Mixing and stirring device for high-viscosity fluid for synthetic resin

A synthetic resin, mixing and stirring technology, applied in the direction of mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of stirring influence, high mixing concentration, high difficulty, etc., to achieve convenient stirring operation, reduce mixing difficulty, The effect of design science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

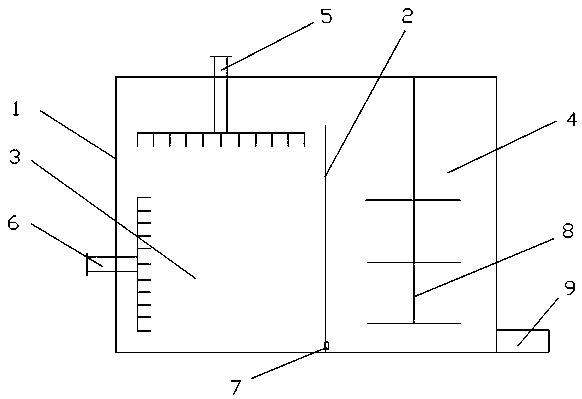

[0014] Such as figure 1 The mixing and stirring device for high-viscosity fluids for synthetic resins includes a housing 1, the housing 1 is divided into a mixing zone 3 and a mixing zone 4 by a partition 2, and the top of the mixing zone is provided with a wall extending from the outside of the housing. A number of No. 1 feed pipes 5 are inserted, and the end of the No. 1 feed pipe 5 located in the mixing zone is provided with a number of spray heads; the inner wall of the mixing zone is provided with a number of No. 2 feed pipes extending from the outside of the shell. 6. The end of the No. 2 feed pipe 6 located in the mixing zone is provided with a number of spray heads; the bottom of the partition 2 is provided with an overflow hole 7; the stirring zone 4 is provided with an agitator 8, and the stirring zone 4 The bottom is provided with discharge port 9.

[0015] During the specific work of the present invention, the solvent is fed separately through the No. 1 feed port ...

Embodiment 2

[0017] Referring to Example 1, the stirrer is provided with several groups of stirring blades.

Embodiment 3

[0019] Referring to Example 1, the height of the spray head provided on the No. 2 feed pipe is not higher than the height of the partition; and the No. 1 feed pipe and the No. 2 feed pipe are vertical in the same plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com