Patents

Literature

40results about How to "Reduce cohesive energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating for inner wall of oil field pipeline and preparation method thereof

ActiveCN101948648AKey lengthImprove mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsVinyl etherToluene diisocyanate

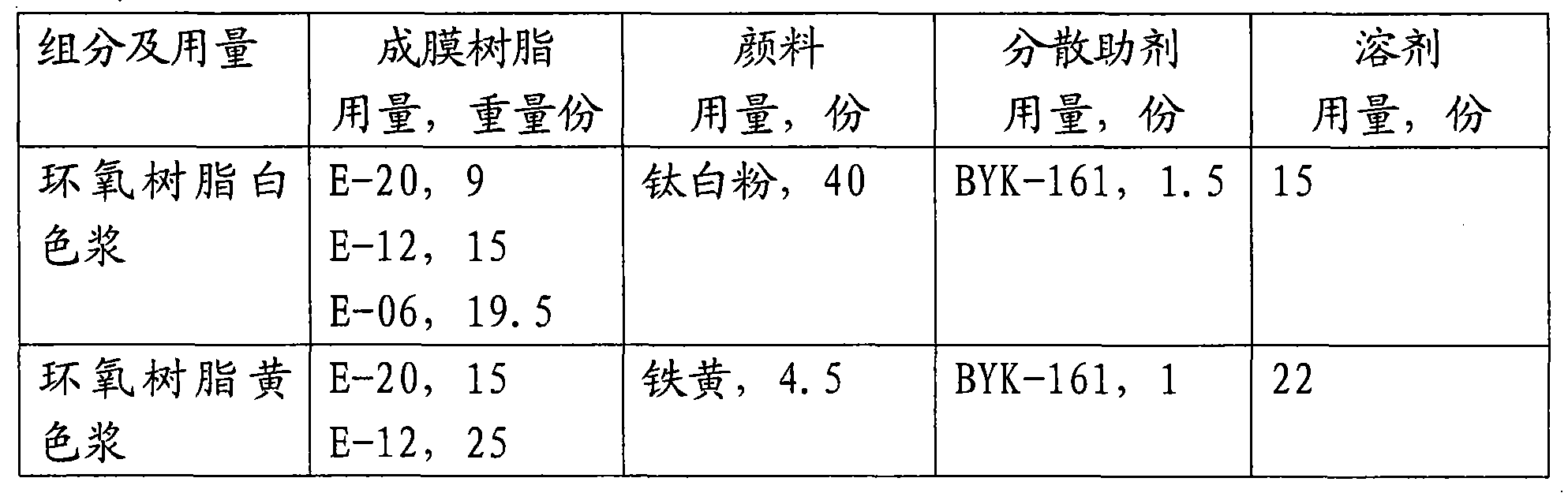

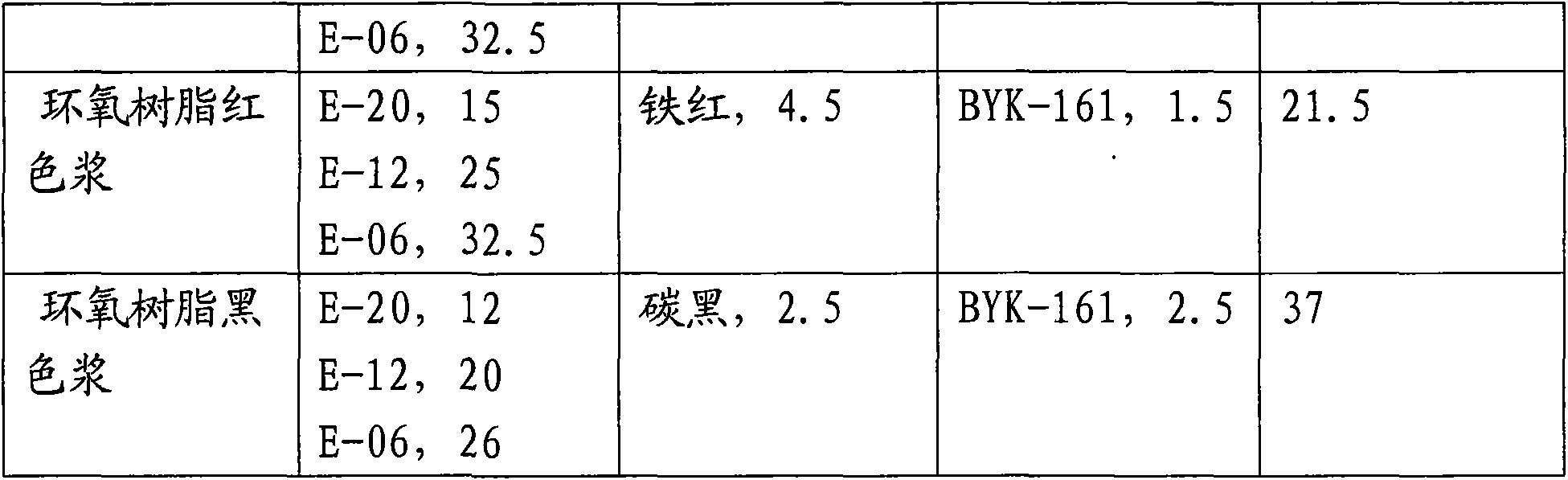

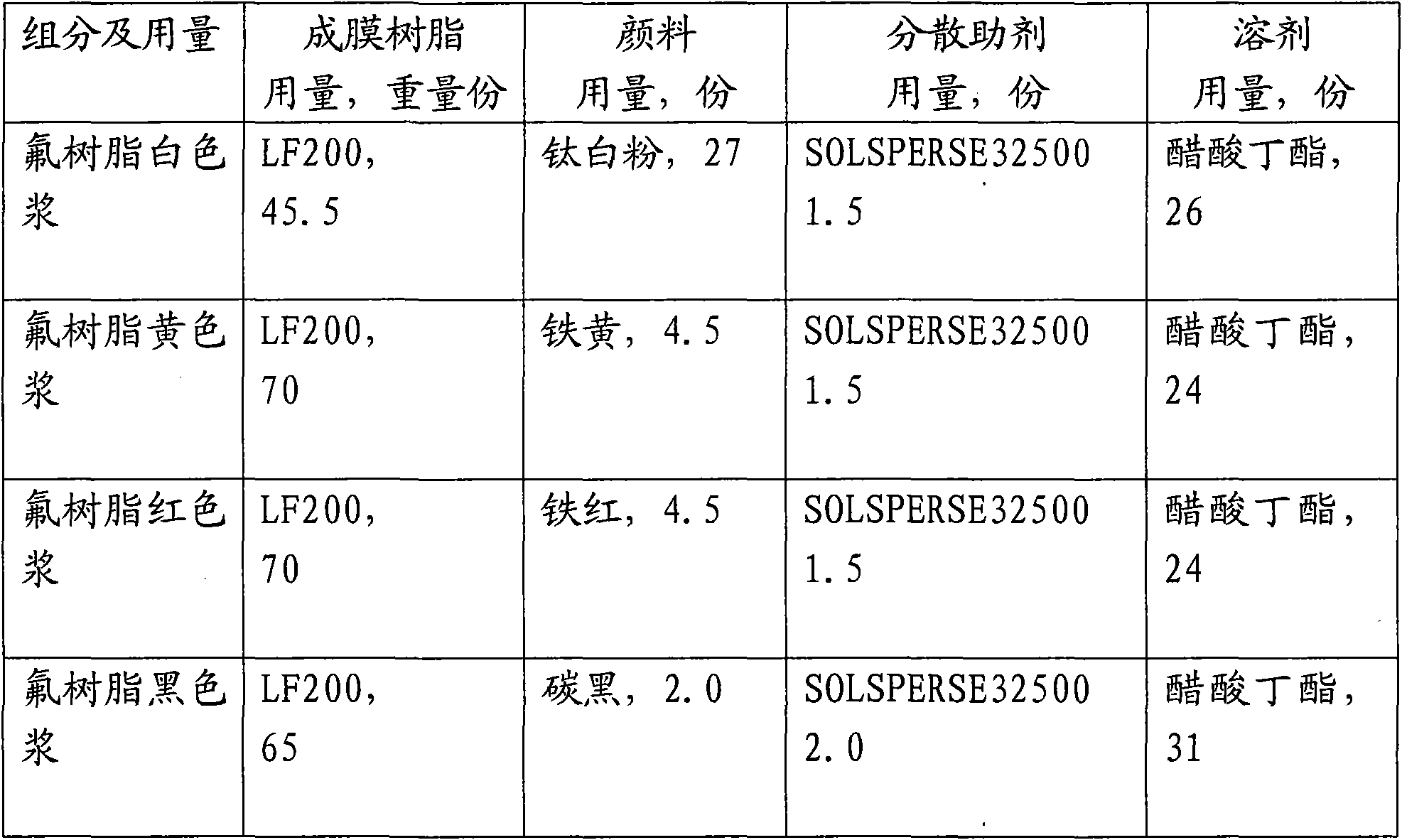

The invention relates to a coating for the inner wall of an oil field pipeline and a preparation method thereof. A component A of the coating consists of the following components in part by weight: 15 to 50 parts of trifluoroethylene-vinyl ether fluoro-resin, 8 to 30 parts of lubricating filler, 1 to 3 parts of dispersing auxiliary agent, 10 to 20 parts of solvent, 15 to 45 parts of colour paste and 1 to 6 parts of lubricating auxiliary agent, wherein the colour paste consists of the following components in part by weight: 40 to 80 parts of film forming resin, 1 to 3 parts of dispersing auxiliary agent, 10 to 40 parts of solvent and 2 to 40 parts of pigment; and the film forming resin is three kinds of biphenol A epoxy resins, namely biphenol A epoxy resinE-20, biphenol A epoxy resin E-12 and biphenol A epoxy resin E-06, or is trifluorochloroethylene-vinyl ether fluoro-resin. A component B of the coating is a curing agent aromatic toluene diisocyanate addition product. Before construction, the component A and the component B are mixed according to a weight ratio of 10 to 1. The coating of the invention is used for coating the inner wall of the oil field pipeline, is corrosion resistant, makes the inner wall of the pipeline have hydrophobic performance and fulfils the aim of reducing resistance and enhancing effect.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Organic silicone modified high water absorption resin and preparation method thereof

The invention discloses an organic silicane high-adsorbing resin, which is copolymerized by soluble polycondensation product and vinyl monomer free radical with the content of organic silica as 0.1-5wt% as vinyl monomer, wherein the organic silicane is represented through Y (CH2) nSiX3 (Y is vinyl, epoxy radical, mercapto radical and so on; X is methoxyl, ethyoxyl, isopropoxy and so on); the resin adsorbs deionized water and salt water, which displays optical, heat and ultraviolet stability in the agricultural and hygiene domain.

Owner:安徽省农业科学院原子能农业应用研究所 +1

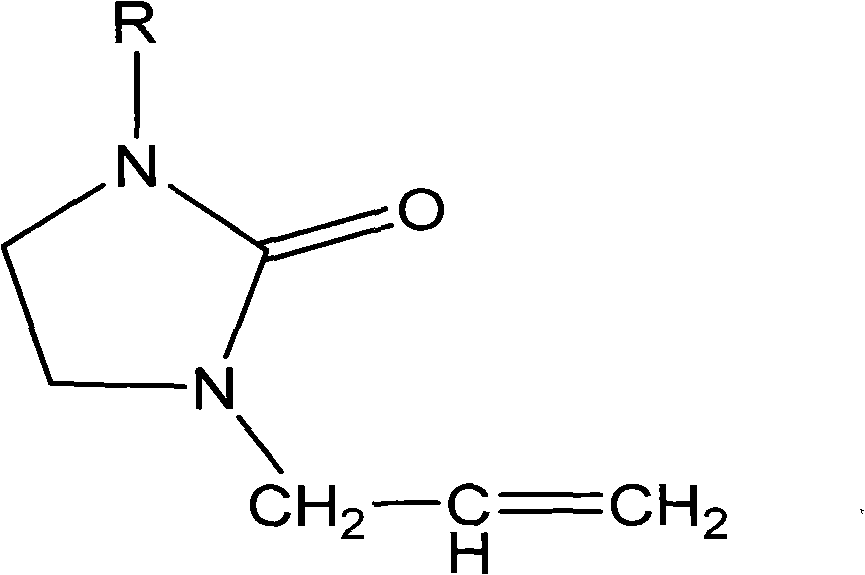

High-hydrophilic and exothermal spinning solution for polyacrylonitrile-based carbon fibers and preparation method thereof

InactiveCN101831729AImprove hydrophilicityReduced spinnabilityFibre chemical featuresCarbon fibersRoom temperature

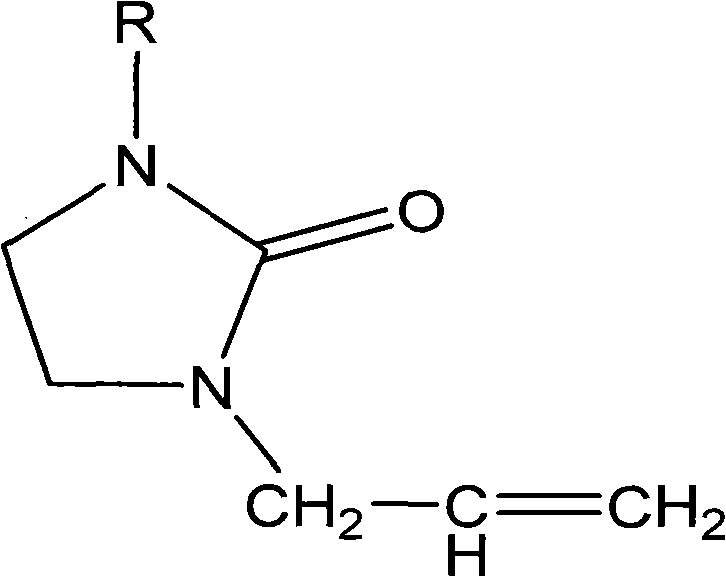

The invention discloses high-hydrophilic and exothermal spinning solution for polyacrylonitrile-based carbon fibers and a preparation method thereof. The spinning solution consists of N,N-dimethyl formamide solution of monomer and co-monomer random copolymer. The preparation method for the spinning solution comprises the following steps of: adding azodiisobutyronitrile initiator, acrylonitrile main monomer, allylimidazolidone co-monomer and N,N-dimethyl formamide solvent into a reaction kettle with a condensation and mechanical stirring device, stirring and mixing the components at the room temperature, bubbling the mixture for 10 to 40 minutes by using nitrogen, then reacting the mixture for 6 to 36 hours at the constant temperature of between 50 and 70 DEG C under the protection of the nitrogen, and then removing residual monomers and bubbles to obtain the spinning solution with high hydrophilic property and good exothermal property, wherein the main monomer accounts for 94 to 98 percent of the total mass of the monomers, the co-monomer accounts for 2 to 6 percent of the total mass of the monomers, the azodiisobutyronitrile accounts for 0.2 to 1.0 percent of the total mass of the monomers, and the mass total concentration of the monomers is 15 to 35 percent. The weight-average molecular weight of the copolymer can be controlled to be between 0.1 and 0.35 million, the contact angle of the copolymer and the water is about 32.3 degrees, and the spinning solution has good hydrophilic property and low exothermal rate.

Owner:BEIJING UNIV OF CHEM TECH

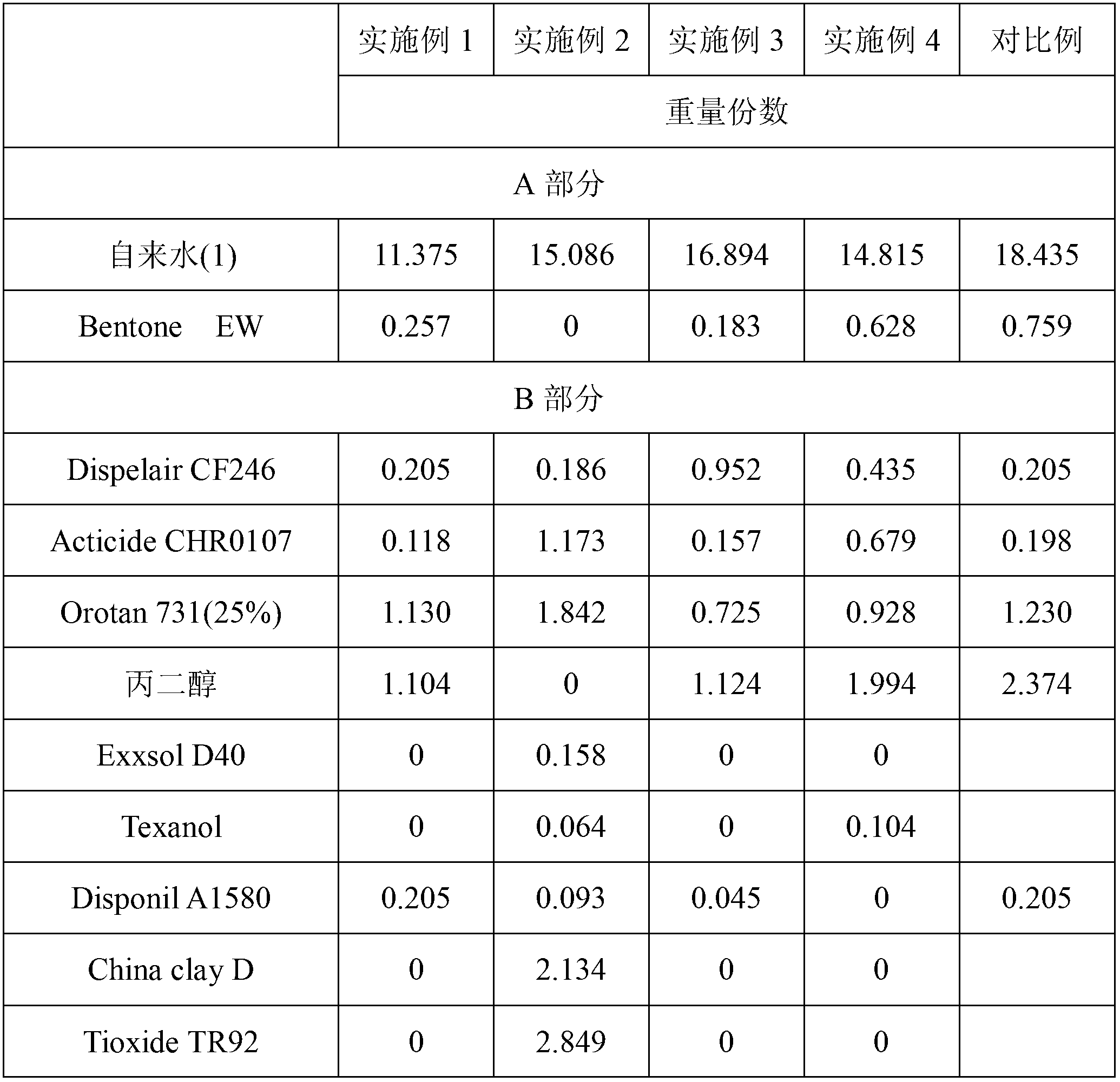

Flame-retardant coating composition

The invention relates to a halogen-free flame-retardant coating composition which comprises the components: 10-80% of film-forming polymer and 5-70% of inorganic flame-retardant material, and is characterized in that the flame-retardant material comprises flame-retardant filler microparticles and metallic tin benzoate and / or basic metallic tin benzoate, wherein the total PVC (polyvinyl chloride) content in the composition is 75-97%, and the film-forming polymer contains organic silicon resin.

Owner:TIANCHANG YINHU PAINT

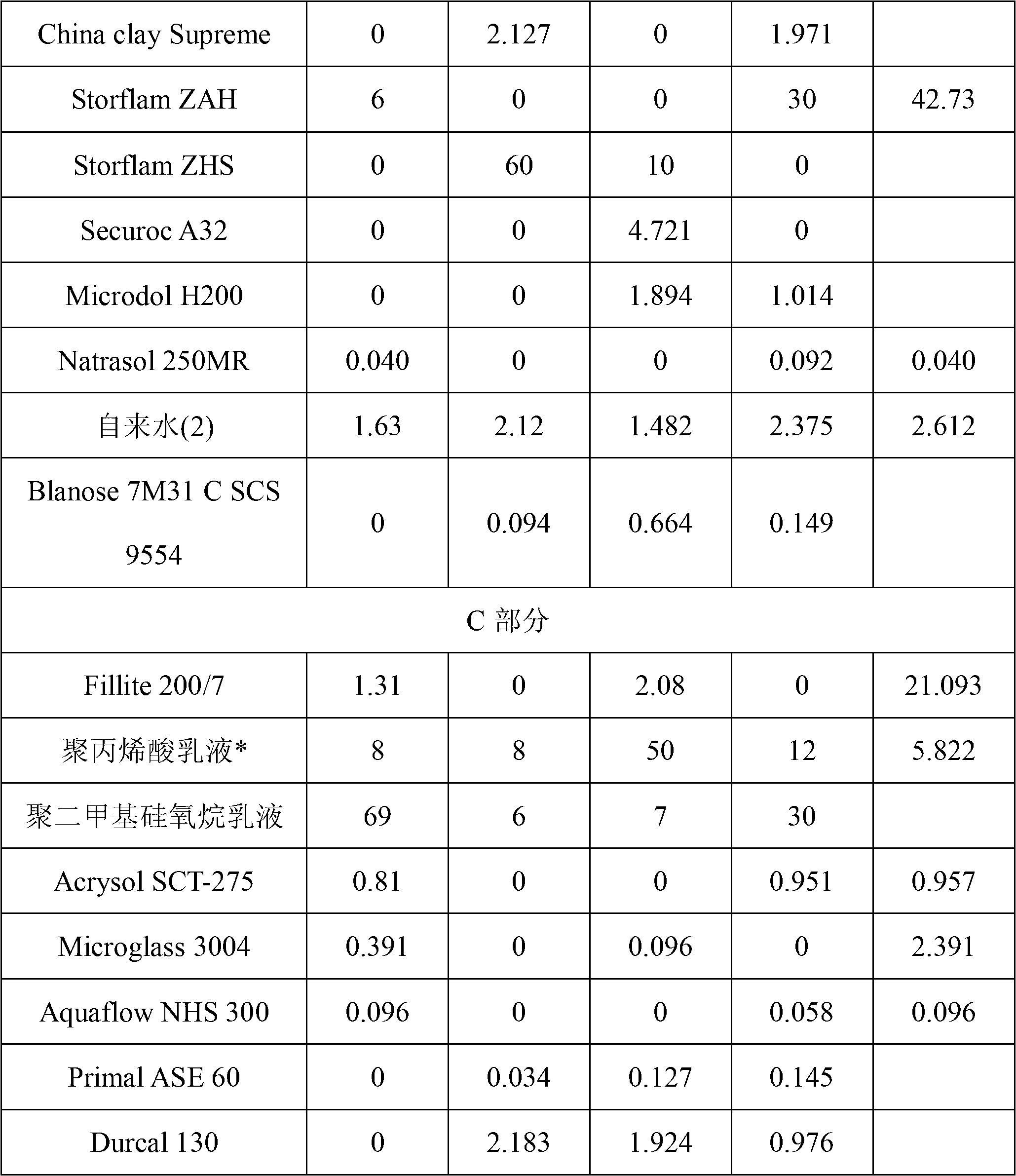

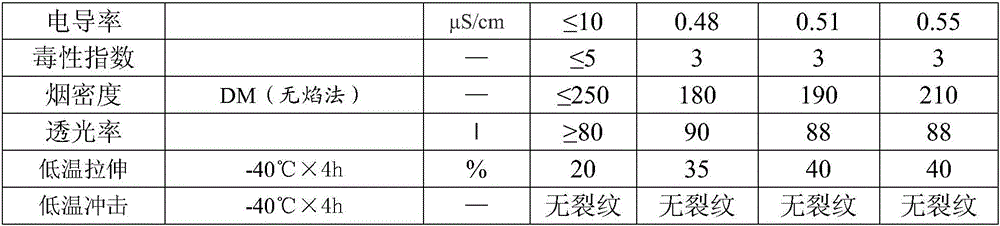

Environmental-protection flame retardant cable material and preparation method thereof

InactiveCN106243479AImprove low temperature performanceImproved low temperature winding performance and low temperature impact performanceRubber insulatorsPlastic/resin/waxes insulatorsCarbon blackAntioxidant

The invention discloses an environmental-protection flame retardant cable material and a preparation method of the environmental-protection flame retardant cable material. The preparation method comprises the following steps: putting EPDM (Ethylene-Propylene-Diene Monomer) rubber and ethylene-vinylacetate rubber into an internal mixer to be mixed, then putting zinc oxide, antioxidants, lubricants, zinc borate and auxiliary crosslinking agents into the internal mixer to be mixed, then putting carbon black pigment, reactive flame retardants, silane coupling agents and processing aids into the internal mixer to be mixed, finally discharging rubber compounds which are uniformly mixed from the internal mixer after the processing aids and peroxide crosslinking agents are put into the internal mixer to be mixed, packaging into triangle bags through an open mill and carrying out fine grinding, and then performing calendaring through a calender to be prepared into slices, thus obtaining the environmental-protection flame retardant cable material. The environmental-protection flame retardant cable material disclosed by the invention has good low-temperature rolling performance and low-temperature impact properties, can effectively lower the production cost of the environmental-protection flame retardant cable material and solve the problem of roll sticking in the EVM mixing process, has good elasticity and flexibility, excellent transparency and surface glossiness and further has good chemical stability, aging resistance and ozone resistant intensity.

Owner:HENGYANG HENGFEI CABLE CO LTD

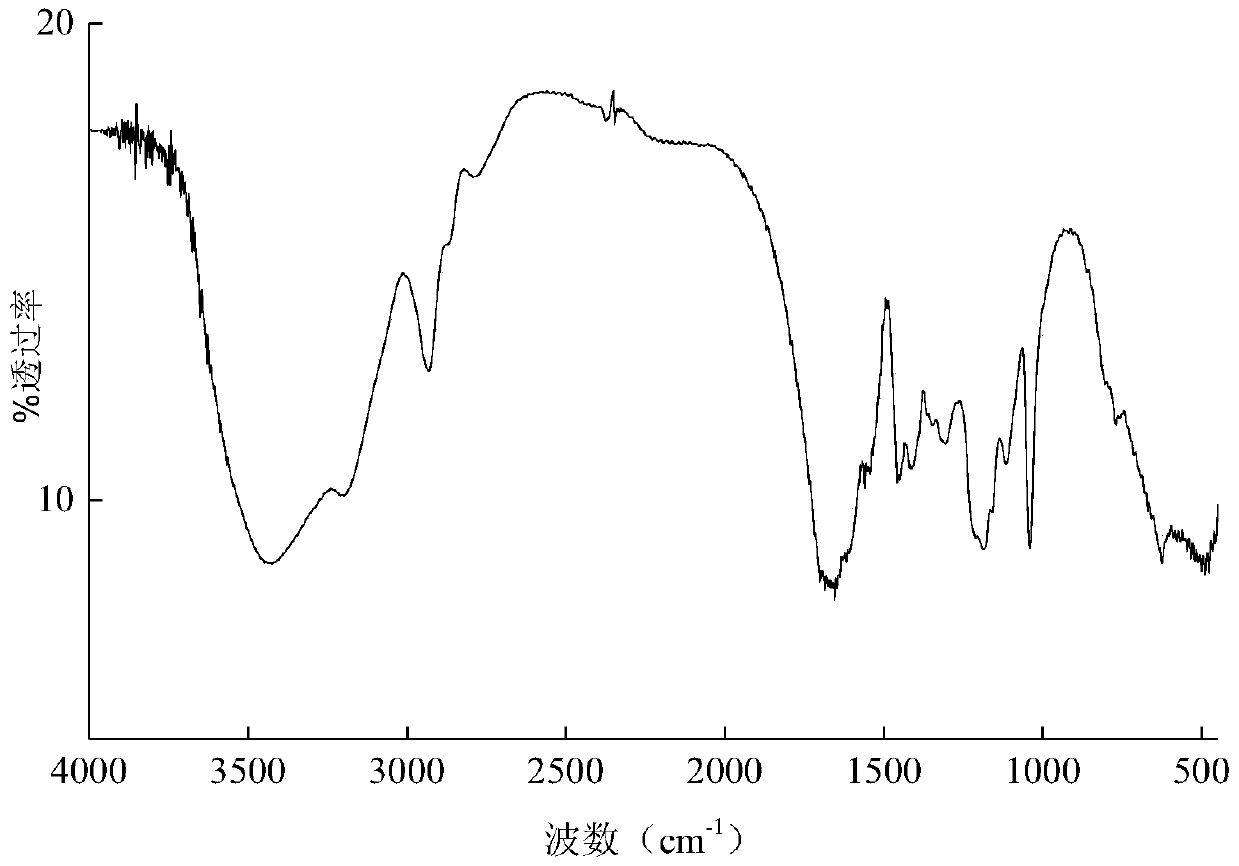

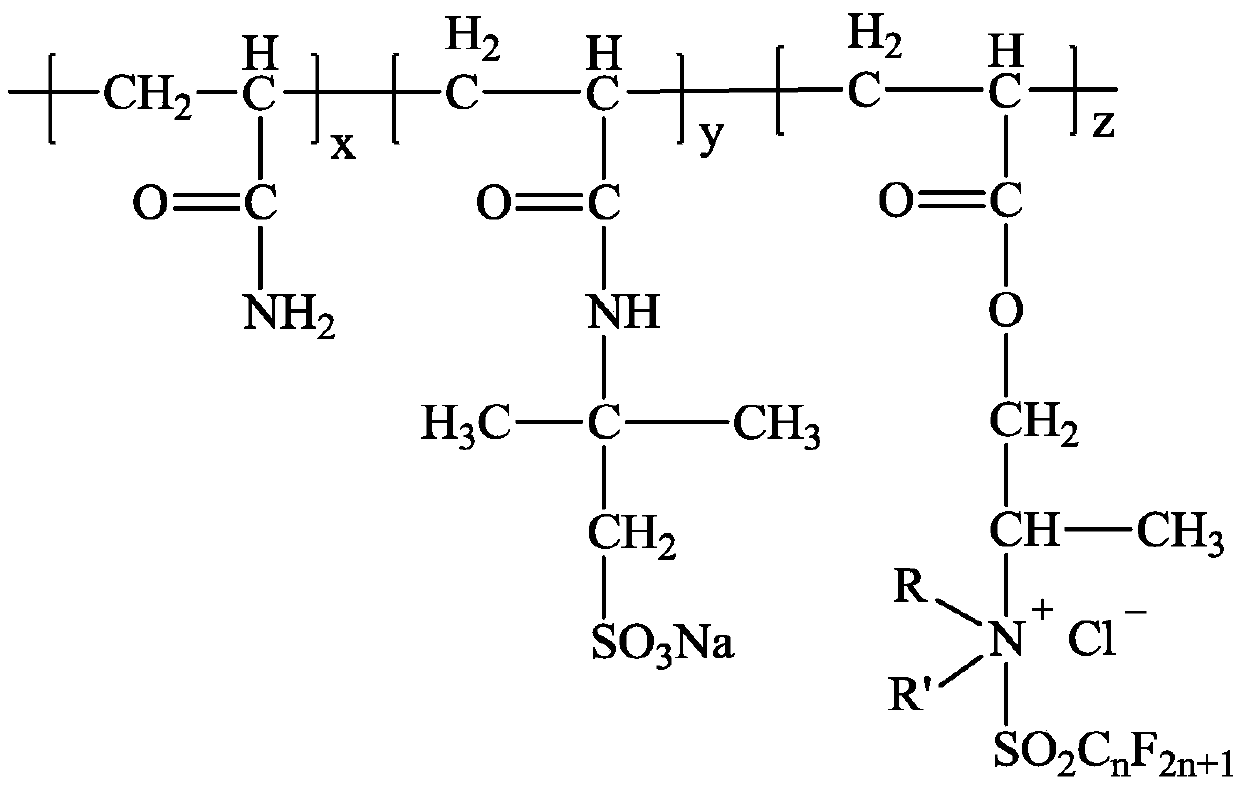

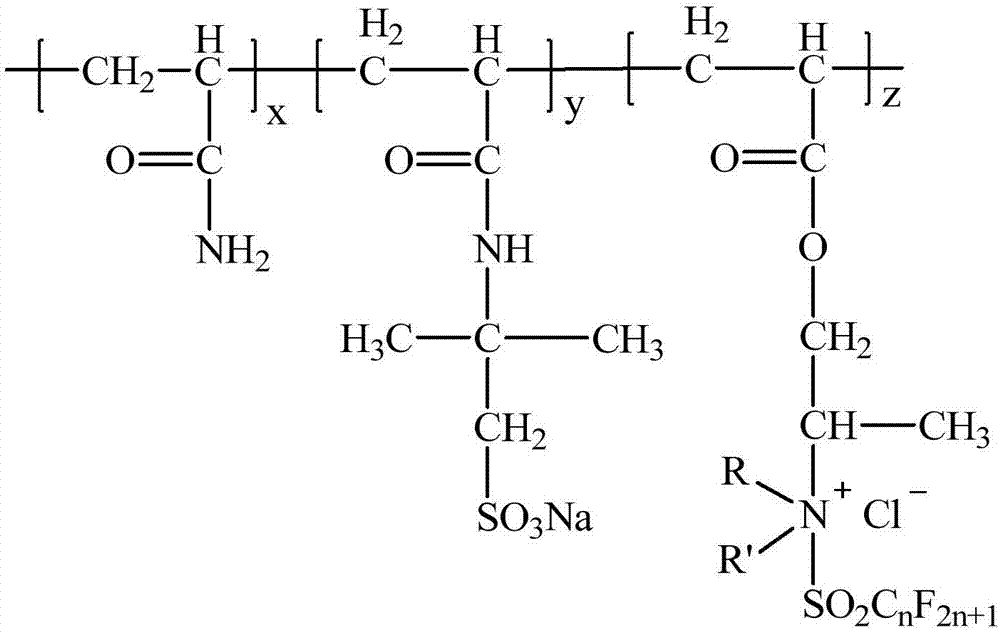

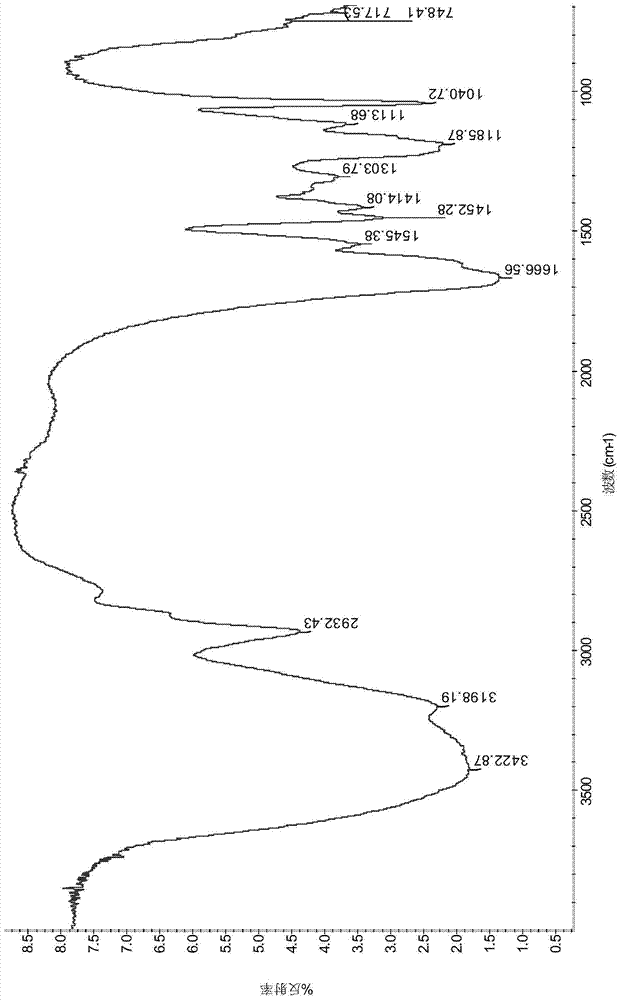

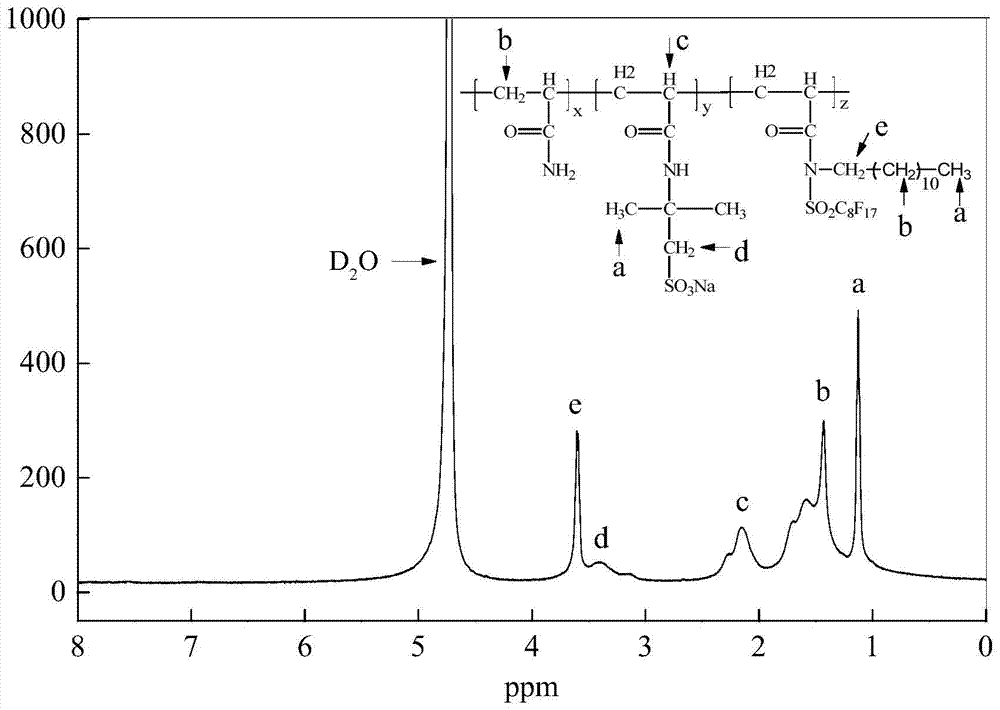

Fluorine-containing hydrophobic-associating surface-active polyacrylamide and preparation method thereof

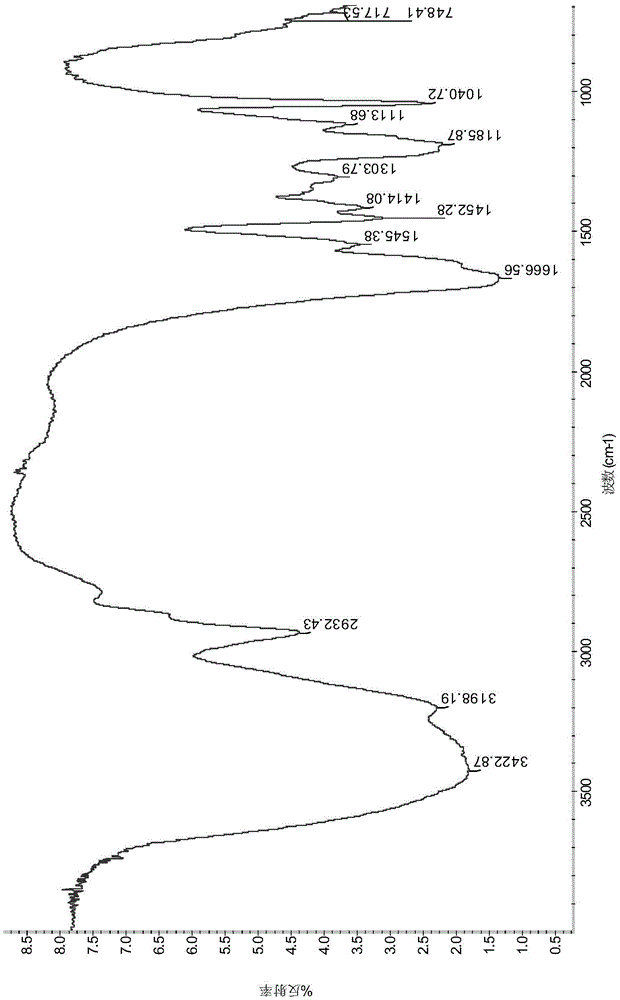

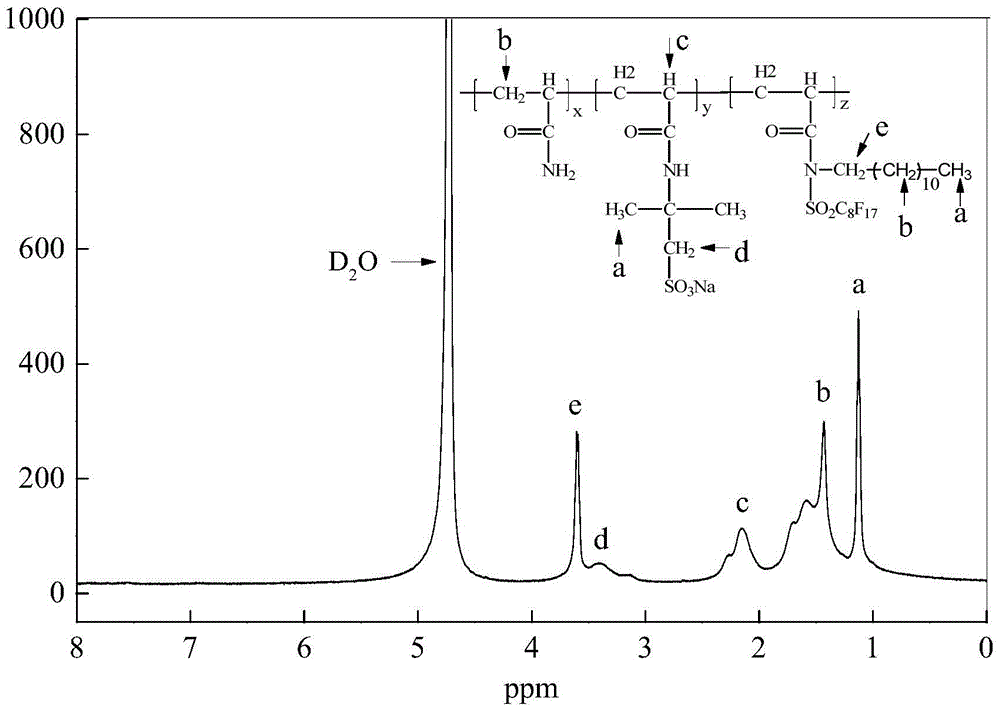

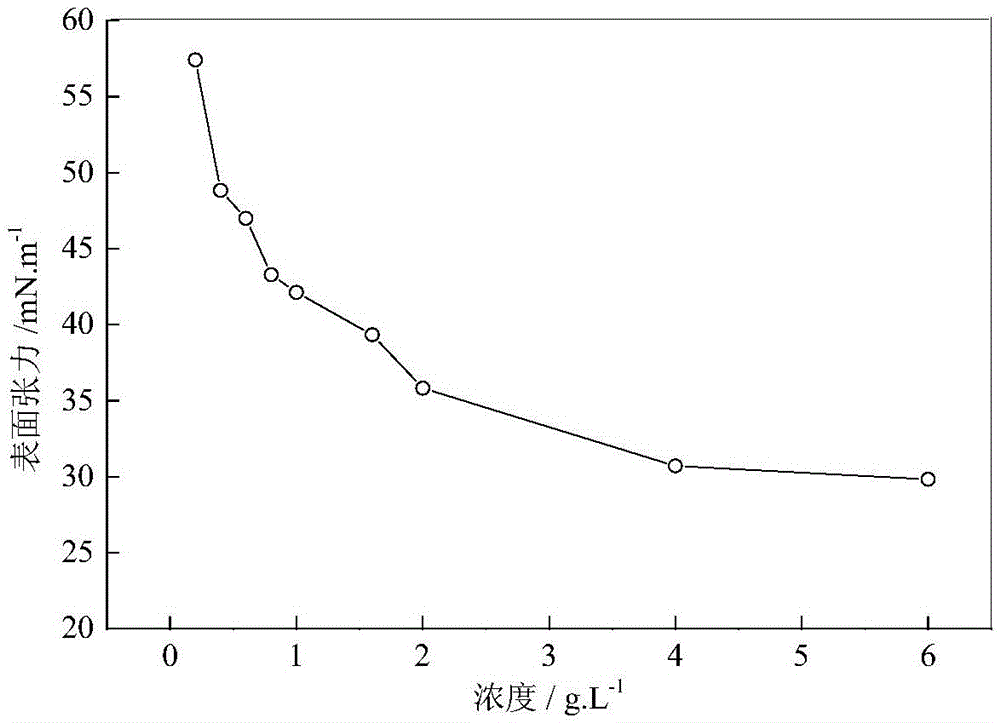

ActiveCN105504153AImprove thermal stabilityStrong chemical stabilityHeat resistanceFluorine containing

The invention discloses fluorine-containing hydrophobic-associating surface-active polyacrylamide which has the following molecular structure (please see the structure in the description), wherein x=100, y=10-20, z=0.05-1.5, n=4 or 6 or 8, and R and R' represent alkyl. The prepared polyacrylamide has the advantages that the excellent tackifying property, heat resistance and salt tolerance are achieved, the surface tension of water can be reduced to 24-32 mN / m, and the good application prospect on tertiary oil recovery, drilling fluid and paint is achieved.

Owner:FUSHUN DRAGON CHEM PLANT

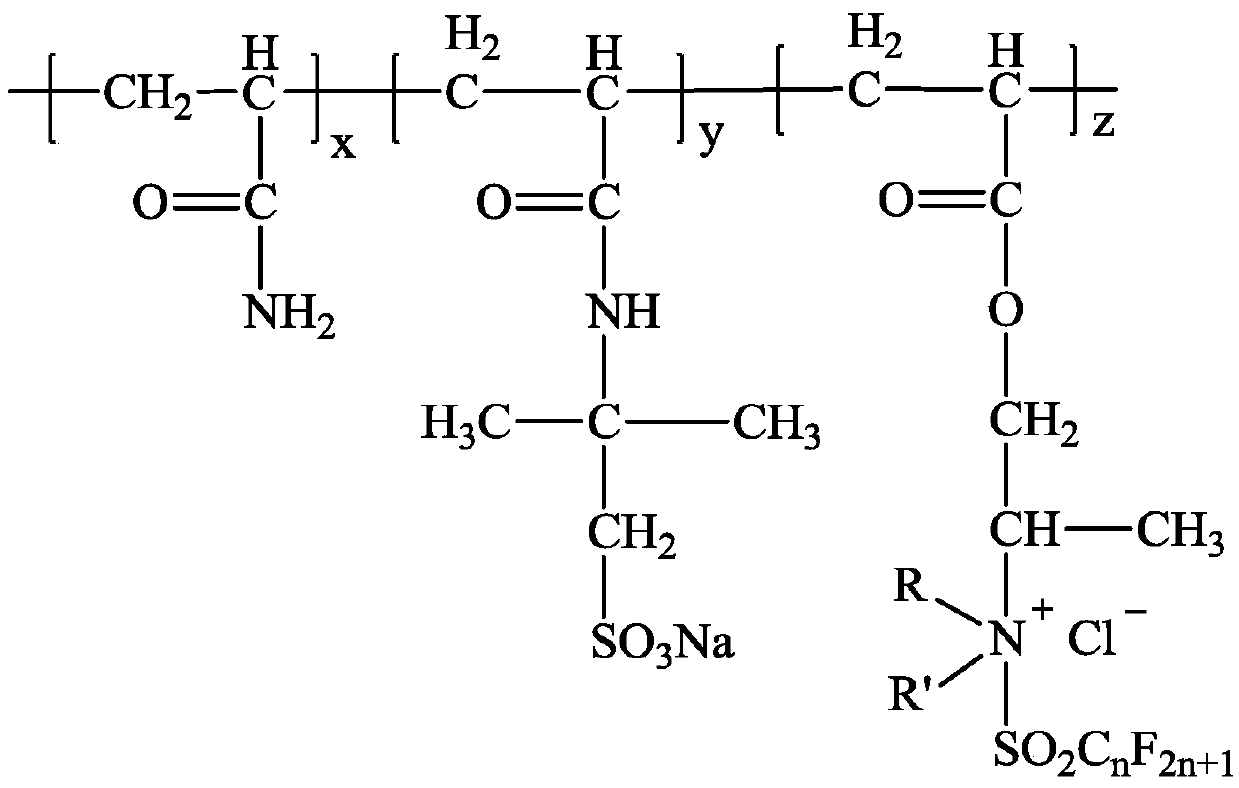

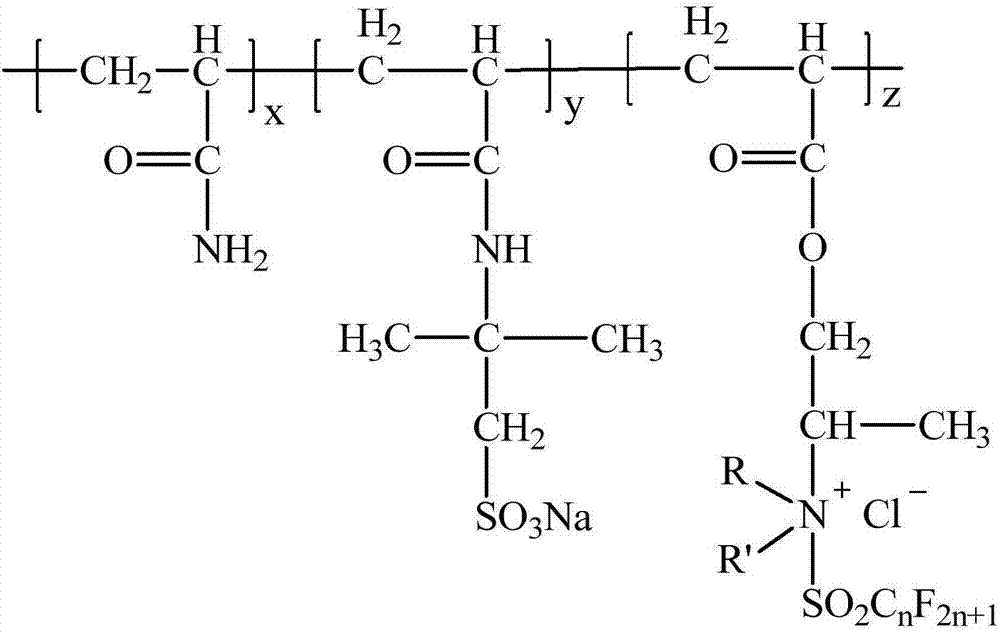

Fluorine-containing double-tail hydrophobically associating polymer and preparation thereof

InactiveCN105461854AReduce cohesive energyLower surface energyDrilling compositionActive polymerPolymer science

The invention discloses a fluorine-containing double-tail hydrophobically associating polymer and a preparation thereof. According to the polymer, a hydrophobic monomer with fluorine-containing double tails and salt-resistant sulfonic acid groups are introduced into macromolecules. Experimental results indicate that the hydrophobically associating surface active polymer can lower surface tension of water to 23-30 mN / m and can further improve oil recovery by 14.12-16.25%. The hydrophobically associating polymer is good in viscosity increasing performance and heat resistance and salt tolerance and low in surface tension and has good application prospect in the aspects of tertiary recovery, drilling fluid and coating.

Owner:YANGTZE UNIVERSITY

Preparation method for nano calcium carbonate special for low modulus silicone adhesive

ActiveCN107118590AGood compatibilityReduce reunionNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsCarbonizationSlurry

The invention discloses a preparation method for nano calcium carbonate special for low modulus silicone adhesive. The preparation method is implemented according to the following steps: 1) preparing Ca(OH)2 slurry; 2) carrying out carbonization; 3) adding a crystal form conditioning agent; 4) carrying out surface treatment; 5) adding a modulus conditioning agent; 6) carrying out filter pressing, drying and smashing on calcium carbonate boiled size in after the modulus conditioning agent is added to prepare the nano calcium carbonate special for the low modulus silicone adhesive, wherein the moisture of the nano calcium carbonate is less than or equal to 0.3%. The nano calcium carbonate prepared by the preparation method has good compatibility with polydimethylsiloxane, and cohesive energy is reduced after the nano calcium carbonate and the polydimethylsiloxane are mixed so as to achieve an effect of lowering silicone adhesive product modulus.

Owner:FUJIAN HONGFENG NANO TECH

Easy-to-tear packaging composite film and extrusion type liquid packaging bag

InactiveCN111204095AReduce the difficulty of recyclingAchieve recyclabilitySynthetic resin layered productsBagsComposite filmLayer thickness

The invention discloses an easy-to-tear packaging composite film. The easy-to-tear packaging composite film comprises an outer protective layer, a middle barrier layer and an inner heat sealing layer,the thickness of the outer protective layer is 12-30 [mu]m, the thickness of the middle barrier layer is 7-30 [mu]m, and the thickness of the inner heat sealing layer is 30-100 [mu]m; and the outer protective layer, the middle barrier layer and the inner heat sealing layer are compounded by adopting a dry compounding process or an extrusion compounding process. An extrusion-type strip-shaped liquid packaging bag prepared from the easy-to-tear composite film has extrusion weak points, so that contents are convenient to extrude.

Owner:JIANGYIN BAOBO PACKING

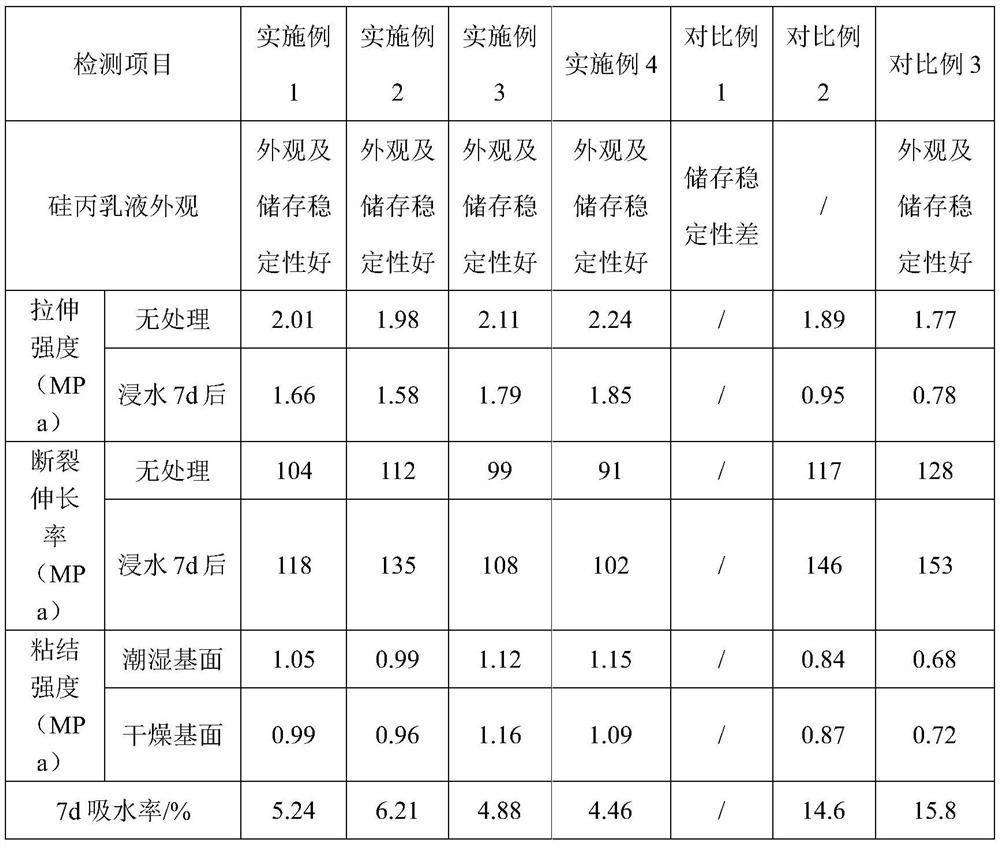

Preparation method of silicon-acrylic emulsion capable of being used for preparing polymer cement-based waterproof coating

ActiveCN112851850AImprove water resistanceGood storage stabilityCement coatingsPolymer scienceDouble bond

The invention discloses a preparation method of a silicon-acrylic emulsion capable of being used for preparing a polymer cement-based waterproof coating. The method comprises the following steps: by adopting an emulsion polymerization method, taking a vinyl monomer, a vinyl-containing functional organic silicon monomer and the like as comonomers, dropwise adding an initiator by virtue of a polymerizable emulsifier and mechanical stirring to enable the monomers to be polymerized and nucleated in water, continuously dropwise adding the initiator and the residual monomers to carry out double-bond free radical polymerization, finally carrying out ice-water bath quenching reaction, and adjusting the pH value to obtain the silicon-acrylic emulsion with the core-shell structure. According to the polymer cement-based waterproof coating prepared from the silicon-acrylic emulsion, the water resistance and the mechanical property of the waterproof coating can be remarkably improved, in addition, due to the fact that silicon-oxygen bonds on a molecular structure are neatly arranged towards the outer layer, the coating has excellent hydrophobicity and air and moisture permeability, and the problems of bulging and falling during construction on a wet base plane are solved.

Owner:江苏雨中情防水材料有限责任公司

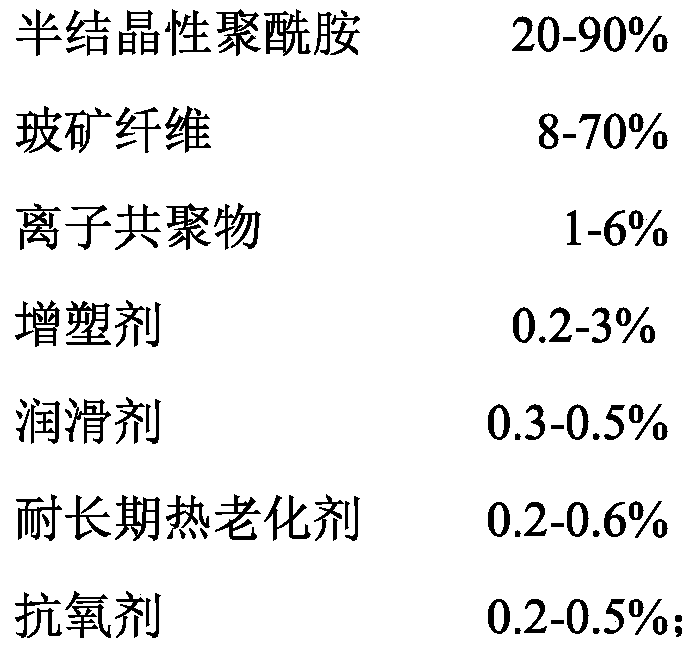

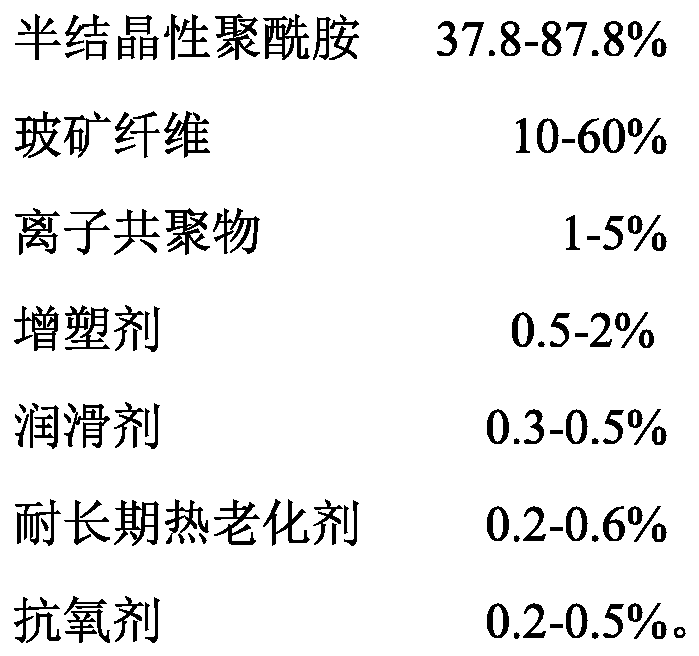

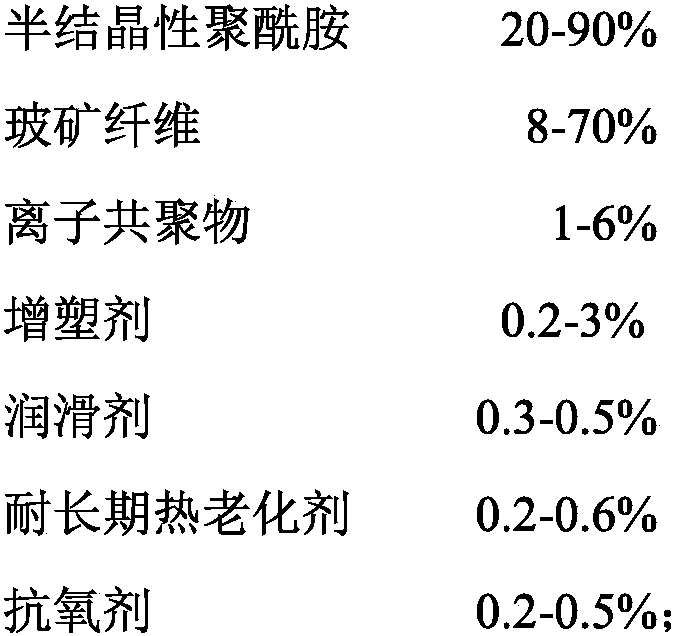

Polyamide material for improving adhesion effect of paint as well as preparation method and application of polyamide material

The invention discloses a polyamide material for improving the adhesion effect of paint as well as a preparation method and application of the polyamide material. The polyamide material is composed ofthe following components in percentages by weight: 20-90% of semi-crystalline polyamide, 8-70% of glass mineral fibers, 1-6% of an ion copolymer, 0.2-3% of a plasticizer, 0.3-0.5% of a lubricant, 0.2-0.6% of an agent resistant to long-term heat aging, and 0.2-0.5% of an antioxidant. According to the method, the ion copolymer having a carboxyl side group in a molecular side chain and the polyamideplasticizer capable of suppressing hydrogen bonding from being formed among molecular chains of the semi-crystalline polyamide and reducing the crystallization ability of a polyamide material are used to modify the semi-crystalline polyamide material to obtain high fluidity and an unexpectedly good coating adhesion effect.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD +1

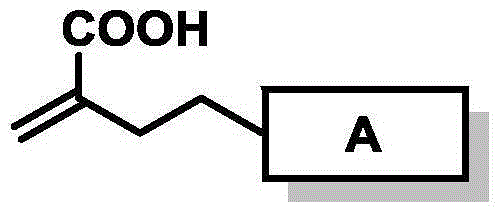

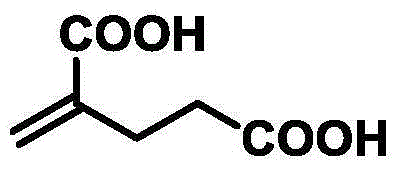

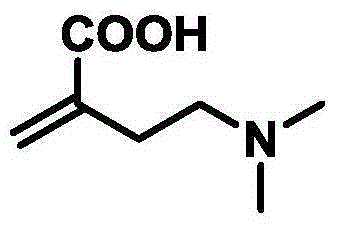

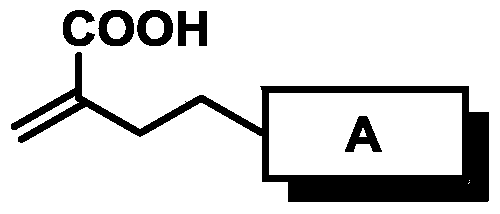

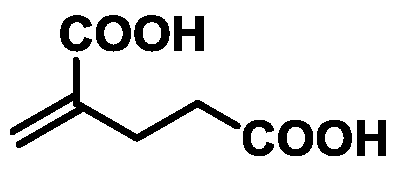

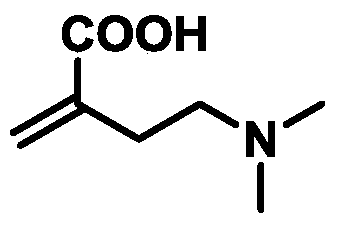

Polyacrylonitrile-based carbon fiber spinning solution and preparing method of polyacrylonitrile-based carbon fiber spinning solution

ActiveCN105085797AImprove hydrophilicityIncrease in sizeMonocomponent synthetic polymer artificial filamentPolymer scienceAcrylonitrile

The invention provides a polyacrylonitrile-based carbon fiber spinning solution and a preparing method of the polyacrylonitrile-based carbon fiber spinning solution. The spinning solution is prepared from monomers, radical initiators and solvent reaction liquid through copolymerization; the mass concentration of the monomers in the reaction liquid is 15 to 35 percent; the radical initiators account for 0.2 to 1 percent of the monomer total weight; the balance is the solvent; the monomers comprise acrylonitrile monomers accounting for 95 to 99.5 percent of the total mass of the monomers and copolymer monomers accounting for 0.5 to 5 percent of the total mass of the monomers; the copolymers are hydrophilic copolymer monomers containing 2-methylene butyric acid groups. The preparing method comprises the following steps that (1) the raw materials are proportionality added into a reaction kettle, are stirred and mixed, and are subjected to nitrogen bubbling for 10 to 40 minutes; (4) under the nitrogen protection, the reaction is taken at the constant temperature being 50 to 70 DEG C for 6 to 36h; (3) residue monomers and bubbles are removed to obtain the spinning solution. The designed copolymer monomers can improve densification agents of resin hydrophilia and can also improve the oxygen permeability and the spinnability. The spinning solution obtained by the method has high hydrophilicity and good heat release performance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Preparation method of adhesive for compounding mirror surface substrate

InactiveCN111117550AAct as a bondGood storage stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolymer science

The invention provides a preparation method of an adhesive for compounding a mirror surface substrate. The preparation method comprises the following steps: carrying out polymerization reaction on dicyclohexylmethane diisocyanate and polytetramethylene ether glycol; adding a proper amount of epoxy resin into the reaction system for block modification; employing methyl ethyl ketoxime as a sealing agent to seal terminal-NCO, and preparing a modified polyurethane prepolymer with a hydrophilic chain extender; adding triethylamine to neutralize the reaction product, adding water to emulsify the reaction product, then carrying out chain extension again by using hydrazine hydrate, and finally carrying out defoaming, thickening, leveling, anti-sticking and the like treatment, so as to obtain the adhesive for compounding the mirror surface substrate. The adhesive obtained by the method has good initial adhesion when a mirror surface substrate is compounded at normal temperature, so that the mirror surface substrate is good in laser effect and high in peel strength after hot pressing and clamping.

Owner:JIANGSU HUAXIN NEW MATERIAL

Solvent-free single component polyurethane waterproof paint and production technology thereof

ActiveCN110922882AReduce cohesive energySolve environmental and safety issuesAnti-corrosive paintsPolyurea/polyurethane coatingsIsocyanateCorrosion resistant

The invention discloses a solvent-free single component polyurethane waterproof paint, and relates to the field of waterproof paints. The polyurethane waterproof paint comprises following components:low viscosity bio-based polyether polyol, siloxane modified isocyanate, and glycidyl butyl ether. Metal and amine polyurethane catalysts are not used; a plasticizer or an organic solvent is not needed; and the waterproof paint can quickly cure at a room temperature. The produced solvent-free single component polyurethane waterproof paint has the advantages that the hydrogen bond association between molecules is eliminated, the cohesive energy of the system is reduced, the safety and environmental protection problems of a common polyurethane product are solved perfectly; at the same time, problems caused by using a large amount of low viscosity plasticizers and latent curing agents such as material migration, offensive odor, bad hand feeling, and the like are solved; the solvent-free singlecomponent polyurethane waterproof paint is environmentally friendly, safe, and pollution-free, has a strong substrate binding force, is waterproof and corrosion resistant, and can be applied to waterproof projects that have high requirements on environmental protection.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Preparation method of modified polyvinyl chloride jacket used for cable production

InactiveCN107880451AEasy to useImprove stabilityPlastic/resin/waxes insulatorsCrack resistancePolyvinyl chloride

The invention relates to the technical field of cable processing and production, and discloses a method for preparing a modified polyvinyl chloride sheath used in cable production. Nanomaterials are used to modify polyvinyl chloride, and the addition of metal nanoparticles increases the The distance between the polyvinyl chloride copolymer molecules reduces the cohesive energy of the molecular chain, thereby reducing the environmental stress cracking performance. The proportion of fractures in the test of low-temperature impact embrittlement performance at minus 40°C is within 0-0.01%, which can meet the requirements. The requirement of working at minus 40°C improves the comprehensive usability of polyvinyl chloride. It can pass the combustion test of UL910 or NFPA 262 when used as a cable sheath. The oxygen index reaches 50, and the amount of smoke is low. Oxygen stability and service life are significantly improved, and the resistance to cracking in stressful environments is improved.

Owner:铜陵市远维线缆有限公司

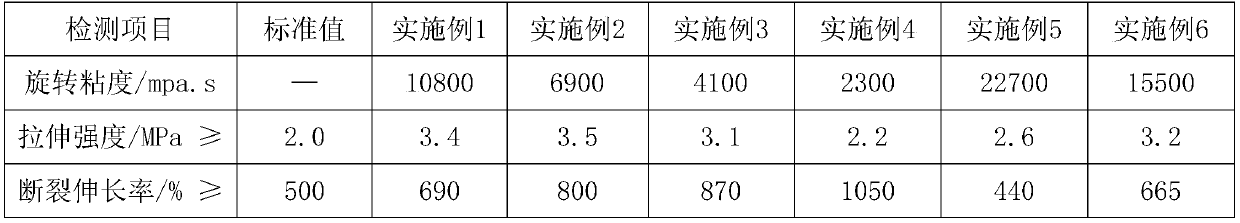

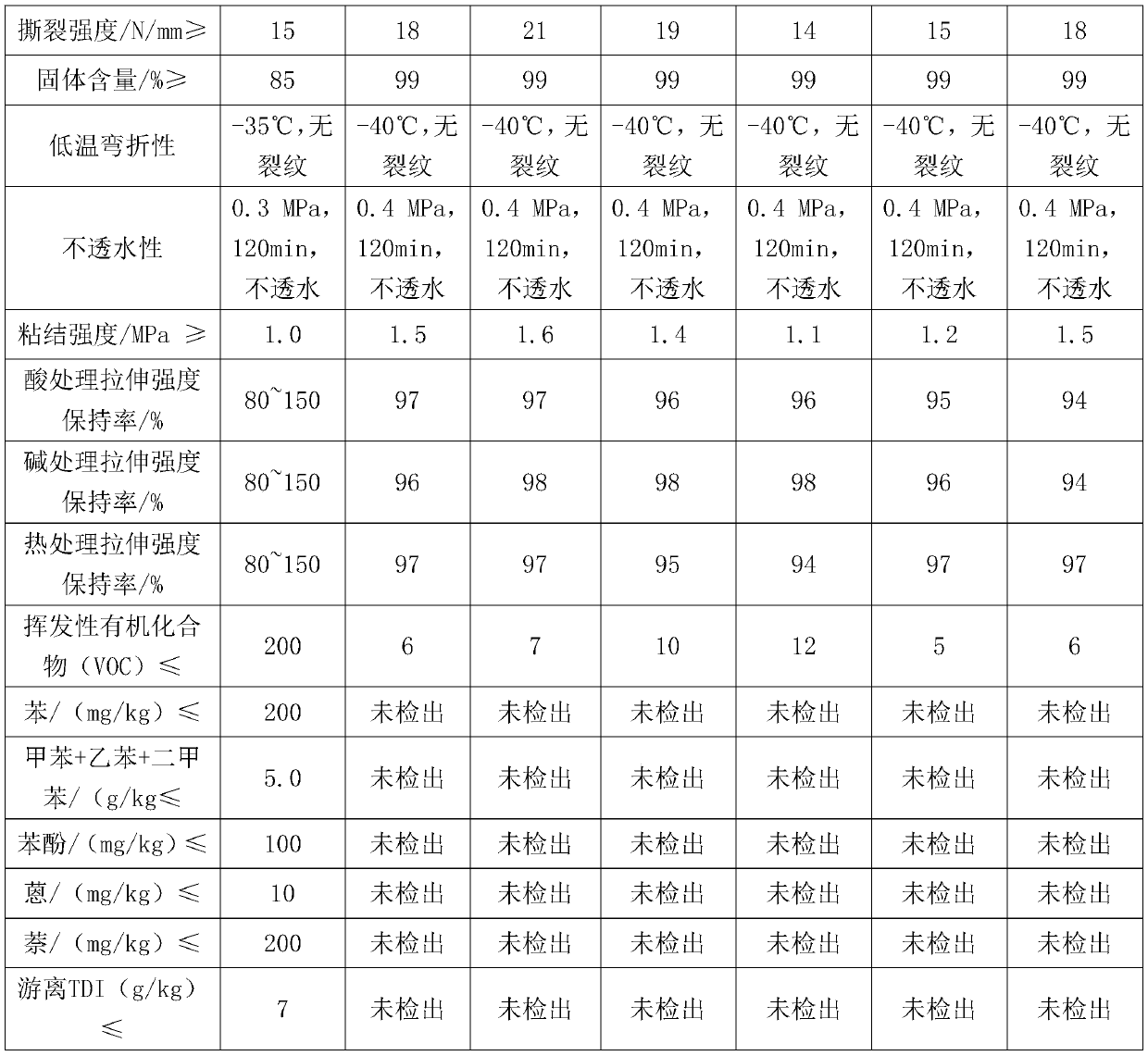

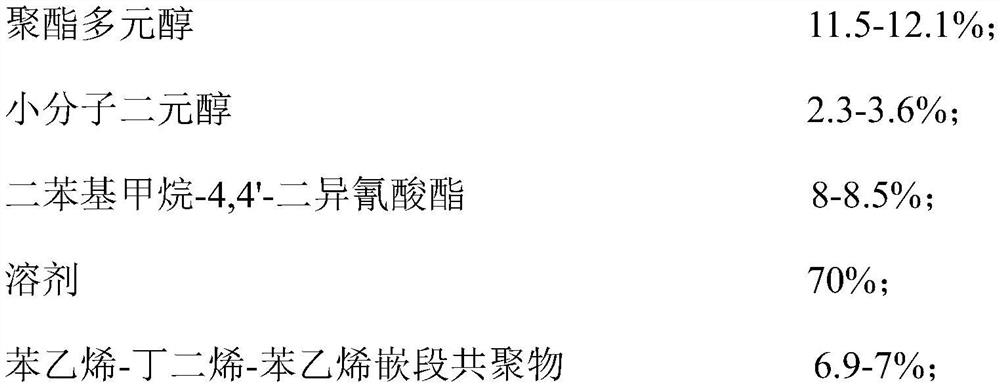

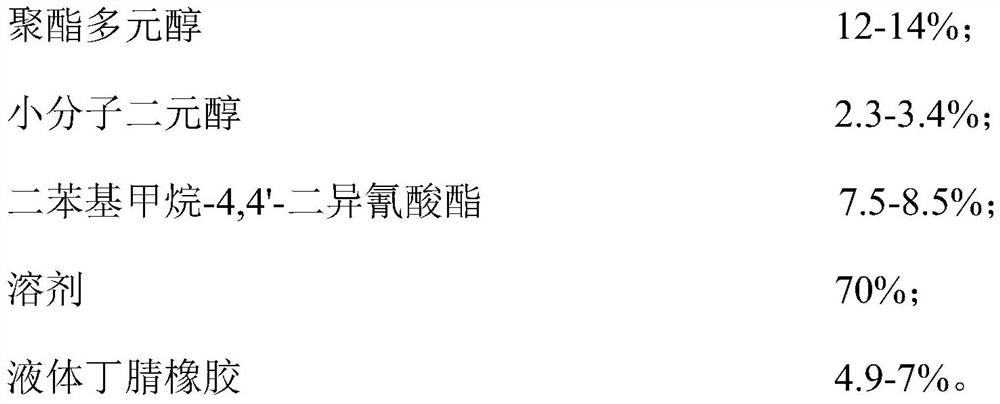

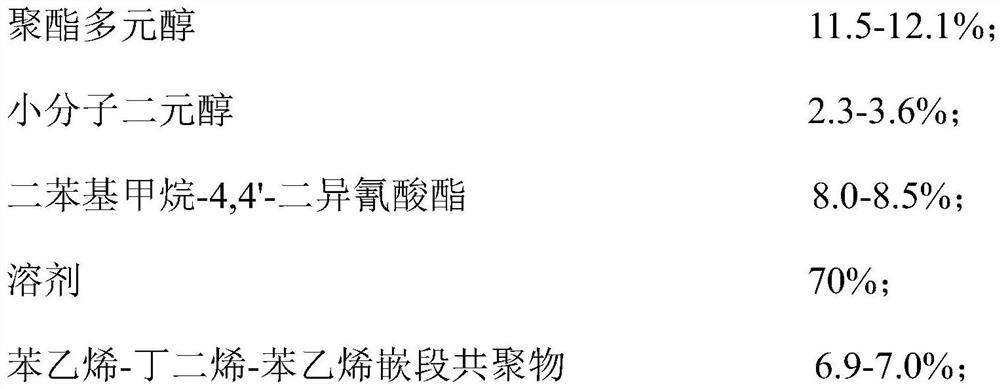

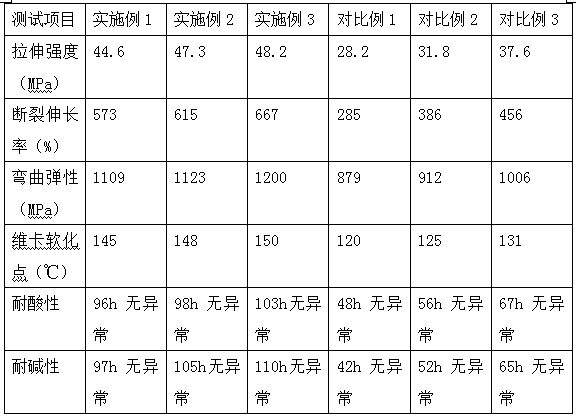

Polyurethane resin composition and preparation method and application thereof

ActiveCN112724655ALower relative polarityGood flexibility at low temperatureUpperBootlegsPolyesterDi-isocyanate

The invention provides a polyurethane resin composition and a preparation method and application thereof, the polyurethane resin composition comprises a first composition and a second composition, the first composition comprises the following components in percentage by weight: 11.5-12.1% of polyester polyol, 2.3-3.6% of micromolecular dihydric alcohol, and 8-8.5% of diphenylmethane-4, 4-diisocyanate, 70% of a solvent and 6.9-7% of a styrene-butadiene-styrene block copolymer; and the second composition is prepared from the following components in percentage by weight: 12-14% of polyester polyol, 2.3-3.4% of micromolecular dihydric alcohol, 7.5-8.5% of diphenylmethane-4, 4'-diisocyanate, 70% of a solvent and 4.9-7% of liquid nitrile rubber. Compared with conventional polyurethane resin, the polarity of the polyurethane resin composition is reduced, injection molding of the polyurethane resin composition and TPR can be achieved, and the polyurethane resin composition is suitable for the field of shoe leather materials.

Owner:SHANGHAI HUIDE TECH CO LTD

Preparing method for HDPE pipe

InactiveCN110744845APlay a cooling rolePlay a role in enhancing protectionInorganic material artificial filamentsTubular articlesMethacrylateFiber

The invention belongs to the technical field of plastic pipe preparing and particularly relates to a preparing method for an HDPE pipe. By means of the preparing method, kaolin, aluminum oxide, titanium dioxide, aluminum phosphate and water are mixed, an outer rubber pipe layer is entangled and wrapped by silicon-aluminum reinforced fibers to be arranged into the inner layer of a double-layer corrugated pipe die, the inner layer is filled with filling glue, the double-layer corrugated pipe die is put into a hot pressing device to be subjected to hot pressing, and the HDPE pipe is extruded. Bymeans of the preparing method for the HDPE pipe, the heat conduction coefficient of graphite powder with the fineness being 200 meshes is relatively large, a cooling effect is achieved, and a protection effect is achieved on the HDPE pipe through the silicon-aluminum reinforced fibers. High density polyethylene powder is adopted as the main raw material to prepare an outer rubber pipe layer in a vulcanization forming manner, the HDPE pipe is enhanced through silicon-aluminum reinforced fiber layer wrapping, EPDM has low-temperature elasticity, and toughness and elasticity of the HDPE pipe areimproved; in addition, the EPDM has the good oil resistance property and the good acid and alkali corrosion resisting performance; and a layer of anti-corrosion protection film is provided, meanwhile,zinc methacrylate is adopted as a heat-resisting antioxidant, compatibility of components doped in the HDPE pipe is improved, the anti-corrosion performance is improved, and a wide application prospect is achieved.

Owner:张业毅

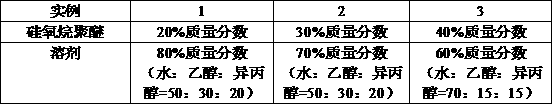

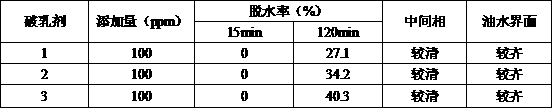

Crude oil demulsifier used at normal low temperature

InactiveCN109575984AReduce surface tensionReduce cohesive energyDewatering/demulsification with chemical meansHydrocarbon oils treatmentDemulsifierOil water

The invention relates to a crude oil demulsifier used at normal low temperature. The demulsifier includes the following components: silicone polyether having a mass percent of 10-50%, the viscosity of200-300 cSt, the HLB value of 7-10, and a closed-cup flash point of more than 60 DEG C, and a solvent including a mixture of one or more and having the mass percent of 50-90%. The silicone polyetherin composition of the crude oil demulsifier has different structures and molecular weight distribution; the crude oil demulsifier has a high efficiency oil-water demulsification effect; siloxane has low surface tension, low cohesive energy and low temperature sensitivity; demulsification can be achieved at the low temperature of 30 DEG C; the addition amount is reduced by more than 50% than that of polyether surfactant alone; and the dehydration rate is fast, the demulsification effect is good, and the comprehensive cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Easy-to-peel hot sealing film

InactiveCN110041618AExcellent peelabilityHigh heat sealing strengthPolyethylene terephthalatePlasticizer

The invention discloses an easy-to-peel hot sealing film. The easy-to-peel hot sealing film is prepared from the following components: polypropylene resin, polyethylene terephthalate, a modifying agent, basalt fibers, nano titanium dioxide, a coupling agent, amidation modified vermiculite flour and a plasticizer. The easy-to-peel hot sealing film prepared by the invention is applicable to heat-sealing packing of objects including various foods and the like and has good peeling performance.

Owner:合肥绿普包装材料有限公司

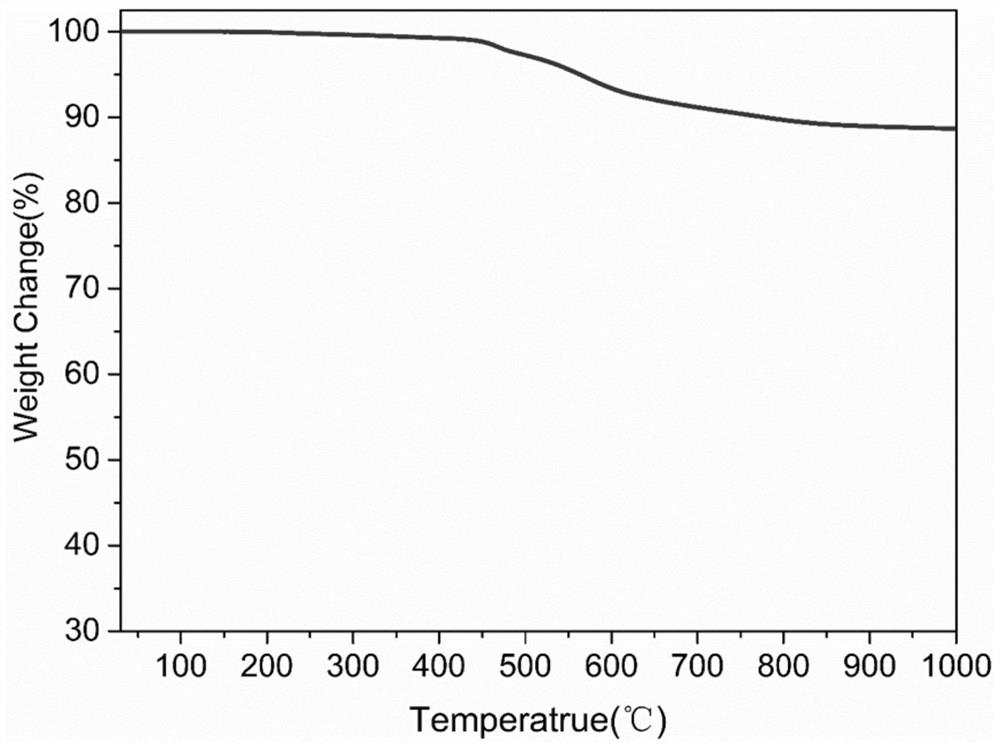

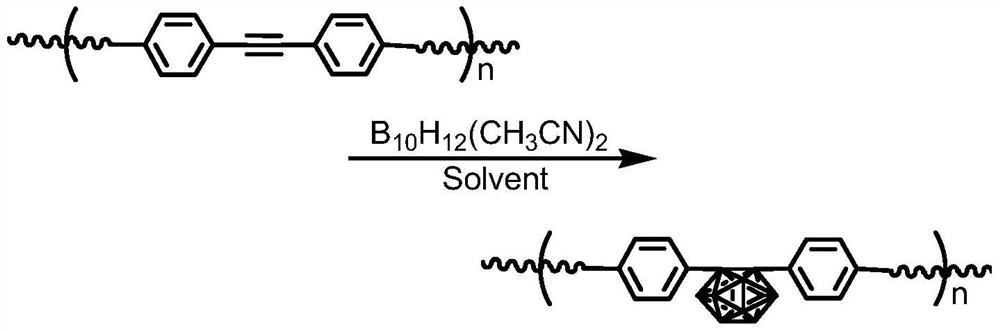

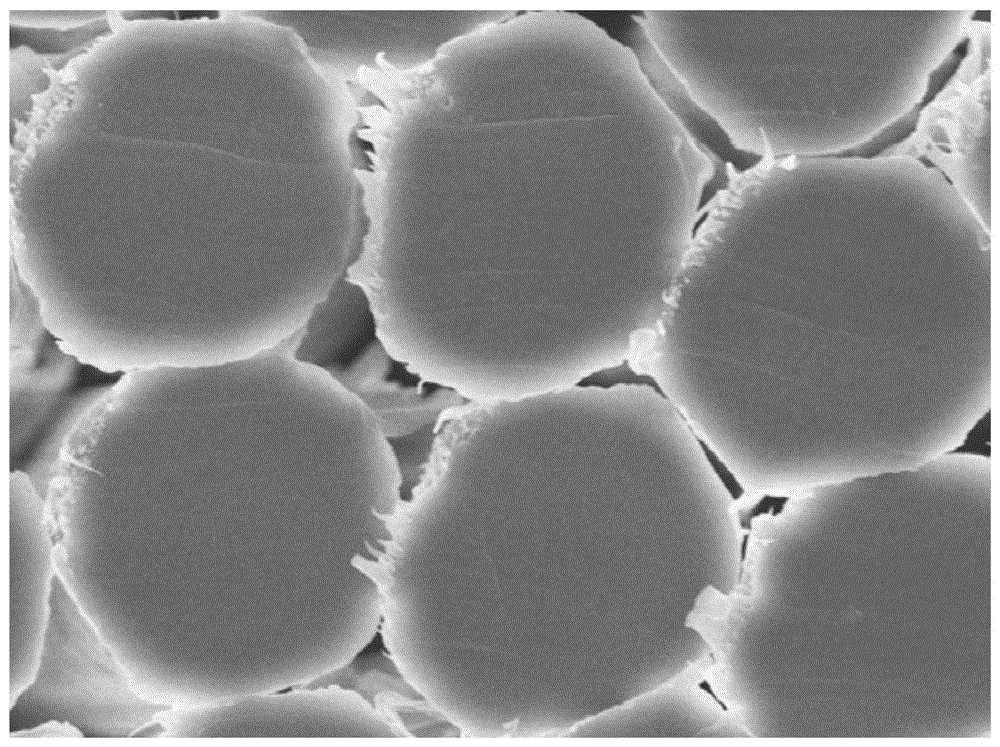

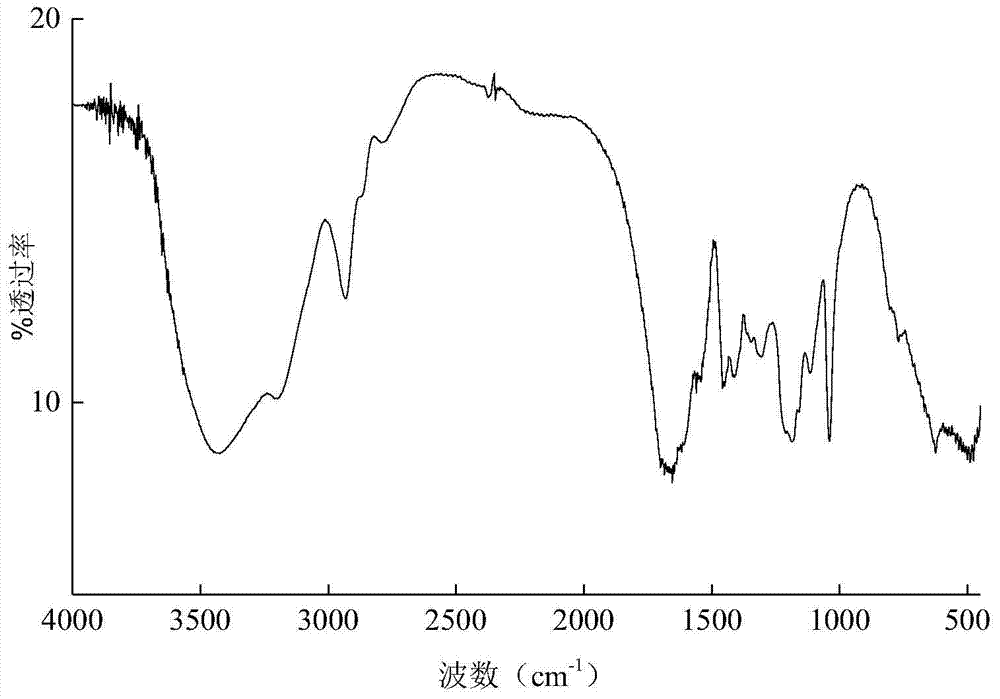

Preparation method of high-temperature-resistant polyimide resin

ActiveCN114790289AIncrease temperatureOvercome the defects of limited molecular weight and low degree of polymerizationImidePolymer science

The invention relates to a preparation method of high-temperature-resistant polyimide resin, and belongs to the technical field of high polymer materials. The method comprises the following steps: synthesizing a fluorinated polyimide polymer with a main chain containing alkynyl, and introducing a carborane structure into the main chain of the polymer by utilizing a macromolecular reaction to obtain the high-temperature-resistant polyimide resin. The method overcomes the defects that the molecular weight of the polyimide polymer is limited and the polymerization degree is low due to the fact that a carborane structure with large steric hindrance exists in reaction raw materials and influences increase of molecular chains of the reaction raw materials in the prior art, and the length and the molecular weight of the molecular chains can be designed according to actual application requirements; according to the high-temperature-resistant polyimide resin designed and synthesized by the method, fluorine atoms and a carborane structure with excellent thermal stability are introduced into a molecular main chain, so that the high-temperature-resistant polyimide resin has high thermal stability and thermal oxygen stability, low dielectric constant, refractive index, water absorption, cohesive energy and surface free energy, is hydrophobic and oleophobic, and has wider application potential.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A kind of preparation method of pan precursor for carbon fiber

ActiveCN104231158BImprove controllabilityIncrease productivityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentCarbon fibersAcrylonitrile

The invention provides a method for preparing polyacrylonitrile (PAN) precursors for carbon fibers. The method first adopts an aqueous phase precipitation polymerization process to produce PAN polymer, specifically: ammonium persulfate-sodium bisulfite-ferrous sulfate is used as the initiation system, vinyl acetate is used as the second comonomer, and carboxylic acid vinyl The compound is the third comonomer, sulfuric acid is used as the pH regulator, and the precipitation copolymerization reaction is carried out with acrylonitrile in the water phase with a pH value of 2 to 5. After the reaction is completed, the reaction system is alkalized with ammonia water, and then After separation, washing and drying, the PAN polymer powder is obtained; then, the PAN polymer powder is dissolved in a polar organic solvent to prepare a PAN spinning solution, and then the PAN precursor is prepared by a wet spinning process. The method has low cost and high production efficiency, and the prepared PAN precursor has a good structure, can meet the requirements of large-scale production of carbon fibers, and is beneficial to improving the performance of carbon fibers and reducing production costs.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of fluorine-containing hydrophobic association surface-active polyacrylamide and its preparation method

ActiveCN105504153BImprove thermal stabilityHigh temperature resistanceHeat resistanceFluorine containing

The invention discloses fluorine-containing hydrophobic-associating surface-active polyacrylamide which has the following molecular structure (please see the structure in the description), wherein x=100, y=10-20, z=0.05-1.5, n=4 or 6 or 8, and R and R' represent alkyl. The prepared polyacrylamide has the advantages that the excellent tackifying property, heat resistance and salt tolerance are achieved, the surface tension of water can be reduced to 24-32 mN / m, and the good application prospect on tertiary oil recovery, drilling fluid and paint is achieved.

Owner:FUSHUN DRAGON CHEM PLANT

A kind of fluorine-containing double tail hydrophobic association polymer and its preparation method

InactiveCN105461854BStrong salt resistanceImprove thermal stabilityDrilling compositionActive polymerPolymer science

The invention discloses a fluorine-containing double-tail hydrophobically associating polymer and a preparation thereof. According to the polymer, a hydrophobic monomer with fluorine-containing double tails and salt-resistant sulfonic acid groups are introduced into macromolecules. Experimental results indicate that the hydrophobically associating surface active polymer can lower surface tension of water to 23-30 mN / m and can further improve oil recovery by 14.12-16.25%. The hydrophobically associating polymer is good in viscosity increasing performance and heat resistance and salt tolerance and low in surface tension and has good application prospect in the aspects of tertiary recovery, drilling fluid and coating.

Owner:YANGTZE UNIVERSITY

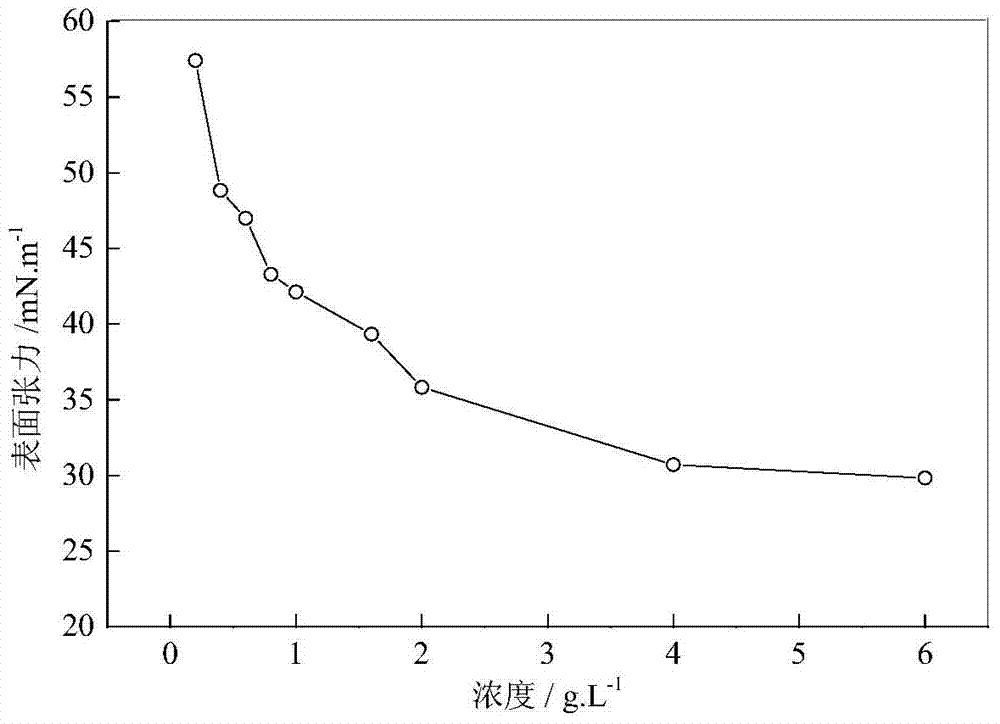

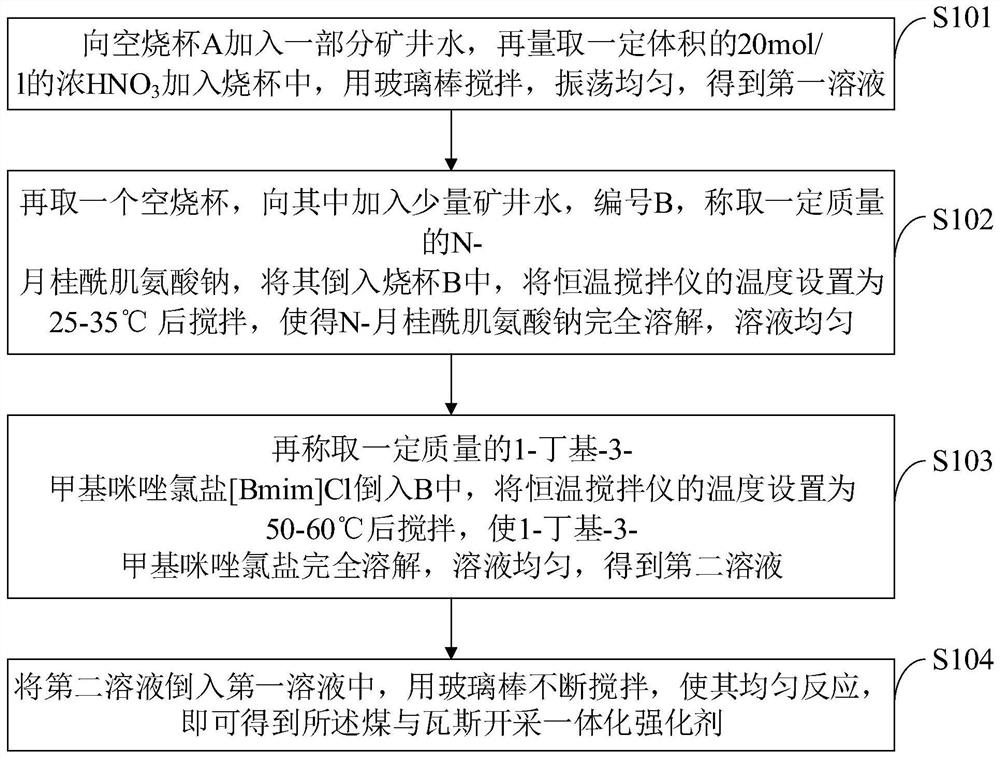

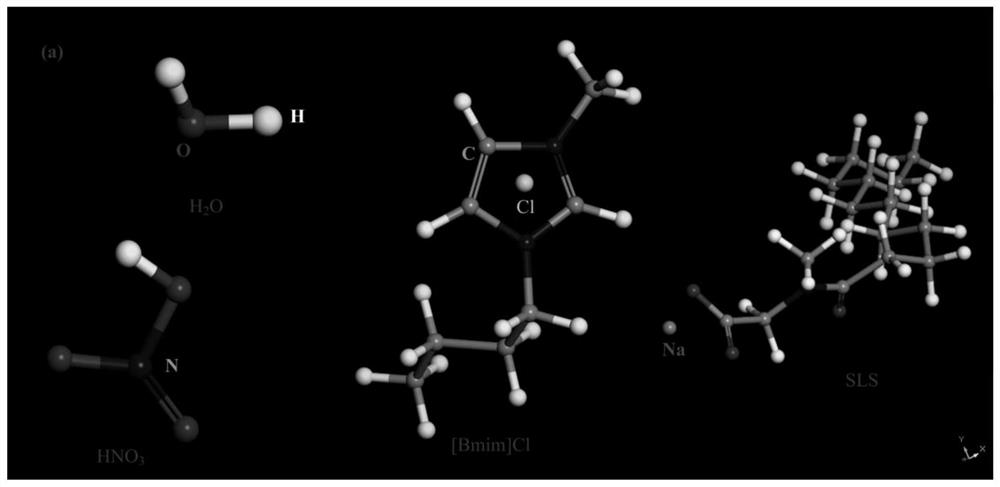

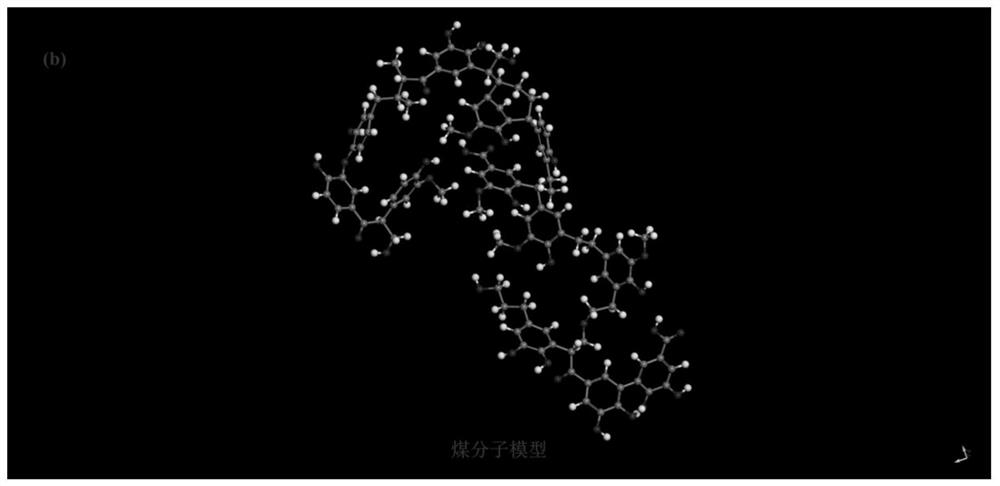

An integrated anti-reflection enhancer for coal and gas mining, preparation method and application

ActiveCN112342007BThe number of pores increasesReduce mineral contentOther gas emission reduction technologiesFluid removalProcess engineeringChloride

The invention belongs to the technical field of high-efficiency and safe production in mines, and discloses an integrated anti-reflection enhancer for coal and gas mining, a preparation method and an application thereof. According to mass percentage, it consists of 6%-10% of 20mol / l concentrated nitric acid, 1 %-5% sodium N-lauroyl creatine, 2%-6% 1-butyl-3-methylimidazolium chloride and mine dust control water. The physical and chemical modification of the coal body by the coal and gas mining integrated enhancer provided by the invention can increase the wettability of the coal body, suppress and reduce the generation of dust in the coal seam mining process, greatly improve the permeability of the coal body, and improve the coal seam Occurrence and mining conditions are conducive to the efficient development and utilization of coalbed methane, improving coalbed methane mining to alleviate energy shortages, preventing gas disasters in underground coal mines, and reducing greenhouse gas emissions. Safe and efficient production level.

Owner:SHANDONG UNIV OF SCI & TECH

A kind of polyacrylonitrile-based carbon fiber spinning solution and preparation method thereof

ActiveCN105085797BImprove hydrophilicityIncrease in sizeMonocomponent synthetic polymer artificial filamentPolymer scienceAcrylonitrile

The invention provides a polyacrylonitrile-based carbon fiber spinning solution and a preparing method of the polyacrylonitrile-based carbon fiber spinning solution. The spinning solution is prepared from monomers, radical initiators and solvent reaction liquid through copolymerization; the mass concentration of the monomers in the reaction liquid is 15 to 35 percent; the radical initiators account for 0.2 to 1 percent of the monomer total weight; the balance is the solvent; the monomers comprise acrylonitrile monomers accounting for 95 to 99.5 percent of the total mass of the monomers and copolymer monomers accounting for 0.5 to 5 percent of the total mass of the monomers; the copolymers are hydrophilic copolymer monomers containing 2-methylene butyric acid groups. The preparing method comprises the following steps that (1) the raw materials are proportionality added into a reaction kettle, are stirred and mixed, and are subjected to nitrogen bubbling for 10 to 40 minutes; (4) under the nitrogen protection, the reaction is taken at the constant temperature being 50 to 70 DEG C for 6 to 36h; (3) residue monomers and bubbles are removed to obtain the spinning solution. The designed copolymer monomers can improve densification agents of resin hydrophilia and can also improve the oxygen permeability and the spinnability. The spinning solution obtained by the method has high hydrophilicity and good heat release performance.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

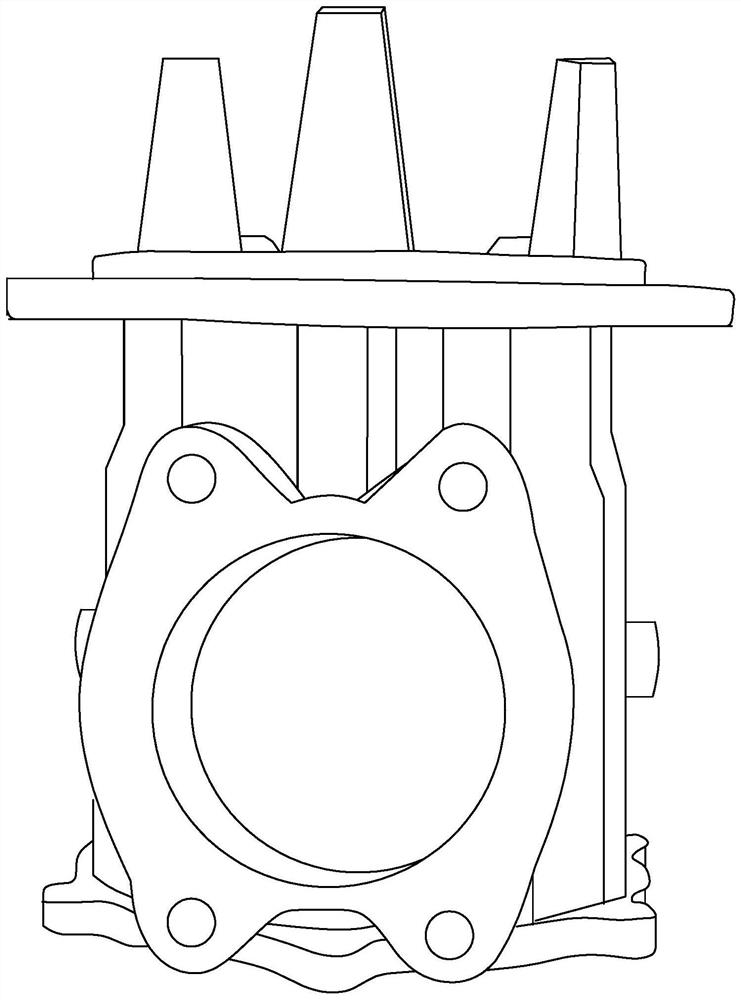

Self-sealing magnetic oil absorption filter aluminum die-casting blank shell and machining process thereof

PendingCN112694830AEvenly dispersedImprove wear resistancePolyamide coatingsTetrafluoroethylenePolyamide

The invention relates to the field of aluminum castings, and discloses a self-sealing magnetic oil absorption filter aluminum die-casting blank shell and a machining process thereof. The self-sealing magnetic oil absorption filter aluminum die-casting blank shell comprises a shell body, and the shell body is treated with a surface treating agent. The preparation method comprises the following steps of S1, polishing, S2, preparing a surface treating agent, S3, conducting electrostatic spraying, and S4, high-temperature curing. The machining process has the following advantages and effects that the polytetrafluoroethylene is mixed in the polyamide resin, and a solid lubricating film can be formed on the surface to reduce the friction coefficient so as to increase the wear resistance when the resin is abraded with other materials; propylene glycol fatty acid ester can react with polyamide resin to generate a certain plasticizing effect, cohesive energy among molecules in the resin is reduced, mutual friction between the polyamide resin and polytetrafluoroethylene components is weakened, so that polytetrafluoroethylene is uniformly dispersed in the resin, and the purpose of improving the wear resistance of a coating formed by the surface treating agent is achieved.

Owner:温州市秀存液压机械有限责任公司

Organic silicone modified high water absorption resin and preparation method thereof

The invention discloses an organic silicane high-adsorbing resin, which is copolymerized by soluble polycondensation product and vinyl monomer free radical with the content of organic silica as 0.1-5wt% as vinyl monomer, wherein the organic silicane is represented through Y (CH2) nSiX3 (Y is vinyl, epoxy radical, mercapto radical and so on; X is methoxyl, ethyoxyl, isopropoxy and so on); the resin adsorbs deionized water and salt water, which displays optical, heat and ultraviolet stability in the agricultural and hygiene domain.

Owner:安徽省农业科学院原子能农业应用研究所 +1

Low softening point thermoplastic polyurethane hot melt adhesive and preparation method thereof

InactiveCN103102861BImprove flexibilityImprove cohesive strengthPolyureas/polyurethane adhesivesPolyesterWater vapor

The invention discloses a low-softening point thermoplastic polyurethane hot melt adhesive and a preparation method thereof. The hot melt adhesive comprises the following components: 95-100 parts by weight of polyester polyol; 0-5 parts by weight of polyether diol; diisocyanate; and a chain extender. The preparation method consists of: adding polyester polyol and polyether diol into a reaction kettle, raising the temperature to 100DEG C-130DEG C under the protection of nitrogen, conducting dehydration till no water vapor is steamed, and lowering the temperature to 60-70DEG C; adding diisocyanate into the reaction kettle evenly within 2-3h, then leaving the materials to react for 2-4h at a temperature of 110-120DEG C; and adding the chain extender into the reaction kettle to react till wire drawing, and then stopping heating. The thermoplastic polyurethane hot melt adhesive provided in the invention has a softening point lower than 100DEG C and bonding strength on aluminum Ly-12 up to over 4MPa. Besides, the preparation method of the thermoplastic polyurethane hot melt adhesive is simple, reaction conditions are mild, and each technology parameter is easy to control, so that the thermoplastic polyurethane hot melt adhesive can be produced in large scale.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

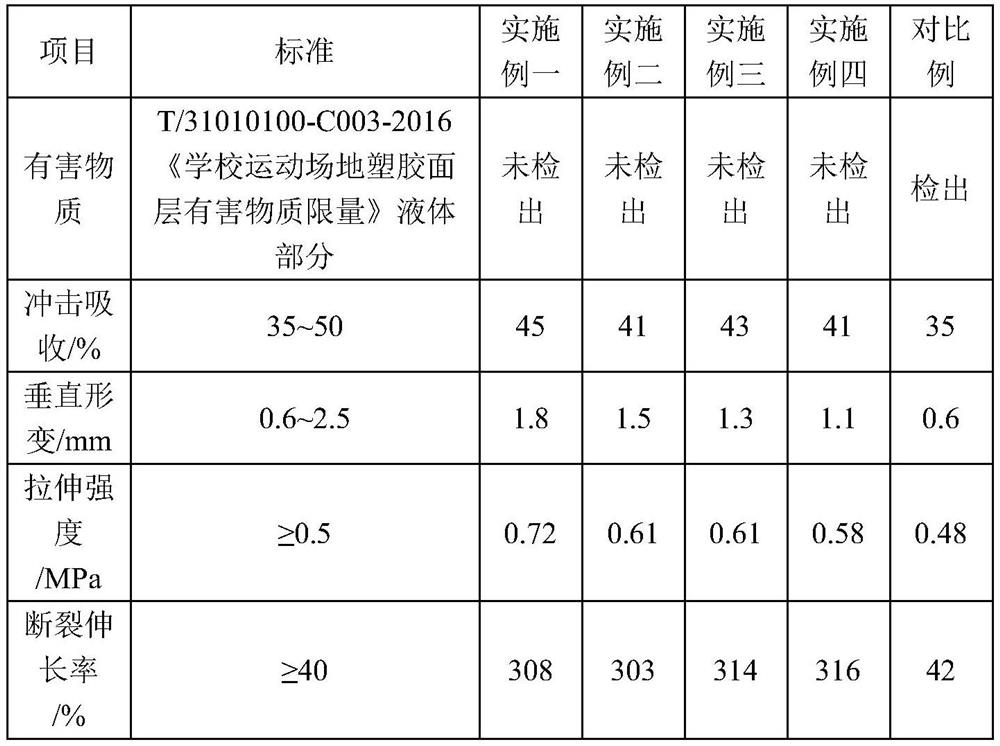

A kind of polyurethane ball court material and preparation method thereof

The invention discloses a polyurethane court material and a preparation method thereof. The technical scheme mainly includes that the polyurethane court material comprises, by weight, 60-100 parts of polyether polyol, 8-15 parts of diphenylmethane diisocyanate, 15-30 parts of reinforcing fillers, 10-20 parts of aromatics removing solvent oil, 0.05-0.1 part of composite catalysts and 0.5-3 parts of auxiliaries. In an environment with the aromatics removing solvent oil, the polyether polyol and water in other fillers can be taken out, the steric hindrance of the aromatics removing solvent oil is reduced, the polarity difference among the aromatics removing solvent oil and other components is decreased, the aromatics removing solvent oil is prevented from forming hydrogen bonds with hydroxyl of alcohol and affecting reaction speed, dehydration efficiency can be improved, and reaction thoroughness is enhanced.

Owner:江苏耐斯坦建设有限公司

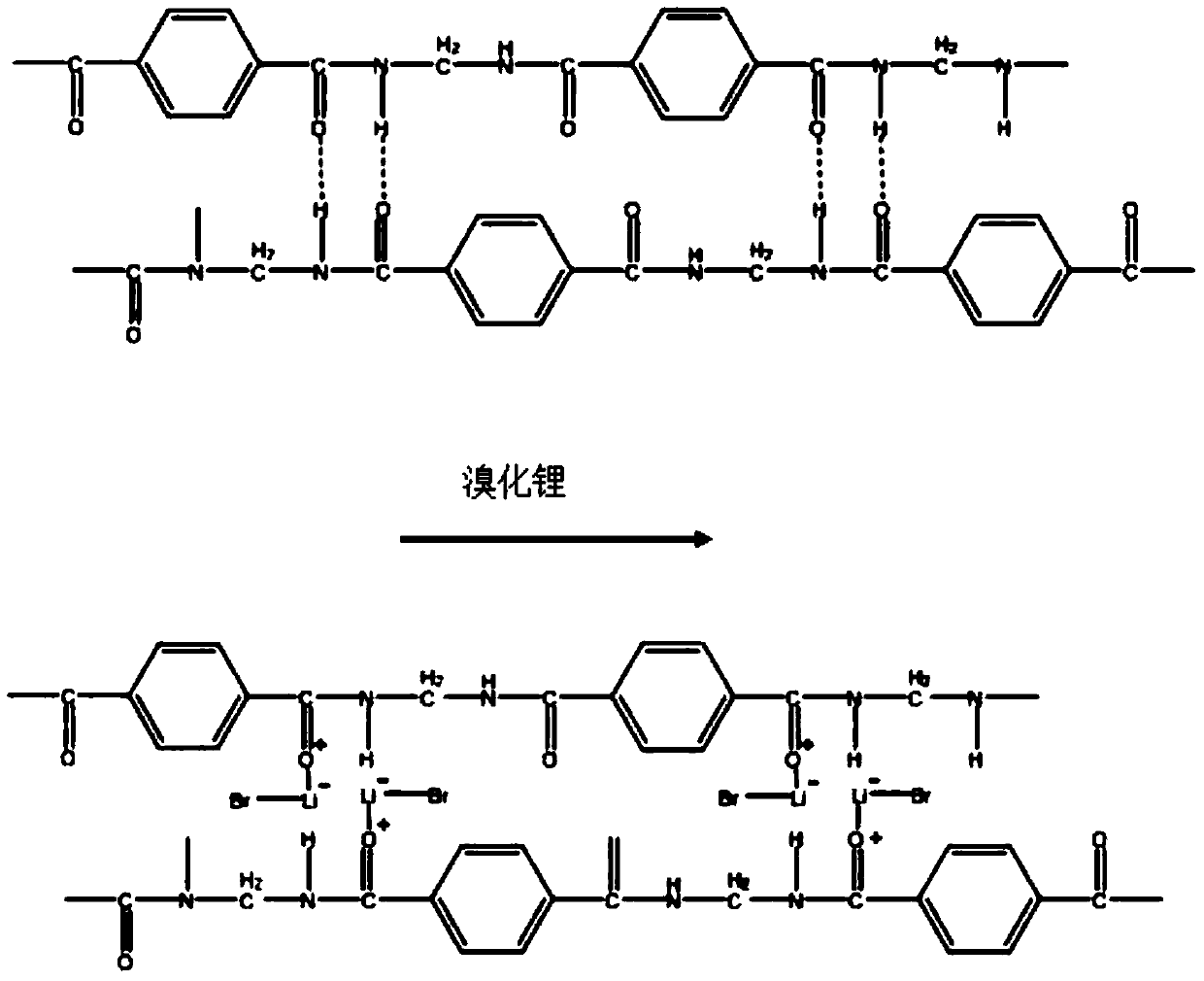

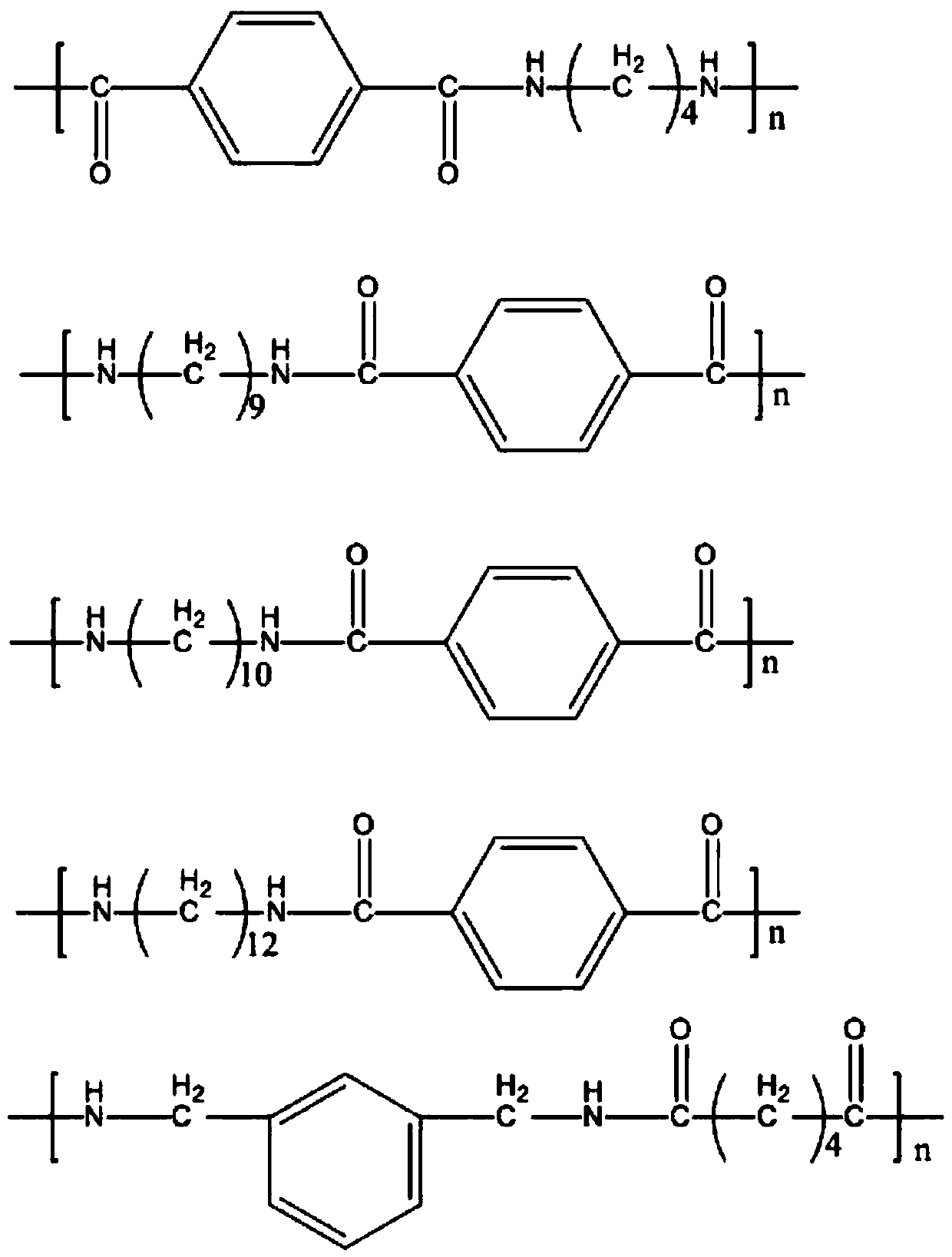

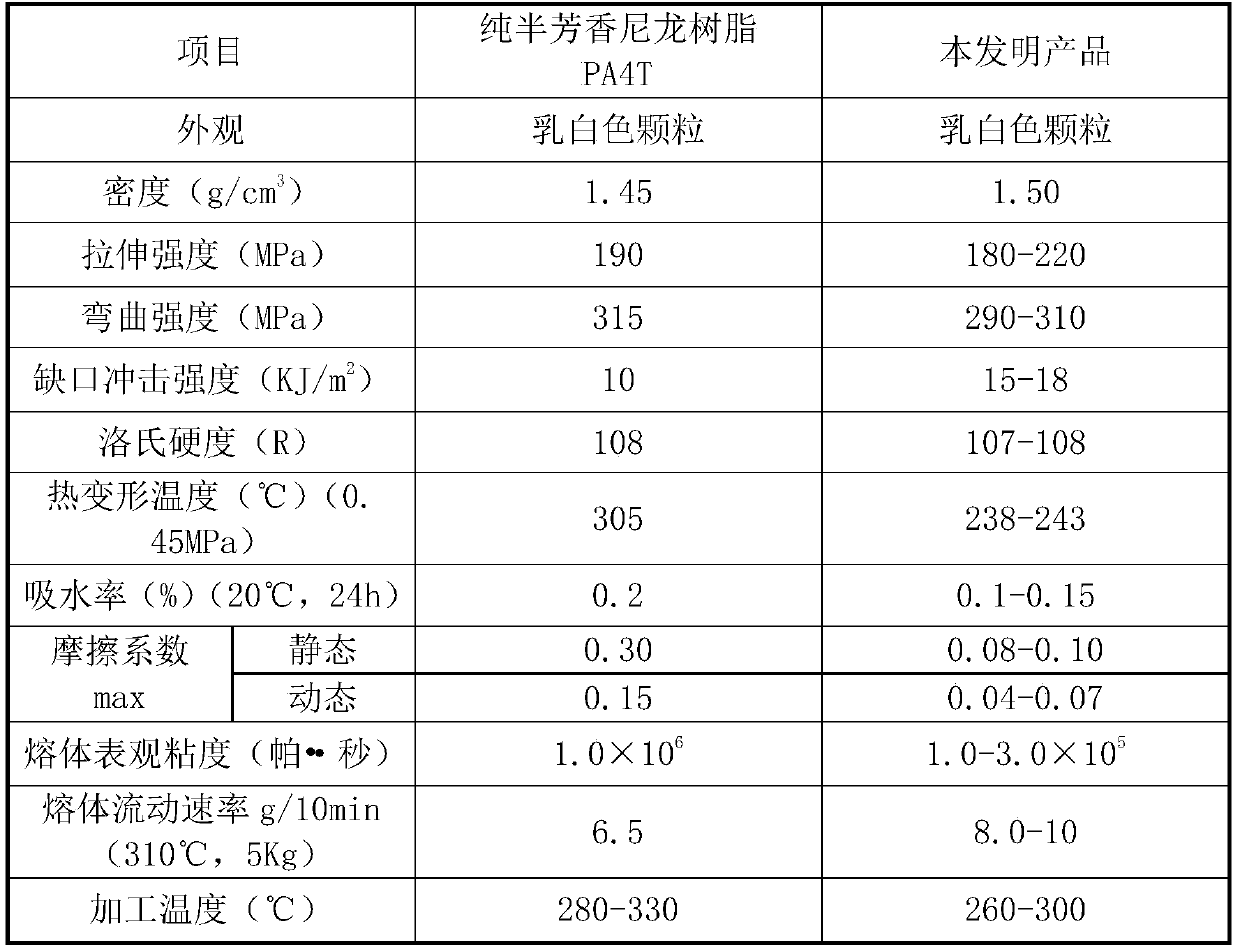

Semi-aromatic nylon modified composite material and preparation method thereof

PendingCN111440438AReduce intermolecular forcesReduce cohesive energyComposite materialMelt viscosity

The invention discloses a semi-aromatic nylon modified composite material. The raw material composition comprises the following components by weight: 80-100 parts of semi-aromatic nylon resin, 15-25 parts of silane modified calcium sulfate whiskers, 2-3 parts of lithium halide and 4.6-8 parts of an auxiliary agent. The preparation method comprises the following steps: mixing the dried semi-aromatic nylon resin, the silane modified calcium sulfate whiskers, the lithium halide and the auxiliary agent according to a required ratio, and then discharging the mixture into a parallel twin-screw extruder for melt blending, extrusion and granulation. According to the material, the melt viscosity and the extrusion process temperature are reduced, the comprehensive performance of the material is improved, and the cost is reduced.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com