Production process of plastic-wood garbage box

A technology of production process and dustbin, which is applied in the direction of wood processing equipment, manufacturing tools, pretreatment of molding materials, etc., to achieve the effects of improving efficiency, easy evaporation, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

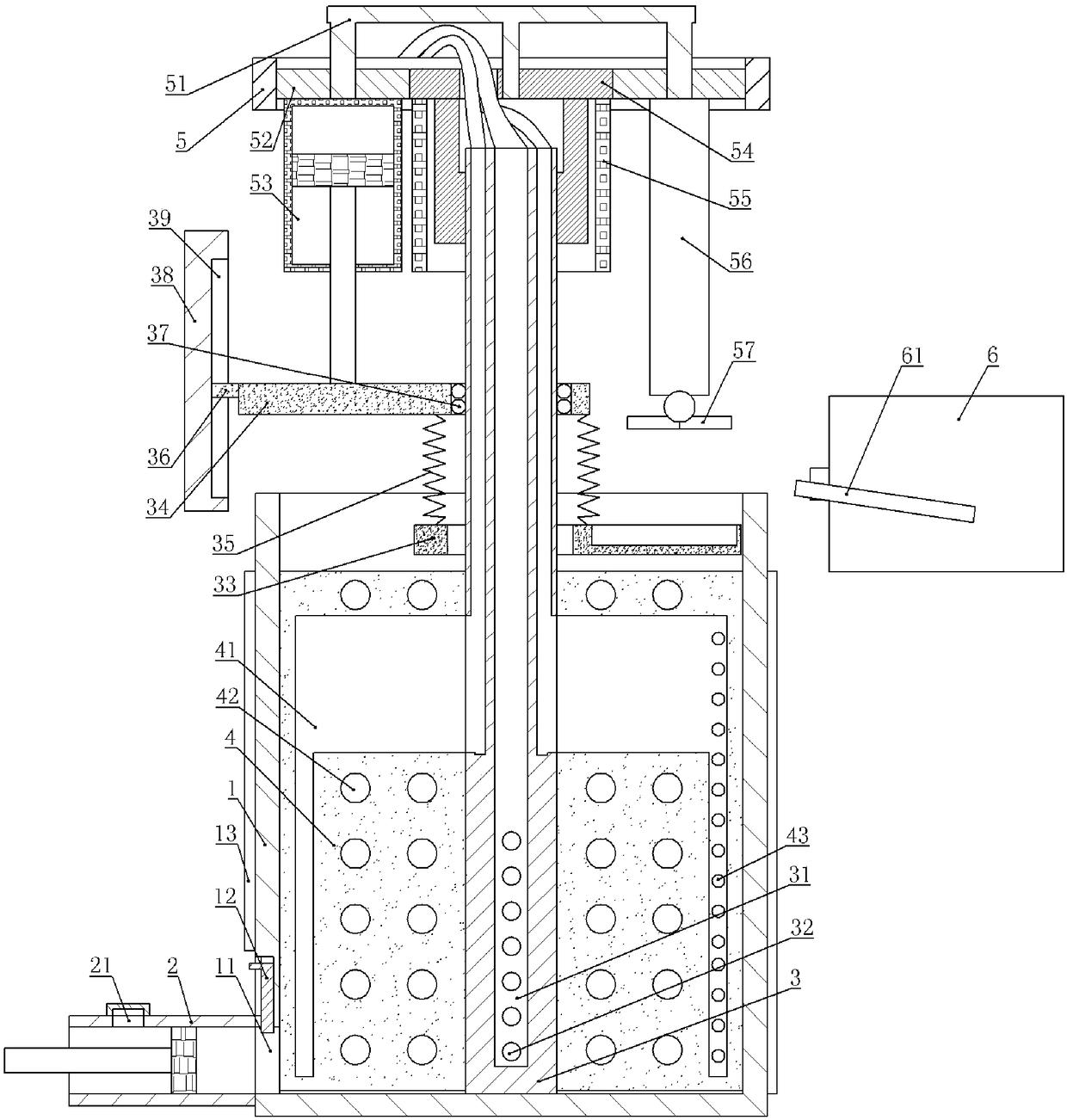

[0022] The following will be further described in detail through specific embodiments: mixing barrel 1, feed channel 11, block 12, heating element 13, feed cylinder 2, inlet 21, stirring shaft 3, return cavity 31, return hole 32, outlet Material tray 33, discharge block 34, spring 35, slider 36, ball 37, frame 38, chute 39, scraper 4, suction chamber 41, through hole 42, suction hole 43, ring gear 5, planet Frame 51, planetary gear 52, intake cylinder 53, sun gear 54, cylindrical cam 55, resist rod 56, material distribution plate 57, discharge cylinder 6, discharge slope 61.

[0023] The reference signs in the accompanying drawings of the specification include:

[0024] A production process of plastic-wood garbage bins, comprising the following steps:

[0025] (1) drying for the first time, using hot air at 70°C to dry the wood until the moisture content inside the wood is reduced to below 5%, and blowing off the dust on the wood surface with strong wind;

[0026] (2) pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com