Modified MQ resin as well as preparation method and application thereof

A resin and modification technology, applied in the field of potting glue, can solve problems such as oil leakage, achieve the effects of shortening process time, improving efficiency, and reducing dissolution process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

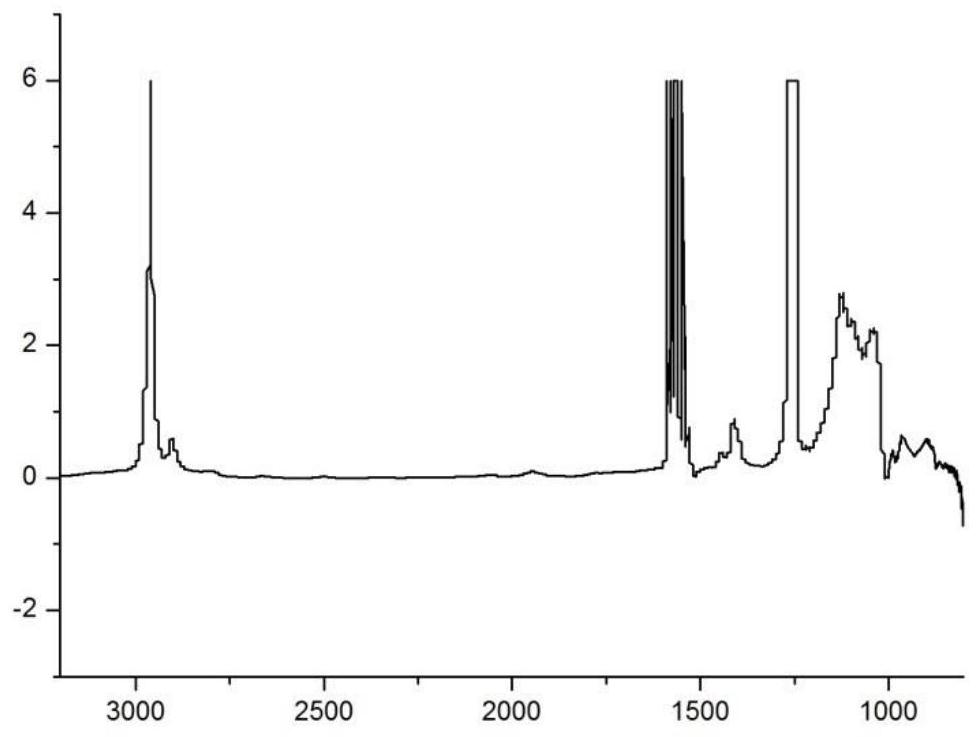

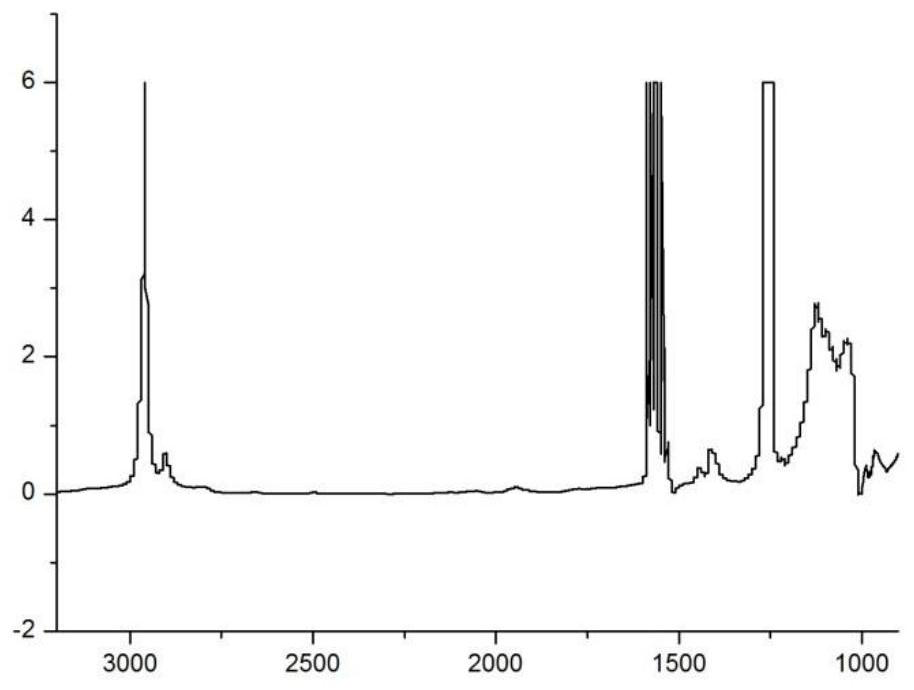

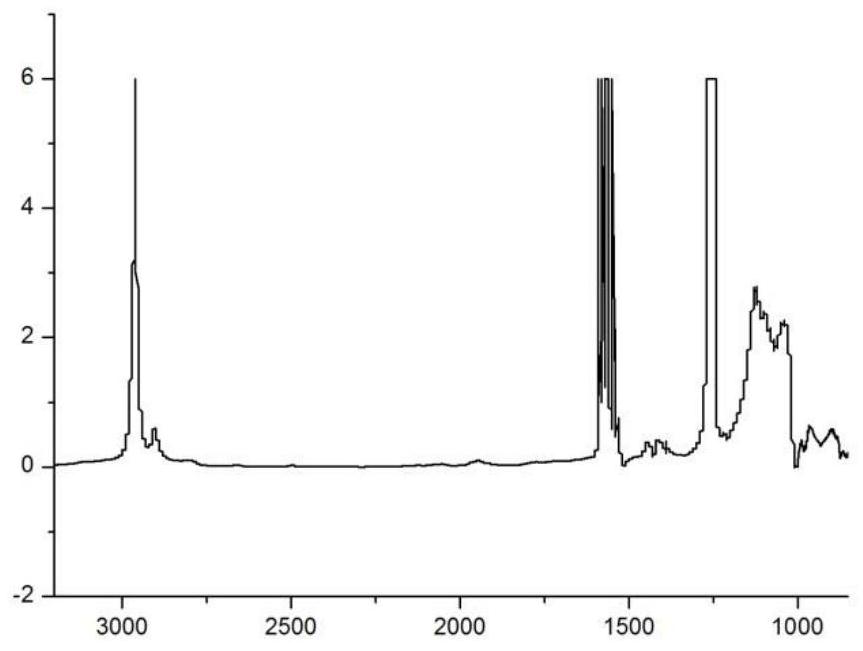

Image

Examples

Embodiment 1

[0125] (1) Preparation of hydrogen-containing MQ resin:

[0126] Equipped with stirrer, thermometer, condenser and N 2 In a three-necked flask with an atmosphere, add 208g of tetraethoxysilane, 59g of hexamethyldisiloxane, 5g of tetramethyldisiloxane, 22g of ethanol, 49g of xylene, 0.5g of 98wt% concentrated sulfuric acid, stir for 30min, and then Add 50g of water dropwise, and the dropwise addition is completed in 30 minutes, then raise the temperature to 85°C and react for 1 hour, then heat up and distill to remove ethanol and water, steam until the liquid phase temperature is 130°C, keep it warm for 4.5 hours and then lower it to room temperature; use xylene to extract, wash with water to the pH value 6.0 to 7.0, add anhydrous calcium chloride and dry until clear and transparent, filter to remove salt, and then rotary evaporate at 130°C to obtain solid hydrogen-containing MQ resin powder.

[0127] The hydrogen content of the product was measured by the method for measuring...

Embodiment 2

[0134] (1) Preparation of hydrogen-containing MQ resin:

[0135] In the three-necked flask equipped with stirrer, thermometer, condenser and N2 atmosphere, add tetramethoxysilane 152g, trimethylchlorosilane 80g, tetramethyldisiloxane 4.7g, ethanol 19g, xylene 43g, 0.5g of 38wt% concentrated hydrochloric acid, stirred for 30min, then added dropwise 53g of water, and the dropwise addition was completed in 25min, then the temperature was raised to 80°C for 1.5h, the ethanol and water were distilled off by heating, steamed to a liquid phase temperature of 120°C, and then dropped after 4 hours of heat preservation. to room temperature; extract with xylene, wash with water until the pH value is 6.0-7.0, add anhydrous calcium chloride to dry until clear and transparent, filter to remove salt, and then rotary evaporate to obtain the solid powder of hydrogen-containing MQ resin.

[0136] The hydrogen content of the product was measured by the method for measuring the hydrogen content. ...

Embodiment 3

[0144] (1) Preparation of hydrogen-containing MQ resin:

[0145] In the three-necked flask equipped with stirrer, thermometer, condenser and N2 atmosphere, add tetrapropoxysilane 264g, diphenyltetramethyldisiloxane 106g, tetramethyldisiloxane 4.5g, ethanol 30g , xylene 67g, trifluoromethanesulfonic acid 0.75g, stir for 30min, then dropwise add water 55g, 35min dropwise, then raise the temperature to 75°C and react for 2h, heat up and distill to remove ethanol and water, steam until the liquid phase temperature is 140°C , kept warm for 5 hours and then lowered to room temperature; extracted with xylene, washed with water until the pH value was 6.0 to 7.0, added anhydrous calcium chloride to dry until clear, filtered to remove salt, and then rotary evaporated to obtain a hydrogen-containing MQ resin solid powder.

[0146] The hydrogen content of the product was determined by the hydrogen content determination method. The hydrogen content of the product was 0.039 wt%, and the M / Q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com