Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

A technology of recycled asphalt and manufacturing method, applied in the direction of solid waste management, sustainable waste treatment, on-site coagulation pavement, etc., can solve the problems of greenhouse gas, wasted energy, oxygen aging, etc. The effect of construction temperature, reducing oxygen aging and improving the quality of waste asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Put 5 parts by weight of SBS, 4 parts by weight of EVA, 1 part by weight of stearic acid, 0.1 part by weight of pyrrole, and 3 parts by weight of microcrystalline wax into the mixer, and mix for about 30 minutes at 135 degrees Celsius to produce uniform fine particles Form plasticizing medium temperature regeneration modifier. Put 98.8 parts by weight of densely graded circulating waste asphalt concrete aggregates crushed into a maximum particle size of 19 mm and 1.2 parts by weight of the medium-temperature regeneration modifier particles produced above into a furnace at 135 degrees Celsius for 30 minutes for heating. Put the heated mixture into a mixer at 135 degrees Celsius and mix for 3 minutes to produce the medium temperature modified recycled asphalt mixture of the present invention.

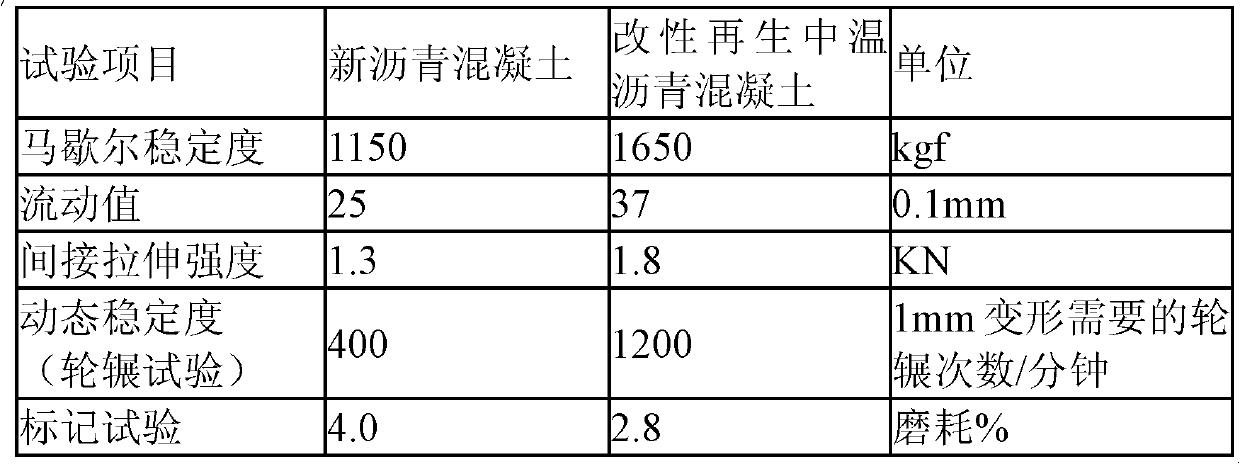

[0044] In order to grasp the quality characteristics of the medium-temperature modified recycled asphalt concrete mixture thus produced, the following tests were carried out. In a...

Embodiment 2

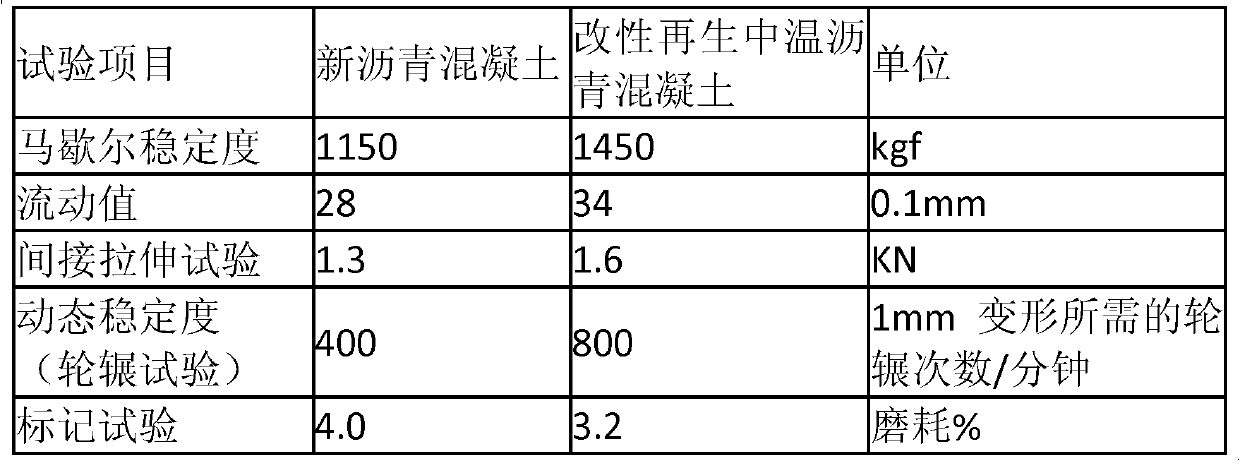

[0056] 100 parts by weight of waste asphalt concrete with a maximum particle size of 19mm and any gradation, 3 parts by weight of clay as a regeneration modifier, 1 part by weight of cement, and 0.2 parts by weight of P-phenylenediamine were put into a mixer at room temperature. , 8 parts by weight of latex solution containing 69% solid powder as a temperature-regulating additive, making it evenly mixed to make the normal temperature modified recycled asphalt mixture according to the present invention. According to the test method described in Example 1, test pieces were manufactured at room temperature from the mixture, and their physical properties were measured after hardening at room temperature for one day. The results are shown in Table 2.

[0057] 【Table 2】

[0058]

[0059] In the case of normal temperature mixing in Example 2, compared with the case of medium temperature mixing Example 1, the physical properties are slightly lowered, but the physical properties of ...

Embodiment 3

[0061] First, melt 100 parts by weight of waste asphalt concrete with a maximum particle size of 19mm and any gradation, and then let a mixer such as 90, and add 4 parts by weight of clay, 1 part by weight of cement and 0.1 part by weight of pyridine as regeneration modifiers , 4 parts by weight of ammonium bicarbonate as a temperature-regulating additive and mixed for about 3 minutes. Bubbles were generated during mixing and an increase in the volume of the bitumen was observed.

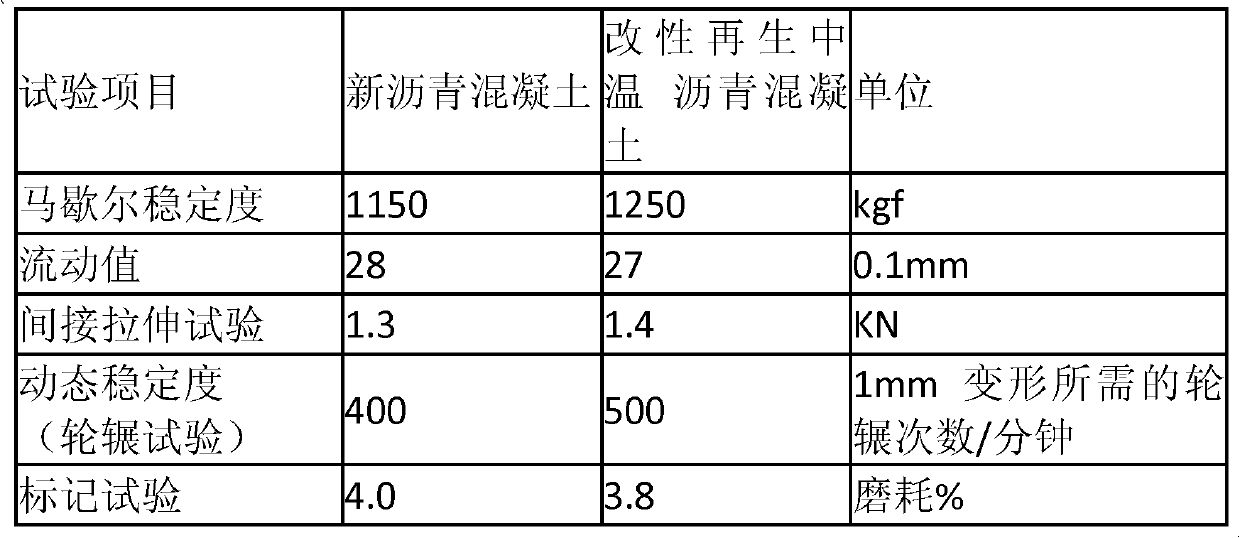

[0062] As described above, the modified medium temperature recycled asphalt mixture according to the present invention was produced. According to the test method described in Example 1, test pieces were made respectively in the half-medium temperature (90°C) and hardened, then their physical properties were measured, and the measurement results were shown in Table 3.

[0063] 【table 3】

[0064]

[0065]It can be seen that the semi-medium temperature mixture in Example 3 is better than the norma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com