Patents

Literature

90results about How to "Save waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

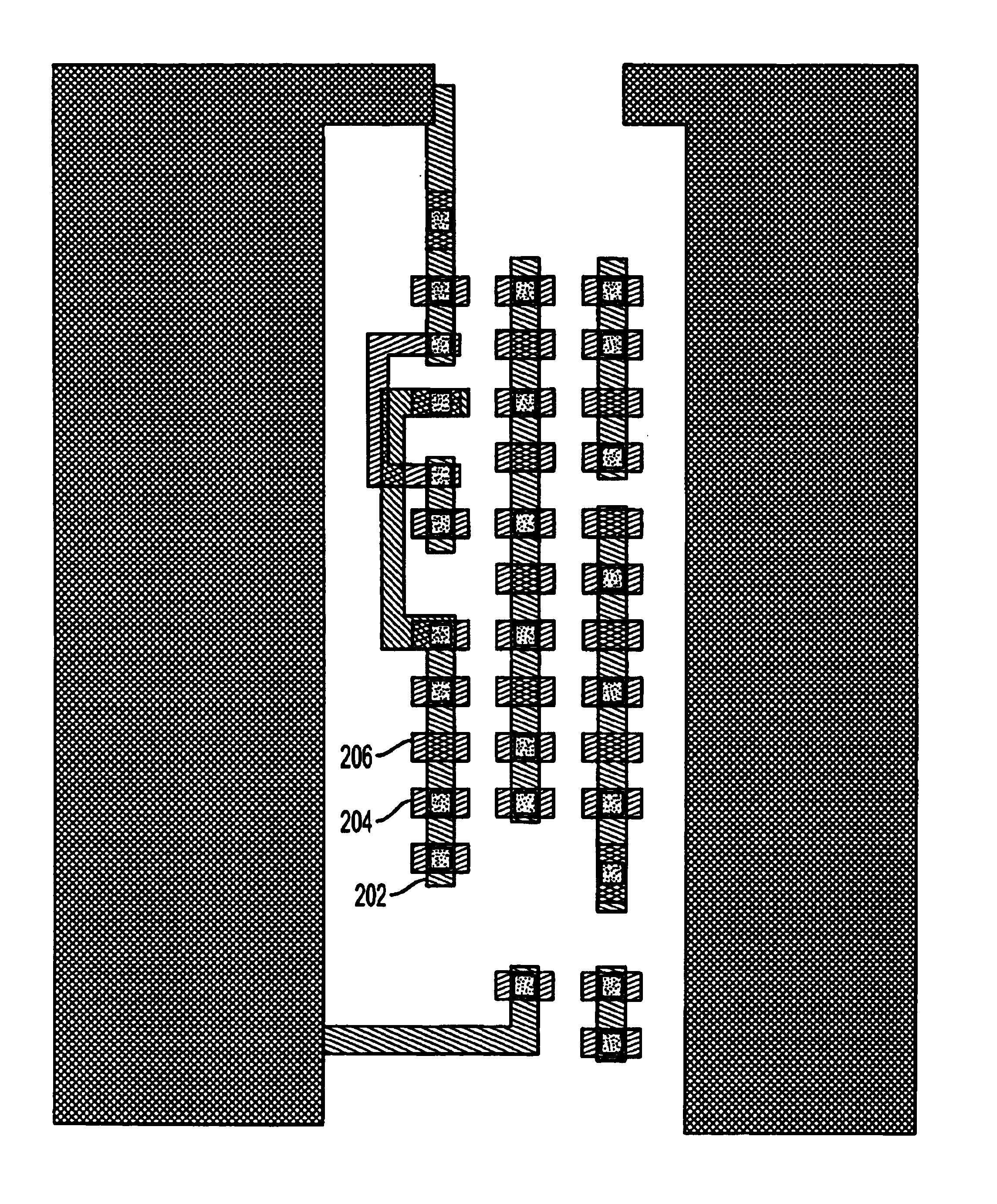

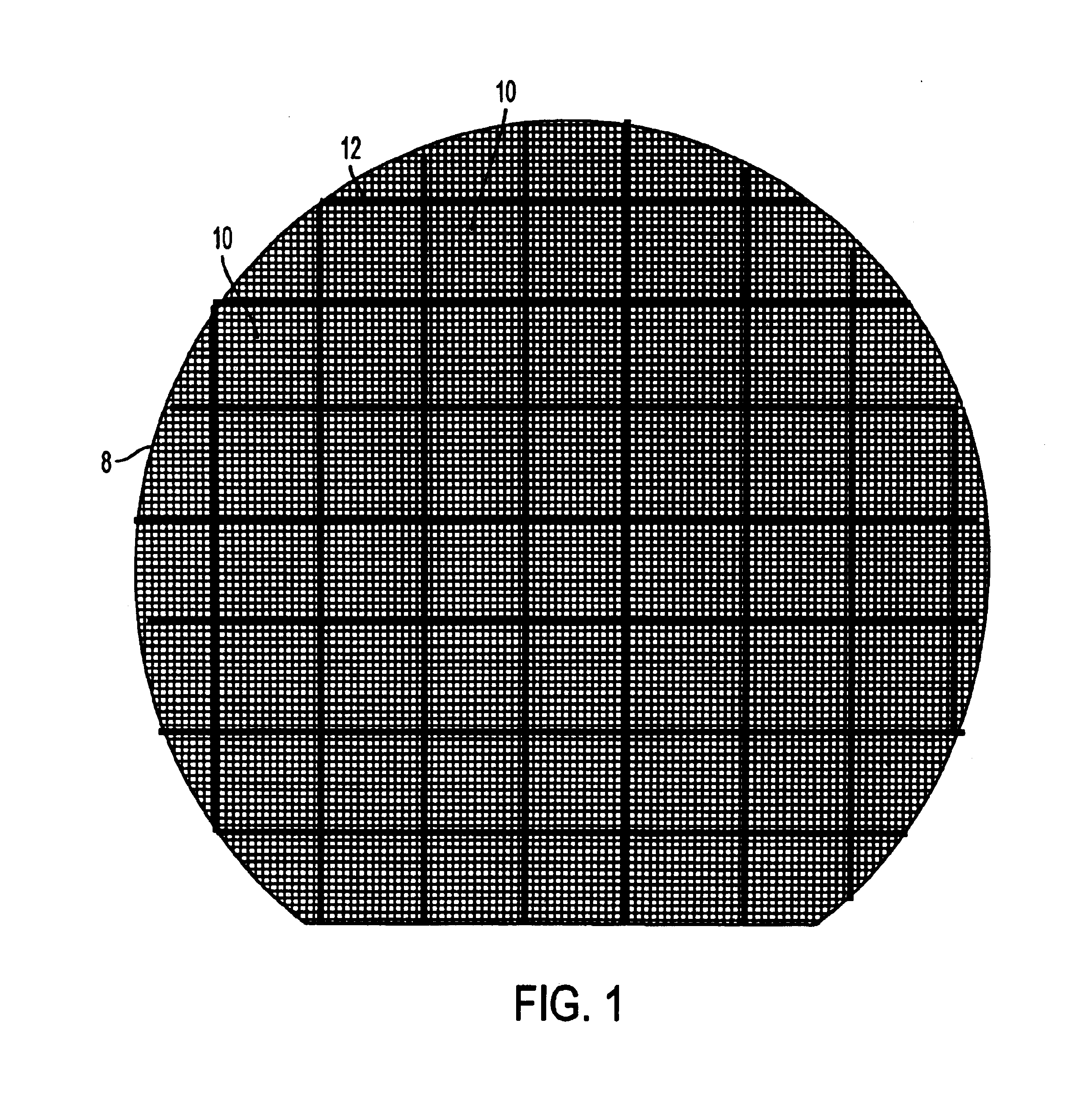

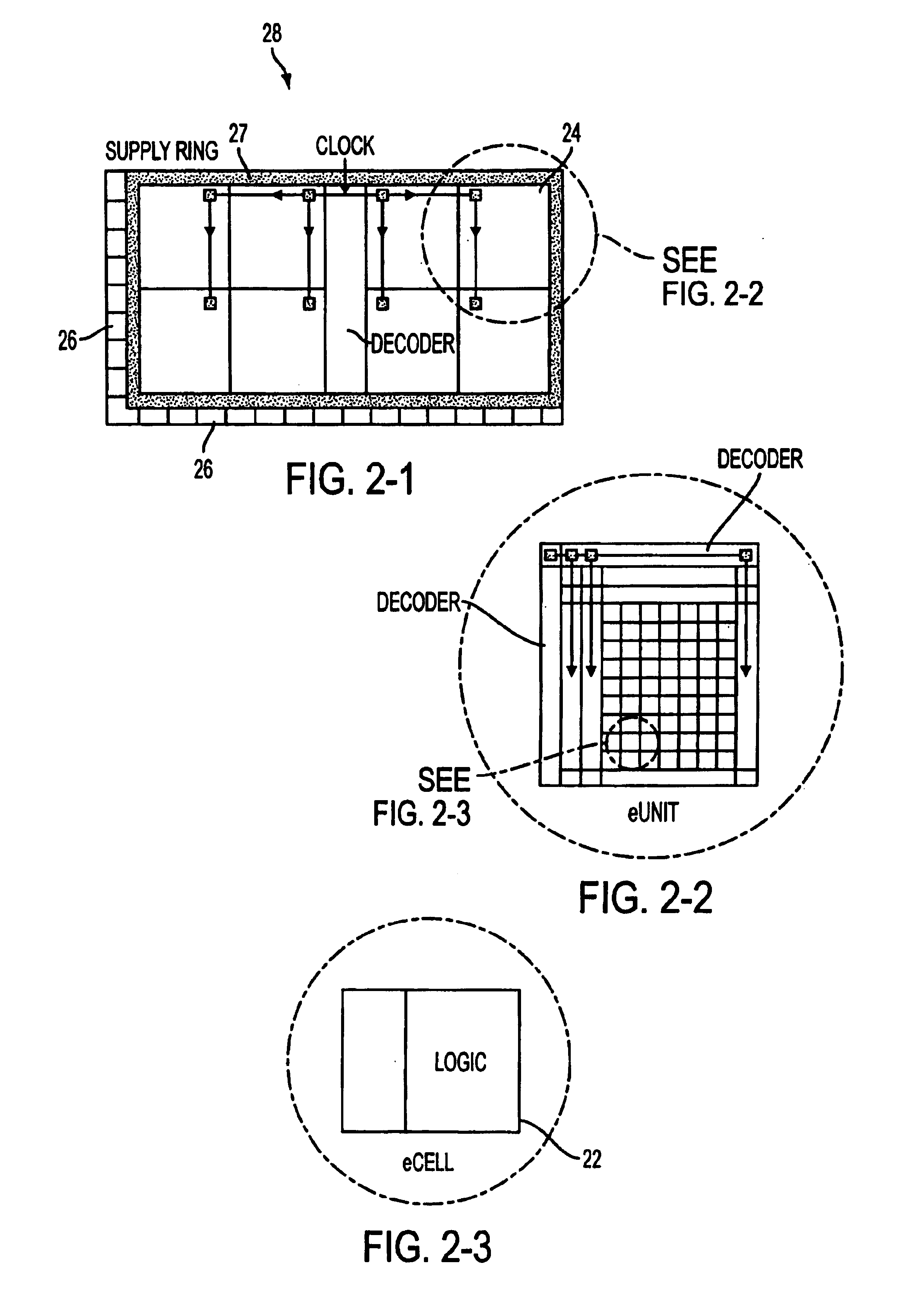

Semiconductor device having borderless logic array and flexible I/O

InactiveUS6953956B2Reduces high cost of manufacturingReduced flexibilitySemiconductor/solid-state device detailsSolid-state devicesRedistribution layerDevice material

Owner:INTEL CORP

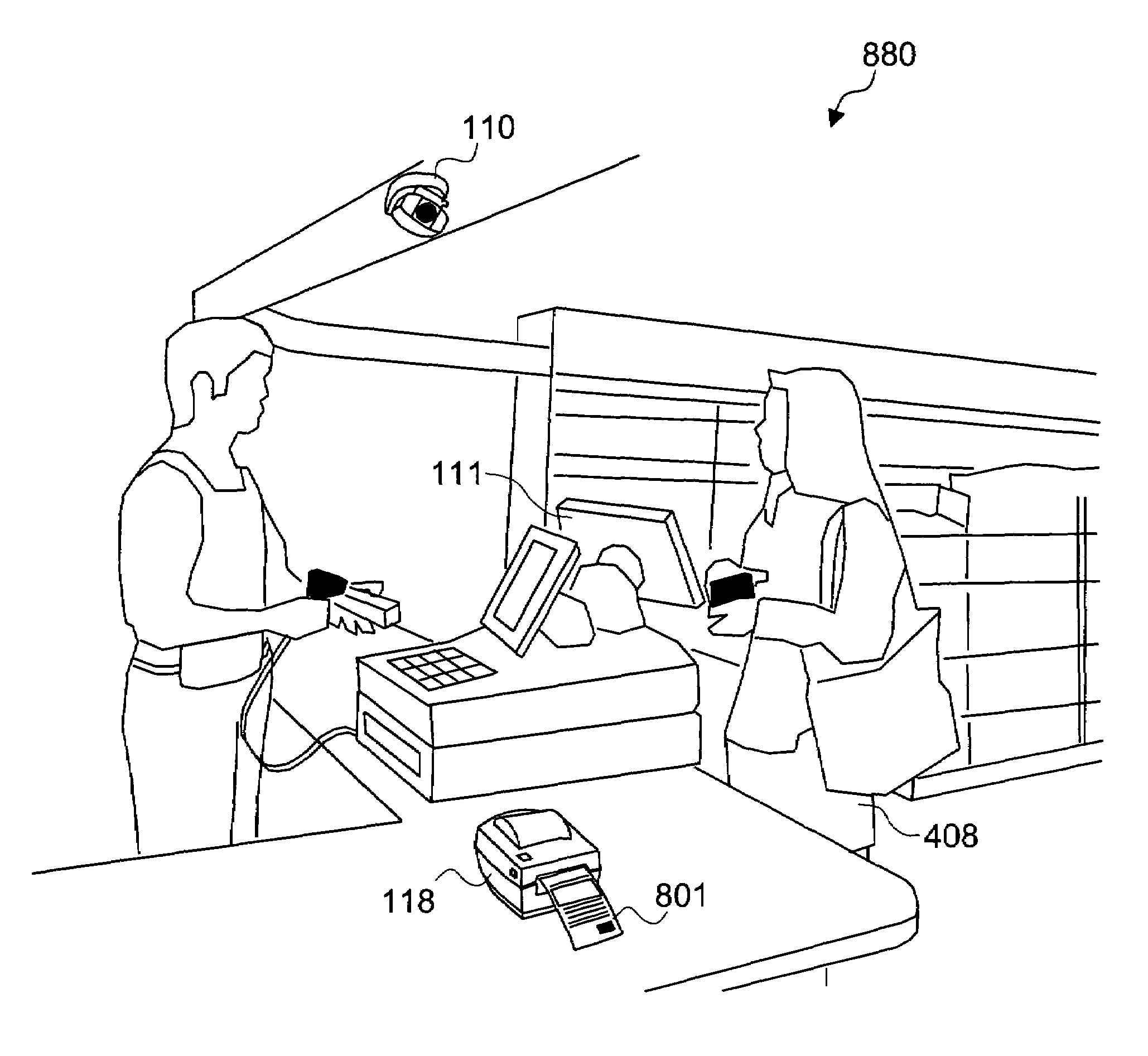

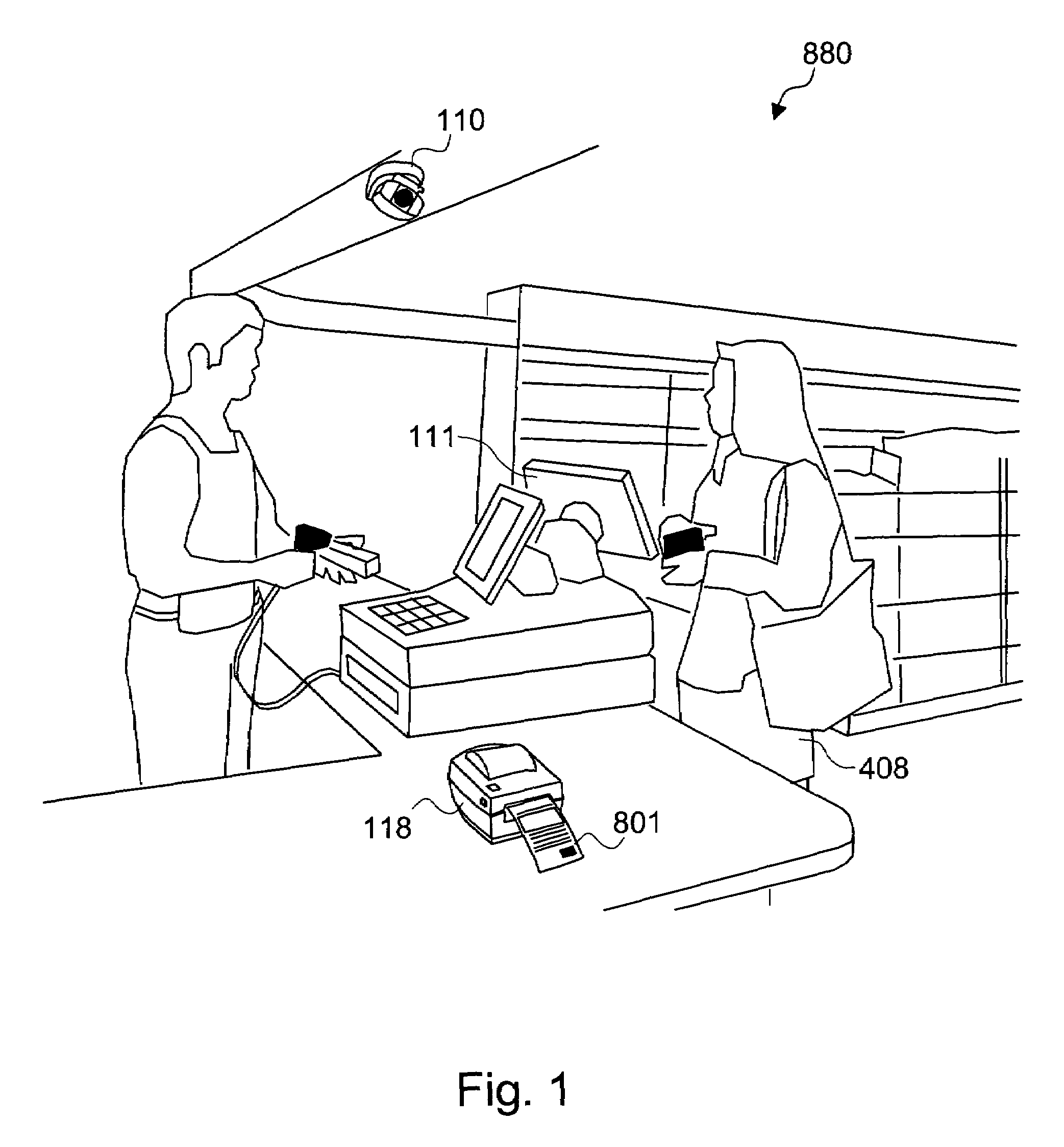

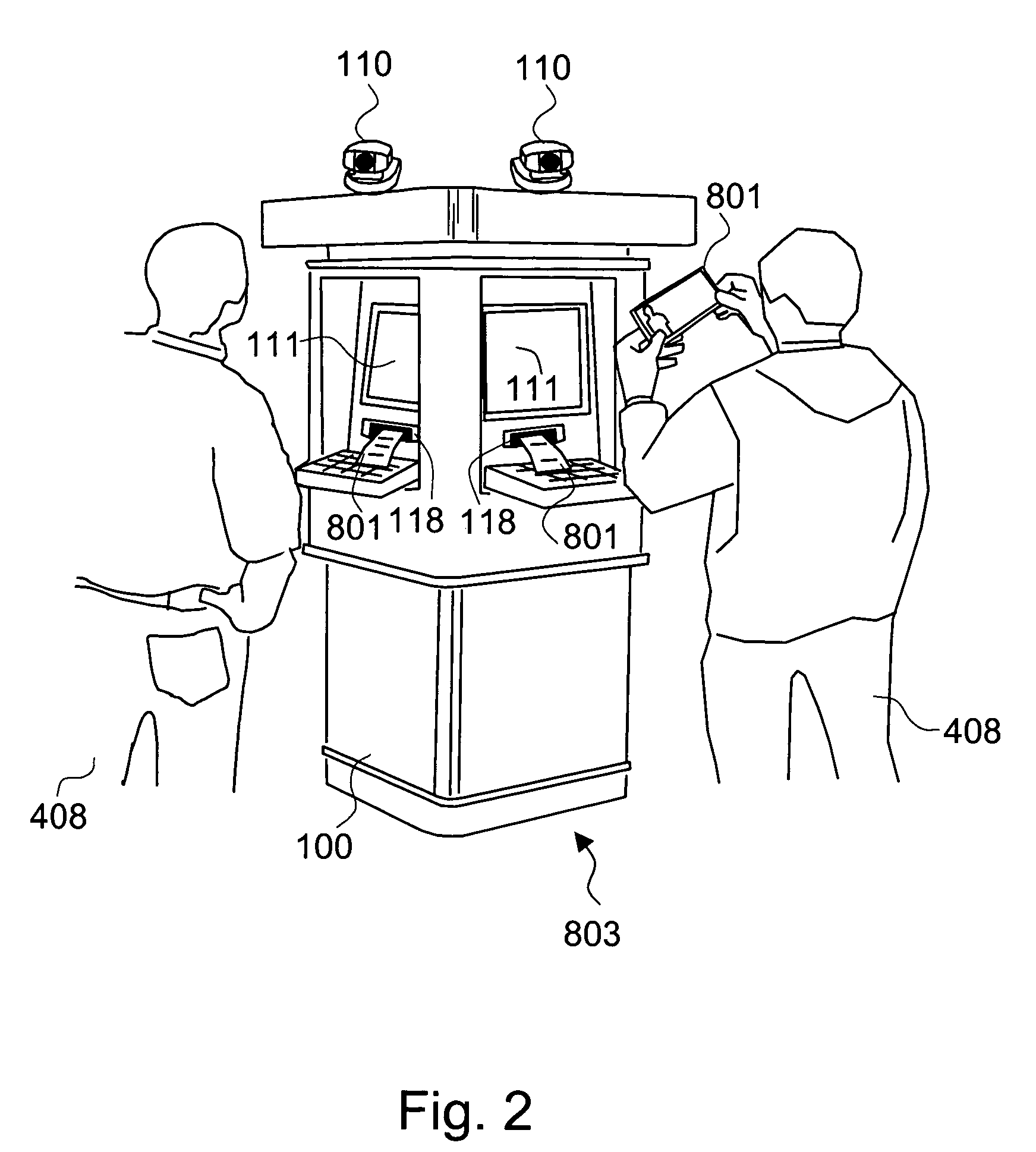

Method and system for printing of automatically captured facial images augmented with promotional content

ActiveUS7283650B1Verify legitimacyAvoid problemsAdvertisementsCharacter and pattern recognitionPublic placeComputer graphics (images)

The present invention is a system and method for printing facial images of people, captured automatically from a sequence of images, onto coupons or any promotional printed material, such as postcards, stamps, promotional brochures, or tickets for movies or shows. The coupon can also be used as a means to encourage people to visit specific sites as a way of promoting goods or services sold at the visited site. The invention is named UCOUPON. A plurality of Computer Vision algorithms in the UCOUPON processes a plurality of input image sequences from one or a plurality of means for capturing images that is pointed at the customers in the vicinity of the system in an uncontrolled background. The coupon content is matched by the customer's demographic information, and primarily, the UCOUPON system does not require any customer input or participation to gather the demographic data, operating fully independently and automatically. The embodiment of the UCOUPON system can be integrated into any public place that requires the usage of coupons, such as existing checkout counters of the retail store environment. The UCOUPON can also be integrated into a stand-alone system, such as a coupon Kiosk system.

Owner:F POSZAT HU

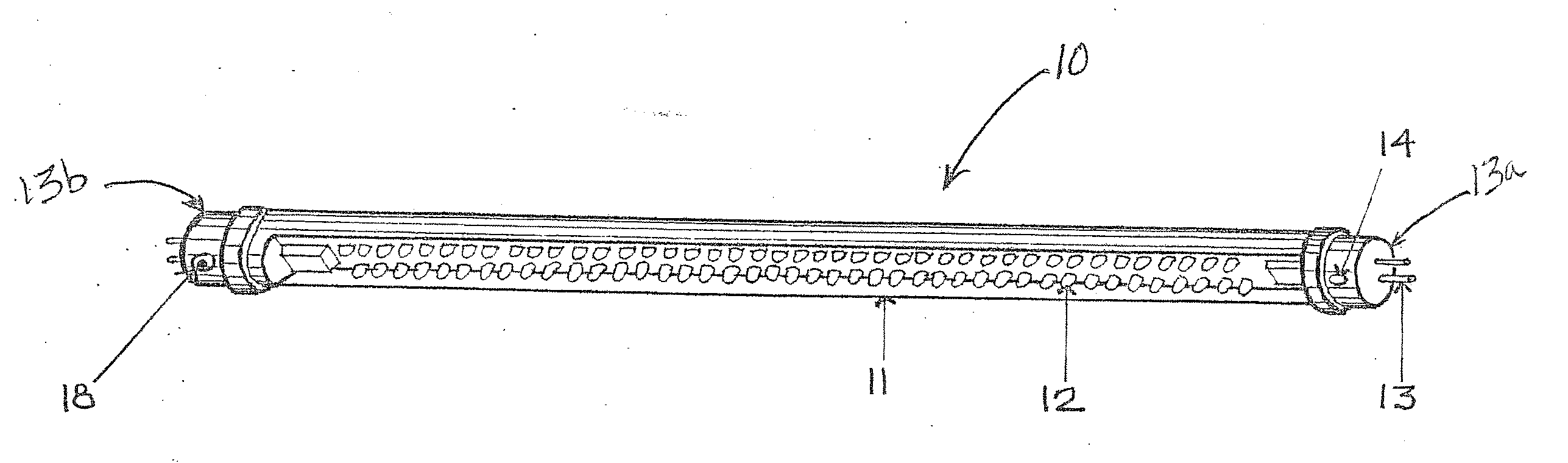

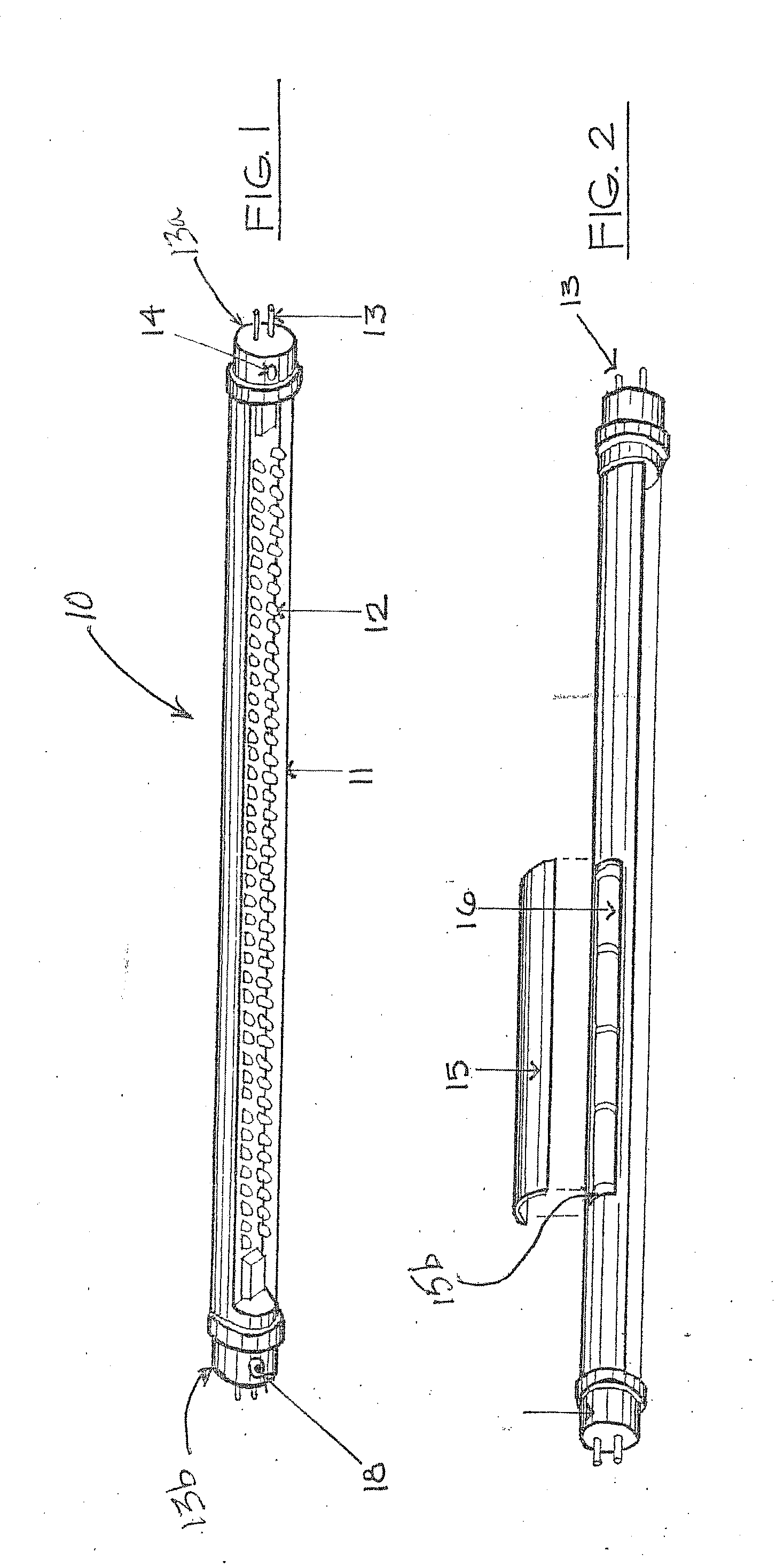

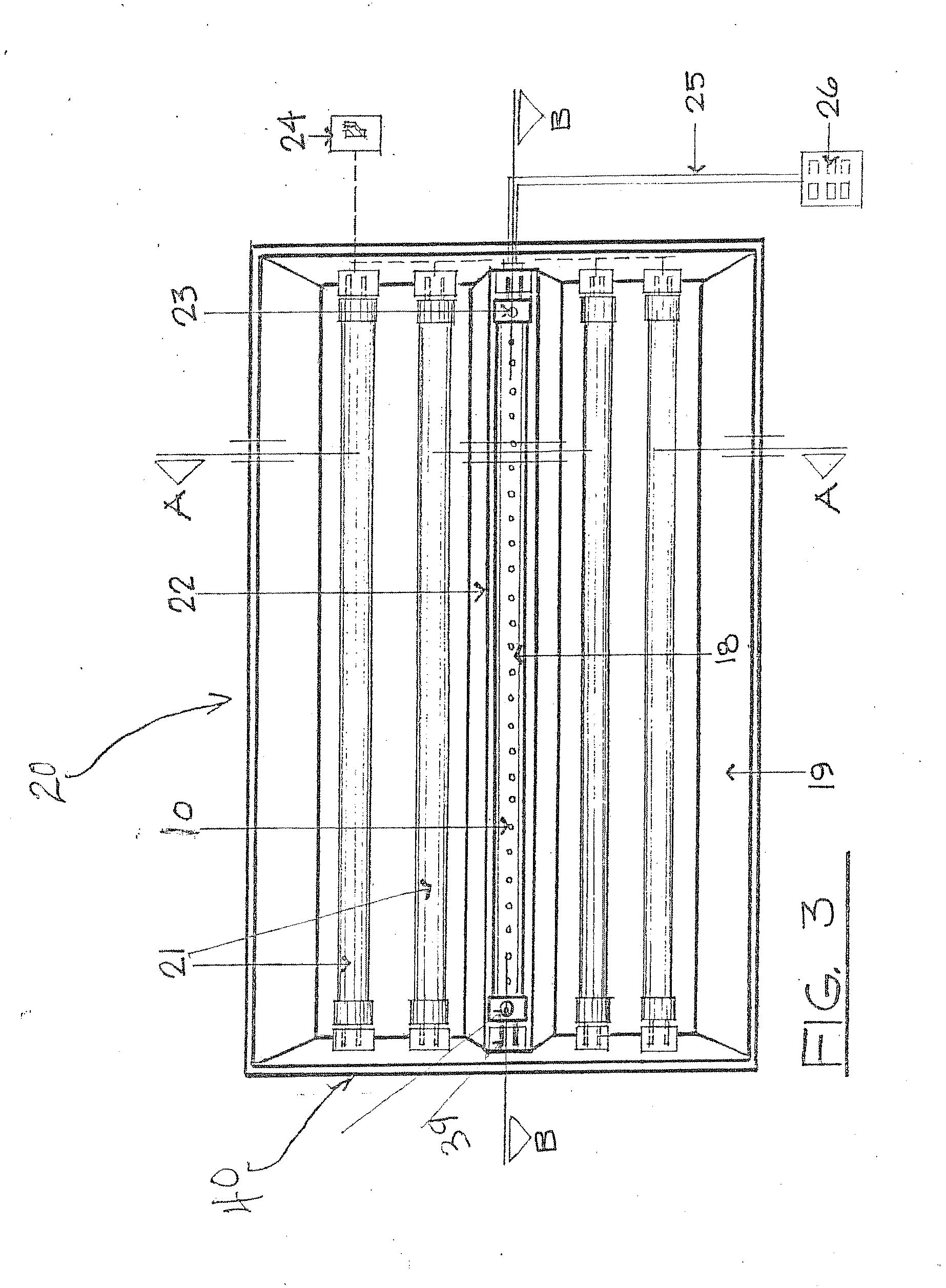

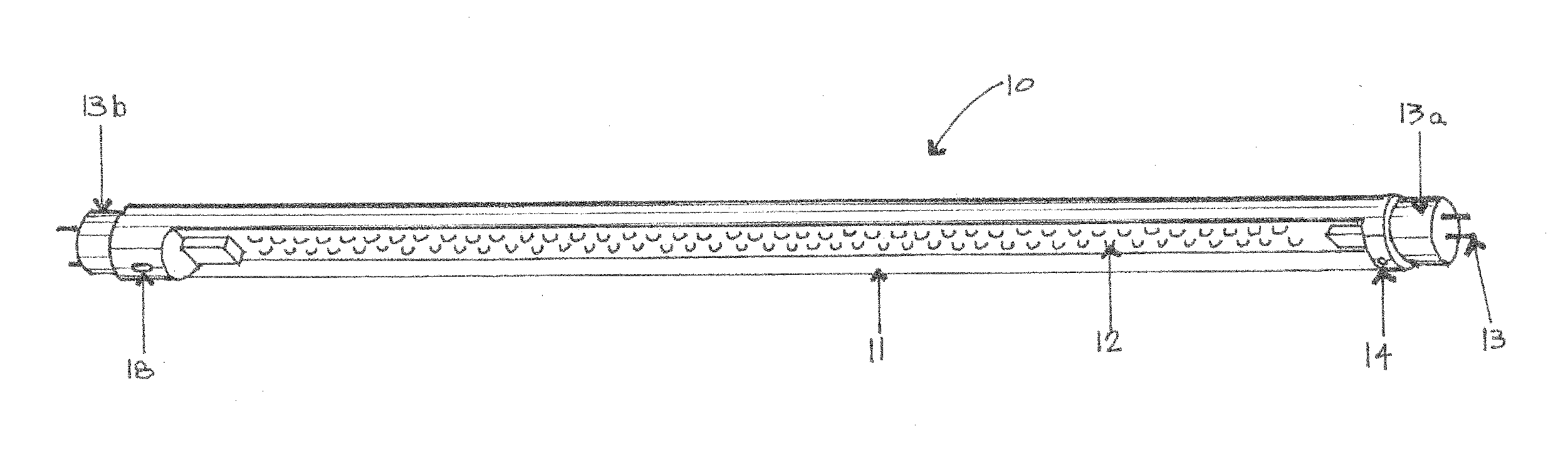

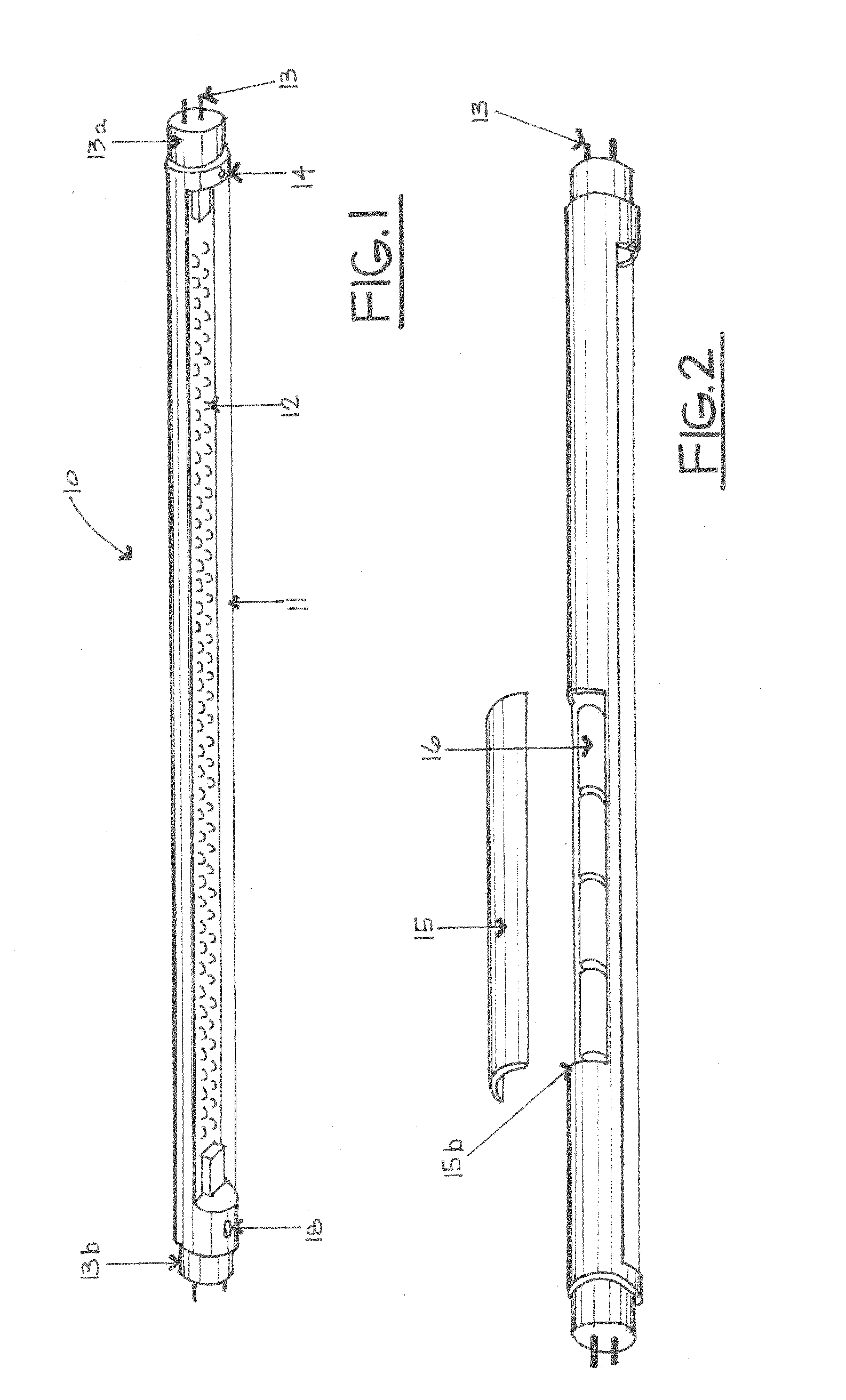

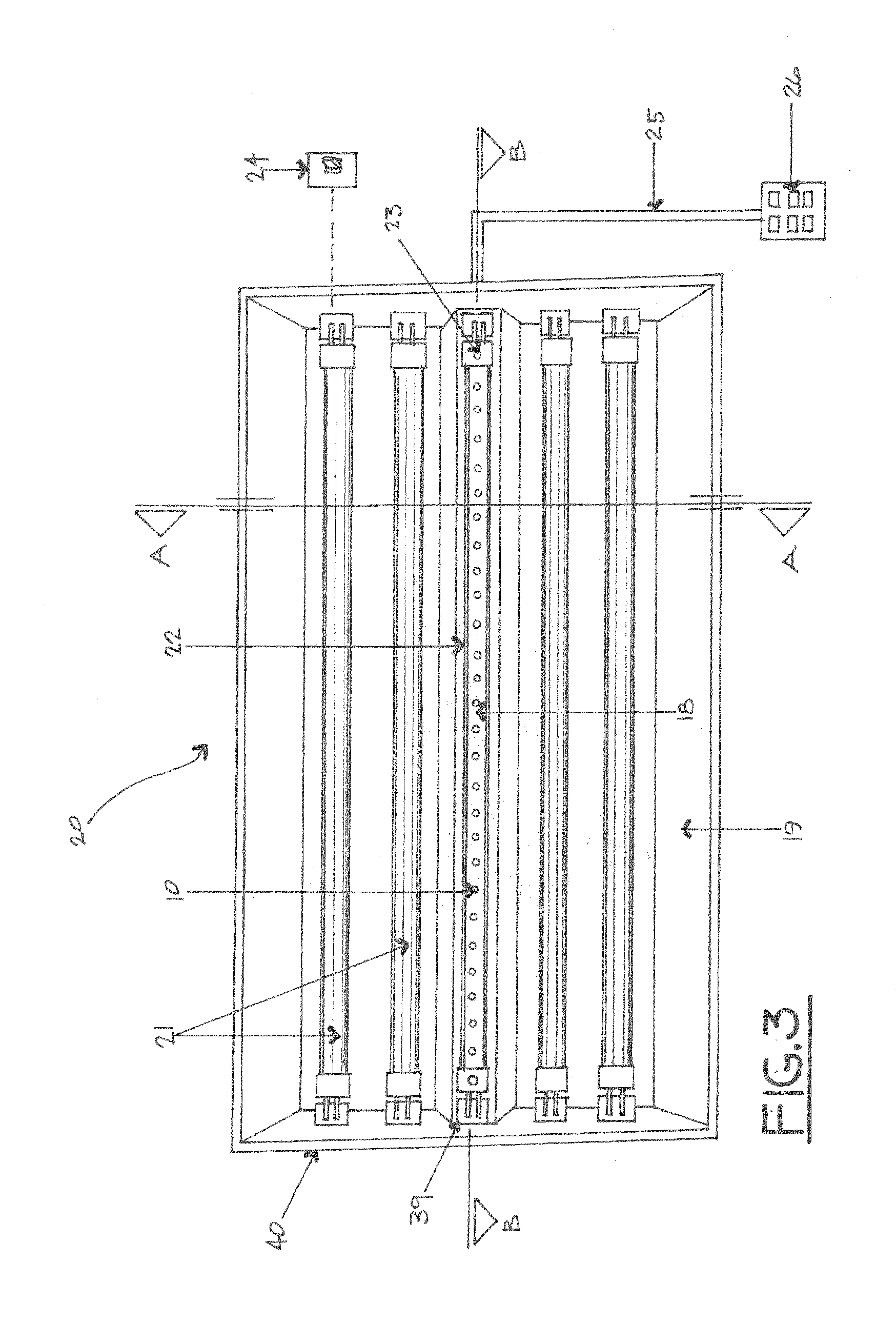

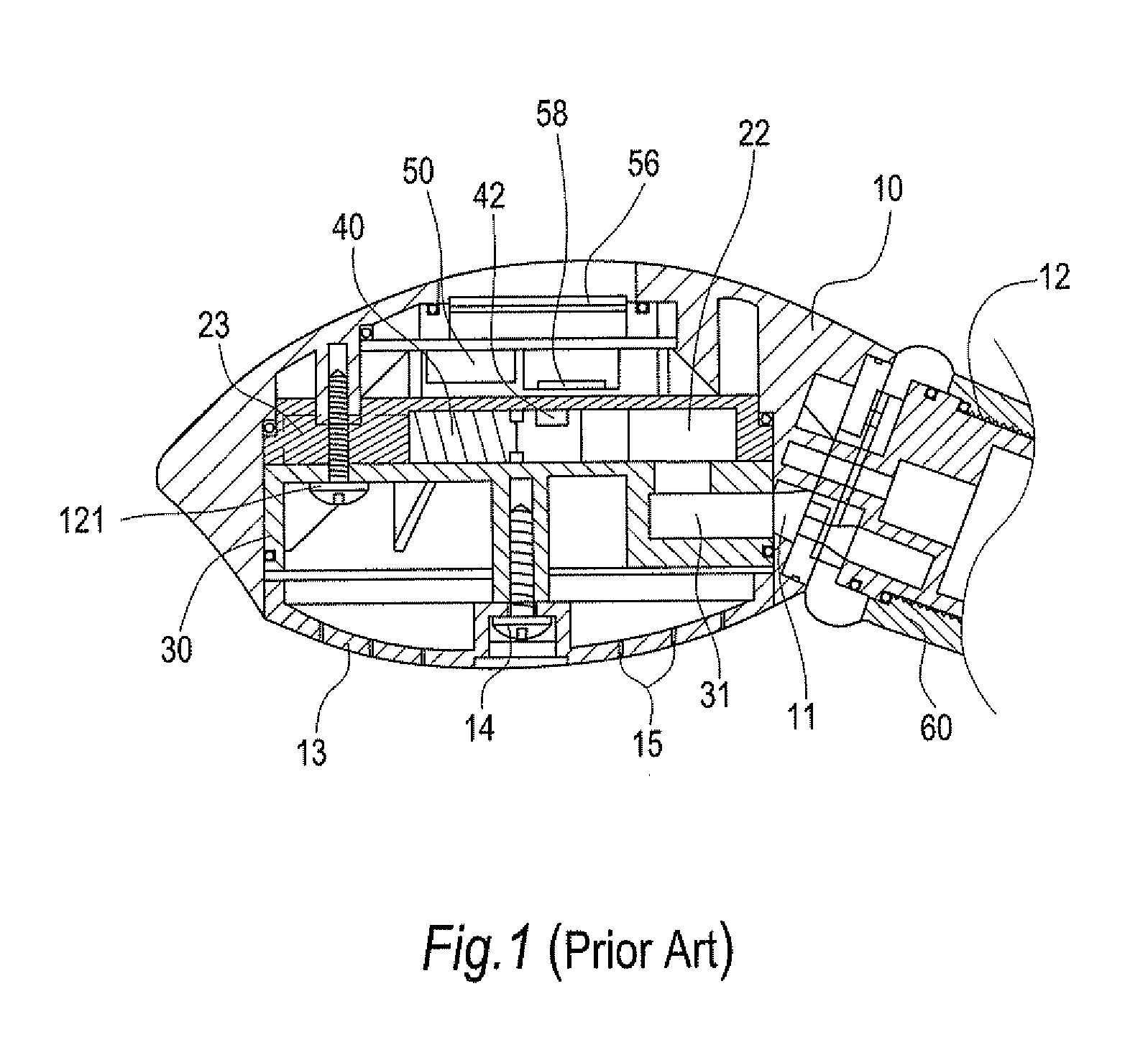

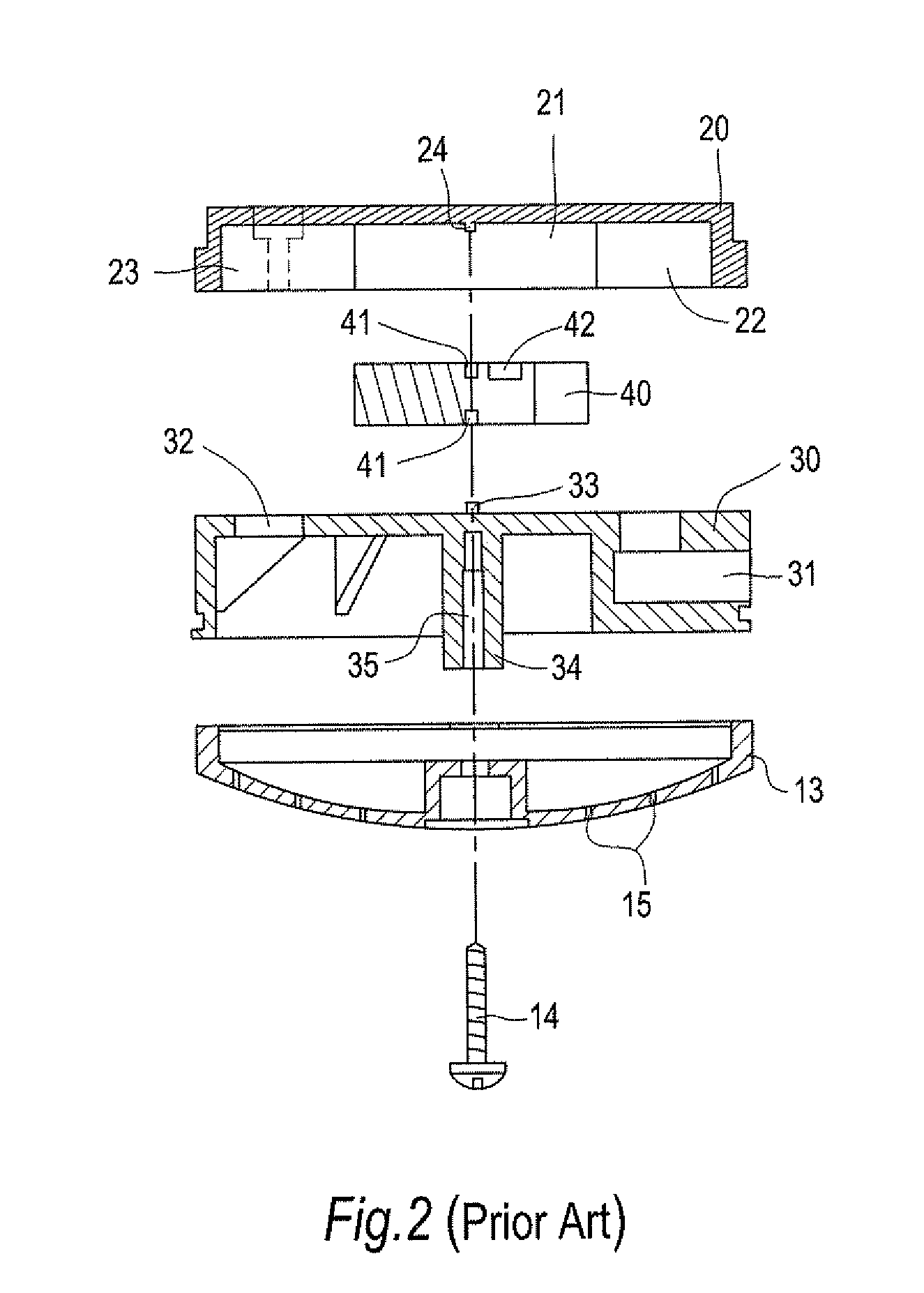

Modular lighting assembly

InactiveUS20120195032A1Reduce wasteEasy to placePlanar light sourcesLight source combinationsModularityComputer module

The present invention includes an LED lighting fixture containing: a housing insert electronically communicating with the light fixture; and one or more LED modules electronically communicating with the housing insert upon receipt of direct current power from the housing insert. One or more LED modules are removably seated within the housing insert for ready replacement of the LED modules while conserving unnecessary waste by preserving the continued use of the housing insert.

Owner:SHEW LARRY N

Lighting system and method of deflection

InactiveUS20130051008A1Reduce wasteConserve unnecessary wastePlanar light sourcesLight source combinationsLighting systemEngineering

Owner:SHEW LARRY N

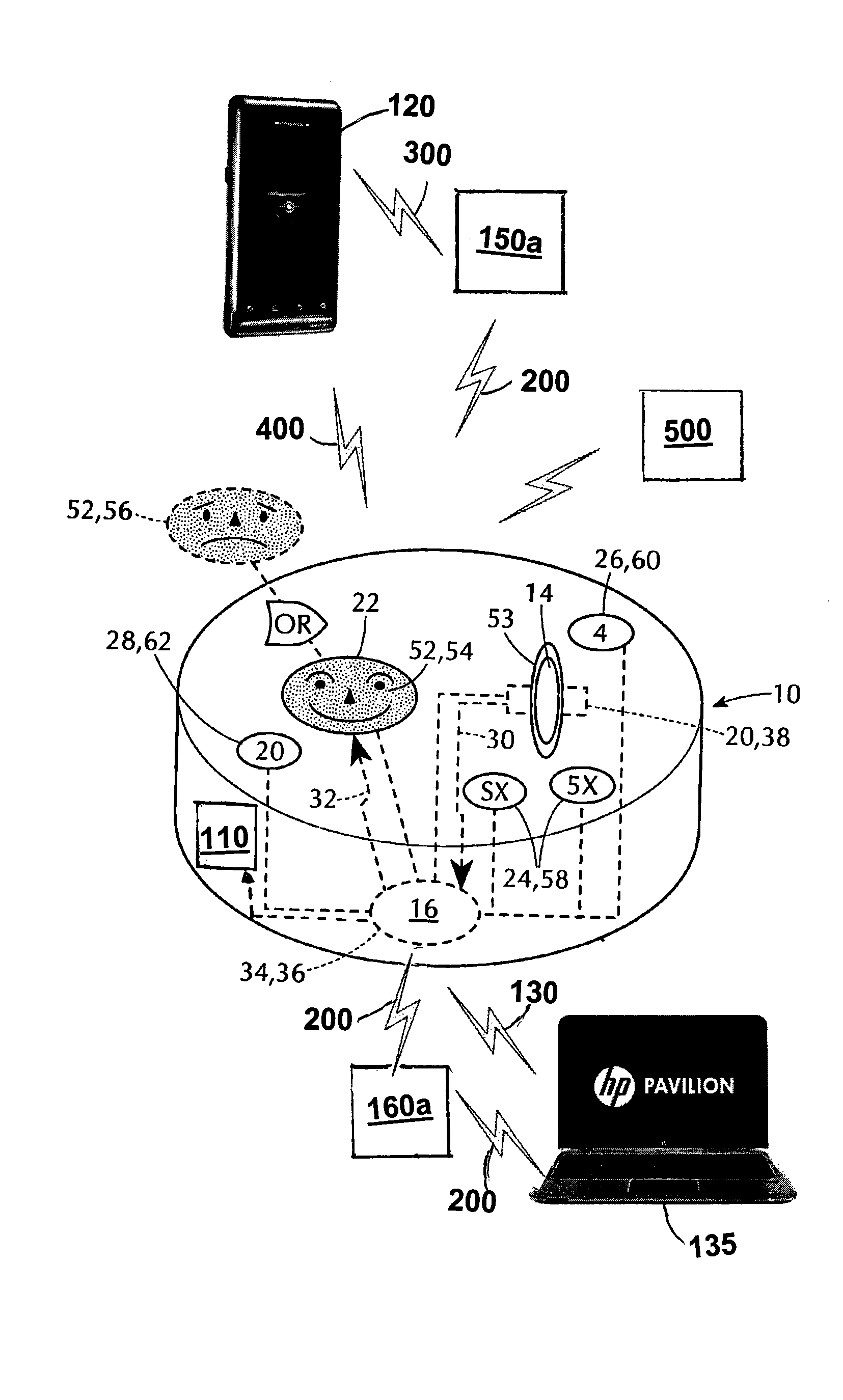

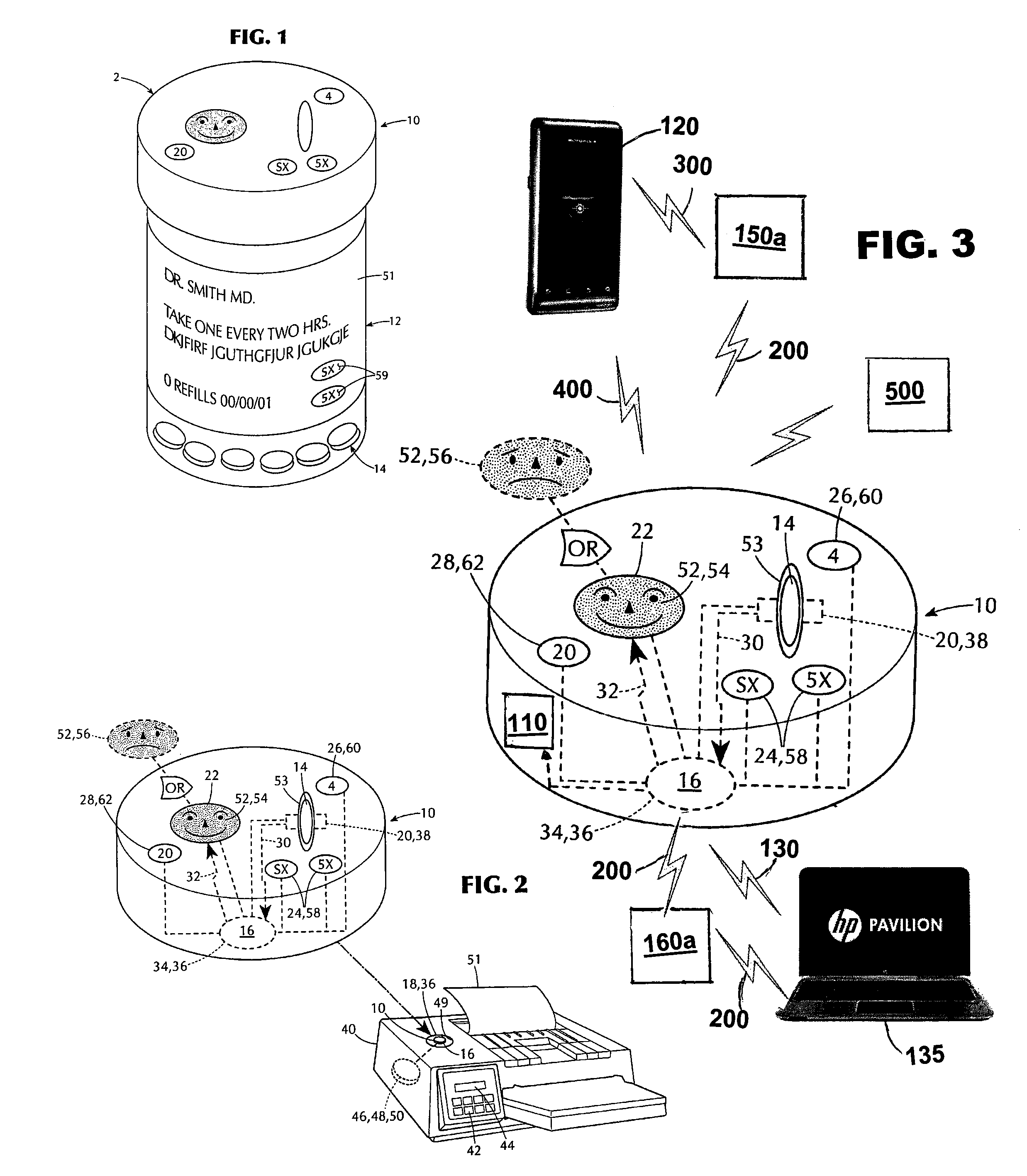

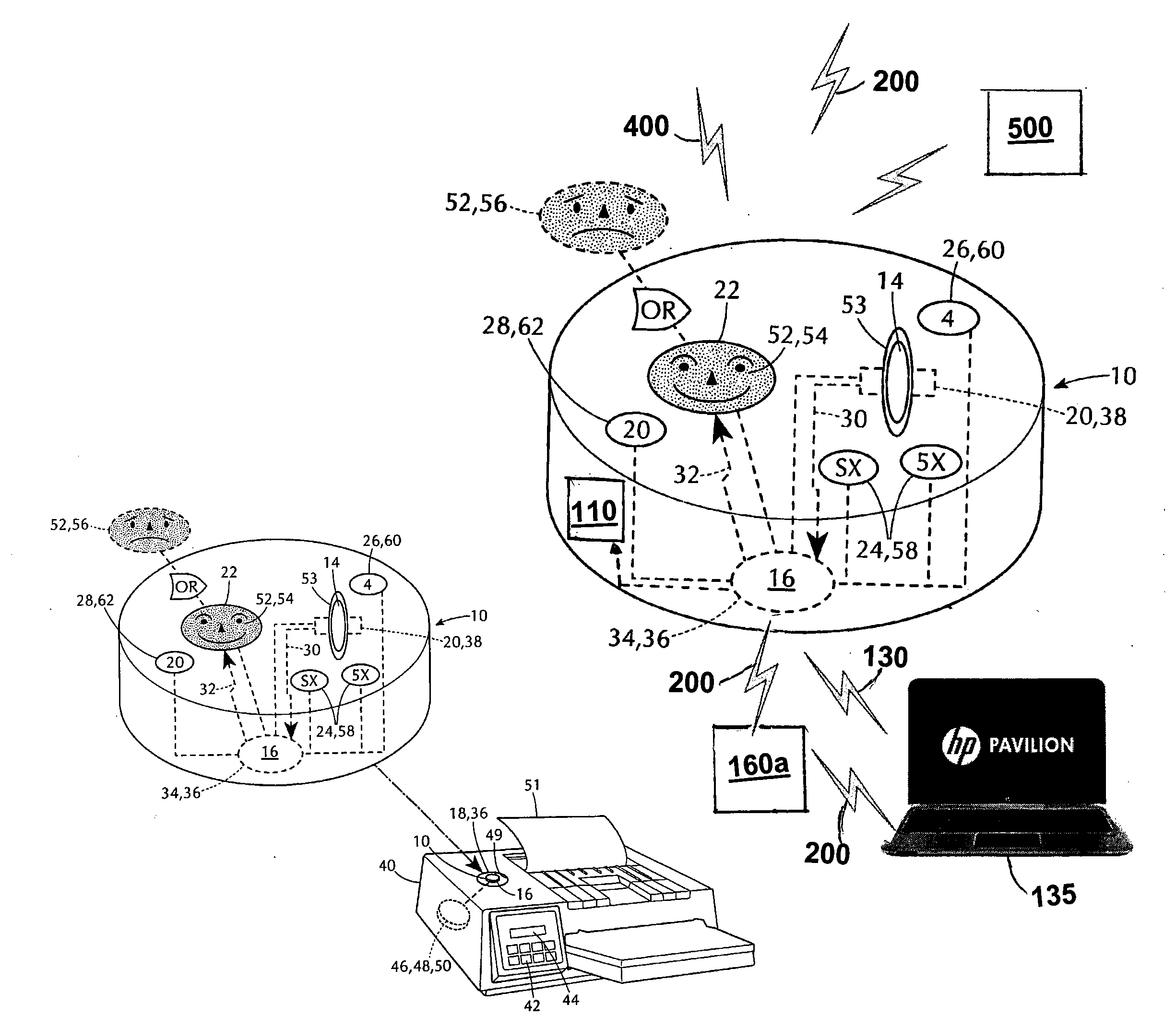

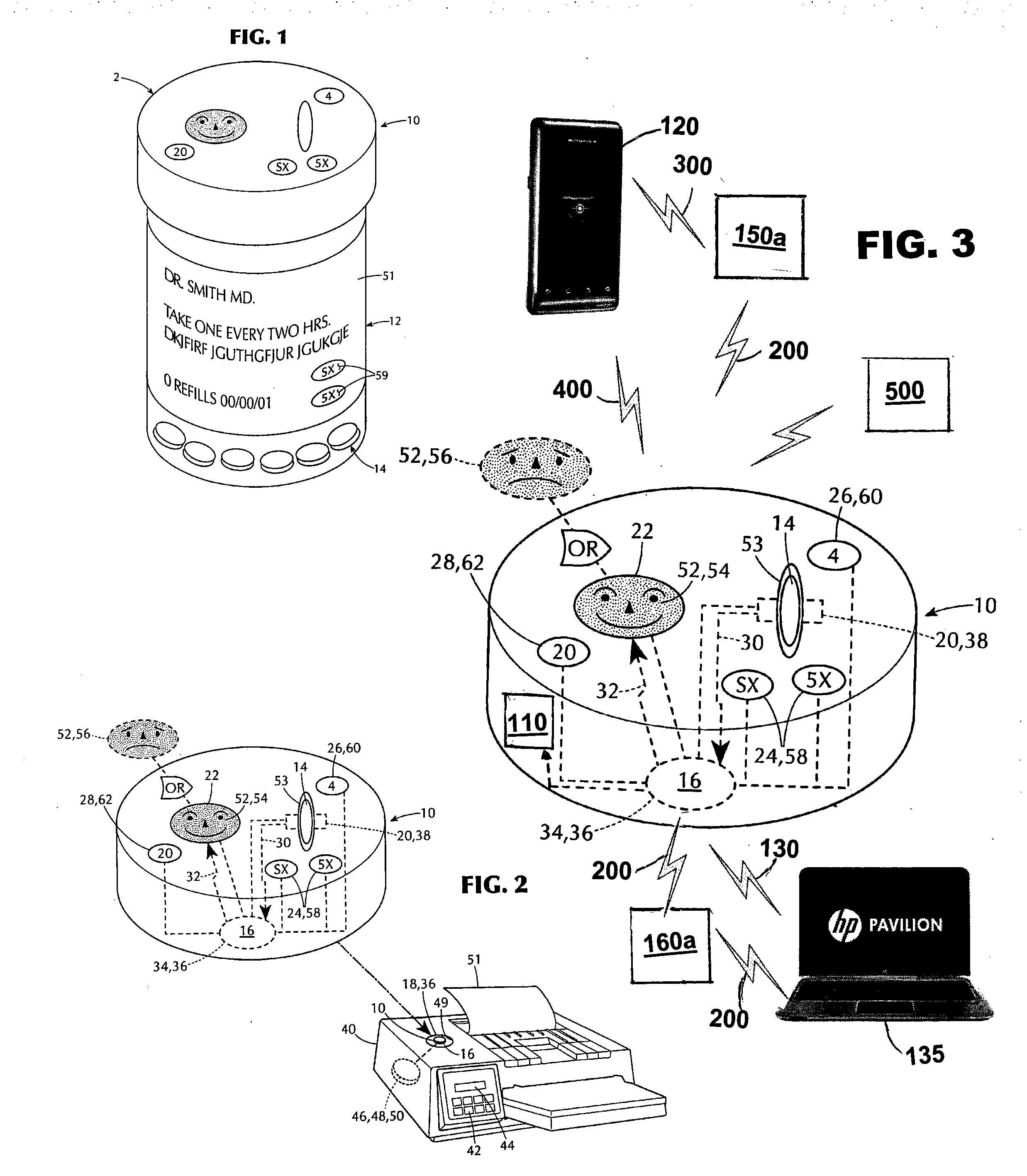

Smart cap with communication function

ActiveUS8319613B2Prevent improper dispensingSave effortData processing applicationsDrug and medicationsPharmacyMedicine

A smart cap for a medical container for the containment of solid medications having unique indicia. The cap is provided with an optical scanner configured with at least one locally contained or external data base having general medication identification data and optionally patient-specific information to scan and identify the medication (and optionally the dosage, specific formulations, manufacturing source, etc.) and to record and correlate information regarding patient medication usage (scanning of a medication is generally considered indicative of actual patient taking of the medication). The cap further comprises communication elements configured to transmit / receive “usage” through scanning of a unit dosage of the medication, to an external data base such as the patient's cell phone and or computer (such as with blue tooth or RF communication) or via a telephone call or internet transmission to a data base of a pharmacy or physician or other health care provider.

Owner:LAZAR STEVEN

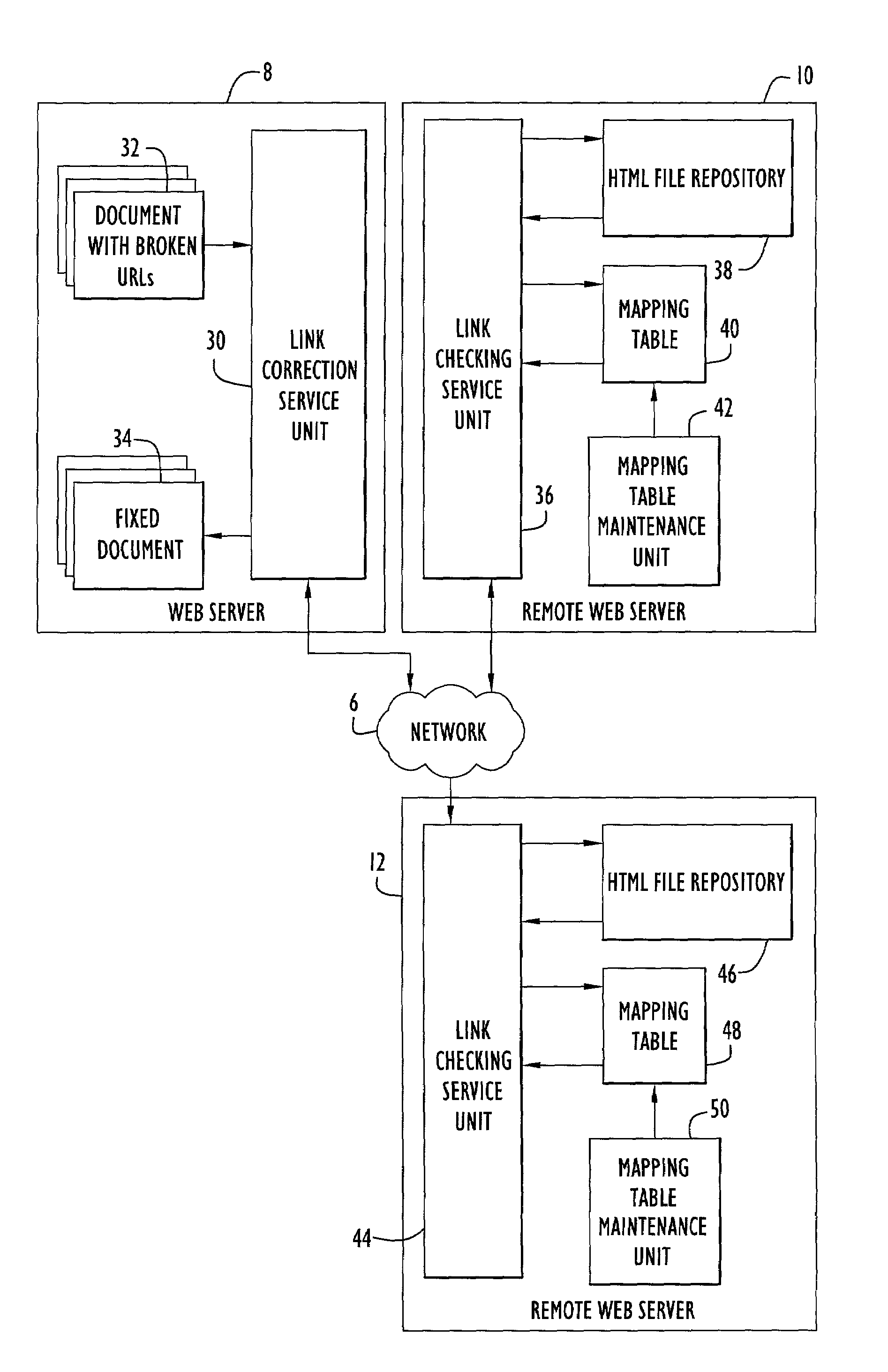

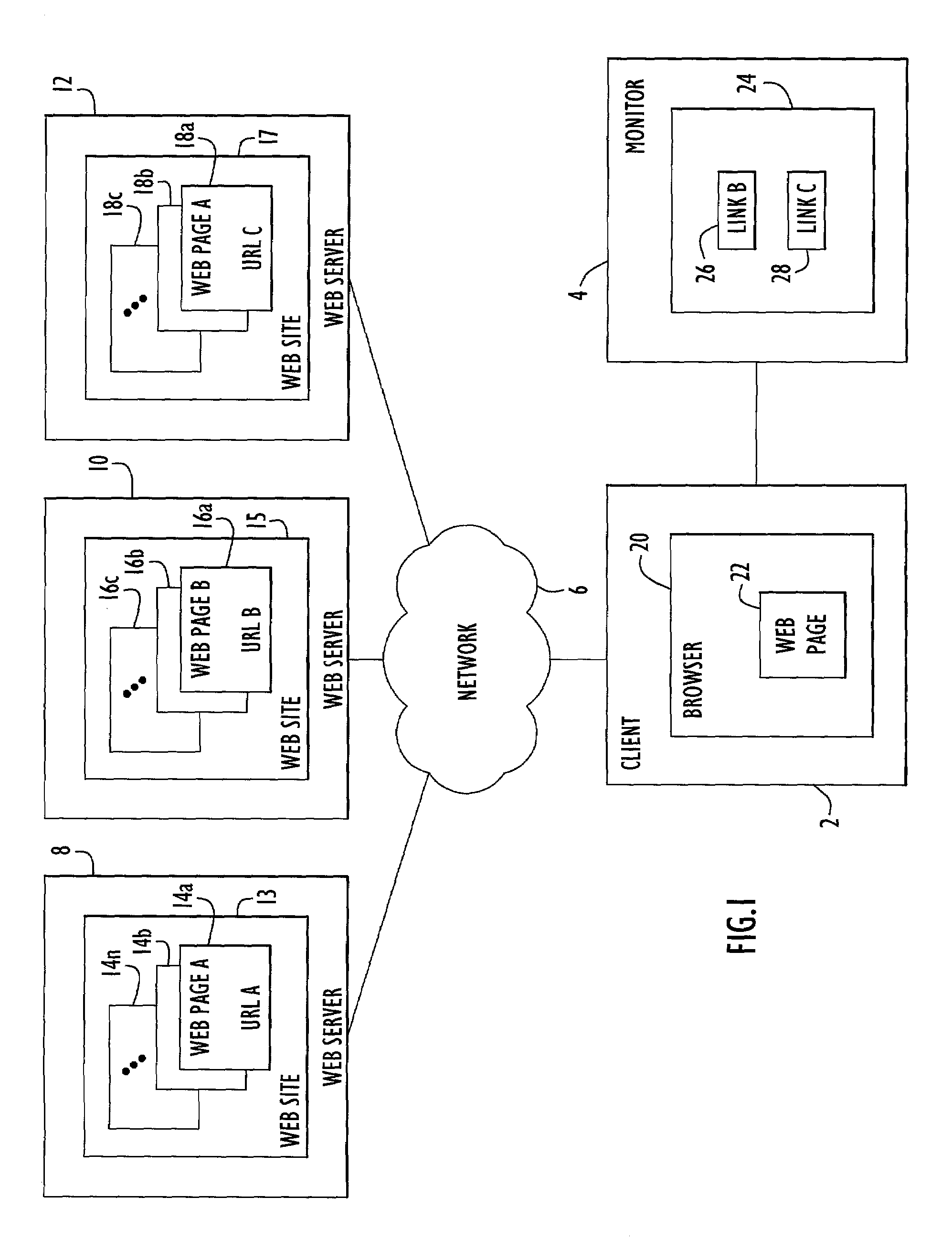

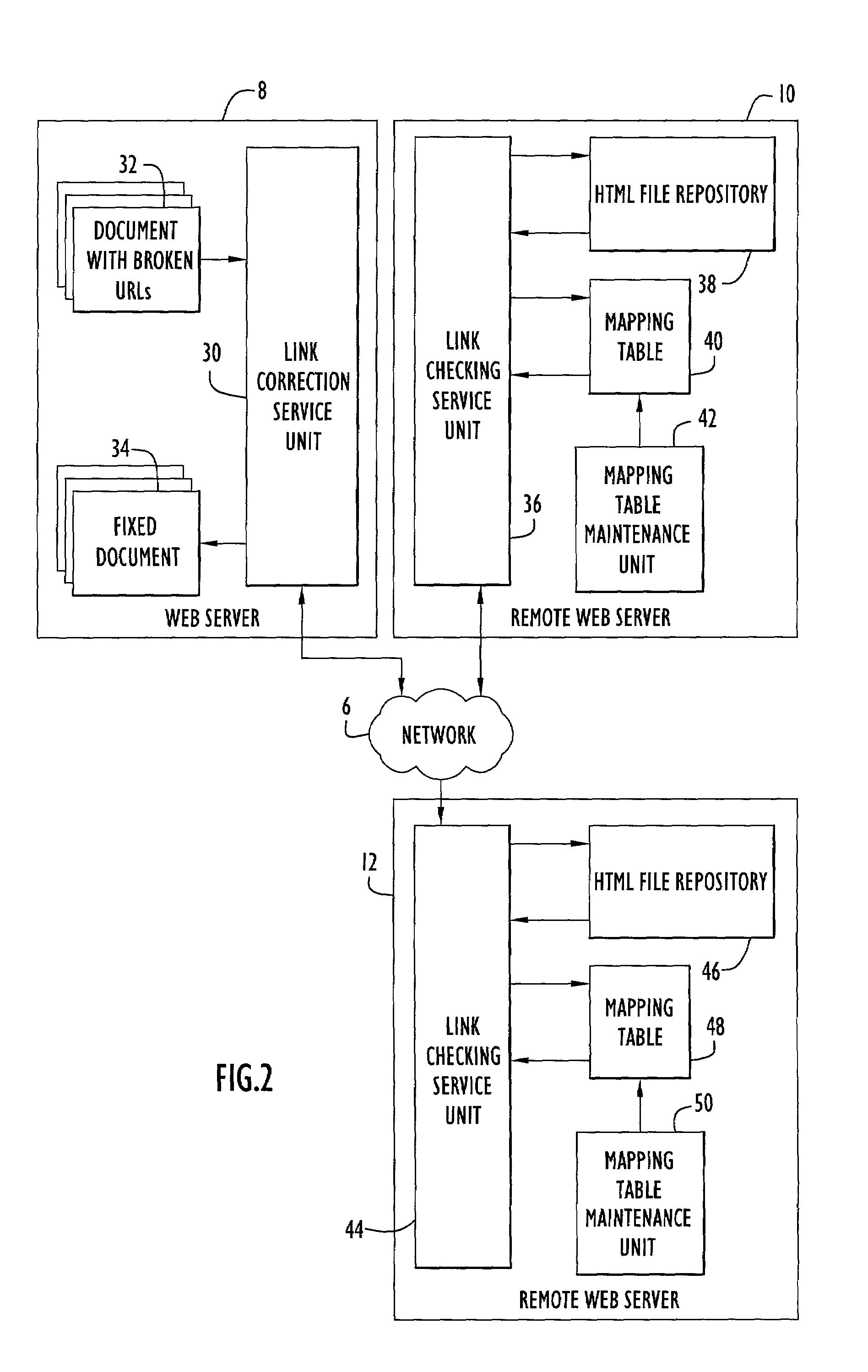

Protocol to fix broken links on the world wide web

InactiveUS7689667B2Saving countless hour wastedSave wasteMultiple digital computer combinationsSpecial data processing applicationsHyperlinkWeb service

A protocol for automatically fixing broken hypertext links is described that can save countless hours wasted by World-Wide Web surfers trying to navigate using a broken link or web authors trying to fix broken links to their web pages. A link correction service checks hypertext links in a document by sending messages according to a hyperlink verification protocol (HLVP) to a remote web server indicated by the link. A link checking service at the remote web server, in response to receiving an HLVP message for a link, consults a mapping table to determine if the link is valid, has changed, has been removed, or is unknown. A response code indicating the status of the link is returned to the link correction service to modify the page accordingly.

Owner:IBM CORP

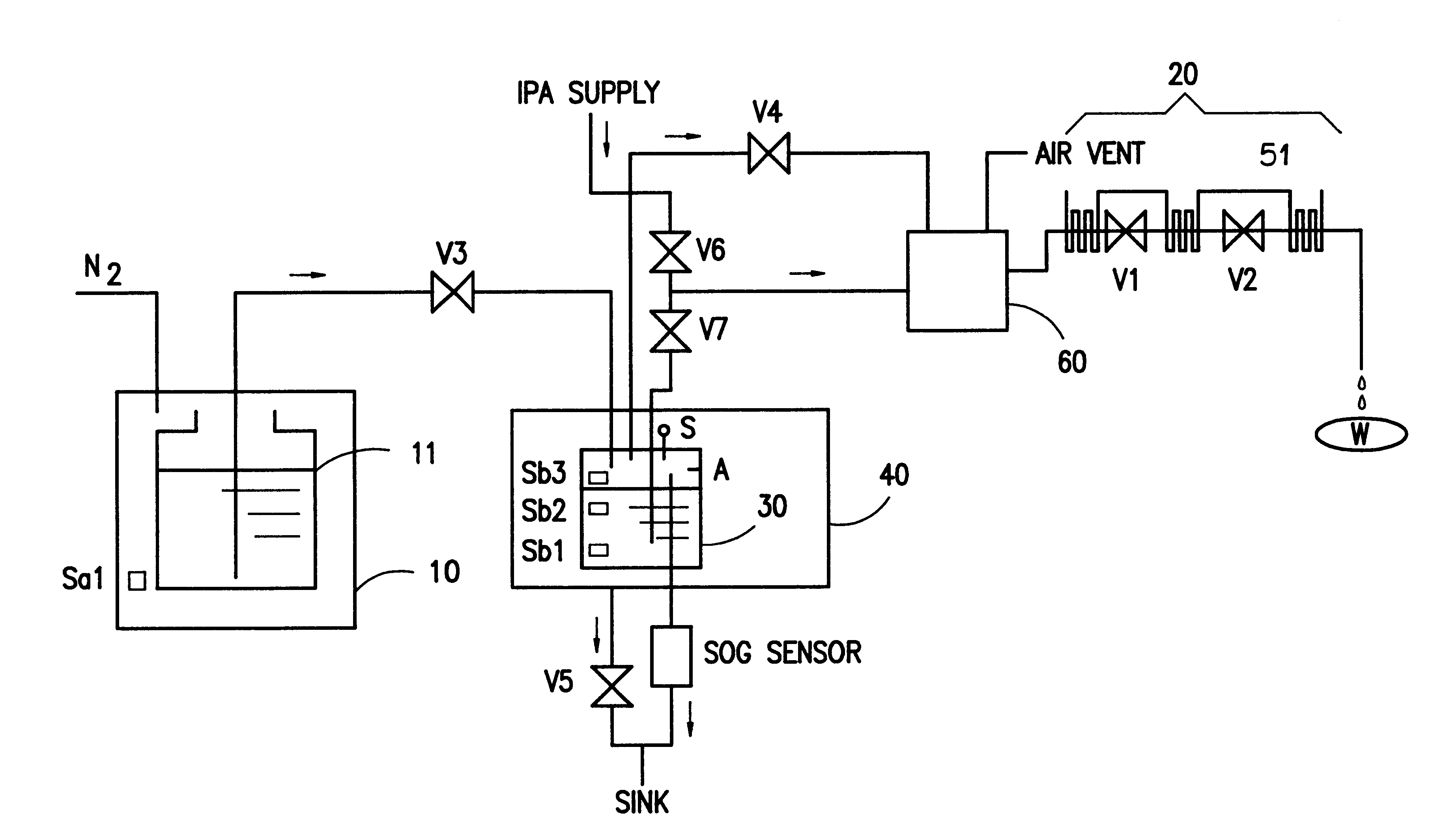

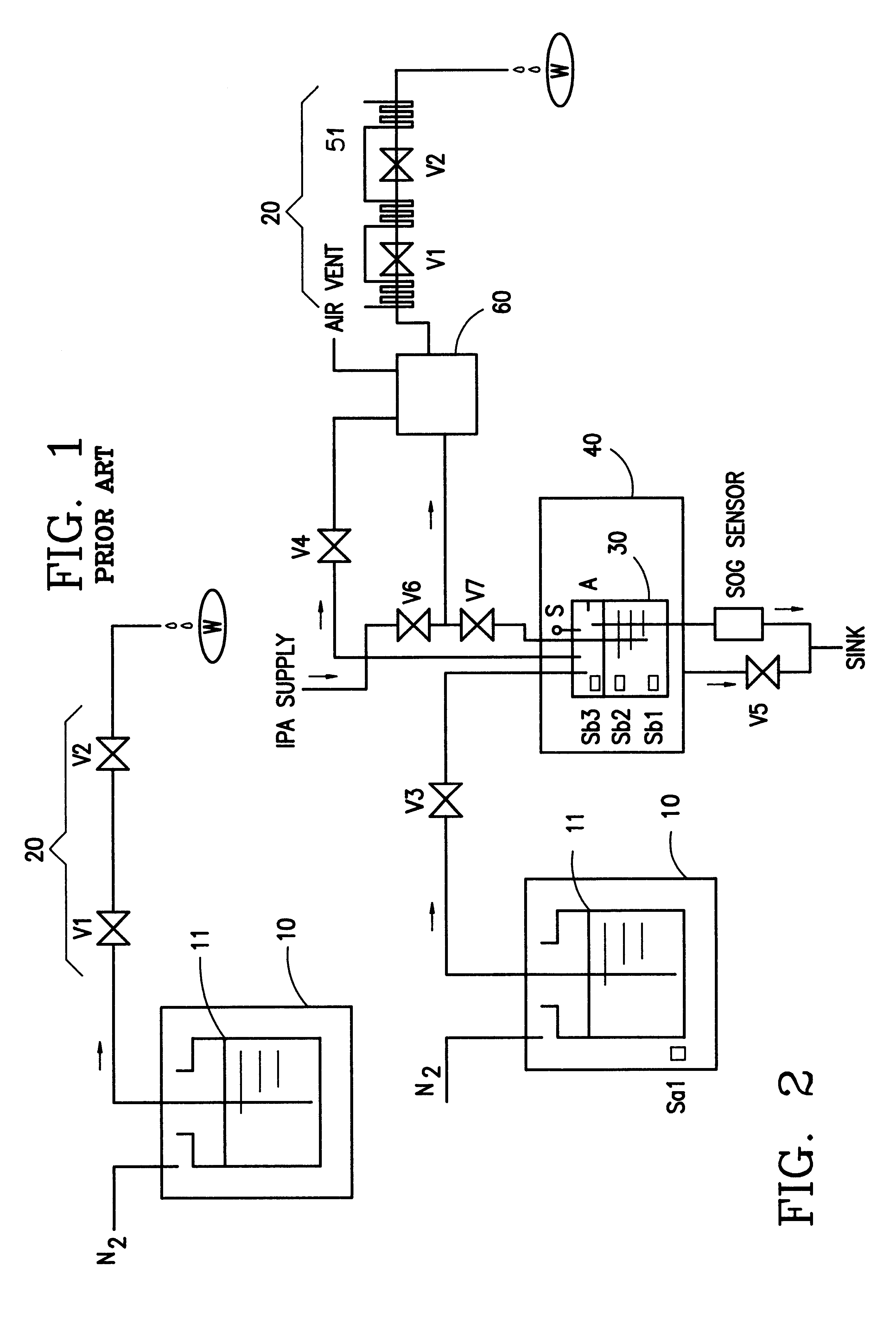

SOG dispensing system and its controlling sequences

InactiveUS6245148B1Continuous productionEasy to operateSpray nozzlesSemiconductor/solid-state device manufacturingManufacturing cost reductionControl signal

The present invention relates to a SOG (Spin-On-Glass) dispensing system and its controlling sequences and, more particularly, to a SOG dispensing system allowing for continuous production and its controlling sequences According to the present invention, a buffer tank, whose wall is set a plurality of level sensors at different level heights, is connected between a source tank with a SOG bottle inside and a coating unit of prior art and then SOG is supplied for a time interval from the source tank into the buffer tank by control signals from these level sensors. Besides, the buffer tank is surrounded with a cooling unit to provide a low temperature enviroment allowing for prolonging life time of SOG and preventing organic solvent inside SOG from evaporating and then crystallizing to form contamination particles at wall of the SOG dispensing system. Thus, the resultant SOG dispensing system, according to the present invention, can resolve a shortcoming of discontinuous production of prior art due to a need for changing the SOG bottle, as well as another shortcoming of residue of the SOG bottle, thereby considerably raising operating efficient of the dispensing system by reducing its idle time and lowering fabrication cost by saving a SOG waste.

Owner:PROMOS TECH INC

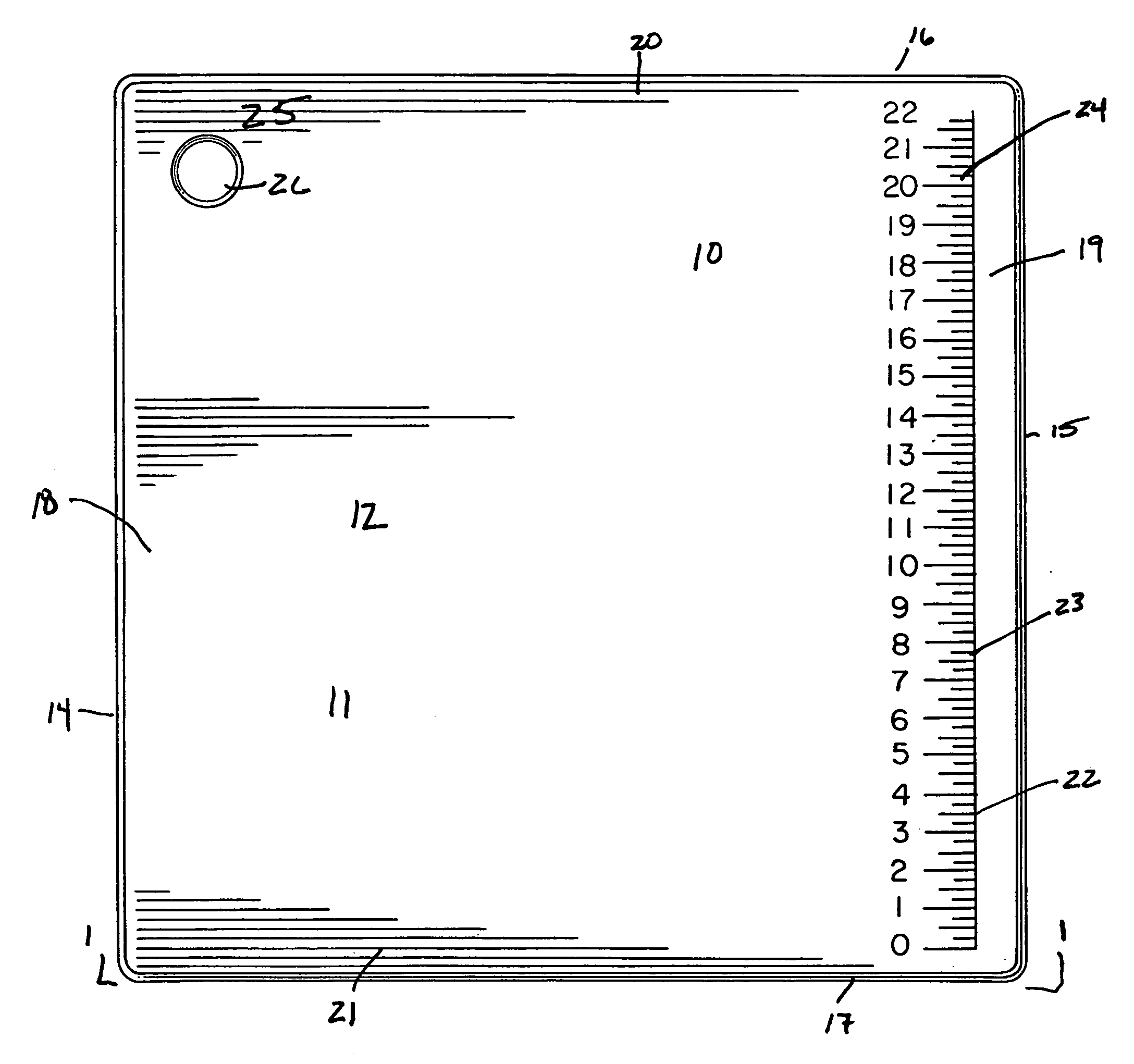

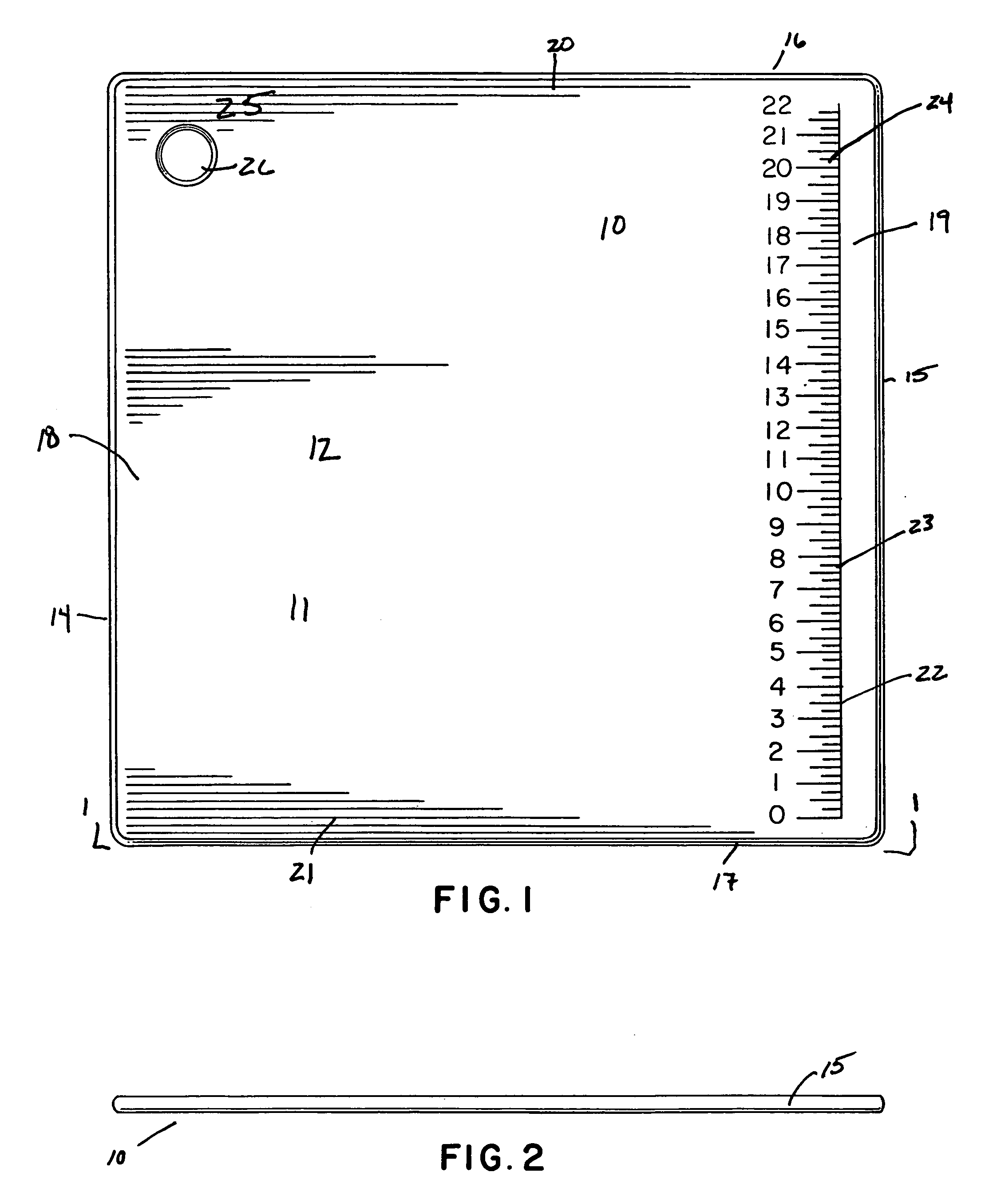

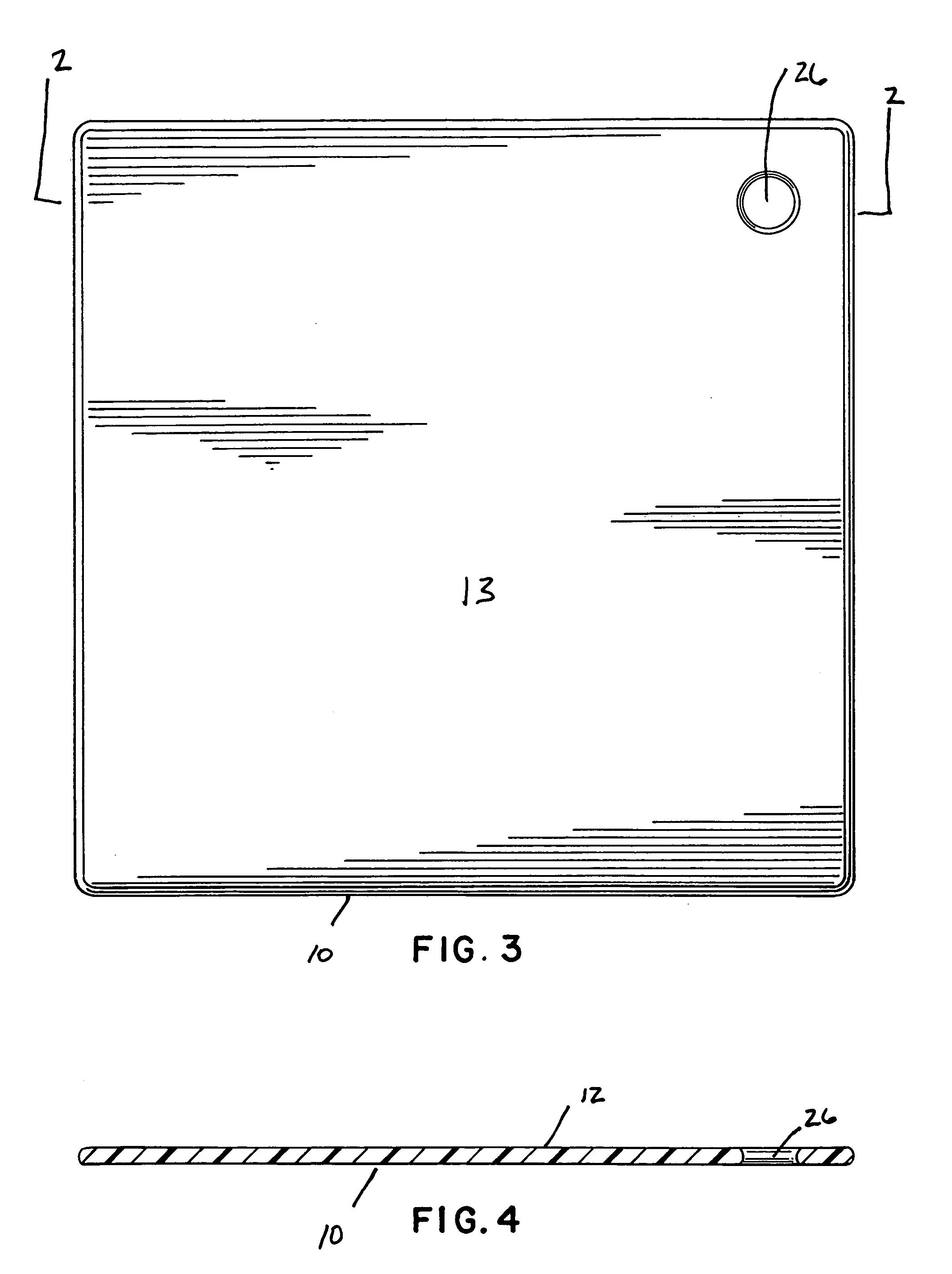

Construction board

InactiveUS6932336B1Effective distributionThe right amountBuilding material handlingPositioning apparatusBrickMaterials science

A mixing and measuring tool formed of high molecular high density polyethylene enables a mason to precisely mix and provide an accurate amount of mortar to each brick saving wasted mortar. The tool presents a frictionless, hard cutting surface for cutting brick or stone. Due to the durable characteristics of the high molecular high density polyethylene, the tool surface will not absorb fluids during mixing yet withstand intense cutting or scraping without damage.

Owner:NUDO PRODS

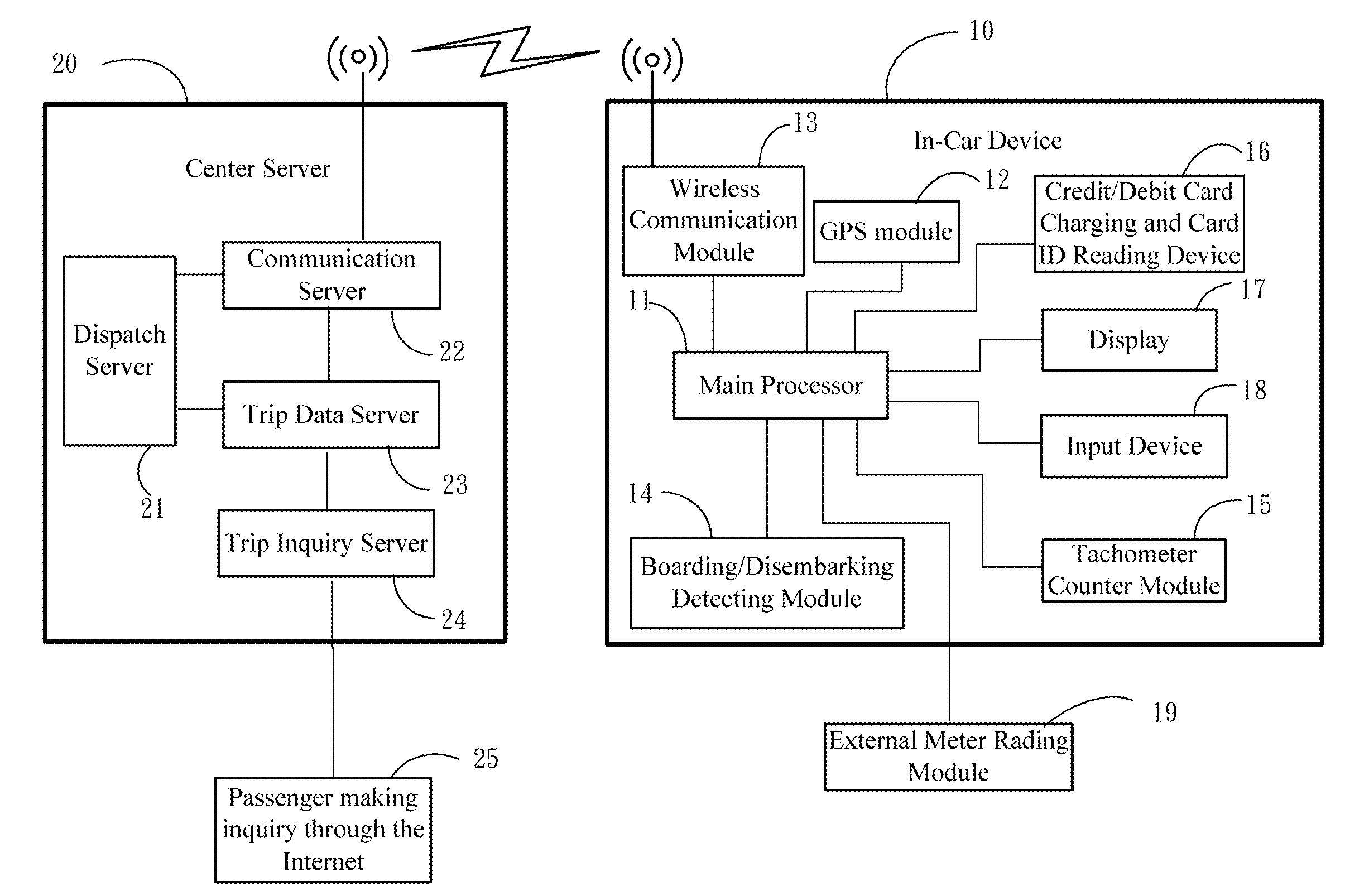

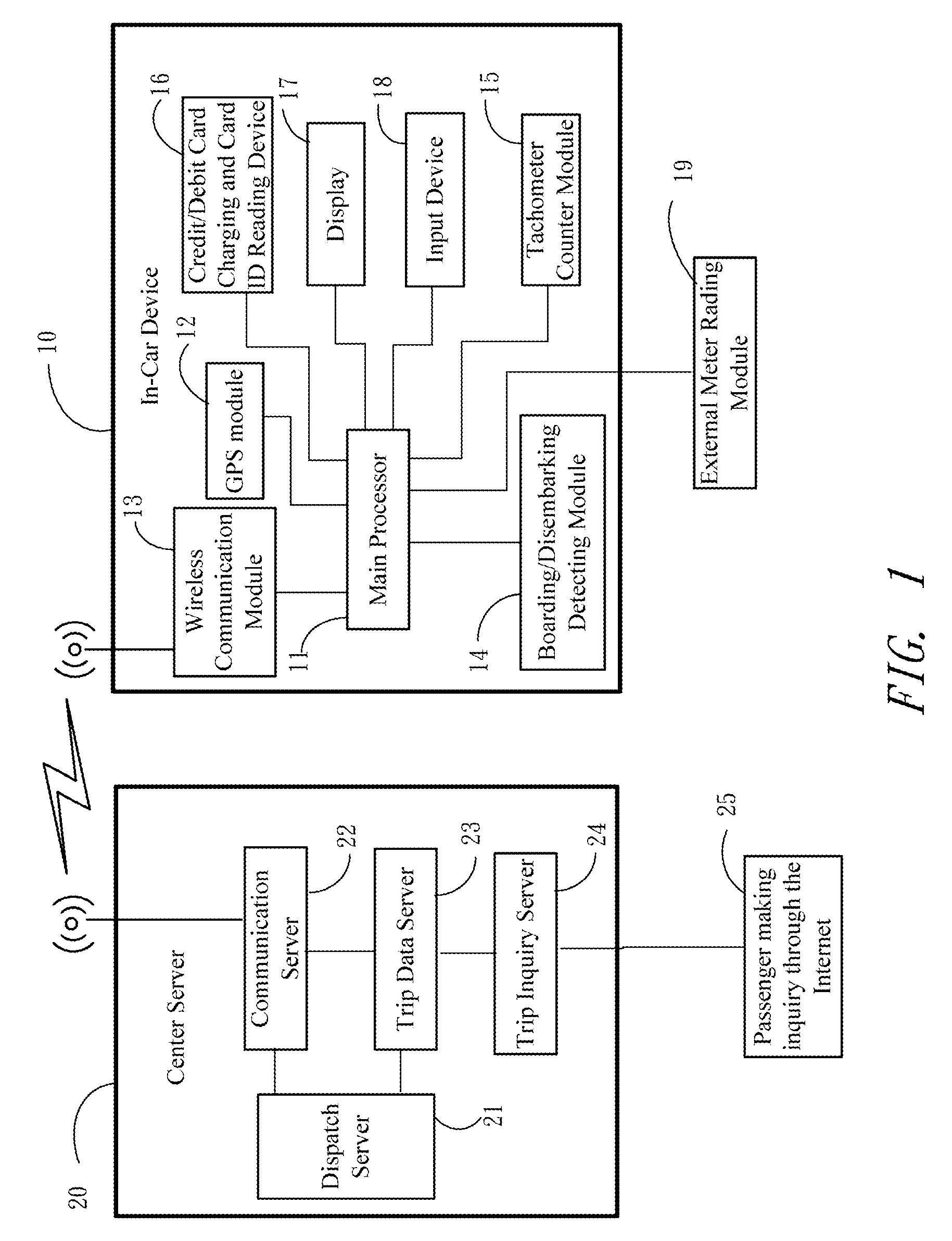

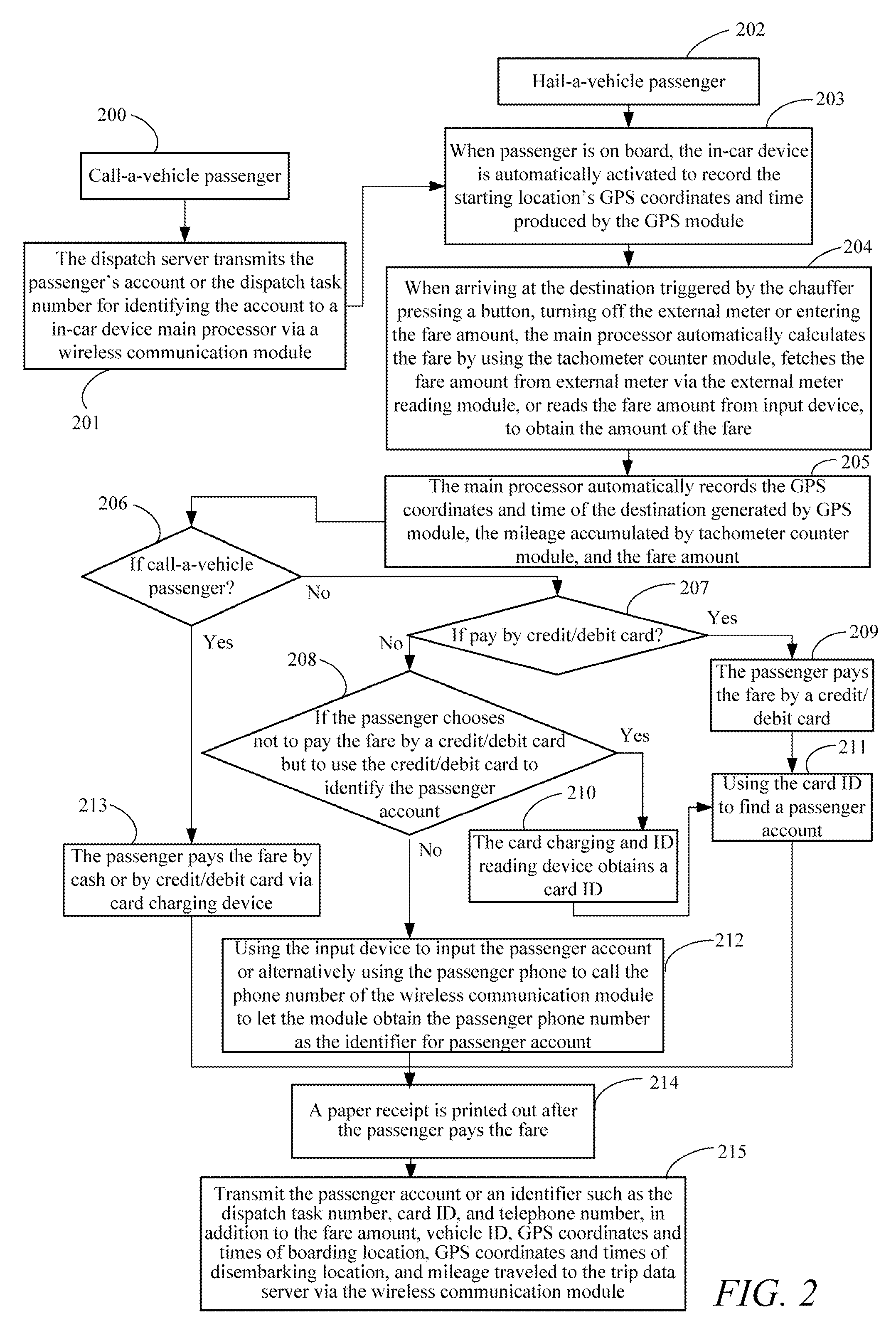

Automatic Electronic Trip Receipt System and Method for Chauffeured Vehicles

InactiveUS20110047037A1Better mechanismLabor savingRegistering/indicating working of vehiclesPayment architectureReceiptCommunications server

The present invention relates to an automatic electronic trip receipt system and method for chauffeured vehicles, and more particularly, to an automatic electronic trip receipt system which combines an in-car device and a center server to automatically generate a electronic trip reports or receipts for a passenger; wherein the center server comprises a dispatch server for transmitting related dispatch data to in-car device, a communication server for wirelessly communicating with the in-car device, a trip data server for storing trip data, and a trip data inquiry server for the passenger to inquire a specified list of trip reports; the in-car device comprises an in-car device main processor for processing signals from modules, which comprise a GPS module, a wireless communication module, a boarding / disembarking detecting module, a tachometer counter module, an external meter reading device and a credit / debit card charging and card ID reading device.

Owner:SHIH TECH

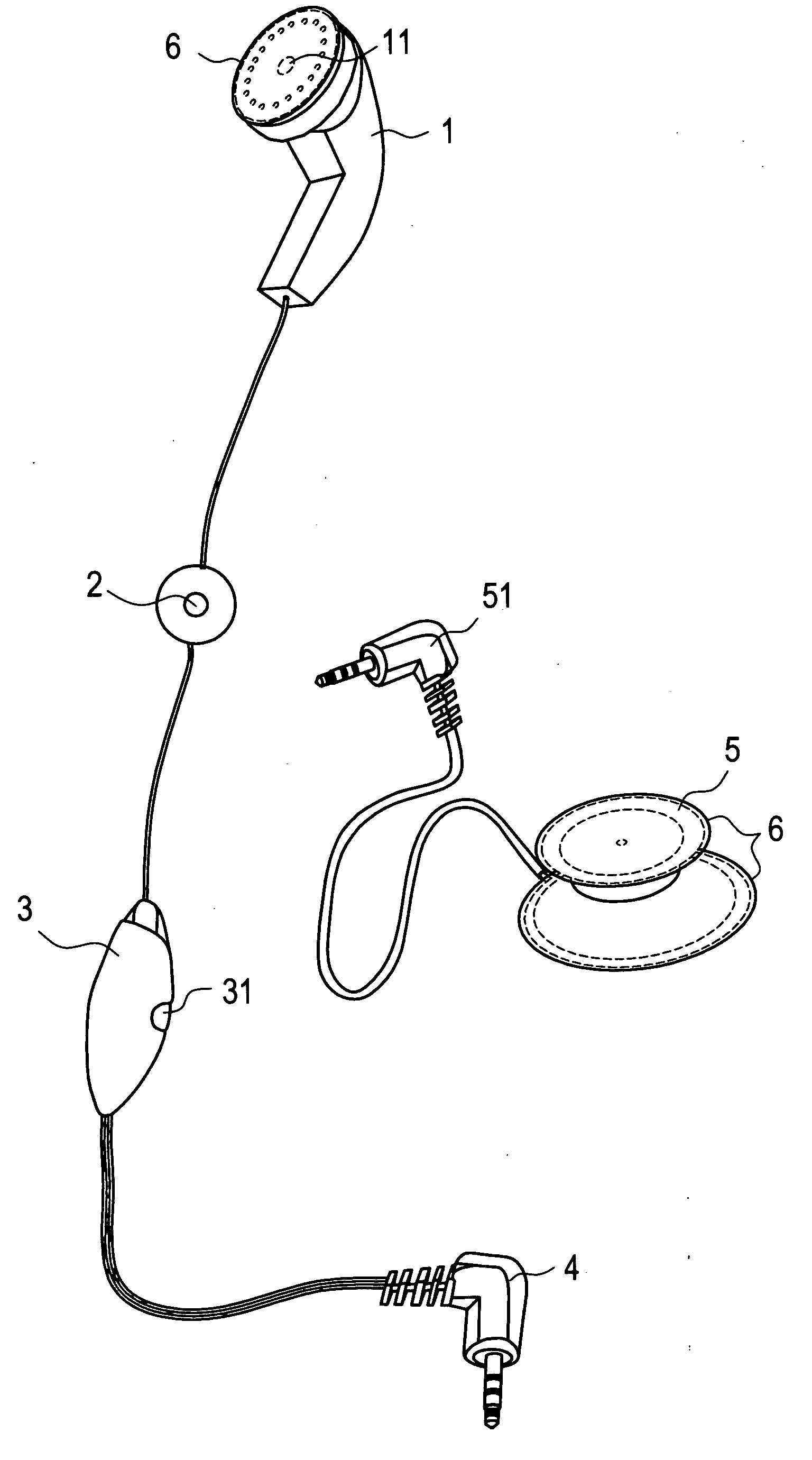

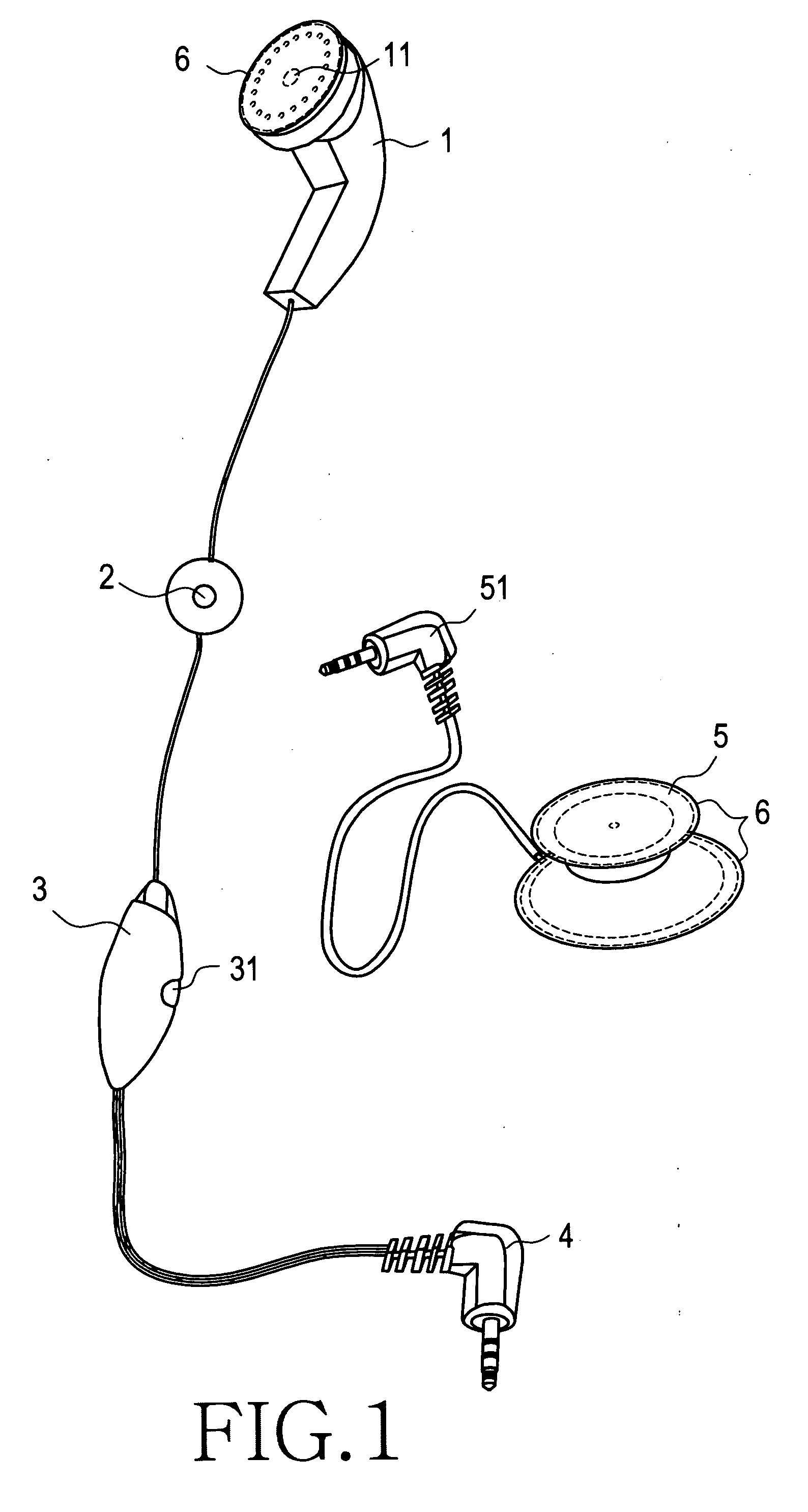

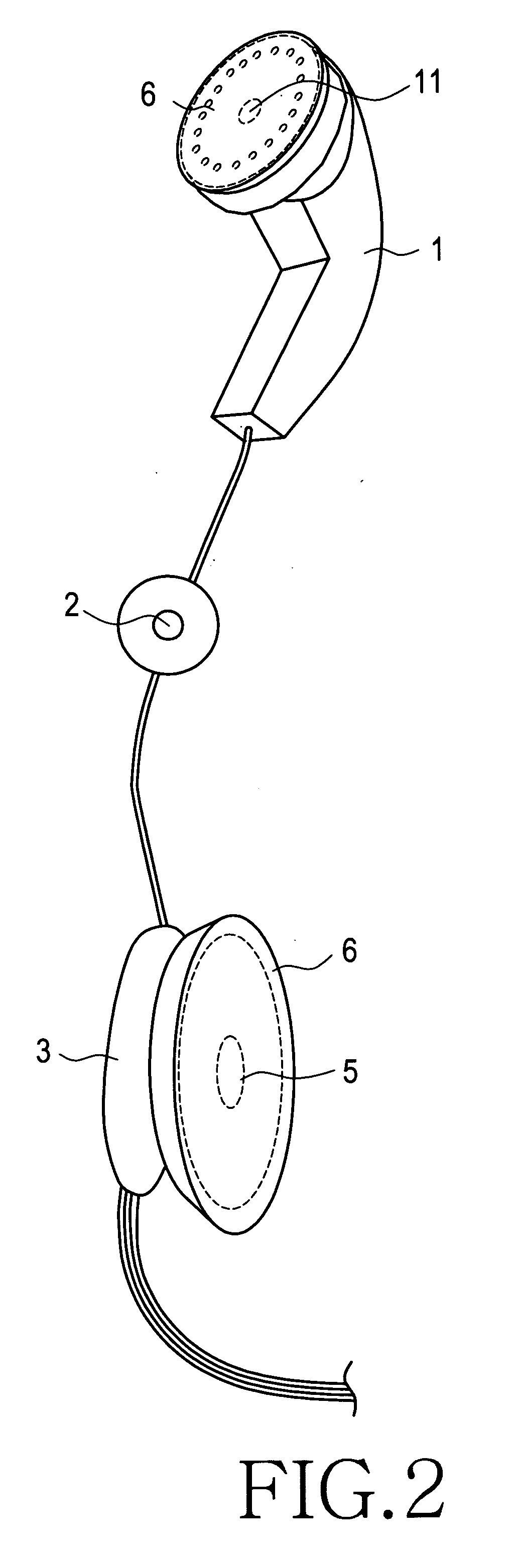

Home health care interacting instrument

InactiveUS20060281975A1Easy accessContinuous measurementStethoscopeCatheterMedical emergencyMedical staff

The integration of physical monitors (e.g. electronic stethoscope, sphygmomanometer etc.) with the earphone or microphone and the usage of communications equipments (e.g. cellular, PDA or computer etc.) let the medical personals evaluate the patient's condition immediately on line; the patient can make use of various physical monitors to check himself / herself by following the guidance and instruction from medical personals. In this way, medical personals remotely could get the most correct information and find the real cause of the disease in a short time.

Owner:YANG CHANG MING

Smart cap with communication function

ActiveUS20110119090A1Shorten the timeSave effortDrug and medicationsContainer filling methodsOptical scannersThe Internet

A smart cap for a medical container for the containment of solid medications having unique indicia. The cap is provided with an optical scanner configured with at least one locally contained or external data base having general medication identification data and optionally patient-specific information to scan and identify the medication (and optionally the dosage, specific formulations, manufacturing source, etc.) and to record and correlate information regarding patient medication usage (scanning of a medication is generally considered indicative of actual patient taking of the medication). The cap further comprises communication elements configured to transmit / receive “usage” through scanning of a unit dosage of the medication, to an external data base such as the patient's cell phone and or computer (such as with blue tooth or RF communication) or via a telephone call or internet transmission to a data base of a pharmacy or physician or other health care provider

Owner:LAZAR STEVEN

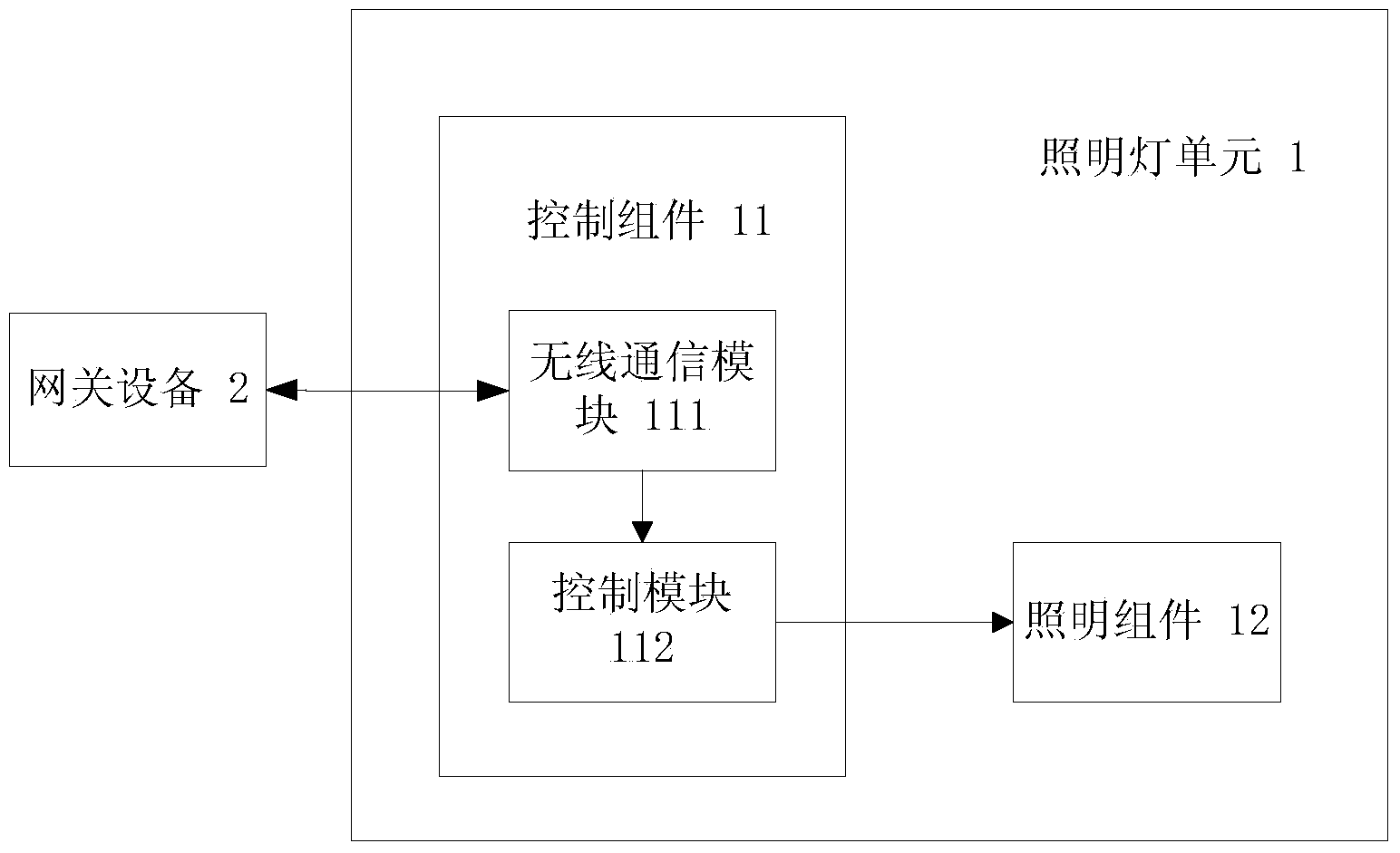

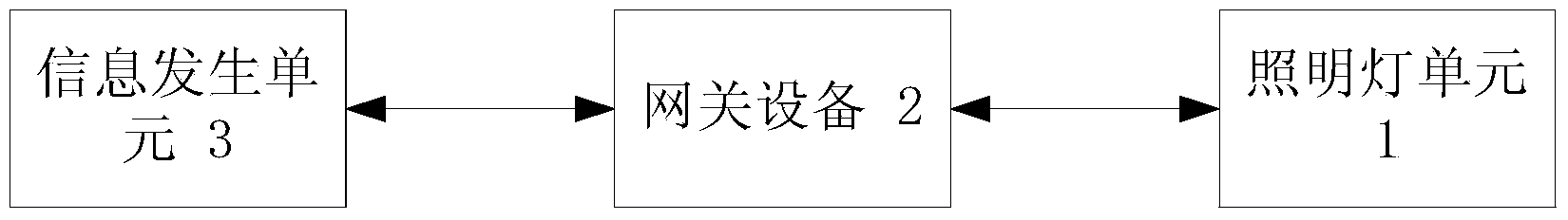

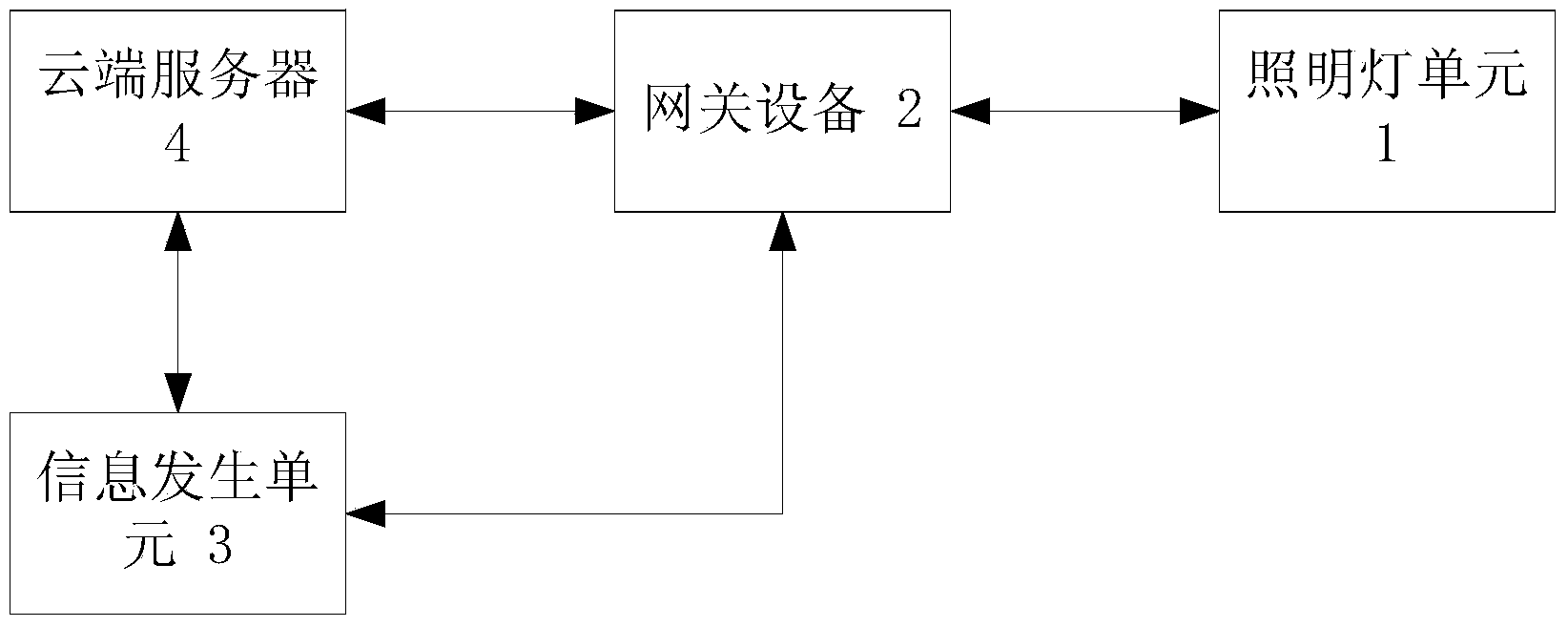

Prompt system for intelligent lighting lamp

InactiveCN104053285ASave wasteEliminate construction difficultiesElectric light circuit arrangementEnergy saving control techniquesIntelligent lightingWireless data

The invention discloses a prompt system for an intelligent lighting lamp. The prompt system comprises a lighting lamp unit, a gateway device and an information generation unit. The gateway device is connected with the lighting lamp unit and the information generation unit respectively through wireless data. When the state of the information generation unit changes, prompt information is generated and sent to the gateway device. The gateway device controls the lighting lamp unit to execute corresponding command actions according to the received prompt information. By means of the prompt system for the intelligent lighting lamp, the information prompt function is achieved for lighting lamps, and the multipurpose function is achieved for the lighting lamps.

Owner:NANJING IOT SENSOR TECH

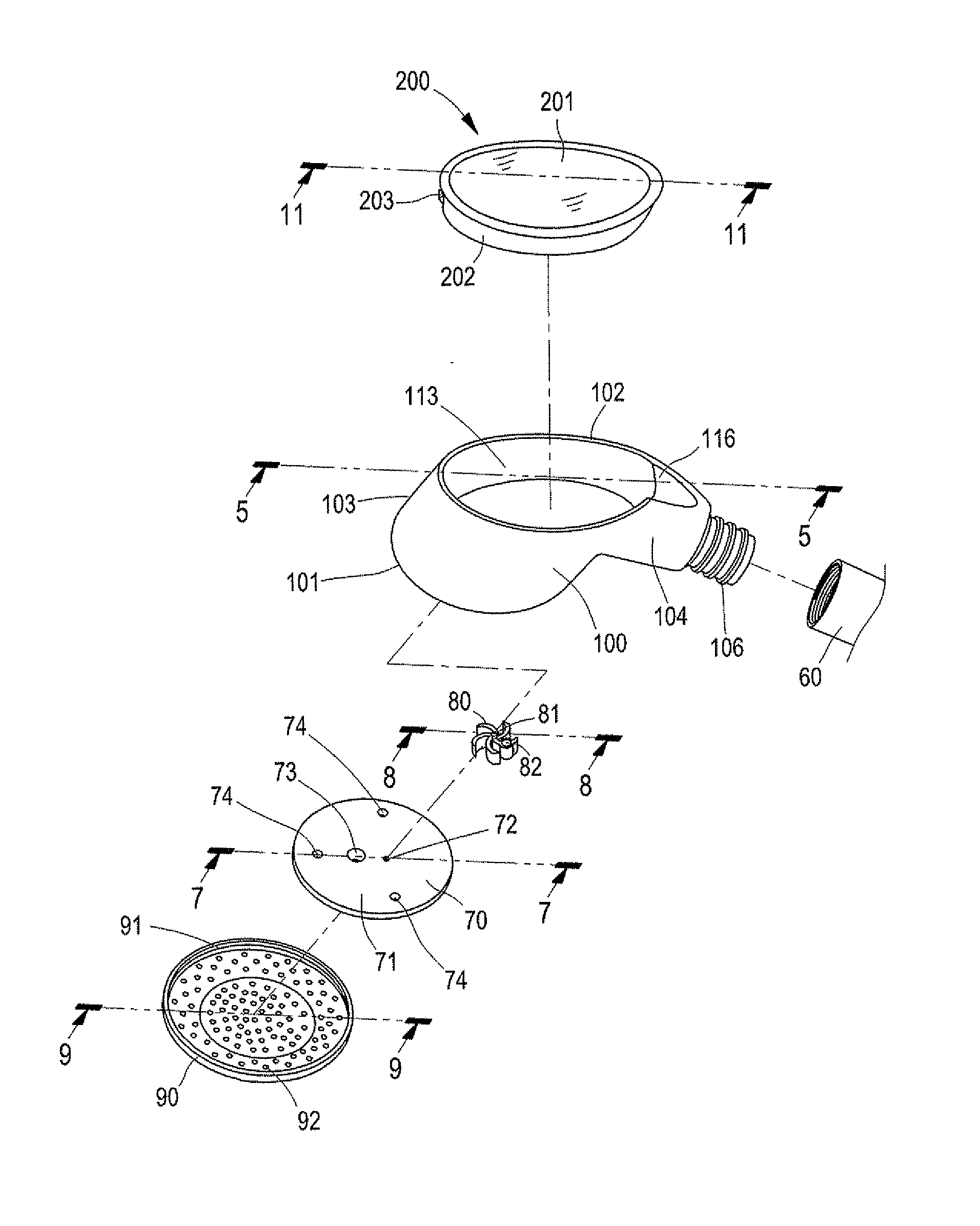

Hand Held Shower Head With Filter Replacing Pre-Alarm Device

ActiveUS20140042240A1Save resource wasteSave moneySpray nozzlesLiquid transferring devicesHand heldEngineering

The present invention provides a hand held shower head with filter replacing pre-alarm device, which comprises a round recess socket containing a detachable alerting pod is created in the reverse side of a shower head shell. A signal circuit device is embedded in the alerting pod for measuring and displaying function. The alerting pod can be either inserted into the recess socket for normal measuring and alerting function or detached off the recess socket for battery recharging operation. Thereby, not only the shower head shell can be adequately powered but also the alerting pod can be separated out of the shower head shell for independently recharging operation so that the entire shower head shell is unnecessary to discarded and replaced even the DC power supply in the signal circuit device is running out. Thus, it not only saves resource waste but also conserves economical expense incurred by frequent replacement of the shower head.

Owner:CAI YING LIN +1

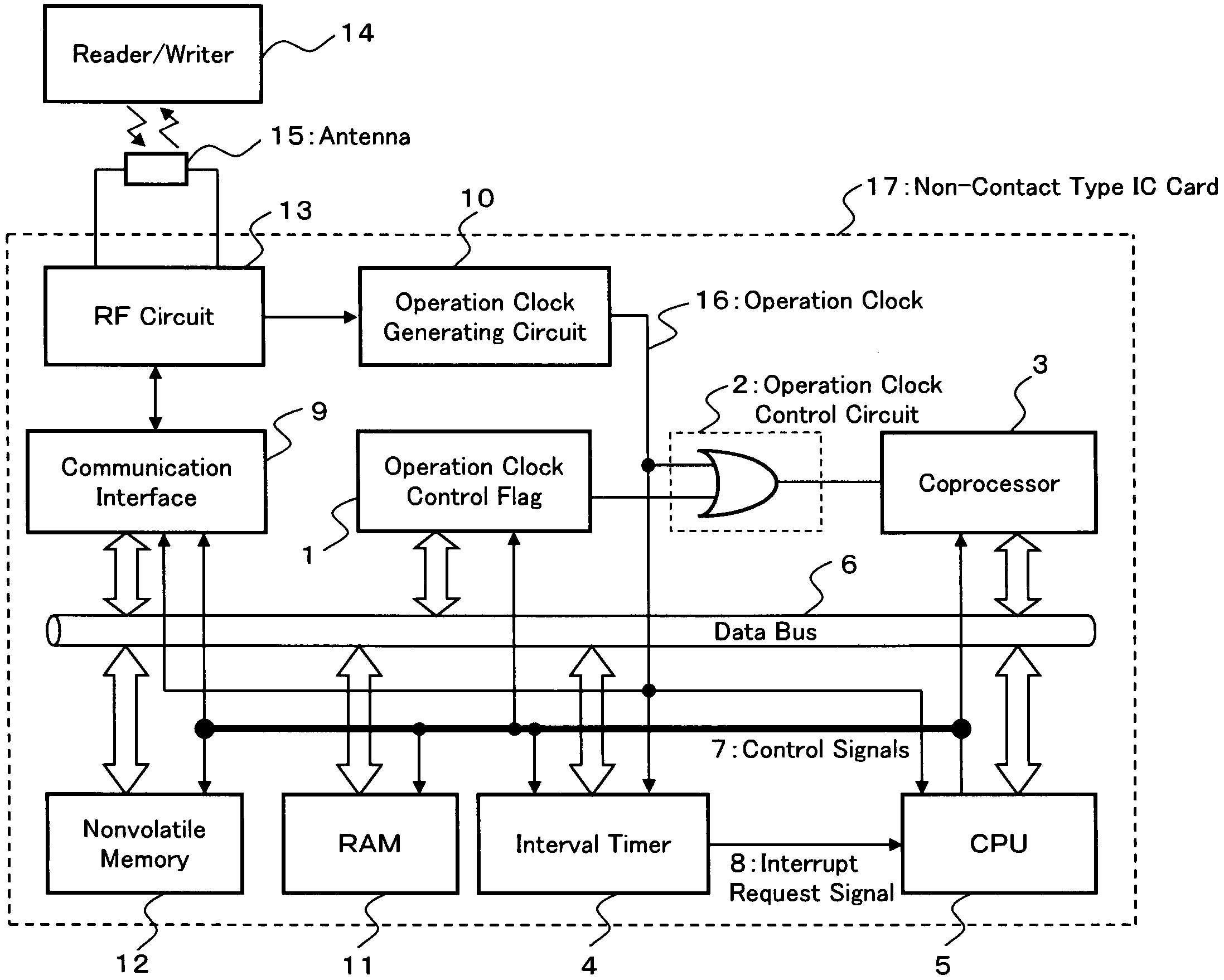

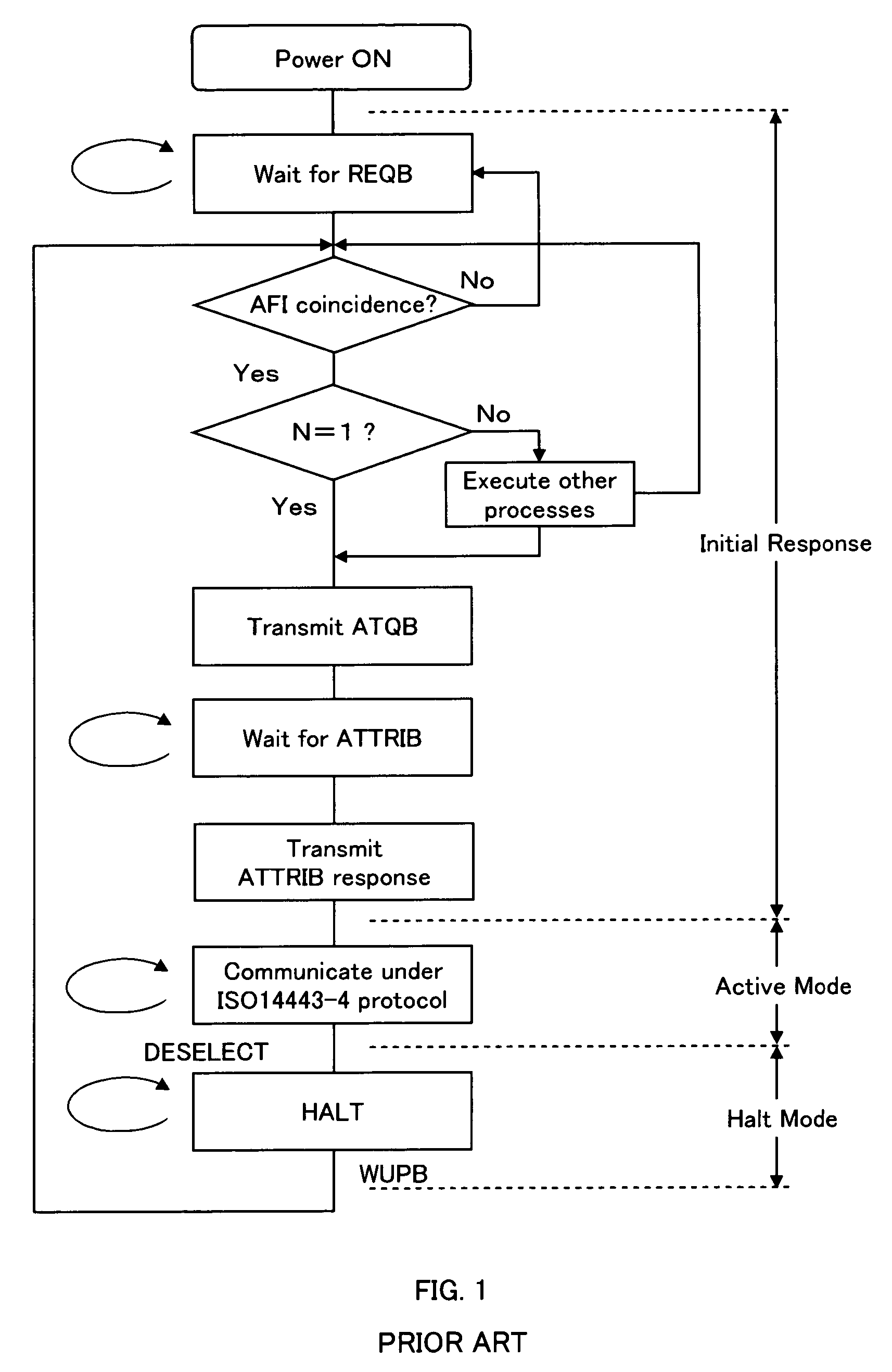

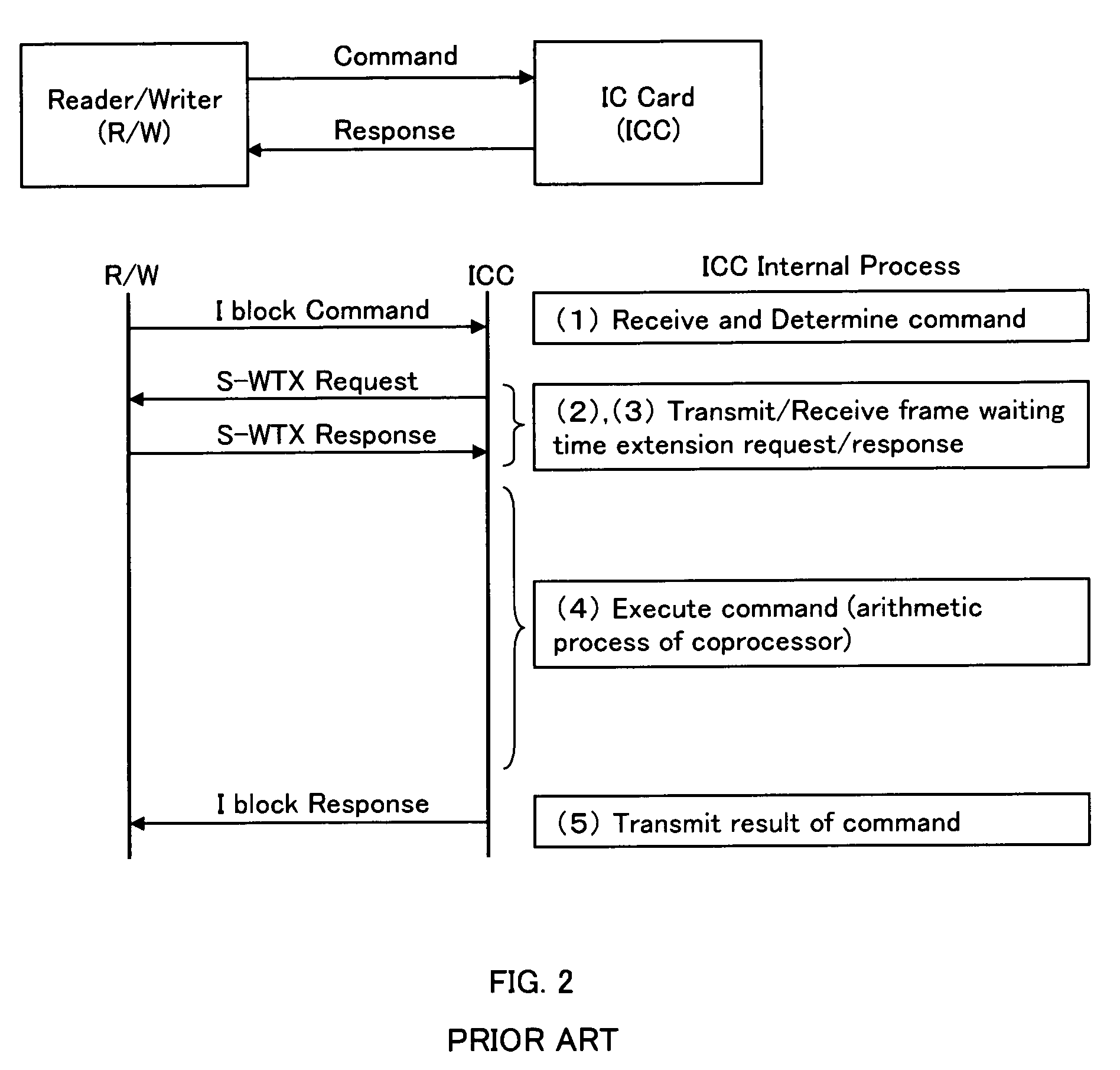

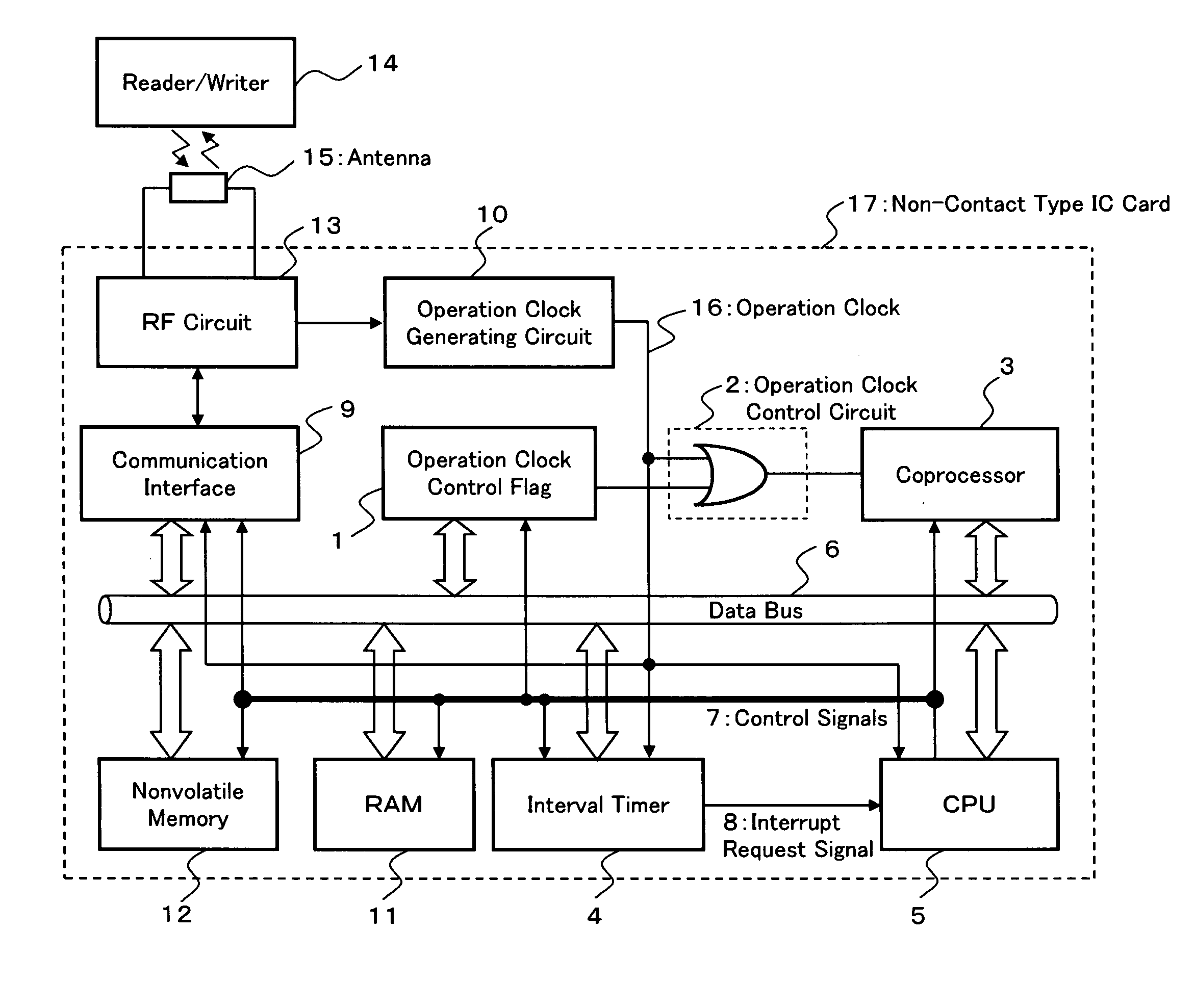

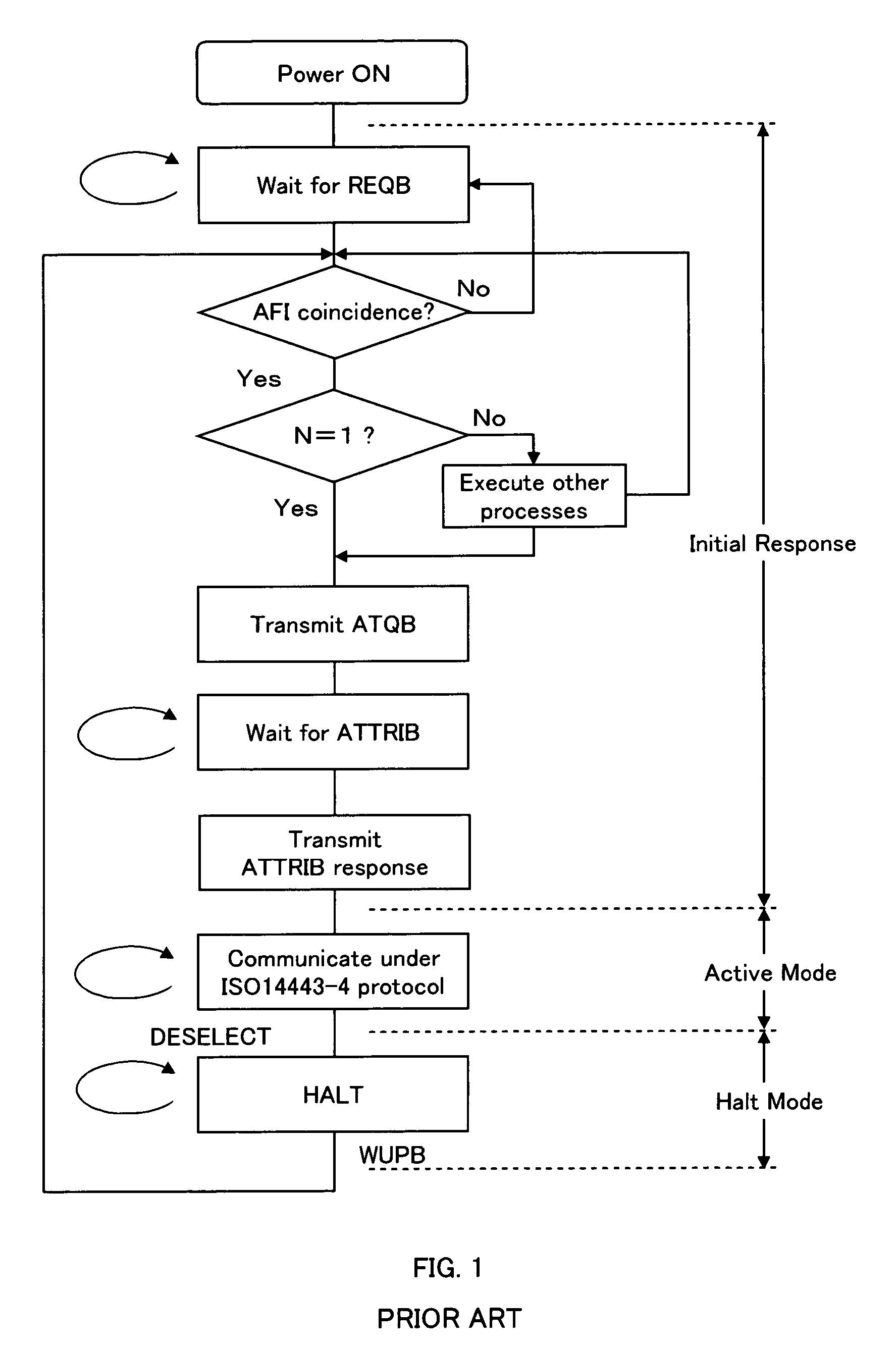

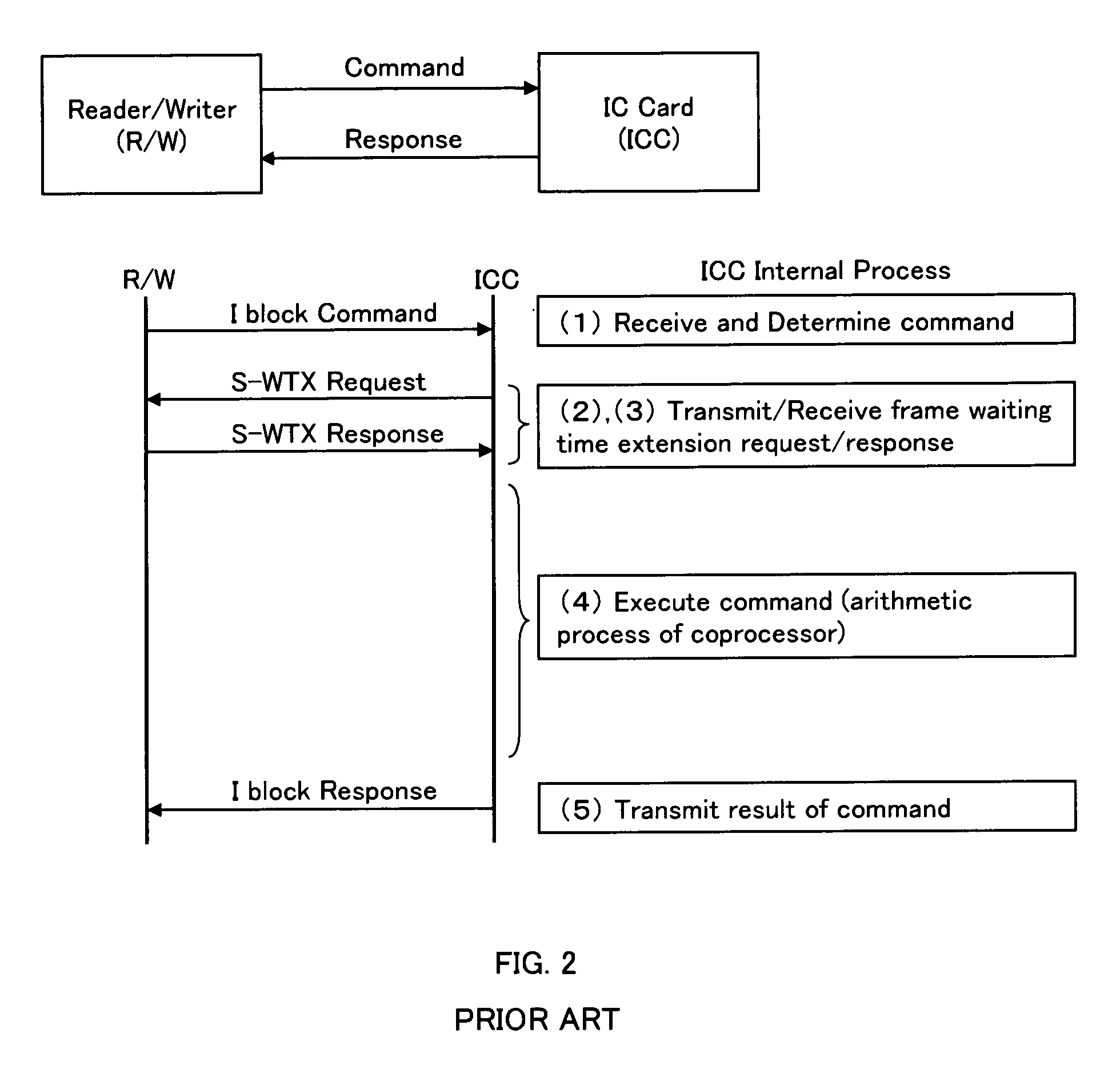

IC card with built-in coprocessor for auxiliary arithmetic, and control method thereof

InactiveUS7364083B2Avoid it happening againFacilitate communicationFloating sedimentation devicesWater treatment parameter controlArithmetic processing unitCoprocessor

An IC card according to the present invention comprises, a built-in coprocessor for an auxiliary arithmetic in addition to a main arithmetic processing unit, an interval timer for outputting an interrupt request signal upon lapse of a set time shorter than the frame waiting time, and coprocessor control means for controlling the coprocessor operation by suspending supply of an operation clock to the coprocessor in accordance with the output of the interrupt request signal and resuming supply of the operation clock to the coprocessor in accordance with a predetermined response input from an external device. Upon receipt of a command from the external device, the contents of the command are determined, and the time shorter than the frame waiting time is set in the interval timer thereby to start the interval timer.

Owner:SHARP KK

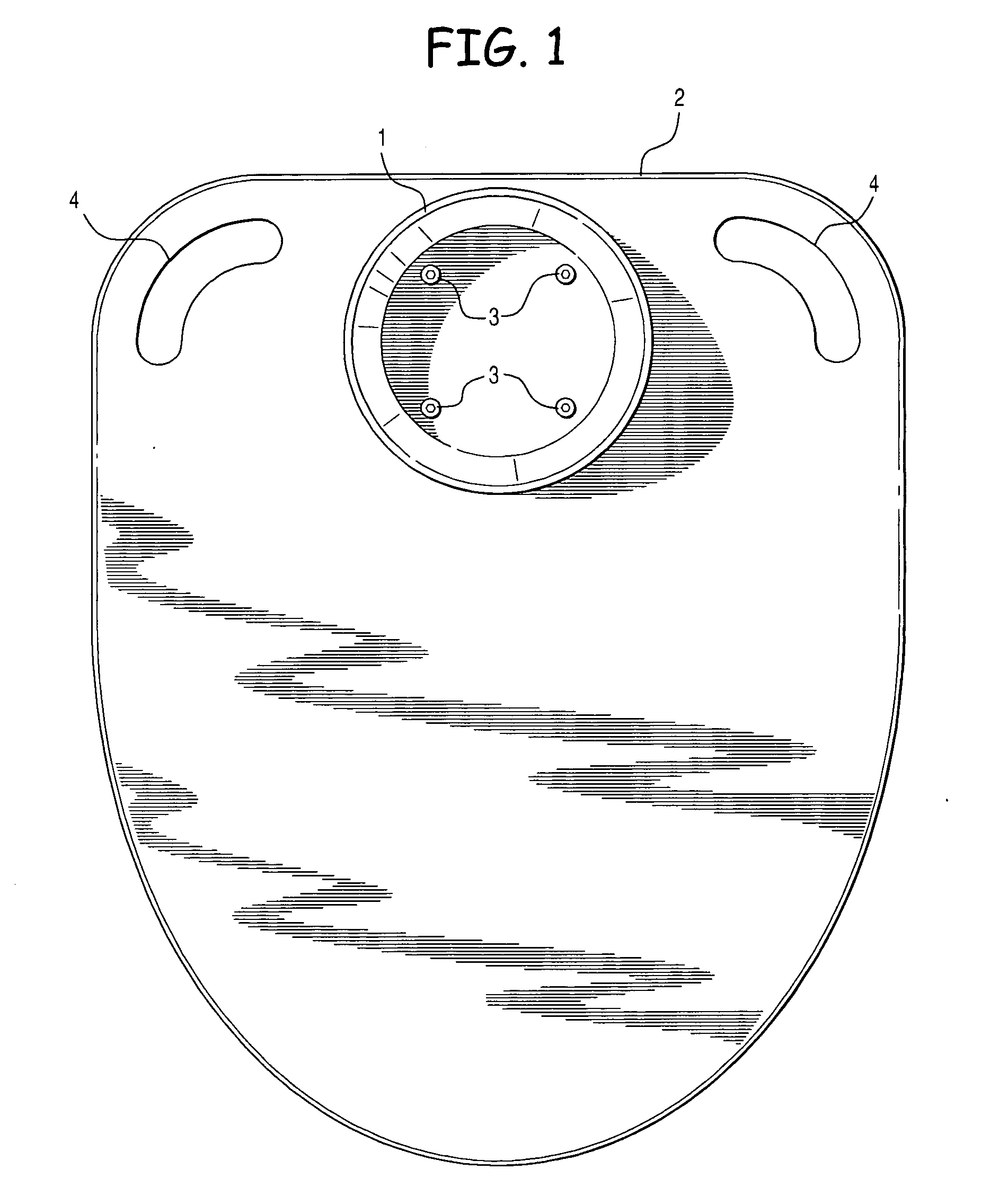

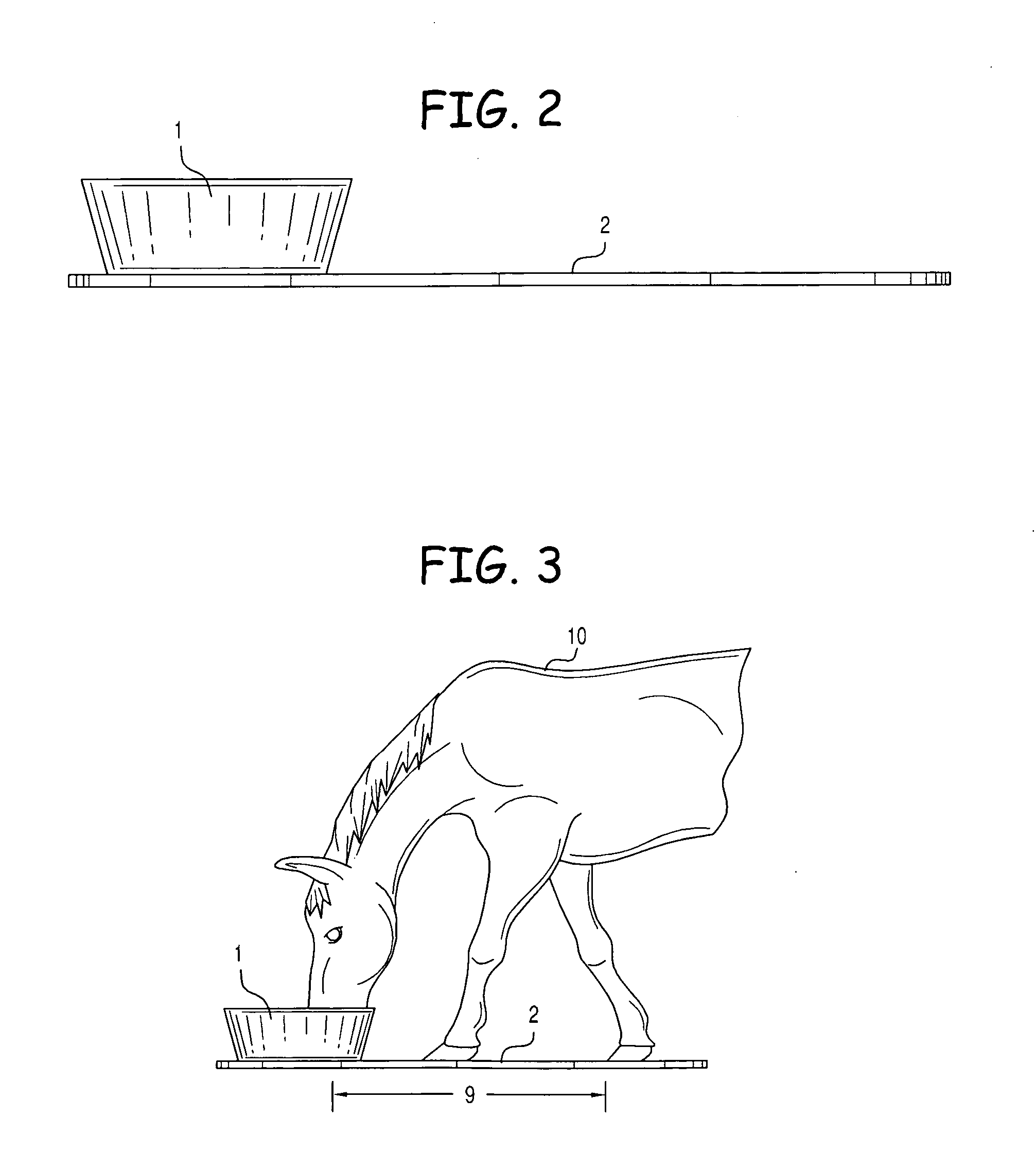

Mat/bowl horse and livestock feeder

InactiveUS20060096544A1Save wasteAvoid healthAnimal feeding devicesAnimal housingEngineeringLivestock

The invention of the mat / bowl horse and livestock feeder is a feeding device that secures a feed bowl in place so that it cannot be moved, flipped or tipped as a horse or livestock feeds from it. It's a large rubber mat with a bowl attached at one end. The animal's weight on the mat portion of it prevents it from moving and stabilizes the bowl in place, securing the contents in the bowl as the animal feeds.

Owner:SPIWAK MARK WILLIAM

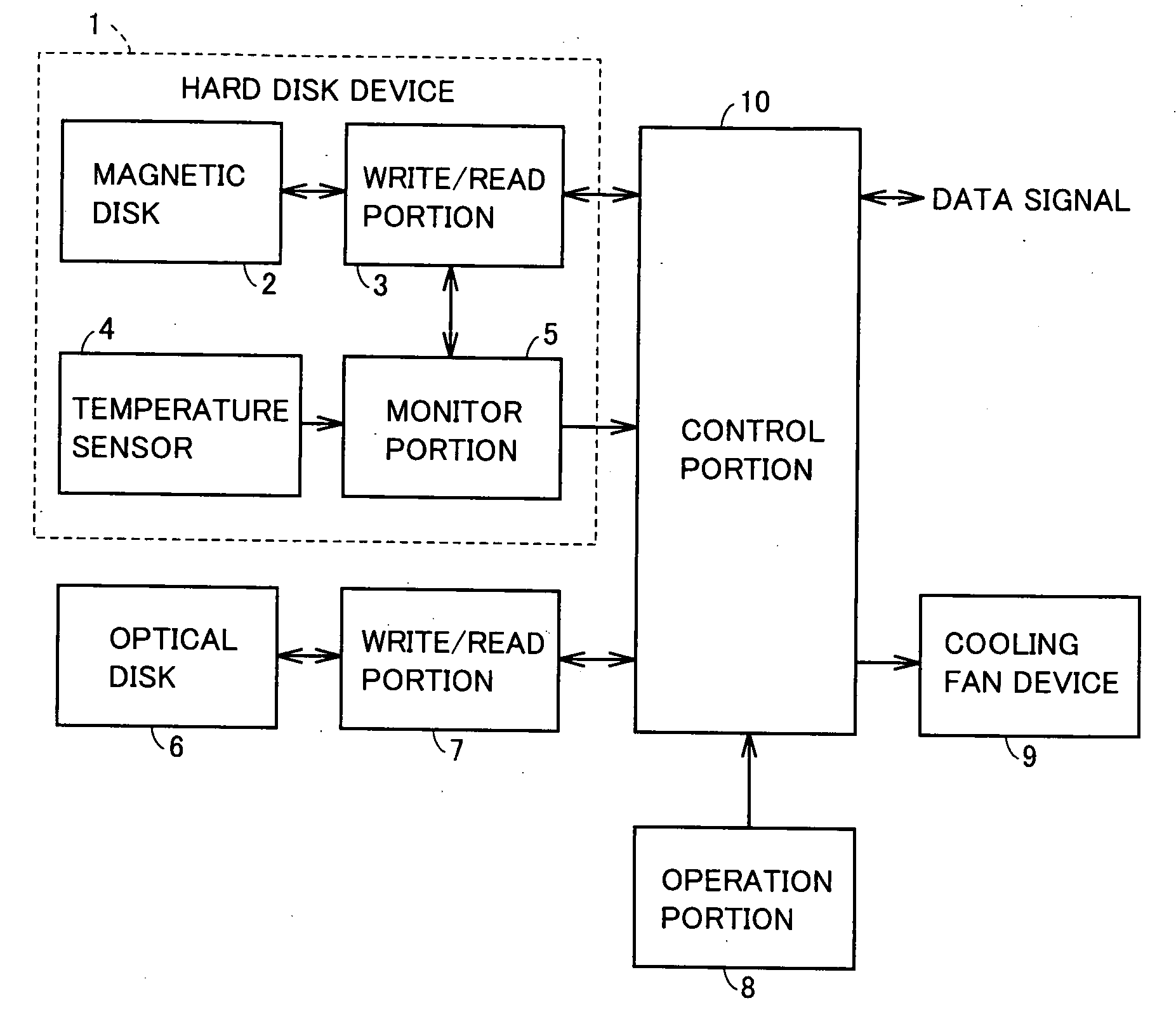

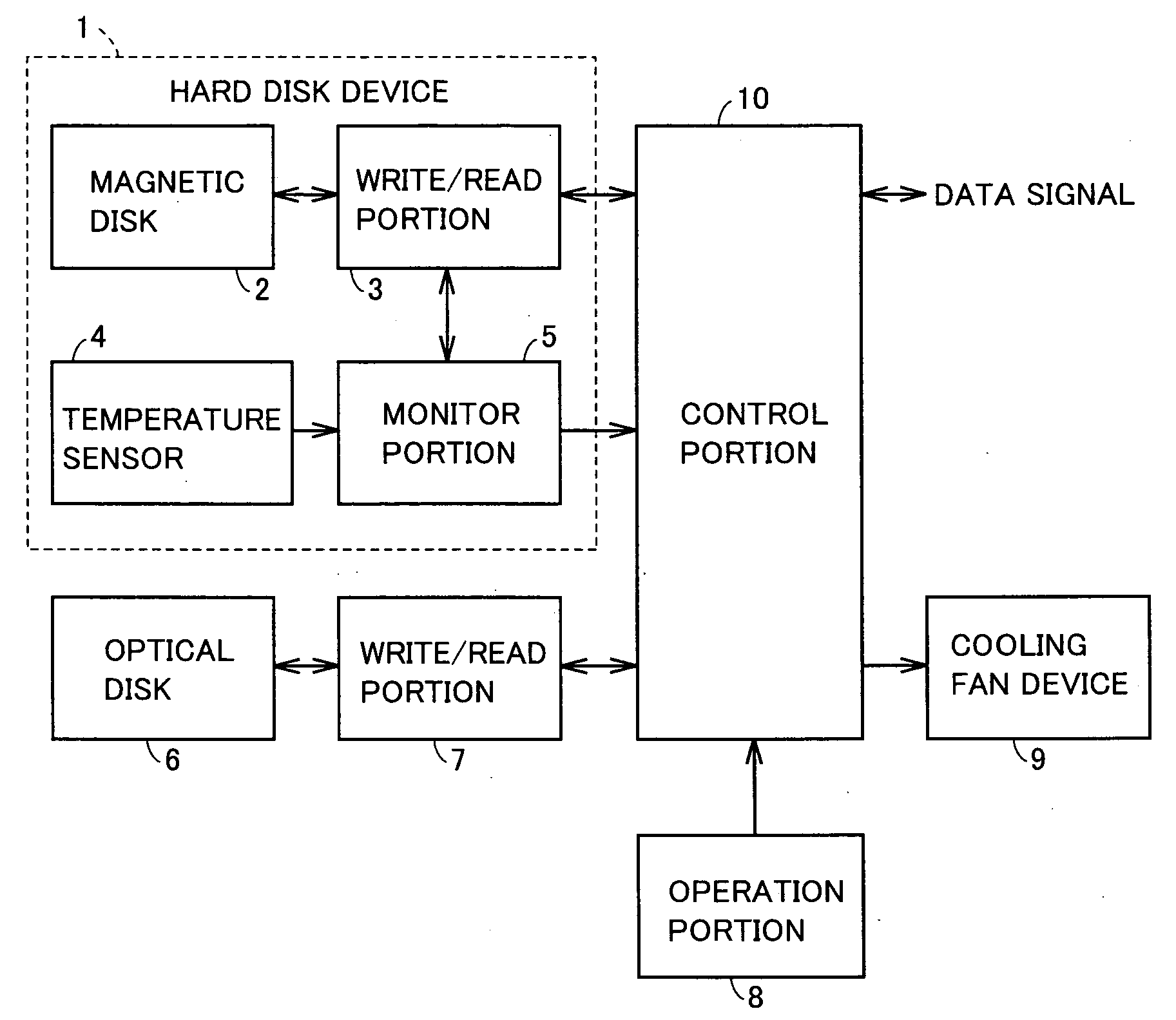

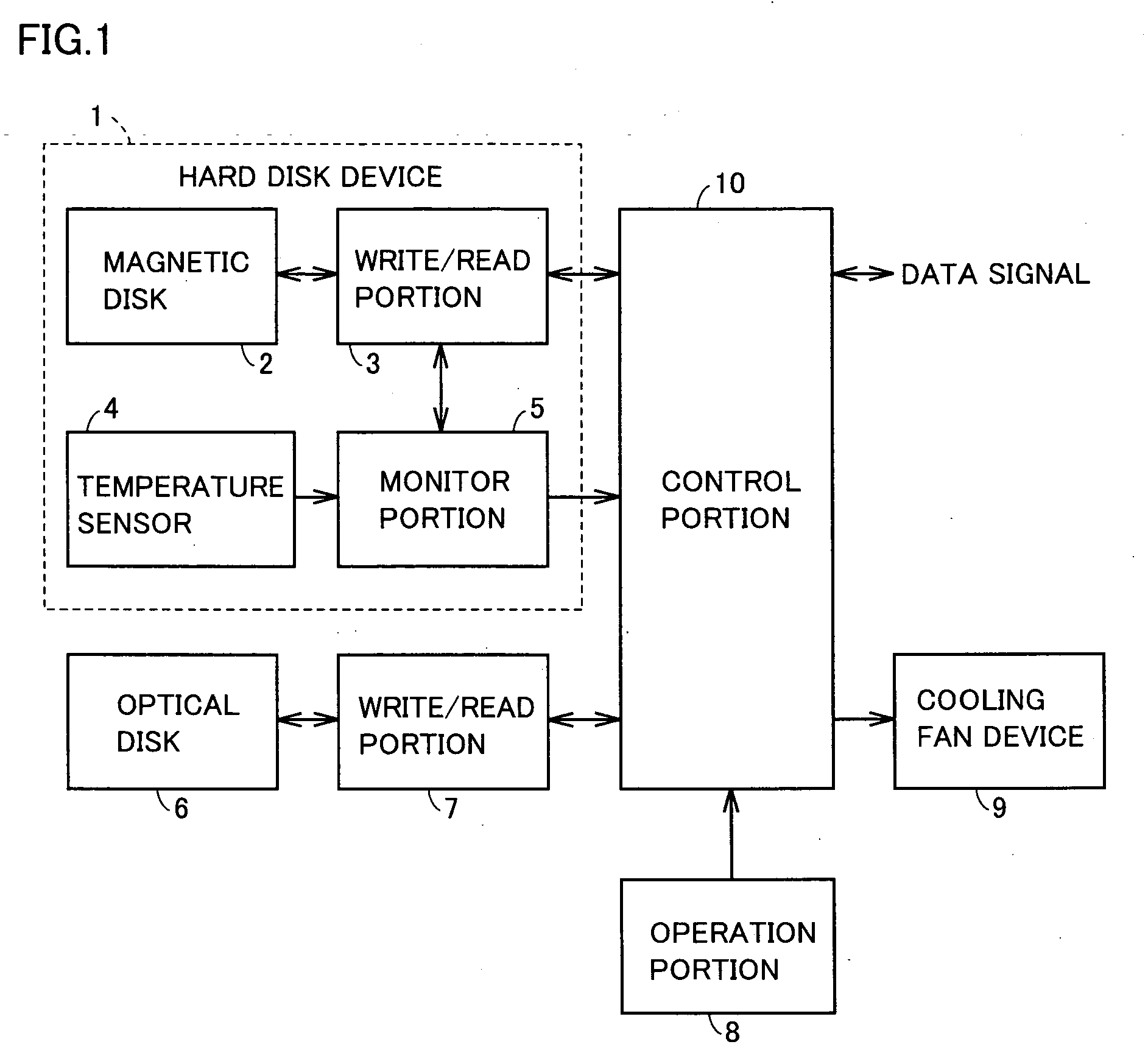

Recording/reproduction apparatus having hard disk device incorporated therein

InactiveUS20070012614A1Low costRaise countReducing temperature influence on carrierDigital data processing detailsDVD recorderData signal

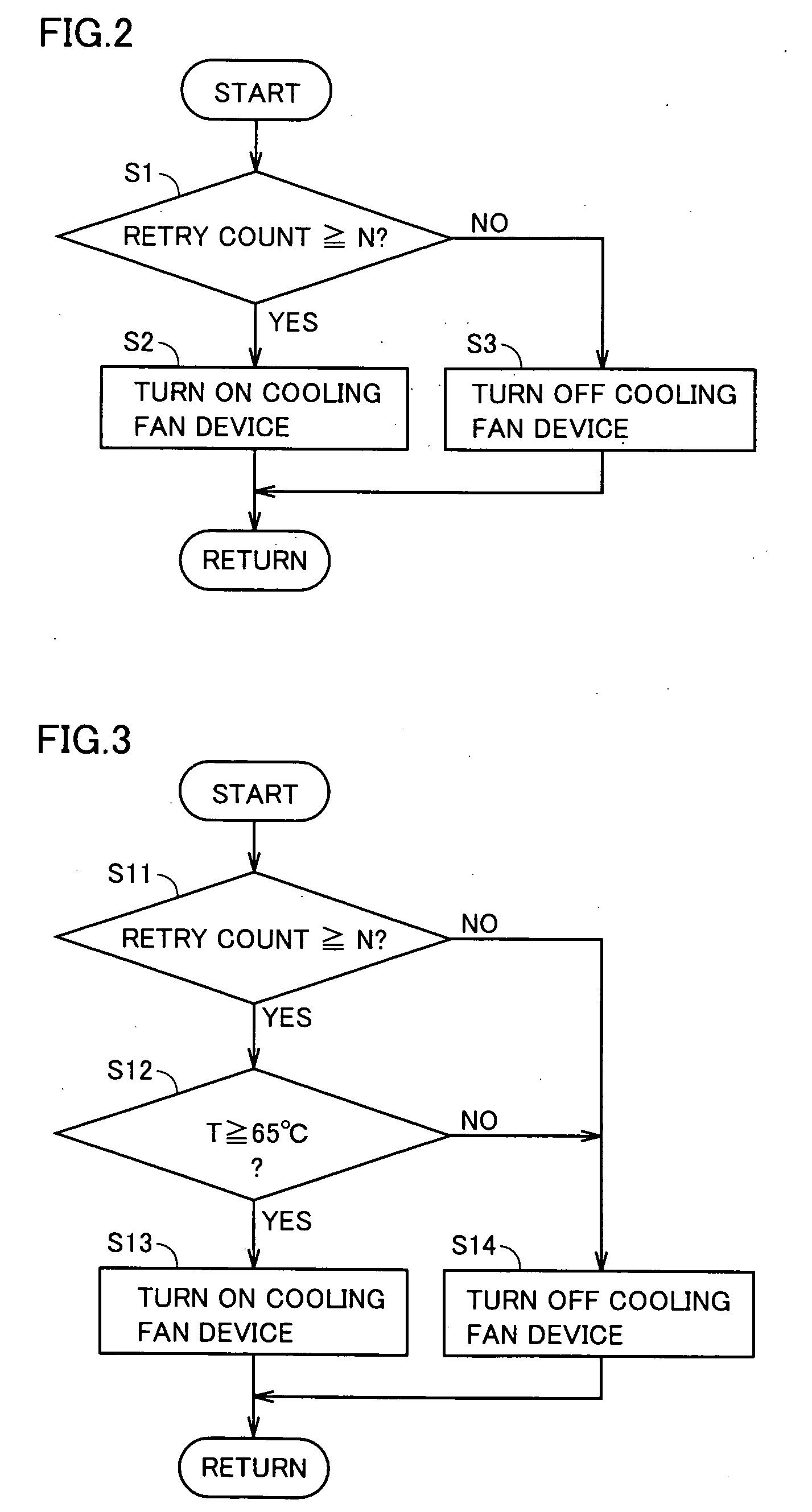

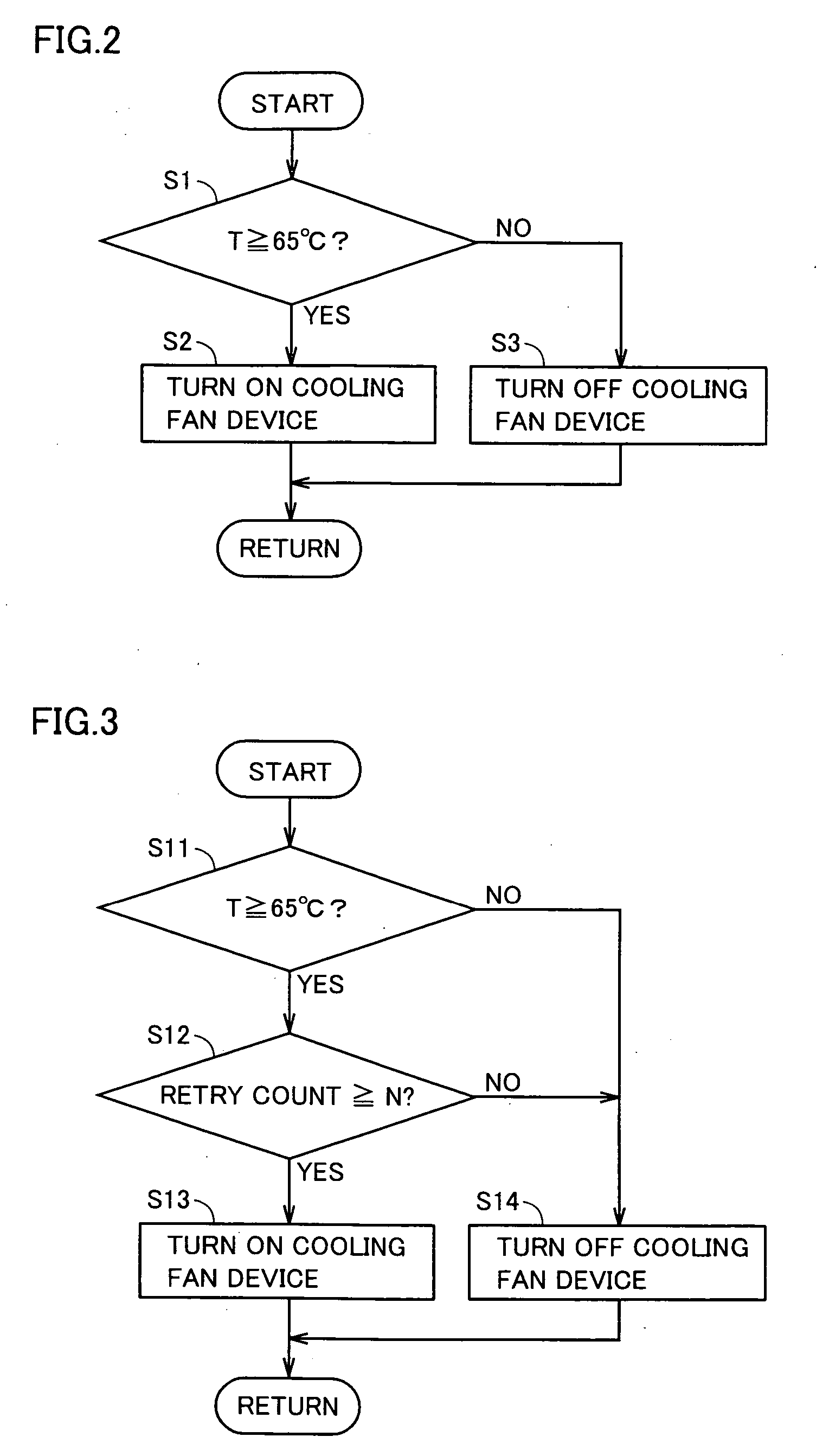

A DVD recorder includes a control portion operating in response to a signal received from a monitor portion of a hard disk device and indicating how many times writing a data signal is retried. If the current retry count is at least a predetermined number of times the control portion turns on a cooling fan device. If the current retry count is smaller than the predetermined number of times the control portion turns off the cooling fan device. As a signal output from the hard disk device can be utilized to control the cooling fan device, the apparatus can be less costly than that provided with a separate, dedicated temperature sensor, as conventional.

Owner:FUNAI ELECTRIC CO LTD

Method of fabricating thin film solar cell and apparatus for fabricating thin film solar cell

InactiveUS20110027938A1Reduce processing costsSave solutionLiquid surface applicatorsSemiconductor/solid-state device manufacturingElectrical batteryEngineering

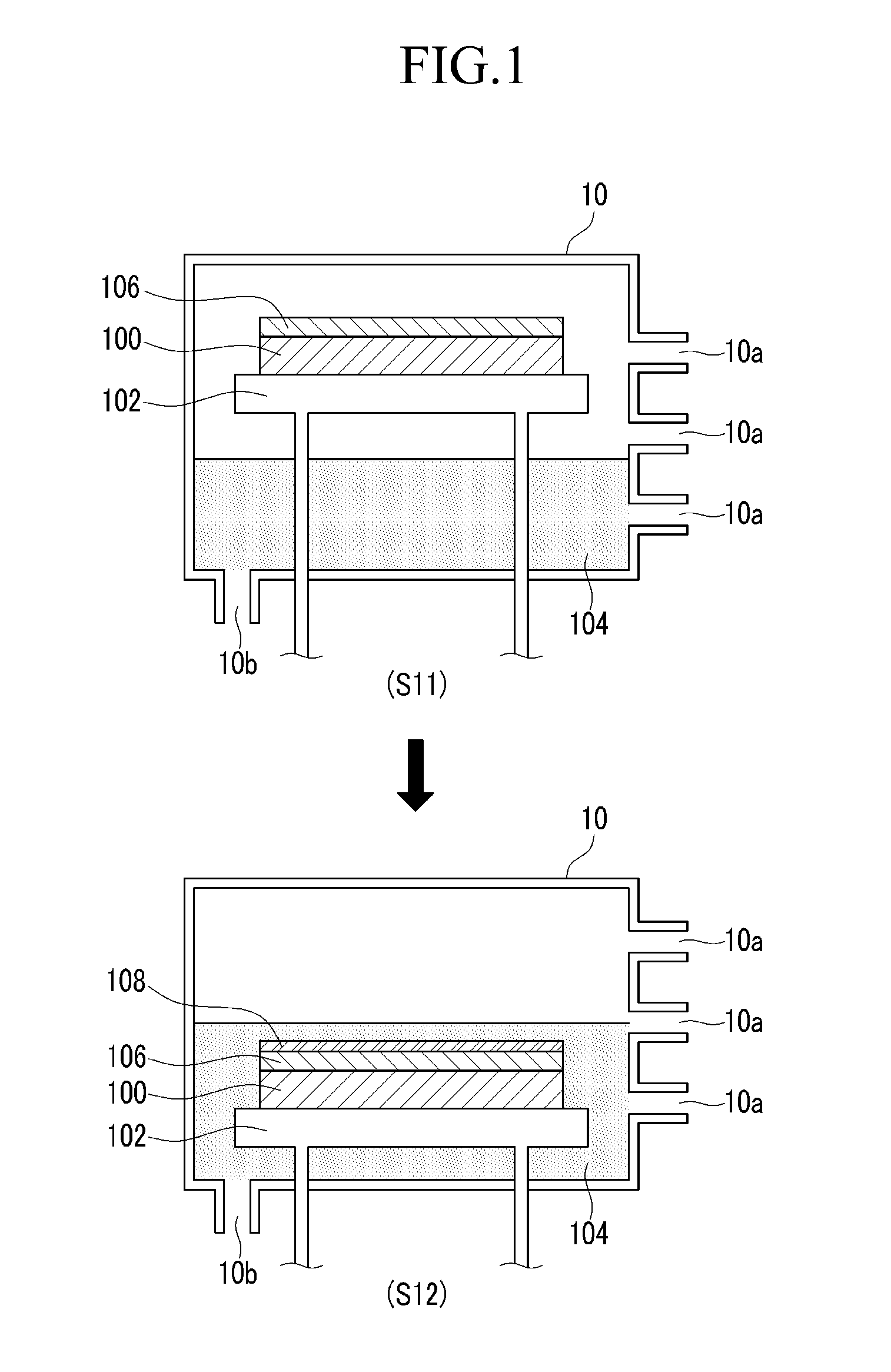

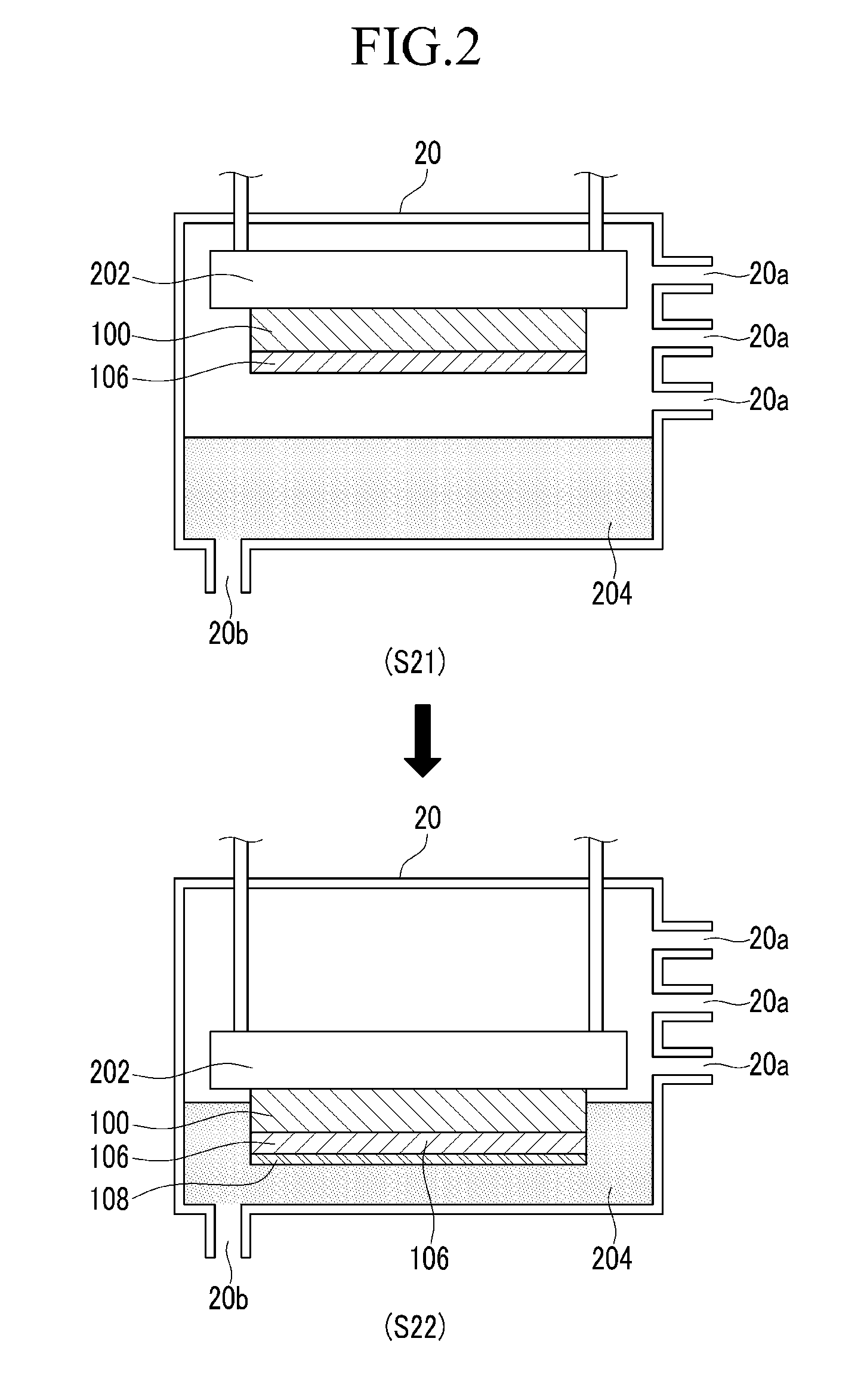

Disclosed is a method of fabricating a thin film solar cell including introducing a reaction solution into a reaction chamber, fixing a supporter onto a loader, disposing the loader in the reaction chamber to immerse the supporter into the reaction solution, and heating the supporter and coating a buffer layer. In addition, an apparatus of fabricating a thin film solar cell including a reaction chamber mounted with an inlet of a reaction solution and an outlet of waste water, and a loader disposed in the reaction chamber and being capable of moving up and down, is disclosed.

Owner:SAMSUNG DISPLAY CO LTD +1

Unit for the transfer and distribution of a liquid and method of manufacturing the same

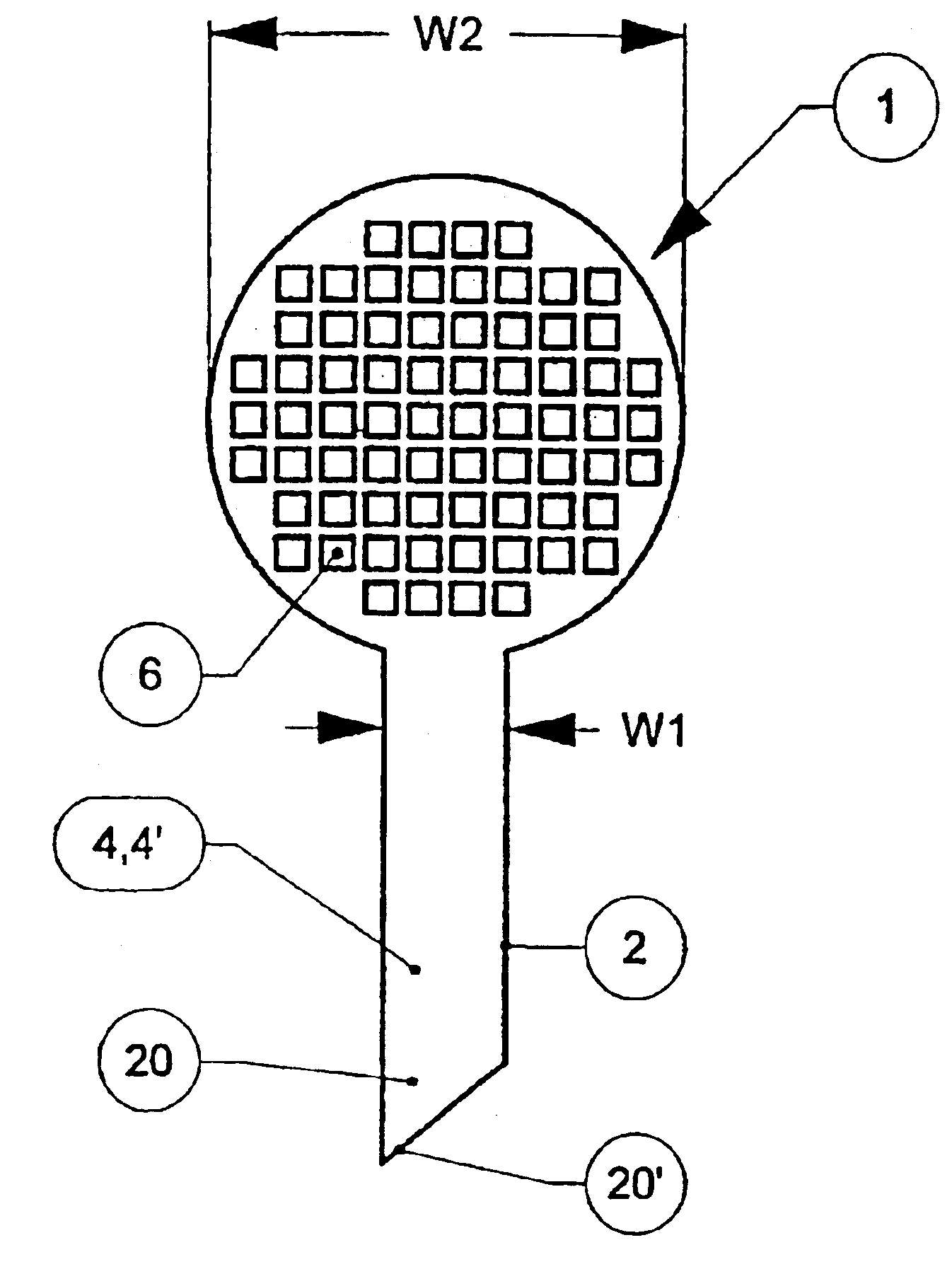

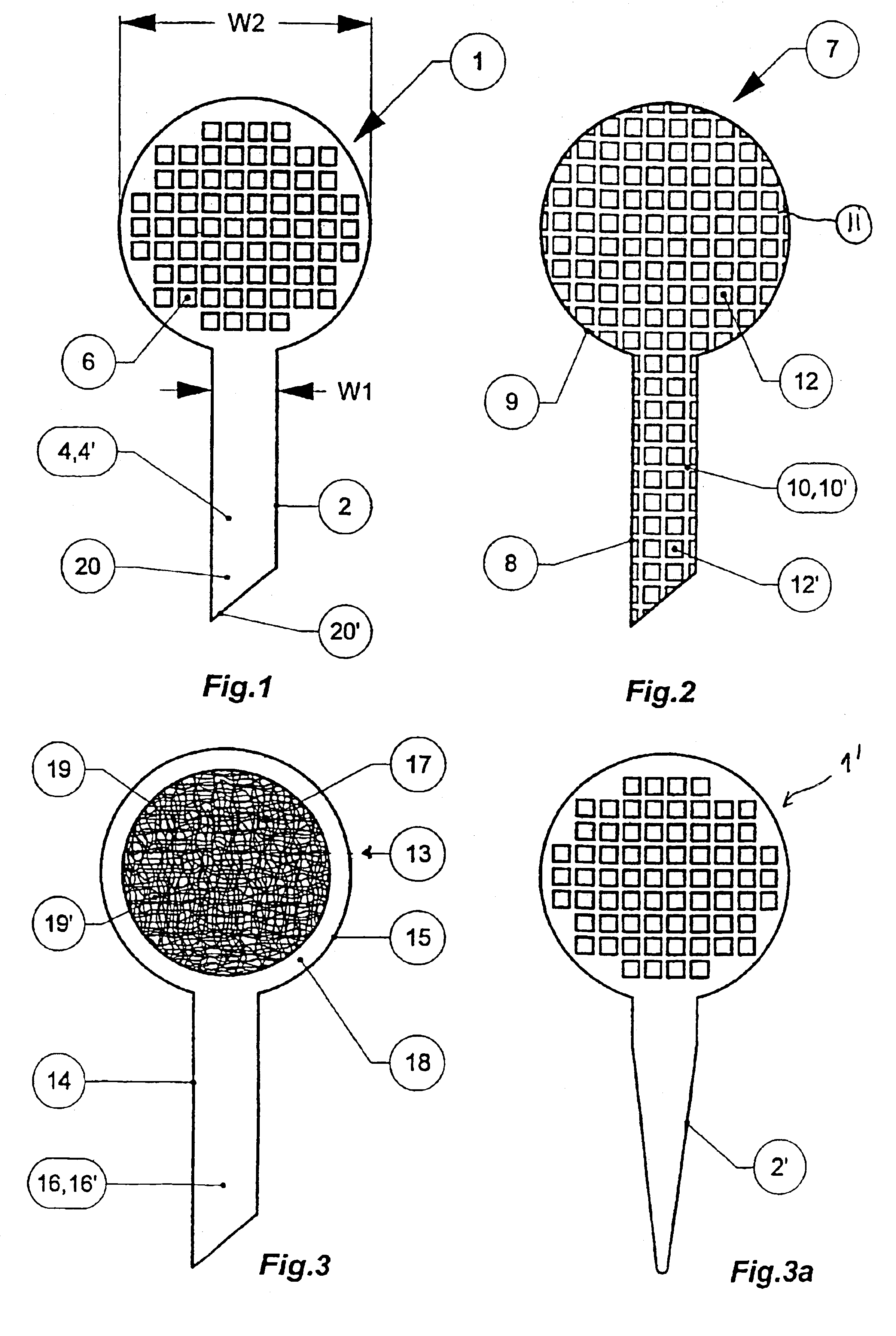

InactiveUS6921025B2Enhanced capillary actionEasy piercingLiquid flow controllersTobacco devicesEngineeringCapillary action

A unit (1) for the transfer and distribution of a liquid (27) using capillary action has an elongated shaft (2) and a screen (3). The shaft (2) includes a first capillary medium (4) suitable for drawing the liquid (27) from a reservoir (26) into the shaft (2) when a bottom portion (20) of the shaft (2) is disposed in the liquid. The screen (3) is connected to the shaft (2) and includes a second capillary medium (5) suitable for receiving the liquid (27) drawn by the first capillary medium (4) and distributing it over at least a major part of the screen (3) where it evaporates.

Owner:GIVAUDAN SA

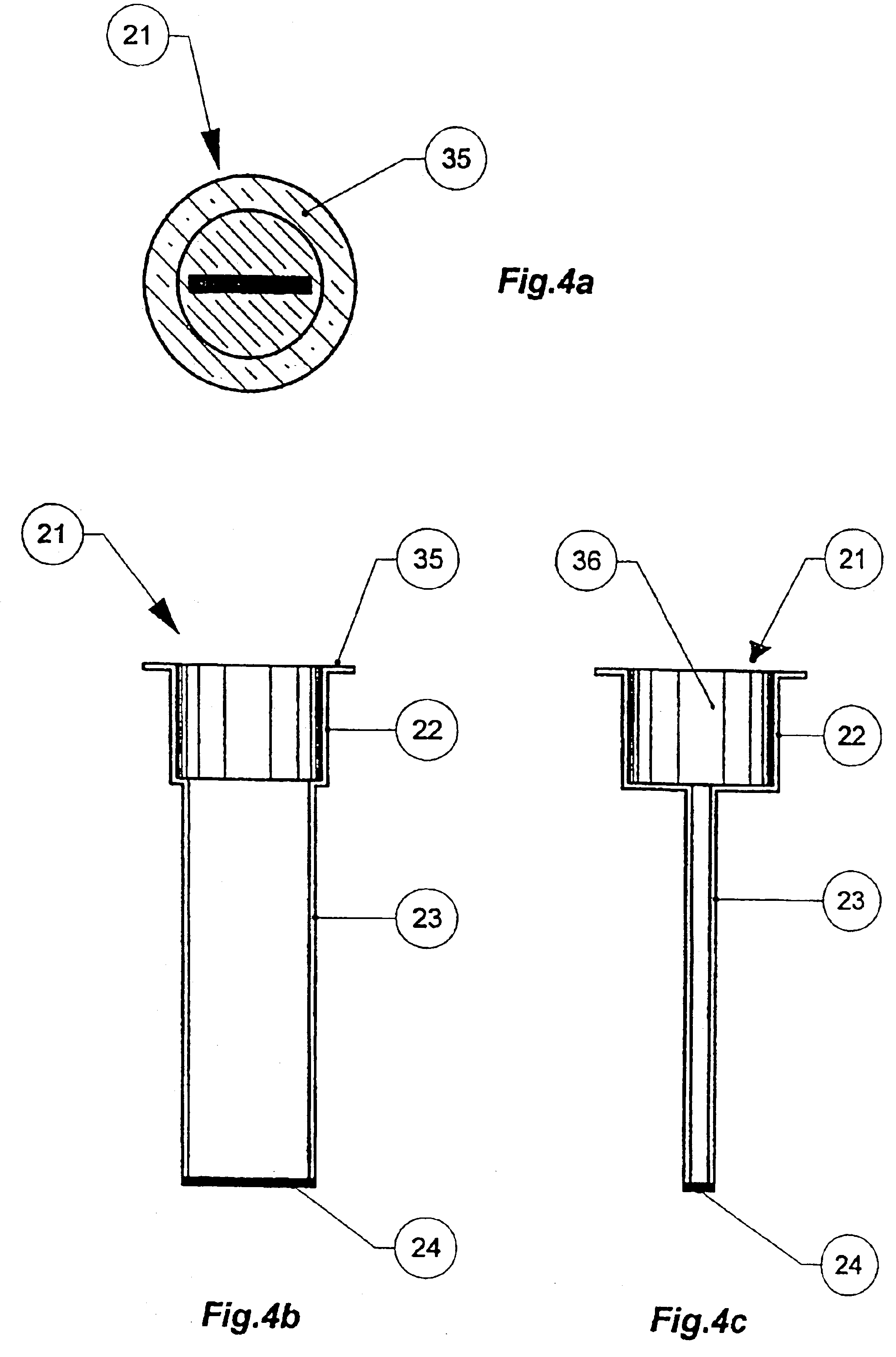

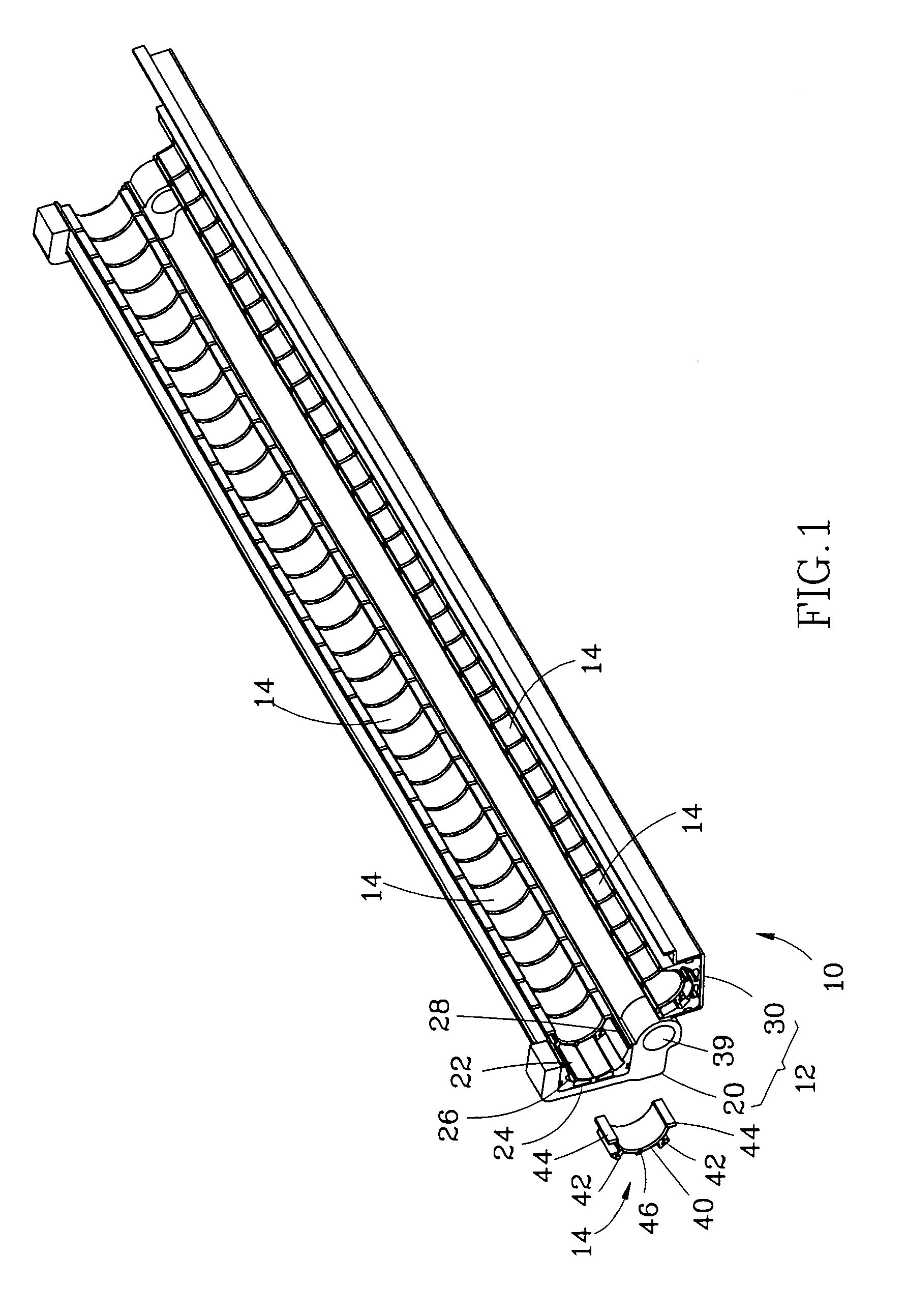

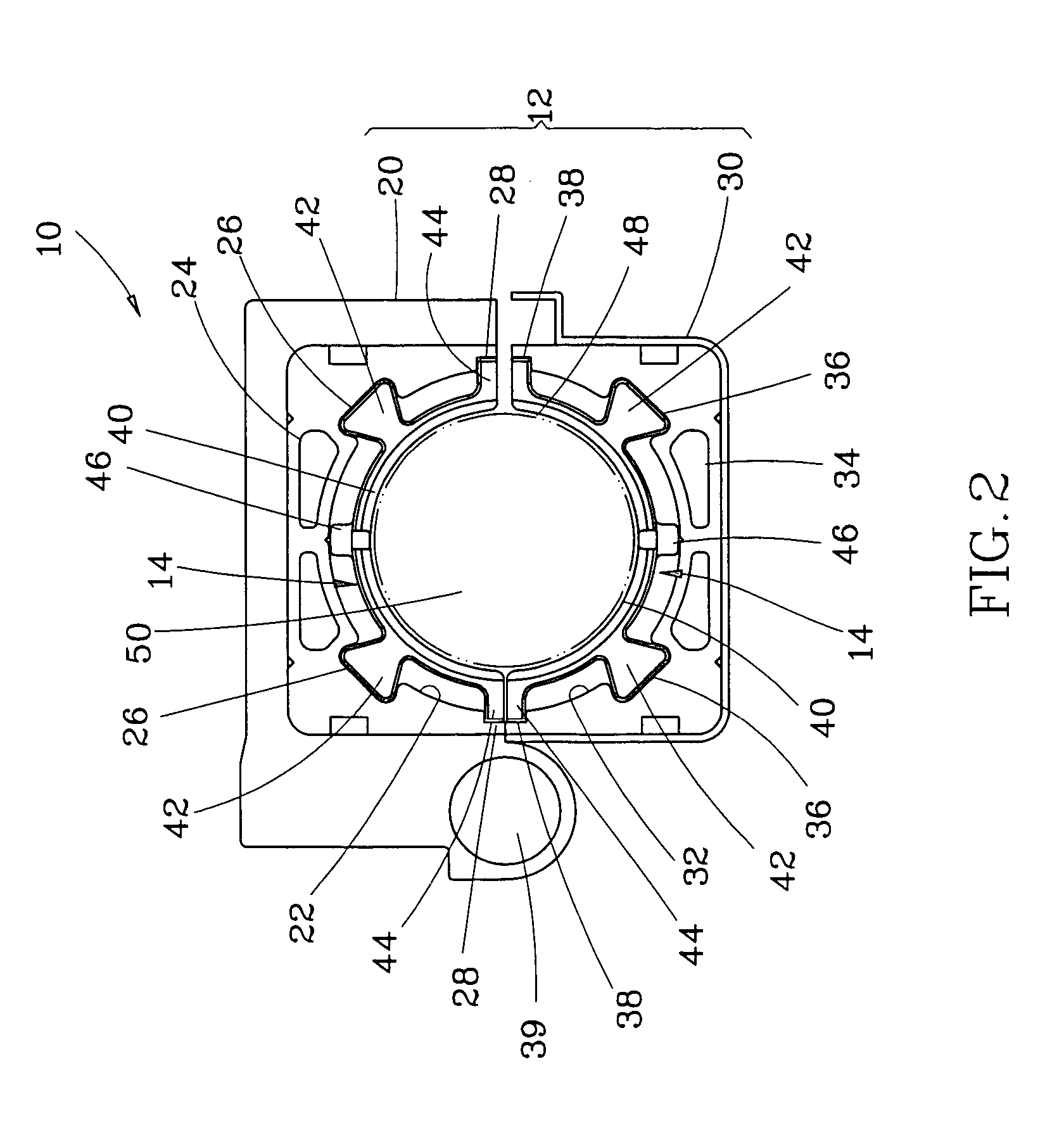

Feeder tube for bar feeder

InactiveUS20060278052A1Avoid environmental pollutionEasy to useLathesAutomatic conveying/guiding stockEngineeringMechanical engineering

For use in a bar feeder, a feeder tube is disclosed to include a holder base and a plurality of support members. The holder base has two hinged holder members each having retaining portions. Each support member has positioning portions respectively detachably engaged with the retaining portions of the holder members, and a bearing portion. The bearing portions of the support members define a cylindrical accommodation space for receiving a bar material therein when the two holder members are close.

Owner:BARLOAD MACHINE

IC card with built-in coprocessor for auxiliary arithmetic, and control method thereof

InactiveUS20050167513A1Avoid shortageExtended waiting timeFloating sedimentation devicesWater treatment parameter controlArithmetic processing unitCoprocessor

An IC card according to the present invention comprises, a built-in coprocessor for an auxiliary arithmetic in addition to a main arithmetic processing unit, an interval timer for outputting an interrupt request signal upon lapse of a set time shorter than the frame waiting time, and coprocessor control means for controlling the coprocessor operation by suspending supply of an operation clock to the coprocessor in accordance with the output of the interrupt request signal and resuming supply of the operation clock to the coprocessor in accordance with a predetermined response input from an external device. Upon receipt of a command from the external device, the contents of the command are determined, and the time shorter than the frame waiting time is set in the interval timer thereby to start the interval timer.

Owner:SHARP KK

Inorganic zinc silicate shop primer based on graphene modification and preparing method thereof

InactiveCN105733325ASolving Dispersion ProblemsFix stability issuesAnti-corrosive paintsGrapheneSolvent

The invention relates to the technical field of coatings, and provides a graphene-based modified inorganic zinc silicate shop primer and a preparation method thereof. When the coating has a low metal zinc content, its protection period can exceed that of inorganic silicic acid with high zinc content. Zinc workshop primer saves the consumption of metal zinc resources, reduces the generation of harmful zinc fog during cutting and welding, and has good storage stability, construction performance and high-speed cutting and welding performance. Divided into two components, the first component is composed of the following raw materials in parts by weight: 0.1-2 parts of auxiliary film-forming resin, 20-30 parts of solvent, 0.1-1 part of dispersant, 20-50 parts of filler, 20-20 parts of zinc powder 30 parts, 1-2 parts of anti-sedimentation agent, 0.1-1 part of graphene; the second component is composed of the following raw materials in parts by weight: 30-50 parts of ethyl silicate, 0.01-0.1 parts of catalyst, deionized water 3 to 5 parts, 45 to 65 parts of solvent.

Owner:XINHE NEW MATERIALS CO LTD

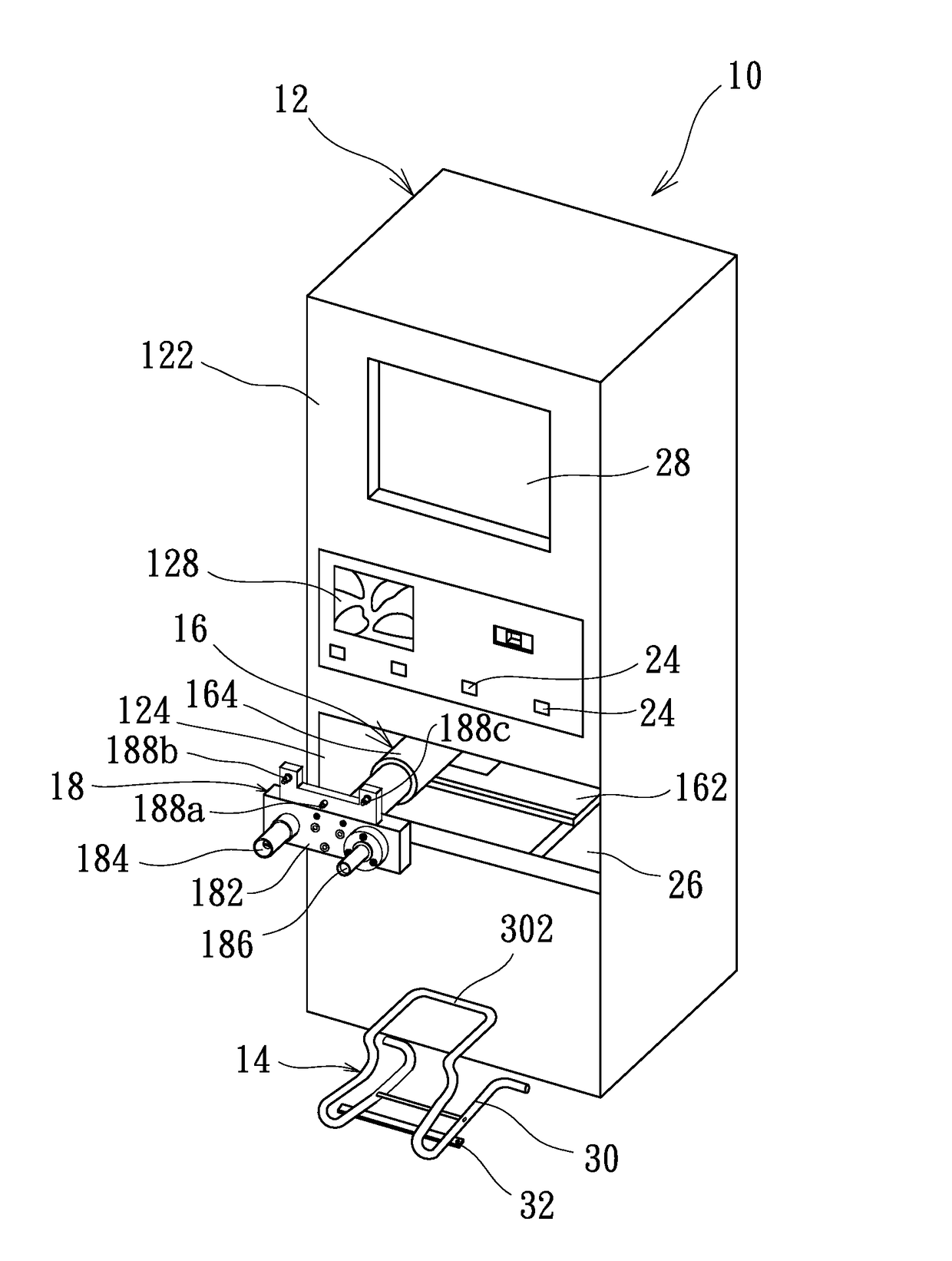

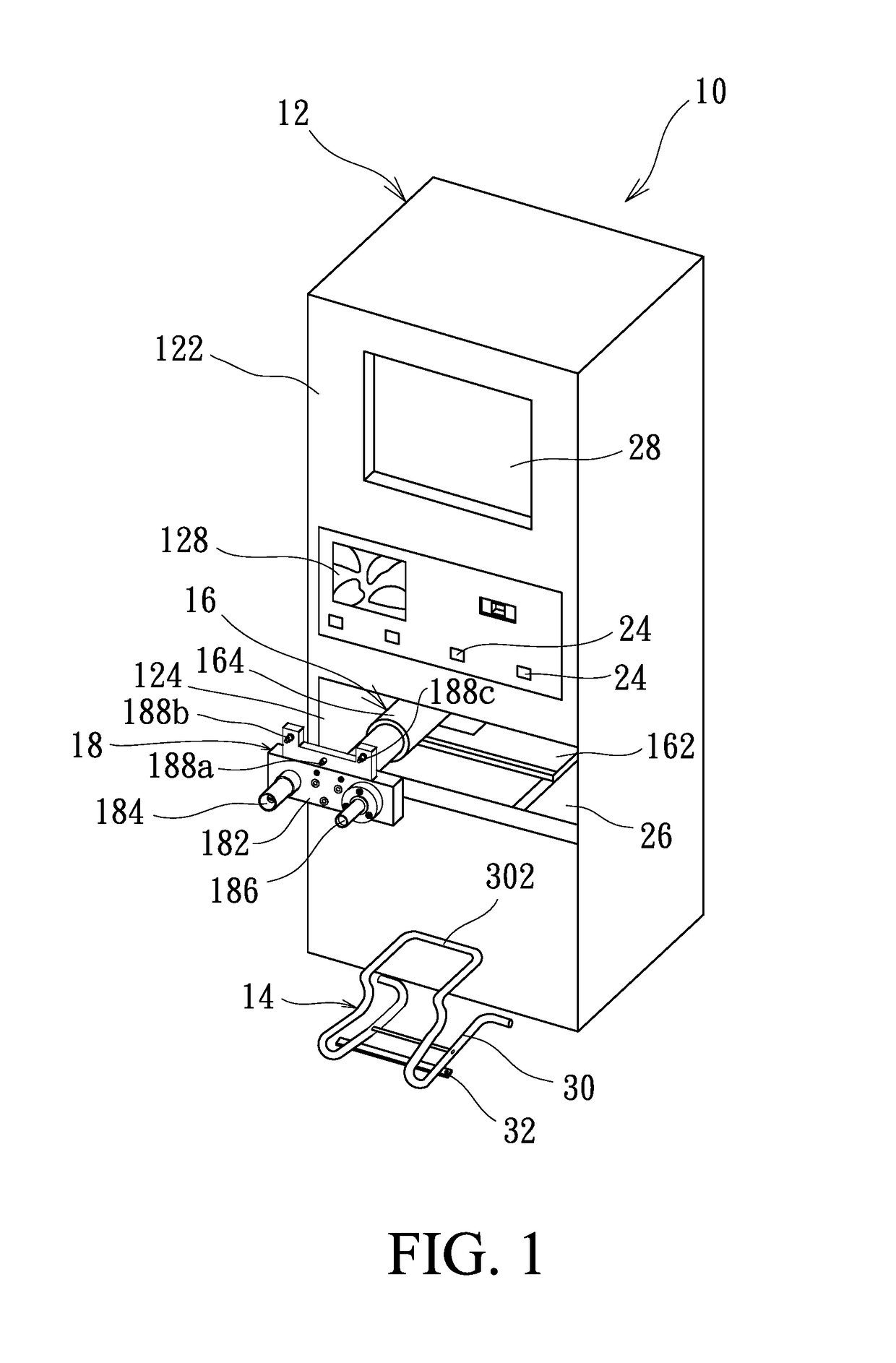

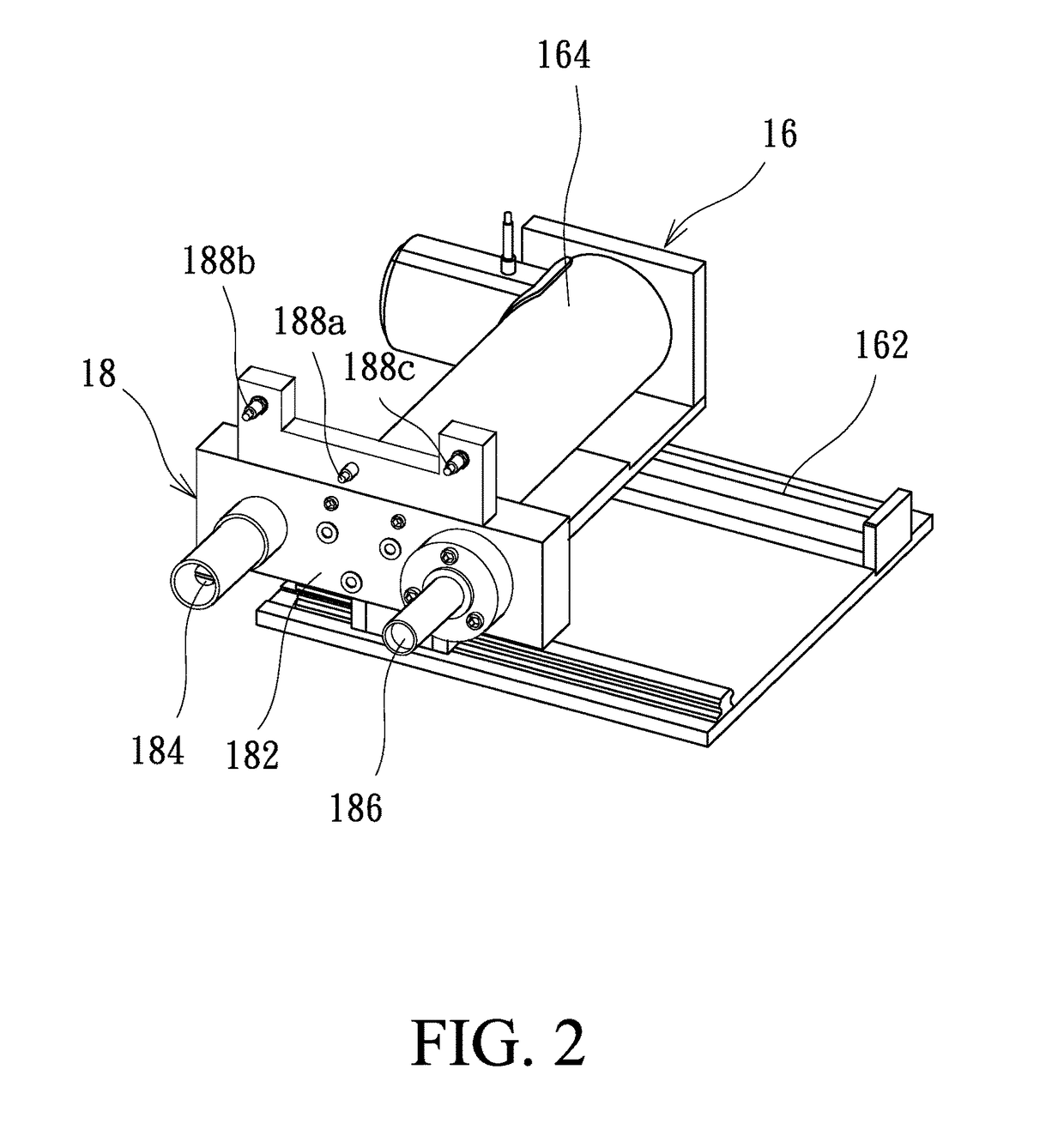

Charging system and charging connector thereof

ActiveUS20170182899A1Reduce labor costsFor automatic positioningCharging stationsElectric devicesElectrical batteryElectric vehicle

Provided is a charging system and a charging connector thereof. The charging system includes a charging stand, a positioning module mounted in front of the front surface of the charging stand for securing the tire of an electric vehicle, and a moving module mounted within and connected to the charging stand. The charging connector includes a positive charging plug and a negative charging plug located on the moving module. The charging connector is connected to the charging stand. When the electric vehicle is secured by the positioning module, the charging stand detects the type of the battery of the electric vehicle and drives the moving module to move outside the charging stand, so that the positive charging plug and the negative charging plug that are isolated from each other are connected to the chargeable positions of the electric vehicle, thereby forming a charging loop.

Owner:HWANG HONG WEN

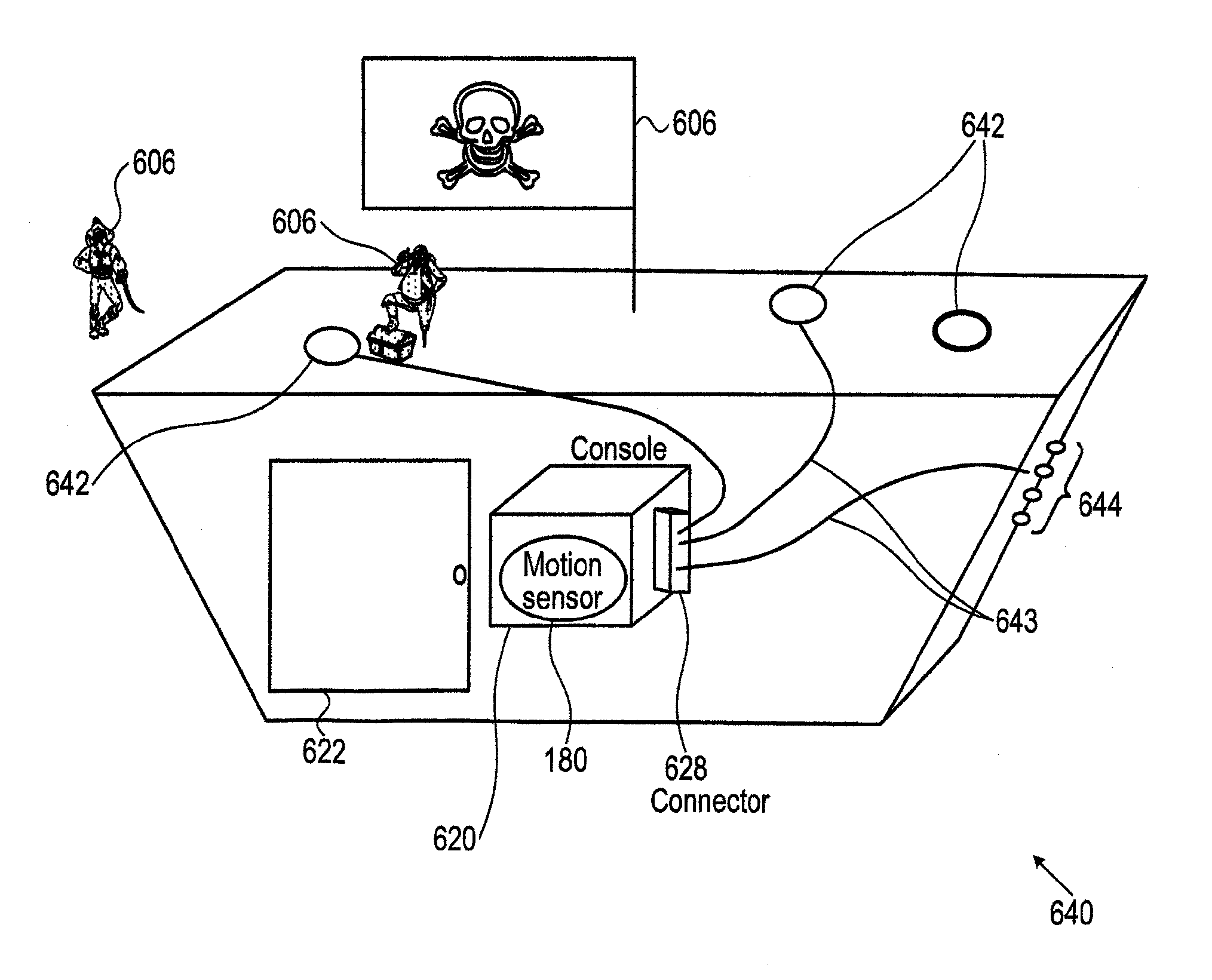

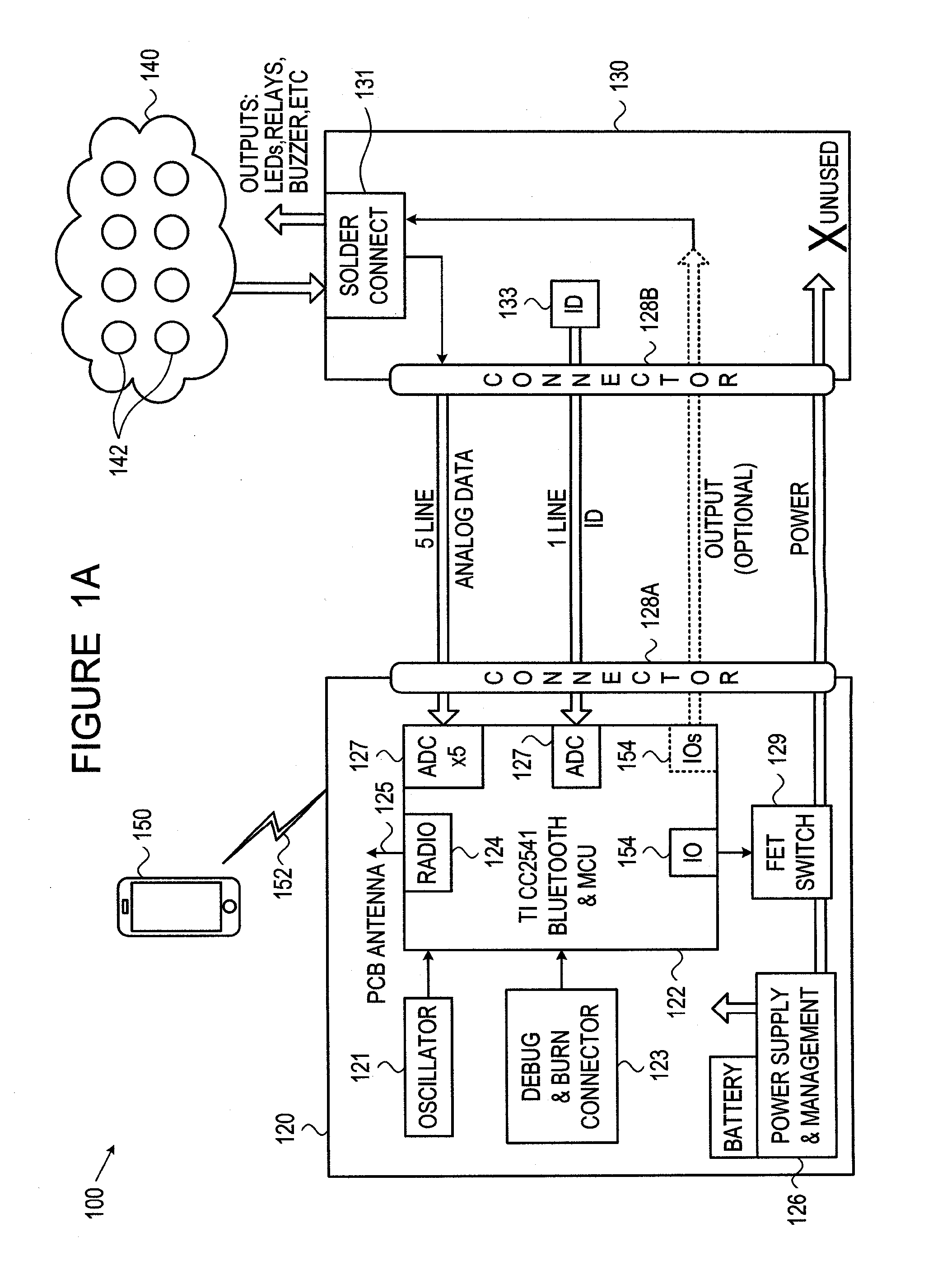

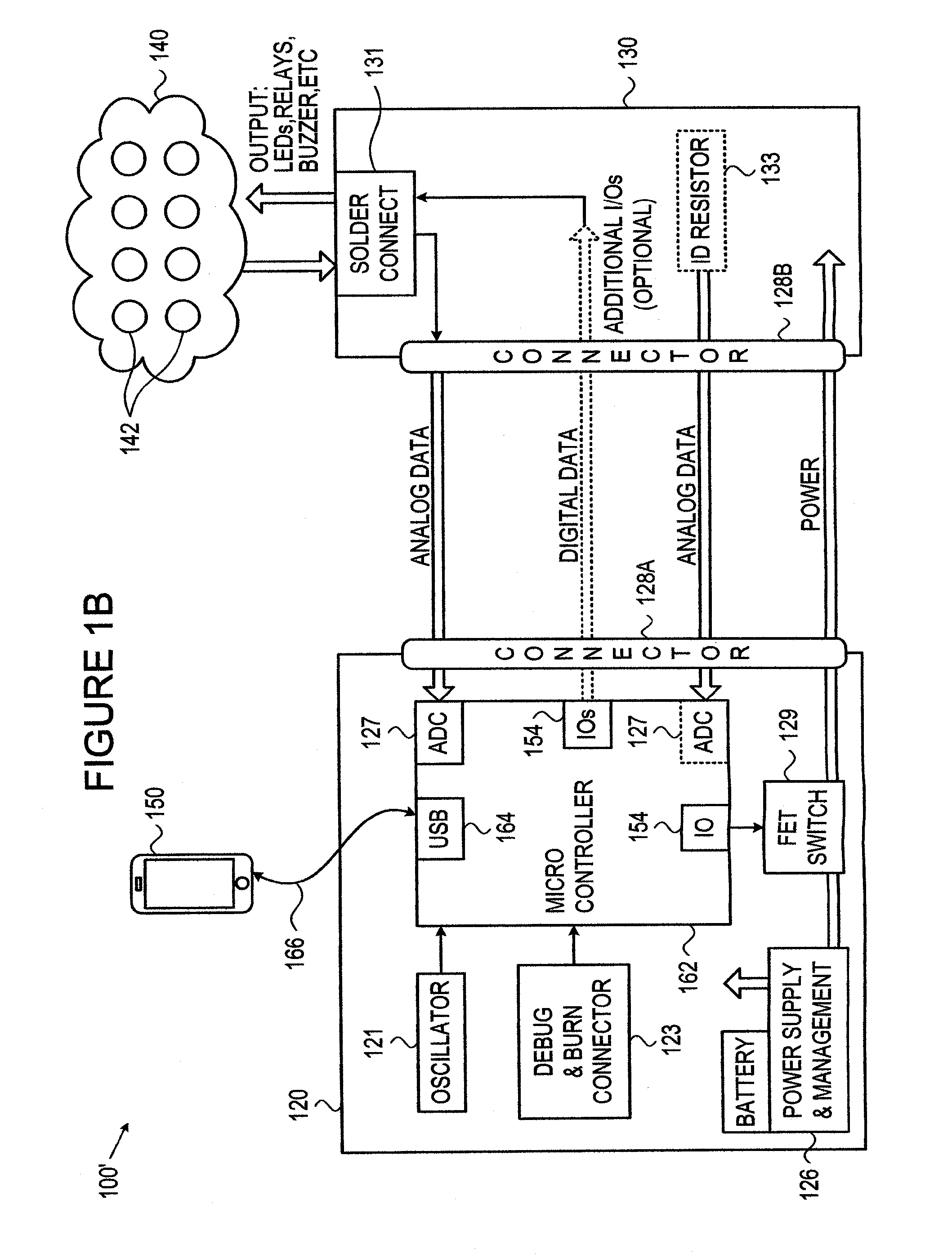

A novel toy console and methods of use

InactiveUS20150321089A1Fasten holdingImprove abilitiesVideo gamesElectrical appliancesEngineeringSmart device

The invention is directed to a novel detachable toy console usable as a control unit for multiple connected toy systems, said toy console is configured and operable to connect interchangeably with at least one smart device and to be attached to a console ready toy and detached from it, to thereby allow a user to use the toy console with another console ready toy, said toy console comprising: a MCU; a communication module for establishing connection with at least one smart device; an external connector for attaching and detaching the toy console to the console ready toy; and a power source. The toy console may further comprise a motion sensor and be used as a wearable toy console. The invention is also directed to A wearable toy console usable as a control unit for multiple connected toy systems, configured and operable to connect interchangeably with at least one smart device and to be carried by a toy and / or by a wearable accessory on the hand of a user, wherein the wearable toy console is configured to be passed by the user from one toy to another or to the hand wearable accessory to thereby allow the usage of the toy console with multiple toys.

Owner:SEEBO INTERACTIVE

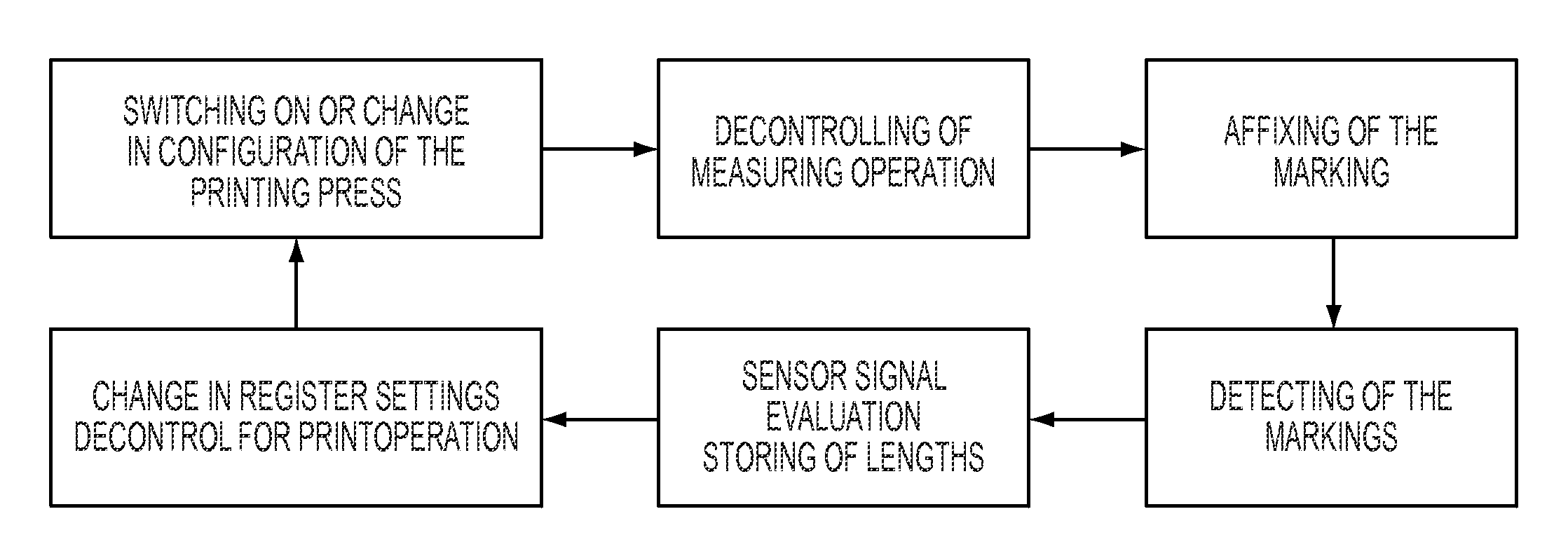

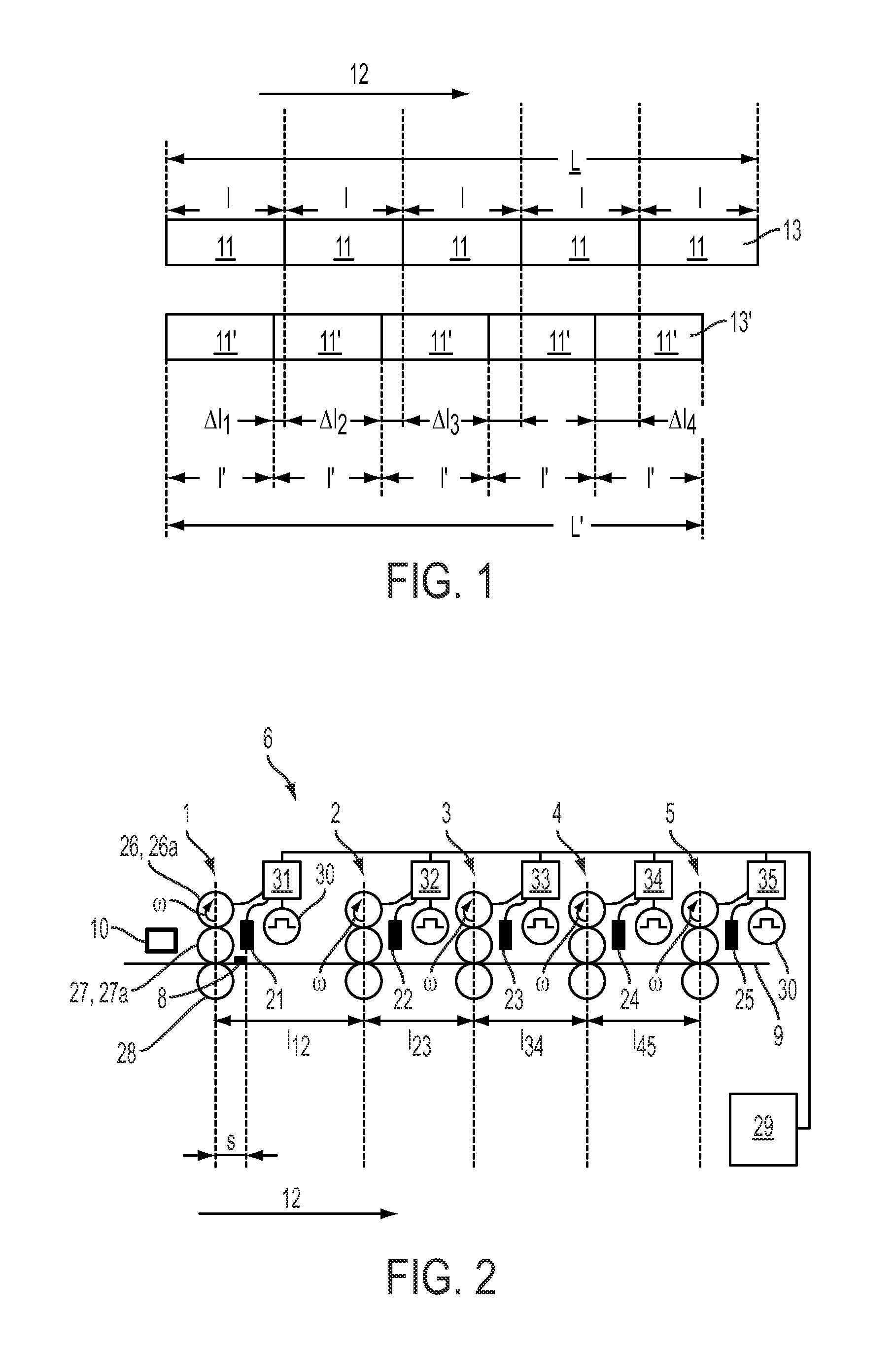

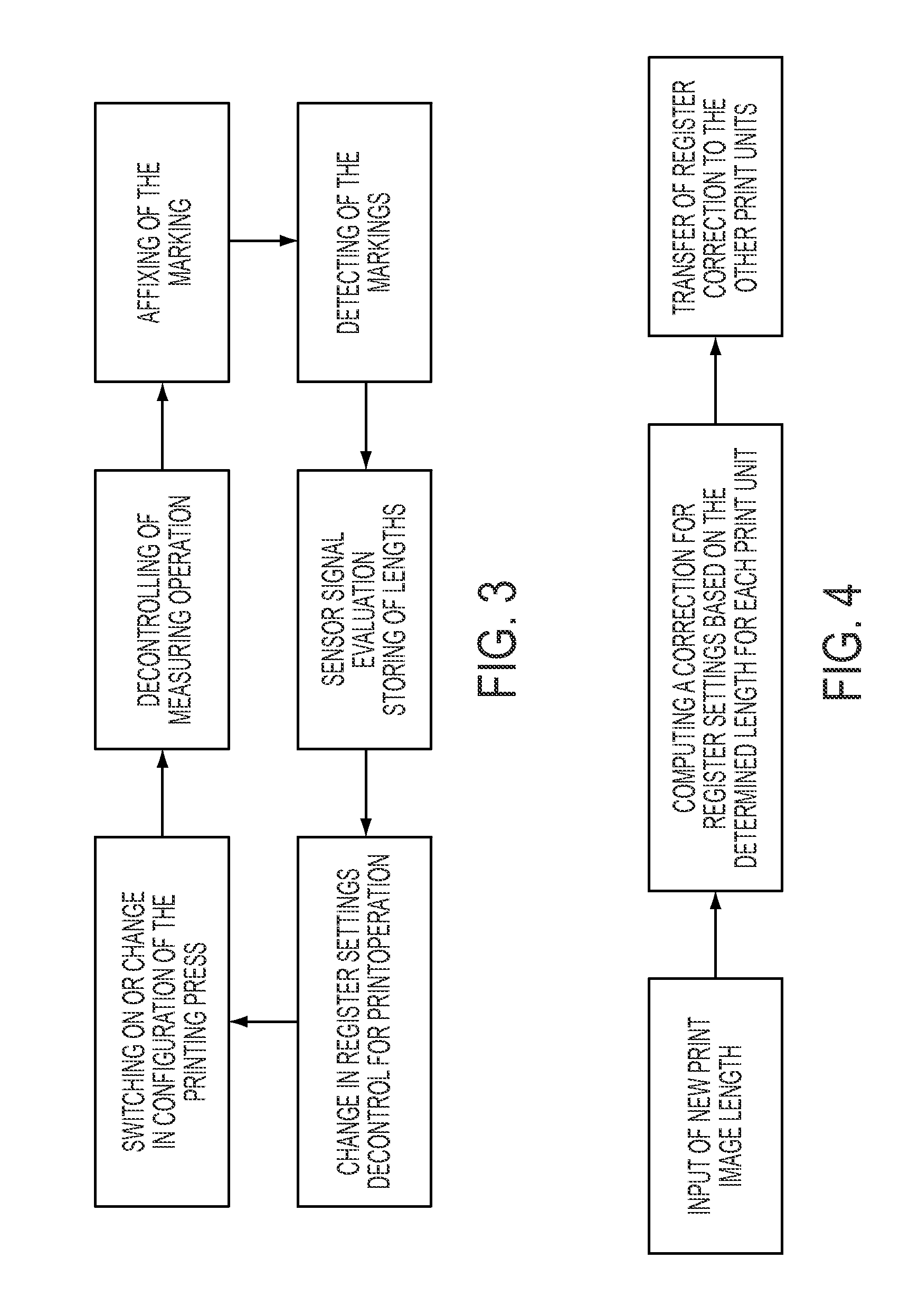

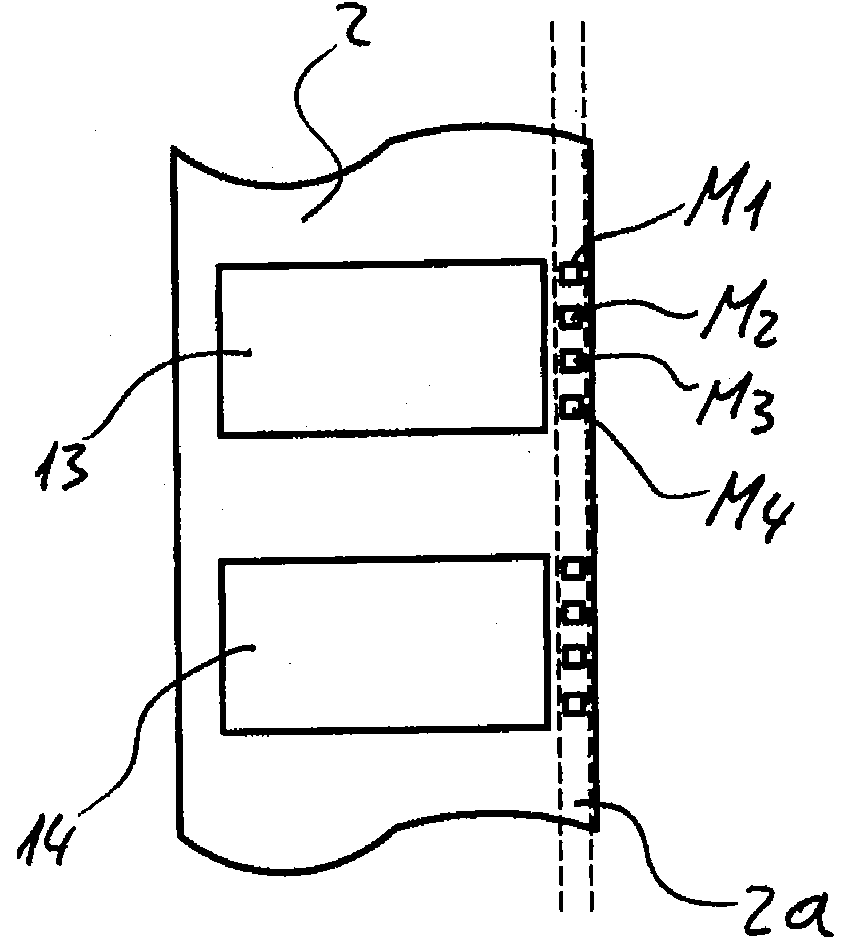

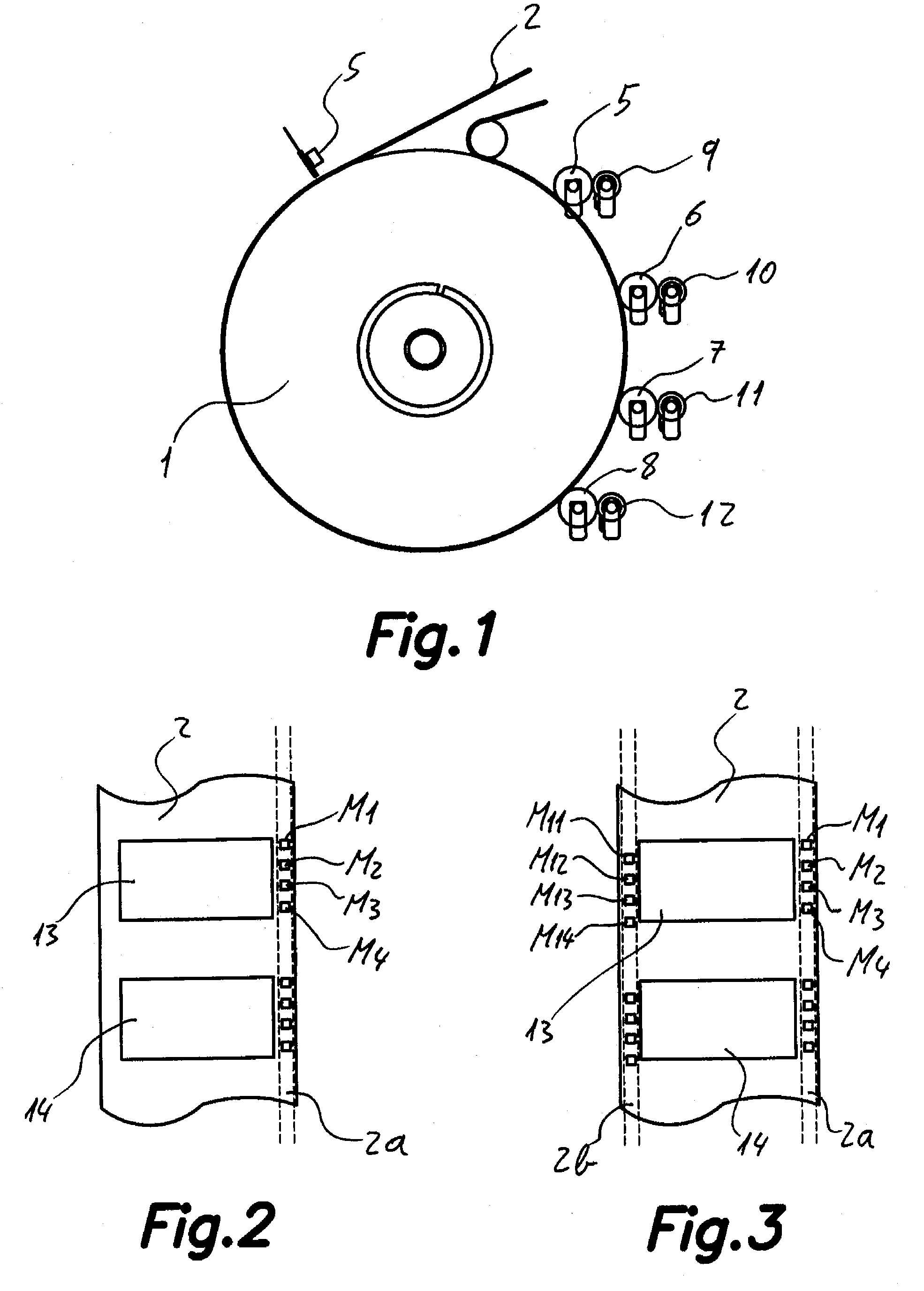

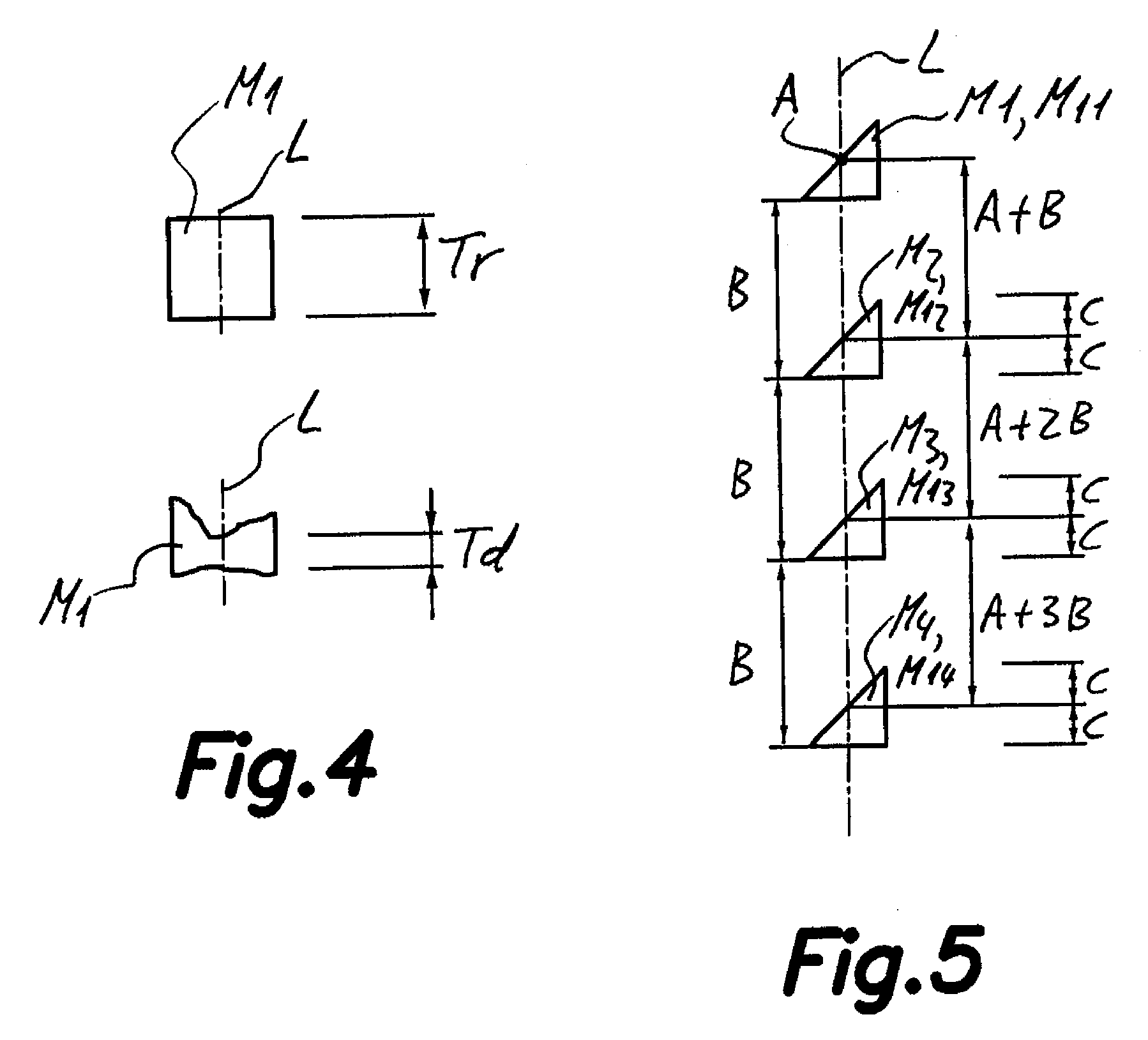

Method and device for controlling the register settings of a printing press

InactiveUS20110297026A1Save setup timeSave waste paperCylinder pressesPlaten pressesProcessor registerControl register

A method for controlling register settings of a printing press, includes rotating imaging cylinders of a first print unit and a second print unit, located downstream of the first print unit in a movement direction of a print medium, at a rotational speed to print an image on the print medium. The method includes of changing a length of the print image to a pre-determined length. The method further includes changing a register setting of the imaging cylinder of the second print unit based on the predetermined change in length of the print image to avoid misalignment of the print image printed by the first and the second print units on the print medium. Changing the register setting is dependent on a length of a section of the print medium between the first and the second print units. A device for controlling register settings of a printing press is also disclosed.

Owner:MULLER MARTINI HLDG

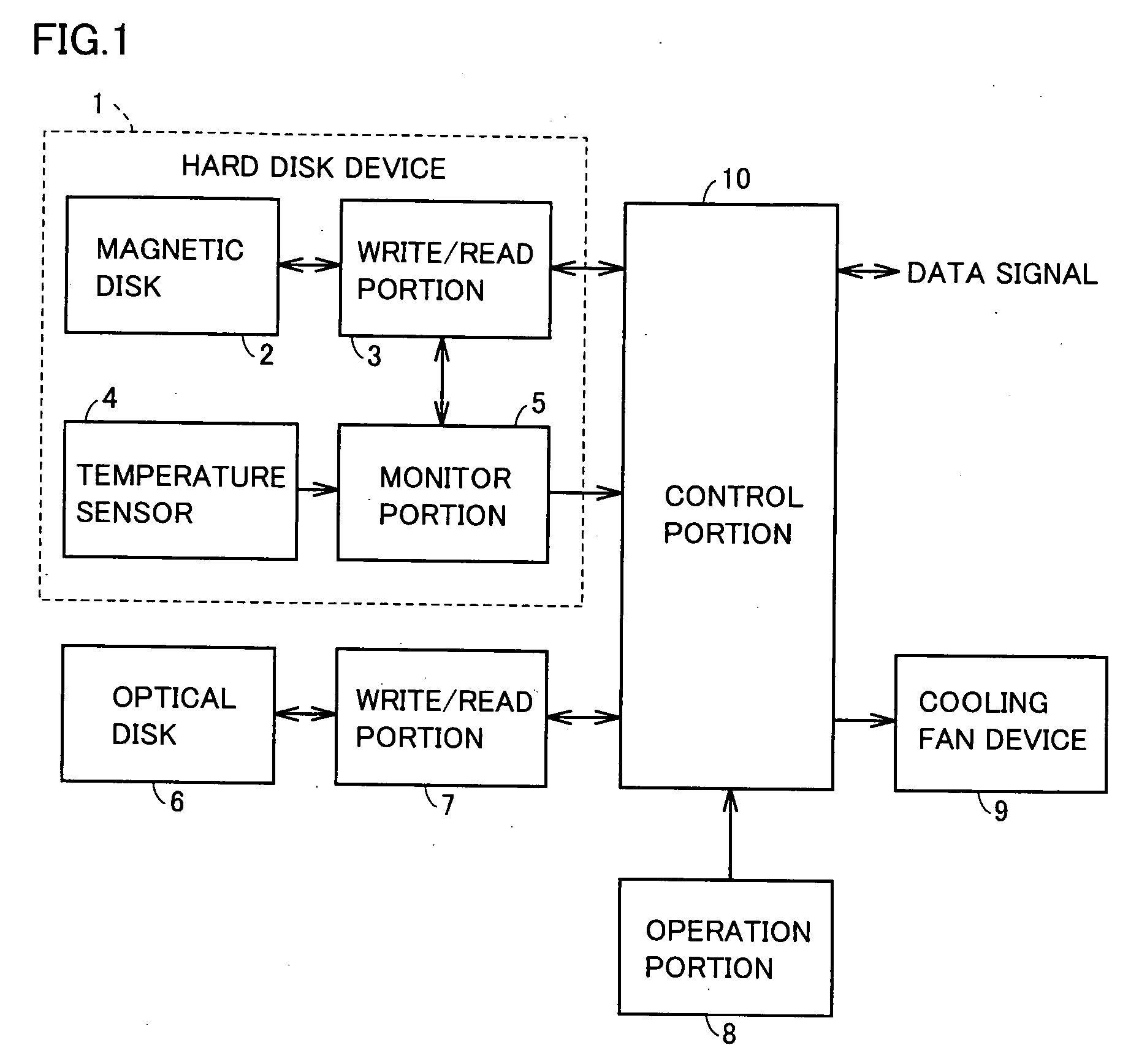

Information recording/reproduction apparatus having hard disk device incorporated therein

InactiveUS20070012615A1Low costSave powerCarrier constructional parts dispositionFilamentary/web record carriersDVD recorderEngineering

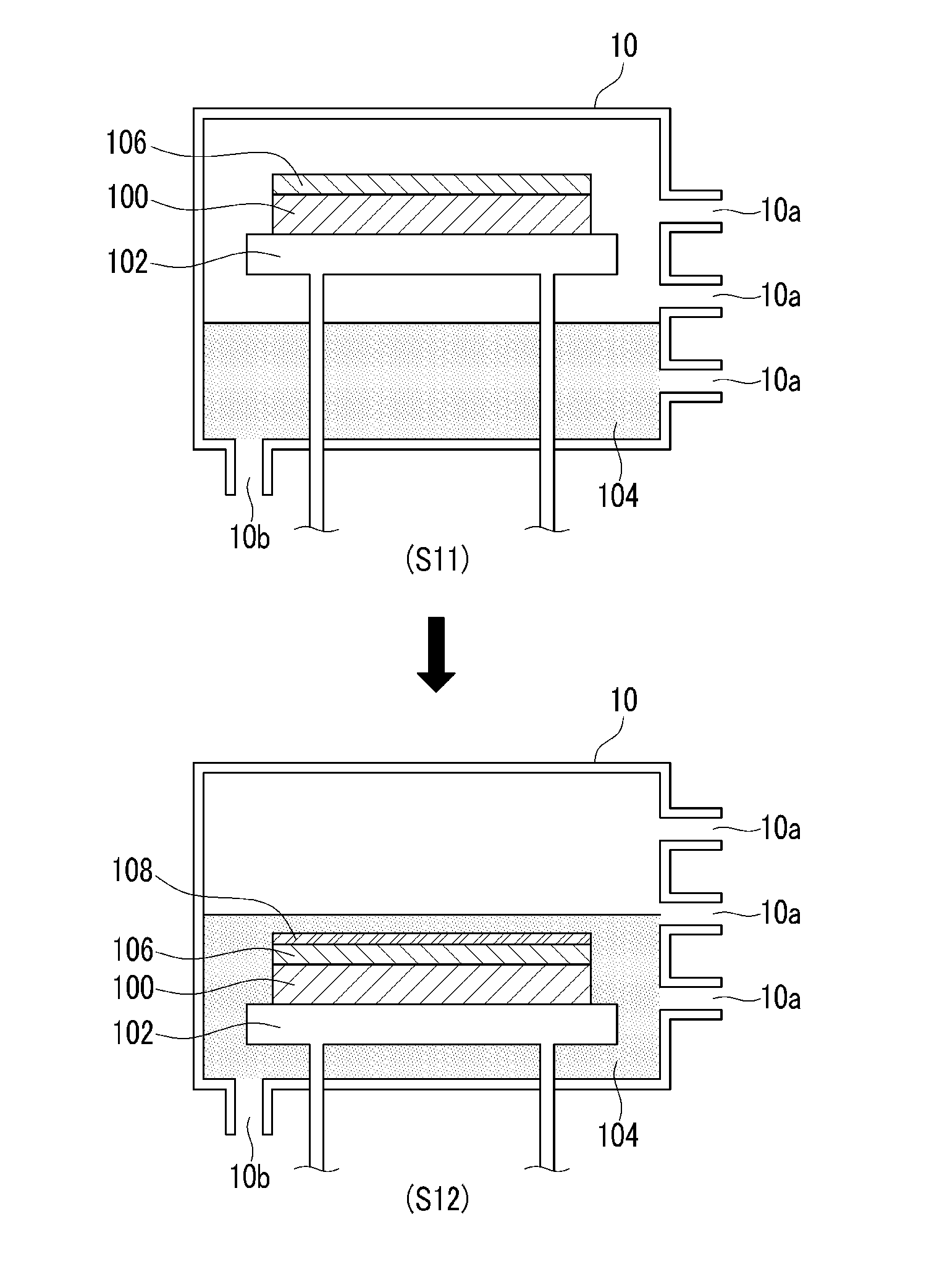

A DVD recorder includes a control portion operating in response to a signal received via a monitor portion from a temperature sensor provided internal to a casing of a hard disk device. If the temperature sensor senses temperature of at least 65° C. the control portion turns on a cooling fan device. If temperature T is lower than 65° C. the control portion turns off the cooling fan device. As the temperature sensor that is previously provided in the hard disk device can be utilized to control the cooling fan device, the apparatus can be less costly than that provided with a separate, dedicated temperature sensor, as conventional.

Owner:FUNAI ELECTRIC CO LTD

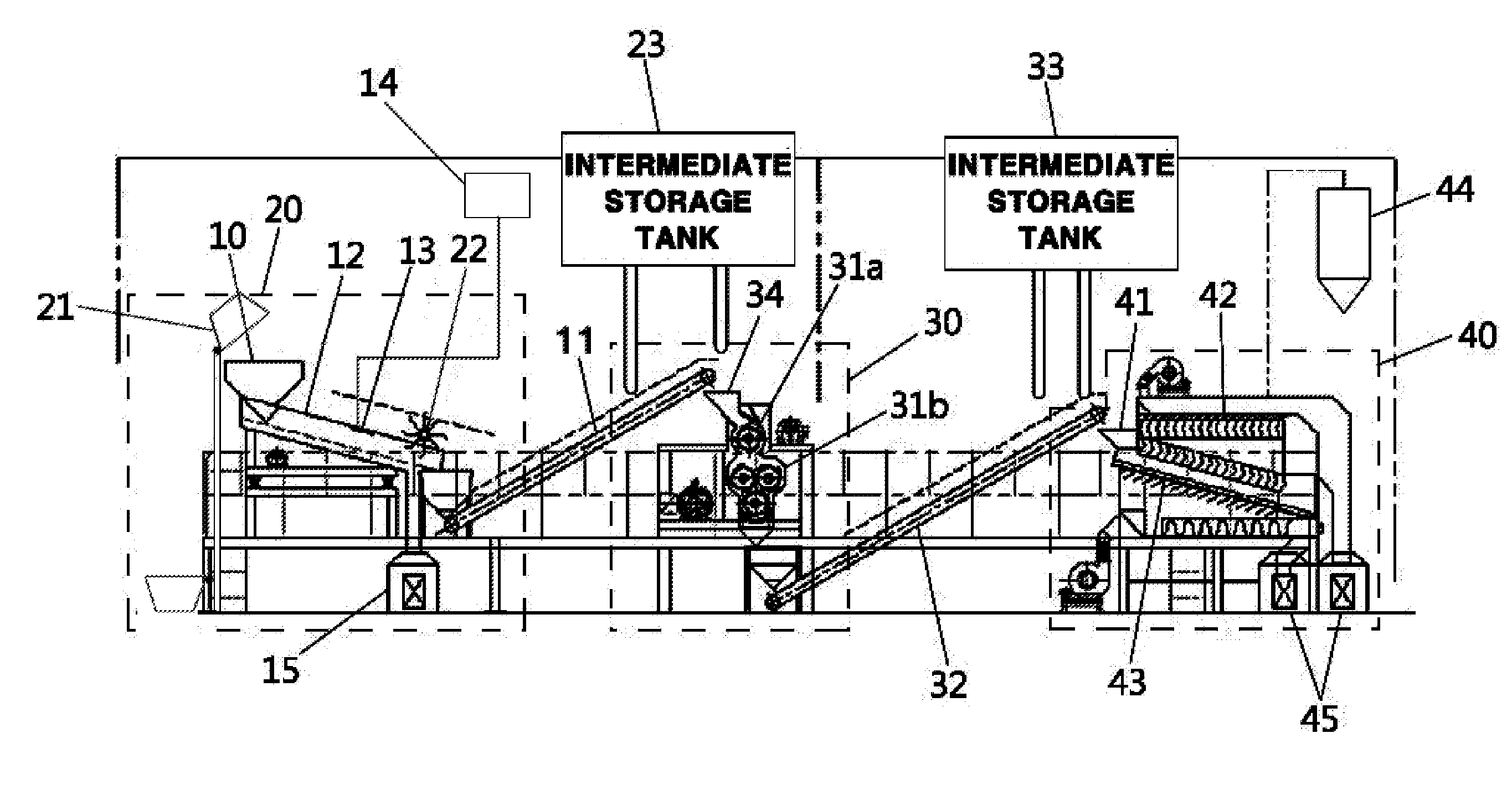

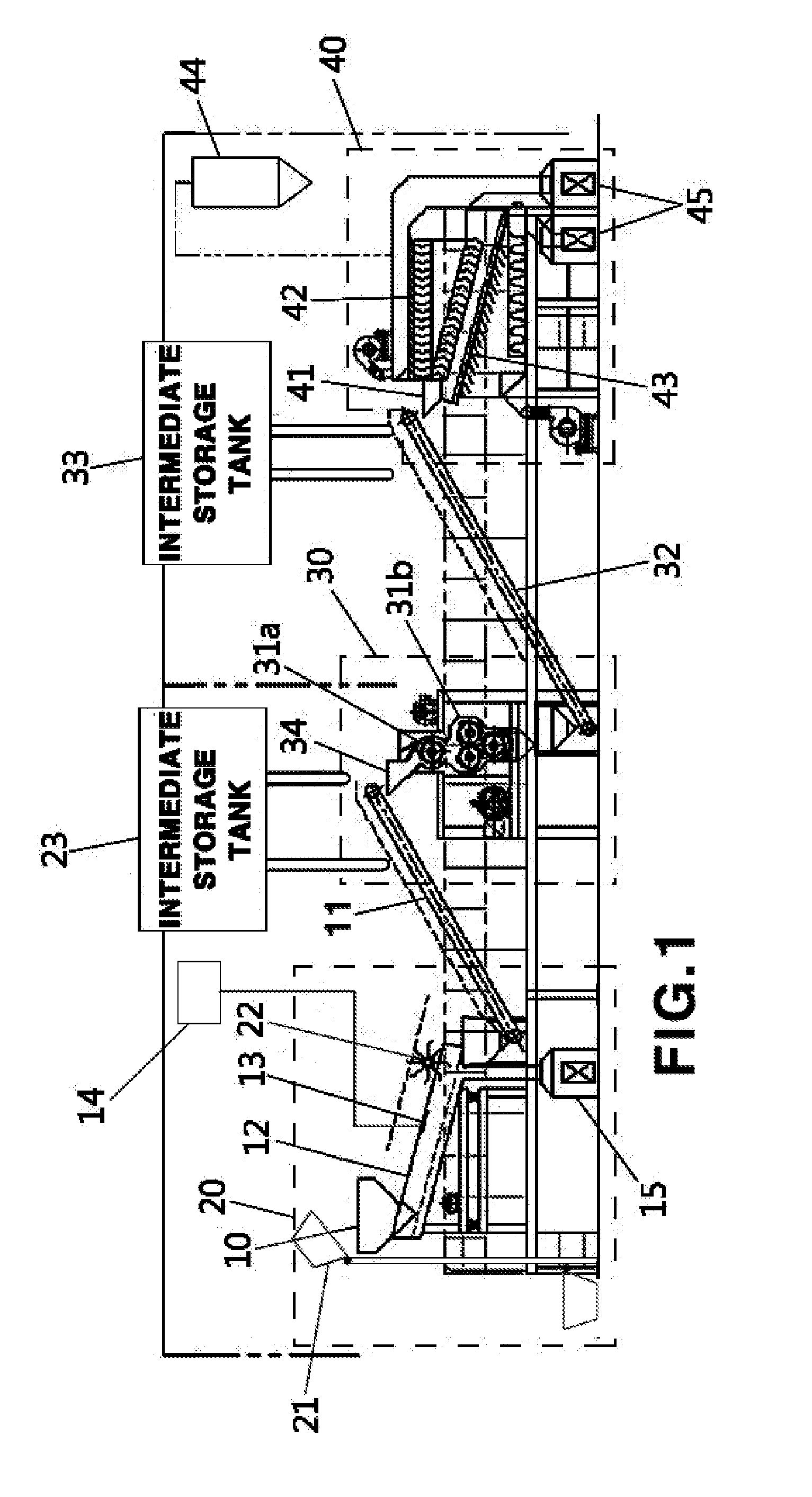

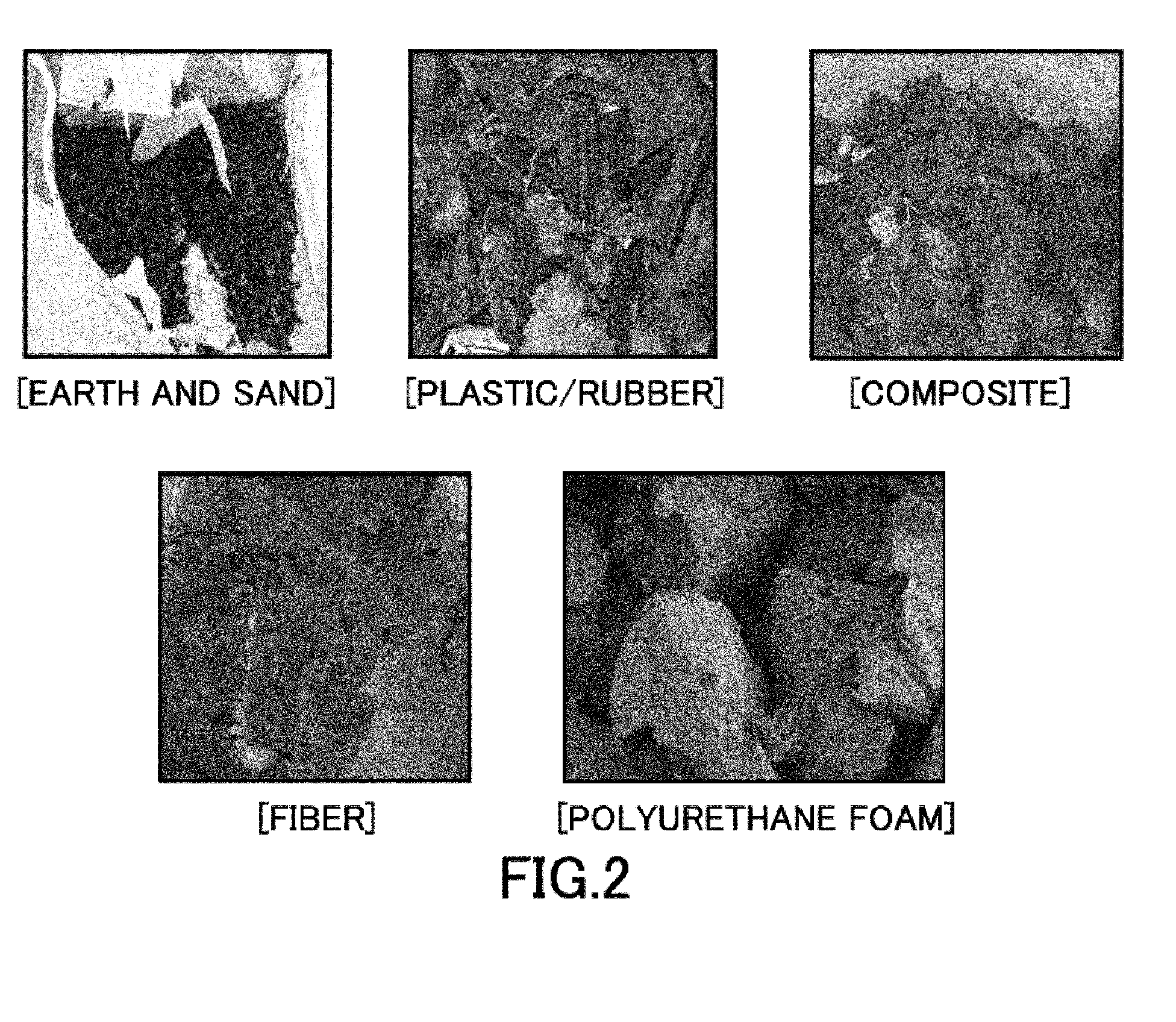

Apparatus for selectively separating polyurethane foam and fiber from automobile shredder residue

ActiveUS20130026262A1Low costHigh recovery rateSolid waste disposalPlastic recyclingFiberEngineering

The present invention provides an apparatus for selectively separating polyurethane foam and fiber from Automobile Shredder Residue (ASR). The apparatus includes a first separator, a second separator, and a third separator. The first separator primarily separates fine particles, such as dirt or glass pieces, from the ASR at a front portion thereof and separates large-sized polyurethane foam and fiber from the ASR at a rear portion thereof. The second separator grinds remaining materials after the primary separation of the first separator. The third separator separates medium-sized polyurethane foam and fiber from the remaining materials after the separation of the first separator and secondarily separates plastics, rubber, and other materials.

Owner:HYUNDAI MOTOR CO LTD

Method of automatically adjusting the printing pressure in flexographic printing machines

InactiveUS20090126591A1Improve printing qualitySave wastePlaten pressesRotary pressesPrinting pressElectrical and Electronics engineering

Owner:COMEXI GRP IND

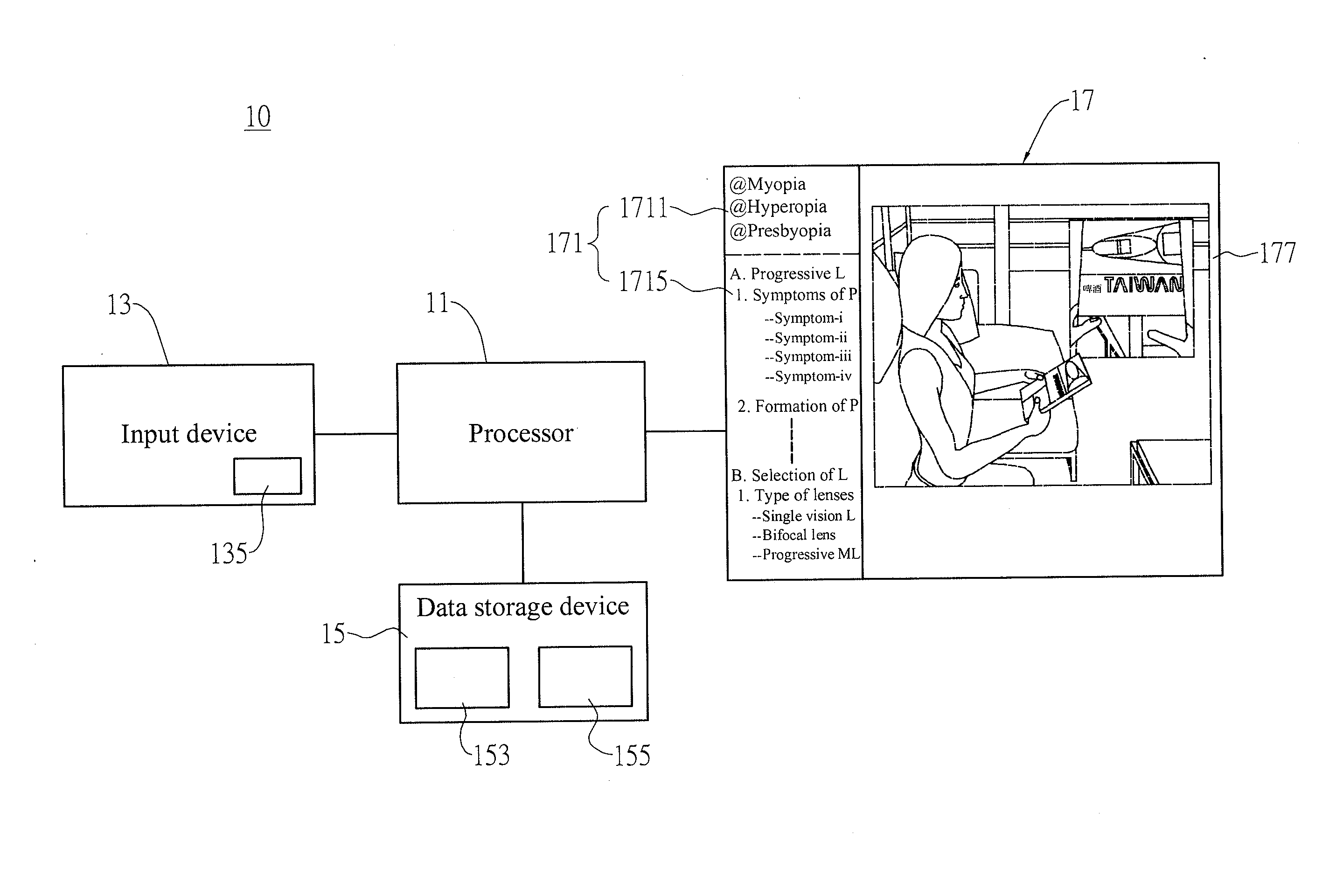

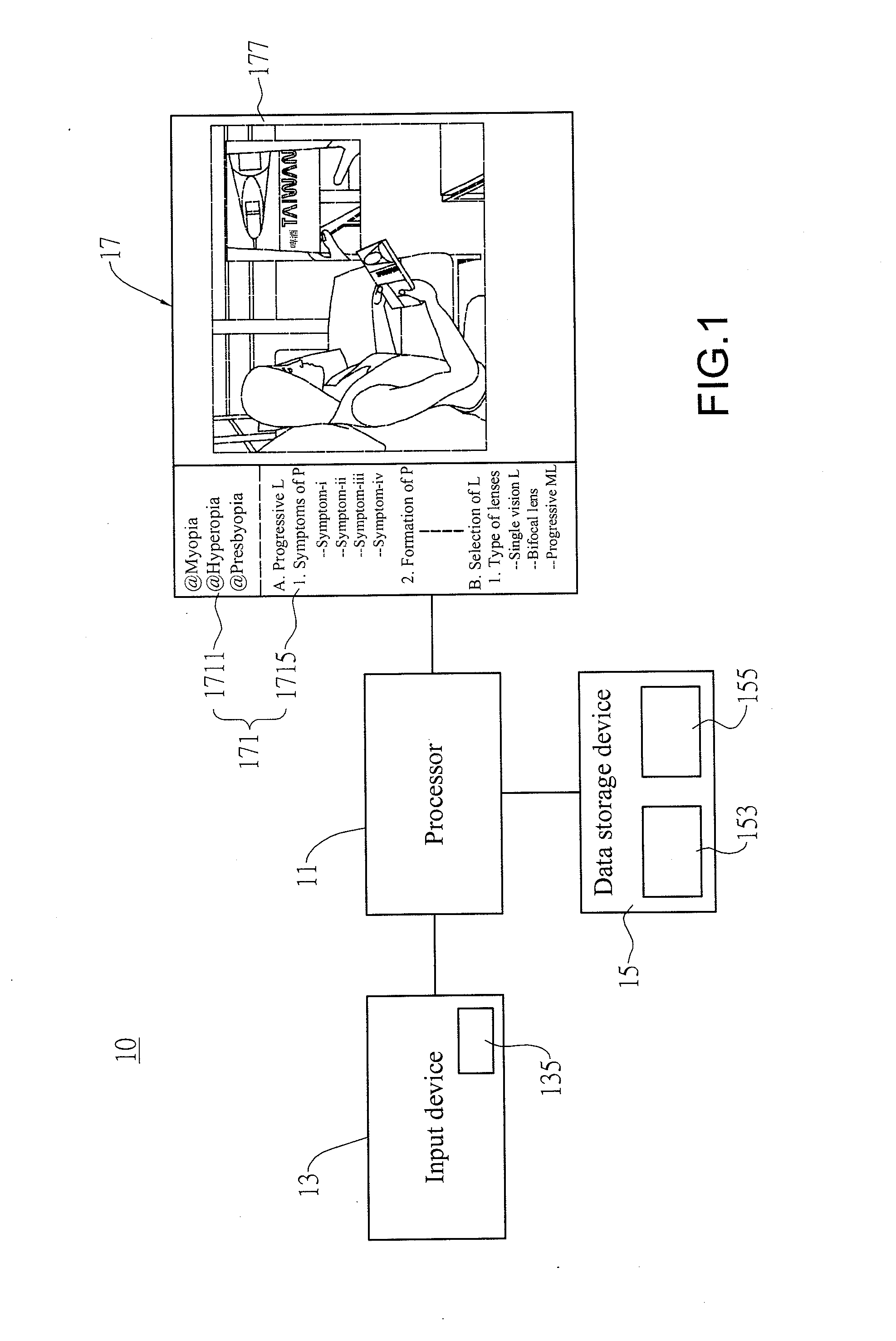

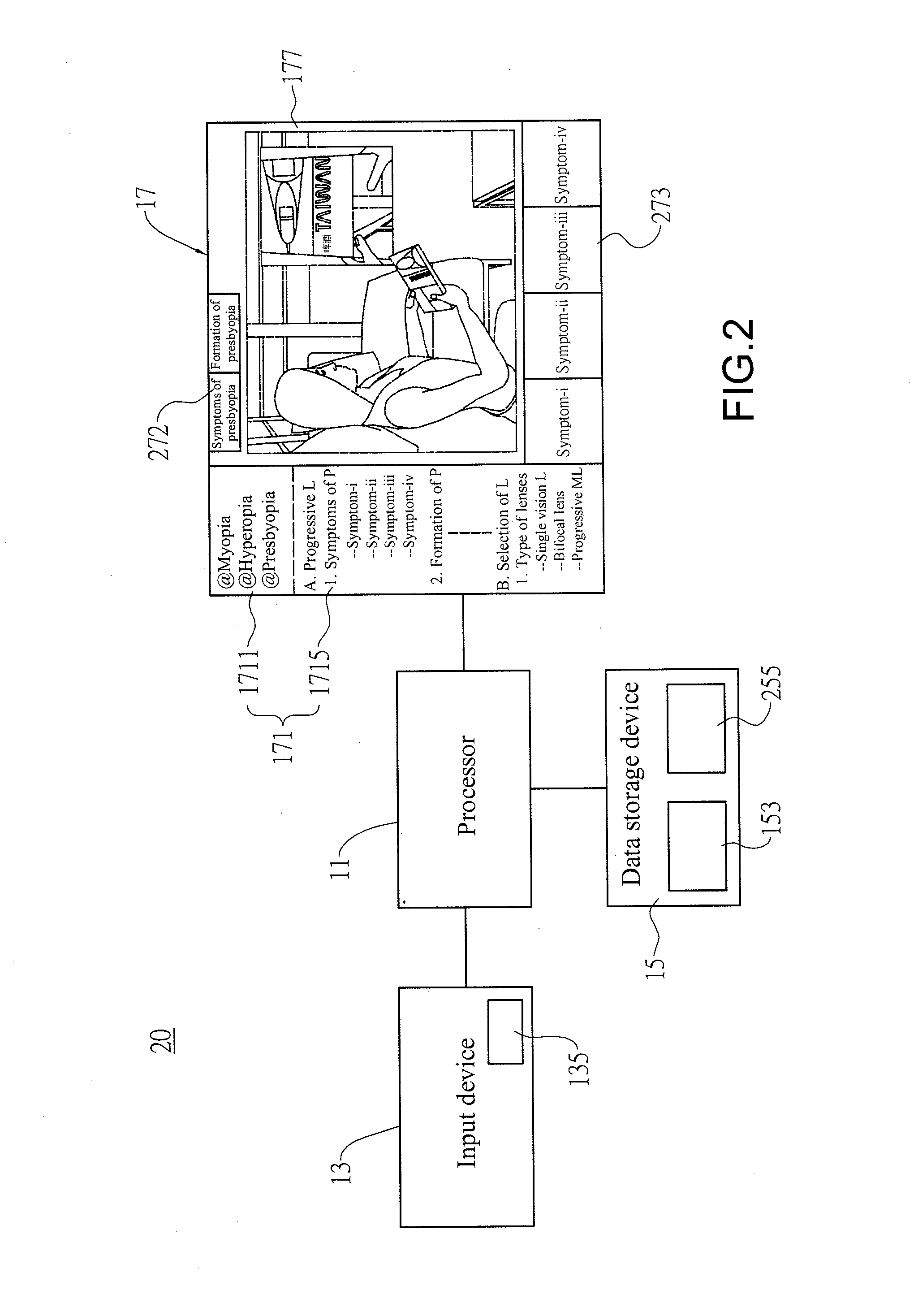

Comprehensive eyeglass dispensing assistance system

InactiveUS20130147725A1Improve performanceSaving much eyeglassMedical simulationInput/output for user-computer interactionElectricityAnimation

A comprehensive eyeglass dispensing assistance system includes an input device, a data storage device and a display device respectively electrically coupled to a processor, which receives an inputted instruction signal from the input device to fetch corresponding eyeglass dispensing desktop data and eyeglass wearing simulation animation data from the data storage devices for display on a menu directory zone and a condition indicator zone on the screen of the display device so that the consumers can understand and judge the symptoms and reasons of their vision acuity and the type or kind of corrective eyeglasses to be selected, facilitating optometric procedure explanation and performance.

Owner:SUNWARD TECH +1

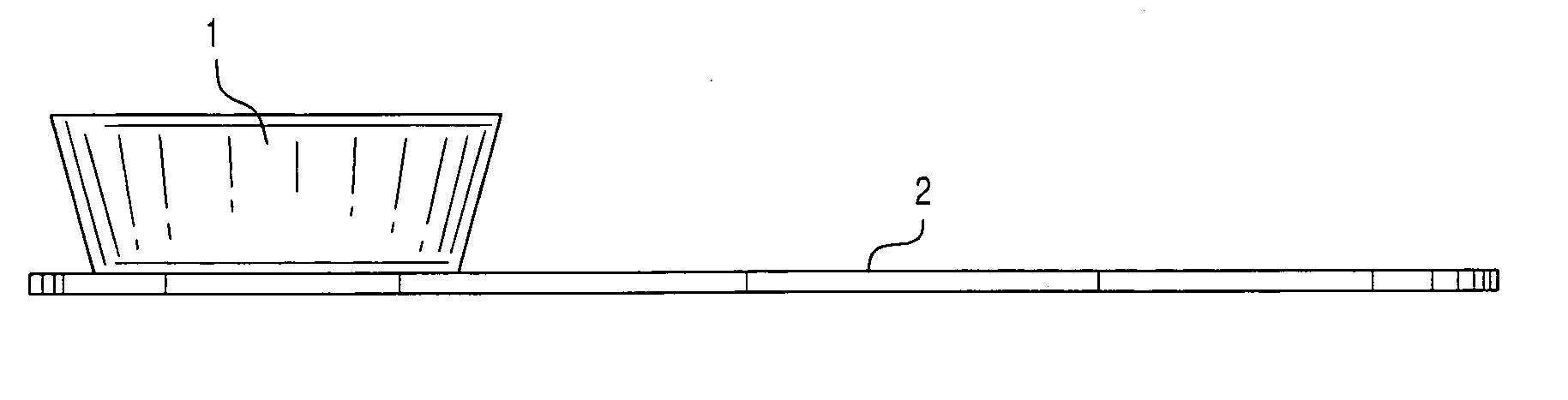

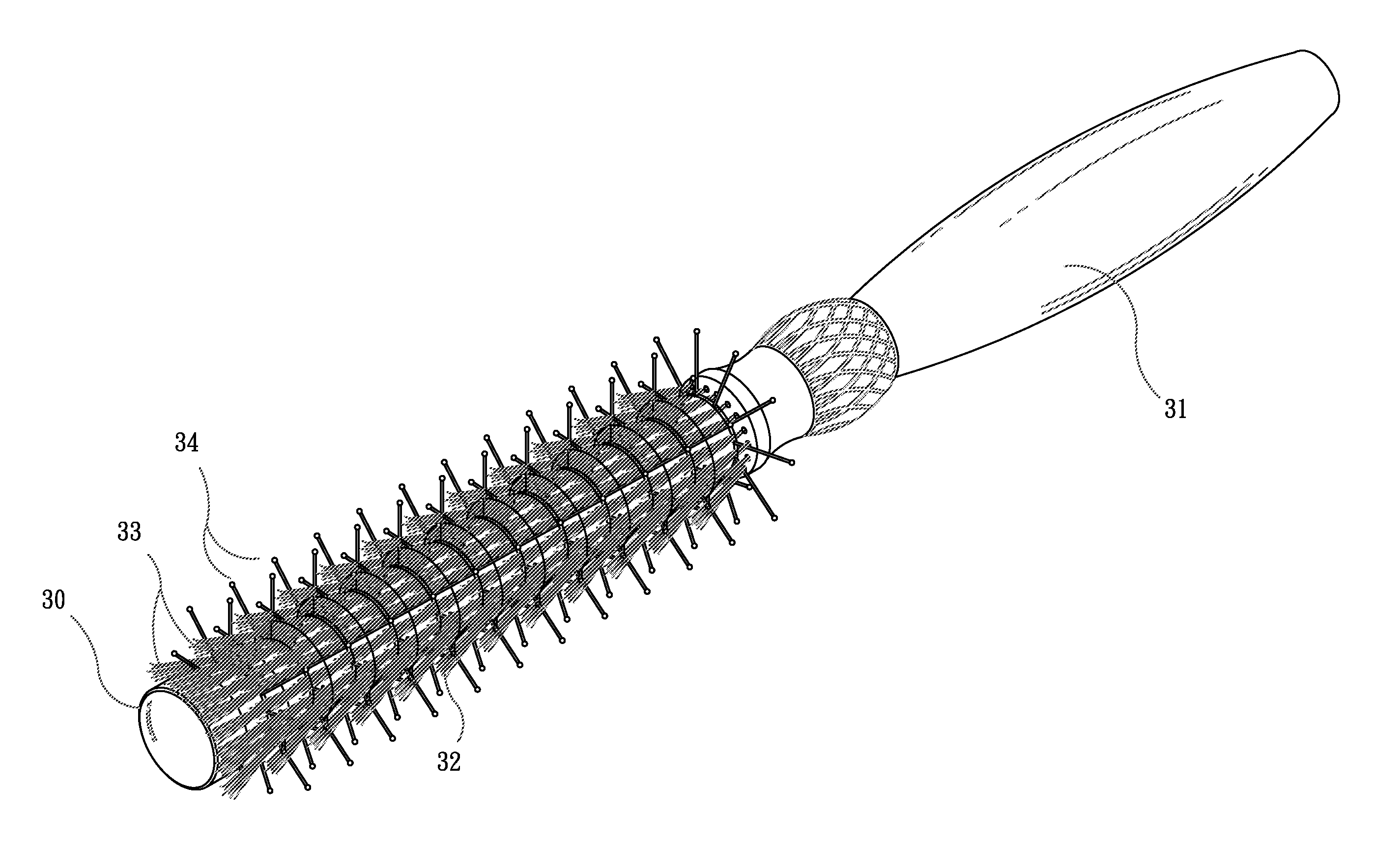

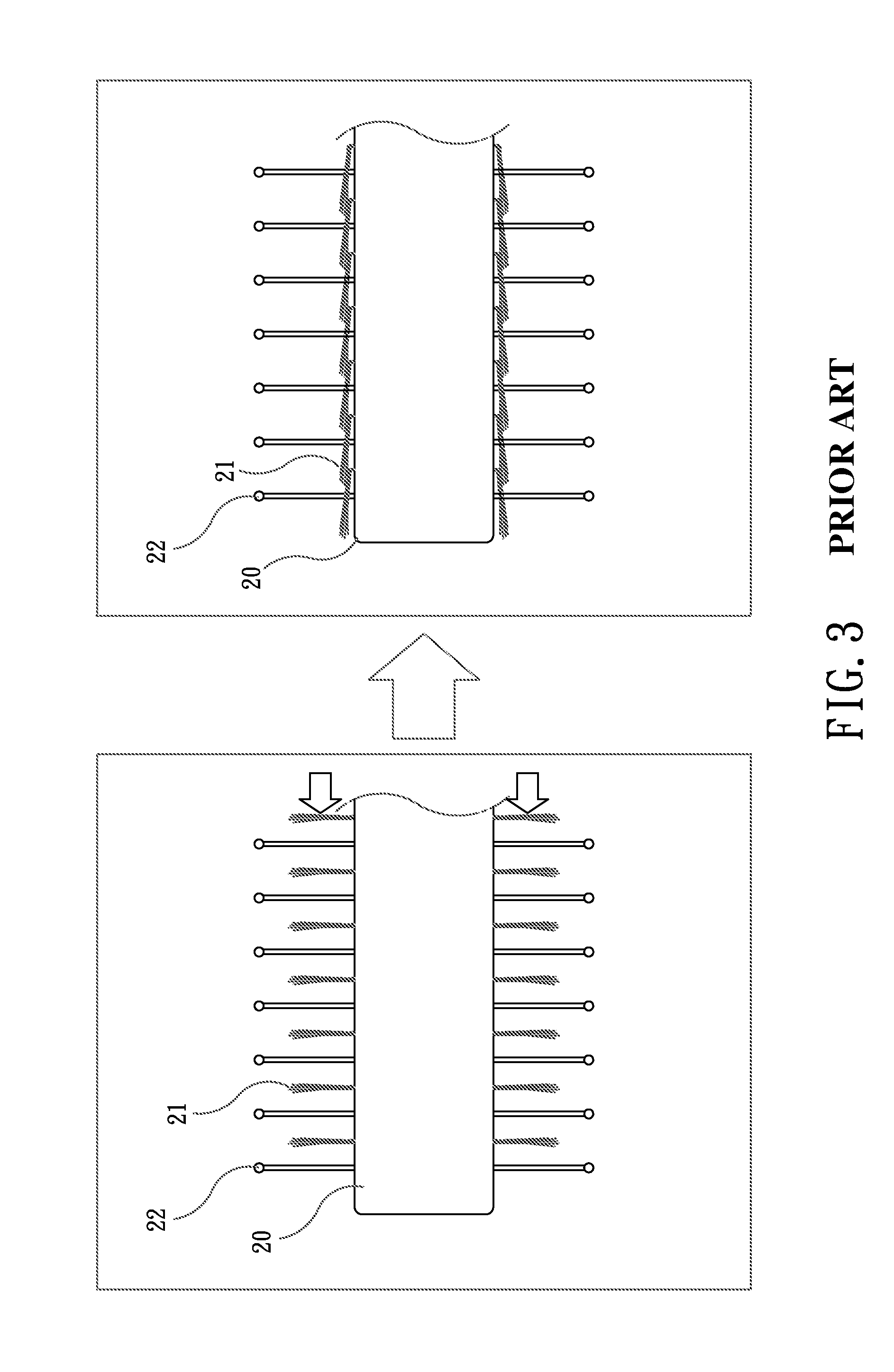

Bristle-pad hairbrush

The present invention relates to a bristle-pad hairbrush, comprising a tuft portion and a handle, wherein the handle is a general handle, and the invention is characterized in that the tuft portion includes a plurality of equidistant tuft flat-position areas with oblique planes. Since the tuft flat-position areas are designed with oblique planes, therefore after bristles are planted onto the tuft flat-position areas, the bristles are obliquely covered onto the tuft portion to naturally form a bristle pad disposed on the tuft portion. The shock absorption of the bristle pad keeps the bristle-pad hairbrush in a gentle and smooth contact with a user's hairs and prevents the bristle-pad hairbrush from pulling and tearing the user's hair, and prevents the user's fallen hairs from remaining or accumulating in the tuft portion.

Owner:TONG FONG BRUSH FACTORY

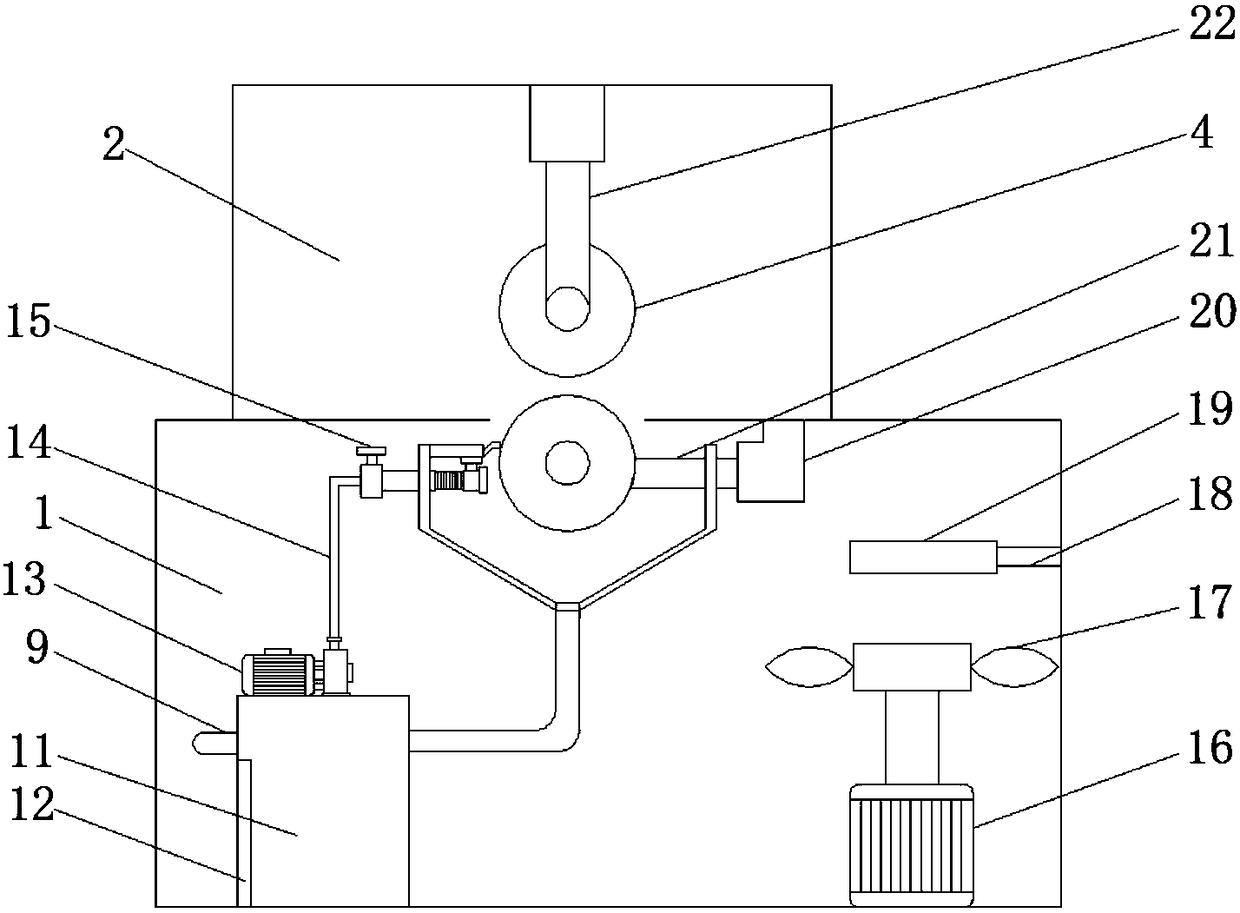

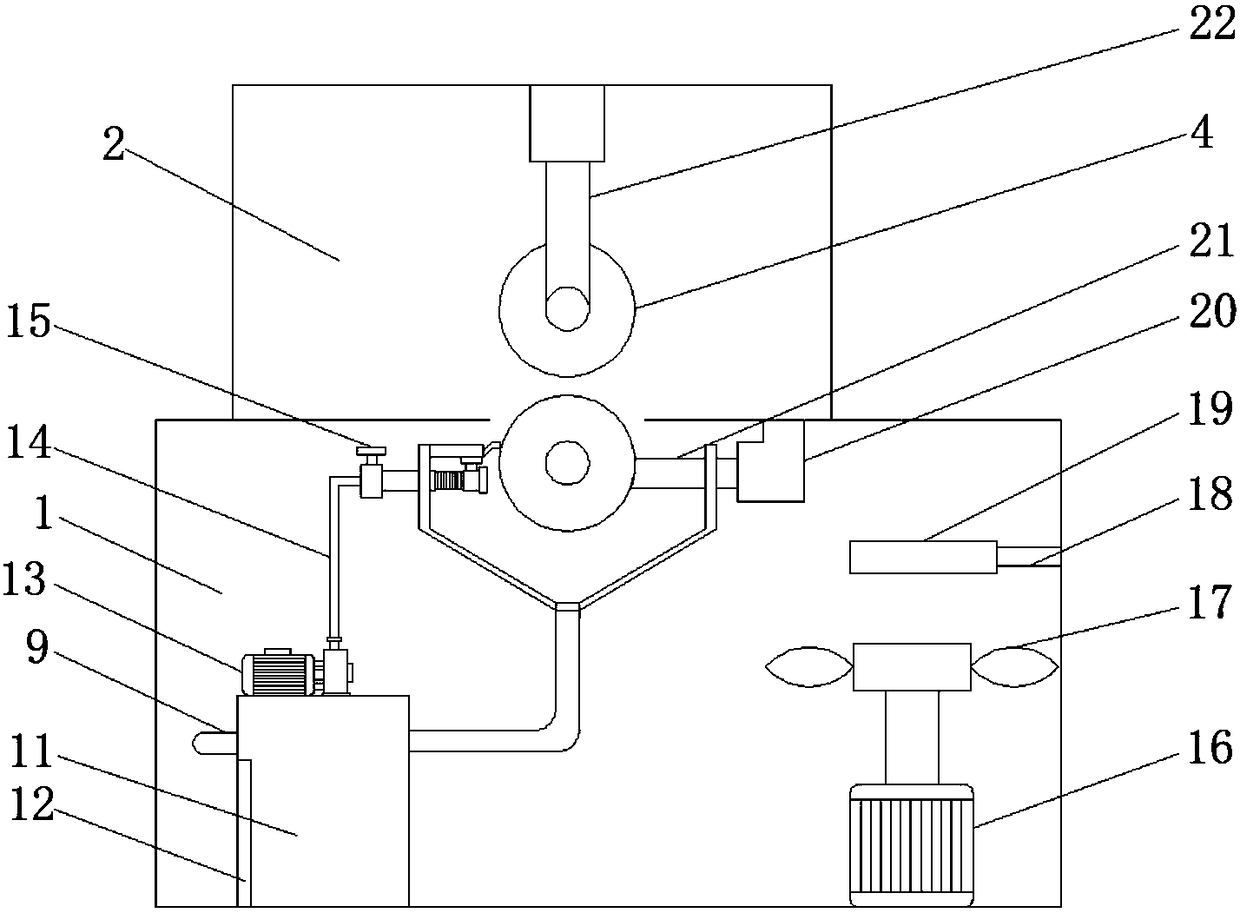

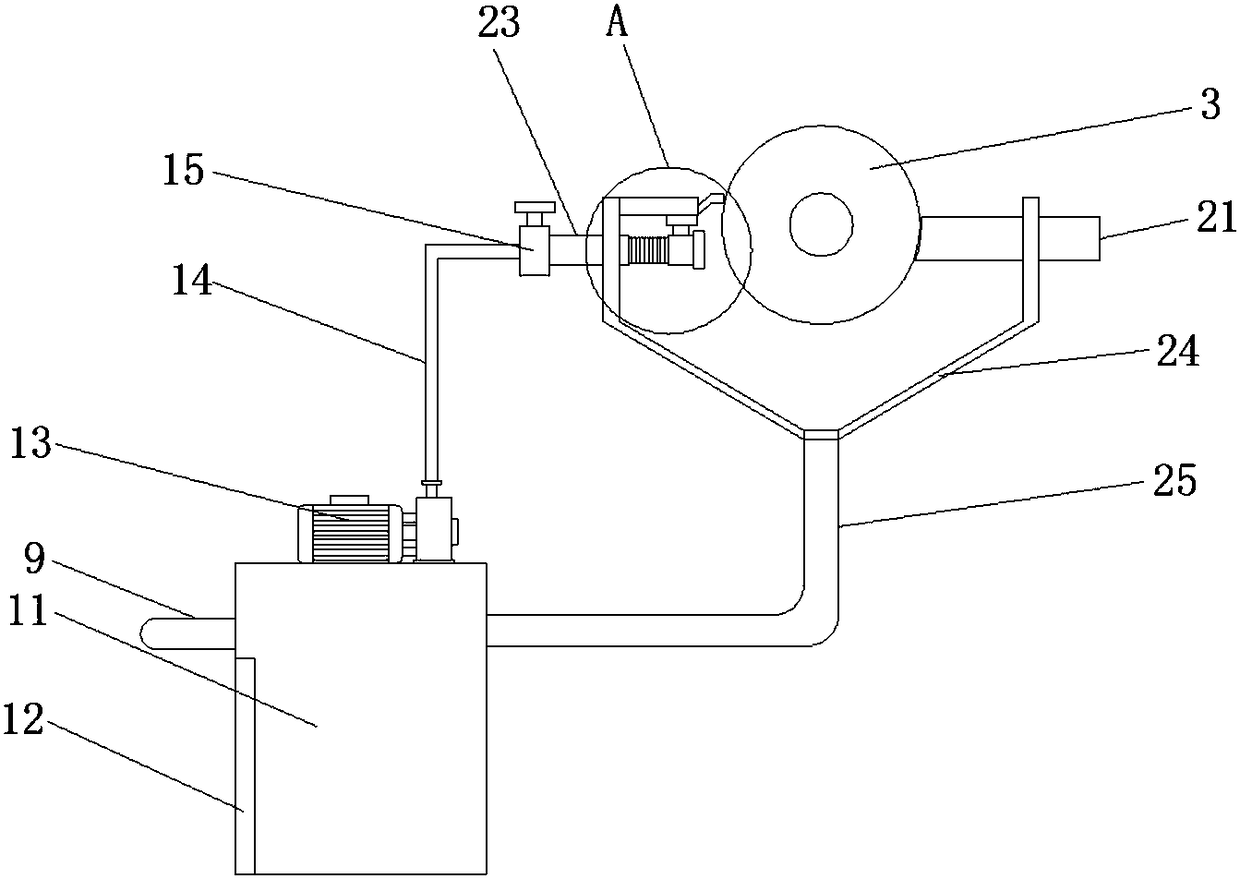

Ink painting device used for intaglio press and facilitating fast ink painting

InactiveCN108638641AEasy to addSave volatilityRotary intaglio printing pressPrinting press partsDrive motorEngineering

The invention discloses an ink painting device used for an intaglio press and facilitating fast ink painting. The ink painting device comprises an intaglio press body and an ink painting box. A platecylinder is arranged in the intaglio press body. The two ends of the plate cylinder are connected with the inner walls of the two sides of the intaglio press body through bearings correspondingly. Oneend of the plate cylinder is fixedly connected with a transmission shaft of a drive motor. The ink painting box is fixed to the portion, at the top end of the plate cylinder, of the intaglio press body. The two ends of the ink painting box communicate. An impression cylinder is arranged in the portion, over the plate cylinder, of the ink painting box. A return device, an ink spraying device and adrying device are further arranged in the intaglio press body. According to the ink painting device used for the intaglio press and facilitating fast ink painting, by means of ink spraying and the design of return of an ink groove and an ink box, the ink painting speed is accelerated, meanwhile, raw materials in the ink box can be added and observed conveniently, operation is more convenient, thedrying speed is higher, and the production efficiency is improved.

Owner:许世能

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com