Multi-layered cement compositions containing photocatalyst particles and method for creating multi-layered cement compositions containing photocatalyst particles

a technology of photocatalyst particles and cement compositions, which is applied in the direction of covering/lining, roads, roads, etc., can solve the problems that cement with photocatalyst properties is not suitable for conventional structural concrete projects, and achieves enhanced organic stain removal, increased aesthetics and photocatalytic properties, and reduced greenhouse gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

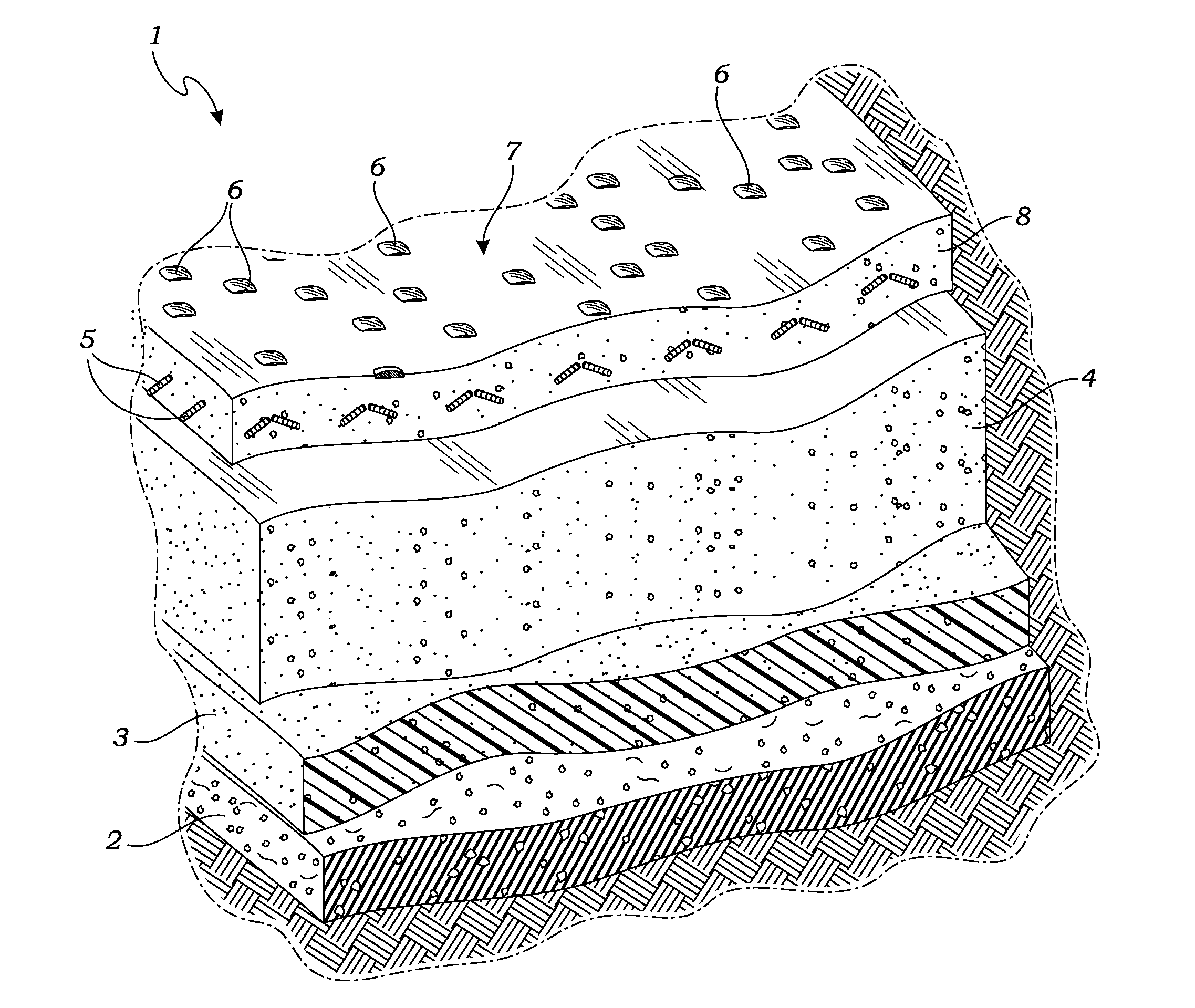

[0024]The present invention addresses the aforementioned disadvantages by providing an improved layered concrete slab, and by providing an improved method for preparing a layered concrete slab. In the most simple terms, the concrete construction includes a base layer of traditional concrete utilizing a traditional cement, and a second upper layer of concrete containing photocatalyst particles upon the first layer of concrete. Preferably, the base layer of traditional concrete is much thicker than the upper layer of concrete containing photocatalyst particles.

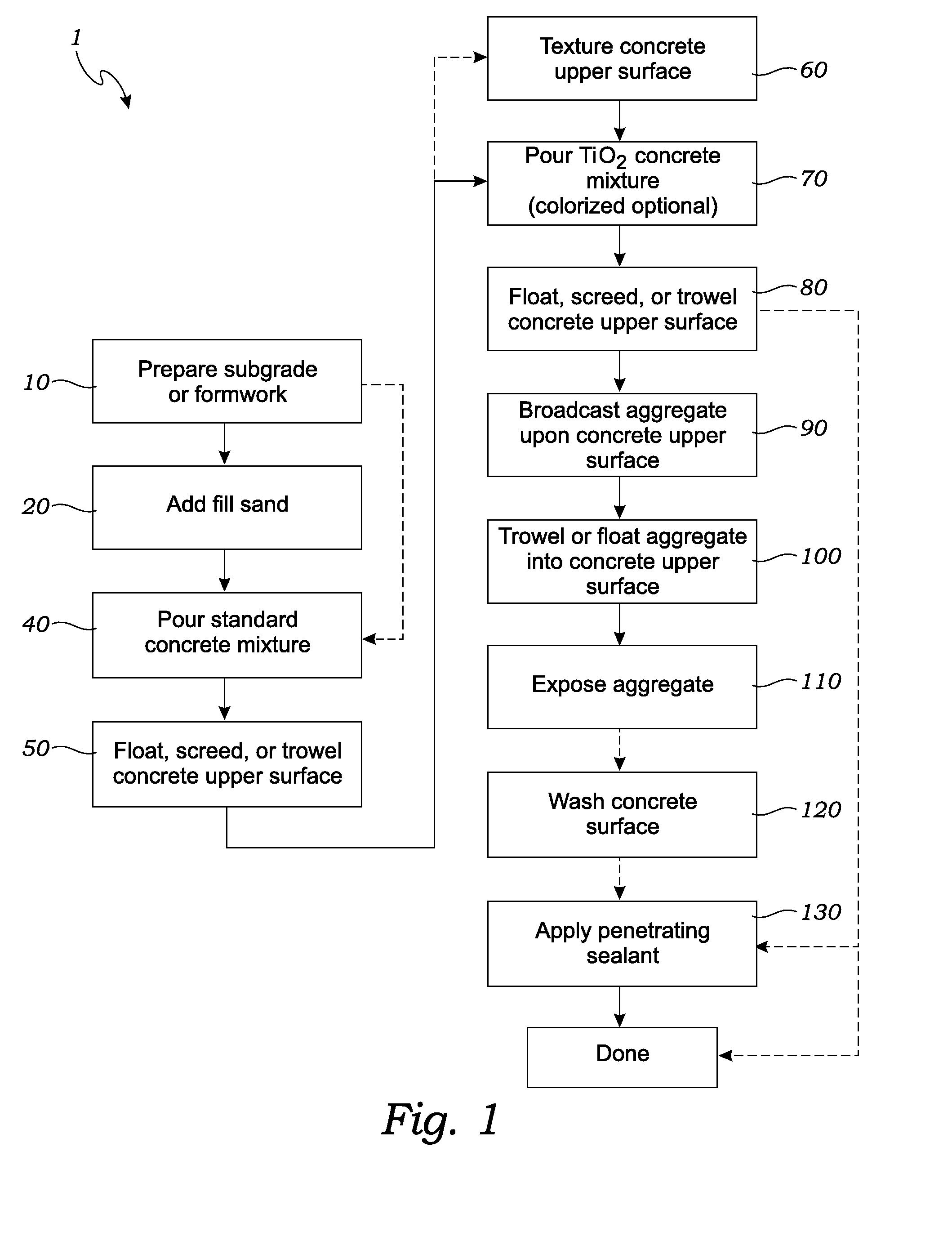

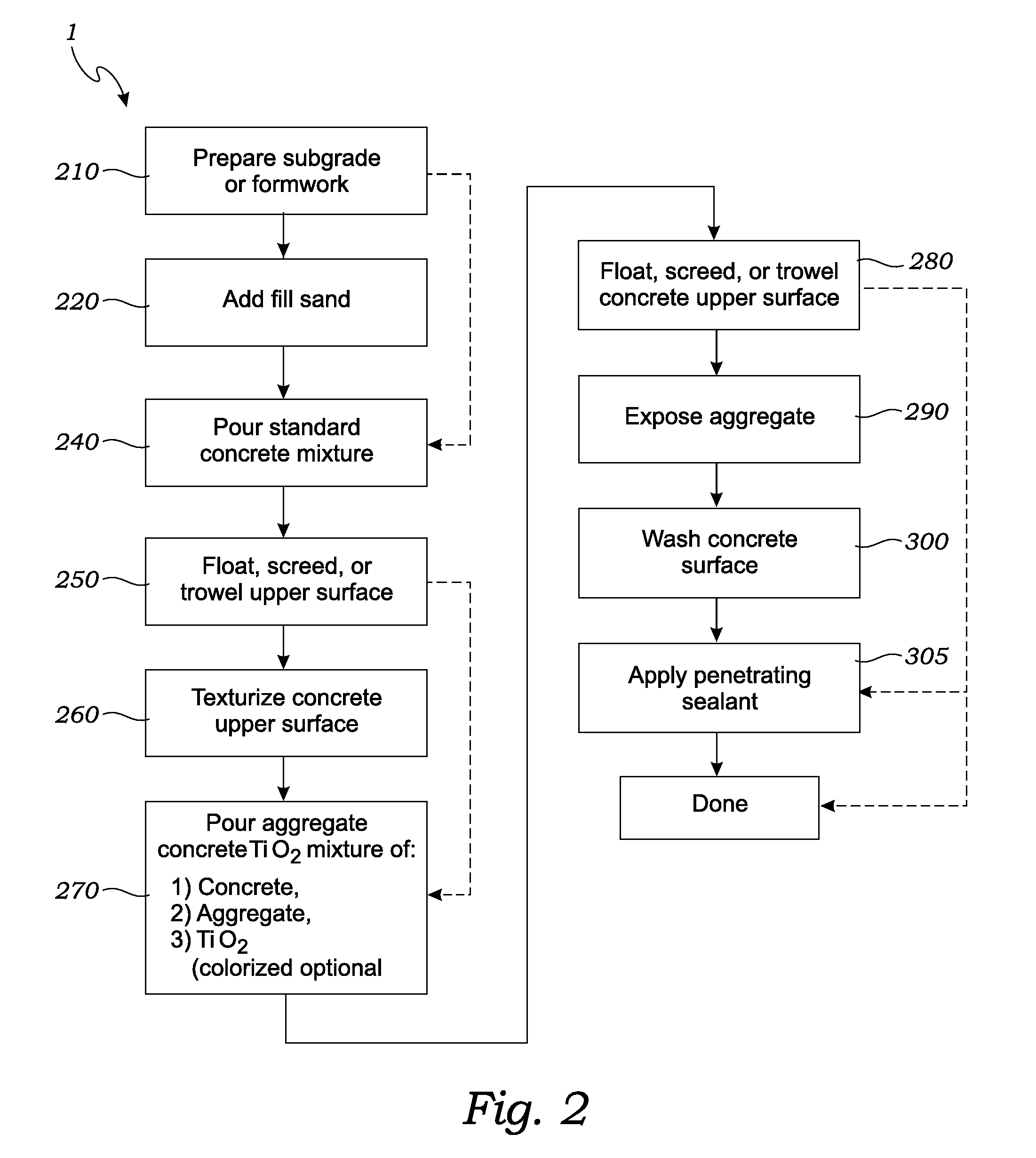

[0025]With reference to FIGS. 1 and 4, a first method of producing the two layer concrete construction of the present invention comprises the initial step 10 of preparing subgrade or formwork for concrete placement. It is envisioned that the present invention will most often require the preparation of the subgrade for creating substantially horizontal surfaces such as for walkways, driveways and the like. However, the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com