Preparation method of insoluble sulfur and used anti-reversion stabilizer thereby

A stabilizer and sulfur technology, which is applied in the preparation/purification of sulfur, chemical instruments and methods, sulfur compounds, etc., can solve the problems affecting product quality and the increase of black spots in insoluble sulfur products, so as to improve reversion and reduce stability Progression and Mixed Difficulty, Effects of Preventing Reversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

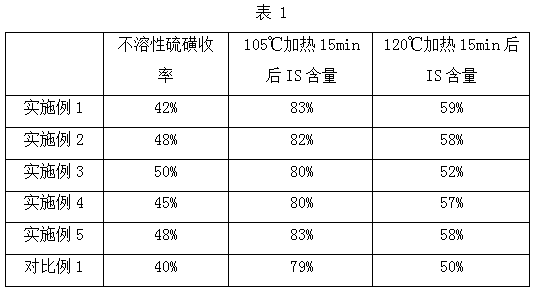

Embodiment 1

[0028]Input 10 tons of liquid sulfur at 120-140°C into the gasifier at a rate of 5 tons / hour. 0.1 kg of gaseous methane is fed into the pipeline at a rate of 0.05 kg / hour. After the liquid sulfur is added, the temperature is raised to 550°C for gasification. The gaseous methane is cracked into active free radicals under the action of sulfur vapor active free radicals. After the gasification is completed, the uniformly mixed gas in the gasifier is passed into the carbon disulfide quenching liquid. During the quenching process, the active free radicals generated by the cracking of methane seal the insoluble sulfur end groups generated by the polymerization of sulfur vapor, and the process is completed. The insoluble sulfur stabilization process is solidified after quenching, then extracted with carbon disulfide, and centrifuged to obtain solid particles. The solid particles are washed with carbon disulfide, dried, and filled with oil to obtain insoluble sulfur products. The obta...

Embodiment 2

[0030] Add 10 tons of liquid sulfur at 120-140°C to the gasifier at a rate of 5 tons / hour. During the feeding process of liquid sulfur, feed it into the liquid sulfur pipeline at a rate of 0.5 kg / hour through a mass flow meter. 1 kg of gaseous methane, after the liquid sulfur is added, is heated to 550°C for gasification, and the gaseous methane is cracked into active free radicals under the action of sulfur vapor active free radicals. After the gasification is completed, the uniformly mixed gas in the gasifier is passed into the carbon disulfide quenching liquid. During the quenching process, the active free radicals generated by the cracking of methane seal the insoluble sulfur end groups generated by the polymerization of sulfur vapor, and the process is completed. The insoluble sulfur stabilization process is solidified after quenching, then extracted with carbon disulfide, and centrifuged to obtain solid particles. The solid particles are washed with carbon disulfide, drie...

Embodiment 3

[0032] Add 10 tons of liquid sulfur at 120-140°C to the gasifier at a rate of 5 tons / hour. During the feeding process of liquid sulfur, feed it into the liquid sulfur pipeline at a rate of 5 kg / hour through a mass flow meter. 10 kg of gaseous methane. After the liquid sulfur is added, the temperature is raised to 550°C for gasification, and the gaseous methane is cracked into active free radicals under the action of sulfur vapor active free radicals. After the gasification is completed, the uniformly mixed gas in the gasifier is passed into the carbon disulfide quenching liquid. During the quenching process, the active free radicals generated by the cracking of methane seal the insoluble sulfur end groups generated by the polymerization of sulfur vapor, and the process is completed. The insoluble sulfur stabilization process is solidified after quenching, then extracted with carbon disulfide, and centrifuged to obtain solid particles. The solid particles are washed with carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com