Easy-to-tear packaging composite film and extrusion type liquid packaging bag

A composite film and packaging bag technology, applied in the field of plastic packaging, can solve the problems of unsuitable automatic equipment processing, easy liquid leakage, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

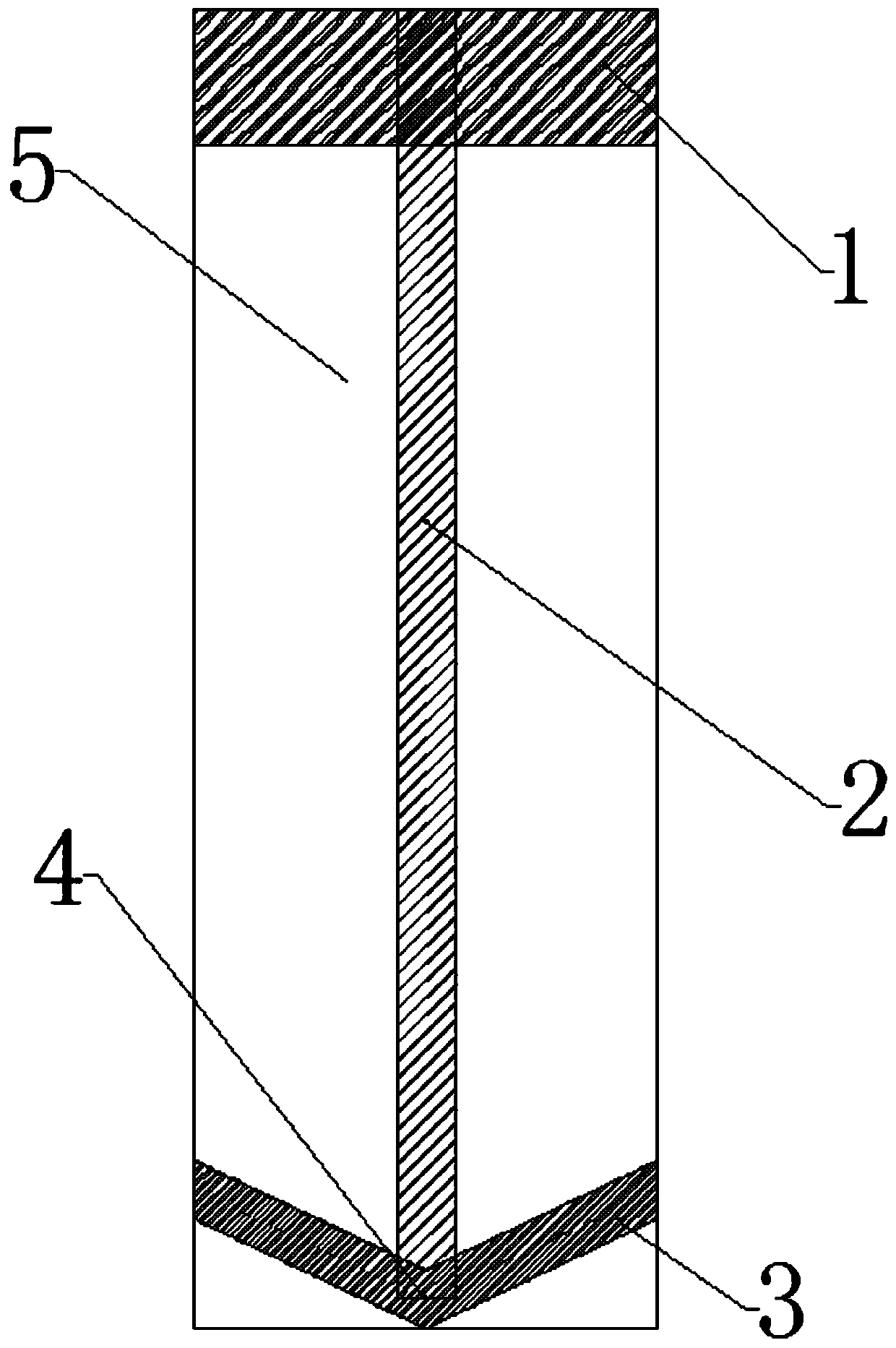

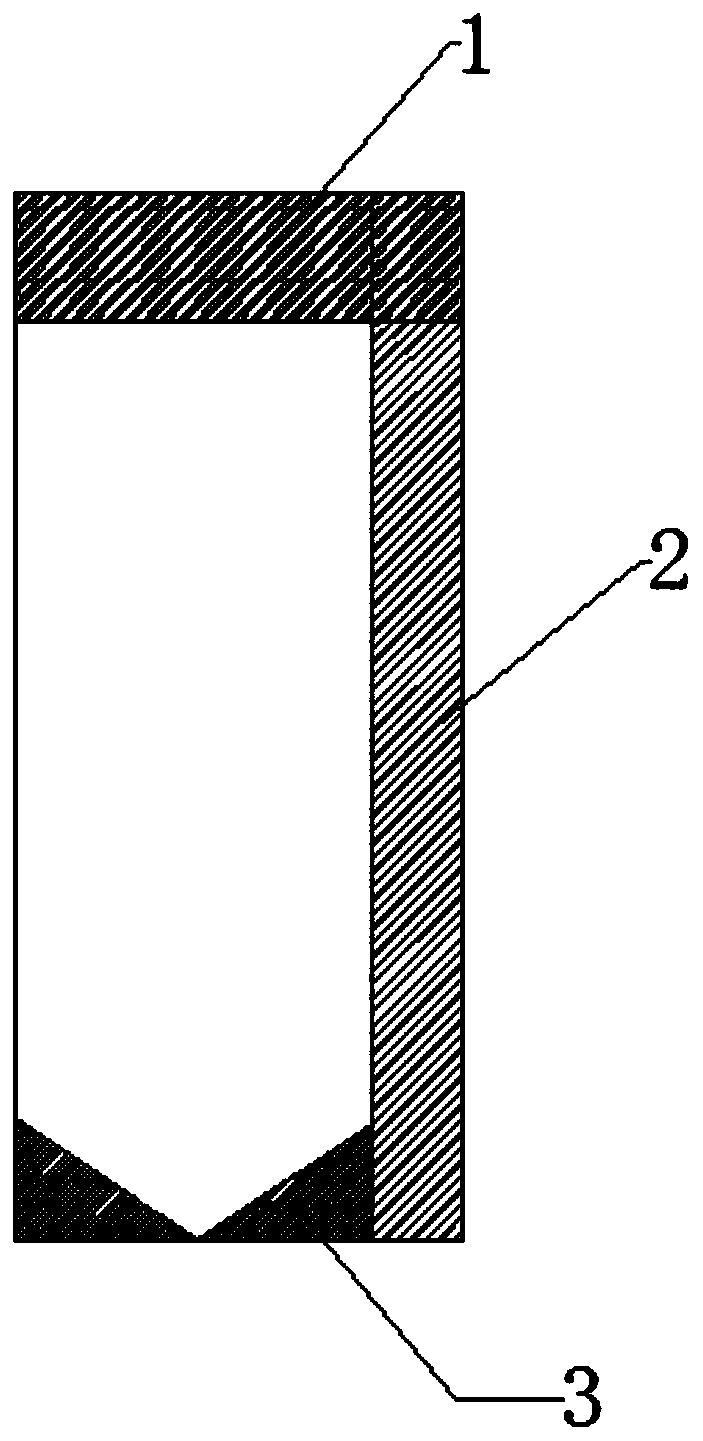

[0032] An easy-to-tear packaging composite film, including an outer protective layer, a middle barrier layer and an inner heat-sealing layer; the thickness of the outer protective layer is 12 μm, and the outer protective layer is PET; the thickness of the middle barrier layer is 7 μm, and the middle barrier layer It is VMPET; the thickness of the inner heat-sealing layer is 30 μm; the outer protective layer, the middle barrier layer and the inner heat-sealing layer are compounded by dry compounding process.

[0033]The matrix of the inner heat-sealing layer is metallocene polyethylene, which is filled with calcium carbonate, and the particle size of calcium carbonate is 0.1-0.3 μm; the addition amount of metallocene polyethylene resin in the inner heat-sealing layer is 100 parts, the addition amount of calcium carbonate is 10 parts; First the metallocene polyethylene resin of 5 parts of calcium carbonate and 33 parts is blended, melted, granulated, and then the metallocene poly...

Embodiment 2

[0036] An easy-to-tear packaging composite film, comprising an outer protective layer, a middle barrier layer and an inner heat-sealing layer, the thickness of the outer protective layer is 12 μm, and the outer protective layer is PET; the thickness of the middle barrier layer is 7 μm, and the middle barrier layer It is VMPET; the thickness of the inner heat-sealing layer is 30 μm; the outer protective layer, the middle barrier layer and the inner heat-sealing layer are compounded by dry compounding process.

[0037] The matrix of the inner heat-sealing layer is metallocene polyethylene, polybutene-1 and calcium carbonate are added to the metallocene polyethylene, the addition amount of metallocene polyethylene is 100 parts, and the addition amount of polybutene-1 is 110 parts , the added amount of calcium carbonate is 5 parts, and the added amount of slip agent is 1.5 parts; the inner heat-sealing layer is prepared by casting or blown film technology.

[0038] The extruded st...

Embodiment 3

[0040] An easy-to-tear packaging composite film, comprising an outer protective layer, a middle barrier layer and an inner heat-sealing layer, the thickness of the outer protective layer is 12 μm, and the outer protective layer is PET; the thickness of the middle barrier layer is 7 μm, and the middle barrier layer It is VMPET, and the thickness of the inner heat-sealing layer is 30 μm; the outer protective layer, middle barrier layer and inner heat-sealing layer are compounded by dry compounding process.

[0041] The matrix of the inner heat-sealing layer is a linear low-density polyethylene matrix, and polybutene-1 and polypropylene are added to the linear low-density polyethylene matrix. The amount of linear low-density polyethylene added is 100 parts, and the addition of polybutene-1 The amount is 50 parts, the addition amount of polypropylene is 60 parts, the addition amount of blocking agent is 1 part, and the addition amount of smooth agent is 1.5 parts. The inner heat-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com