High-purity gold-silver-palladium-platinum alloy bonding wire and preparation method thereof

An alloy bonding, gold and silver technology, applied in metal processing equipment, equipment for feeding molten metal into casting molds, casting equipment, etc., can solve problems such as unsatisfactory mixing effect, waste of water resources, waste of cooling heat of casting molds, etc. To achieve the effect of shortening the time required for smelting, speeding up the cooling rate, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a high-purity gold-silver-palladium-platinum alloy bonding wire, which contains 4-7% of gold, 85-94% of silver, 3-4% of palladium and 1-2% of platinum.

Embodiment 2

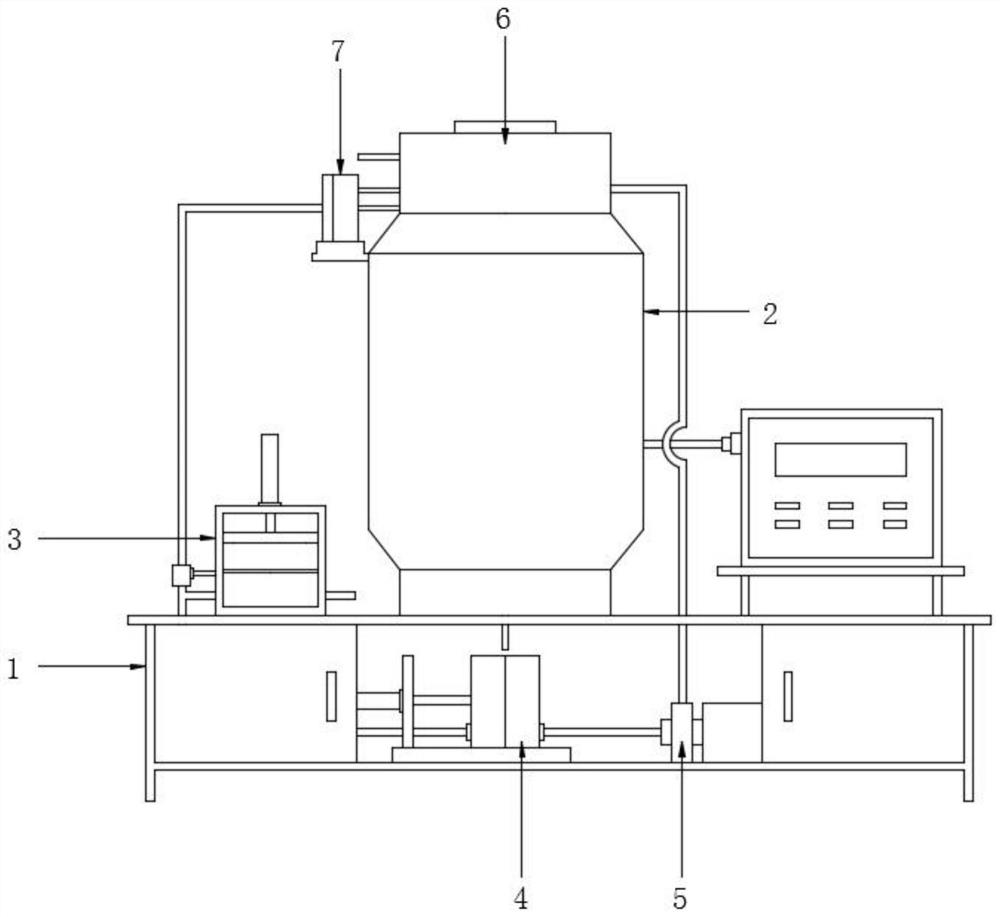

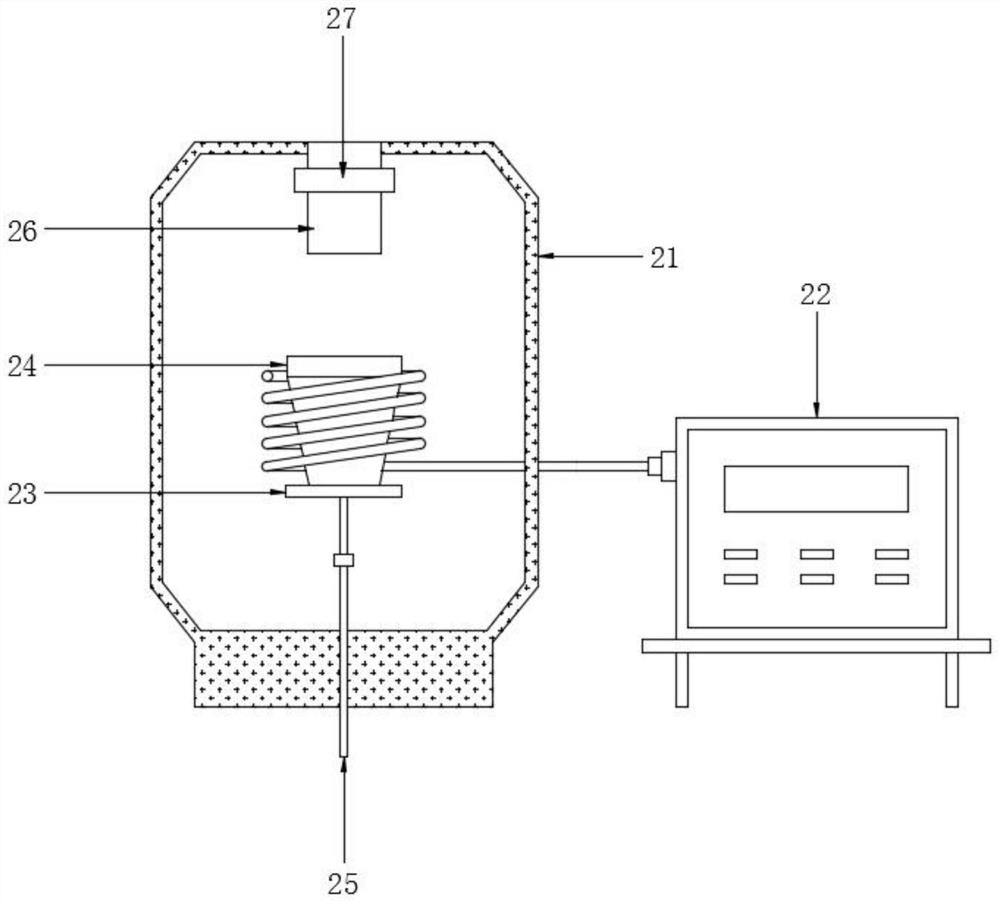

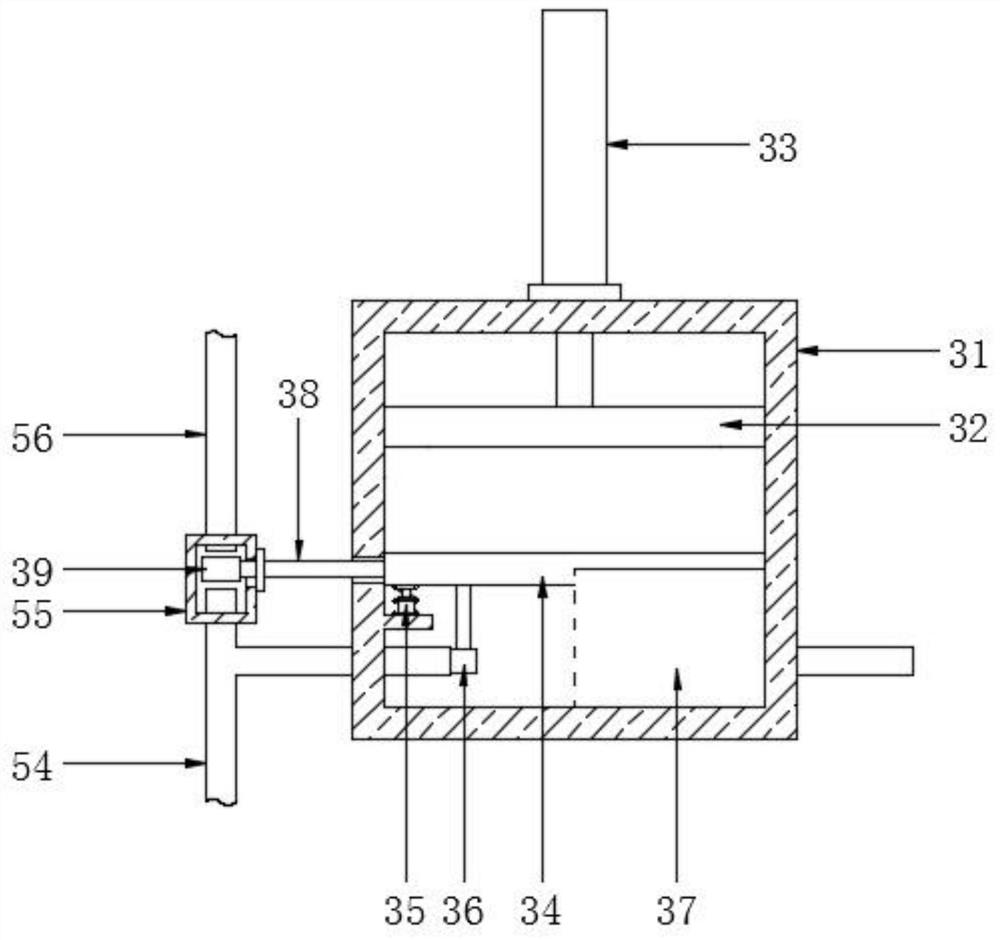

[0042] The present invention also provides a method for preparing a high-purity gold-silver-palladium-platinum alloy bonding wire. The method is realized by using a preheating preparation device. The preheating preparation device includes an equipment box 1, and the top of the equipment box 1 is provided with The vacuum smelting mechanism 2 and the preheating mechanical mixing mechanism 3, the preheating mechanical mixing mechanism 3 is located on the left side of the vacuum smelting mechanism 2, and the vacuum smelting mechanism 2 melts the first batch of materials and the second batch of materials , the first hydraulic cylinder 33 in the preheating mechanical mixing mechanism 3 drives the pressure plate 32 to pressurize and mix the first batch of materials, and the equipment box 1 is provided with a casting mechanism 4 and a waste heat utilization mechanism 5. The molten metal output pipe 25 in the vacuum smelting mechanism 2 inputs the smelted molten metal into the casting m...

Embodiment 3

[0056] Described method specifically comprises the following steps:

[0057] S1. Addition of raw materials: During the discharge of molten metal produced in the previous processing step, the first batch of materials is stacked on the top of the metal carrier plate 34, and the second batch of materials is put into the left chamber of the hopper 63 At this time, the first batch of materials presses the elastic member 35 through the metal bearing plate 34, and the metal bearing plate 34 drives the second blocking block 39 to descend through the lifting cross bar 38. At this time, the hot air distribution pipe 54 is located at the first The output end inside the housing 31 is opened, and the output end of the hot air distribution pipe 54 located inside the second housing 55 is blocked;

[0058]S2. Utilization of waste heat and preheating of the first batch of materials: start the vacuum pump 52, and the vacuum pump 52 extracts the air inside the top cover 61 through the vacuum tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com