Preparation method of nanometer manganese oxide electrode materials of super capacitor

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc. Effective control of electrode materials and other issues to achieve the effect of increased specific surface area, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

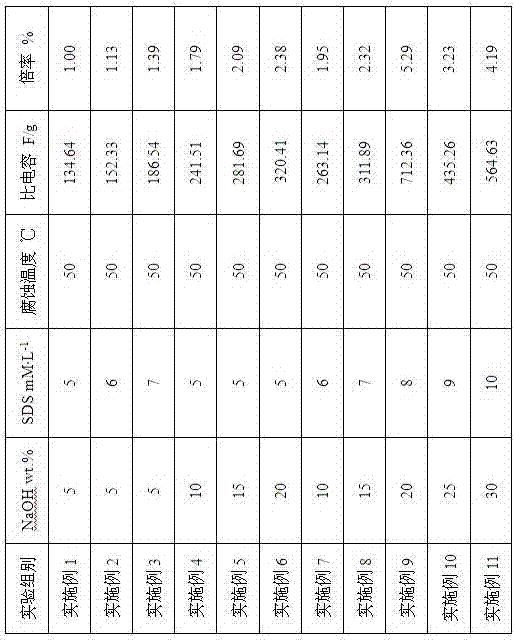

[0027] A preparation method of a supercapacitor nano manganese oxide electrode material, comprising the following steps:

[0028] (1) Put the pure aluminum block into the ceramic crucible of the outer graphite crucible, heat and melt it with an intermediate frequency induction furnace; wait for the aluminum block to be completely melted, then add the electrolytic manganese sheet, continue to heat up to 1400 ° C, stir with a carbon rod to determine the metal manganese Completely dissolve, so that the mass percentage of manganese in the alloy liquid is 25%, the rest is aluminum (Al) and no more than 0.5% of unavoidable impurities. After 15 minutes of heat preservation, the alloy liquid is left to stand and cooled to about 1200 ° C and cast into a metal mold for molding , to obtain Al-25%Mn alloy ingot;

[0029] (2) Mechanically cut the cast Al-25%Mn alloy ingot into small pieces and put them into a quartz tube with an open bottom, at 2.0×10 -2 Under the vacuum degree of Pa, the...

Embodiment 2

[0035] (3) Corrode the alloy thin strip in a NaOH solution with a mass fraction of 5%, and add a molar concentration of 6mM L to the corrosion solution -1 The surfactant sodium lauryl sulfate controls the corrosion environment, the corrosion temperature is 50 °C, until there are no obvious bubbles in the solution, the remaining flaky or powder solids in the solution are cleaned, dried, ground into powder, and naturally Oxidation to obtain nano manganese oxide powder;

[0036] (4) Using absolute ethanol as a dispersant, mix the dried manganese oxide powder, acetylene black, and binder polytetrafluoroethylene in a mass ratio of 80:10:10, and heat it to 65°C in an agate mortar. After grinding for 15 minutes, make a paste, apply it evenly on the pretreated foamed nickel, press it into an electrode material under a pressure of 10 MPa in a powder tablet press, and then dry the electrode material in an electric heating constant temperature drying oven at 70°C until it has a constant ...

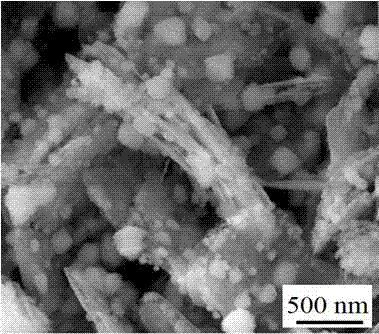

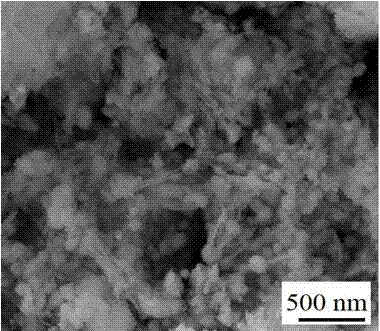

Embodiment 3

[0040] (3) Corrode the alloy thin strip in a NaOH solution with a mass fraction of 5%, and add a molar concentration of 7mM L to the corrosion solution -1 The surfactant sodium lauryl sulfate controls the corrosion environment, the corrosion temperature is 50 °C, until there are no obvious bubbles in the solution, the remaining flaky or powder solids in the solution are cleaned, dried, ground into powder, and naturally Oxidation to obtain nano manganese oxide powder;

[0041] (4) Using absolute ethanol as a dispersant, mix the dried manganese oxide powder, acetylene black, and binder polytetrafluoroethylene in a mass ratio of 80:10:10, and heat it to 65°C in an agate mortar. After grinding for 15 minutes, make a paste, apply it evenly on the pretreated nickel foam, and press it into an electrode material under a pressure of 10MPa in a powder tablet press, and then dry the electrode material in an electric heating constant temperature drying oven at 70°C until it reaches a cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com