Coal and gas exploitation integrated permeability-increasing enhancer as well as preparation method and application thereof

A technology for strengthening agent and gas, applied in the fields of mining fluids, chemical instruments and methods, and earthwork drilling, etc., can solve the problems of small permeability enhancement range, small coal seam porosity, and poor coal wettability, etc., to reduce the gas-liquid surface Tension, mineral content reduction, calorific-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

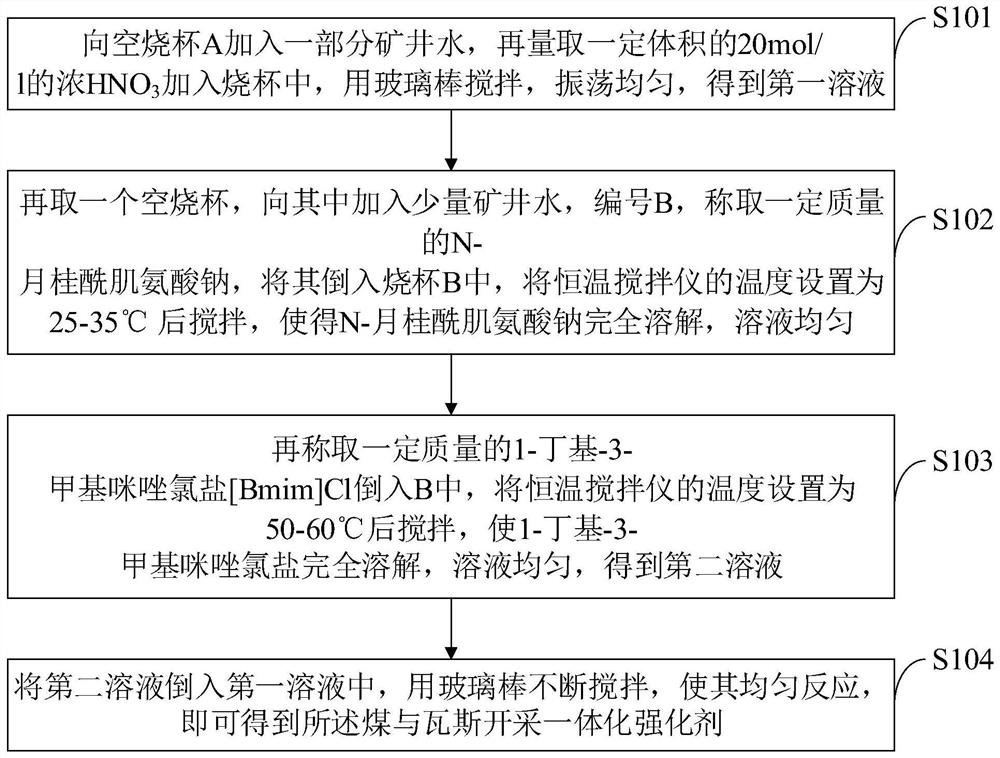

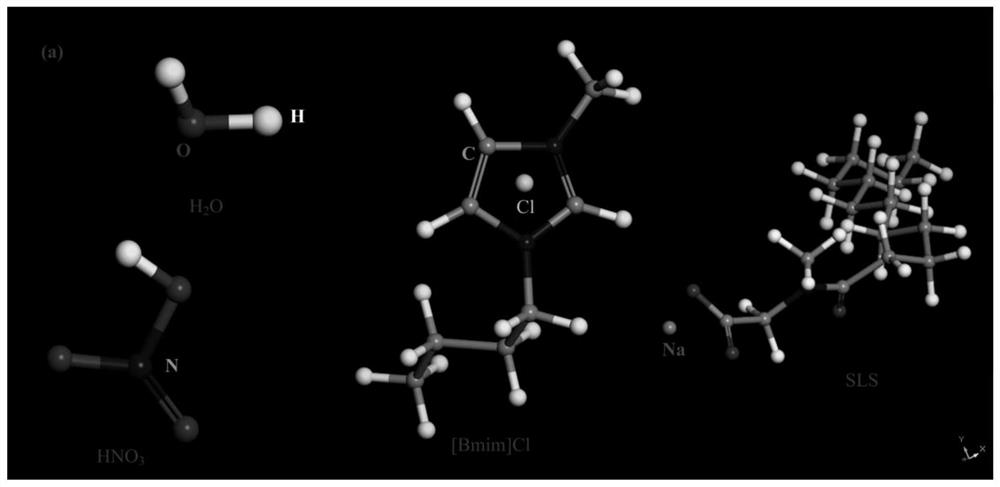

[0057] Add 150ml of mine water to the empty beaker A, and then measure a certain volume of concentrated HNO 3 (20mol / l) into the beaker, stir with a glass rod, oscillate evenly to obtain the first solution; then take an empty beaker, add 30ml of mine water, code B, and weigh a certain amount of N-lauroyl sarcosine Sodium, pour it into beaker B, set the temperature of the constant temperature stirrer at 25-35°C and stir, so that the sodium N-lauroyl sarcosinate is completely dissolved and the solution is uniform; then weigh a certain amount of 1-butyl -3-Methylimidazolium chloride ([Bmim]Cl) was poured into B, and the temperature of the constant temperature stirrer was set at 50-60°C and stirred to completely dissolve 1-butyl-3-methylimidazolium chloride, The solution is uniform to obtain the second solution; the second solution is poured into the first solution, and stirred continuously with a glass rod to make it react evenly, so that the final HNO 3 The concentration is 6%:...

Embodiment 2

[0059] Add 150ml of mine water to the empty beaker A, and then measure a certain volume of concentrated HNO 3 (20mol / l) into the beaker, stir with a glass rod, oscillate evenly to obtain the first solution; then take an empty beaker, add 30ml of mine water, code B, and weigh a certain amount of N-lauroyl sarcosine Sodium, pour it into beaker B, set the temperature of the constant temperature stirrer at 25-35°C and stir, so that the sodium N-lauroyl sarcosinate is completely dissolved and the solution is uniform; then weigh a certain amount of 1-butyl -3-Methylimidazolium chloride ([Bmim]Cl) was poured into B, and the temperature of the constant temperature stirrer was set at 50-60°C and stirred to completely dissolve 1-butyl-3-methylimidazolium chloride, The solution is uniform to obtain the second solution; the second solution is poured into the first solution, and stirred continuously with a glass rod to make it react evenly, so that the final HNO 3 The concentration is 6%:...

Embodiment 3

[0061] Add 150ml of mine water to the empty beaker A, and then measure a certain volume of concentrated HNO 3 (20mol / l) into the beaker, stir with a glass rod, oscillate evenly to obtain the first solution; then take an empty beaker, add 30ml of mine water, code B, and weigh a certain amount of N-lauroyl sarcosine Sodium, pour it into beaker B, set the temperature of the constant temperature stirrer at 25-35°C and stir, so that the sodium N-lauroyl sarcosinate is completely dissolved and the solution is uniform; then weigh a certain amount of 1-butyl -3-Methylimidazolium chloride ([Bmim]Cl) was poured into B, and the temperature of the constant temperature stirrer was set at 50-60°C and stirred to completely dissolve 1-butyl-3-methylimidazolium chloride, The solution is uniform to obtain the second solution; the second solution is poured into the first solution, and stirred continuously with a glass rod to make it react evenly, so that the final HNO 3 The concentration is 6%:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com