Patents

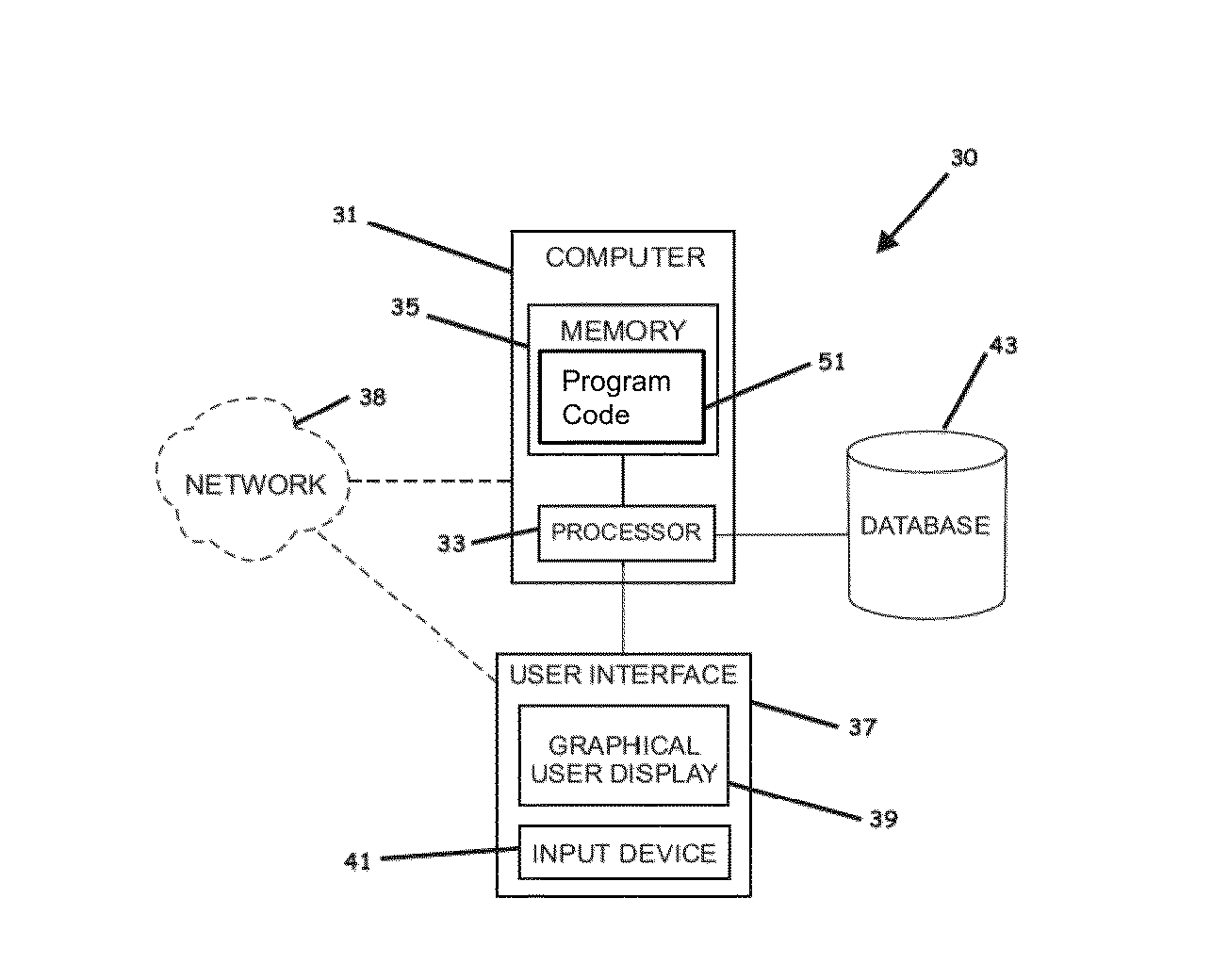

Literature

397 results about "Greenhouse gas reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Greenhouse Gas (GHG) Reduction As outlined in Executive Order (EO) 13693, Planning for Federal Sustainability in the Next Decade, the goal of reducing greenhouse gas emissions is to minimize the contributions to the greenhouse effect which contributes to global warming and subsequent adverse environmental and human health.

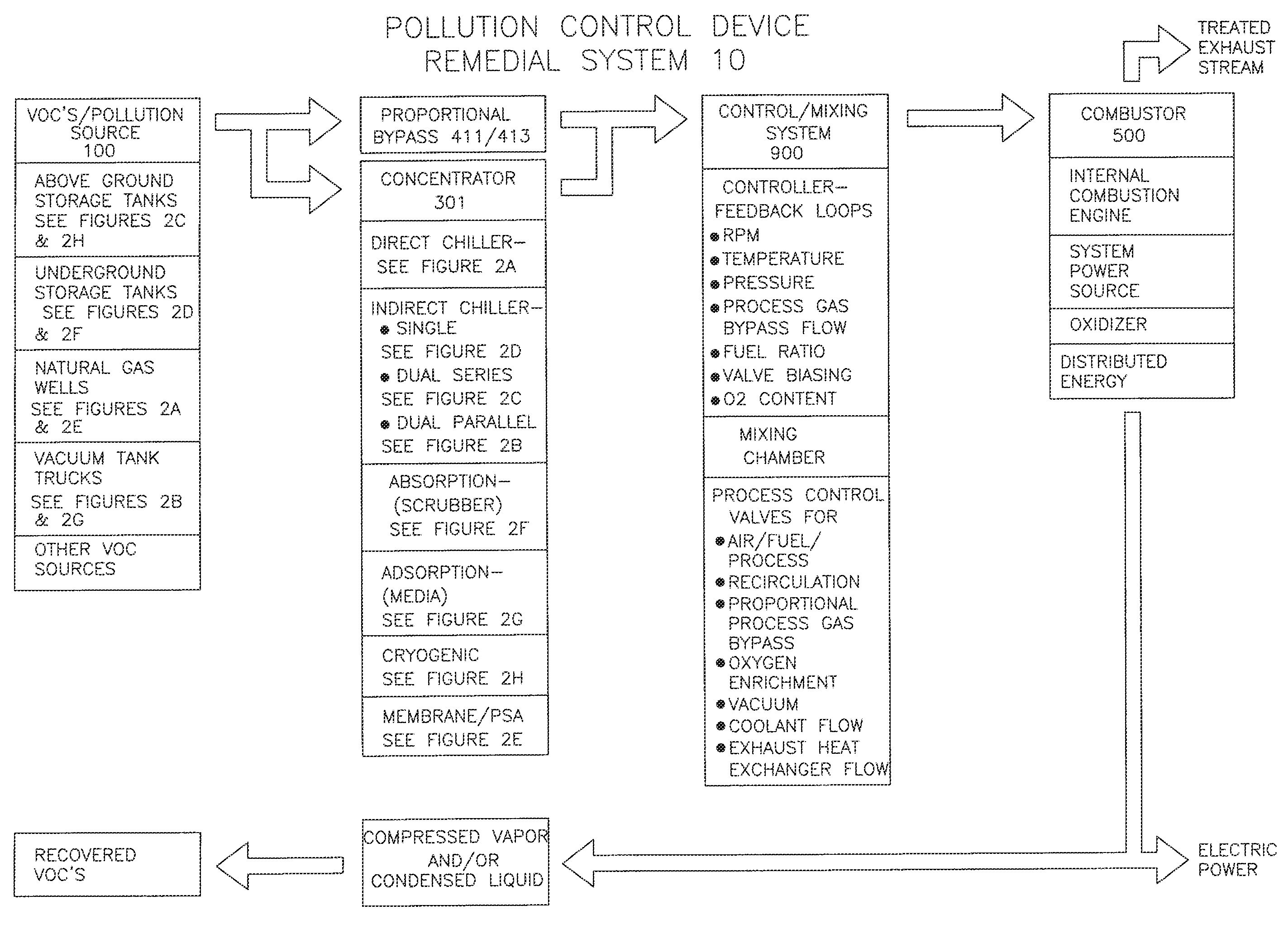

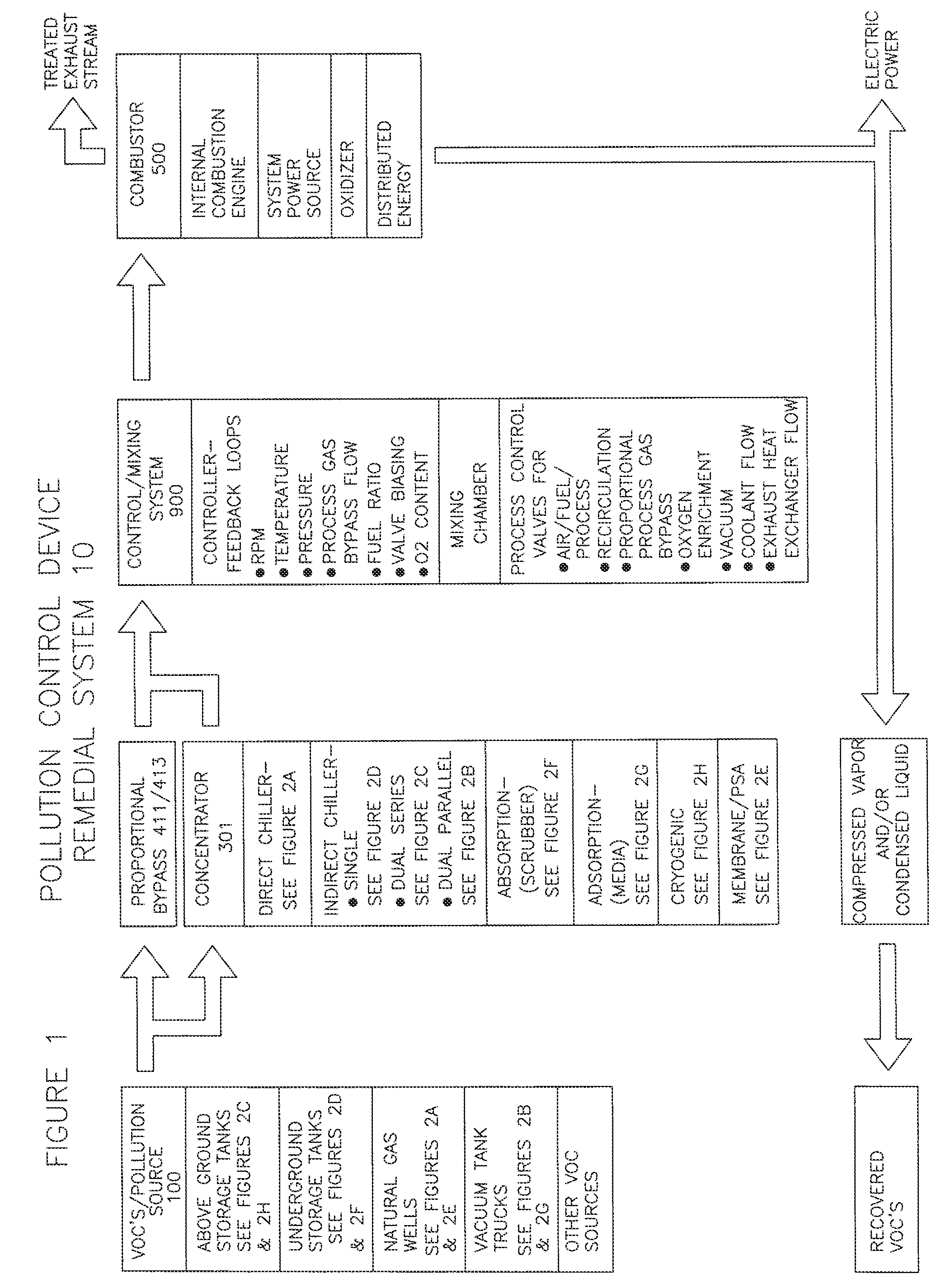

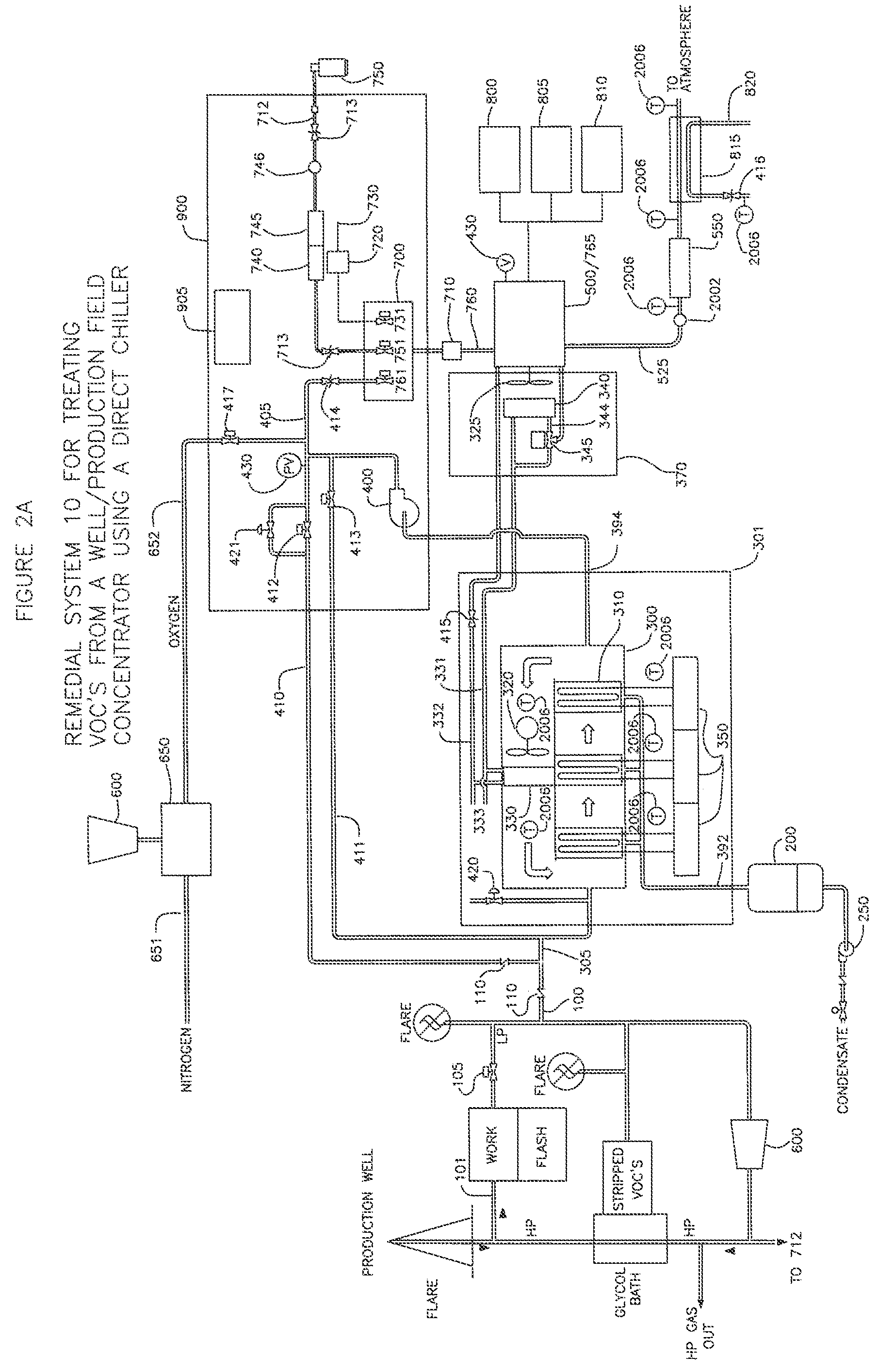

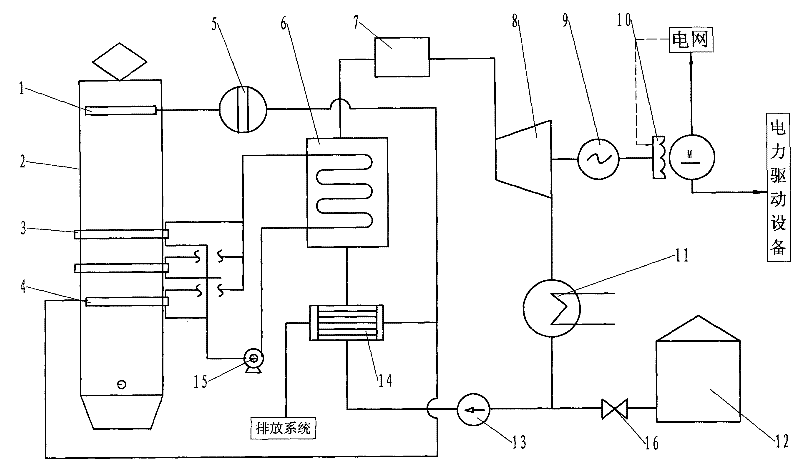

Remedial system: a pollution control device for utilizing and abating volatile organic compounds

ActiveUS8776734B1Easy to useTreatment safetyGas treatmentNon-fuel substance addition to fuelHybrid systemControl system

A remedial pollution control system for treating volatile organic compounds that may include a vapor concentrator connected to a line that is laden with volatile organic compounds, the concentrator has an organic condensate output line and a vapor output line; a mixing chamber adapted to receive air provided from an air supply line, combustible fuel from an alternate fuel supply line, and a vapor stream from the vapor output line to produce a mixed fuel supplied to an internal combustion engine, a control mixing system with a controller for producing a proper air to fuel ratio in the mixed fuel supply, and power generated to operate other devices used to more efficiently abate volatile organic compounds and reduce greenhouse gas emissions.

Owner:INNOVATIVE ENVIRONMENTAL SOLUTIONS LLC DBA REMEDIATION SERVICE INTL

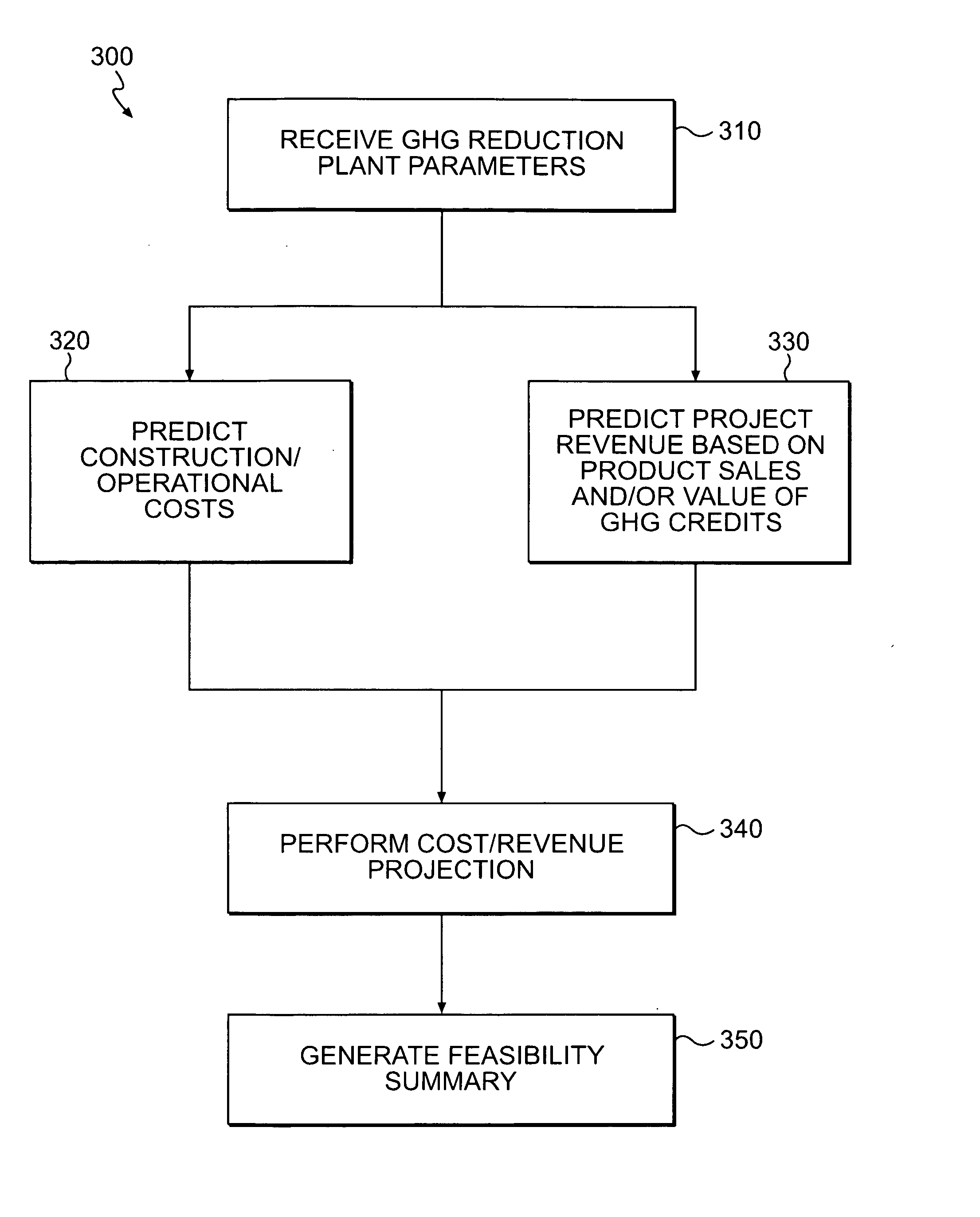

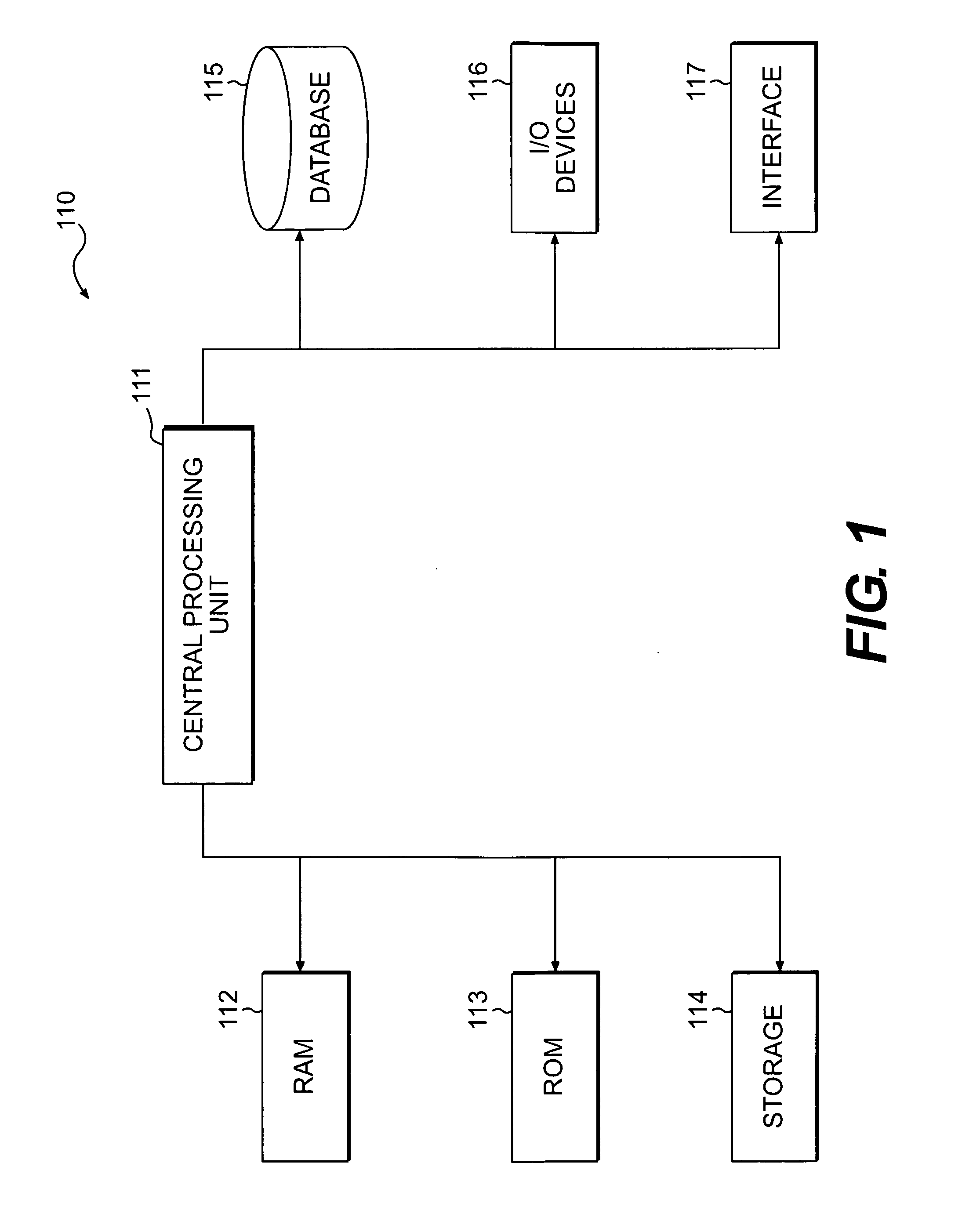

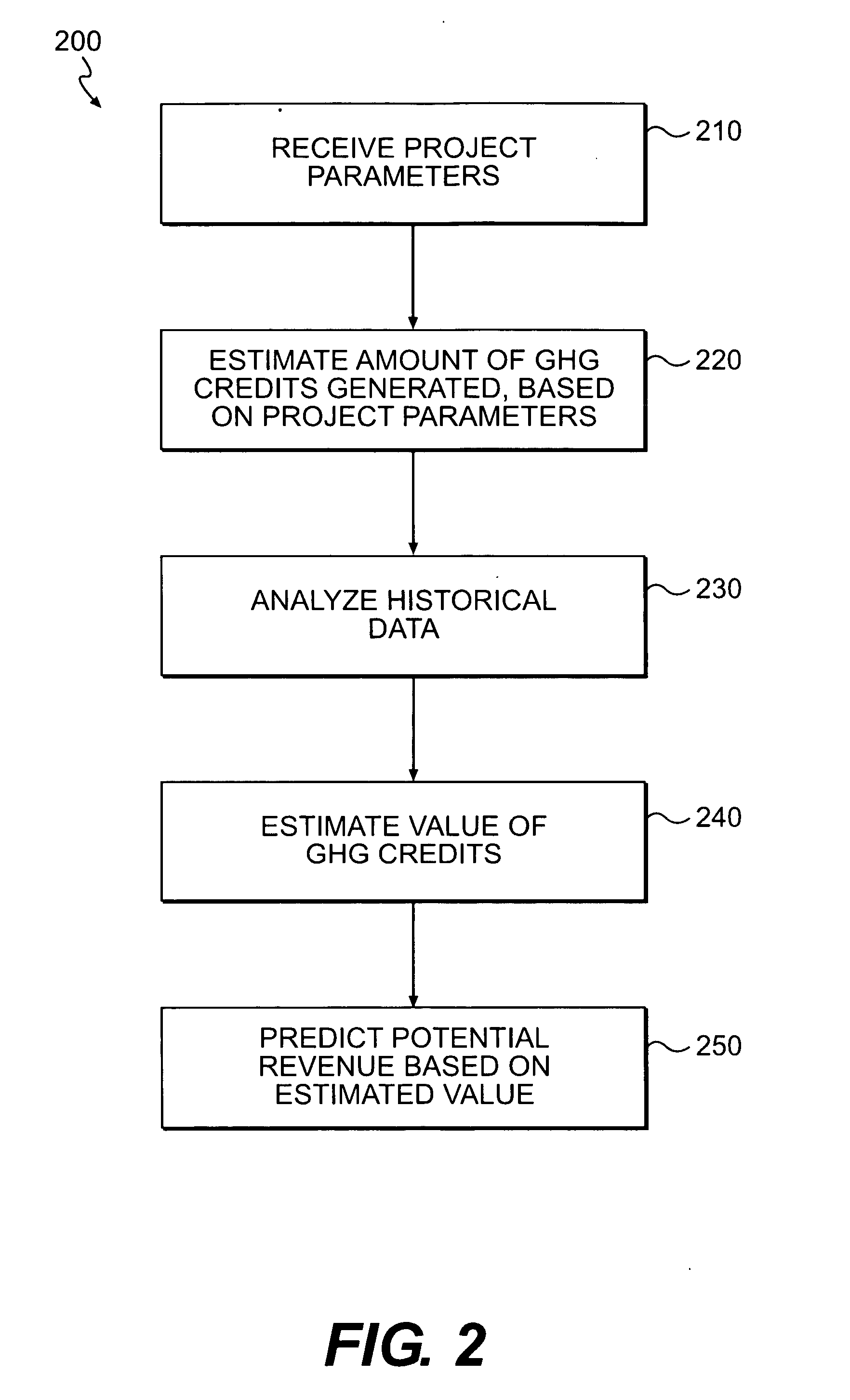

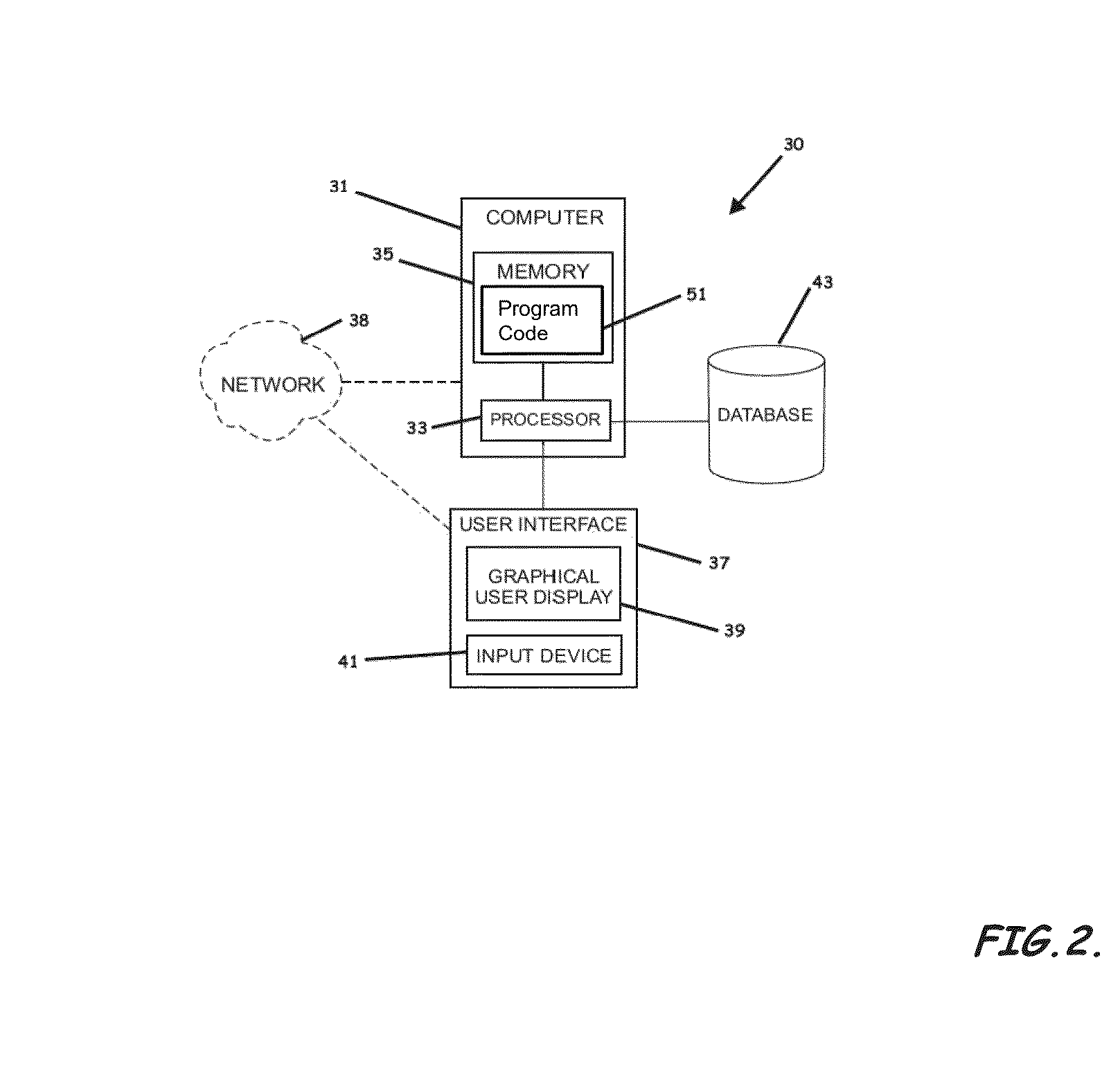

Method for determining a future value of greenhouse gas credits

InactiveUS20070203722A1Data processing applicationsTechnology managementEngineeringGreenhouse gas reduction

A method for evaluating a greenhouse gas reduction project is disclosed. The method includes receiving one or more parameters associated with a greenhouse gas reduction project. The method also includes determining an amount of greenhouse gas credits potentially generated during the lifecycle of a greenhouse gas reduction project. The method further includes analyzing historic data associated with a price history of greenhouse gas credits. The method also includes estimating a future value of the greenhouse gas credits based on the analysis trends and inputs. The method further includes predicting a potential revenue generated from a greenhouse gas reduction project based on the future value of the generated greenhouse gas credits.

Owner:CATERPILLAR INC

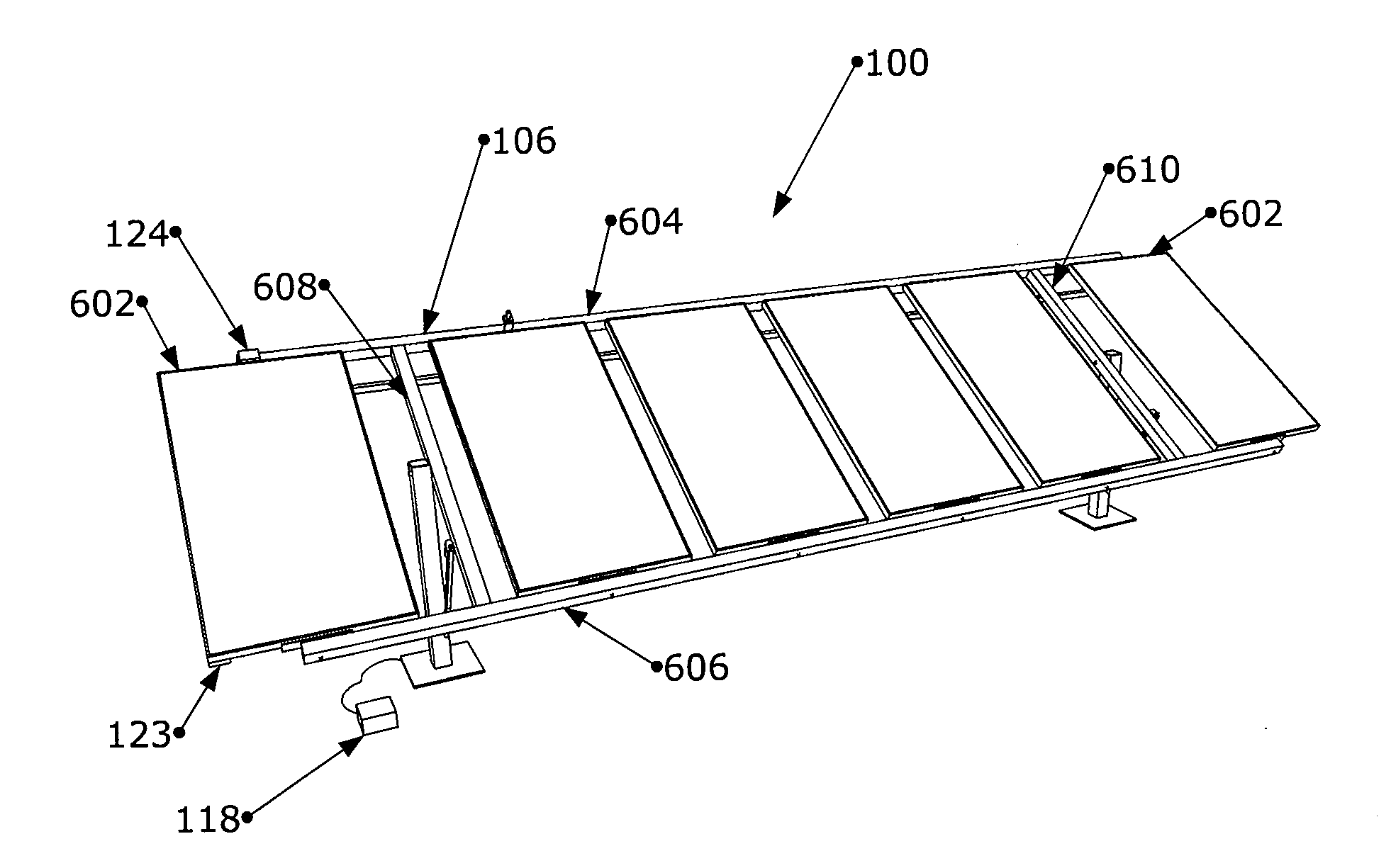

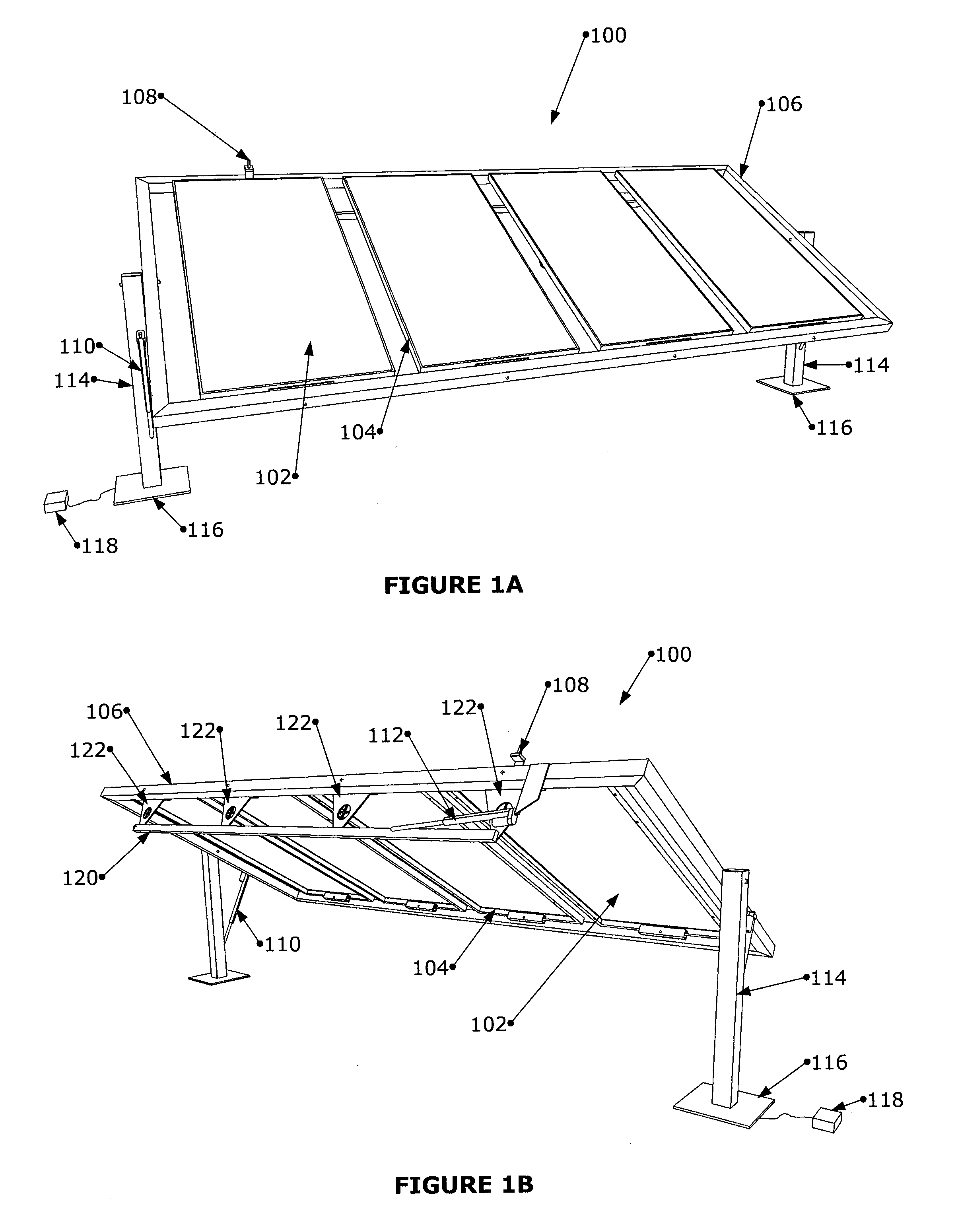

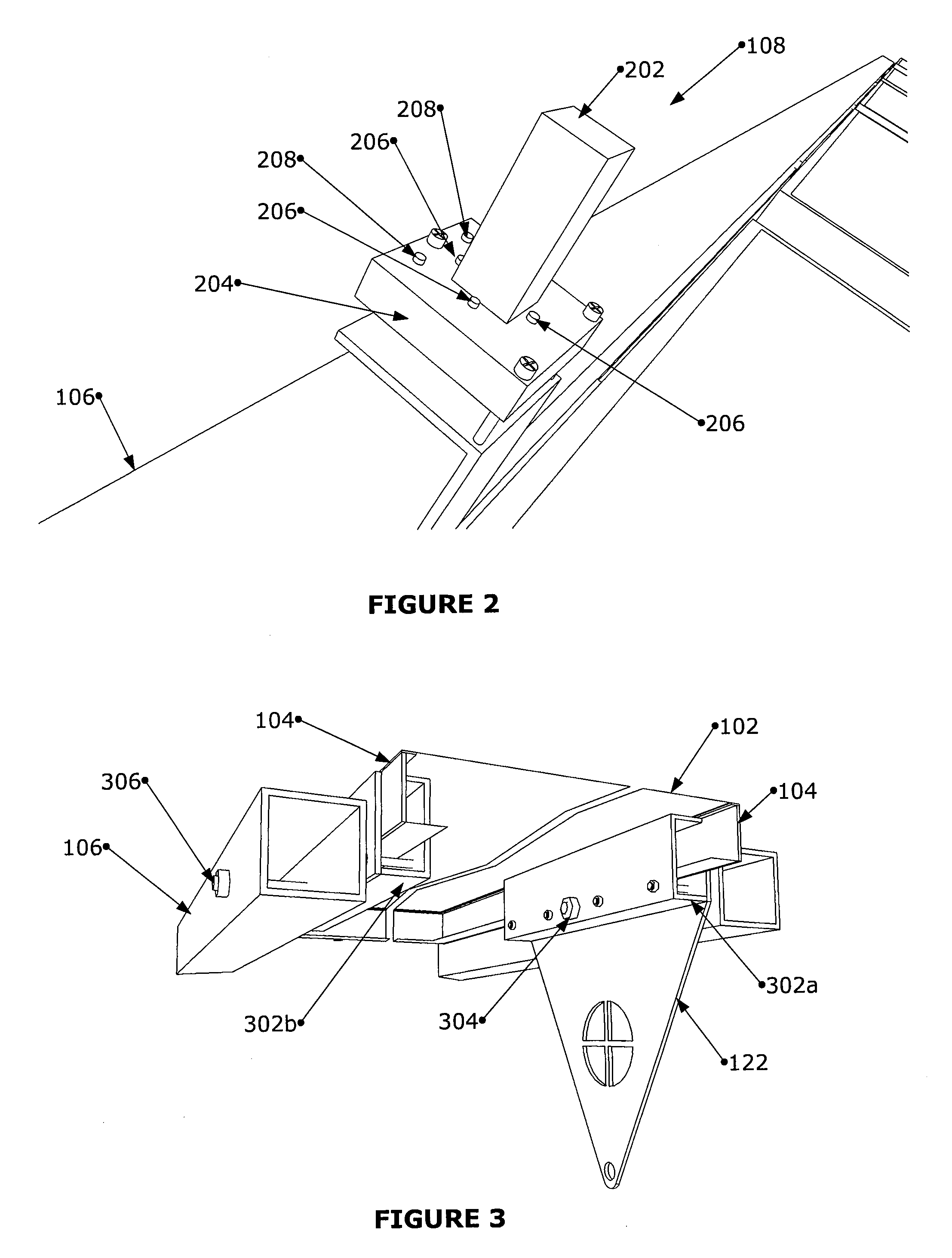

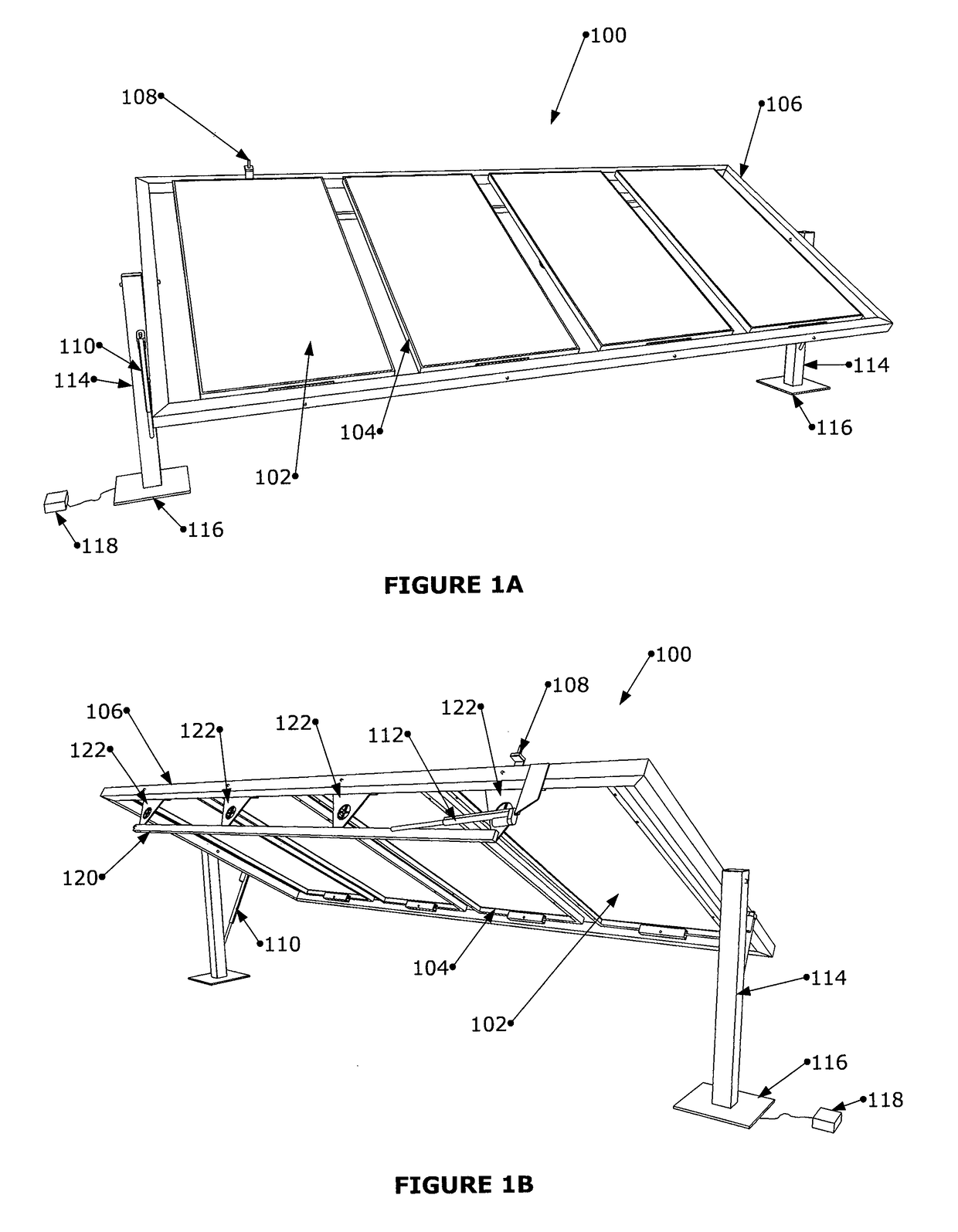

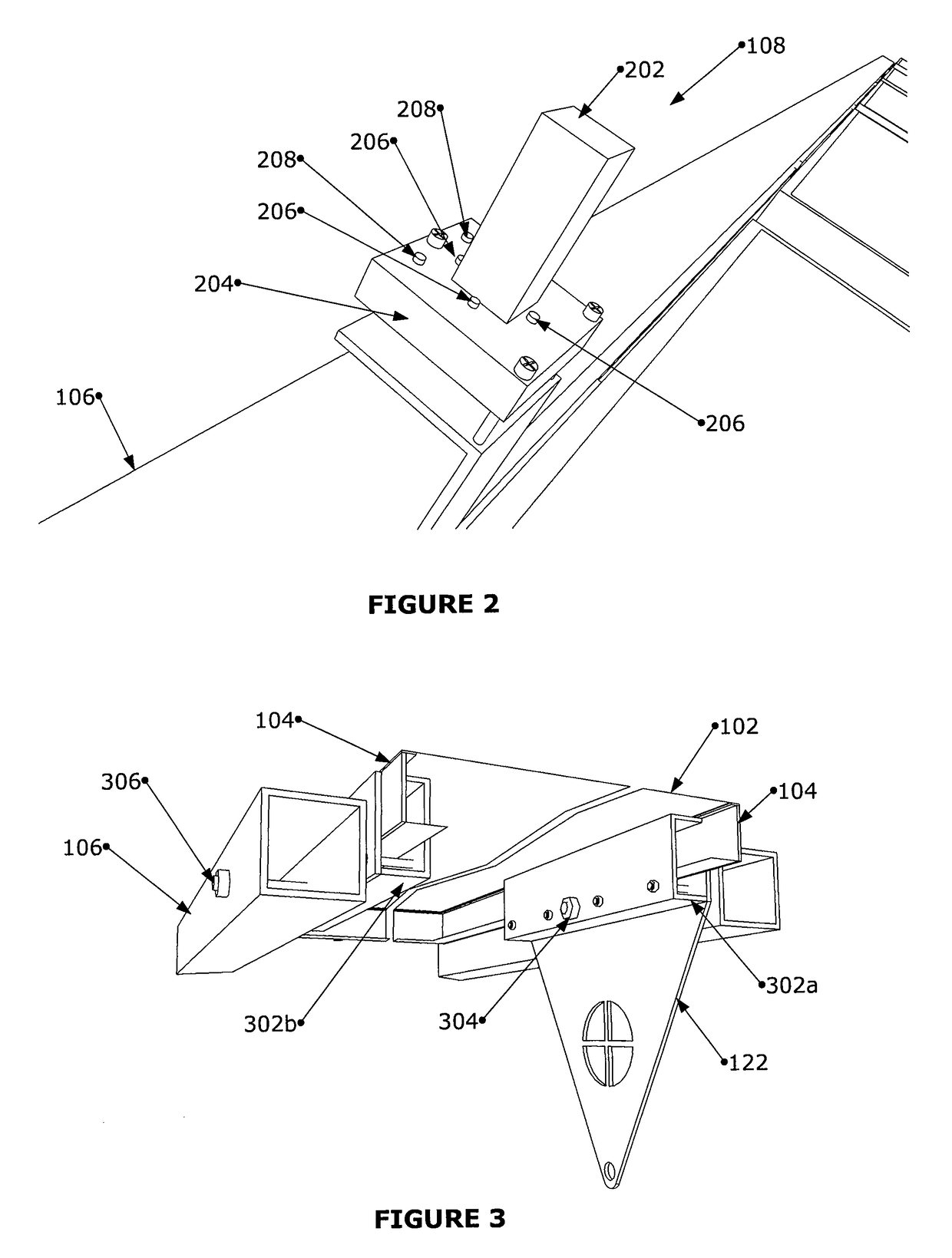

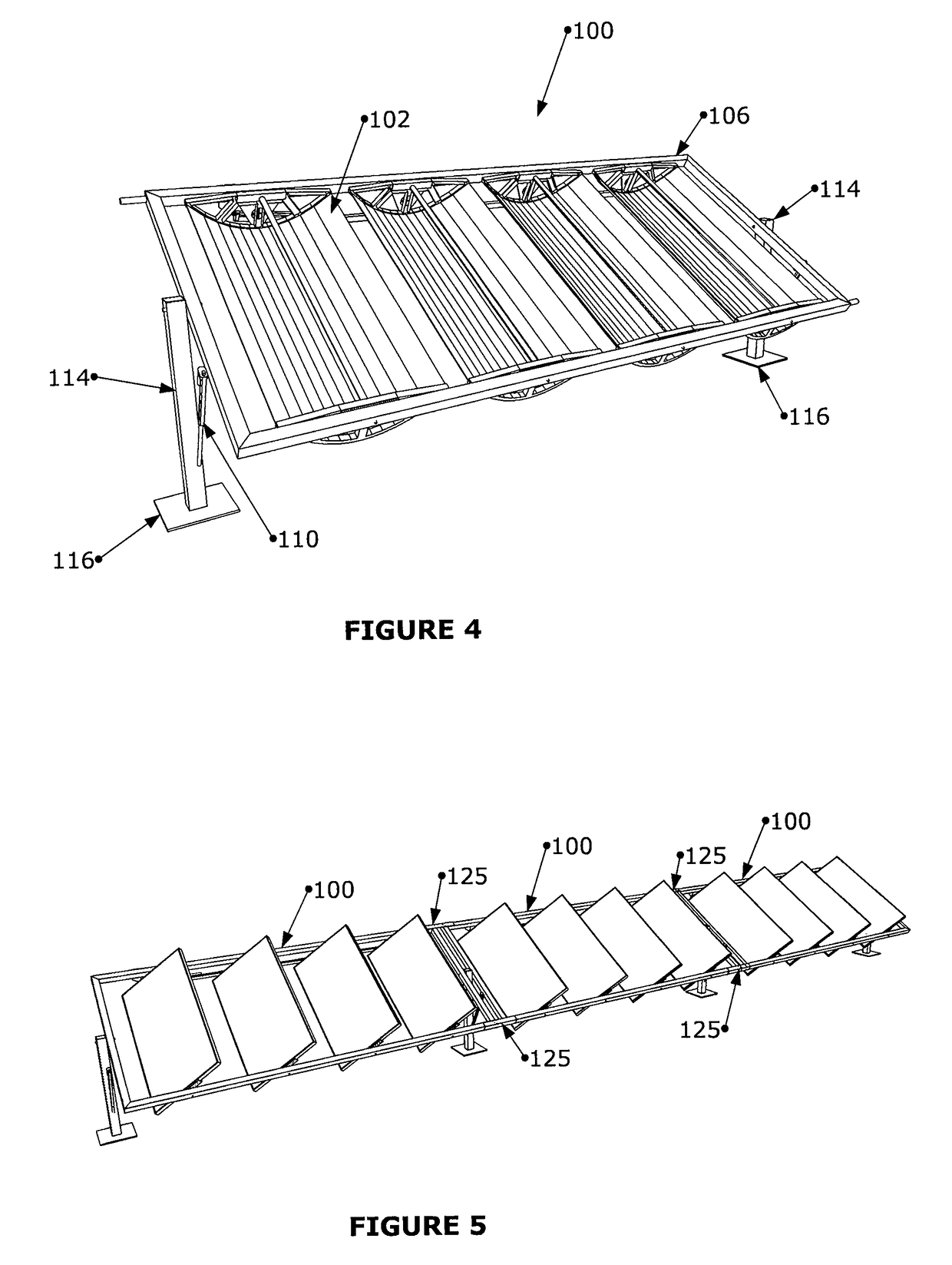

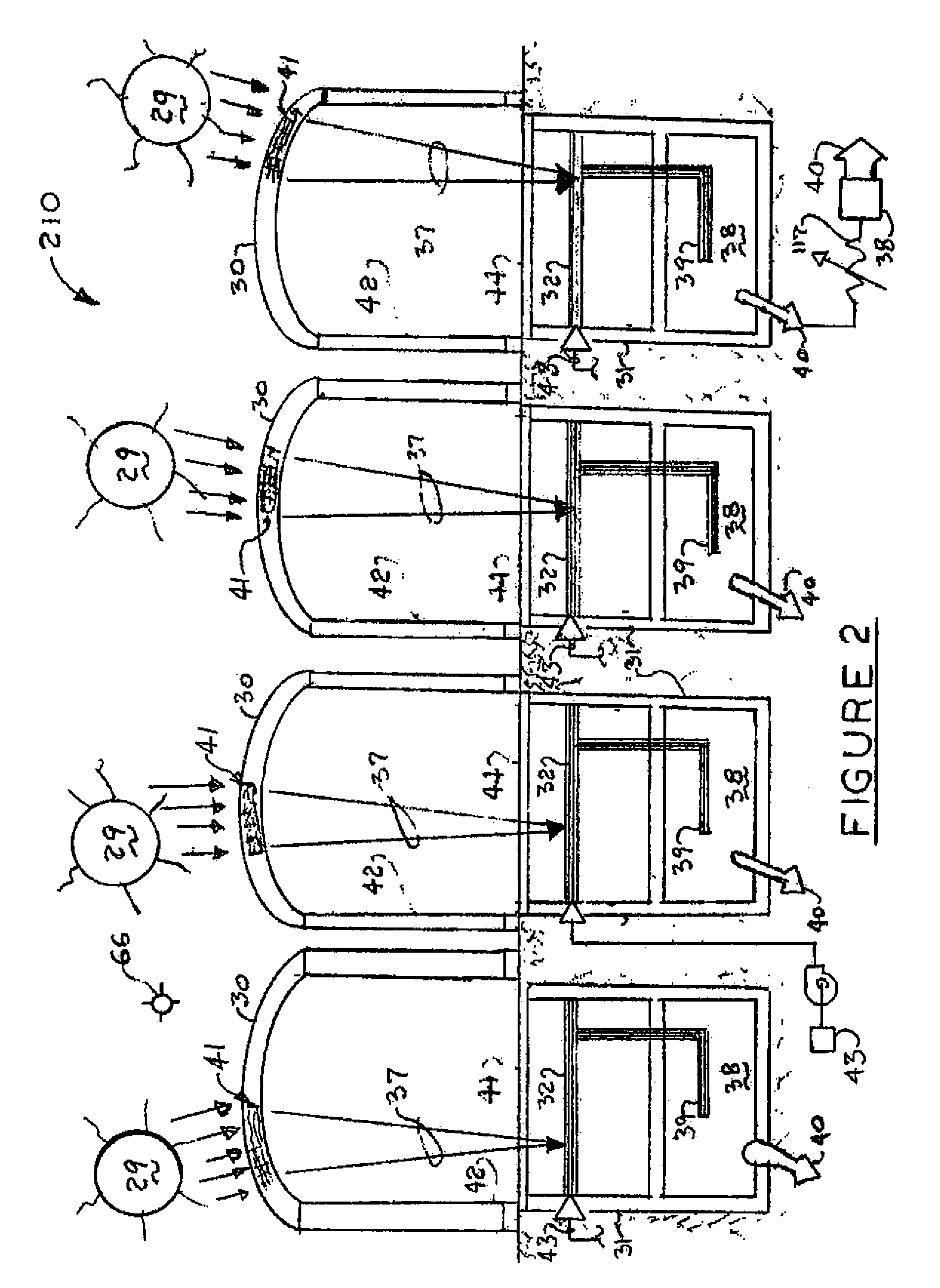

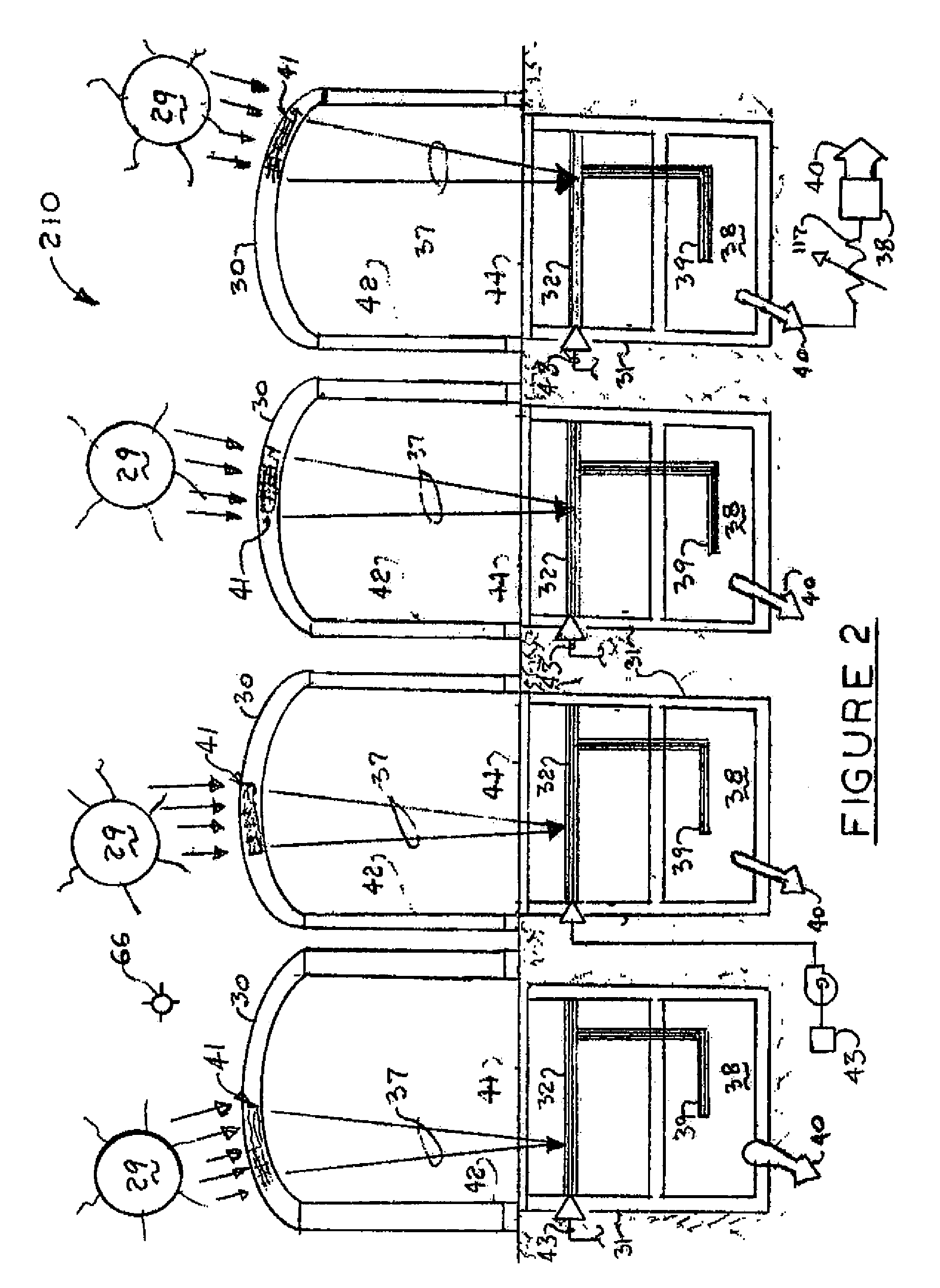

High efficiency counterbalanced dual axis solar tracking array frame system

ActiveUS20110073161A1Minimizes wind loadingReduce windOptical radiation measurementSolar heating energyPhotovoltaic solar energyShadowings

A high efficiency, environmentally friendly system comprising a plurality of photovoltaic solar collecting panels (PV panels) is disclosed. The system comprises an outer frame to which a plurality of inner frames are mounted to which the plurality of PV panels are attached. To minimize shadowing by the outer frame upon one or more PV panels, at least one PV panel may extend beyond an endpoint of the main frame. The system also comprises an outer frame rotation actuator that rotates the outer frame and an inner frame rotation actuator that rotates the inner frames and the plurality of PV panels. The solar tracking array frames disclosed herein help to improve the quality of the environment by conserving a variety of energy resources (e.g., fossil fuels, hydroelectric energy, etc.) The solar tracking array frames disclosed herein also help to reduce greenhouse gas emissions, as solar tracking array frames do not produce carbon dioxide byproducts.

Owner:SCANLON MARK +1

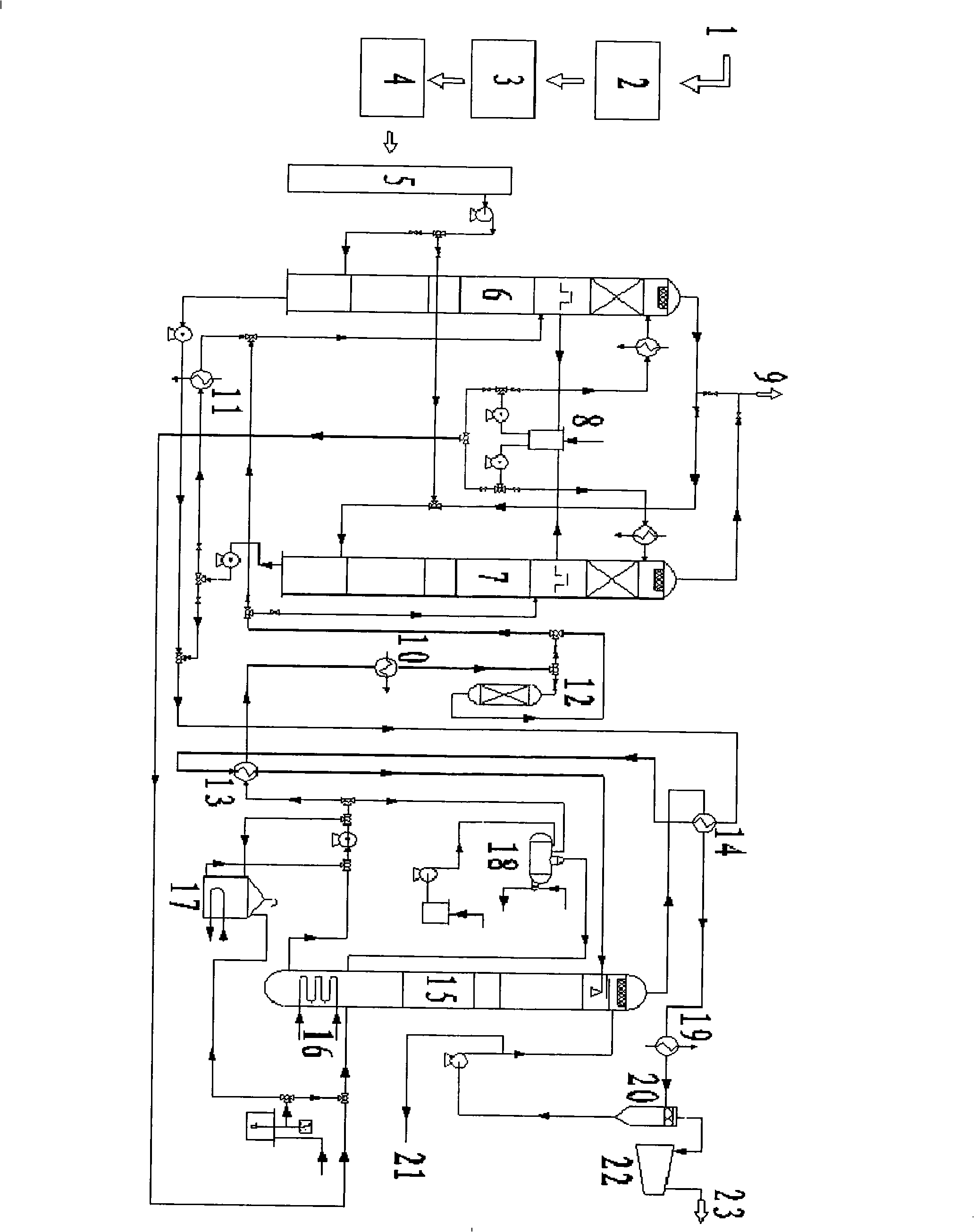

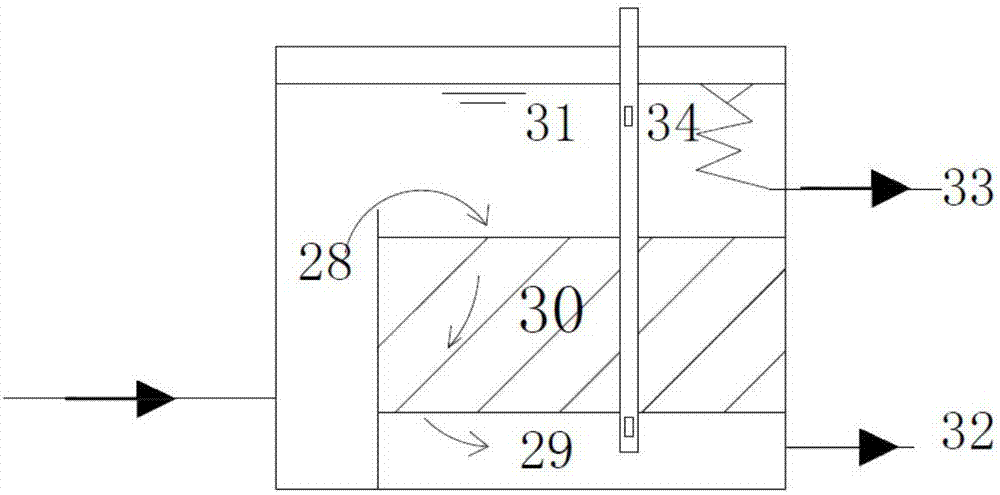

Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

The invention provides a method and a device for collecting carbon dioxide in smoke gas of a coal-fired power plant. The device consists of a smoke gas pretreatment system, absorption towers, a regeneration tower, an exhaust scrubbing system, a solution heating recoverer, a product gas processing system (comprising a condenser, a gas-liquid separator and a compressor). The device is integrated with the prior smoke gas purification device of the coal-fired power plant, and is provided with a high-efficiency whirlcone and a chemical absorption system, so that mass carbon dioxide gas exhausted from a coal-fired boiler can be collected, and the emission of greenhouse gas can be reduced; the special arrangement of double absorption towers ensures more flexible operation of a collecting system, and improves the operational reliability; an absorption solution reclaiming process reduces the consumption of the solution; the arrangement of a lean-rich solution heat exchanger and a product gas rich solution heat exchanger reduces the energy consumption of the collecting system; and the steam consumption can be effectively reduced by adopting a built-in solution boiling unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

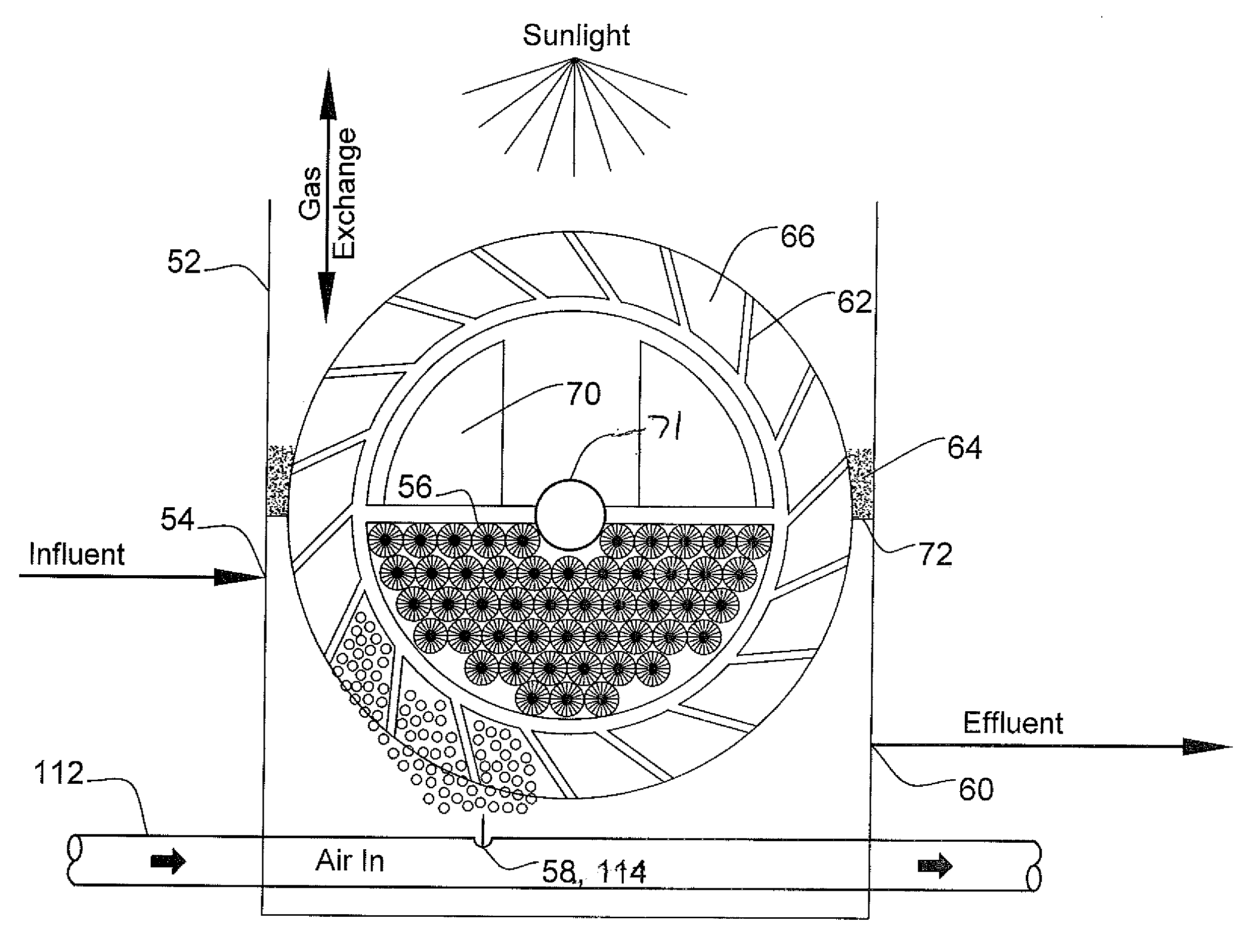

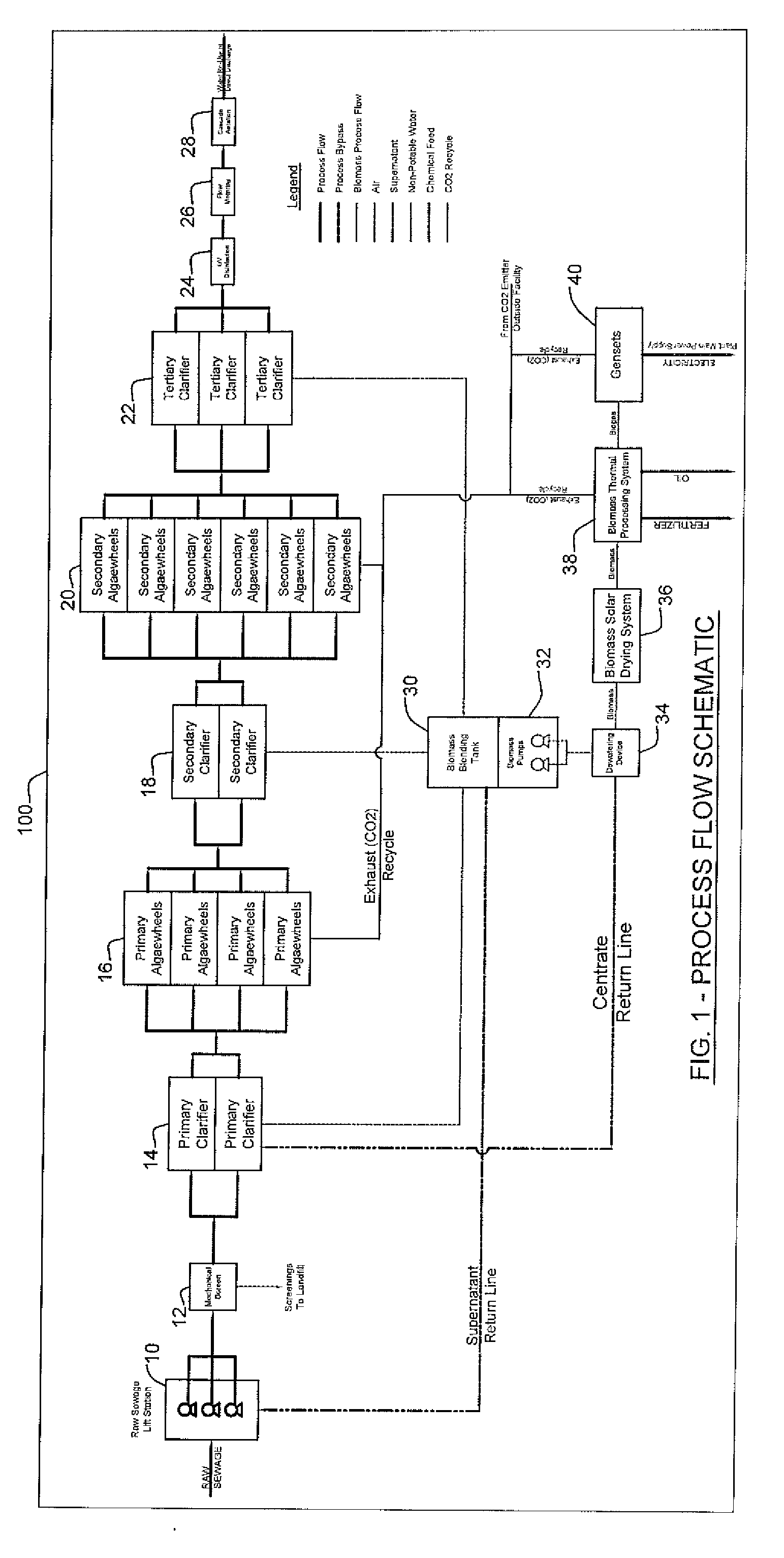

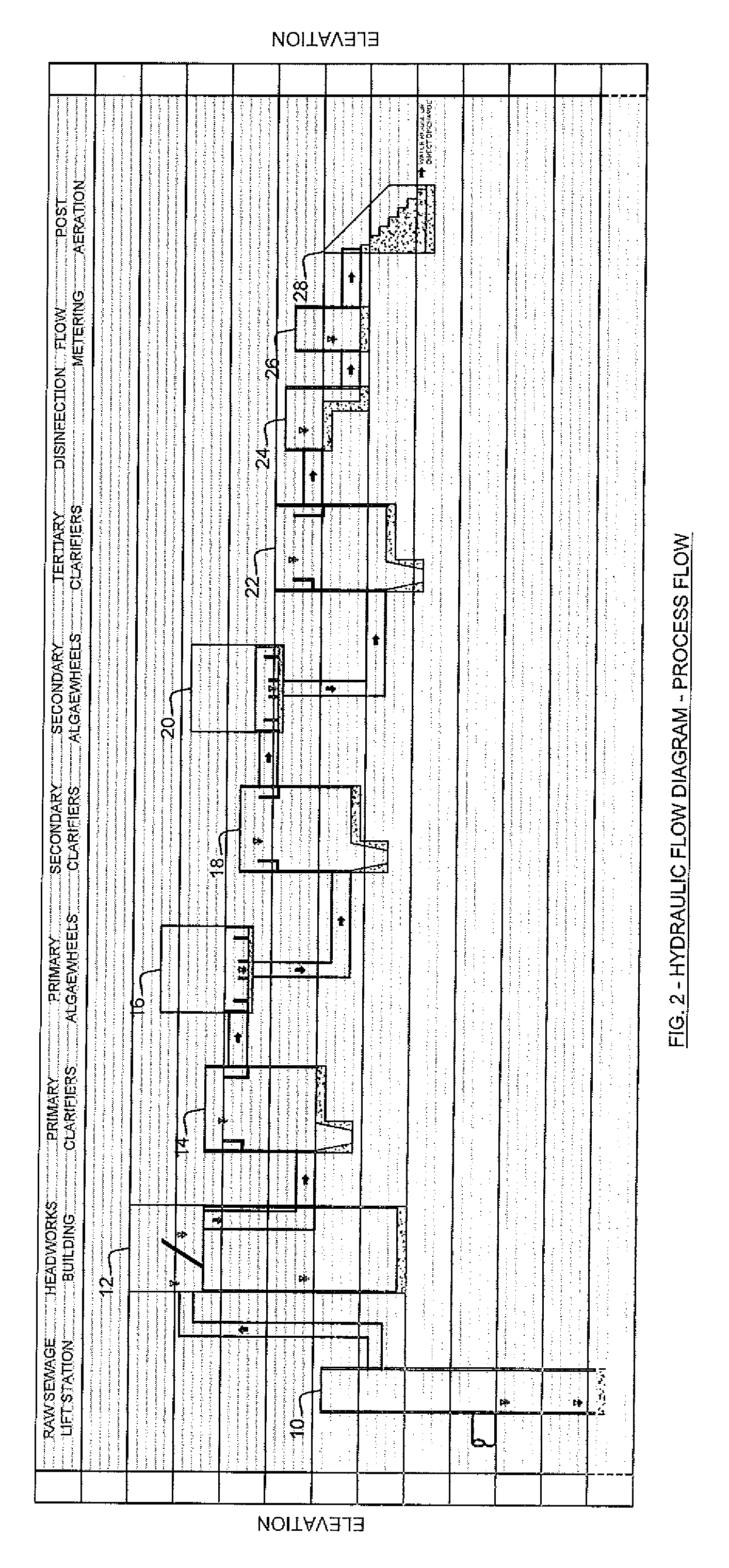

Apparatus and Process for Biological Wastewater Treatment

ActiveUS20090230040A1Bio-organic fraction processingTreatment using aerobic processesSustained growthBiofuel

A self-sustaining wastewater treatment facility abates greenhouse gas abatement, captures CO2 and produces biomass to address multiple critical environmental needs. The facility includes an array of rotating media wheels that create an optimum ordered mixing of algae for sustained growth. Biomass harvested from the rotating media wheels may be provided to other processing facilities to produce, for instance, bio-fuels. Waste CO2 from the processing facility may also be returned to the treatment system for enhanced algae growth. Bacteria are provided to form a symbiotic relationship with the algae, fueled by sunlight to effectively remove toxic materials from the wastewater. The multi-functional facility may also be integrated into a regenerative facility in which the biomass obtained from the algal and bacterial colonies is used in a separate facility and byproducts of the operation of the separate facility are used by the multi-functional facility to fuel further algal growth.

Owner:LIMCACO CHRISTOPHER A

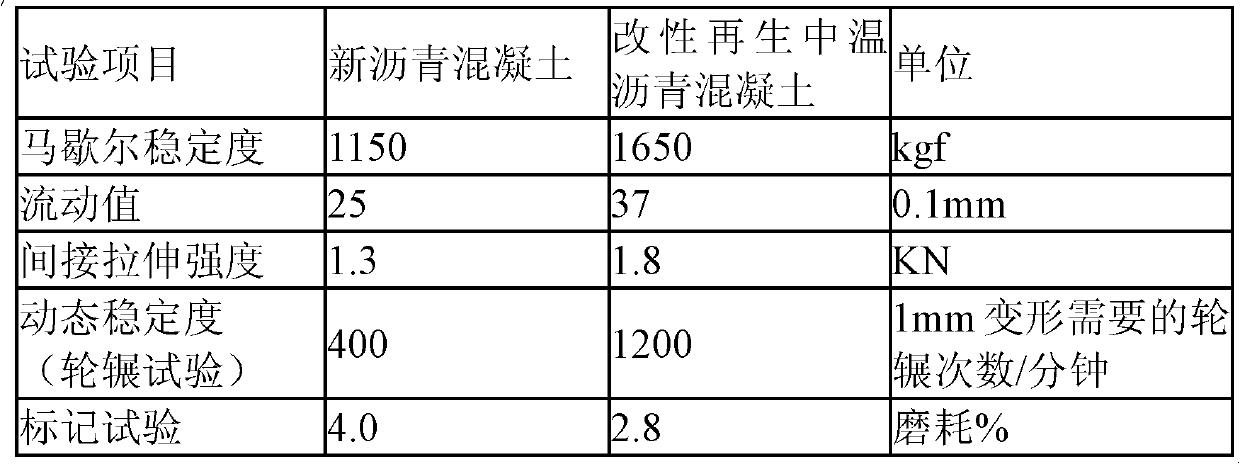

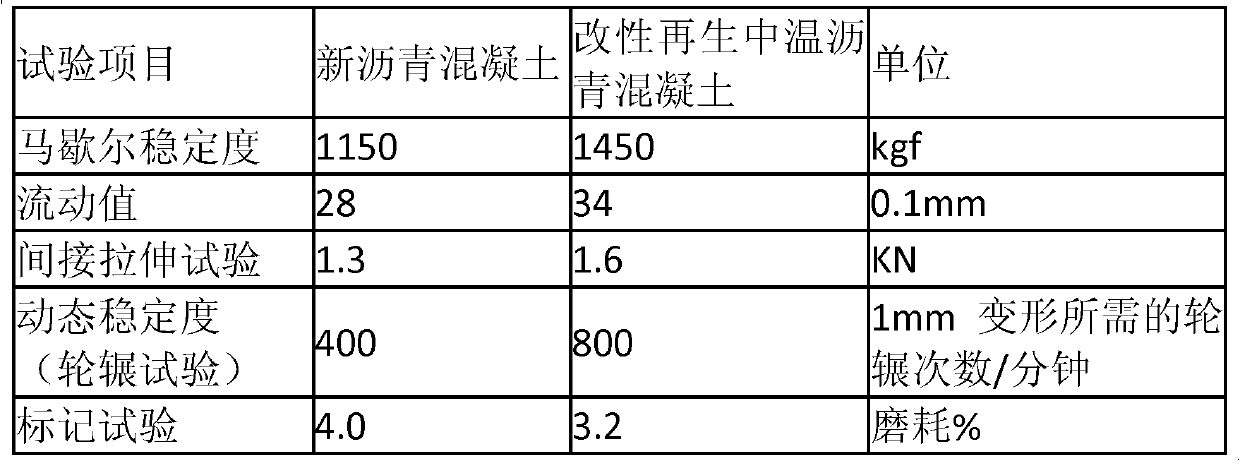

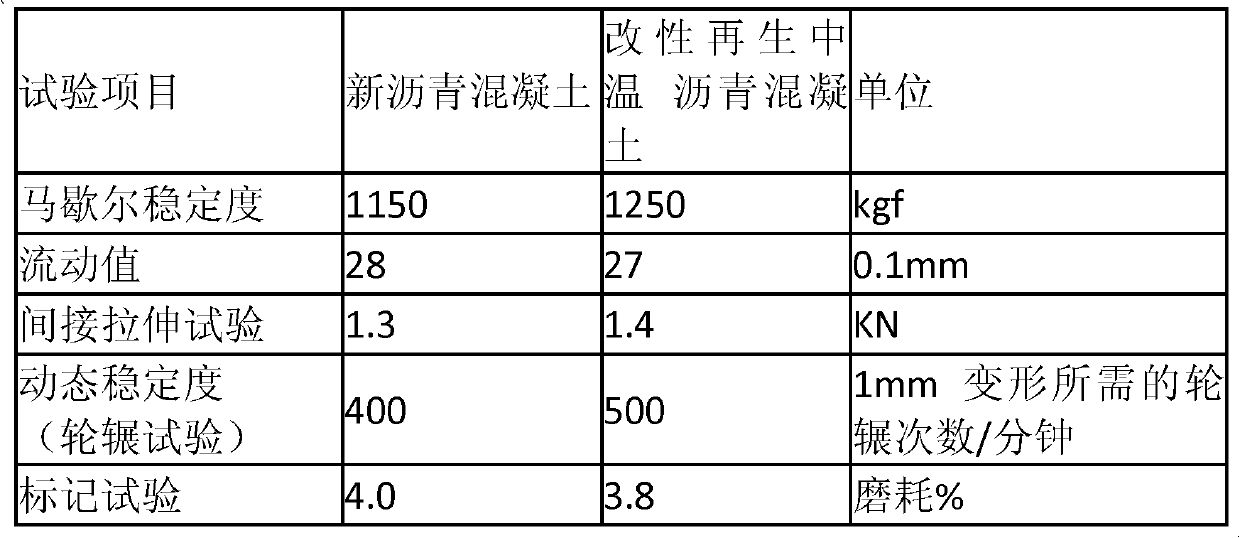

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

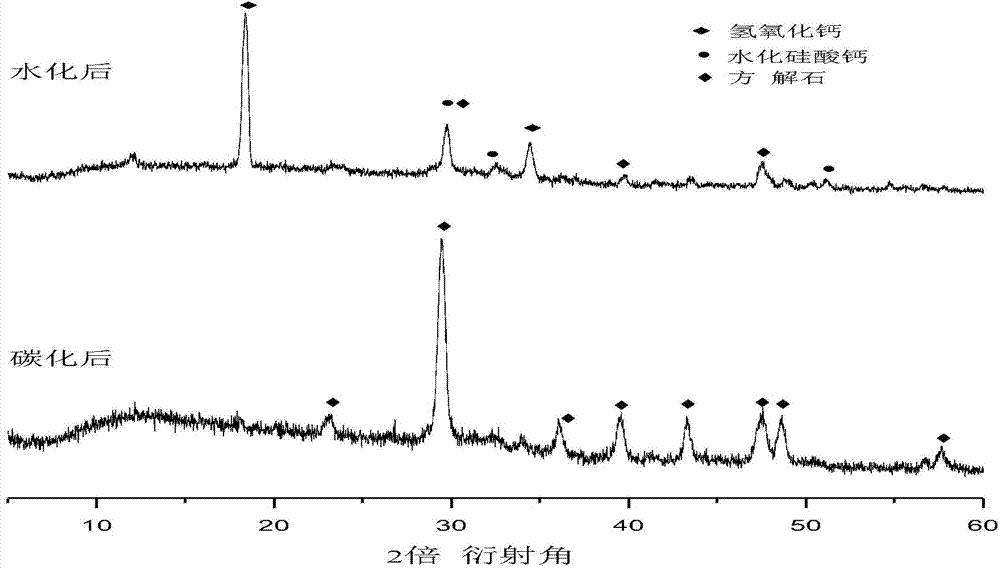

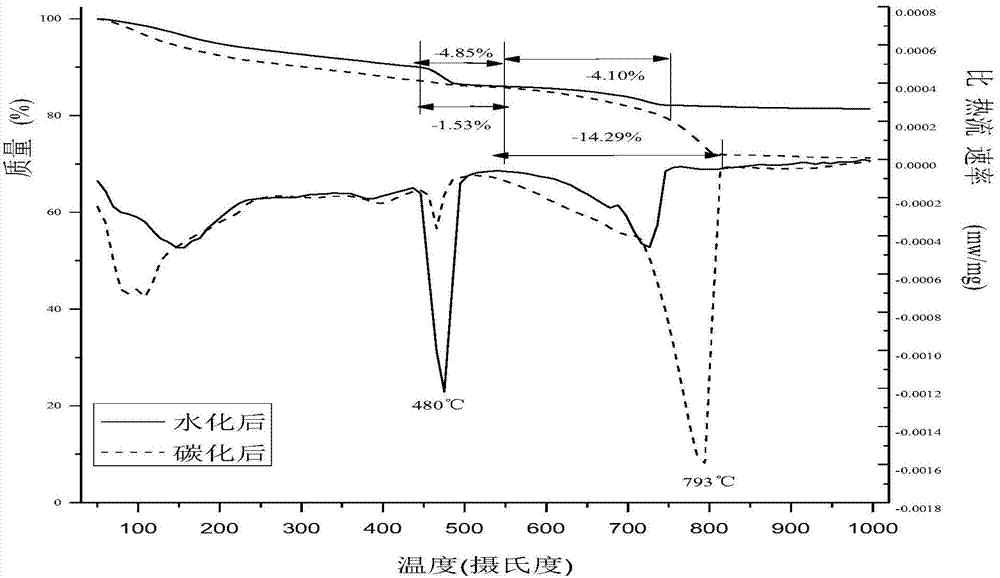

Method for preparing building material products through hydration-carbonation coupling technique

The invention belongs to the technical field of building materials, and provides a method for preparing building material products through processing industrial solid waste by hydration-carbonation coupling technique. The method comprises steps of uniformly mixing the industrial waste comprising at least one of calcium oxide, calcium hydroxide, dicalcium silicate, tricalcium silicate and tobermorite with alkaline excitation material and proper amount of water so as to prepare the blank of the building material product, wherein the industrial waste comprises steel slag, mineral waste residue, furnace slag, coal ash or coal gangue, the alkaline excitation material comprises carbide slag, lime, Portland cement or waste cement; maintaining for a period through hydration, then maintaining through carbonation so as to obtain the carbonate-based building material product. The coupling technique can effectively use the industrial solid wastes such as steel slag, mineral waste residue, furnace slag, coal ash, coal gangue, carbide slag and the like, so that emission of greenhouse gases is reduced, the greenhouse effect is relieved, furthermore, the method can be used for producing the building material products with good properties, effectively uses the waste and is environmentally friendly.

Owner:DALIAN UNIV OF TECH

High efficiency counterbalanced dual axis solar tracking array frame system

ActiveUS8119963B2Improve efficiencyLittle powerOptical radiation measurementAuxillary drivesPhotovoltaic solar energyShadowings

A high efficiency, environmentally friendly system comprising a plurality of photovoltaic solar collecting panels (PV panels) is disclosed. The system comprises an outer frame to which a plurality of inner frames are mounted to which the plurality of PV panels are attached. To minimize shadowing by the outer frame upon one or more PV panels, at least one PV panel may extend beyond an endpoint of the main frame. The system also comprises an outer frame rotation actuator that rotates the outer frame and an inner frame rotation actuator that rotates the inner frames and the plurality of PV panels. The solar tracking array frames disclosed herein help to improve the quality of the environment by conserving a variety of energy resources (e.g., fossil fuels, hydroelectric energy, etc.) The solar tracking array frames disclosed herein also help to reduce greenhouse gas emissions, as solar tracking array frames do not produce carbon dioxide byproducts.

Owner:SCANLON MARK +1

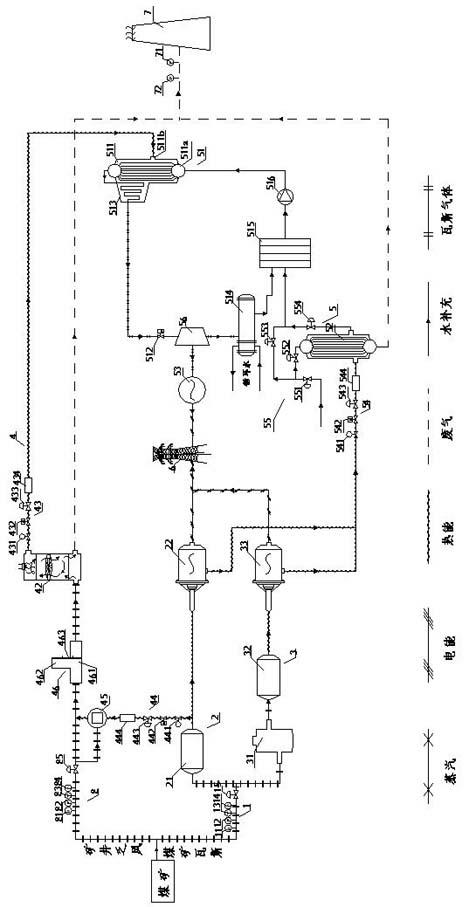

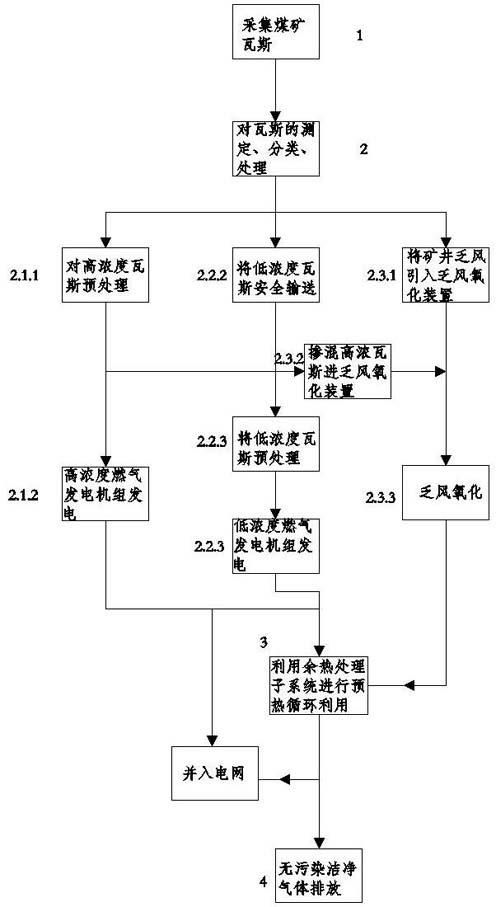

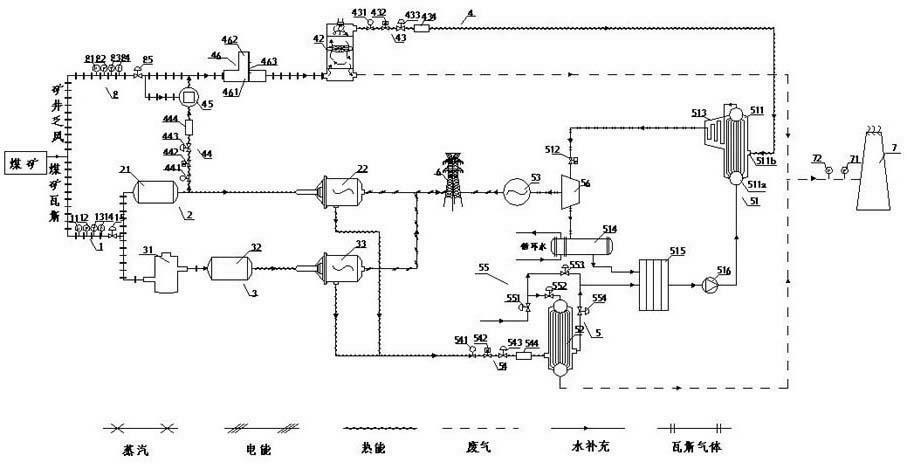

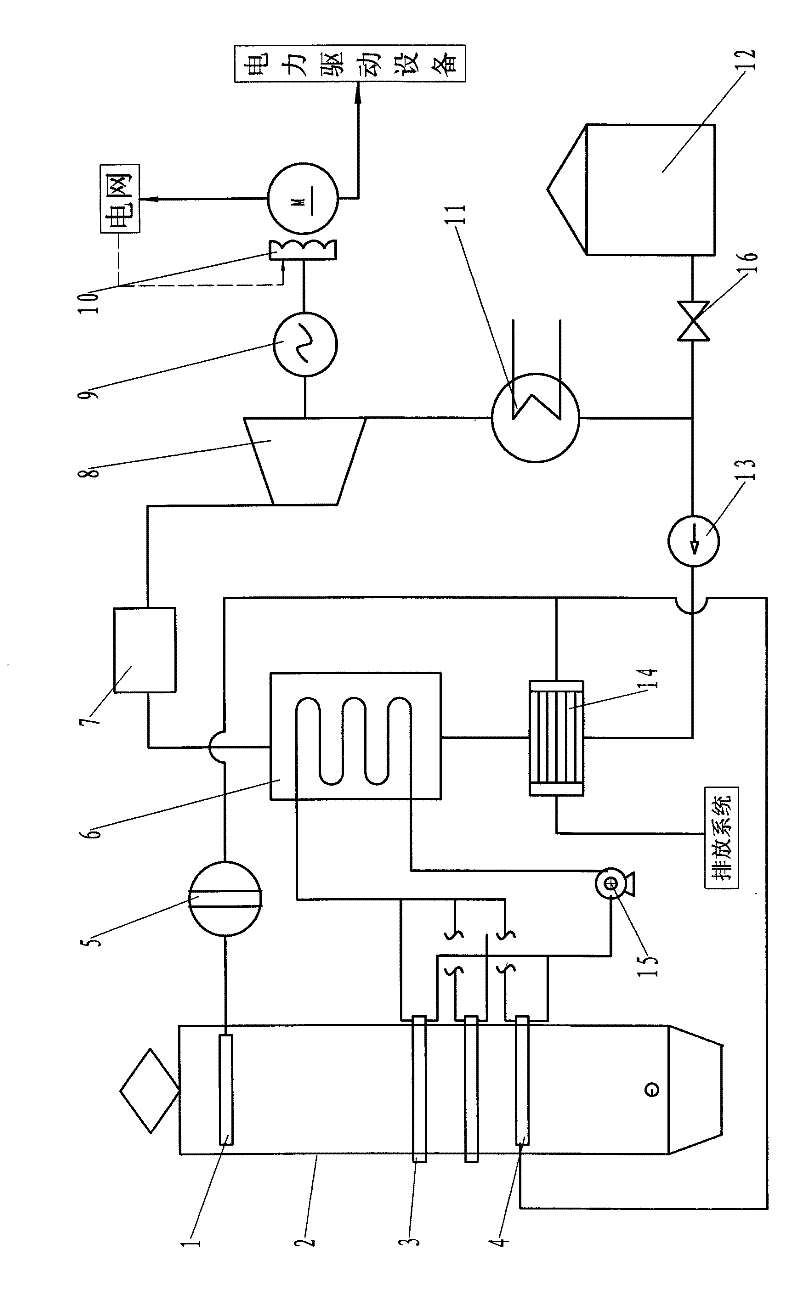

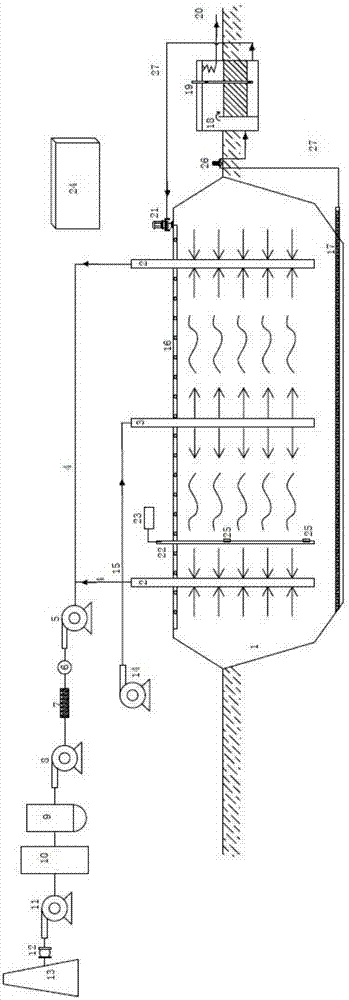

Coal mine gas comprehensive application system and application method thereof

ActiveCN102562131AHigh extraction rateEnsure safe productionMining devicesInternal combustion piston enginesHigh concentrationEngineering

The invention discloses a coal mine gas comprehensive application system and an application method thereof. The system comprises a coal mine ventilation air measuring component, a coal mine gas measuring component, a high-concentration gas treatment subsystem, a low-concentration gas treatment subsystem, a coal mine ventilation air treatment subsystem and an afterheat treatment subsystem, wherein a high-concentration gas pre-treatment device and a high-concentration gas generator set are connected via a pipeline to form the high-concentration gas treatment subsystem, a safe conveying device, a low-concentration gas pre-treatment device and a low-concentration gas generator set are connected via pipelines to form the low-concentration gas treatment subsystem, the high-concentration gas generator set and the low-concentration gas generator set are respectively connected with a power grid via cables, a ventilation air delivering connecting device, a mixing device and a ventilation air oxidization device are connected via pipelines to form the coal mine ventilation air treatment subsystem, and the afterheat treatment subsystem is respectively connected with the high-concentration gas treatment subsystem, the low-concentration gas treatment subsystem and the coal mine ventilation air treatment subsystem. The coal mine gas comprehensive application system and the application method can be used for comprehensively applying gas with different concentrations, utilization rate of the gas is the highest, emission of greenhouse gas is reduced, and comprehensive recycling of energy is realized.

Owner:SHANGHAI PANGEA INVESTMENT

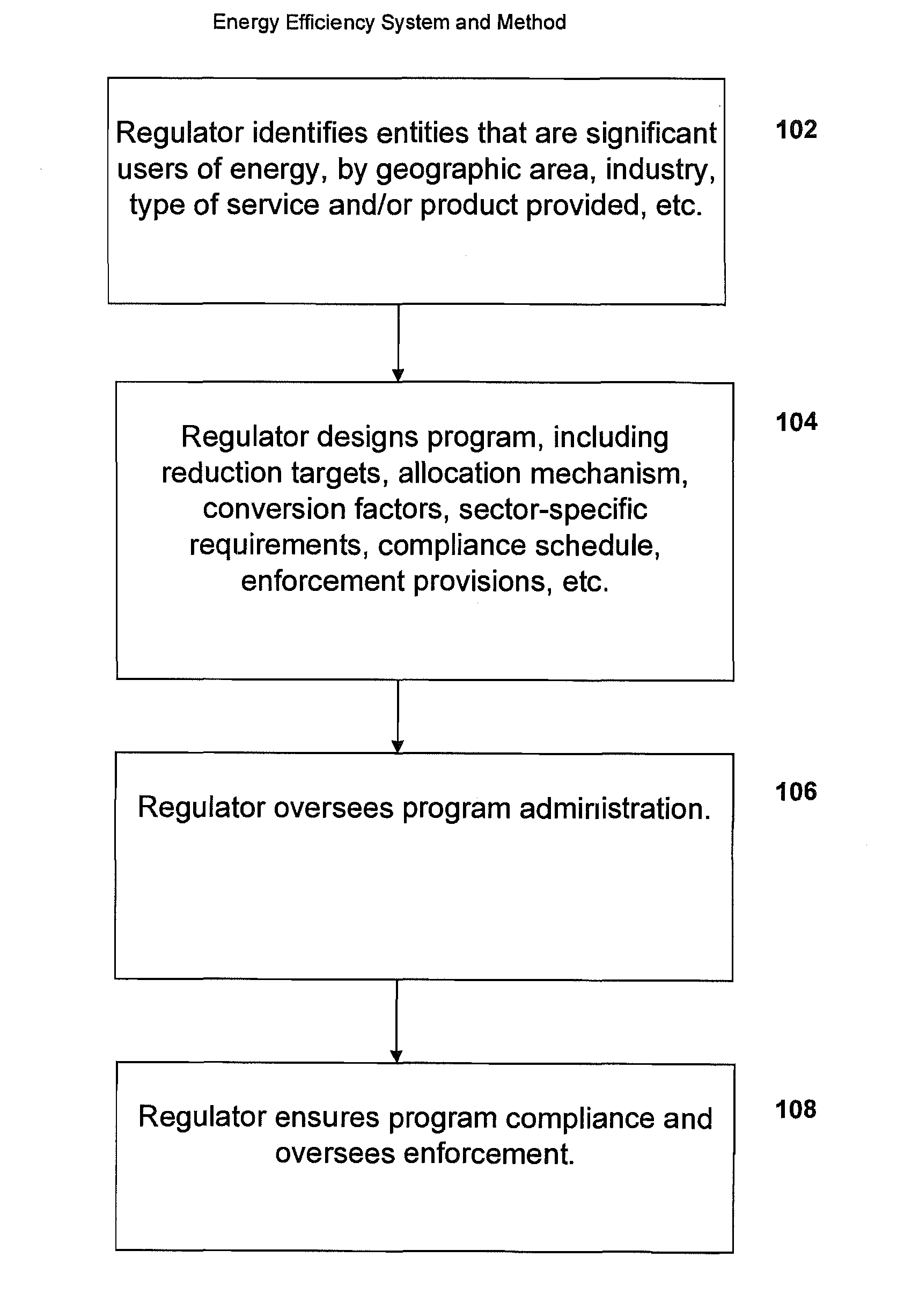

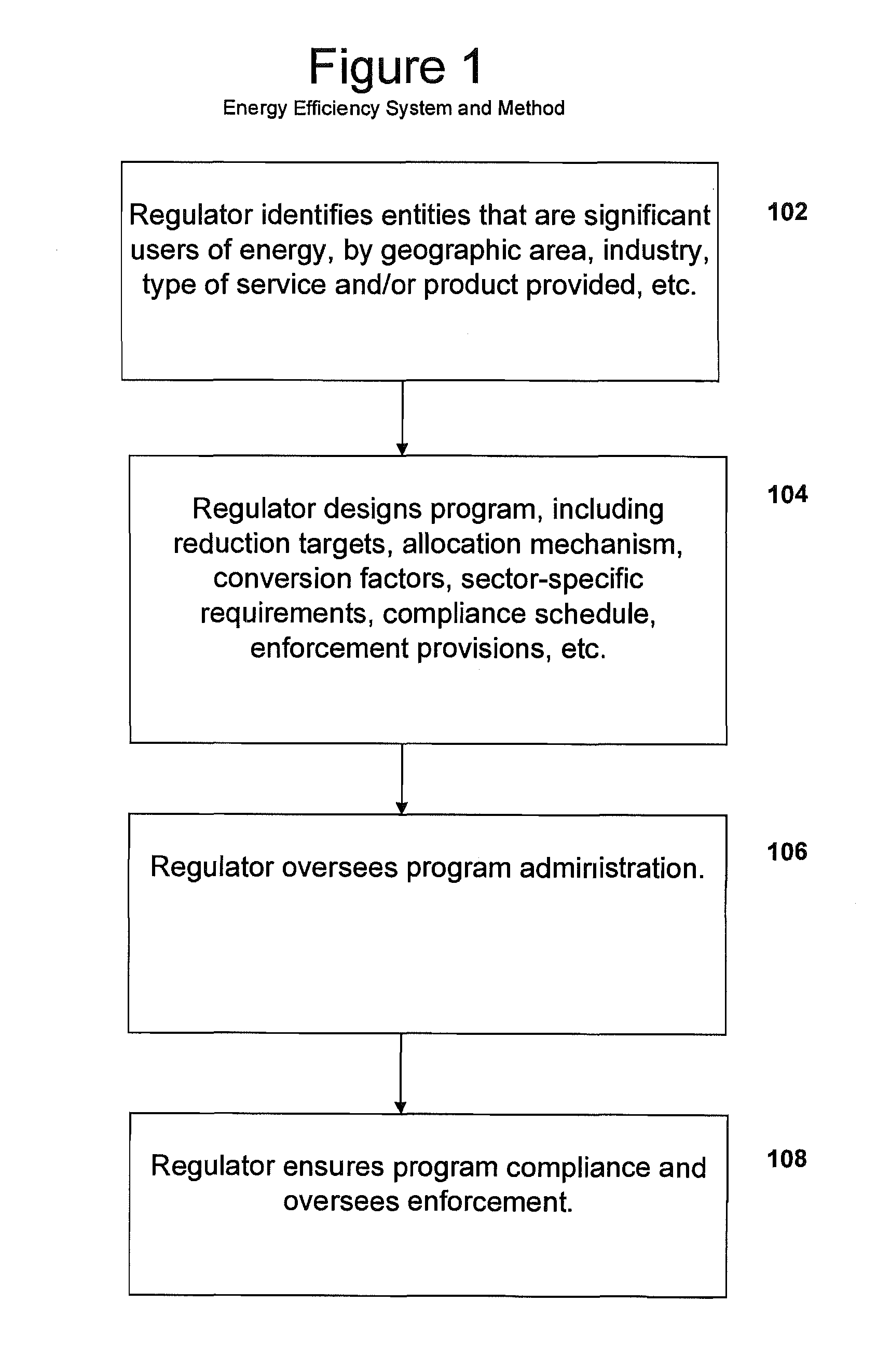

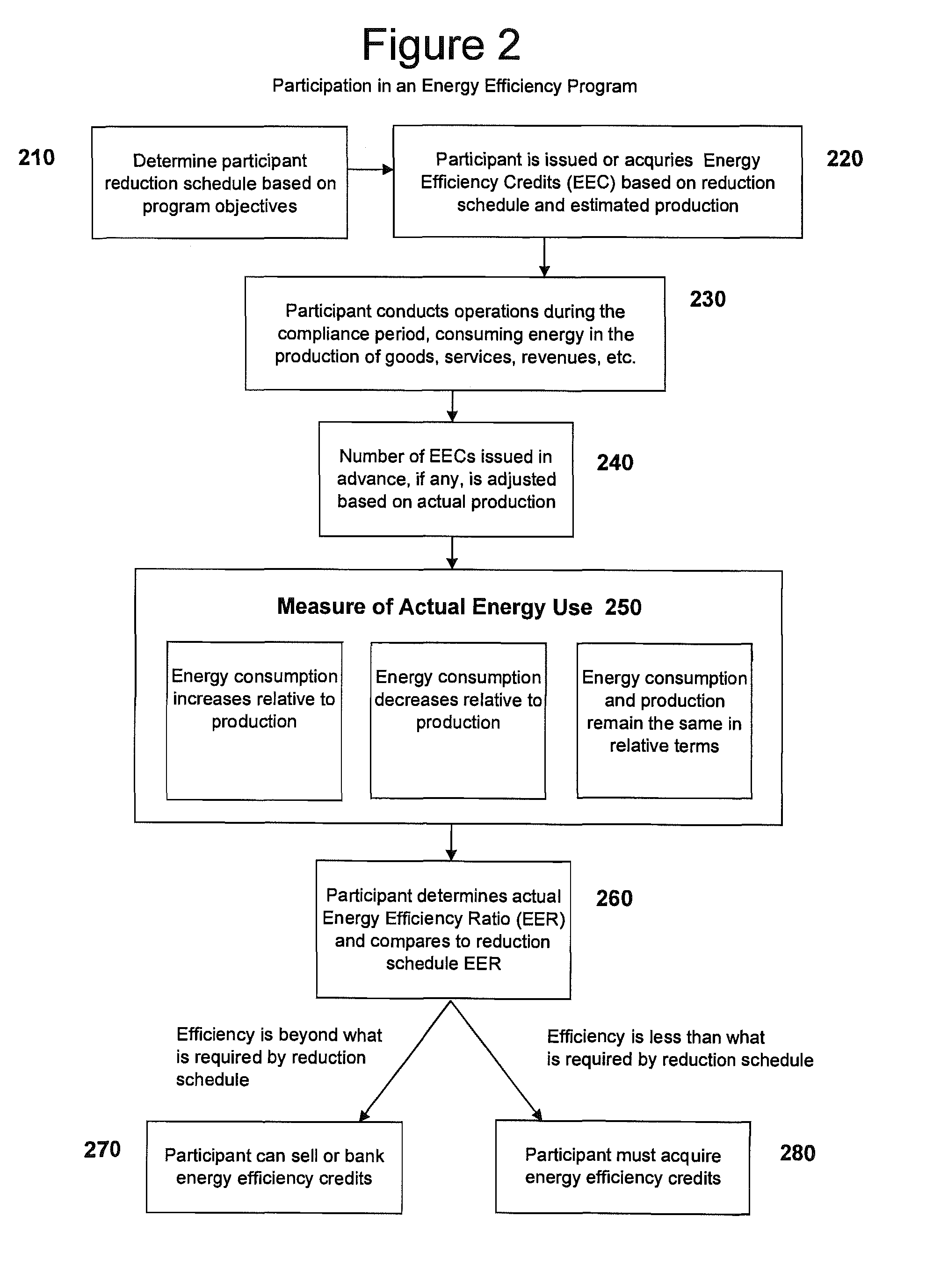

System, method, and media for trading of energy efficiency

ActiveUS20100332275A1Facilitates efficiency in tradingReduce transaction costsFinanceTechnology managementTime scheduleBusiness efficiency

A method for reducing greenhouse gas emissions by promoting more efficient energy use, by establishing a measure of efficiency, defined as a ratio of a measure of energy use to a measure of production; establishing a reduction schedule that sets limits on the energy efficiency ratio, with the schedule covering a series of compliance time periods and requiring efficient energy use during those time periods; establishing a transferable credit representing an amount of energy and establishing a tradable financial instrument representing a number of energy efficiency credits; issuing a plurality of energy efficiency credits to the entities; establishing a trading system to facilitate the sale and purchase of the financial instruments; and requiring entities to comply with the reduction schedule by making operational improvements or acquiring and surrendering credits to thus increase the efficiency of energy use in turn reducing greenhouse gas emissions.

Owner:CHICAGO CLIMATE EXCHANGE

Equipment for recycling low-temperature heat of lime kiln

ActiveCN102338565ALow costTake advantage ofIncreasing energy efficiencySteam engine plantsThermal energyHeat conducting

The invention provides equipment for recycling low-temperature heat of a lime kiln; the equipment mainly comprises the lime kiln, a working medium storage tank, a working medium preheater, a steam generator, a steam adjusting device, a steam turbine, a generator, a transmitter and a condenser. A working medium is preheated by using low-temperature gas of the lime kiln through the working medium preheater; the preheated working medium is converted into steam by using the heat discharged by heat-conducting oil through the steam generator; and then the generator is driven to generate power by utilizing the steam turbine, and the generated power can be supplied to electrical equipment of the lime kiln device, and also can be merged into a general power grid. When the power is insufficient, the power from the general power grid can be supplemented to power driving equipment of the lime kiln, therefore, the operation flexibility is high. By adopting the equipment, the low-temperature heat of the lime kiln can be fully utilized, meanwhile, the emission of greenhouse gases is reduced, and the production cost of lime is reduced. The equipment can be used for recycling the low-temperature heat of the lime kiln and also can be used for recycling the energy of other low-temperature heat source systems.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

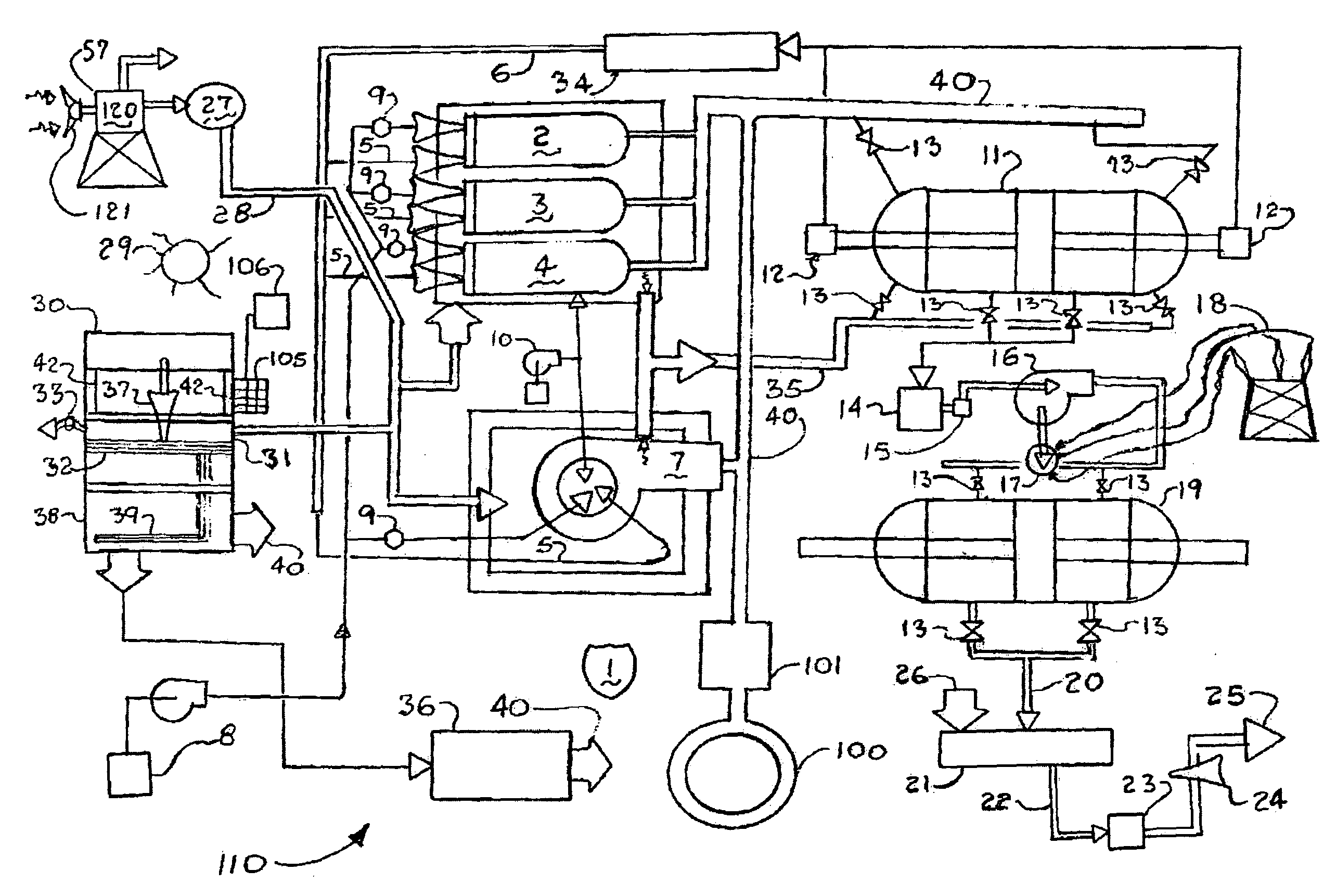

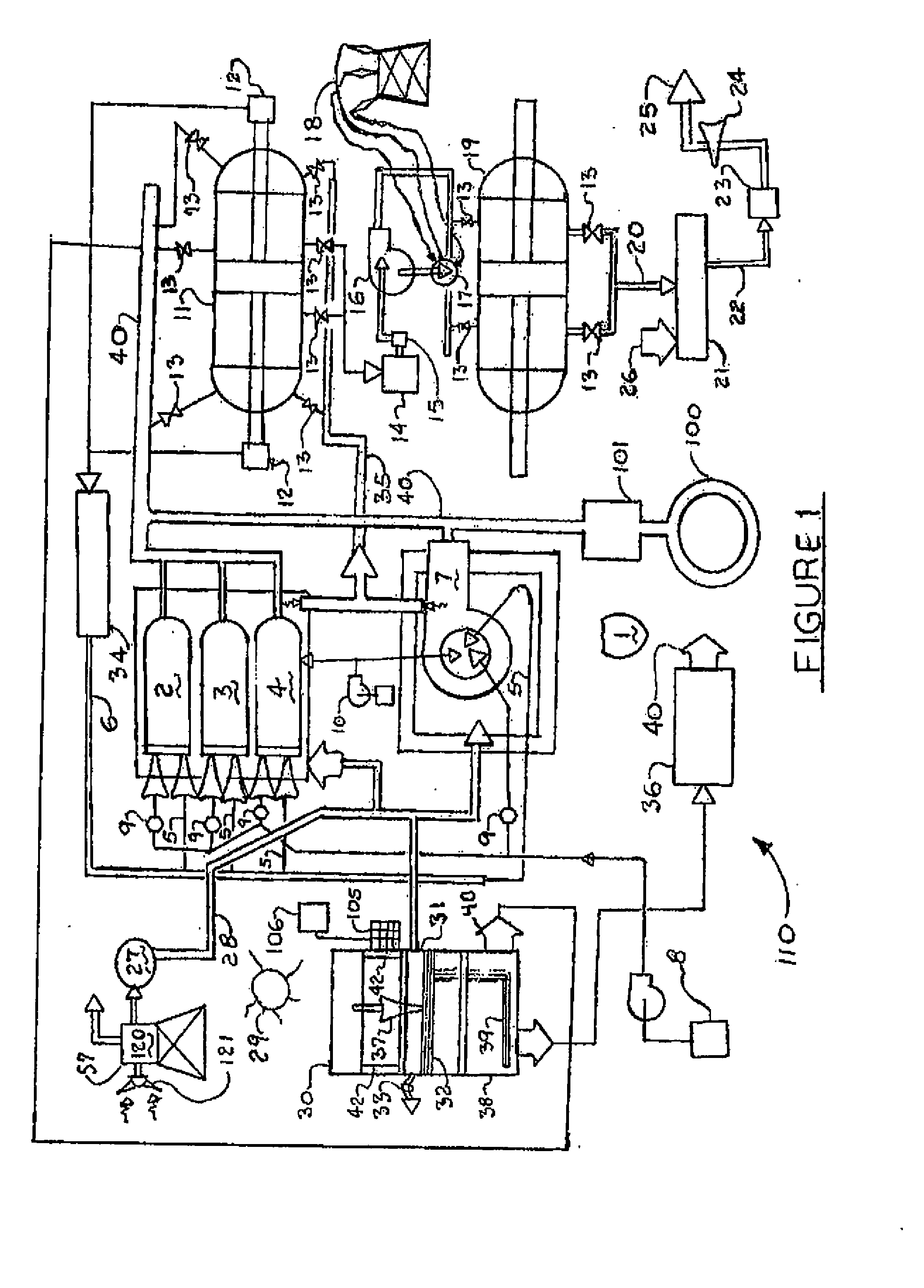

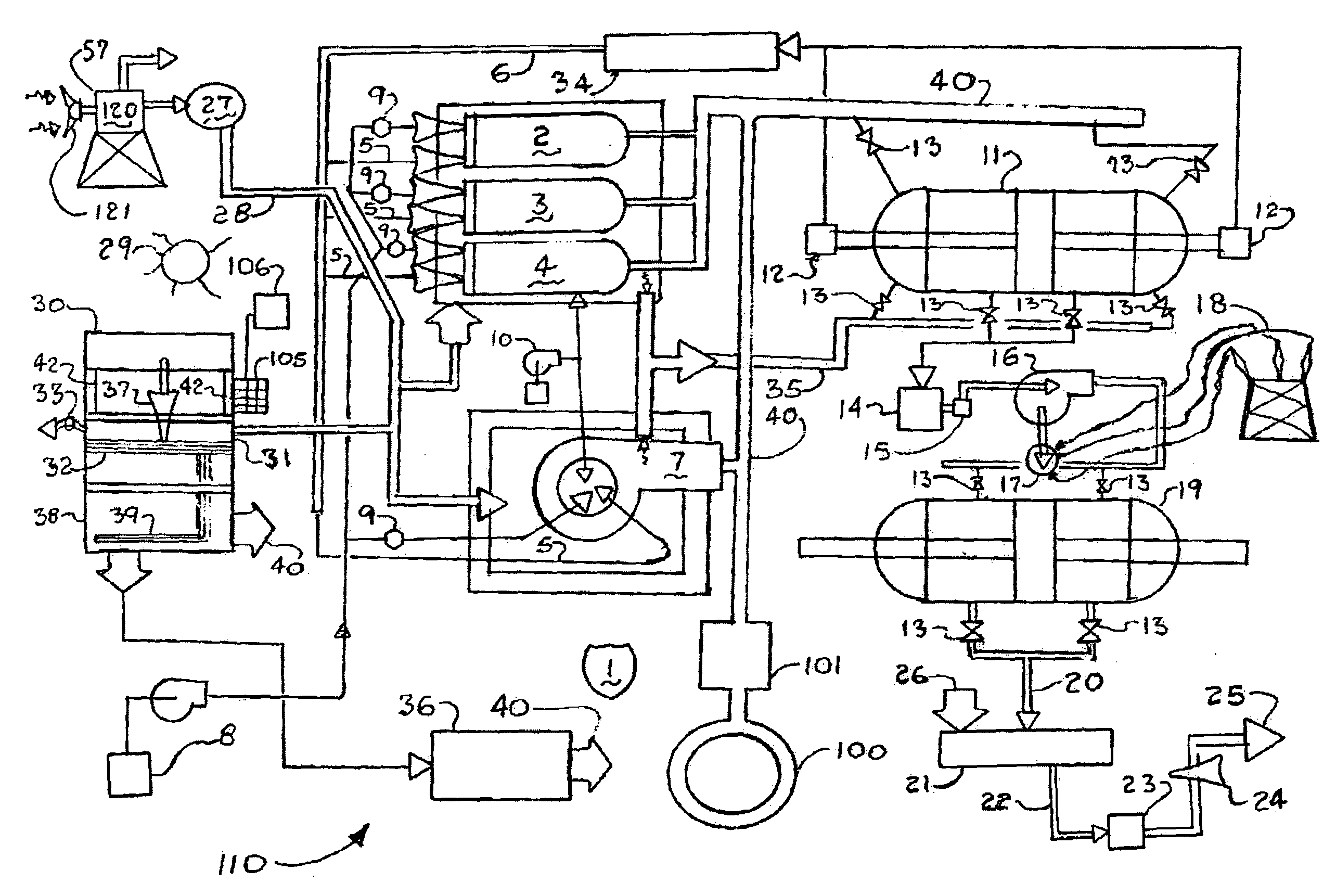

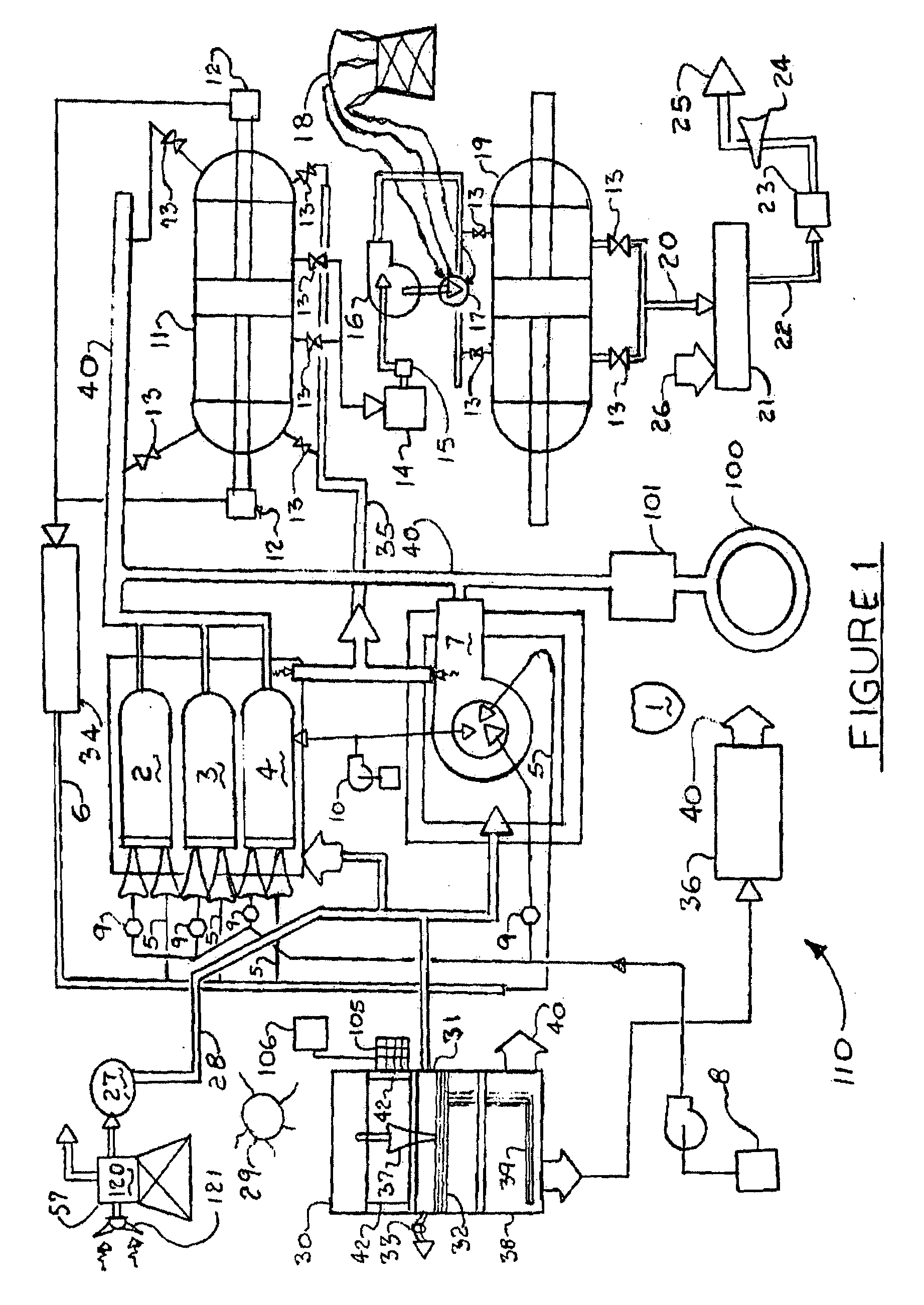

Power generating systems and methods

InactiveUS7654073B2Emission reductionSlowing global warmingPower plant arrangements/mountingPV power plantsWorking fluidHigh pressure

A power-generating system is provided for operating adiabatically and reducing emissions of greenhouse gases contributing to global warming. The system may include gas reactors and / or combustors that burn a fuel and an oxygen-containing gas under substantially adiabatic conditions such that high-pressure combustion products and low pressure combustor housing cooling air are combined to produce a medium pressure working fluid. Higher thermal efficiencies reduce emissions of greenhouse gases. Products of combustion can be processed to further reduce emissions of carbon dioxide and other greenhouse gases from portable and stationary exhaust-producing devices using different fuels. The system may also include solar collectors that pick up a spectrum of solar energy by means of cells containing fluids, aligned to concentrate the solar rays. The collectors may pick up direct and / or diffused solar radiation and can be used to power self-propelled vehicles or function as a roof of a building.

Owner:PRIMLANI INDRU J

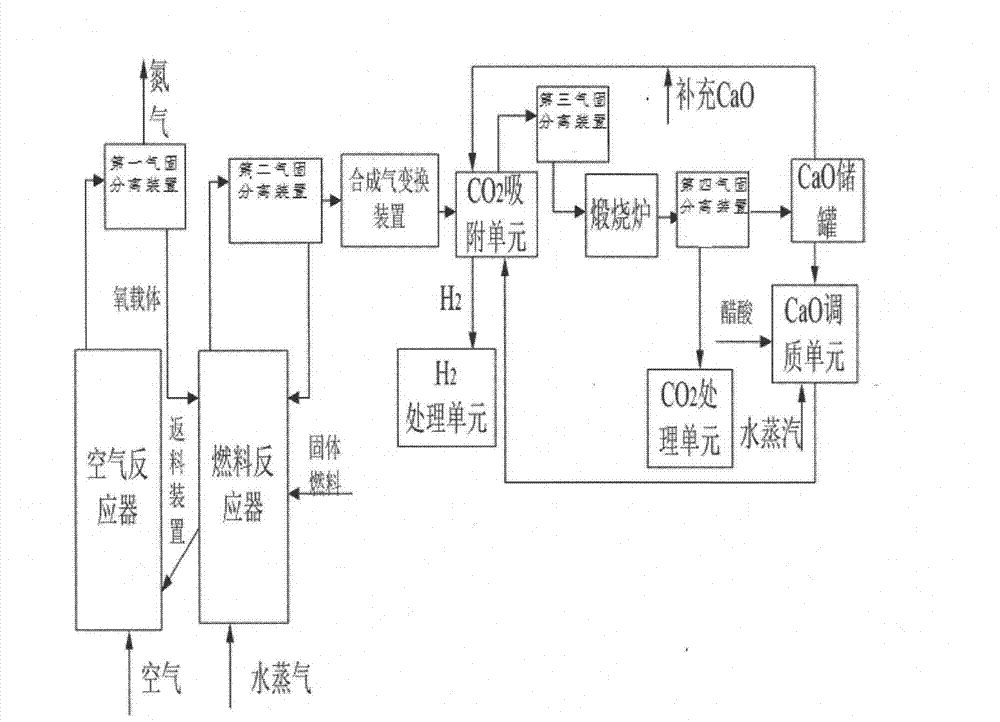

Solid fuel chemical-looping gasification hydrogen production system and method

ActiveCN103113917AEfficient separationAchieve near-zero emissionsHydrogen separation using solid contactCombustible gas productionSolid fuelProcess engineering

The invention provides a solid fuel chemical-looping gasification hydrogen production system and method. The solid fuel chemical-looping gasification hydrogen production system is characterized by comprising an air reactor, wherein the air reactor is connected with a first gas-solid separation device; the first gas-solid separation device is connected with a fuel reactor; the fuel reactor is connected with a second gas-solid separation device; a gas outlet of the second gas-solid separation device is connected with a synthetic gas converter; the synthetic gas converter is connected with a CO2 adsorption unit; a discharge port of the CO2 adsorption unit is connected with an H2 processing unit; an outlet of the CO2 adsorption unit is connected with a third gas-solid separation device; a CaCO3 solid outlet of the third gas-solid separation device is connected with a calcining furnace; the calcining furnace is connected with a fourth gas-solid separation device; a gas outlet of the fourth gas-solid separation device is connected with a CO2 processing unit; a solid outlet of the fourth gas-solid separation device is connected with a CaO storage tank; and the CaO storage tank is connected with the CO2 adsorption unit. The system can implement near zero discharge of CO2 in the hydrogen production process, and thus, reduces the influence of greenhouse gas on the environment.

Owner:SHANGHAI BOILER WORKS

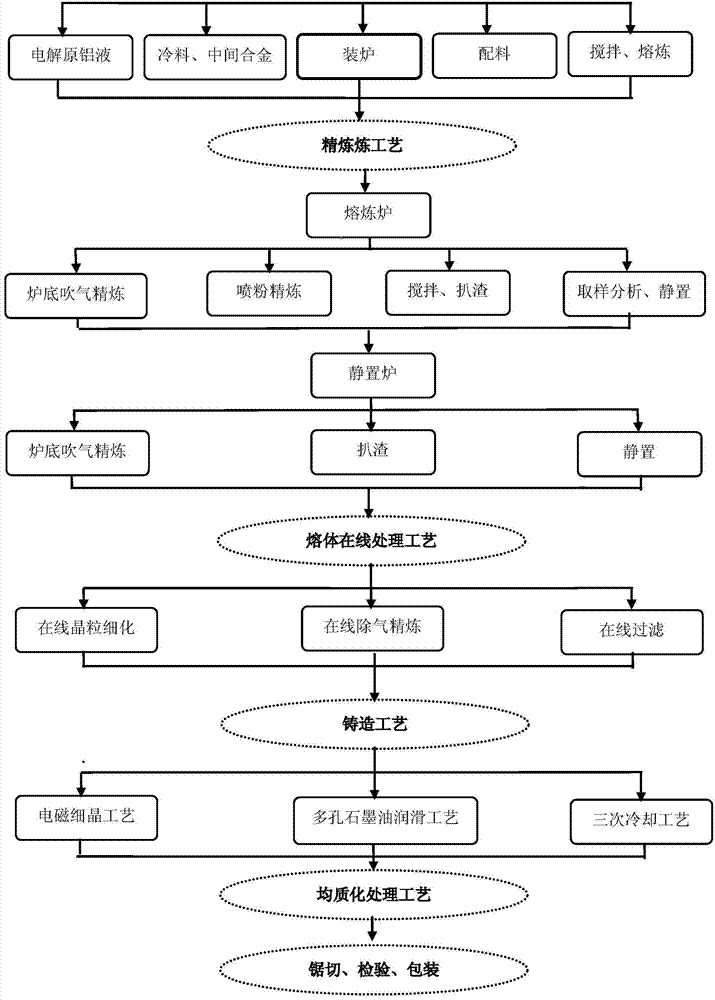

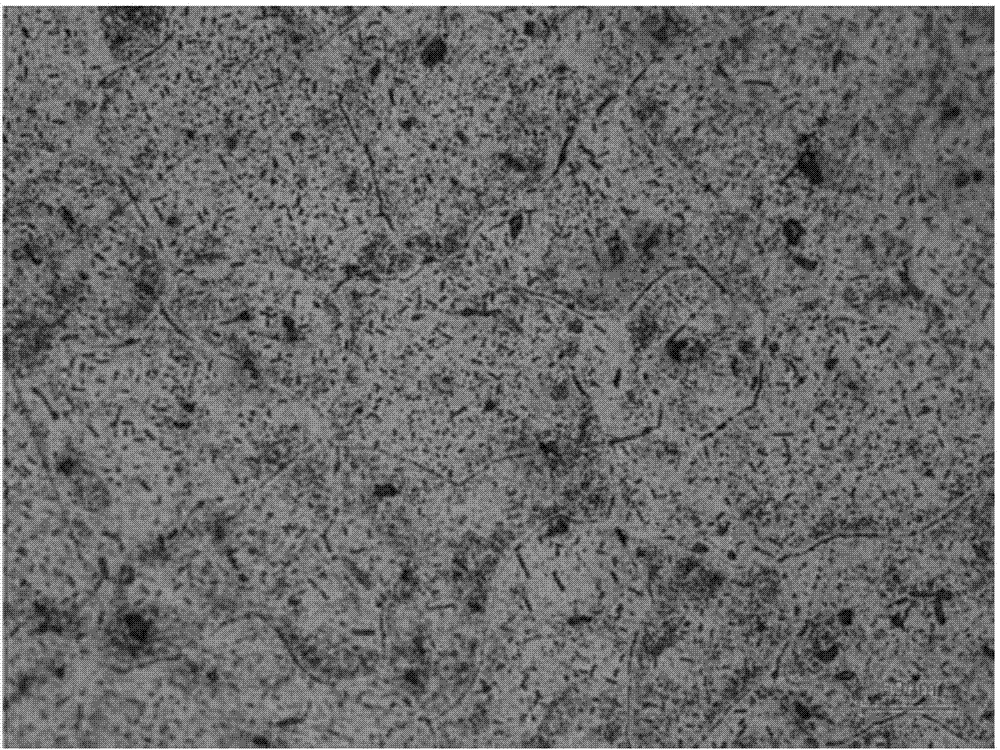

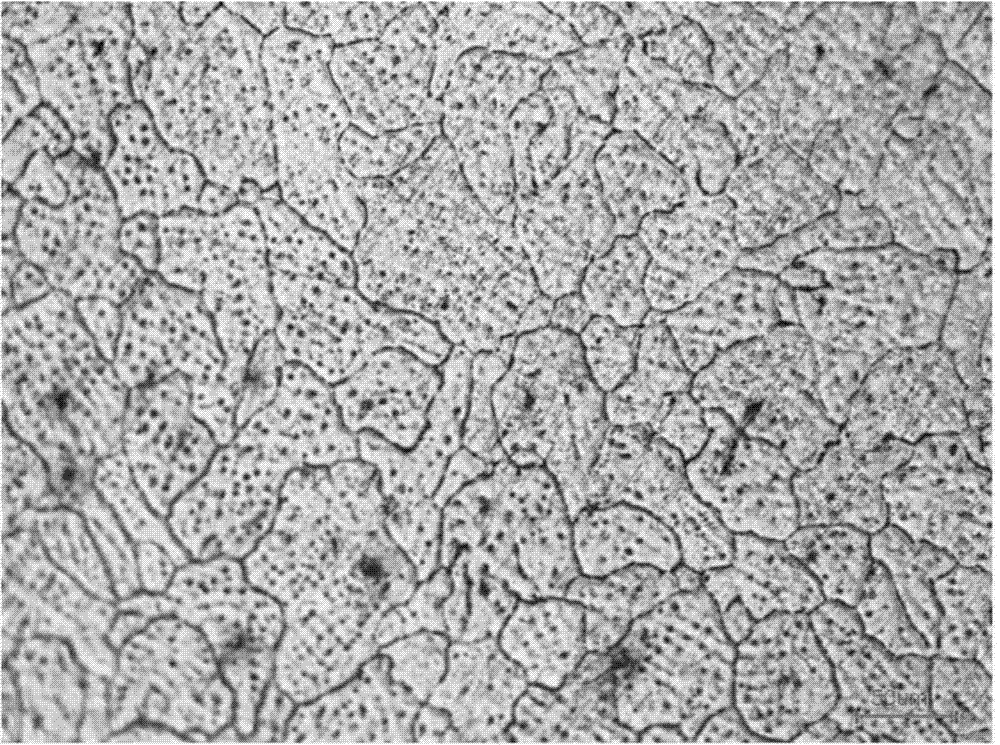

Production method of large diameter 6063 aluminum alloy round ingot casting billet

Owner:YUNNAN RUNXIN ALUMINUM

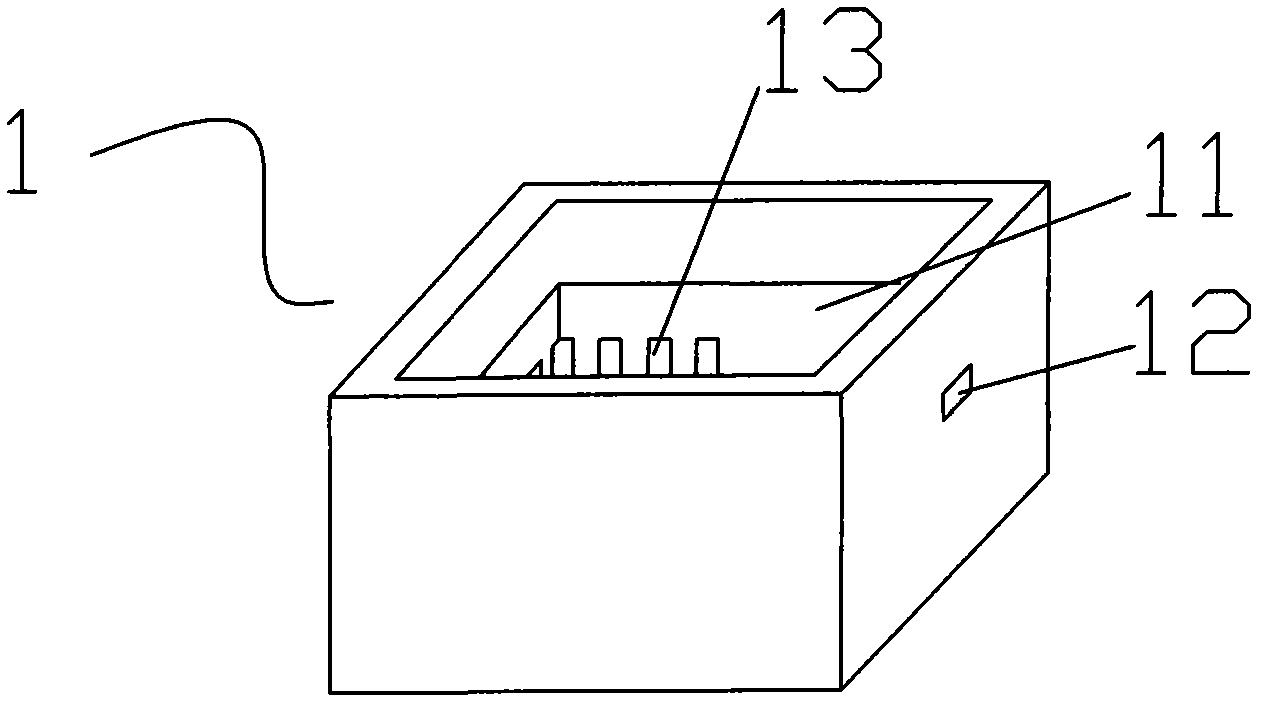

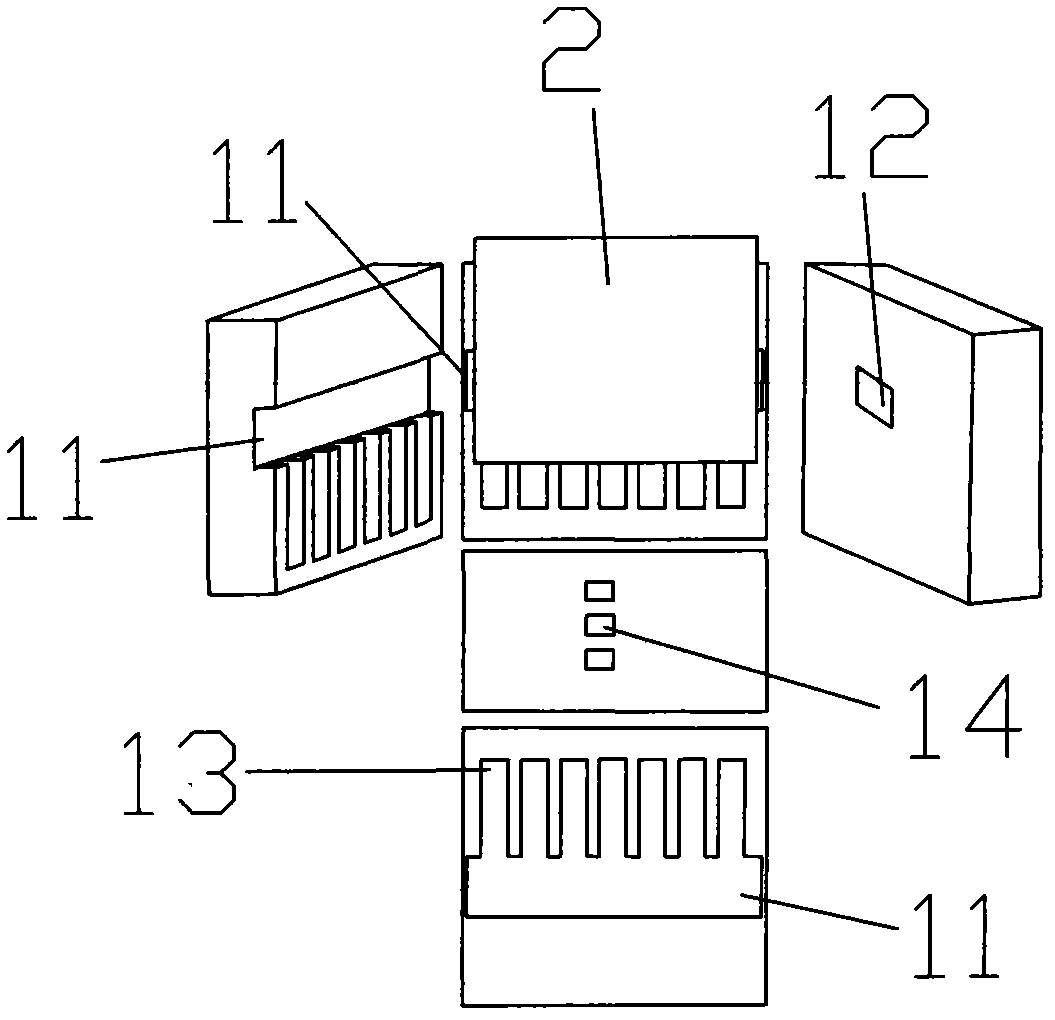

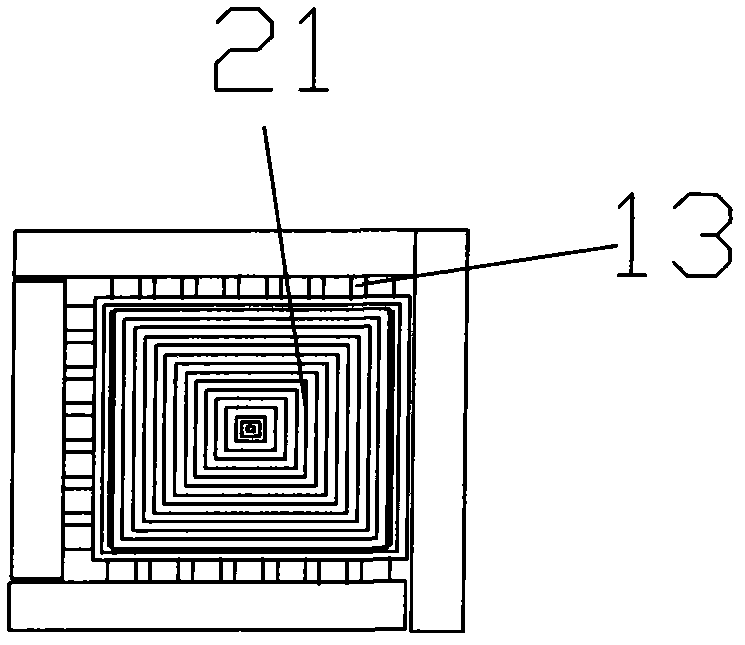

Efficient energy-saving steam cabinet

ActiveCN102631131AEmission reductionImprove energy savingCooking vesselsBoiler controlCombustion chamberProcess engineering

The invention discloses an efficient energy-saving steam cabinet. The efficient energy-saving steam cabinet comprises an oven body, wherein a plurality of combustion heads are arranged inside the oven body; the plurality of combustion heads are located in a combustion chamber; a steam generating pot is arranged on the combustion chamber; a horizontal discharge flue is arranged at the lateral wall of the combustion chamber; a smoke discharge port is arranged on the side wall of the combustion chamber; and a burner port is arranged at the bottom of the combustion chamber. The efficient energy-saving steam cabinet disclosed by the invention has the beneficial effects of being obvious in energy-saving effect, very little in exhausted air quantity, very high in energy utilization rate and very obvious in national energy-saving and emission-reducing effects, and the utilization efficiency of the heat energy can be up to over 90%, the discharge temperature is close to ambient temperature, and the discharge of greenhouse gas is greatly reduced.

Owner:浙江合隆智能设备有限公司

Grain saving type feedstuff substituting food to reduce greenhouse gases

InactiveCN101107969APromote resource utilizationEasy constructionFood processingAnimal feeding stuffGrazingForest industry

The invention discloses a grain-saving type feed replacing the grain to deduce the greenhouse gasses, which is mainly composed of a lees and / or Jerusalem artichoke, drugs reducing the emission of animal waste gas, straws, grazing, tree or normal feeds. The invention, besides suits the normal feeding, is also applicable for multi-functional grain-saving type ''carbon culture'' and ''lees or Jerusalem artichoke;; feed, fuel and ethanol industrial integrating livestock breeding, forest industry and firedamp with compact shaped fuel as ''alcohol to gasline'', ''ordure to electricity'', ''fart to cylinder gas'', ''branch to coal'', ''forest to meats'' co-produced meat, eggs and milk, ethanol and canned firedamp. Farmers, besides using feeding with castoff and planting trees and grasses to resolve the meat demanding in China, also can become the industrial worker for planting ''energy'' by conducting the multi-functional production for reducing the greenhouse gases, which is beneficial for the reusing the castoff, promoting the construction of the energy forest and fast-growing and high-yield plantation with low cost, small investment, simpleness and practicability and conforms to the harmonious circulation between human and nature.

Owner:窦观一

Method for preparing precipitated silica by adopting micro-silica fume as raw material

The invention relates to a method for preparing precipitated silica by adopting micro-silica fume as a raw material, and belongs to the technical field of high value utilization of ferrosilicon alloy industrial waste. The method comprises the following steps: adopting micro-silica fume as a raw material, adding sodium hydroxide to prepare a premix; carrying out a preheating treatment to a temperature of 40-95 DEG C, and adjusting a solid content to 15-45 wt% in a hot alkali dissolving and boiling kettle; introducing water vapor, heating to the temperature of 120-220 DEG C, holding the pressure and the temperature for 1-6 hours, then carrying out filtration and separation to obtain a sodium silicate solution; adding hot water to the sodium silicate solution until the SiO2 content is 2.5-12.0 wt% and the temperature is 40-95 DEG C, then adding a surfactant and introducing CO2, stopping the reaction when the pH value is reduced to 8.5-10.0, then carrying out filtration and separation to obtain solid filter residues; preparing the residues into the suspension liquid having the residue content of 15-40 wt%, then adding an inorganic acid, an organic acid or a mixed solution comprising an inorganic acid and an organic acid, aging for 0.5-2.0 hours to prepare the silica. The method provided by the present invention has the following advantages that: the micro-silica fume is adopted as the raw material; the silica is synthesized through the carbonization method; the integration of the carbon dioxide capturing and the resource utilization process of the industrial waste is realized; the greenhouse gas emission is reduced; a new method for low-cost production of the silica is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

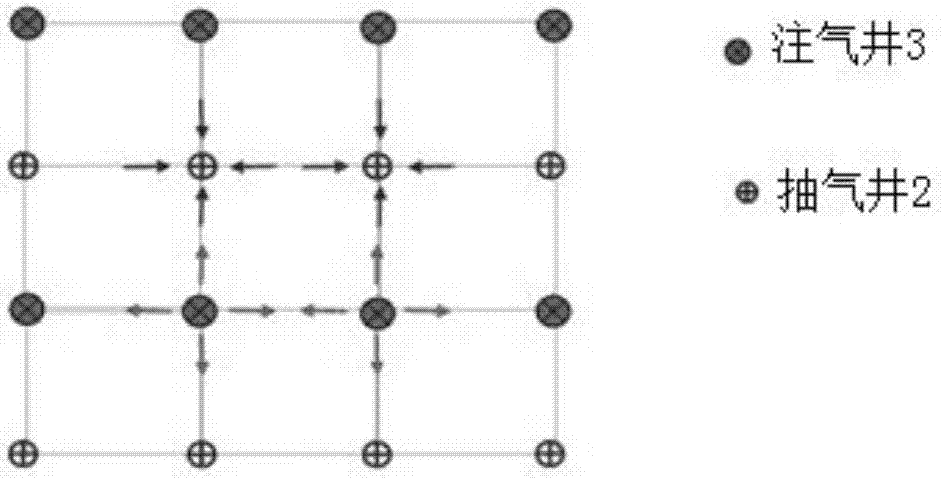

Garbage landfill aerobiotic ecological restoration system and method

InactiveCN107876539APromote decompositionImprove circulation efficiencyMethane captureSolid waste disposalCombustionLitter

The invention discloses a garbage landfill aerobiotic ecological restoration system. The system comprises the steps that an air injection subsystem injects air, oxygen or a mixture of the air and theoxygen into a garbage heap body; an air drawing subsystem draws landfill gas in the garbage heap body and feeds the landfill gas into a landfill gas combustion subsystem to be combusted; a leachate drawing regulation and storage subsystem collects and stores garbage leachate in the garbage heap body; a leachate irrigation subsystem draws the garbage leachate and injects the garbage leachate into the garbage heap body again; and a monitoring subsystem monitors the operation condition of the system. According to the system, the aerobic biology reaction treatment technology is taken as a body, the air or oxygen, the leachate and the like are added to a landfill through a controllable manner according to the biology degradation needs of garbage in the landfill, the landfill garbage biology degradation and stability rate is accelerated, leachate reinjection fully utilizes various microorganisms and water, degrading of organic matter in the garbage is accelerated, the treatment cost is reduced, meanwhile, the landfill torch combustion technology is utilized, the landfill gas is treated in a centralized manner, and emission of greenhouse gas is reduced.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

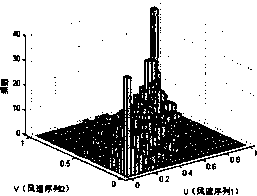

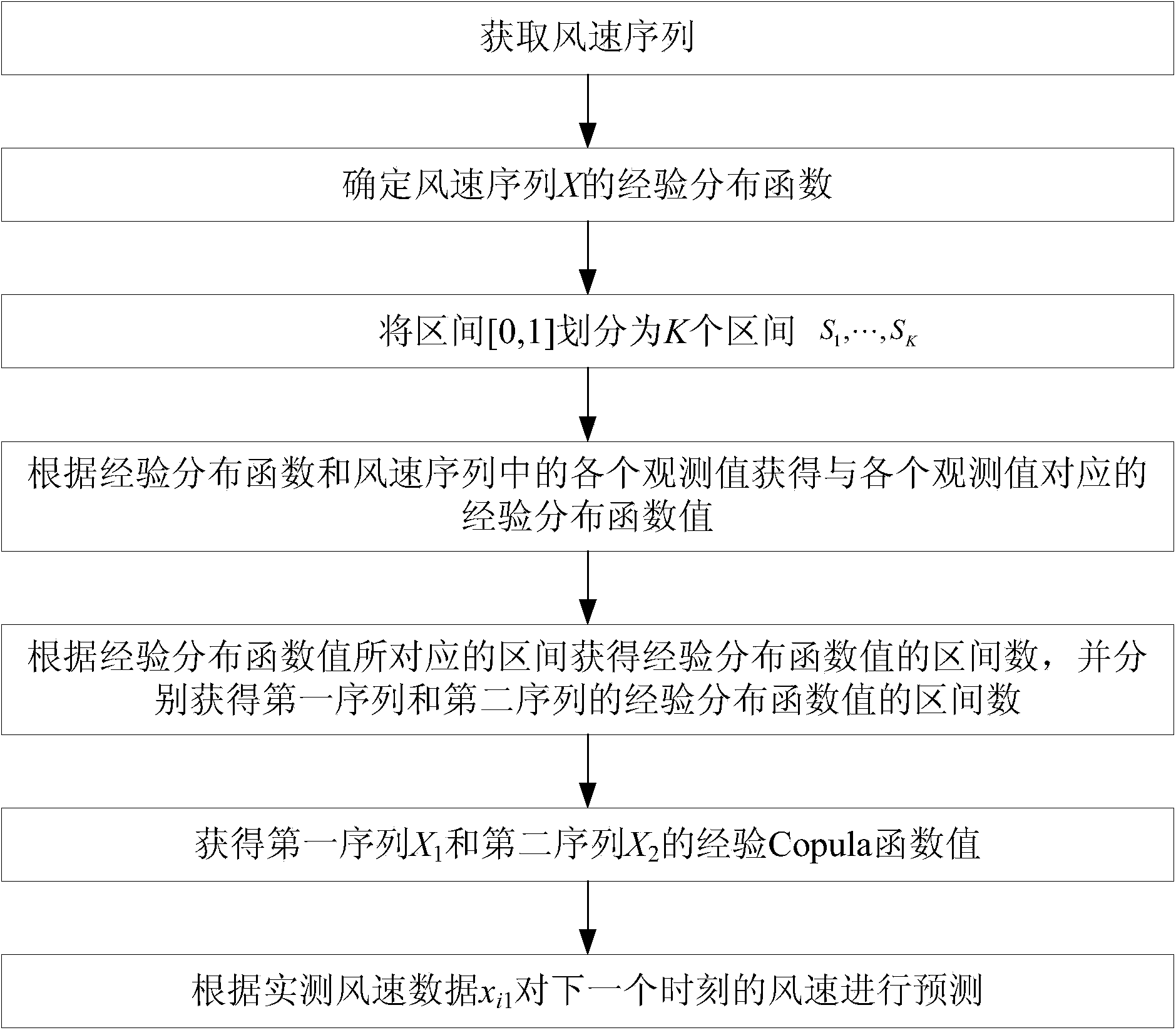

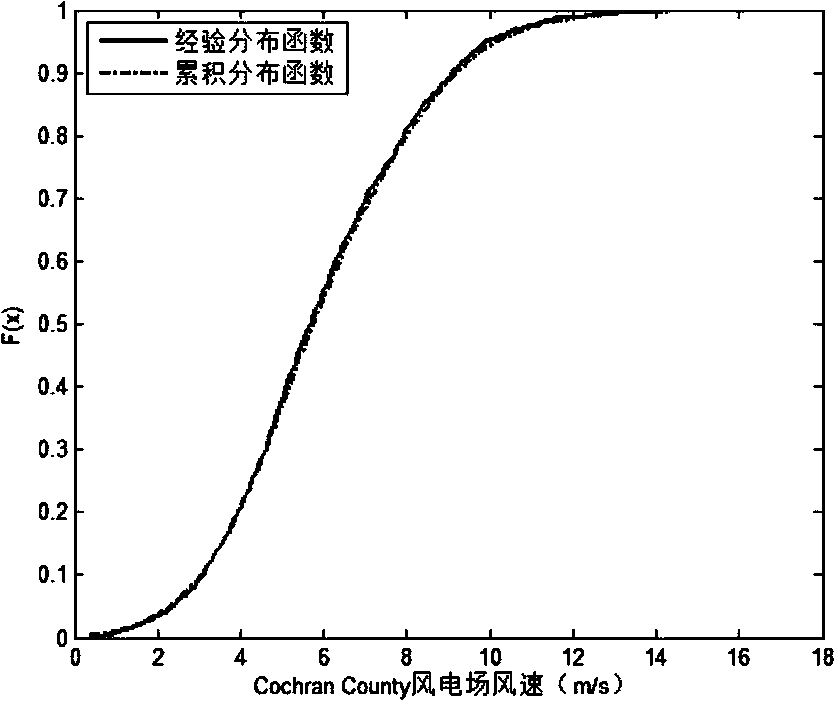

Method for wind speed prediction based on experience Copula function

ActiveCN103902837AGuaranteed uptimeImprove economySpecial data processing applicationsData setConfidence interval

The invention discloses a method for wind speed prediction based on an experience Copula function. According to the method, no limits exist on marginal distribution and joint distribution, the difficulty of direct construction of a multi-element random variable joint distribution function is avoided, and the statistical situations at various wind speeds can be obtained flexibly according to the constructed experience Copula function, so that the wind speed with the maximum probability value is obtained and used as the predicted wind speed of the next moment. Due to interval division, the wind speeds within a certain range have the same characteristics, and finally wind speed sample data are divided into data sets with different characteristics. Under the conditions that the probability corresponding to the wind speed of the previous moment and different probabilities of the wind speed of the next moment are known, finally, the wind speed corresponding to the probability of the wind speed, with the maximum probability value, of the next moment is selected as the predicted wind speed, and a confidence interval with the confidence coefficient being 1-alpha can be obtained. According to the method for wind speed prediction based on the experience Copula function, it is of great significance in improving the level of power grid running, ensuring safety and stability of an electric power system, improving economy of the electric power system, and reducing greenhouse gas emission.

Owner:GUANGXI UNIV

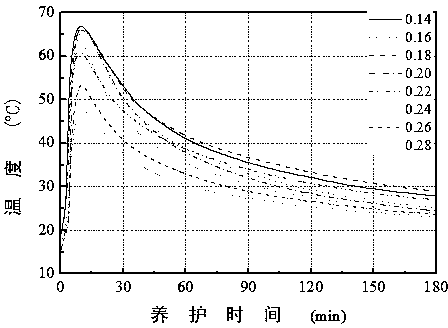

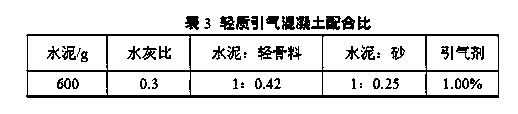

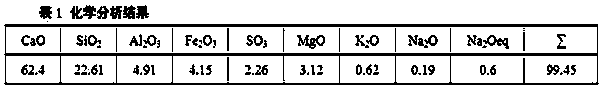

Method for maintaining porous concrete through carbon dioxide

InactiveCN104290183AImprove the ability to absorb carbon dioxide gasControl moisture contentCeramic shaping apparatusAbsorption capacityMixed materials

The invention discloses a method for maintaining porous concrete through carbon dioxide. The method includes the following steps: (1) concrete is mixed and formed; (2) an obtained initial concrete body is placed into a pre-maintenance device for pre-maintenance, wherein the pre-maintenance temperature ranges from 15 DEG C to 25 DEG C, and the relative humidity ranges from 50% to 70%; air circulates through an air blower or a fan, wherein the pre-maintenance time ranges from 1 h to 18 h; (3) when the residual water-cement ratio of the mixed material body obtained after pre-maintenance reaches a preset residual water-cement ratio, the mixed material body is placed into a CO2 maintenance container, vacuumizing is carried out, then CO2 gas is led into the CO2 maintenance container for CO2 maintenance, the gas is discharged after maintenance is completed, and maintenance is stopped. By means of the method, control over the moisture content of the concrete body can be achieved, the carbon dioxide gas absorption capacity of the concrete can be effectively improved, and the quality of a concrete product can be effectively improved; in addition, the waste greenhouse effect gas, namely the carbon dioxide gas can be effectively used, the emission of the greenhouse gas can be reduced, the environment can be protected, and the greenhouse effect can be suppressed.

Owner:HUNAN UNIV

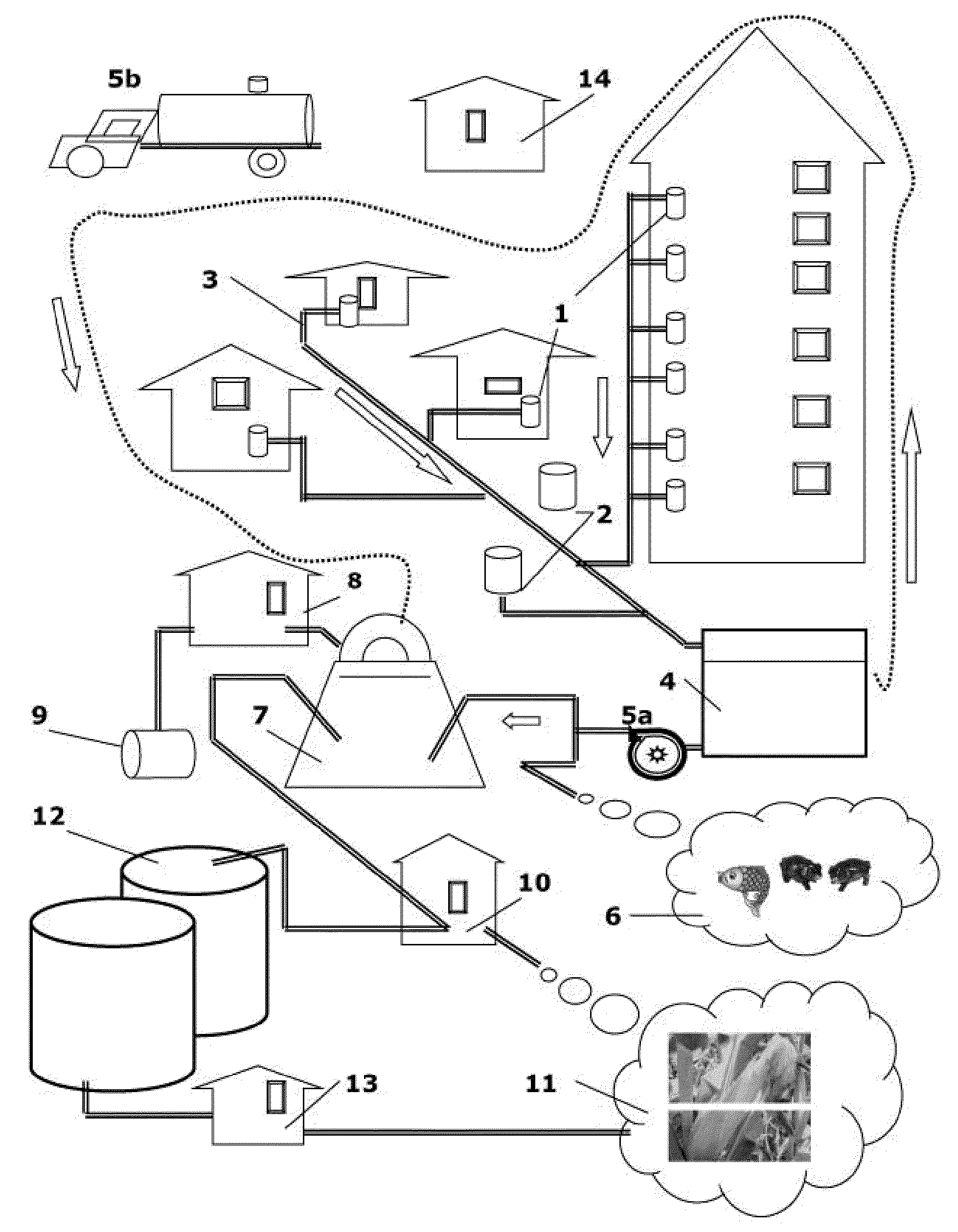

Methods For Planning and Retrofit of Energy Efficient Eco-Industrial Parks Through Inter-Time-Inter-Systems Energy Integration

ActiveUS20130325200A1Quality improvementGood data extractionData processing applicationsComputer controlPower utilityGreenhouse

Methods of providing enhanced energy efficiency and reduced greenhouse gases for an eco-industrial park with retrofit in mind and eco-industrial park retrofit with retrofit in mind, are provided. An exemplary method includes identifying hybrid inter-time zones inter-area matching solutions through selecting best energy efficient routes, generating technically viable energy efficient eco-industrial parks alternatives, identifying best generation and allocation of energy utilities, and synthesizing a combined heat and power utility system that satisfies the eco-park demands during each time zone as well as rendering its best operating scenario at each specific time-zone. This inter-time-zones inter-area integration can include identifying the best and the second best matching solutions among processes in the eco-industrial park for spatial energy integration and the best and second best matching solutions among all time-zones for temporal energy integration and greenhouse gas emissions reduction for the optimal synthesis or retrofit of eco-industrial parks.

Owner:SAUDI ARABIAN OIL CO

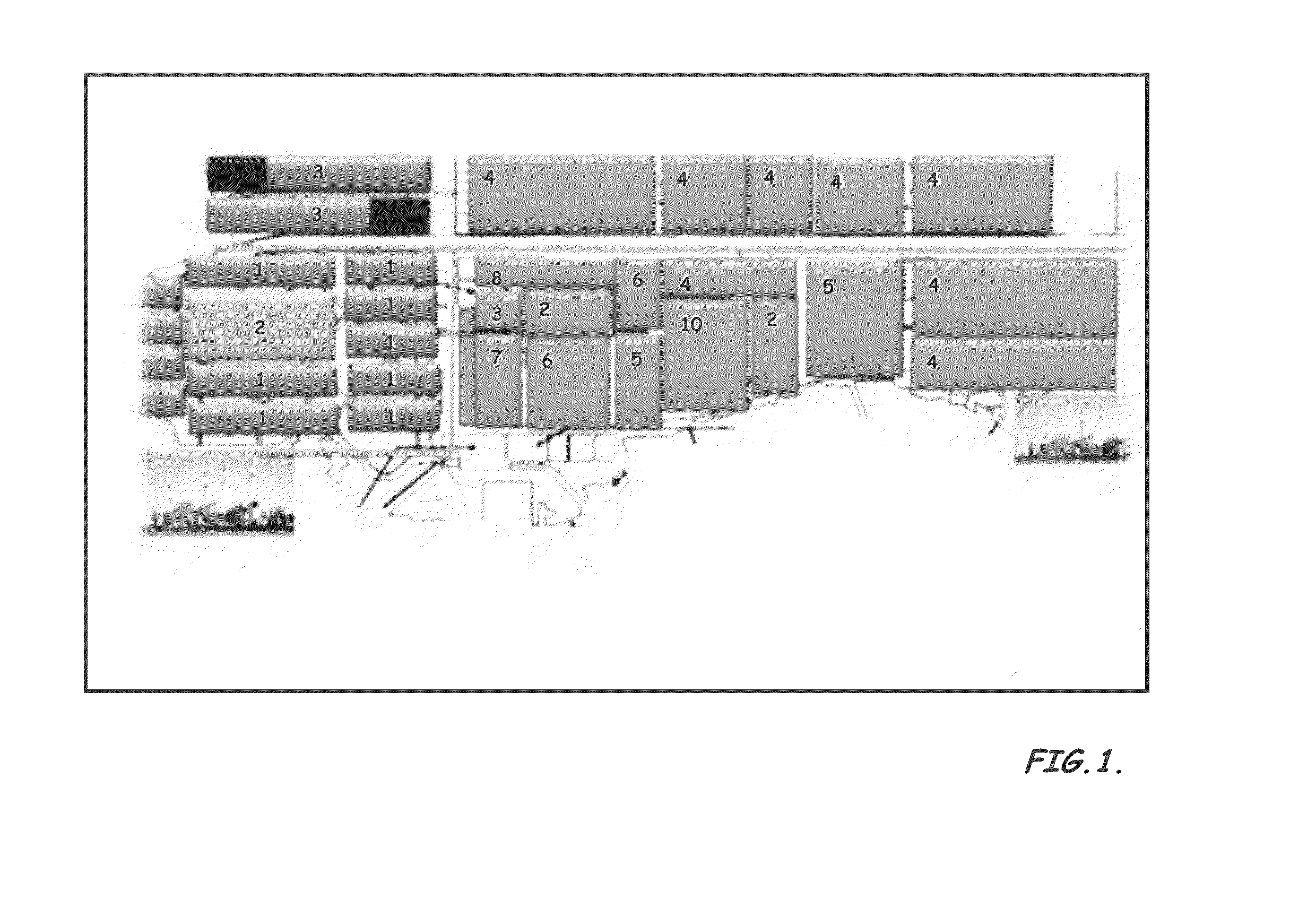

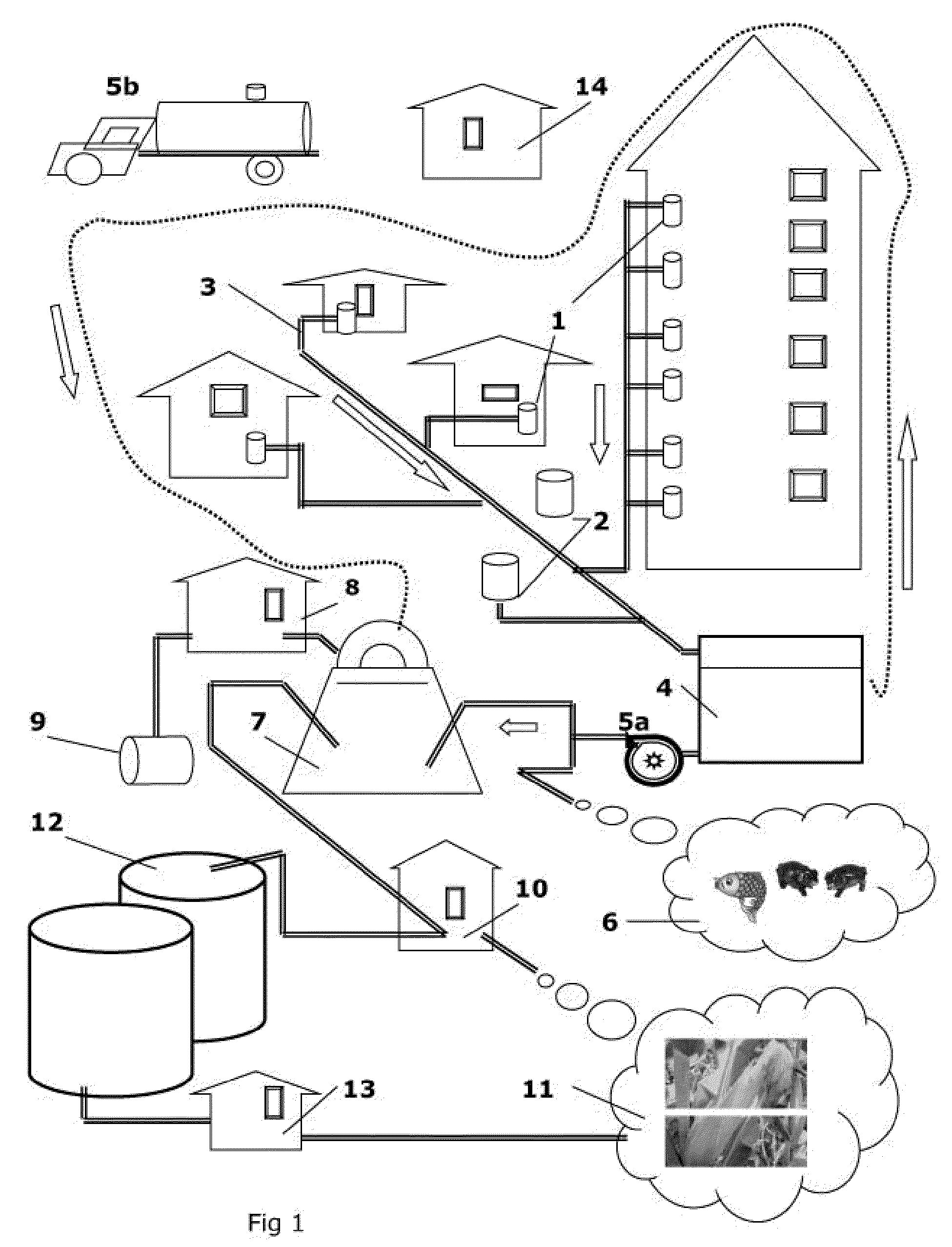

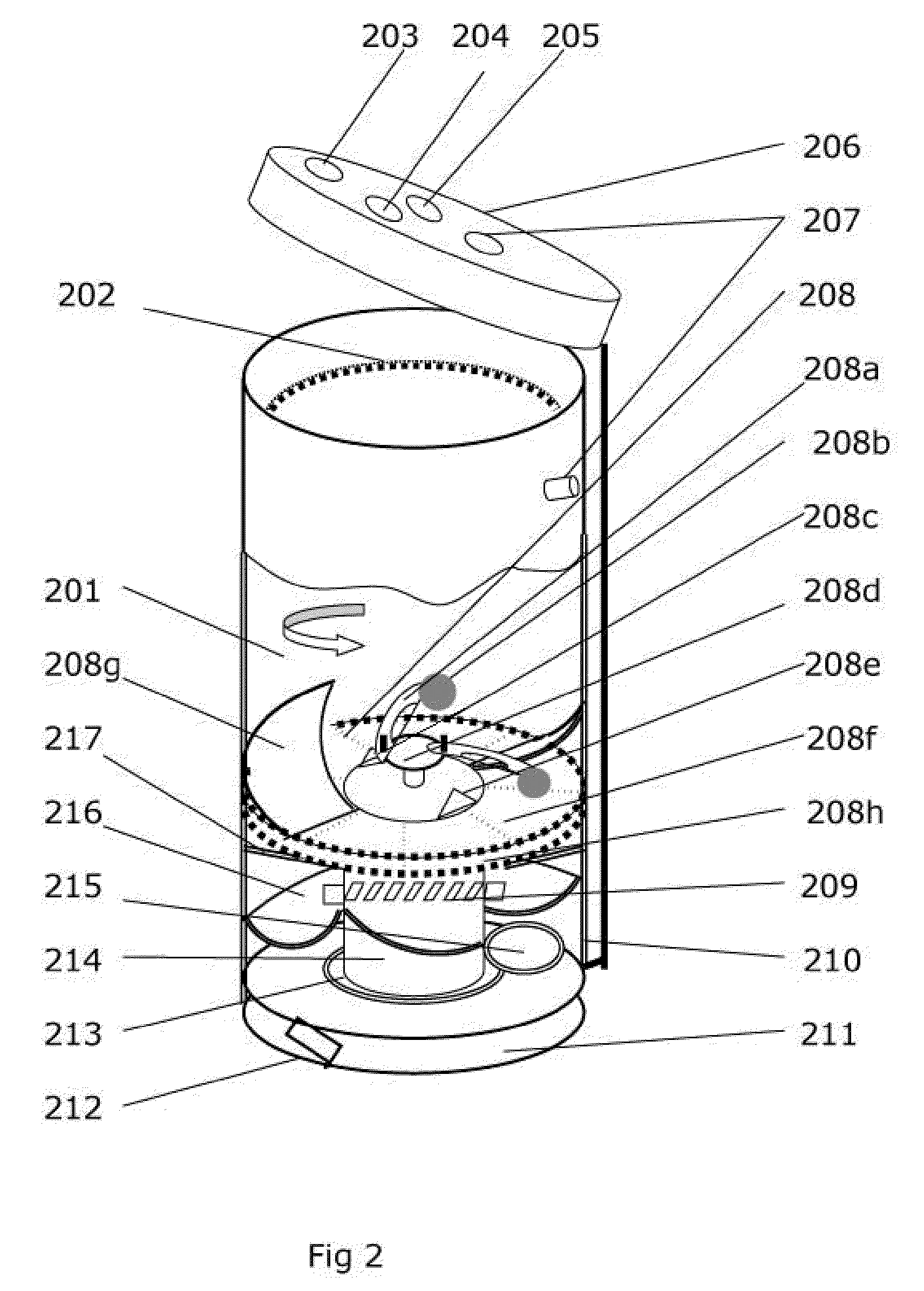

Method and Apparatus of Solid Wastes Automatic Collection Ductwork Evacuation and Comprehensive Utilization

ActiveUS20100243559A1Save wasteIncrease wasteBio-organic fraction processingLiquid degasificationLiquid mediumSystem capacity

The method and apparatus of solid wastes automatic collection ductwork evacuation and comprehensive utilization contemplated to reach a facilitative dropping, quietly, effectively and automatically collecting, evacuating, transporting of all kinds of biodegradable solid waste, getting poly package-less uniform waste particle and jam for recycle that largely reduce the emission of greenhouse gas, pollution of poly package materials, contamination of putrefactive solid waste, generate resource from waste and benefit dwellers, industrials, business units. The disclosed method, procedure and apparatus comprise setting multiple waste grinding collectors indoor and outdoor; cutting, shredding and grinding all kinds of biodegradable solid waste with gaseous and liquid medium into both dry fluidized particle for gaseous medium transportation and wet fluidized jam for liquid medium transportation by the invention multiple waste grinding collectors with multiple functions of automatic information exchange, water proportion, waste cut, shred & grind to satisfy duct pipe evacuation and transportation; Through ductwork pipes, which connect all the waste grinding collectors, pumps with liquid medium, and air pump, suction with gaseous medium, respectively evacuate and transport the fluidized particle and jam into regional collect tanks; By sorting, vehicles, pumps and vacuum aspirators via duct pipeline transport the fluidized particle and jam respectively going to feedstuff plants, bio-purifications, methane generating pools and alcohol generating pools; Methane and alcohol products purified for fuel; Dreg and sludge after disinfecting and sterilization, is respectively transported to farm for irrigation, and transported to dewater chamber to produce organic fertilizer, and further carbonized for fuel; Wastewater purified by filter and activated carbon for recycle and discharged; The regional manage house manages the regional disposal system capacity and to share living regional municipal drainage ductwork and facilities by timer, automatic information exchange assembly and the switch set at the end of the regional municipal drainage pipeline.

Owner:QIU ZEGUO

Power generating systems and methods

InactiveUS20080196410A1Promote reduction in productionEmission reductionPV power plantsGas turbine plantsWorking fluidEngineering

A power-generating system is provided for operating adiabatically and reducing emissions of greenhouse gases contributing to global warming. The system may include gas reactors and / or combustors that burn a fuel and an oxygen-containing gas under substantially adiabatic conditions such that high-pressure combustion products and low pressure combustor housing cooling air are combined to produce a medium pressure working fluid. Higher thermal efficiencies reduce emissions of greenhouse gases. Products of combustion can be processed to further reduce emissions of carbon dioxide and other greenhouse gases from portable and stationary exhaust-producing devices using different fuels. The system may also include solar collectors that pick up a spectrum of solar energy by means of cells containing fluids, aligned to concentrate the solar rays. The collectors may pick up direct and / or diffused solar radiation and can be used to power self-propelled vehicles or function as a roof of a building.

Owner:PRIMLANI INDRU J

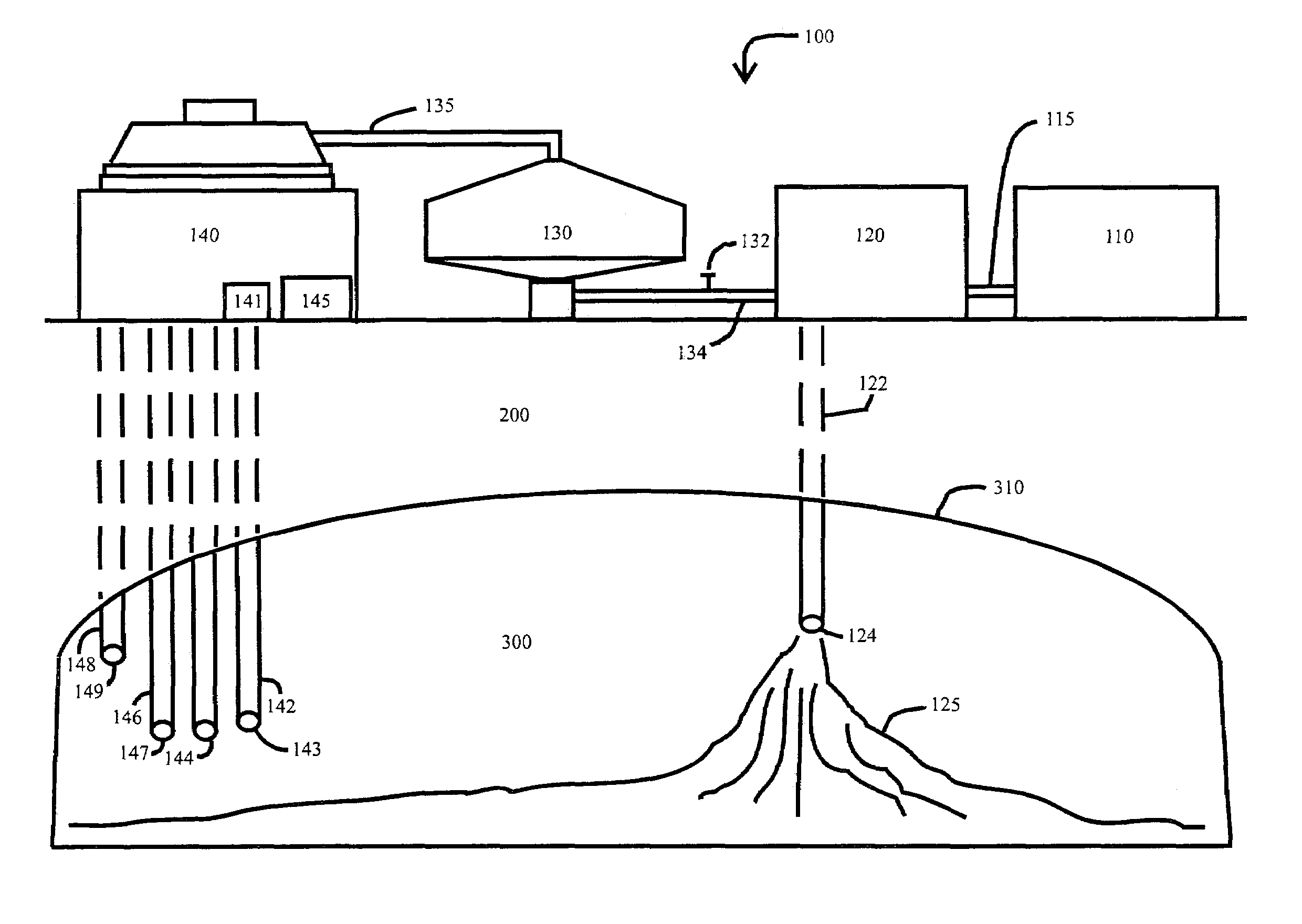

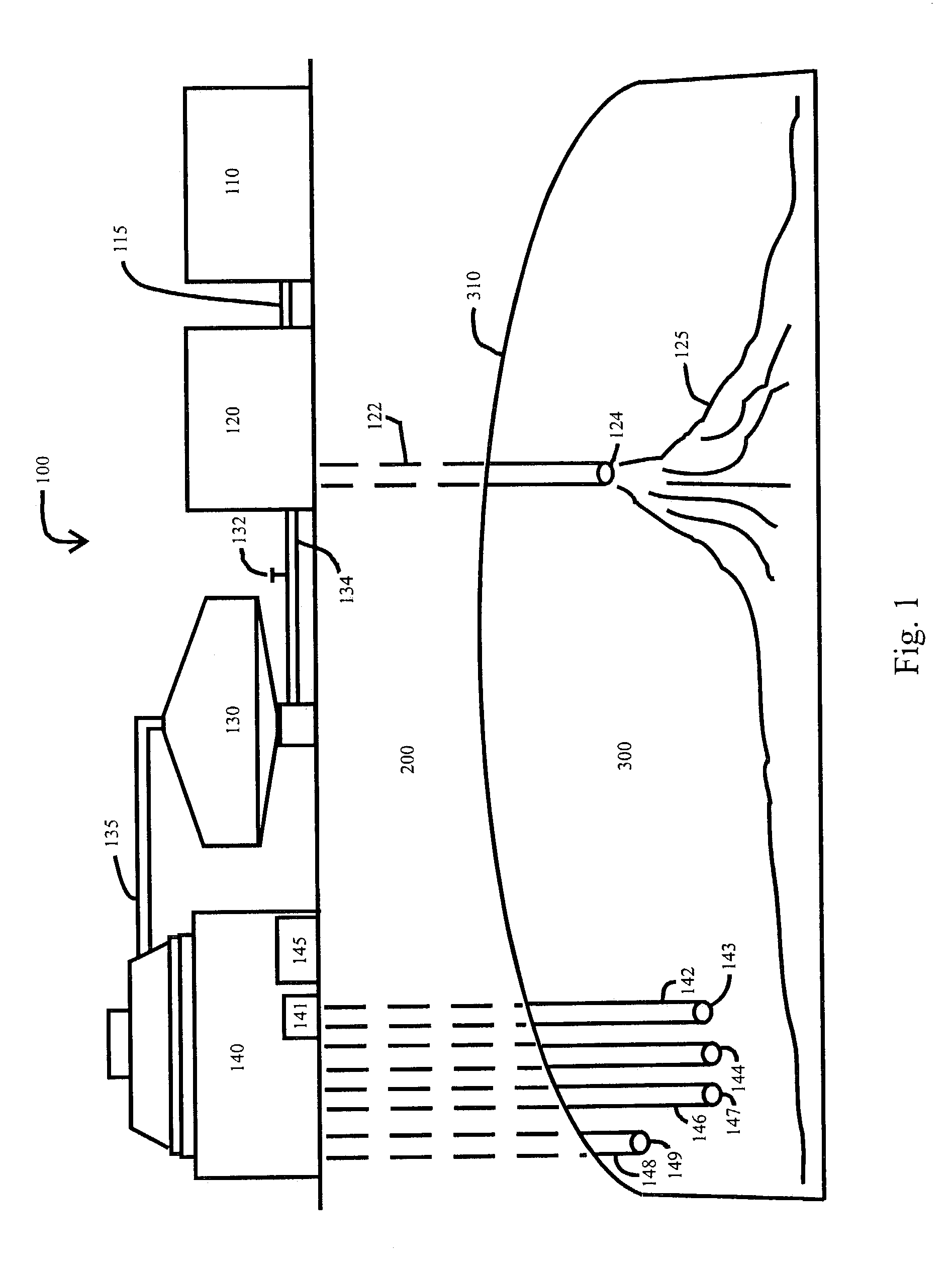

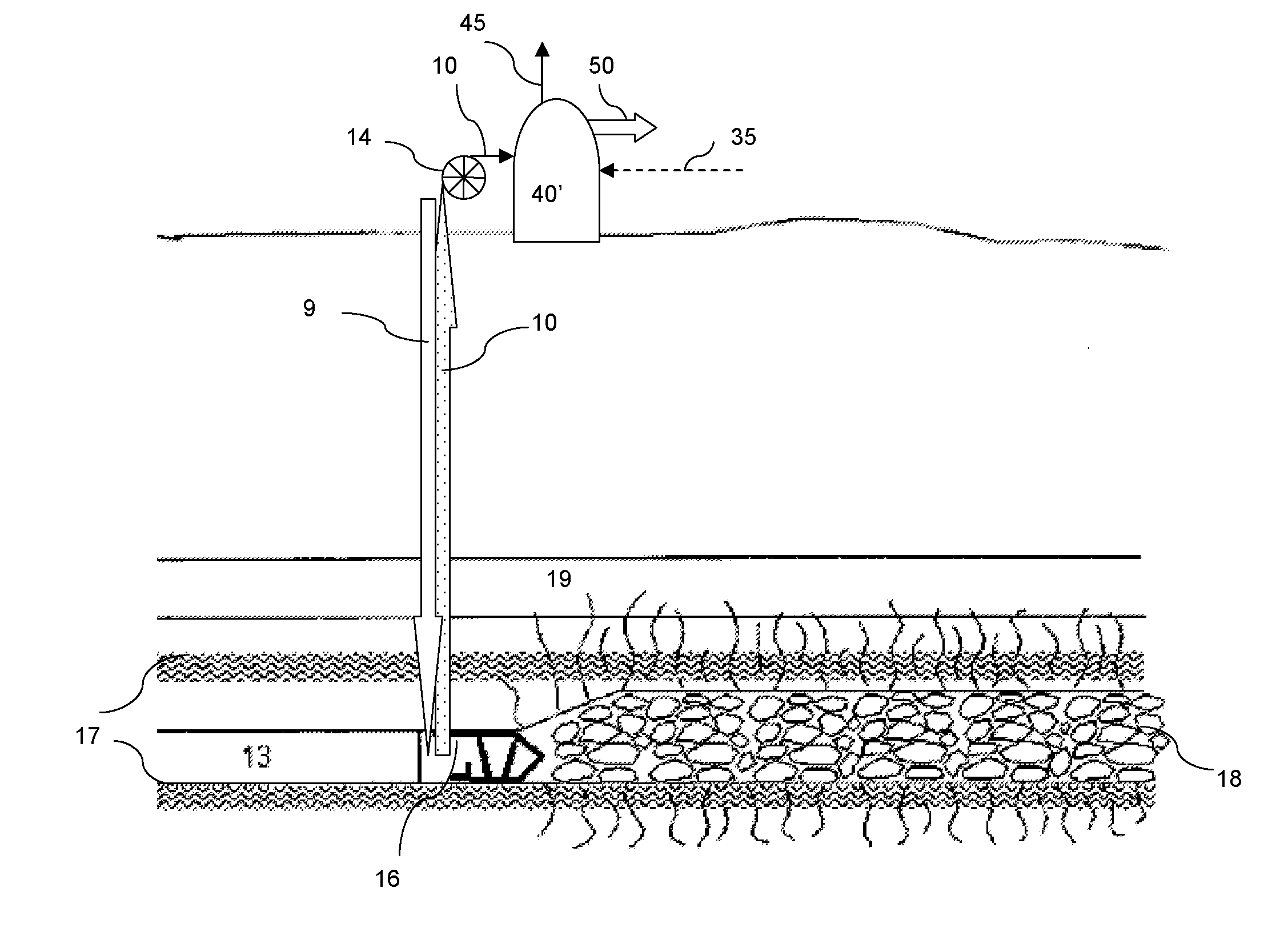

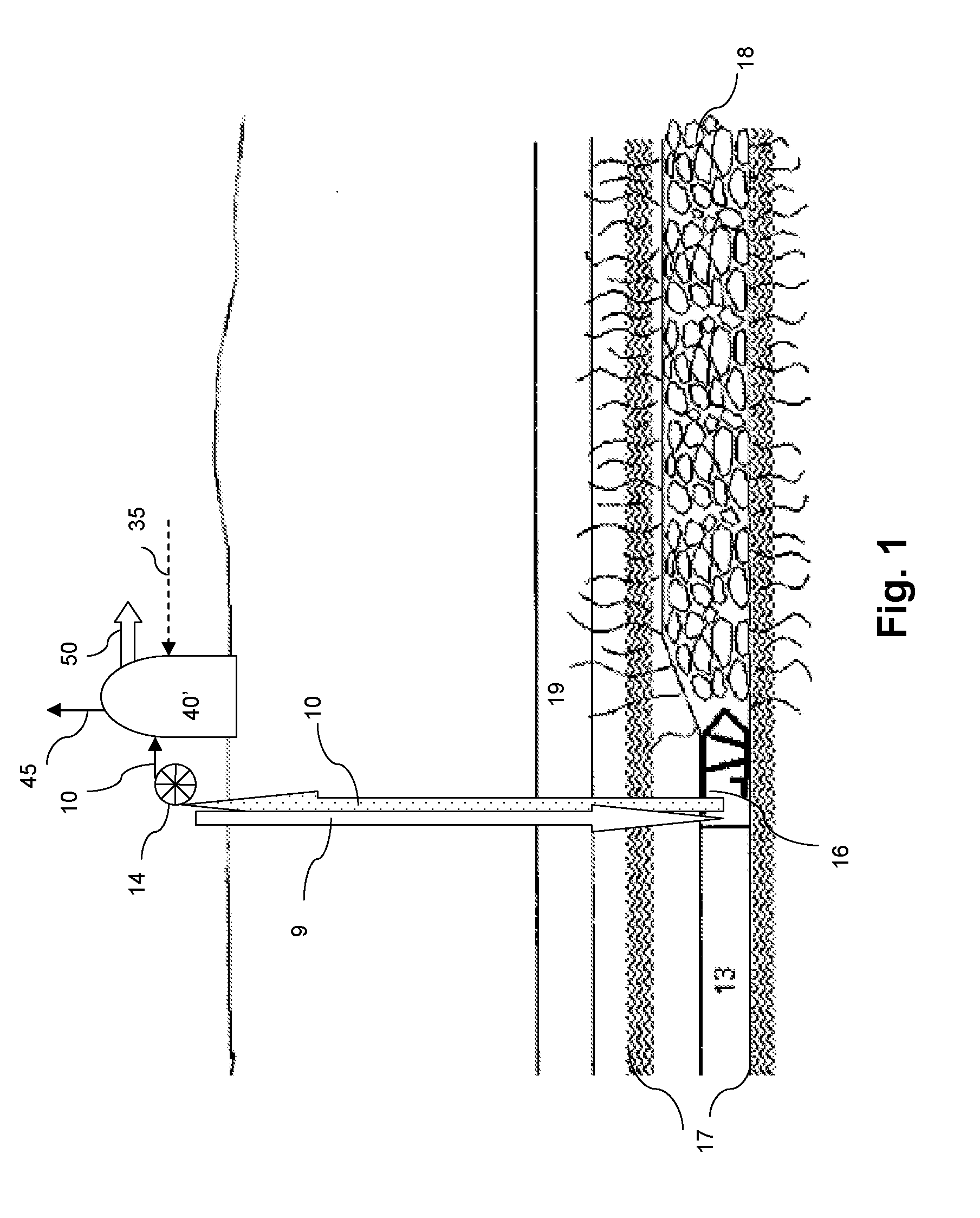

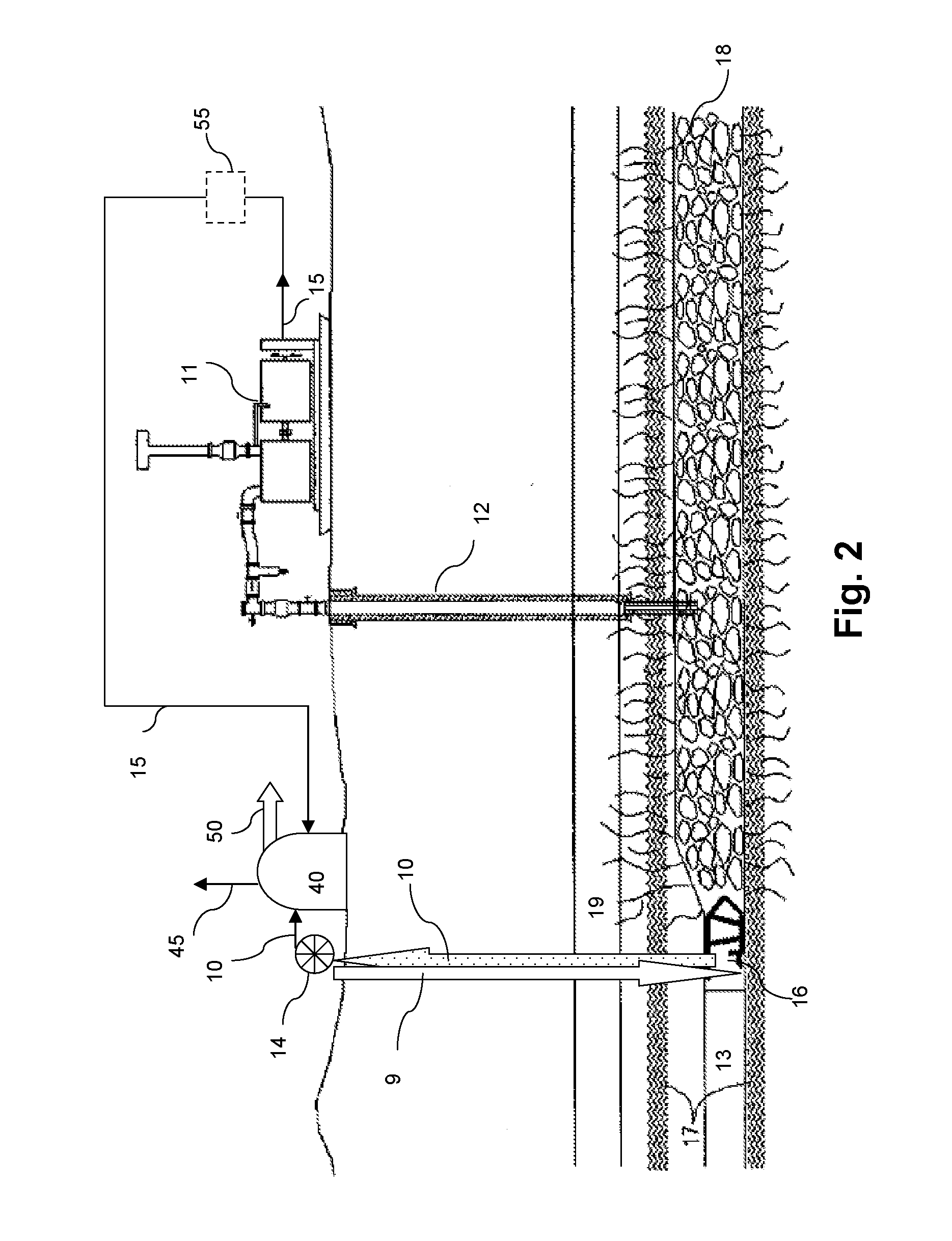

Subterranean waste disposal process and system

InactiveUS7056062B2Safer and cheapEasy to adaptDrying using combination processesSolid waste disposalDiseaseSlurry

A method for using large chambers, located deep within the earth, for the disposal of processed waste is disclosed. In this context, waste includes solid waste from sewage, and other organic-waste materials from urban, agricultural or industrial sources. These wastes will be processed by mechanical pulverization and hydration to produce a slurry, which will be injected into the well's chamber. The anaerobic condition in the chamber will be conducive to the production of gases, especially methane which will be harvested as a source of industrial fuel. Hydrogen, ammonia and other gases will also be harvested. This system will alleviate the acute problem of disposal of wastes from urban agricultural and industrial sources. It will decrease pollution of the air with greenhouse gases and pollution of the land area water with organic wastes and also release of disease-causing pathogens. The system may be adapted to facilitate the disposal of nuclear wastes.

Owner:TAKEUCHI RICHARD T +1

Environment friendly composite material for controlling loss of nitrogen fertilizer and applications

This invention discloses a method for preparing environmentally friendly composite for controlling nitrogen fertilizer loss. The method comprises: (1) mixing attapulgite, chitosan, polyacrylamide, etc.; (2) irradiating at 500-1300 Gy to form the composite. The composite can be mixed with nitrogen fertilizer and granulated to form controlled-release nitrogen fertilizer granules (with diameters of 1.5-3 mm). The composite can cooperatively adsorb and fix nitrogen and decrease fertilizer requirement, thus can prevent nitrogen entry into water and air and efficiently control water eutrophication and greenhouse gas N2O emission. The composite has such advantages as low cost and high efficiency in fixing nitrogen.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

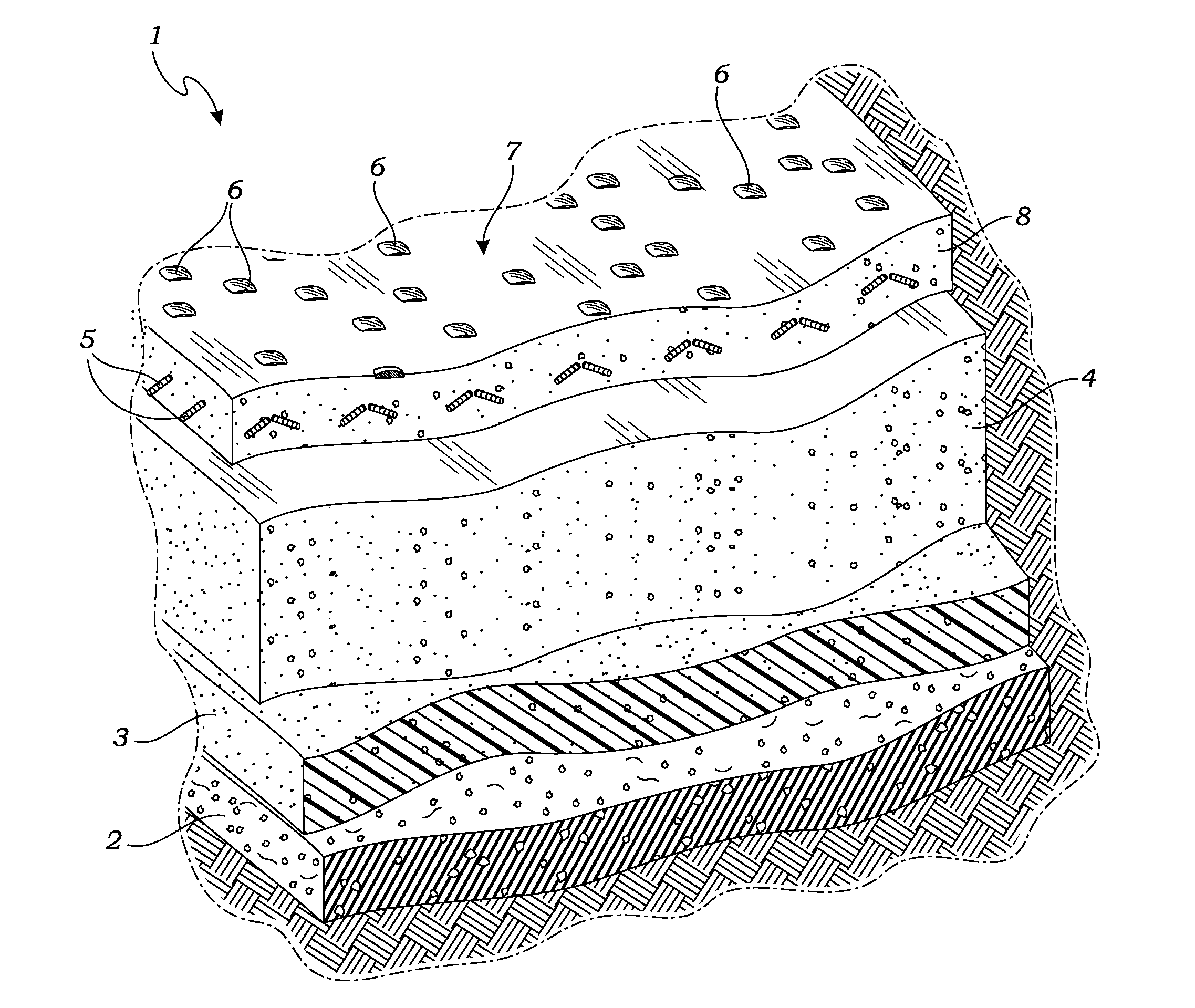

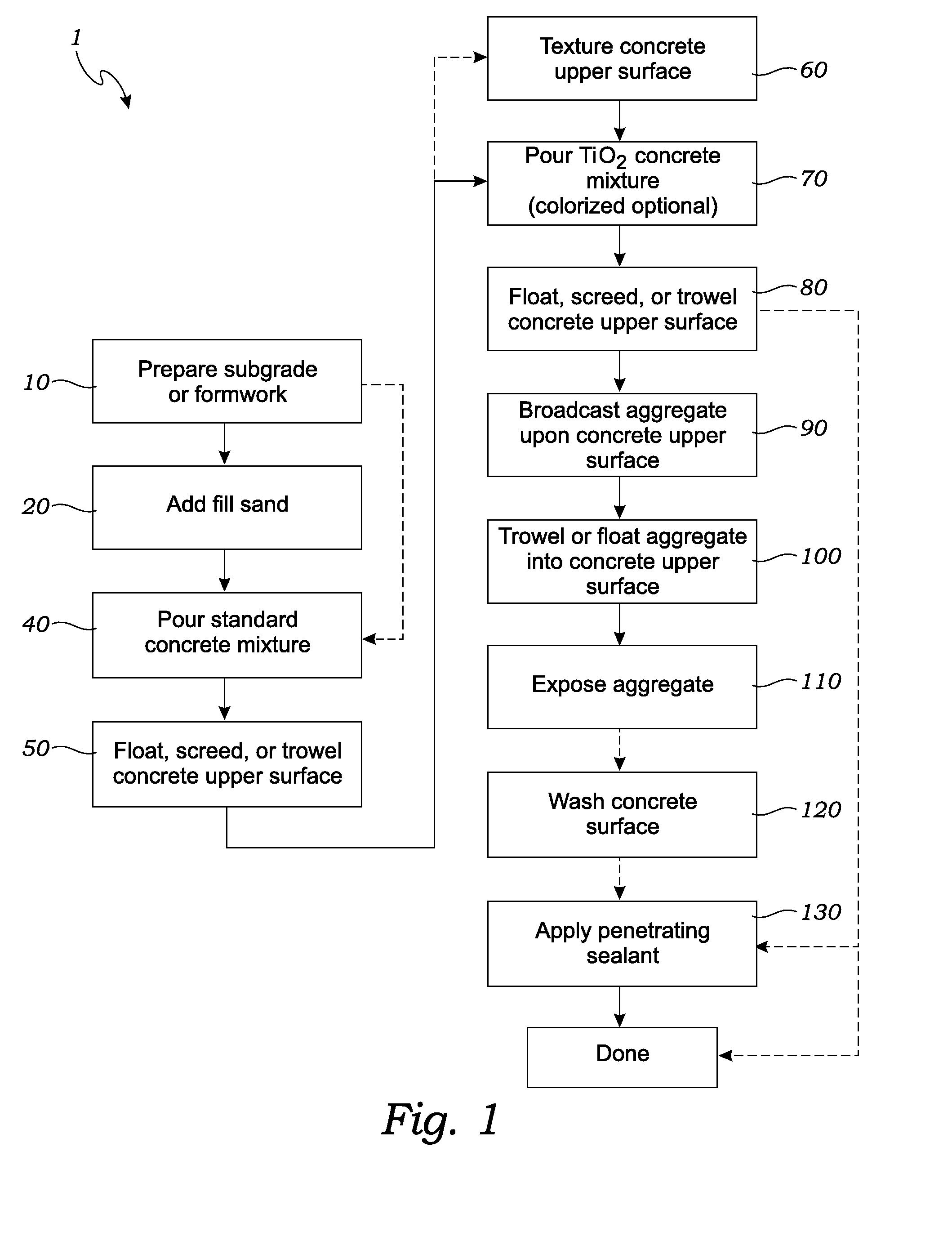

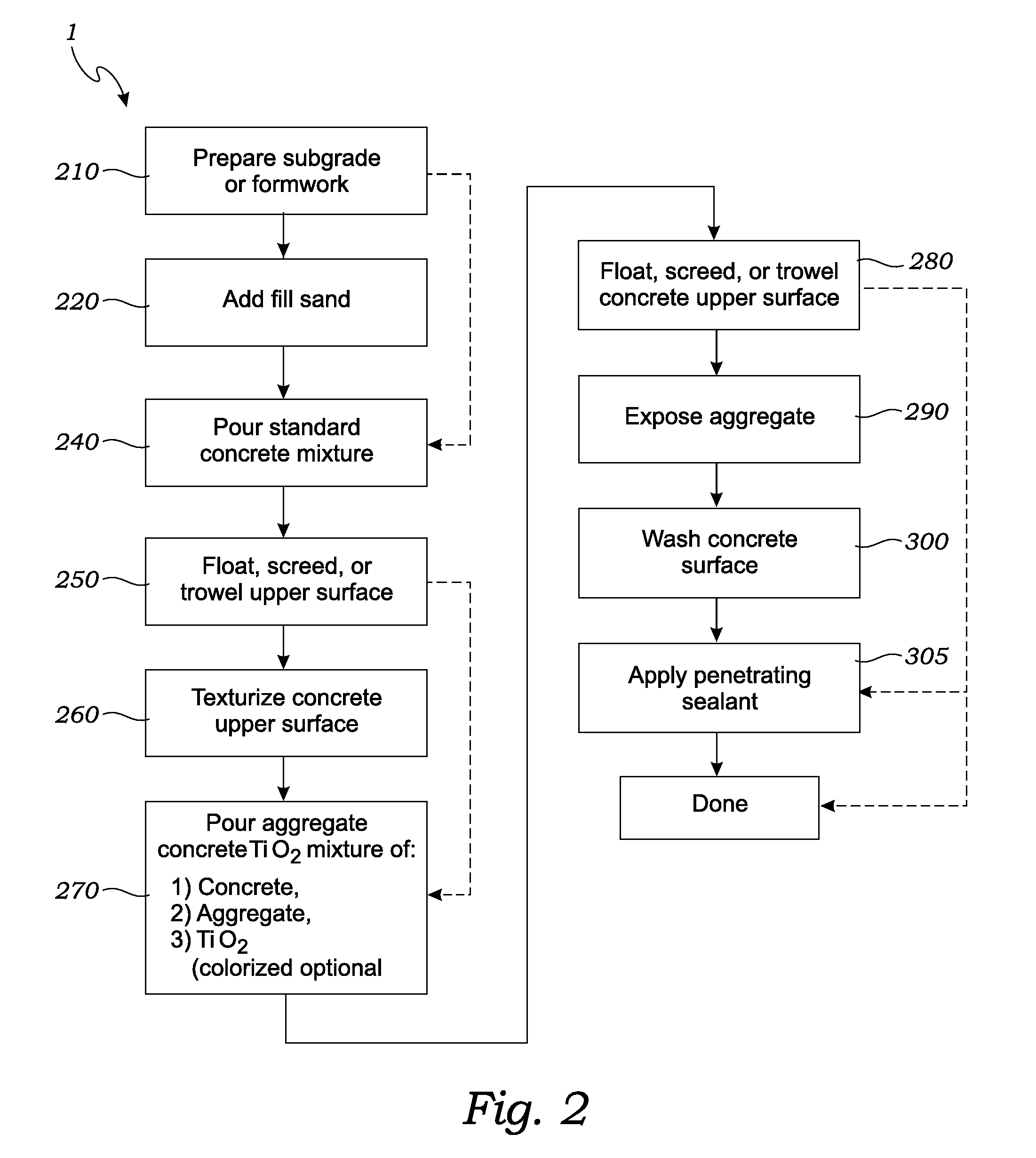

Multi-layered cement compositions containing photocatalyst particles and method for creating multi-layered cement compositions containing photocatalyst particles

InactiveUS20130266370A1Improve aestheticsIncreased photocatalytic propertyIn situ pavingsCovering/liningsGreenhouseGreenhouse gas reduction

A concrete slab construction is provided for use in both horizontal and vertical structures. The slab construction includes two layers. The first layer of concrete is a base layer comprised of traditional concrete materials. In addition, the concrete slab construction includes a second exterior layer of concrete which contains photocatalyst particles. Preferred photocatalytic materials include titanium dioxide in the anatase form. The concrete slab construction provides for reduction of green house gases and reduction in organic stains.

Owner:INTECRETE

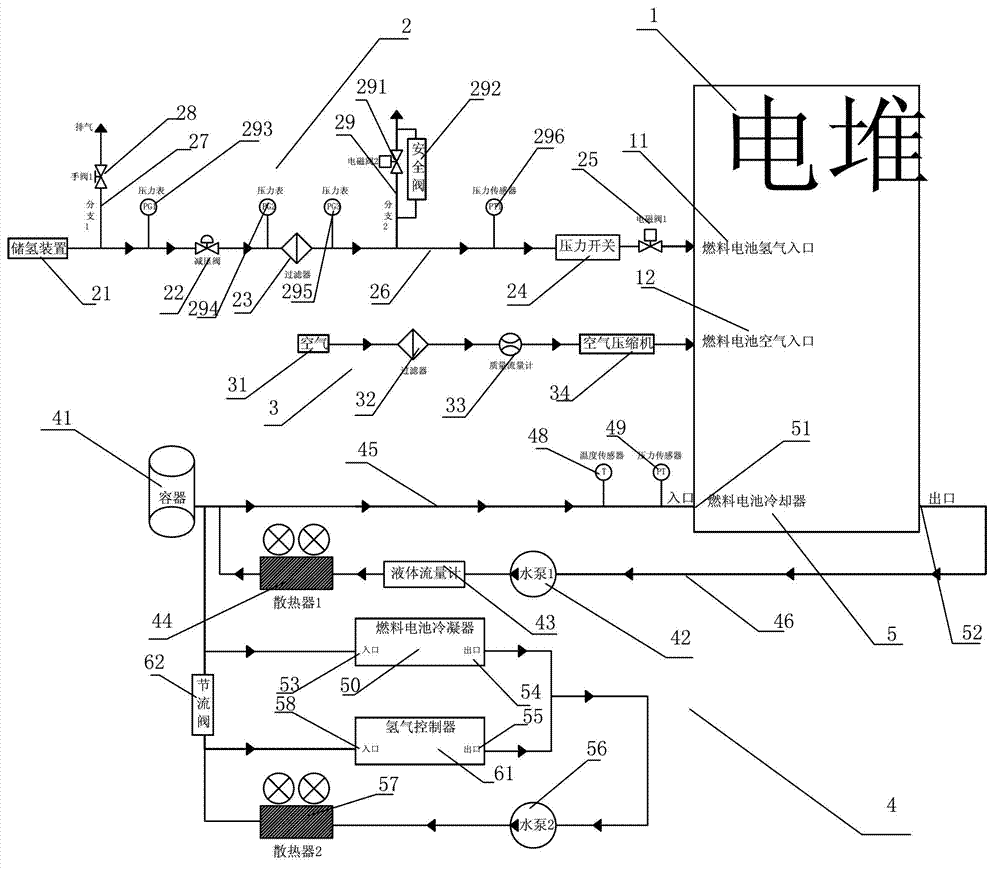

Locomotive traction power system based on fuel cell

InactiveCN103192730AAchieve integrationControl speedFuel cell auxillariesElectric propulsionSolenoid valveHydrogen fuel cell

The invention discloses a locomotive traction power system based on a fuel cell. A fuel hydrogen supply module comprises a hydrogen storage device, a pressure relief valve, a first filter, a pressure switch and a first electromagnetic valve, wherein the hydrogen storage device is communicated with a fuel cell hydrogen inlet through a hydrogen supply pipe; the pressure relief valve, the first filter, the pressure switch and the first electromagnetic valve are sequentially arranged on the hydrogen supply pipe; and hydrogen in the hydrogen storage device passes through the pressure relief valve, the first filter, the pressure switch and the first electromagnetic valve respectively and enters an electric pile. The locomotive traction power system based on the fuel cell has the advantages as follows: the total output power of the locomotive traction power system can be changed in real time by regulating air supply flow so as to regulate the rotation speed of a traction motor and control the speed of a locomotive, as a result, integration of a fuel cell and a power system and highly-automatic operation can be achieved; and through application of the hydrogen fuel cell to the locomotive traction power system, the total greenhouse gas emission can be reduced, the pollution to surroundings of a transport route can be reduced, and dependence of railway transport on oil fuel can be reduced.

Owner:NINGBO BATE TECH

Use of ventilation air methane exhausted during mining of non-combustible ore in a surface appliance

ActiveUS20120264068A1Reducing green house emissionUsed economicallyUnderground miningLiquid carbonaceous fuelsThermal energyCarbon credit

Utilization of mine methane produced by mining a non-combustible ore, such as trona, as an energy source for heat, steam, and / or power generation. Such utilization is beneficial for a surface appliance which is close to surface outlet(s) of mine methane recovery system(s). A method for reducing greenhouse gas emissions generated during mining of a non-combustible ore uses the combustion of co-produced mine methane. The mine methane is recovered in a mine ventilation air exhaust with very low methane content and may be additionally recovered in a drainage gas, such as gob gas, with much higher methane content. The surface appliance may be selected from the group consisting of calciner, dryer, boiler, kiln, furnace, engine, turbine, power generation unit, co-generation unit, and any combinations thereof. Benefits may include reduction in energy purchases, reduction in greenhouse emissions, and / or gain through sale of carbon credits to the carbon market by registering carbon reductions.

Owner:SOLVAY CHEM INC

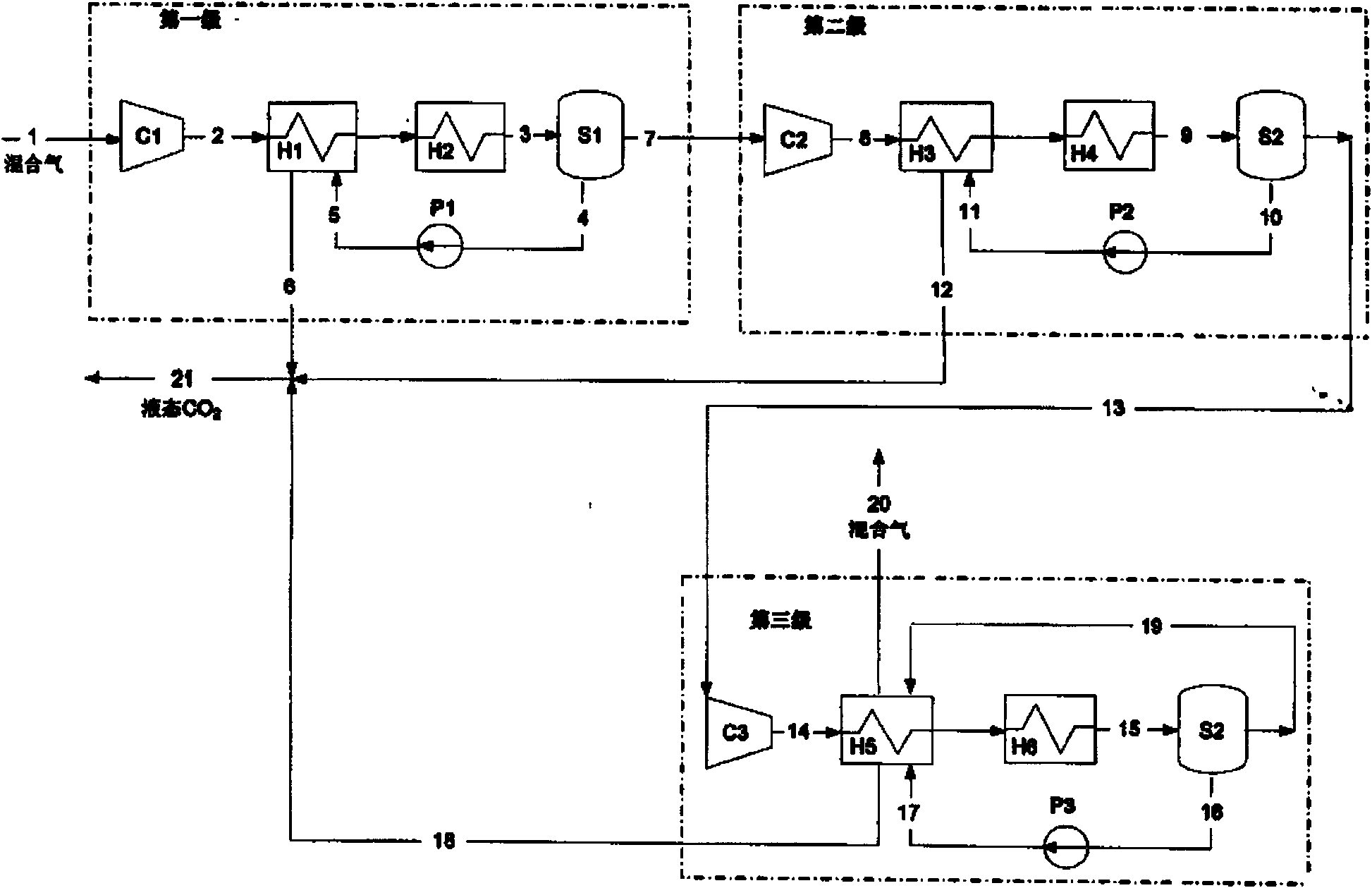

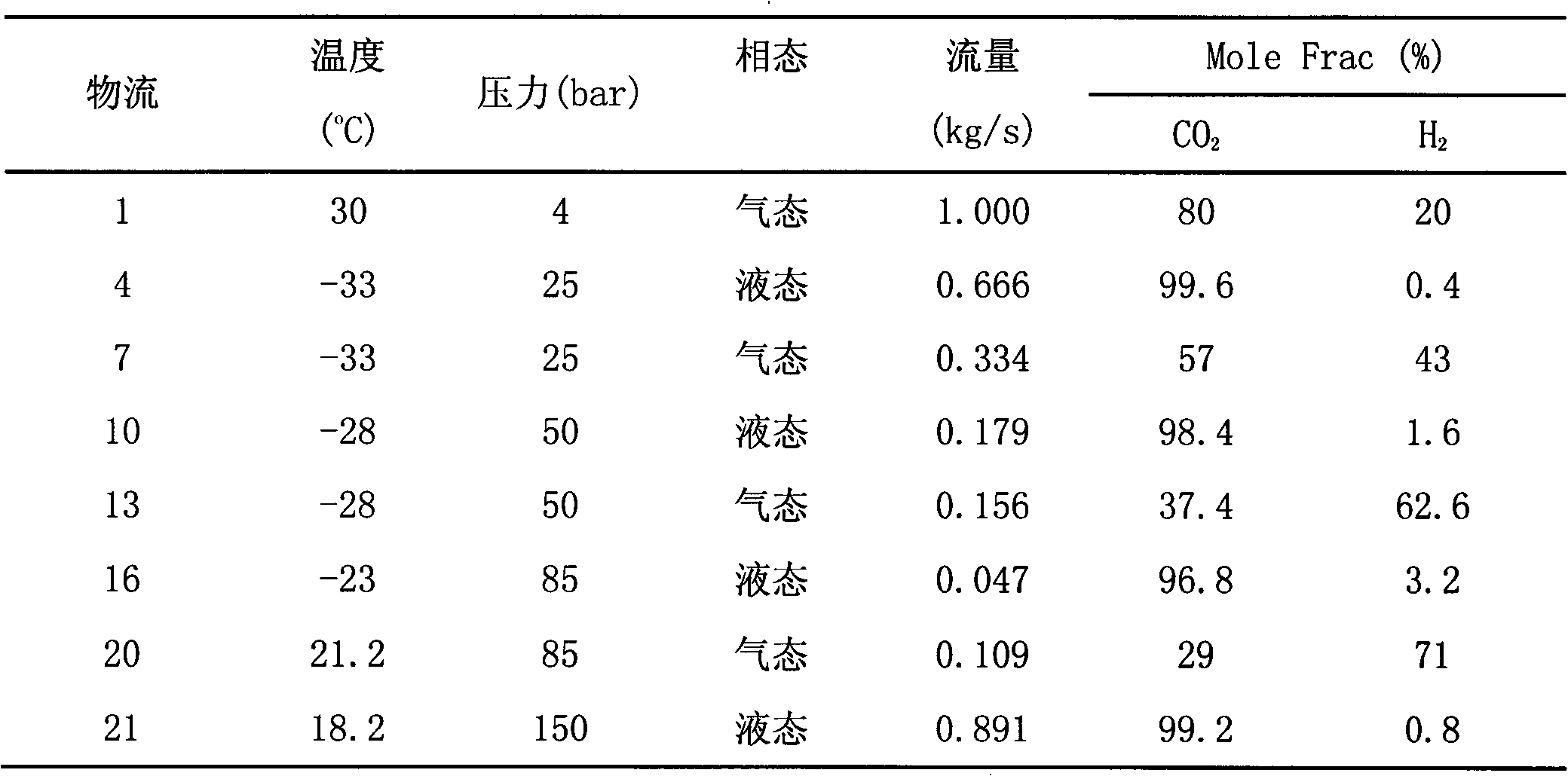

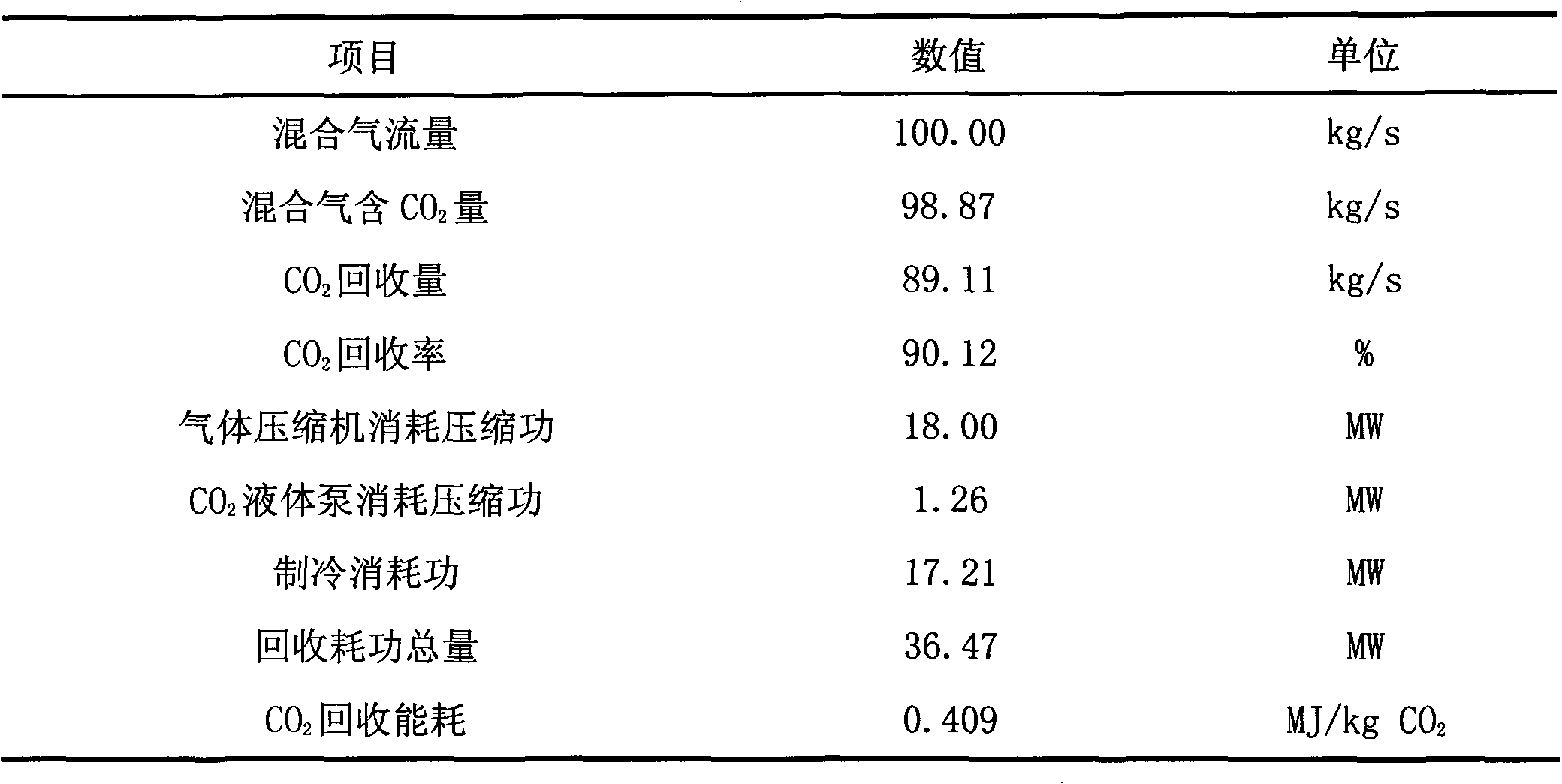

CO2 separation and compression integrated method

InactiveCN101666573AReduction of recycling energy consumptionImprove securitySolidificationLiquefactionCondensation temperatureProduct gas

The invention discloses a CO2 separation and compression integrated method which belongs to the technical field of gas preparation and is used for separating CO2 from gases containing the CO2. The invention improves the phase-transition temperature of CO2 through combining multi-stage compression, multi-stage cooling and multi-stage separation and improving the pressure of gas mixture, ensures a certain separation ratio by adopting a multi-stage separation and multi-stage compression way, and separates most of CO2 in a liquid form from the gas mixture under relatively higher condensing temperature, thereby improving the low-temperature condensing separation method of the CO2, and greatly lowering the energy consumption of recovering the CO2; meanwhile, the whole process does not adopt a chemical solvent, therefore, the lost of equipment is low, the safety is high, and the operation and maintenance cost is greatly lowered. The invention can be widely applied to separate the CO2 from thegas mixture containing the CO2, can produce pure-CO2 products and reduce the emission of greenhouse gases, thereby protecting the human habitat.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

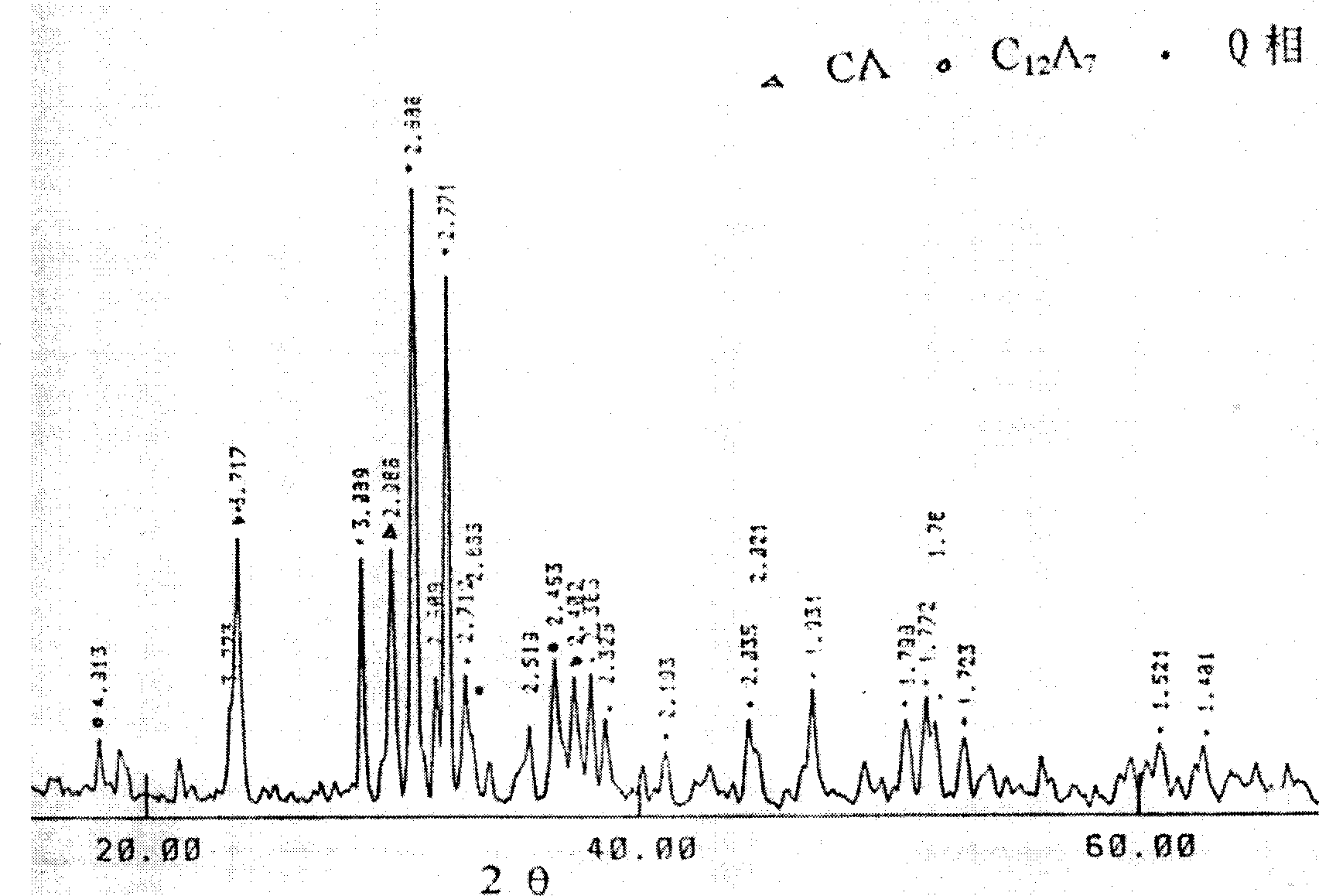

Aluminate cement material of containing mineral in Q phase

The invention provides an aluminate cement material containing. Q phase mineral that weight percenge is 40-80. The invention cement material has advantages of excellent functin of early strength and quick hardening, low firing temp., chalk containing magnesium-silicon and low-grade bauxite can be used as raw material to produce the cement material with high aluminium and low calcium.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com