Solid fuel chemical-looping gasification hydrogen production system and method

A solid fuel and hydrogen production system technology, applied in chemical instruments and methods, using solid contact hydrogen separation, inorganic chemistry, etc., to achieve the effect of increasing production and low-cost hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

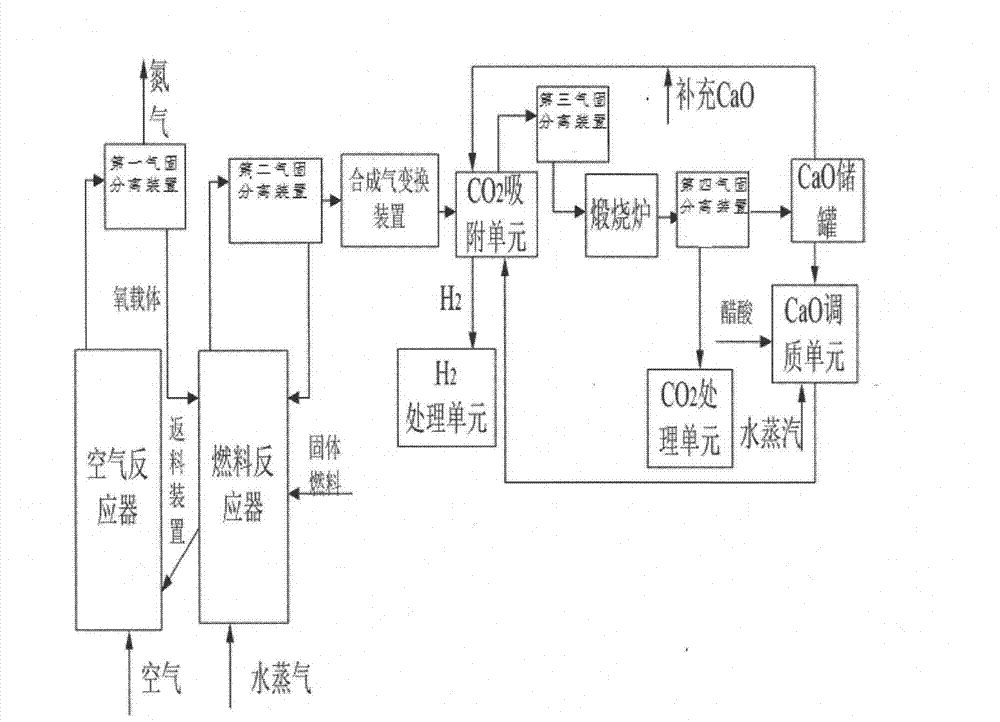

[0022] like figure 1 Shown is a schematic diagram of a solid fuel chemical looping gasification hydrogen production system. The solid fuel chemical looping gasification hydrogen production system consists of an air reactor, a first gas-solid separation device, a feeding device, a fuel reactor, a second gas-solid separation device, a syngas shift device, a CO 2 Adsorption unit, H 2 Processing unit, third gas-solid separation device, calciner, fourth gas-solid separation device, CO 2 It consists of a processing unit, a grinding machine, a CaO storage tank, a CaO conditioning unit and a conveying device.

[0023]The air reactor has an air inlet, the outlet of the air reactor is connected to the inlet of the first gas-solid separation device, the gas outlet (mainly nitrogen) of the first gas-solid separation device is connected to the atmosphere, and the solid outlet of the first gas-solid separation device is conveyed The device is connected to the fuel reactor, and the fuel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com