An integrated anti-reflection enhancer for coal and gas mining, preparation method and application

A strengthening agent and gas technology, applied in mining fluids, chemical instruments and methods, earthwork drilling and mining, etc., can solve the problems of small anti-permeability range, small coal seam porosity, poor coal wettability, etc., to reduce the gas-liquid surface Effects of tension, reduction of mineral content, and increase in calorific value

Active Publication Date: 2022-05-31

SHANDONG UNIV OF SCI & TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] (1) Underground coal seam occurrence and mining conditions are complex, with low coal seam permeability, poor wettability, large mining pollution and low efficiency

[0006] (2) Due to the limitations of these inherent properties, there are low coal seam water injection rates, poor coal wetting performance and large pollution during mining and use.

[0008] In recent years, the mining depth of my country's coal mines has continued to increase, and the level of mechanized and automated mining has gradually increased. 92% of my country's coal production is underground mining, and the average depth has reached 660m. The existing and mining conditions are complex, and there are problems such as small coal seam porosity, low permeability, and poor water injection efficiency. During the production process of coal mines, coal and gas outbursts, roof accidents, and pneumoconiosis and other natural disasters are constantly escalating, resulting in a large number of losses in manpower and material resources.

At present, all kinds of coal mines in my country have more or less adopted some measures to improve the coal body structure and improve high-efficiency and safety production efficiency, such as hydraulic fracturing, hydraulic slotting, pre-splitting blasting, thermal displacement and other anti-reflection technologies; but from In terms of application effect, the effect is not very ideal, such as hydraulic fracturing (there are problems such as small anti-permeability range, fast crack closure, water lock effect, etc.), split water seam blasting (consumption of a lot of manpower and material resources, and the existence of danger) ; Coal seam water injection (low water injection efficiency, poor coal mine application benefits, etc.), heat injection method to coal seam (water or steam heat injection method not only has low efficiency, high energy consumption, but also aggravates the water lock effect), therefore, it is urgent to explore A new type of integrated anti-reflection enhancer and preparation method for coal and gas mining to achieve efficient coal and gas extraction and efficient use of existing resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

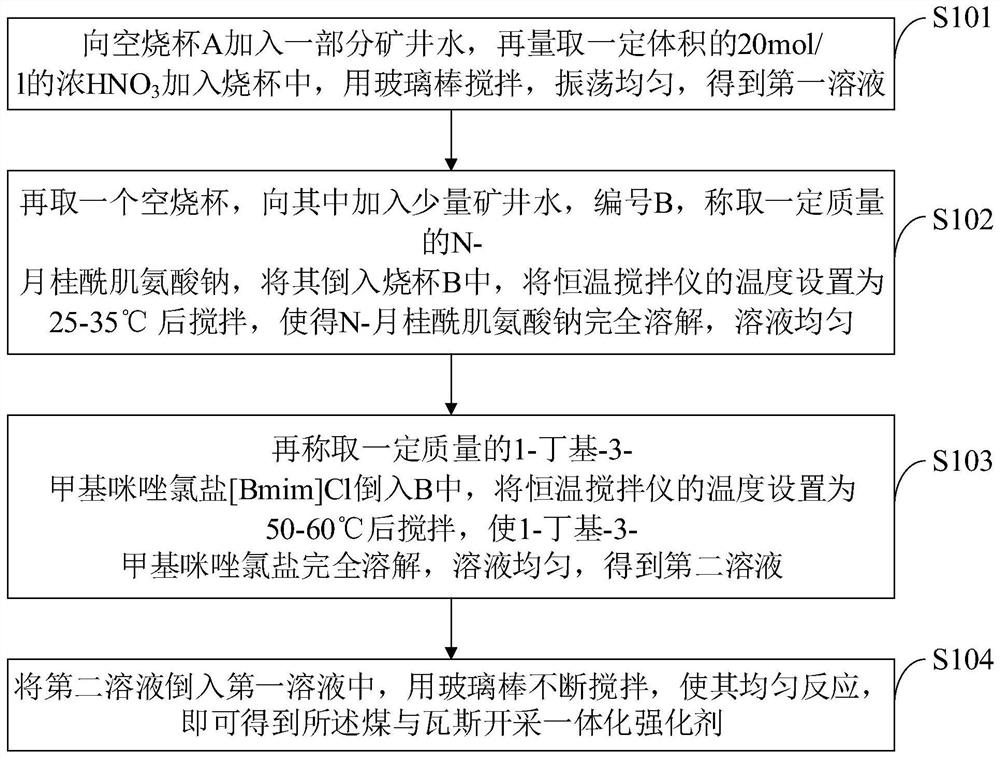

preparation example Construction

[0051] The compound temperature value in step S103 provided in the embodiment of the present invention is 50-60 °C.

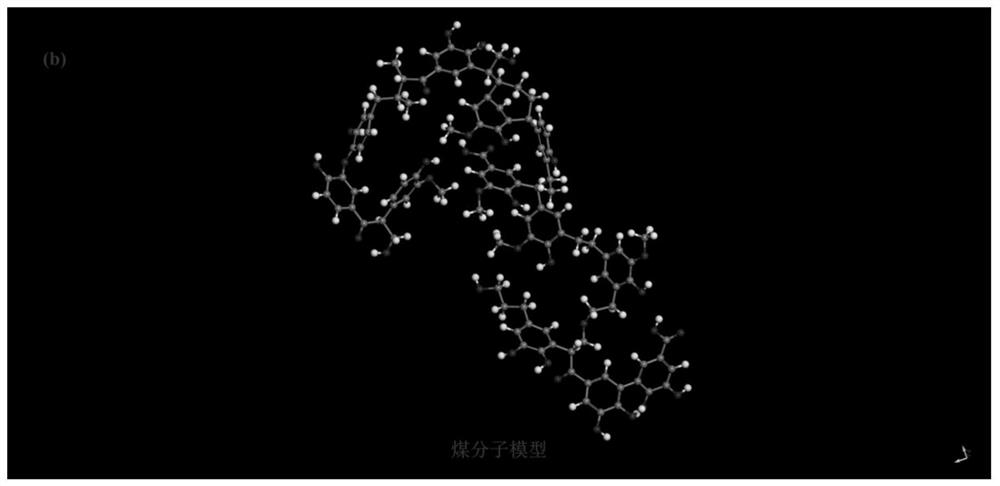

[0053] The molecular dynamics simulation verification effect schematic diagram provided in the embodiment of the present invention is shown in Figure 4.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Login to View More

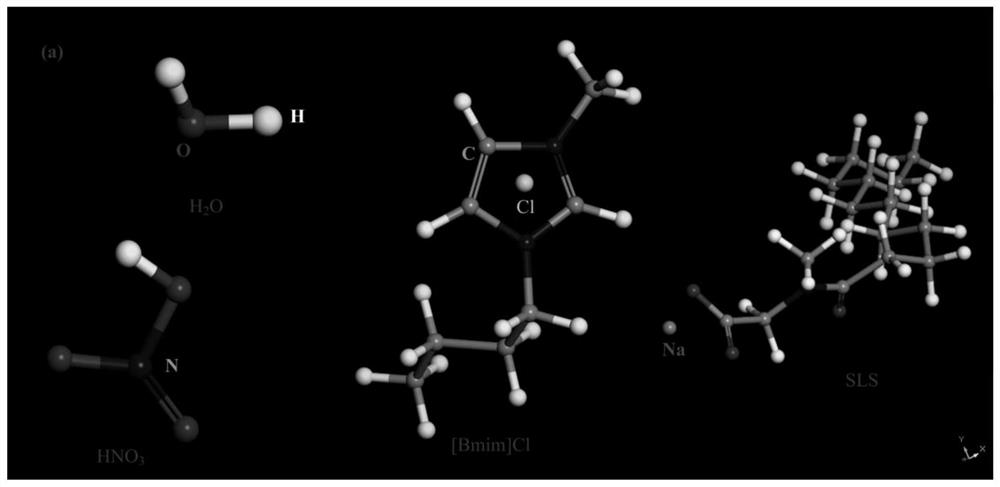

Abstract

The invention belongs to the technical field of high-efficiency and safe production in mines, and discloses an integrated anti-reflection enhancer for coal and gas mining, a preparation method and an application thereof. According to mass percentage, it consists of 6%-10% of 20mol / l concentrated nitric acid, 1 %-5% sodium N-lauroyl creatine, 2%-6% 1-butyl-3-methylimidazolium chloride and mine dust control water. The physical and chemical modification of the coal body by the coal and gas mining integrated enhancer provided by the invention can increase the wettability of the coal body, suppress and reduce the generation of dust in the coal seam mining process, greatly improve the permeability of the coal body, and improve the coal seam Occurrence and mining conditions are conducive to the efficient development and utilization of coalbed methane, improving coalbed methane mining to alleviate energy shortages, preventing gas disasters in underground coal mines, and reducing greenhouse gas emissions. Safe and efficient production level.

Description

A kind of coal and gas mining integrated permeability enhancement enhancer, preparation method and application technical field The invention belongs to mine efficient and safe production technical field, relate in particular to a kind of coal and gas mining integration anti-permeability Strengthening agent, preparation method and application. Background technique At present, coal is China's strategic resource, and the proportions in my country's primary energy production and consumption structure are respectively 65% and 60.3%. 92% of coal production in my country is underground mining, and the average depth has reached 660m. And the mining conditions are complex, and there are problems such as low coal seam permeability, poor wettability, large mining pollution and low efficiency. due to these Due to the limitation of its own nature, it has low coal seam water injection rate, poor coal wettability and pollution in the process of mining and use. The problem of dy...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/60C09K8/74E21B43/26

CPCC09K8/602C09K8/74E21B43/26E21B43/006Y02P90/70

Inventor 周刚李帅龙王凯丽杨阳王勇梅段晋杰贺敏姜文静王存民

Owner SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com