Efficient energy-saving steam cabinet

A high-efficiency energy-saving and steaming cabinet technology, applied in the field of steaming cabinets, can solve the problems of low utilization rate of heat energy and waste, and achieve the effects of high energy utilization rate, obvious energy saving and emission reduction, and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

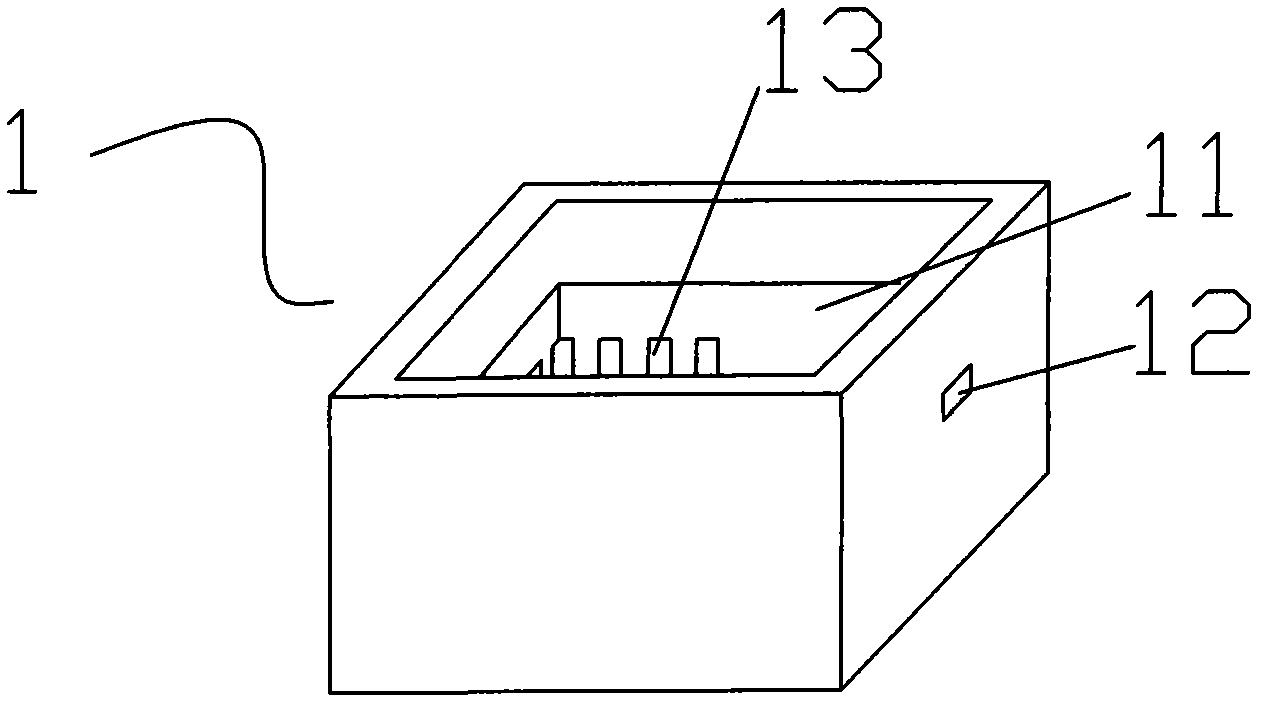

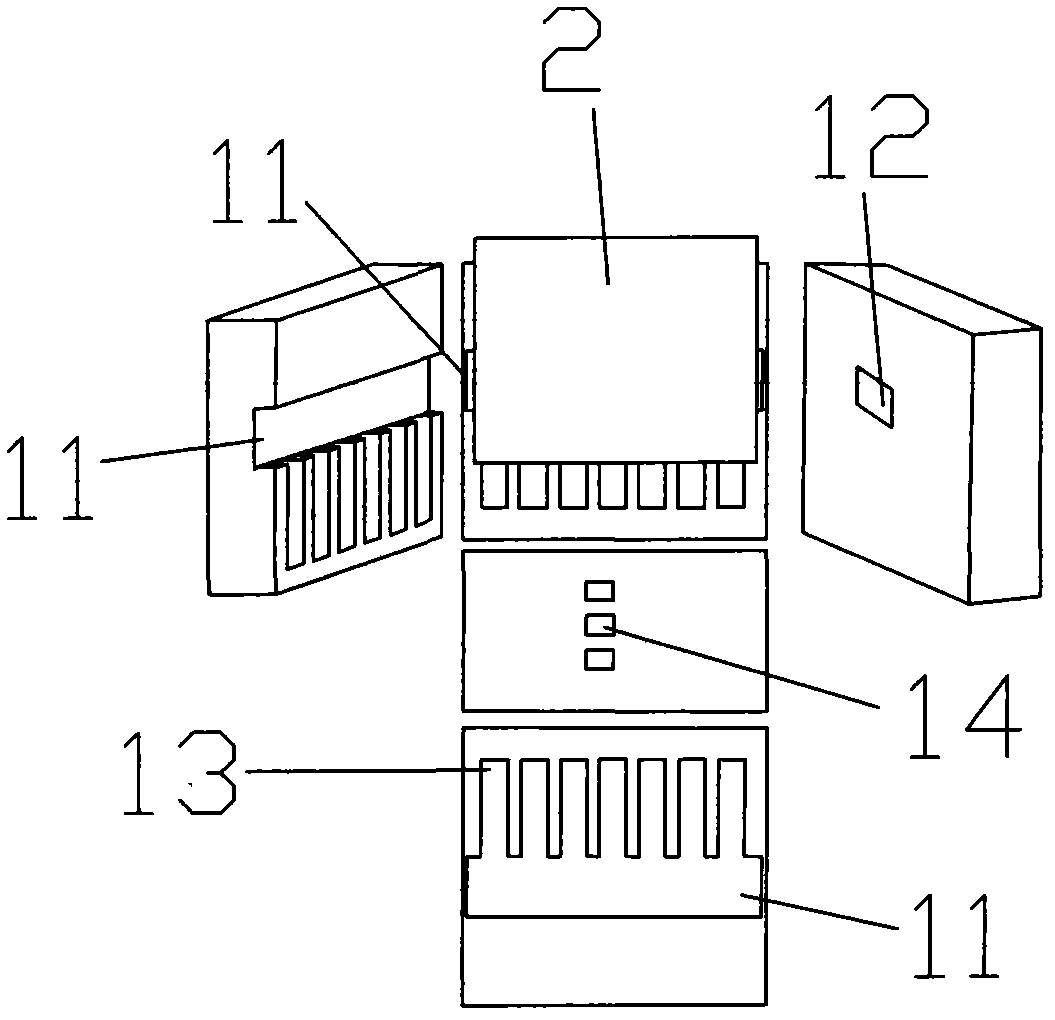

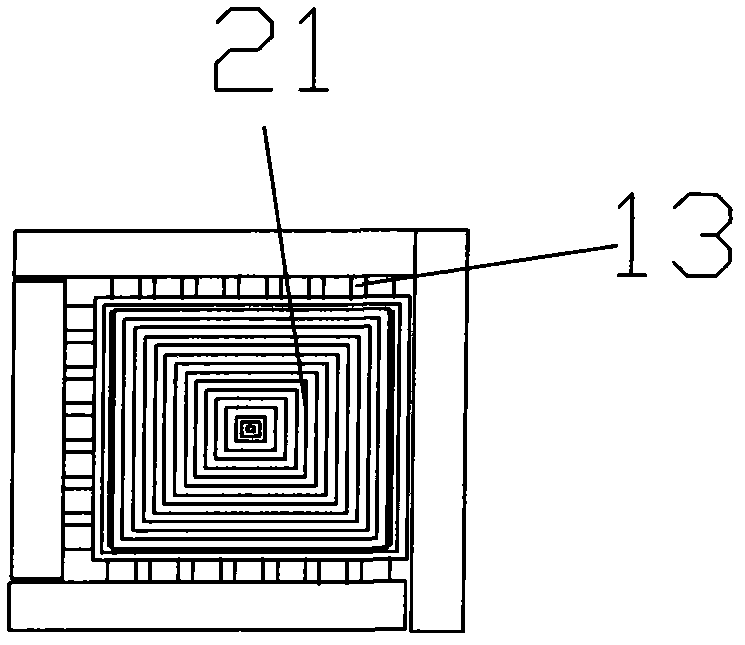

[0026] As shown in the figure, the high-efficiency energy-saving steaming cabinet includes a stove body, and a plurality of combustion heads 39 are installed in the stove body. A horizontal exhaust duct 11 is provided, a smoke exhaust port 12 is provided on the side wall of the combustion chamber 38, a combustion port 14 is provided at the bottom, and concave-convex patterns are provided on the bottom 21 of the steam generating pot of the combustion chamber to facilitate heat absorption. The inner wall of the combustion chamber 38 is provided with a number of vertical split heat conduction grooves 13 and horizontal flue exhaust ducts 11, so that the steam generating pot is suspended and built in the combustion chamber, and the heat of the burning flame is shunted to each heat conduction groove. The surrounding of the steam generating pot buffers the speed at which the heat is taken away with the combustion exhaust gas. At the same time, it also increases the heating area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com