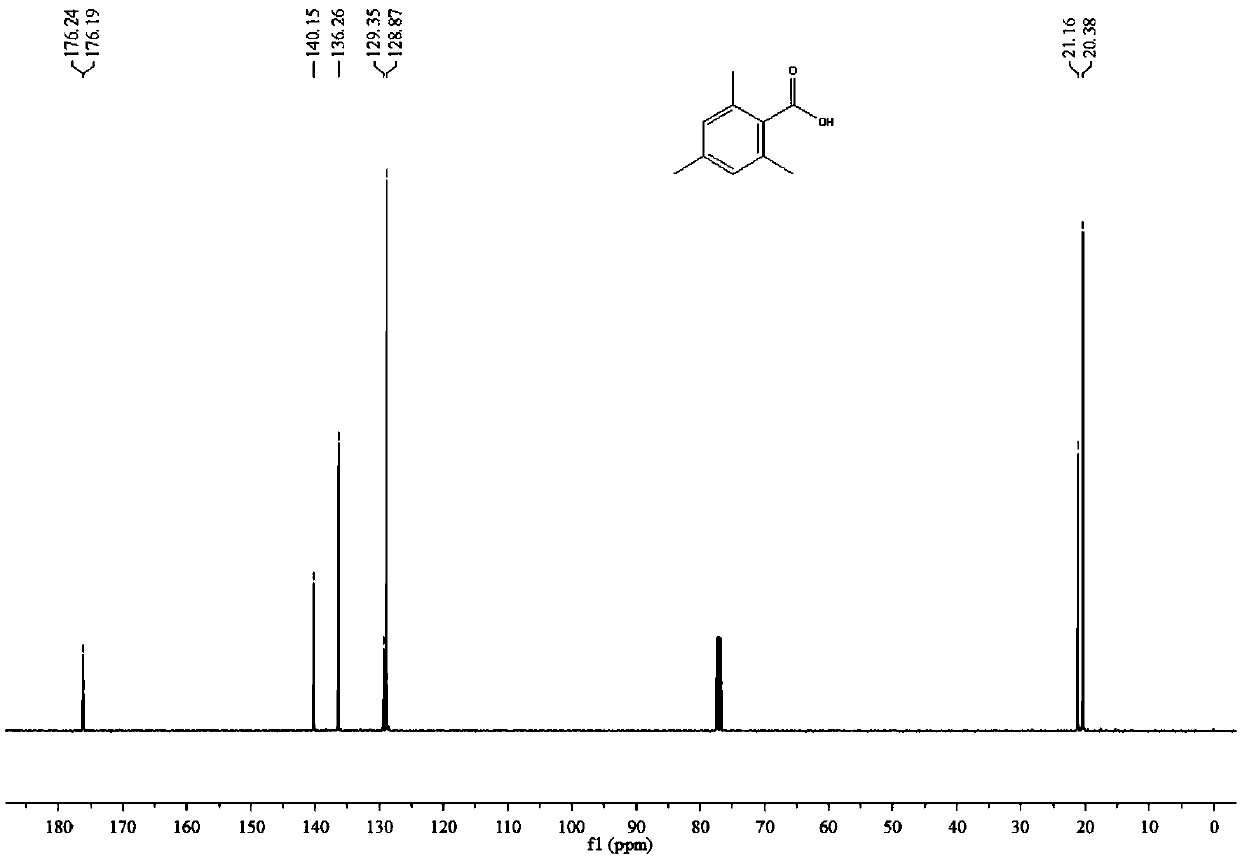

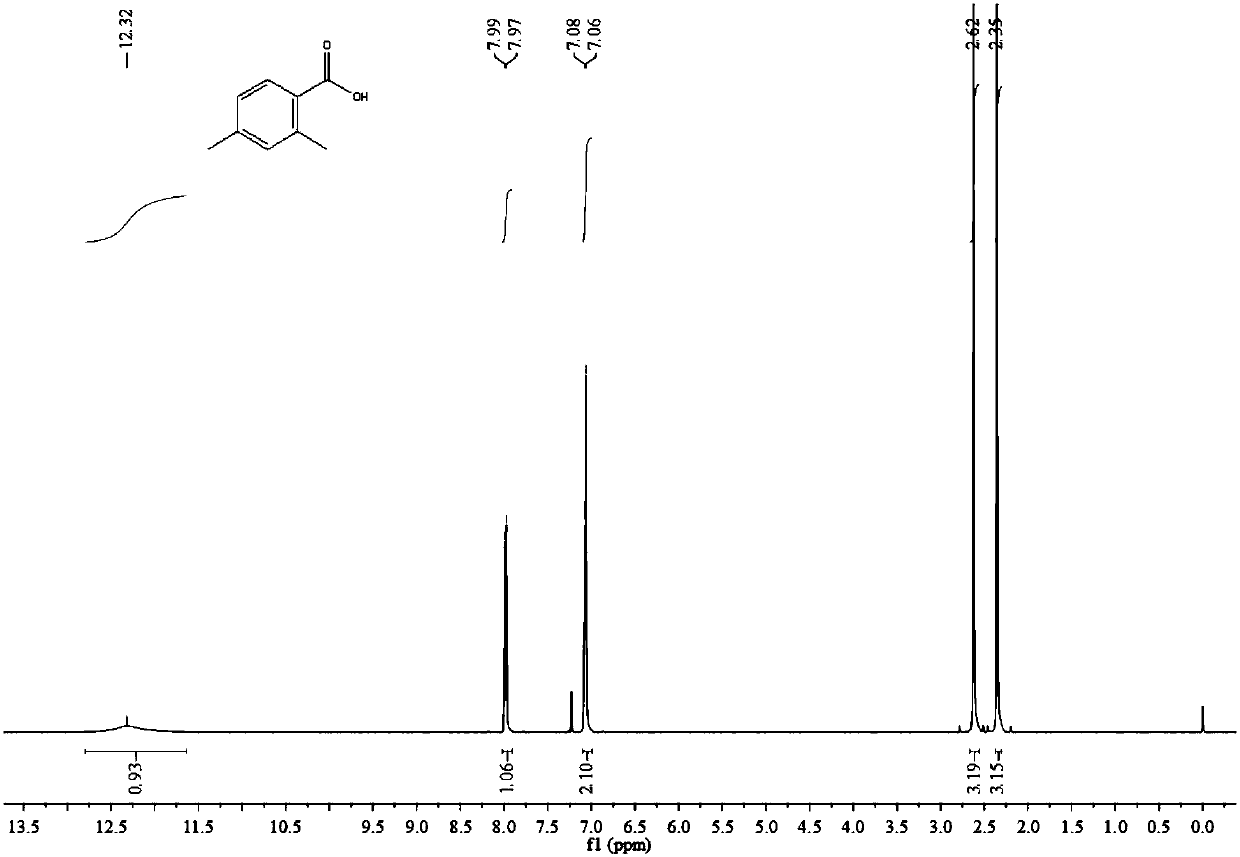

Method for preparing aromatic acid by direct carboxylation of CO2

ActiveCN107827742ATimely neutralizationAvoid complex preparationPreparation from carboxylic acid saltsProductsHalogenHigh pressure

The invention discloses a method for preparing aromatic acid by direct carboxylation of CO2. The method comprises the following steps: (1) adding aromatic hydrocarbon, organic alkali and lewis acid into a high pressure reaction kettle under an inert gas atmosphere, then feeding CO2 gas into the high pressure reaction kettle for reaction, and obtaining reaction liquid with aromatic acid at the endof the reaction; (2) adding water into the reaction liquid obtained in the step (1), then extracting the aromatic acid in the reaction liquid with an extracting agent to enable the aromatic acid in the reaction liquid to enter an extracting phase, separating the extracting phase from raffinate, and concentrating the extracting phase to obtain the aromatic acid. According to the method, complicatedpreparation of ionic liquid is avoided, and organic alkali is timely neutralized with halogen hydride produced by the reaction, so that the balance moves rightwards; at the end of the reaction, the organic alkali also can be recycled through alkali treatment. The method has the advantages of simple operation, mild conditions, green process, low cost and the like, and is expected to be applied toindustrial production.

Owner:SHAANXI COAL & CHEM TECH INST

Easy-to-tear packaging composite film and extrusion type liquid packaging bag

InactiveCN111204095AReduce the difficulty of recyclingAchieve recyclabilitySynthetic resin layered productsBagsComposite filmLayer thickness

The invention discloses an easy-to-tear packaging composite film. The easy-to-tear packaging composite film comprises an outer protective layer, a middle barrier layer and an inner heat sealing layer,the thickness of the outer protective layer is 12-30 [mu]m, the thickness of the middle barrier layer is 7-30 [mu]m, and the thickness of the inner heat sealing layer is 30-100 [mu]m; and the outer protective layer, the middle barrier layer and the inner heat sealing layer are compounded by adopting a dry compounding process or an extrusion compounding process. An extrusion-type strip-shaped liquid packaging bag prepared from the easy-to-tear composite film has extrusion weak points, so that contents are convenient to extrude.

Owner:JIANGYIN BAOBO PACKING

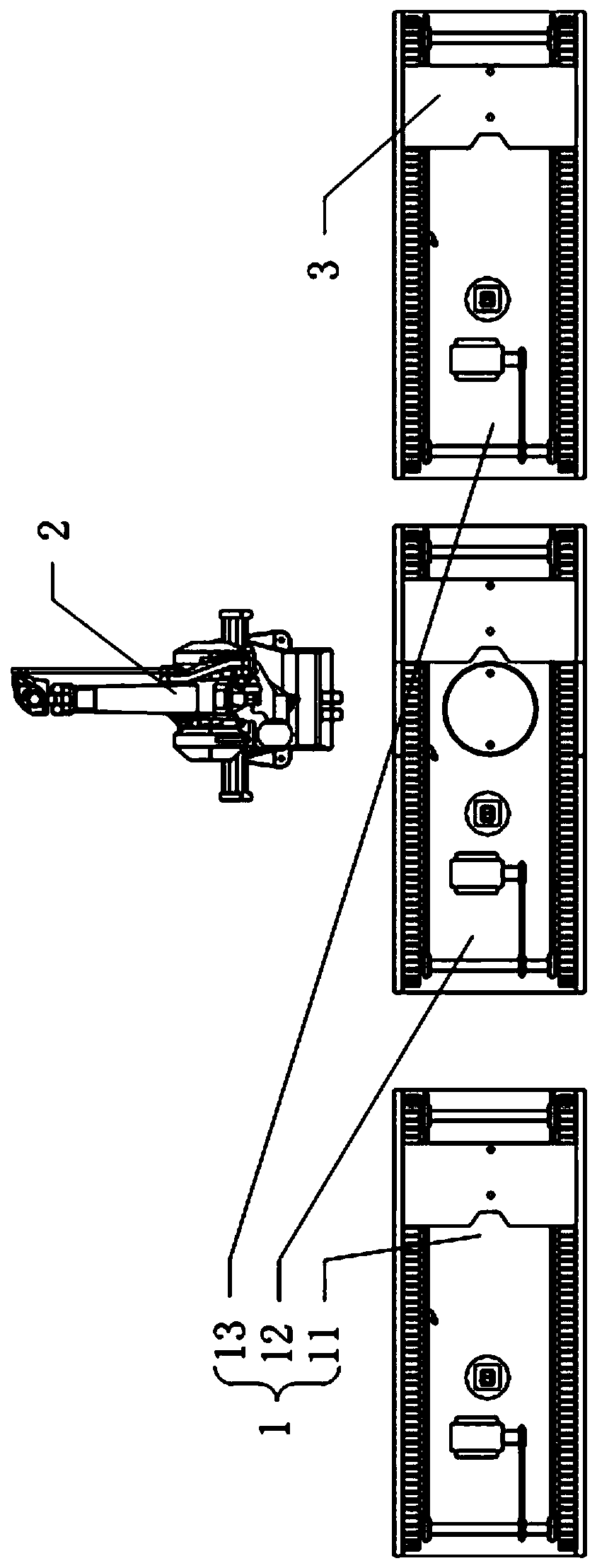

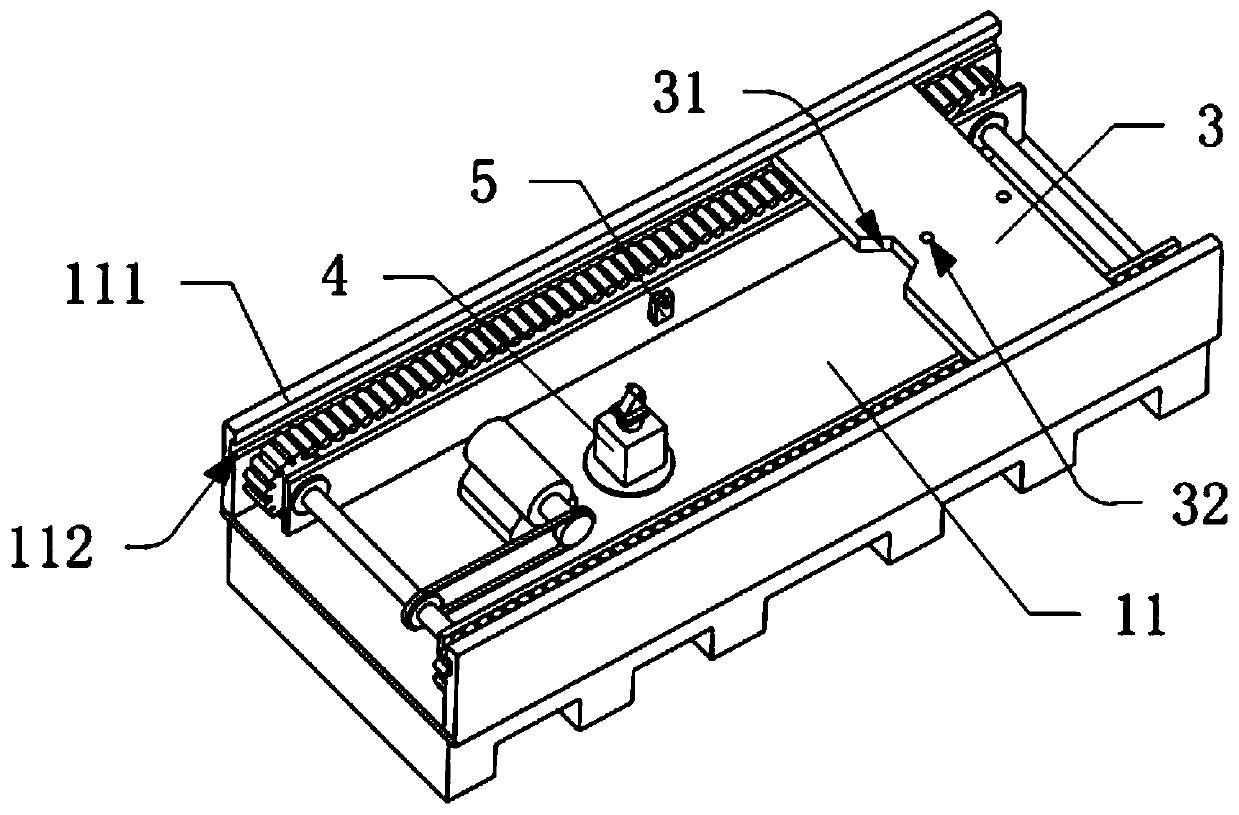

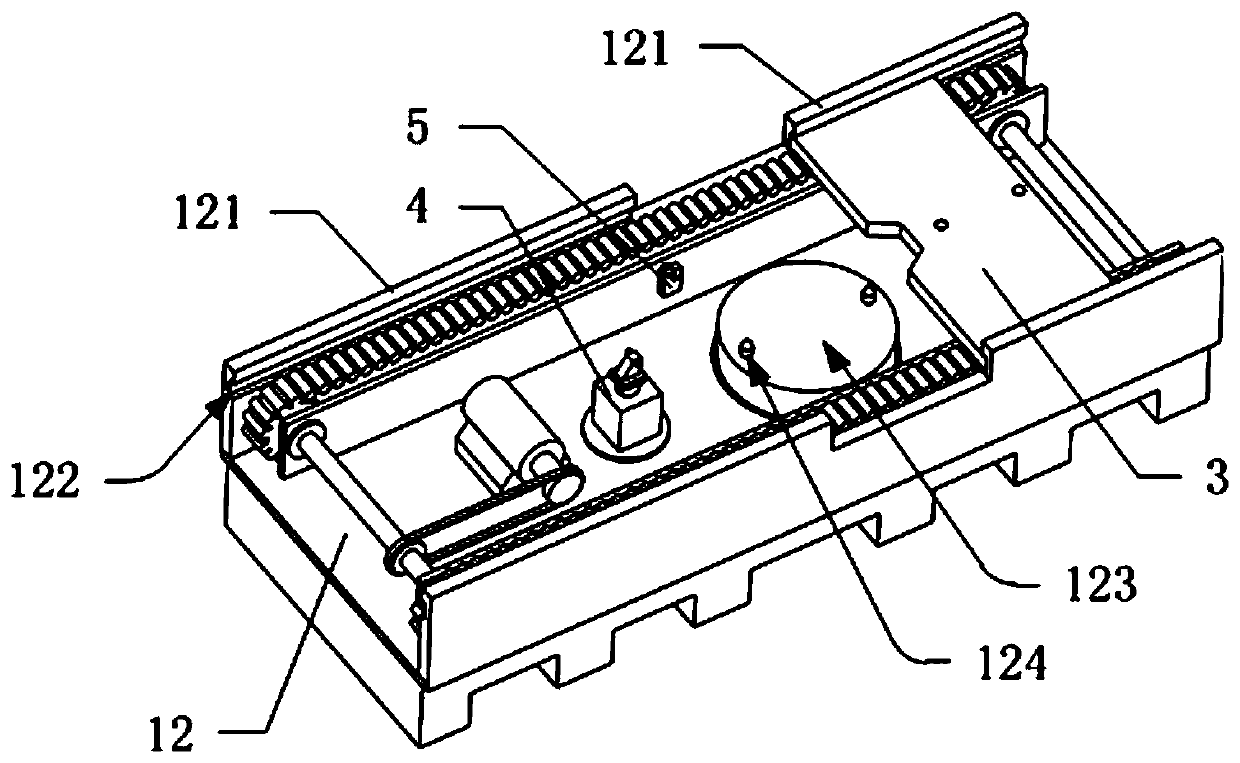

Artificial intelligence fiber spraying system

The invention relates to an artificial intelligence fiber spraying system which includes a spraying robot for resin fiber spraying, three sequentially-connected chain conveyors, a support plate, an auxiliary support frame, a control device, a steam generator, a resin stirrer, a buzzer, a yarn breaking detector, a glass fiber support arranged on one side of the spraying robot and a guide member forguiding glass fiber bundles. The spraying robot is arranged on one side of the chain conveyor located in the middle. The auxiliary support frame stably supports newly-formed bathtub to provide strongsupporting force for the inner top face and the inner side faces of the bathtubs, and deformation of the surfaces of the bathtubs due to the gravity of resin and glass fibers is prevented. Each chainconveyor is provided with a blocking cylinder and a travel switch to realize stopping of the support plate carrying the auxiliary support frame so that the chain conveyors can convey the bathtubs inan orderly manner. The yarn breaking detector monitors whether the glass fiber bundles are broken or not during fiber spraying or whether glass fiber cutter wheels are stuck and cause the condition offiber spraying disability or not. Steam generated by the steam generator heats the resin, melts the resin frozen due to low-temperature freezing, and makes stirring smoother.

Owner:佛山市锦泽致盛智能科技有限公司

Mixing and stirring device for high-viscosity fluid for synthetic resin

PendingCN108745105ASimple structureDesign scienceTransportation and packagingRotary stirring mixersSmall dropletEngineering

The invention discloses a mixing and stirring device for a high-viscosity fluid for synthetic resin. The mixing and stirring device comprises a casing, the casing is divided into a mixing zone and a stirring zone through a partition plate, the top in the mixing zone is provided with a plurality of feeding pipes 1 extending into the top from the outer part of the casing, the end of the feeding pipe1 in the mixing zone is provided with a plurality of nozzles, the side in the mixing zone is provided with a plurality of feeding pipes 2 extending into the side from the outer part of the casing, the end of the feeding pipe 2 in the mixing zone is provided with a plurality of nozzles, the bottom of the partition plate is provided with an overflow hole, a stirrer is arranged in the stirring zoneand the bottom of the stirring zone is provided with a discharge outlet. The mixing and stirring device has a simple structure and a scientific design. A plurality of chemical solvents are sprayed into a reaction chamber and are mixed in the form of small droplets in the reaction chamber so that the difficulty of mixing is reduced and the solvents subjected to the preliminary mixing enter the stirring zone and are stirred.

Owner:JIANGSU BOYAN ELECTRONICS TECH

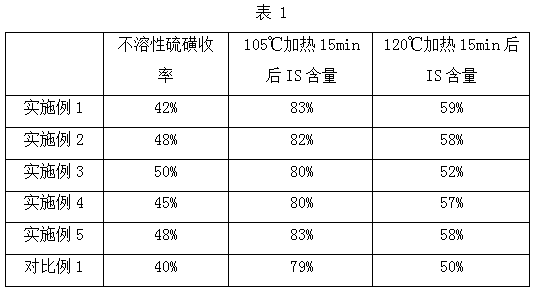

Preparation method of insoluble sulfur and used anti-reversion stabilizer thereby

ActiveCN109368599AReduce pollutionReduce preparationSulfur preparation/purificationDecompositionEnd-group

Owner:SHANDONG YANGGU HUATAI CHEM

Waste emulsion sludge treatment method

ActiveCN109385321ALow costThe treatment method is economical and practicalBiofuelsSolid fuelsEmulsionPrill

The invention discloses a waste emulsion sludge treatment method, and belongs to the field of industrial waste treatment methods. The waste emulsion sludge treatment method comprises the following steps: 1, proportioning materials: quantitatively proportioning waste emulsion sludge and fly ash for next-step operation; 2, mixing: mixing materials proportioned in the proportioning step, namely repeatedly performing rolling, stirring and mixing operation thereon to obtain powdery particles; 3, discharging: outputting a finished product obtained in the mixing step, wherein the water content of thefly ash proportioned in the proportioning step is lower than or equal to 1%, the water content of the waste emulsion sludge is lower than or equal to 50%, and the content of particles with the particle size being smaller than or equal to 1mm in the proportioned fly ash is higher than or equal to 90%. According to the waste emulsion sludge treatment method, no chemical reaction occurs and no new pollutant is produced during treatment, two industrial wastes, namely the waste emulsion sludge and the fly ash, are treated, the obtained product can be fully burned as a fuel, the treatment cost is low, the treatment method is simple, the problem that the existing waste emulsion sludge is difficult to treat is solved, and industrialized application is easy.

Owner:马钢集团设计研究院有限责任公司

Vehicle anti-aging rubber

Vehicle anti-aging rubber comprises natural rubber, butadiene styrene rubber, butadiene rubber, epichlorohydrin rubber, silicone rubber, polyurethane rubber, ethylene propylene rubber, aromatic oil, stearic acid, coupling agents, plant polyphenol, sodium citrate, citric acid, petroleum resin, propiono phosphoric acid dioctadecyl ester, palmitamide, methyl propionate, p-phenyl dual amine, muscone, salicylic acid, argil, aromatic oil, microcrystalline cellulose, microcrystalline wax, boron carbide, magnesium stearate, polyisobutylene rubber and bismuth oxide. The anti-aging rubber can achieve excellent anti-aging effects, and aging resistance and heat resistance of the rubber are excellent.

Owner:ANHUI RUNKANG RUBBER & PLASTIC TECH CO LTD

Vehicle siloxane damping elastomer

The invention discloses a vehicle siloxane damping elastomer. The vehicle siloxane damping elastomer comprises the following components: 100 parts by weight of polysiloxane matrix resin, 10-20 parts by weight of oligomeric polyester polyol with number-average molar mass of 100-150, 1-5 parts by weight of organic bentonite, 50-60 parts by weight of silicone oil, 20-30 parts by weight of silica dioxide, 20-30 parts by weight of glass beads and 2-3 parts by weight of antioxidant, wherein the weight ratio of the oligomeric polyester polyol to the organic bentonite is (4-6):1. The vehicle siloxane damping elastomer disclosed by the invention has good machinability and high system homogeneity; a product obtained by machining the vehicle siloxane damping elastomer has good quality and bright and clean surface as well as good elasticity, strong sound insulation and noise elimination capacity and good stretching and restoration performance.

Owner:LIUZHOU XINGTA IND & TRADE

High-purity gold-silver-palladium-platinum alloy bonding wire and preparation method thereof

PendingCN114005808ARaise the initial temperatureIncreased time required for smeltingSemiconductor/solid-state device detailsSolid-state devicesPlatinumAlloy

The invention discloses a high-purity gold-silver-palladium-platinum alloy bonding wire and a preparation method thereof, and relates to the technical field of alloy materials. The high-purity gold-silver-palladium-platinum alloy bonding wire comprises the following components in percentage by weight: 4-7% of gold, 85-94% of silver, 3-4% of palladium and 1-2% of platinum. According to the invention, no matched water cooling needs to be arranged during actual implementation, so that the equipment cost is reduced, waste heat generated in the cooling process can be recycled, the mechanical mixing effect of the first batch of raw materials is more ideal, the time required by the process is further shortened, and more energy conservation and environmental protection are realized while the production efficiency is improved.

Owner:江西蓝微电子科技有限公司

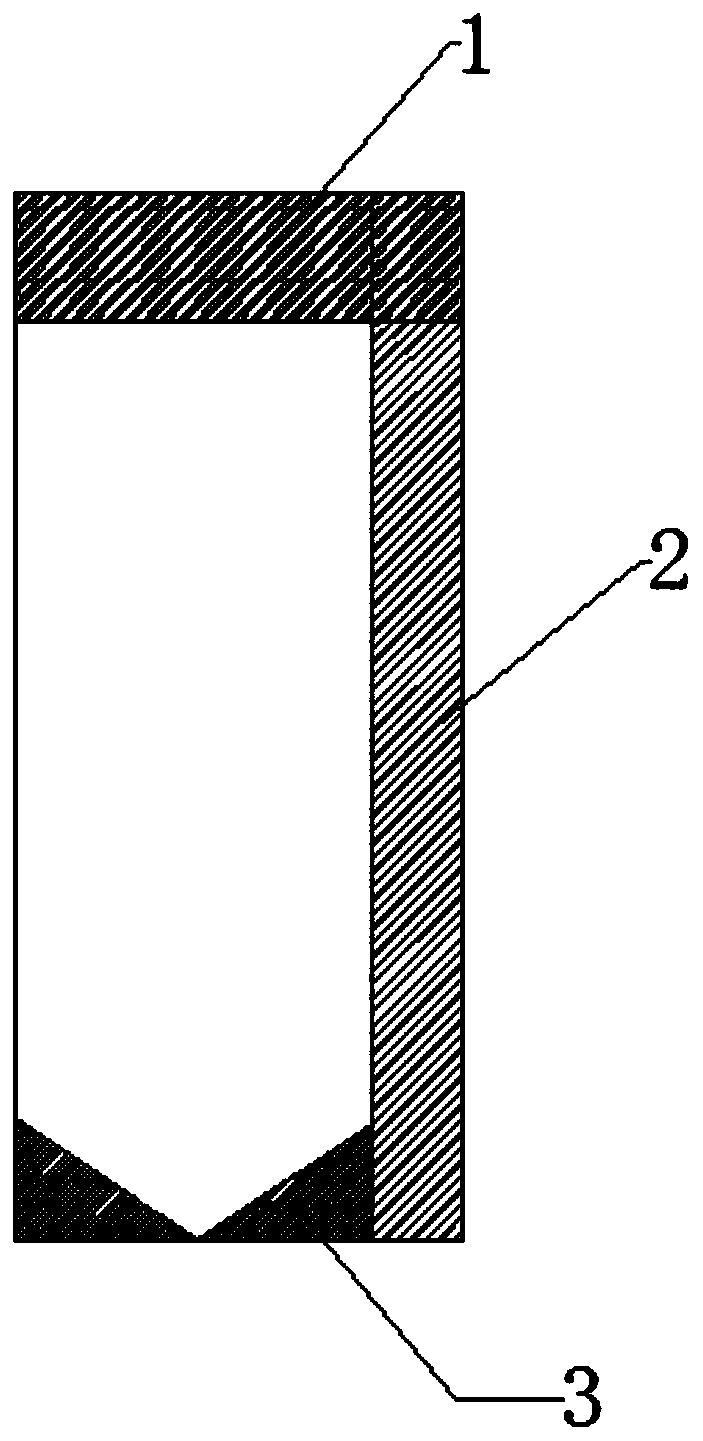

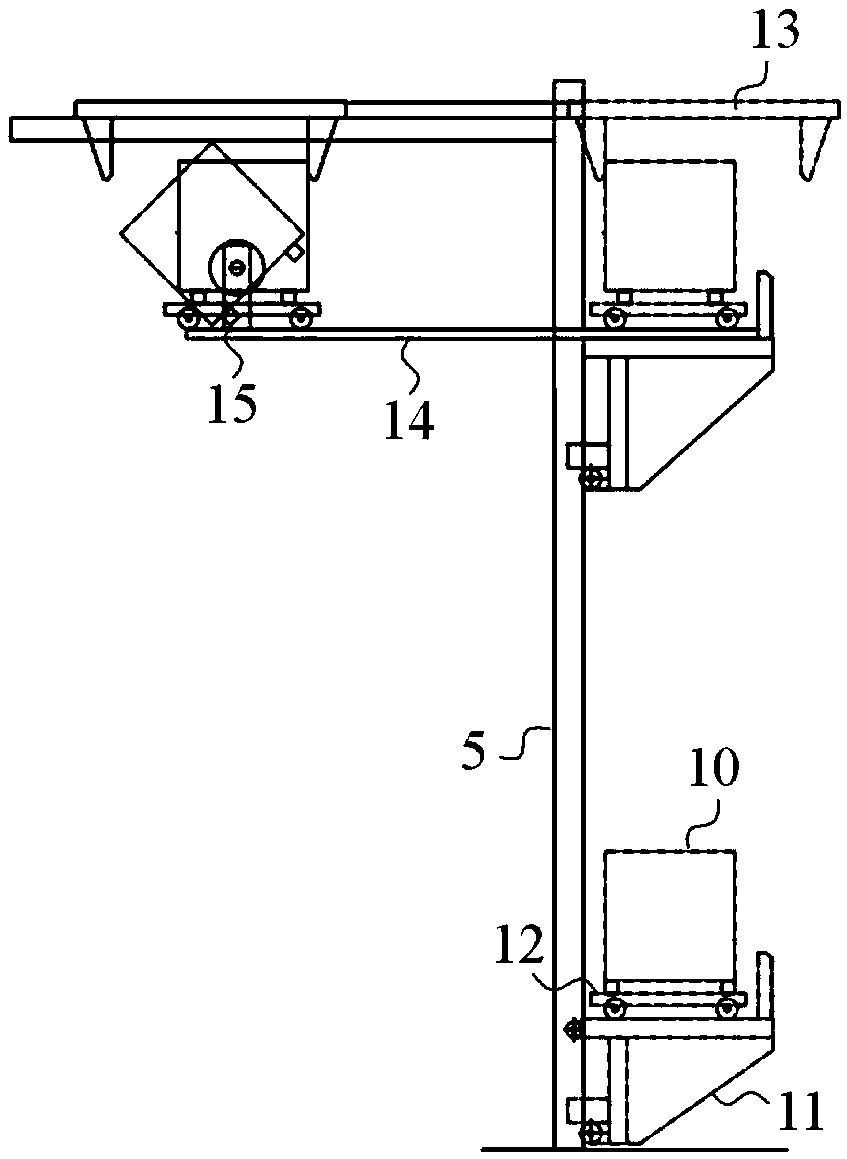

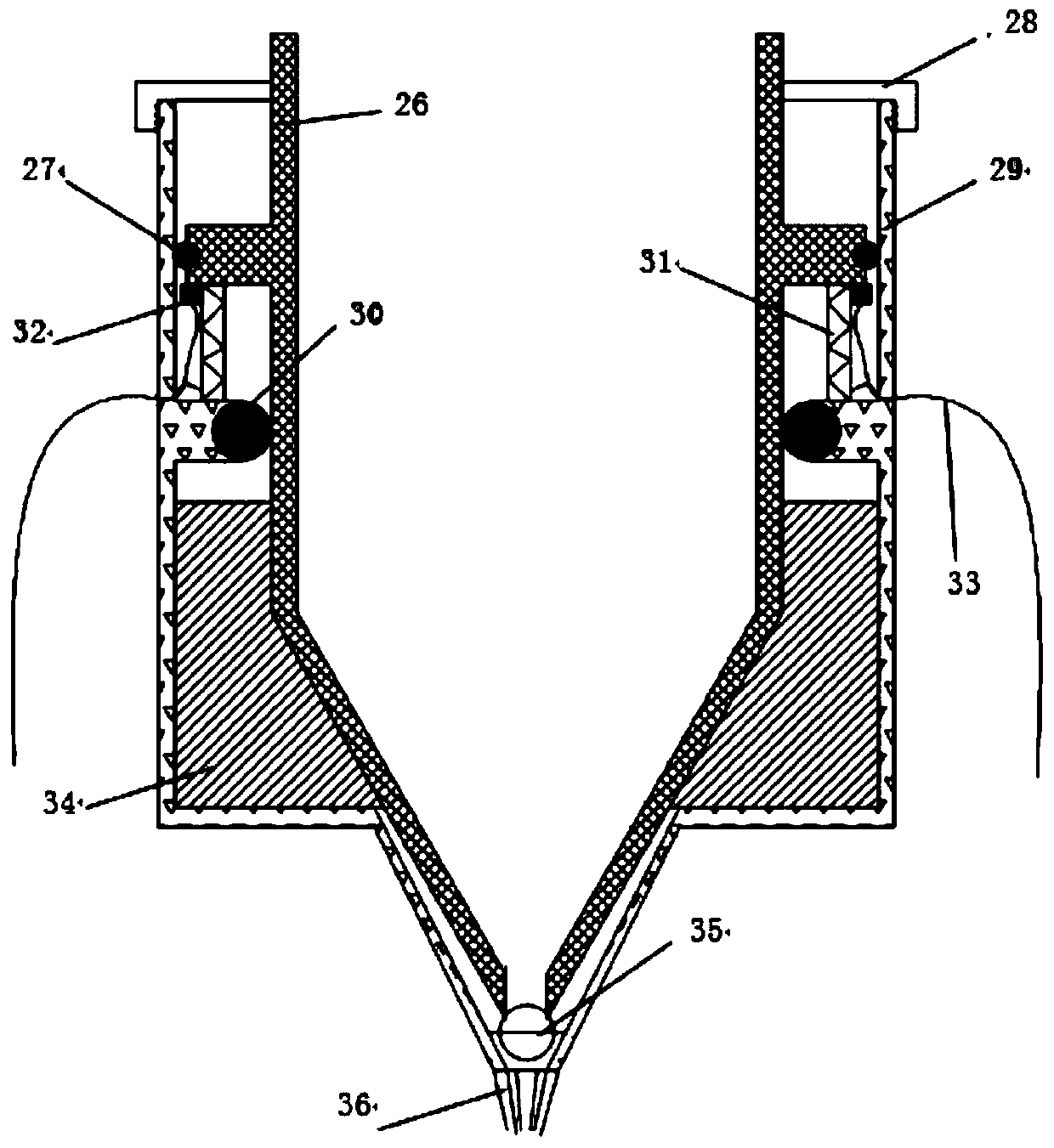

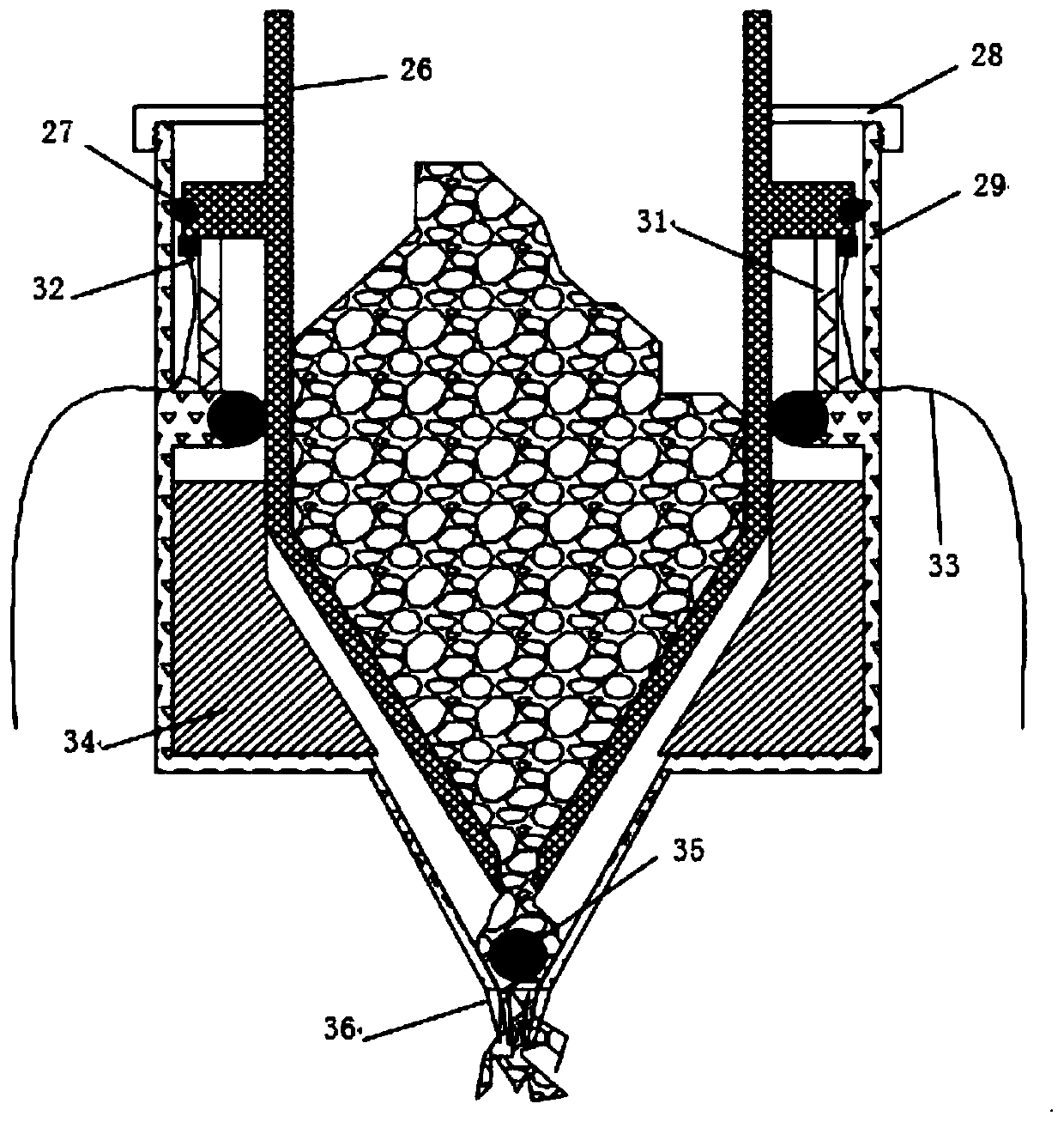

Method for producing carbon-containing titanium sponge and device thereof

The invention discloses a method for producing carbon-containing titanium sponge and a special device for the method. The method comprises the following steps of pre-adding a carbon-containing compound before titanium sponge is produced from titanium tetrachloride, and then reducing the titanium tetrachloride premixed with the carbon-containing compound to obtain carbon-containing titanium sponge with uniform components, wherein the carbon-containing compound is titanium tetrachloride. According to the method, titanium tetrachloride is directly added before the generation of titanium sponge, and the content of carbon in titanium tetrachloride is controlled so as to achieve the purpose that the content of carbon in titanium tetrachloride is stably controlled; no carbon powder needs to be additionally added during the smelting of a titanium alloy, and thus the segregation of carbon element components and local defects in the titanium alloy caused by the conventional adding method are avoided; sizes of carbides and particles precipitated in the titanium alloy of the carbon-containing titanium sponge are very ideal, the negative impact of a carbon element added in the titanium alloy is effectively solved, meanwhile, the difficulty in preparing and mixing the titanium alloy is reduced, the uniform components and stable quality of titanium alloy ingots are ensured, and a series of technical difficult problems caused by adding the carbon element during the smelting of the titanium alloy at home are solved.

Owner:朝阳金达钛业股份有限公司

Beef pickling equipment convenient for spice adding

The invention relates to the technical field of beef pickling equipment, and discloses beef pickling equipment convenient for spice adding. The equipment comprises a pickling tank and a tank cover, wherein the tank cover is in threaded connection to the surface of the pickling tank; a bearing is fixedly embedded in the surface of the pickling tank; a stirring shaft is fixedly connected to the inner surface of the bearing; a motor mounting plate is fixedly connected to the surface of the pickling tank; a servo motor is fixedly connected to the upper surface of the motor mounting plate through bolts, and the output shaft of the servo motor is fixedly connected with the left end of the stirring shaft; a stirring rod is fixedly connected to the surface of the stirring shaft, and is positionedinside the pickling tank; a first conical cylinder is fixedly connected to the inner surface of the tank cover; and a second conical cylinder is movably connected with the outer surface of the first conical cylinder. According to the beef pickling equipment, the problem that the stirring difficulty is increased since spices are accumulated on beef when spices are added with current beef pickling equipment can be solved due to the arrangement of the first conical cylinder, the second conical cylinder, a third conical cylinder, a disc and a movable rod.

Owner:ANHUI DONGSHENG FOOD

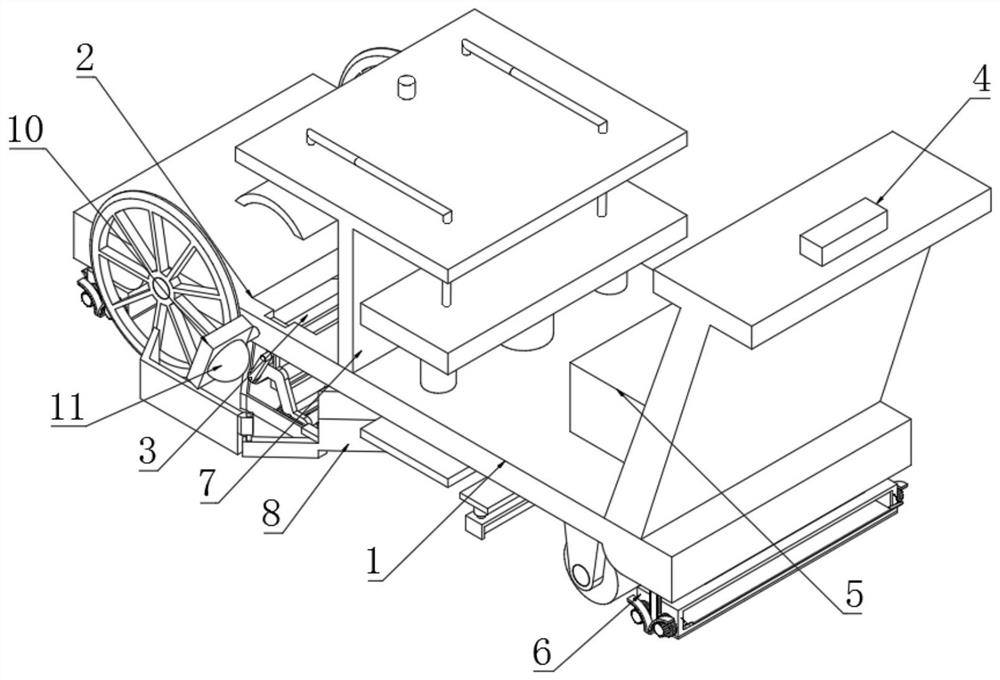

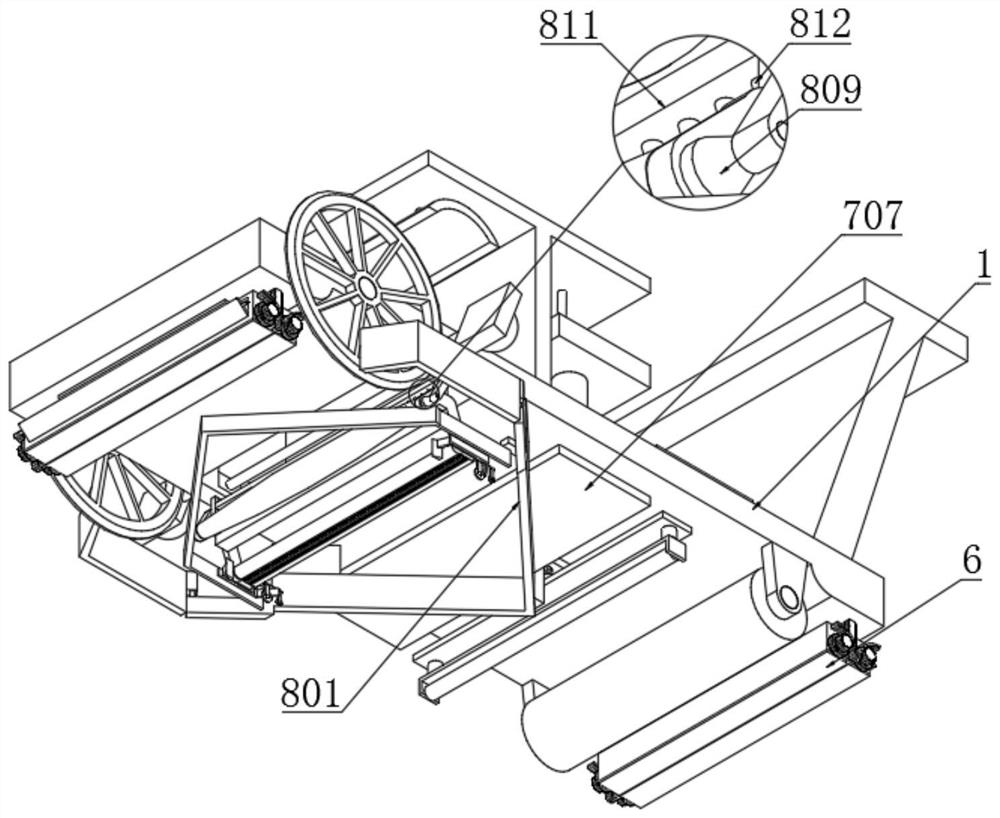

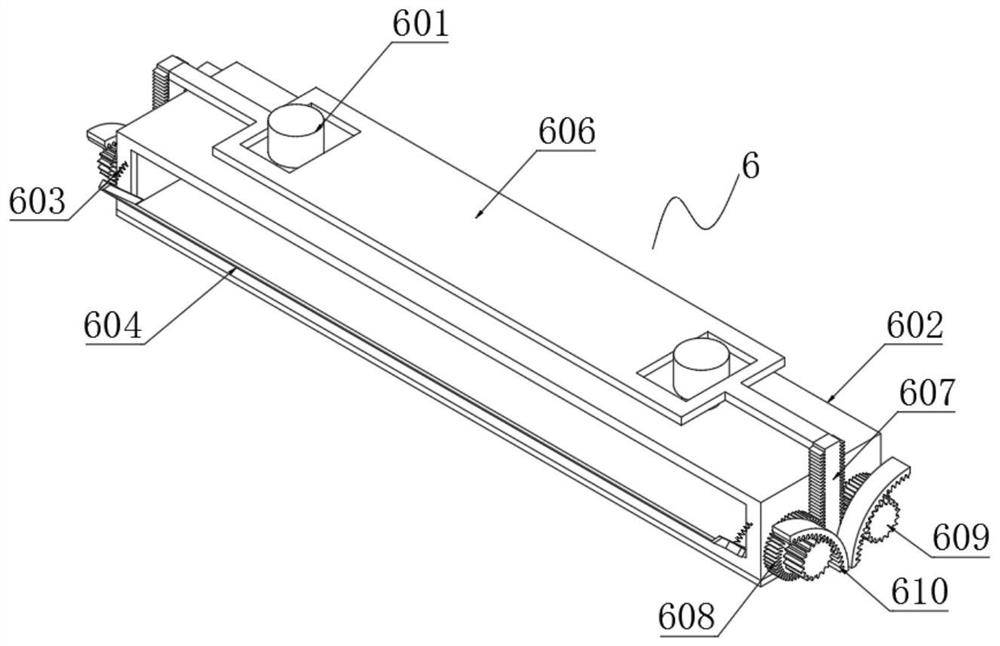

Agricultural multifunctional integrated mulching film laying device

PendingCN113557897AImprove work efficiencySave time on manual fillingSpadesPloughsCartAgricultural engineering

The invention discloses an agricultural multifunctional integrated mulching film laying device which comprises a cart, a notch is formed in one side of the top end of the cart, a placement roller is clamped to the middle of the inner wall of the notch, a controller is fixedly installed on the edge of one side of the top end of the cart, a storage battery is fixedly installed in the middle of the top end of the cart, integrated ditching assembly mechanisms are symmetrically installed on the two sides of the bottom end of the cart, and each integrated ditching assembly mechanism comprises a press-fit electric telescopic rod, a press-fit frame, an arc spring, a soil collecting plate, a movable electric push rod, a movable frame, a double-face sawtooth strip, a driving gear, a connecting gear, an arc insection strip and a rotary cover plate. Through the integrated ditching assembly mechanisms, horizontal ditching can be conveniently conducted on soil, the ditching difficulty of workers is reduced, meanwhile, mulching films in horizontal ditches can be extruded, so that the mulching films and the plane are connected more stably, and the problem that workers need to spend time carrying out ditching in the prior art is solved.

Owner:蓝柱平

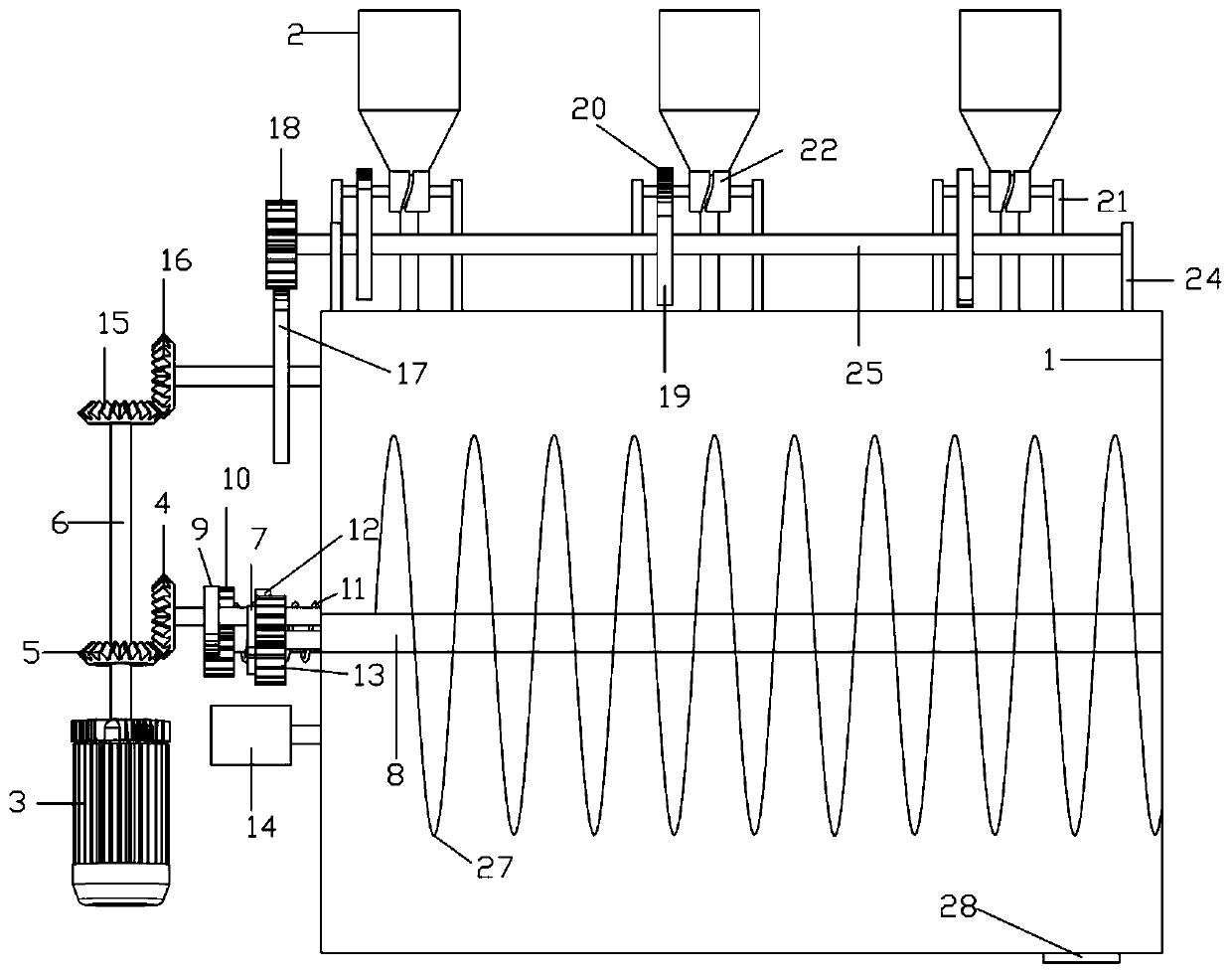

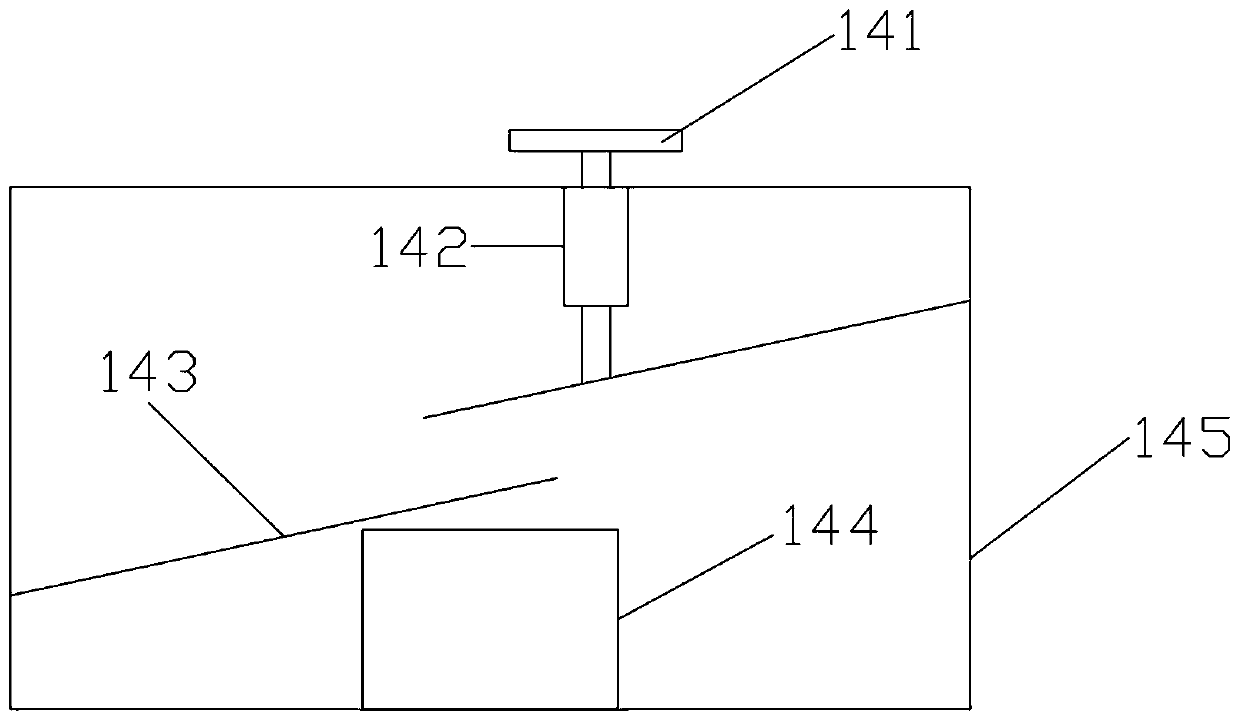

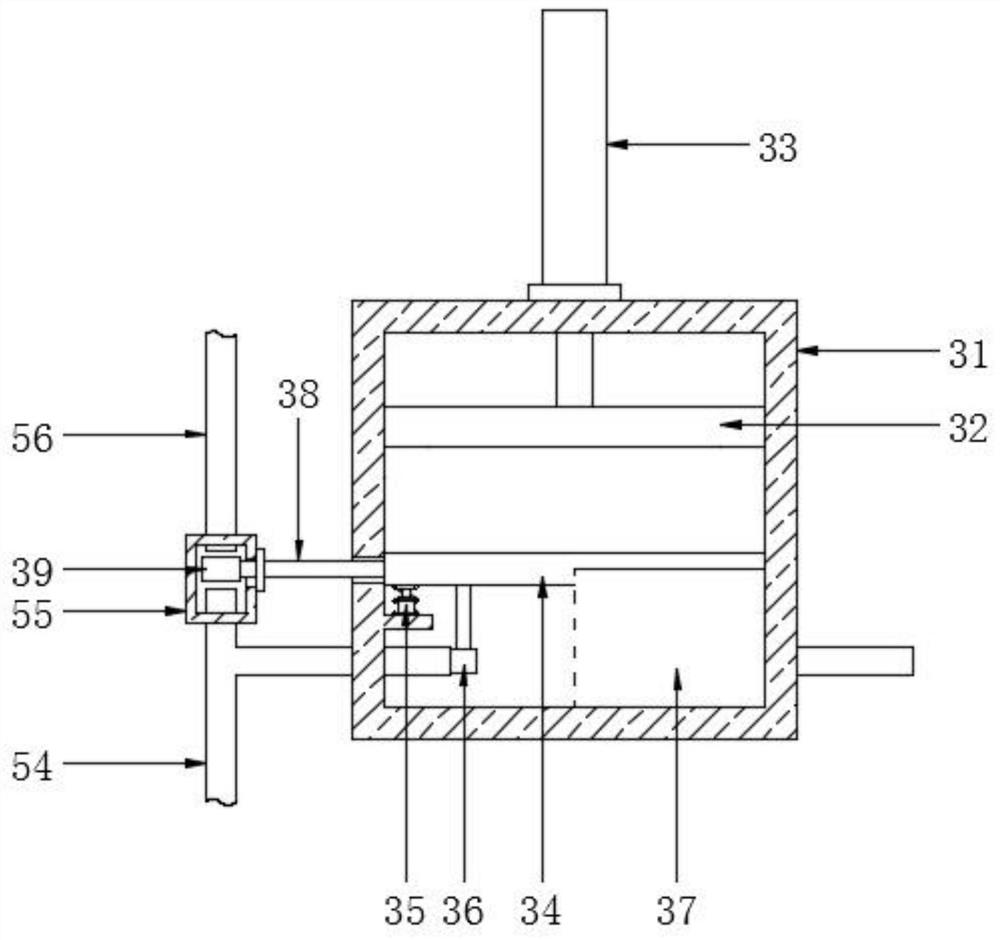

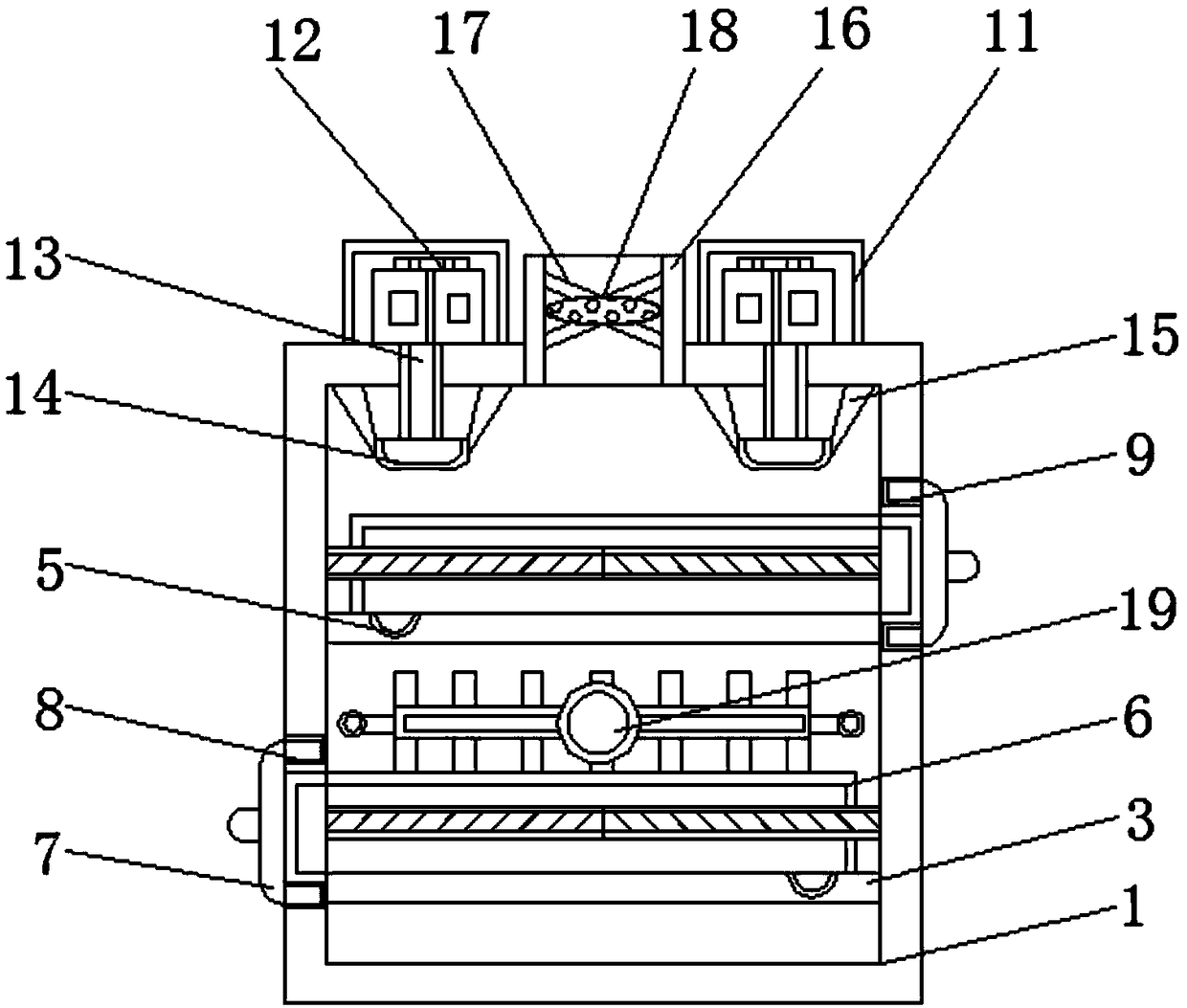

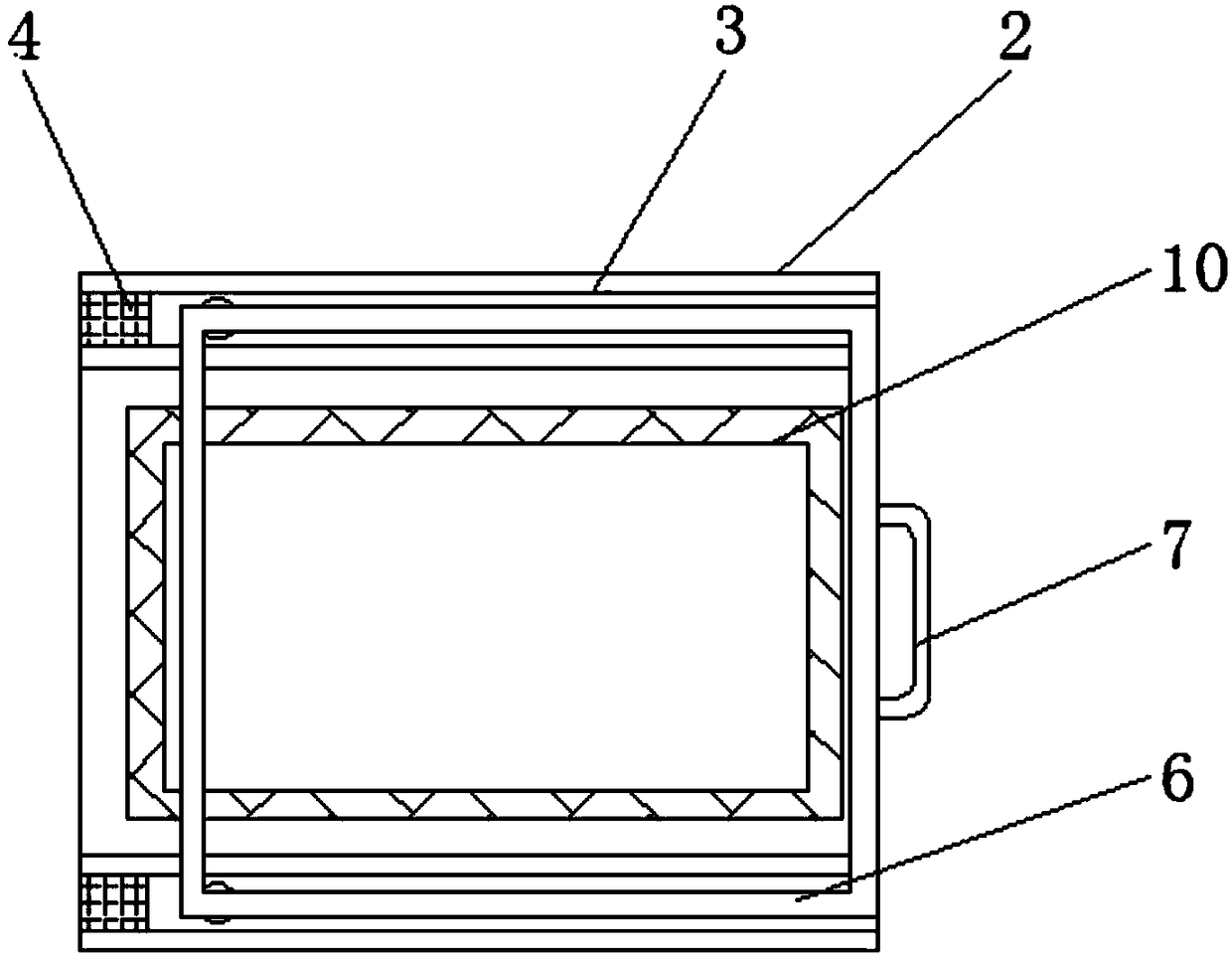

Equipment for atomizing ultrafine powder, cement, water reducer and water for concrete mixing

PendingCN110355876AEasy to removeReduce lossMixing operation control apparatusIngredients weighing apparatusEngineeringMixed materials

The invention relates to equipment for atomizing ultrafine powder, cement, water reducer and water for concrete mixing. The equipment comprises a plurality of material weighing and feeding cabins, a plurality of liquid weighing and feeding cabins, an atomizing cabin and a stirring cabin. The material weighing and feeding cabins and the liquid weighing and feeding cabins are arranged on the upper part of the atomizing cabin, the stirring cabin is fixed to the lower end of the atomizing cabin, blowers are arranged at discharge openings of the material weighing and feeding cabins, and atomizing chambers are arranged at discharge openings of the liquid weighing and feeding cabins. Compared with the prior art, the equipment has the beneficial effects that conventional mixing equipment is integrated and improved, and the mixing difficulty under a low water cement ratio is reduced by atomized mixing; a conventional mechanical cabin is remained, the cabin door is improved, a mechanical arm controls the semi-round cabin door to open and close, and a mixed material is can be eliminated conveniently and rapidly after improvement, and meanwhile, the material loss is reduced; by designing the weighing and feeding cabins, the material inputting proportion can be controlled effectively, so that the manpower and input are reduced, and the equipment is convenient and rapid.

Owner:UNIV OF SCI & TECH LIAONING

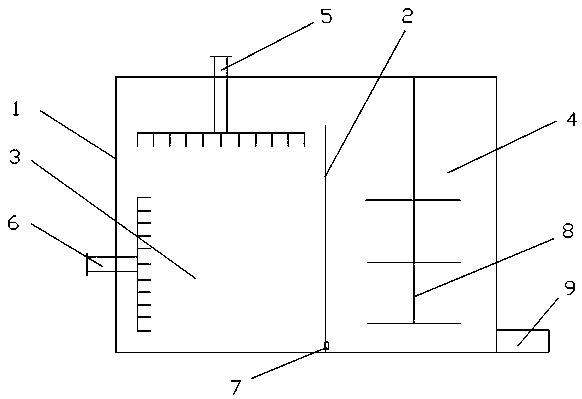

Layered efficient mud treatment device

PendingCN108218183ASimple structureSpeed up dryingSludge treatment by de-watering/drying/thickeningDispersed particle separationTherapeutic effectEngineering

The invention discloses a layered efficient mud treatment device. The layered efficient mud treatment device comprises a treatment tank, motor frames and an exhaust port, wherein a flat plate is arranged at the inner part of the treatment tank; sliding rails are arranged at two sides of the flat plate; sliding rail check blocks are arranged at the tail parts of the sliding rails; small pulleys arearranged at the inner parts of the sliding rails; pull rings are fixedly arranged at the outer side of a mud collection plate; the outer sides of protruding blocks are tightly adhered to grooves; electric heating elements are arranged at the inner part of the flat plate; first motors are arranged at the inner parts of the motor frames; first rotating shafts are arranged under the first motors; draught fan fixing frames are fixedly arranged at the outer sides of draught fans. The layered efficient mud treatment device disclosed by the invention is complete in inner structure, a mud treatment effect is better, and one-off treatment capacity of mud is larger; secondly, when the layered efficient mud treatment device is used for treating the mud, consumed time is shorter, and air cannot be polluted by a gas discharged during a mud treatment process.

Owner:HEFEI UNIV

Production process of plastic-wood garbage box

InactiveCN108582392AWon't uniteReduce wasteDomestic articlesHollow articlesCompression moldingGranularity

The invention relates to the production field of plastic-wood products, in particular to a production process of a plastic-wood garbage box. The production process is characterized by comprising the following steps: (1) first time drying: drying a wood till the water content of the wood is reduced to below 5%; (II) crushing: crushing the wood processed in the step (I) to wood powder, the granularity of which is 0.15-0.5mm; (III) second time drying: drying the wood powder processed in the step (II) till the water content of the wood powder is reduced to below 1-2%; (IV), mixing: introducing thewood powder processed in the step (III) and other raw materials in proportion into a mixing device, and heating the mixture; and keeping the temperature in the mixing device at 80-150 DEG C till theraw materials are uniformly mixed; and (V) mold pressing: introducing the mixed material flowing out of the mixing device into a mold for compression molding, and taking a garbage box from the mold. According to the scheme, carbonization of the wood powder can be reduced.

Owner:XINJIANG HUATING IND & TRADE

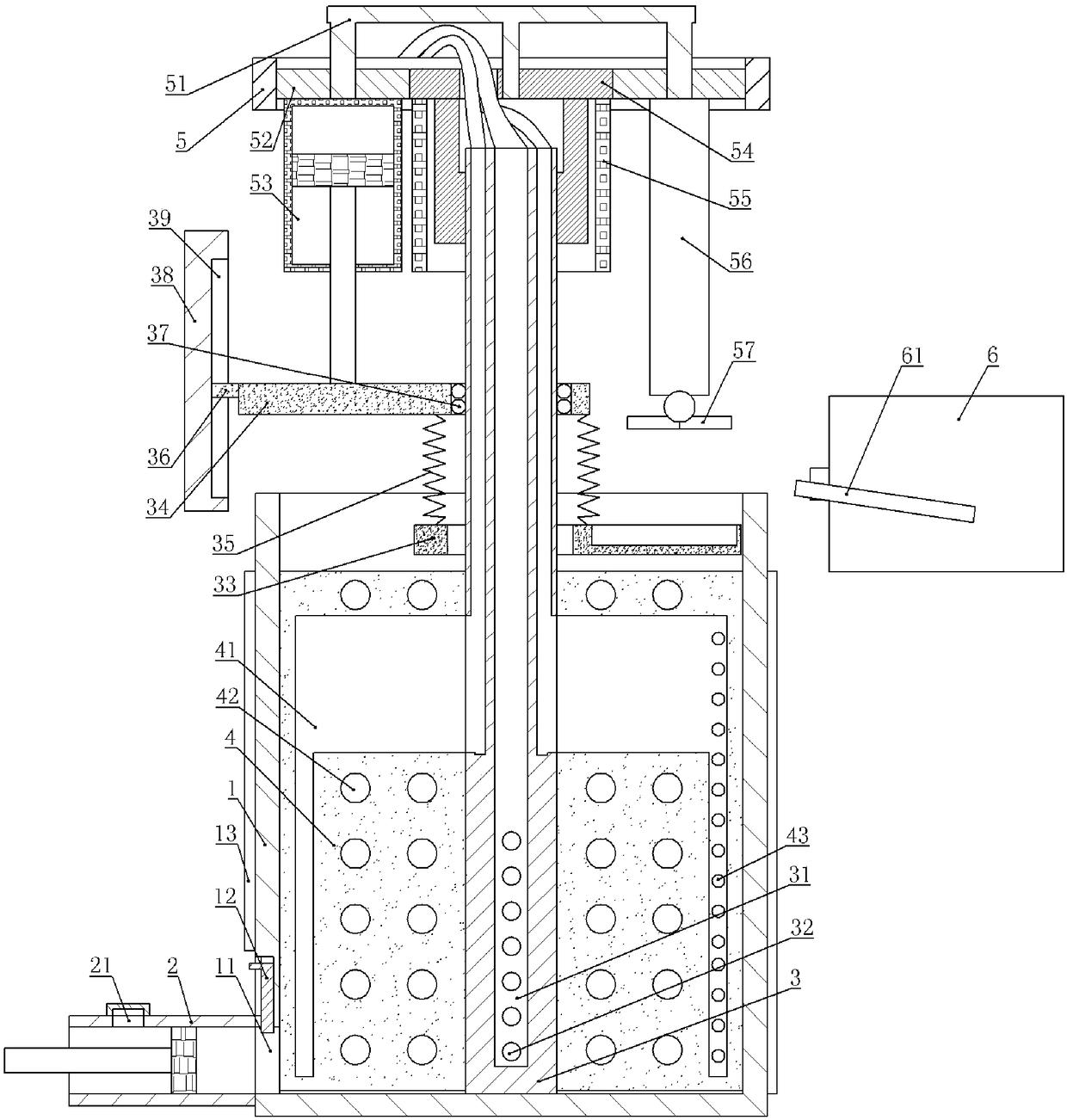

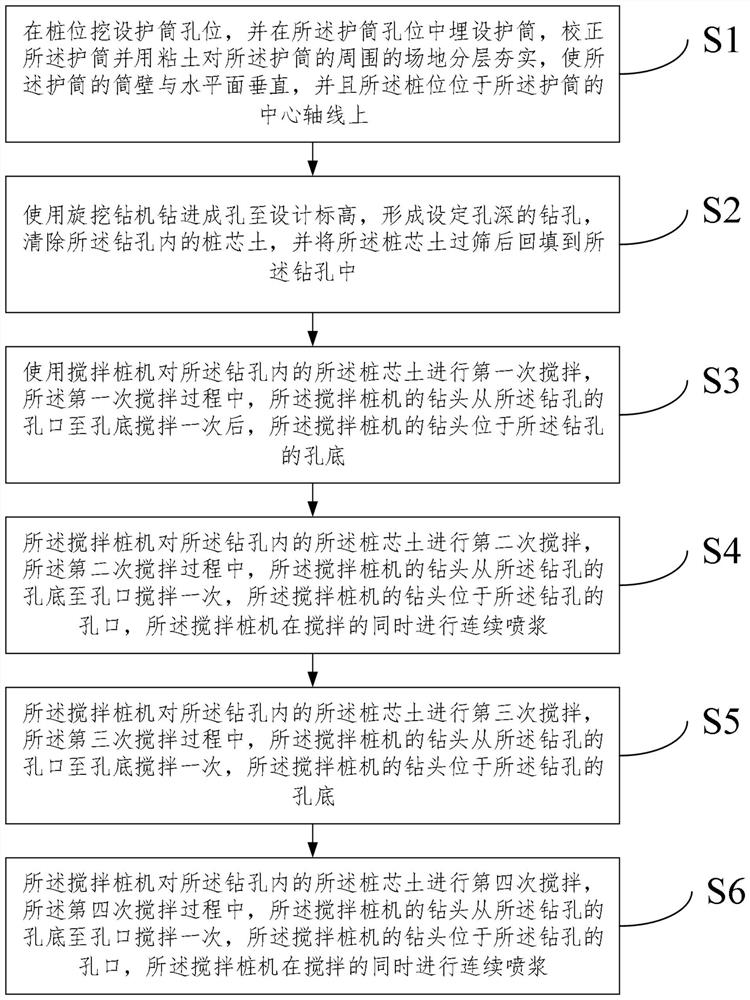

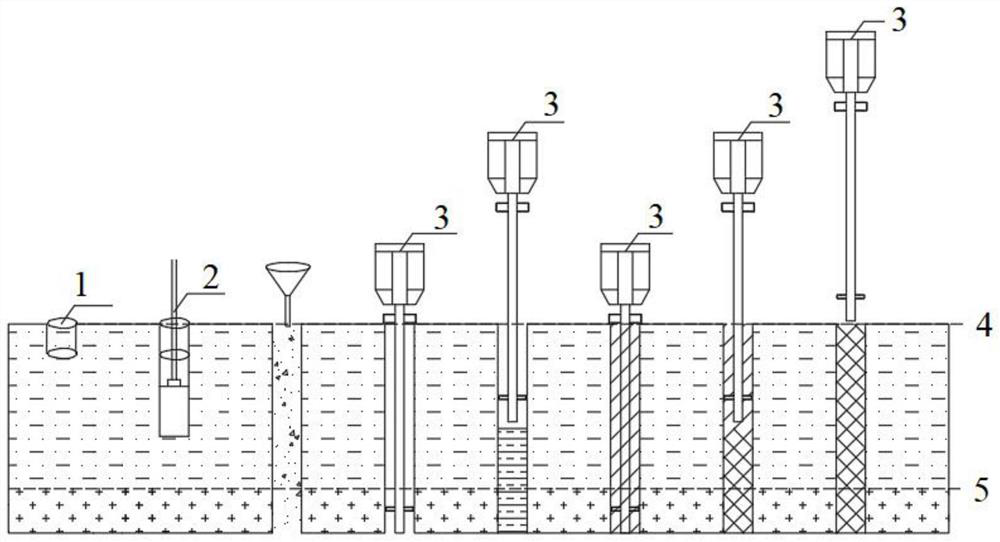

Construction method of large-diameter mixing pile suitable for high underground water level hard soil layer

InactiveCN114059527AReduce wearGood anti-seepageProtective foundationDirectional drillingSoil scienceSoil mixing

The invention relates to a construction method of a large-diameter mixing pile suitable for a high underground water level hard soil layer, which comprises the following steps: a pile casing hole site is dug at a pile site, and a pile casing is buried, so that the wall of the pile casing is vertical to the horizontal plane; a rotary drilling rig is used for drilling a formed hole to the designed elevation, pile core soil in the drilled hole is removed, and the pile core soil is backfilled into the drilled hole after being sieved; and the pile core soil in the drilled hole is stirred for four times through a stirring pile machine, and connected guniting is conducted during second-time stirring and fourth-time stirring. The rotary drilling rig is used for guiding holes, so that the subsequent stirring pile machine can drill smoothly; fine-grained soil is screened out from pile core soil excavated by the rotary drilling rig, and then the fine-grained soil is backfilled into the drill hole; the mixing pile machine is centered in place, a drill rod sinks to the bottom of a hole, guniting is conducted while stirring and rising are conducted, operation is repeated, even stirring is guaranteed, meanwhile, the stirring difficulty is effectively reduced, abrasion of a stirring rod is reduced, and the stirring efficiency is improved; and finally, the rod is lifted out of the hole to wait for solidification of the soil body, and the cement-soil mixing pile with good impermeability is formed.

Owner:深圳市基础工程有限公司

Silicone rubber roller elastic material and preparation method thereof

PendingCN113715185AIncrease blocking strengthReduce the difficulty of mixingPolymer chemistryPolymer science

The invention discloses a silicone rubber roller elastic material and a preparation method thereof, and relates to the technical field of silicone rubber preparation. The silicone rubber roller elastic material comprises a preparation barrel, the top of the preparation barrel is fixedly connected with a supporting frame, a stirring motor is installed at the top of the supporting frame, and an output end of the stirring motor extends to the lower portion of the supporting frame. The stirring motor comprises a stirring device, a trigger device and a driving device, wherein the stirring device is provided with a stirring shaft, and stirring plates are uniformly mounted on the outer side of the stirring shaft; the trigger device is provided with a stress plate, the stress plate is in sliding connection with the stirring plate, and a buffer spring is fixedly connected between the stress plate and the stirring plate; and the driving device is provided with a magnet block. According to the silicone rubber roller elastic material and the preparation method thereof, the purpose of reducing the silicone rubber preparation difficulty is achieved, the viscosity degree of silicone rubber raw materials in the stirring process is conveniently judged, the stirring efficiency of the silicone rubber raw materials is improved, and the accuracy degree of viscosity detection of the silicone rubber raw materials is increased.

Owner:罗小龙

Modified MQ resin as well as preparation method and application thereof

ActiveCN112574421AShort dissolution timeSimple processNon-macromolecular adhesive additivesPolymer scienceSealant

The invention provides modified MQ resin as well as a preparation method and application thereof, belonging to the technical field of pouring sealants. The modified MQ resin prepared by using the method provided by the invention belongs to solvent-free liquid MQ resin and is environment-friendly and low in VOC, and a process can be simplified. Under the condition that the reinforcing effect is notchanged basically, the method has the advantages that dissolving time for glue preparation is shortened, the time of a dissolving process is shortened, and efficiency is improved; the viscosity of the resin is reduced, the flowability of the resin is improved, potting leveling is more sufficient, and process operation is facilitated; and steric hindrance is reduced, crosslinking and curing are easy, and the process time is further shortened. The modified MQ resin is used in the field of pouring sealants, can effectively solve the problem of oil seepage of the pouring sealants, and prolongs the bonding life of the pouring sealants with base materials.

Owner:WANHUA CHEM GRP CO LTD +1

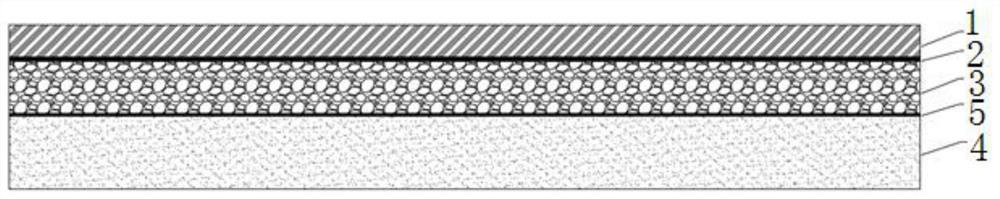

BRT station heavy traffic road section pavement structure and construction method

The invention discloses a BRT station heavy traffic road section pavement structure and a construction method. The pavement structure is composed of a high-viscosity high-modulus skeleton dense type mixture upper surface layer, a modified asphalt macadam connecting layer, a rigid-flexible composite asphalt mixture middle surface layer, and a modified asphalt suspension dense type mixture lower surface layer. The mixture upper surface layer is composed of fine-particle-size aggregate, ultrahigh-viscosity modified asphalt, a fiber stabilizer, a high-modulus additive and the like, and the anti-loosening and anti-deformation capacity of the surface layer is improved; the connecting layer is composed of aggregate with a single particle size and modified asphalt; the middle surface layer is formed by pouring mixed base slurry into a matrix asphalt mixture, so that the overall bearing capacity of the pavement layer is improved; and the mixture lower surface layer is composed of medium-grain or coarse-grain aggregate and modified asphalt, and the stability of the pavement layer is improved. The pavement structure is high in overall strength, strong in rut deformation resistance, good in durability and excellent in surface layer wear resistance and slide resistance, and can effectively improve the pavement quality and prolong the service life of the heavy traffic road section of a BRT station.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com