Patents

Literature

111results about How to "Small pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

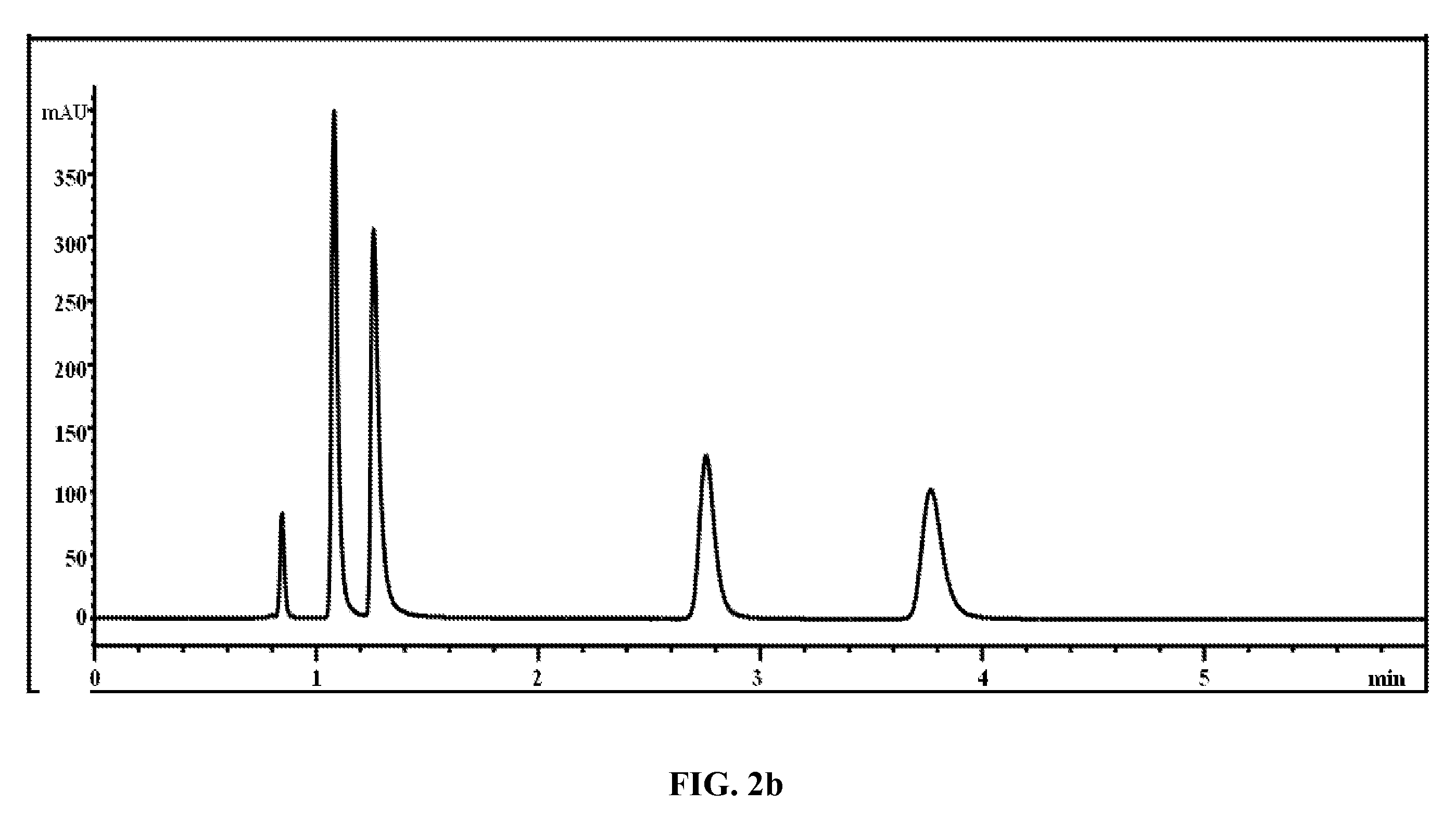

Method for analyzing a fluid sample

InactiveUS6881541B2Small pore sizePrevent cloggingBioreactor/fermenter combinationsHeating or cooling apparatusBiologyReaction chamber

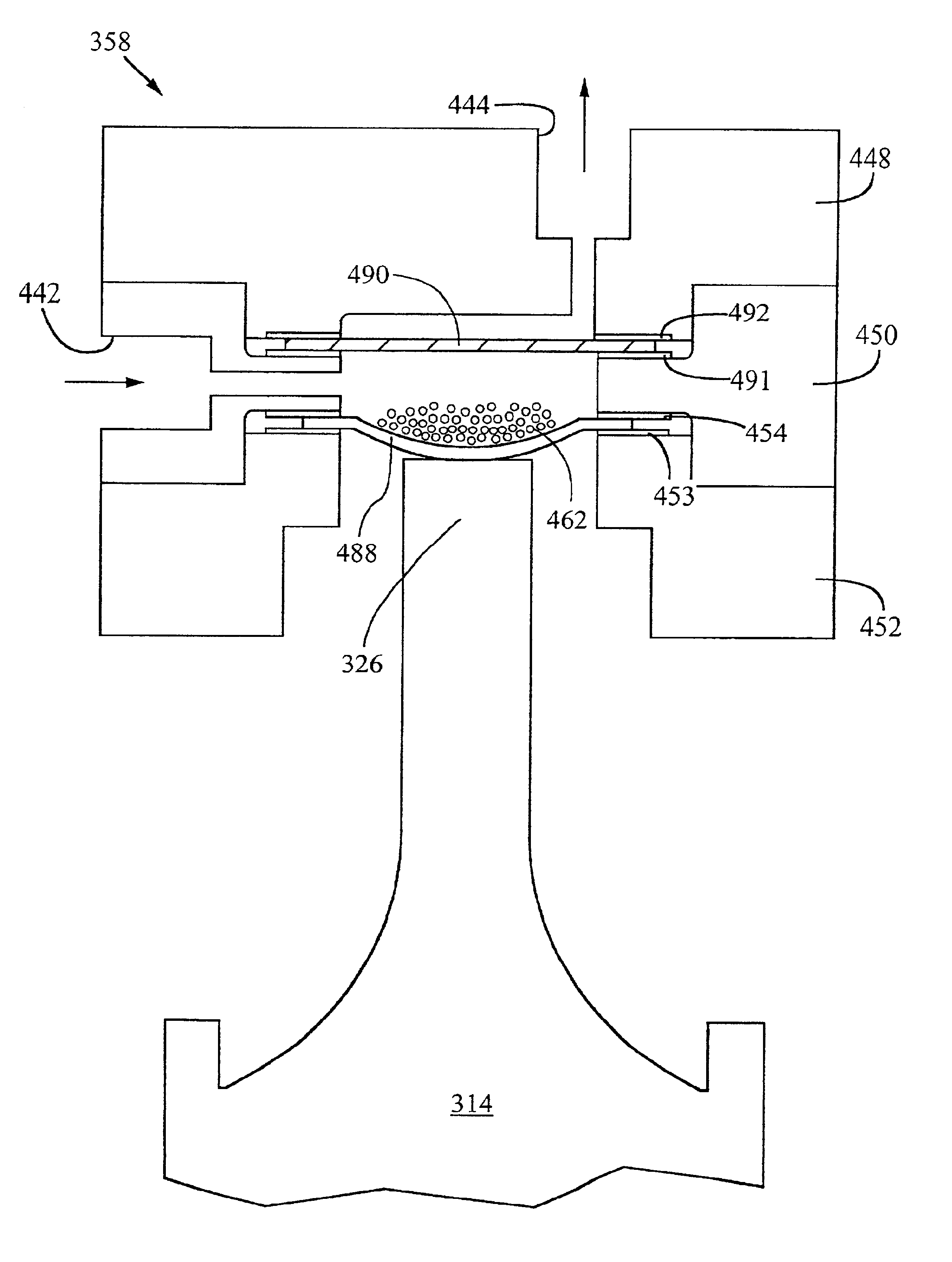

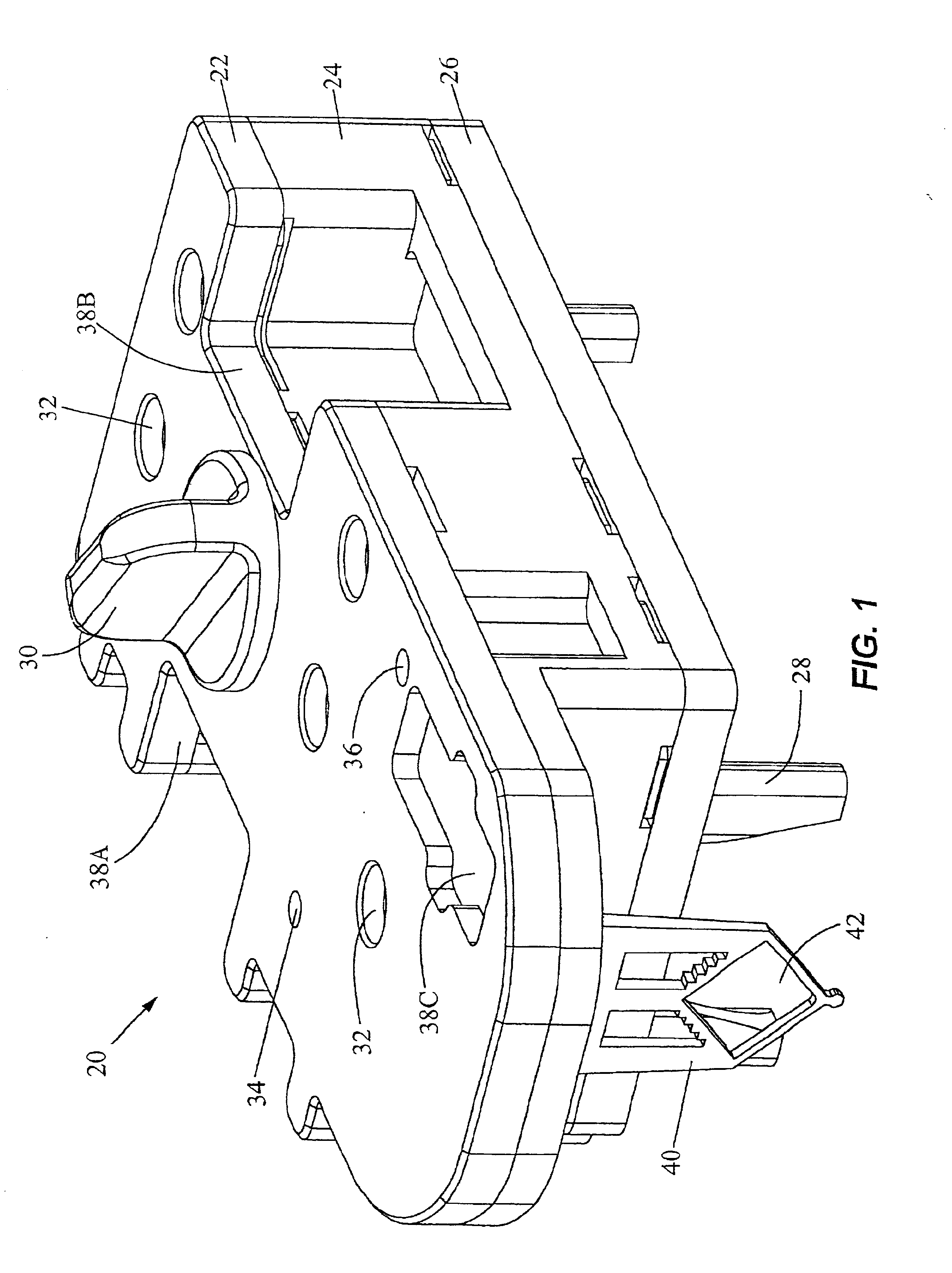

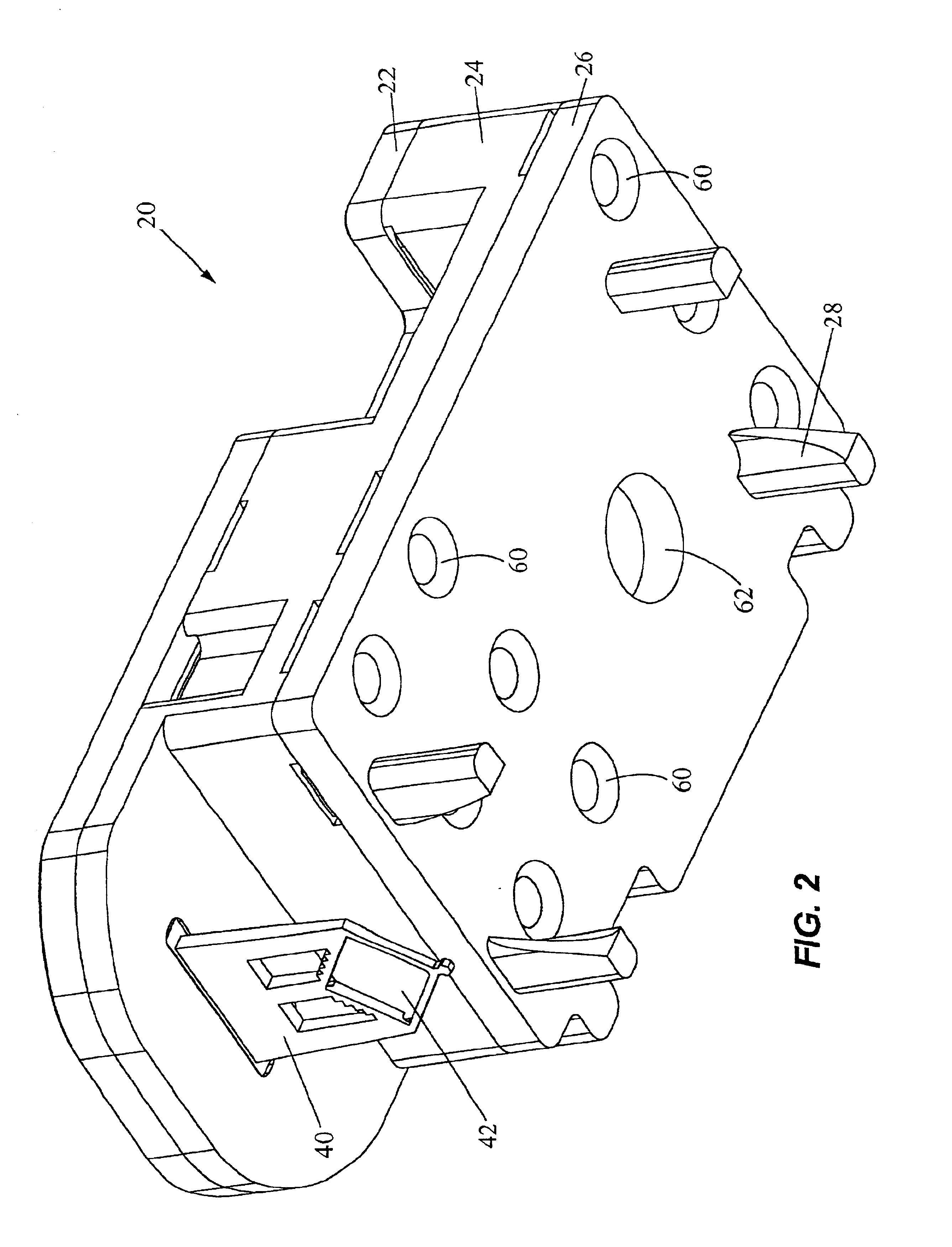

A method for extracting nucleic acid from a fluid sample comprises the steps of introducing the sample into a cartridge having a sample flow path and a lysing chamber in the sample flow path. The lysing chamber contains at least one filter for separating cells or viruses from the sample. The sample is forced to flow through the lysing chamber to capture the cells or viruses with the filter, while used sample fluid flows to waste. The captured cells or viruses are disrupted to release their nucleic acid, the nucleic acid is eluted from the lysing chamber, and optionally the nucleic acid is amplified and detected in a reaction chamber of the cartridge.

Owner:CEPHEID INC

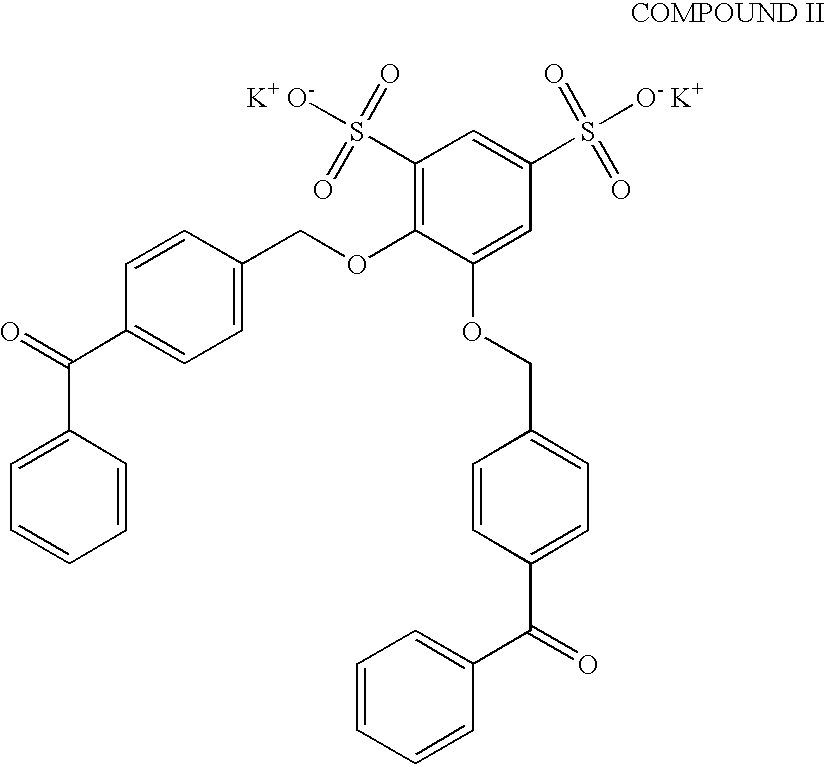

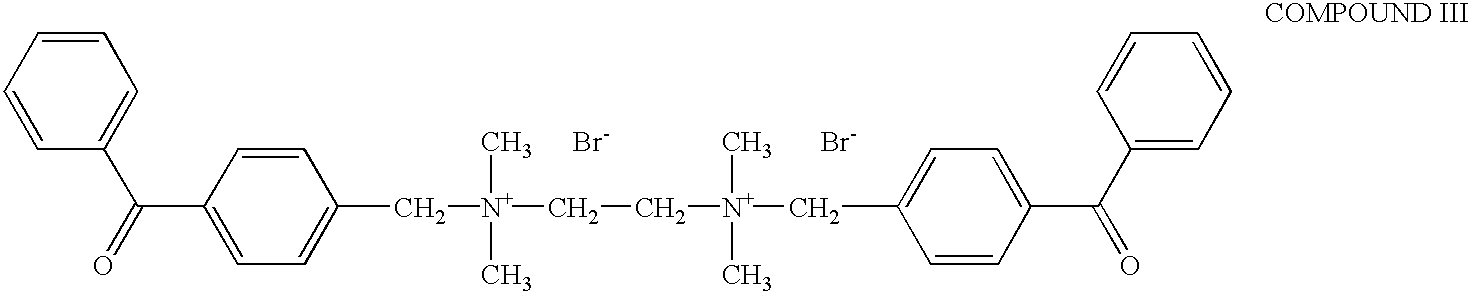

Reagent and method for providing coatings on surfaces

InactiveUS20030165613A1Easy to controlImprove coating efficiencyMaterial nanotechnologySurgeryPorosityBiological activation

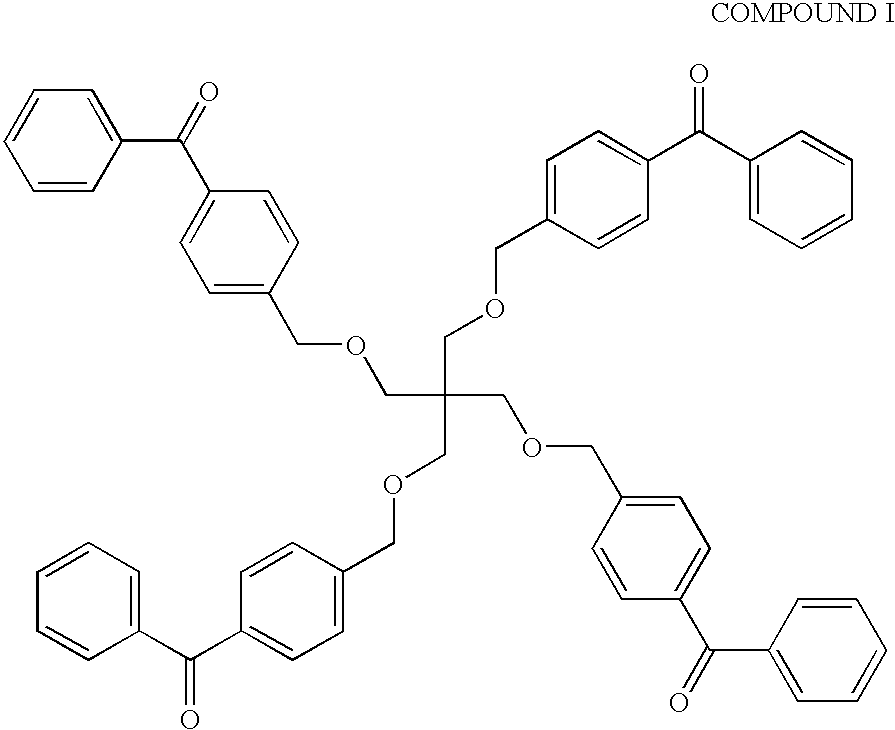

A grafting reagent and related method of using the reagent to form a polymeric layer on a support surface, and particularly a porous support surface, in a manner that provides and / or preserves desired properties (such as porosity) of the surface. The reagent and method can be used to provide a thin, conformable, uniform, uncrosslinked coating having desired properties onto the surface of a preformed, and particularly a porous, polymeric substrate. The method includes the steps of a) providing a porous support surface, b) providing a nonpolymeric grafting reagent comprising a photoinitator group, c) providing one or more polymerizable monomers adapted to be contacted with the surface, in the presence of the grafting reagent, and to be polymerized upon activation of the photoinitiator; and d) applying the grafting reagent and monomer(s) to the surface in a manner, and under conditions, suitable to coat the surface with the grafting reagent and to cause the polymerization of monomers to the surface upon activation of the grafting reagent.

Owner:SURMODICS INC

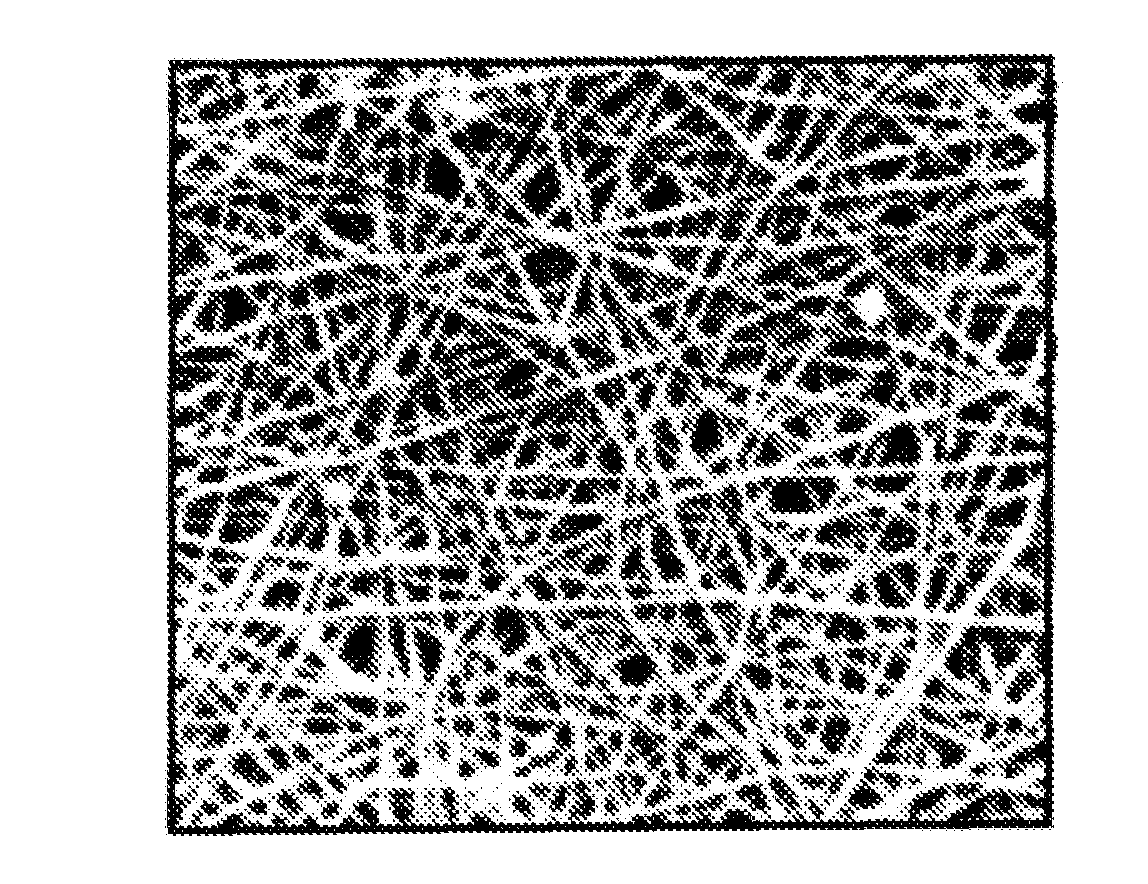

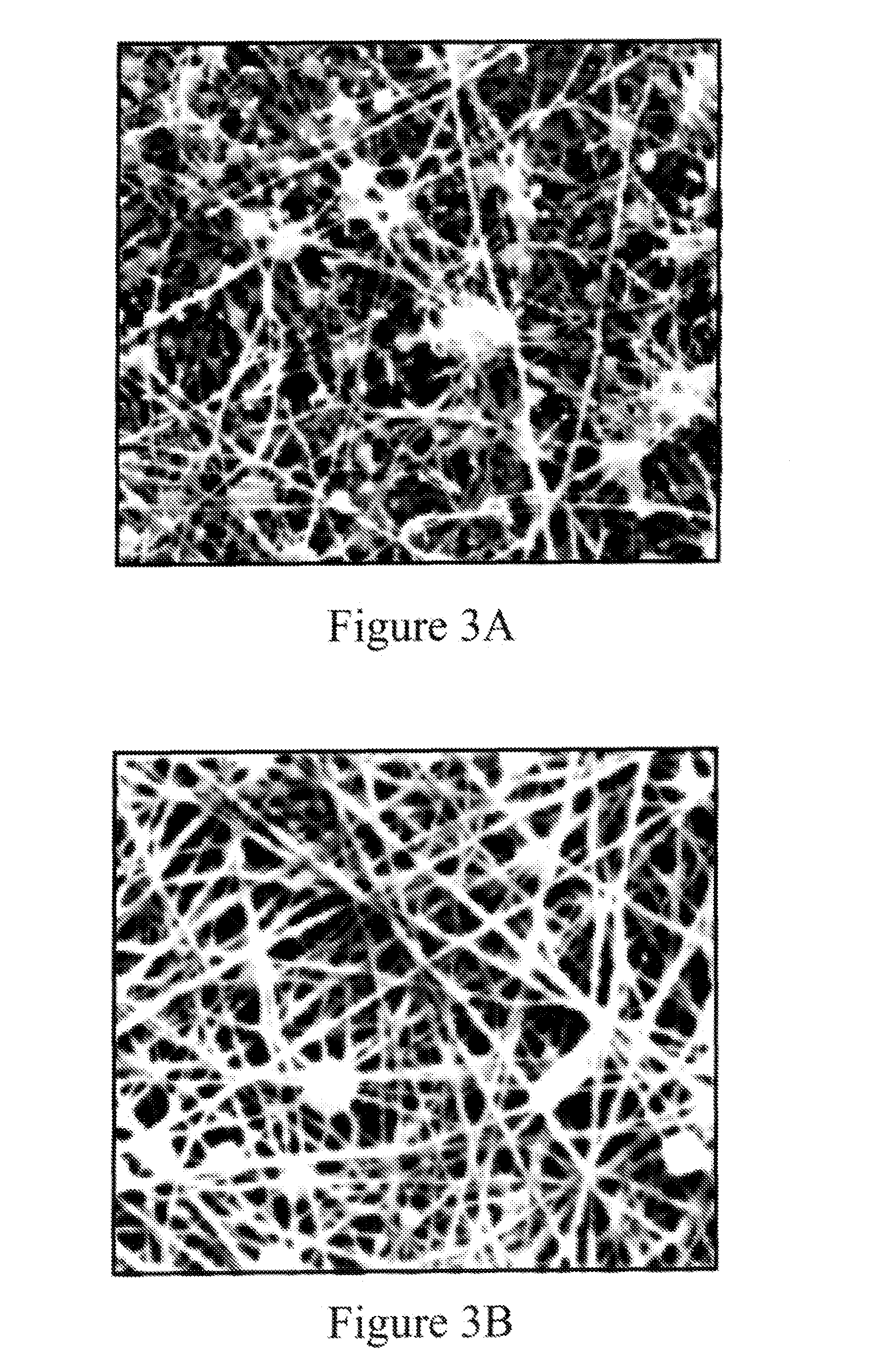

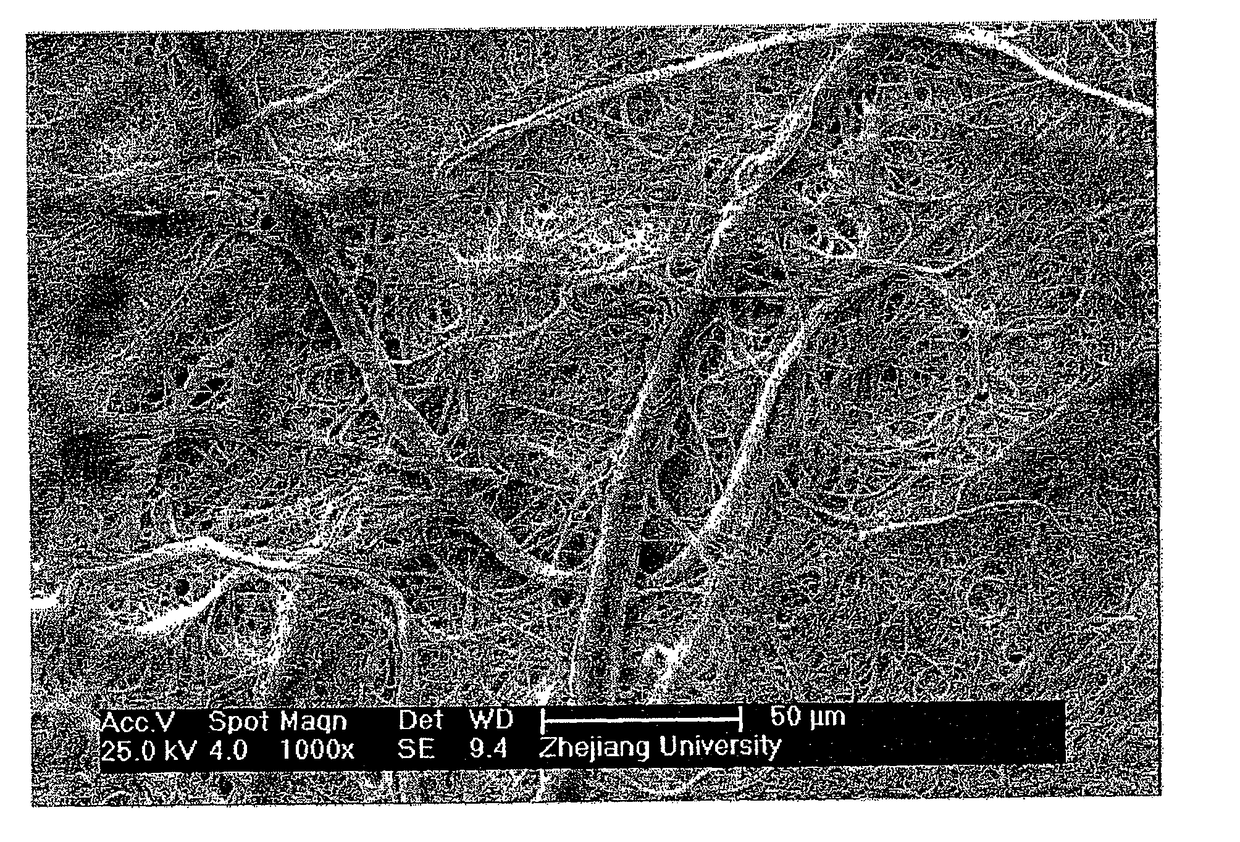

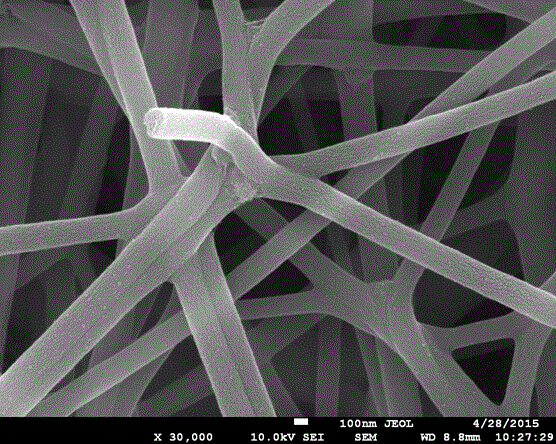

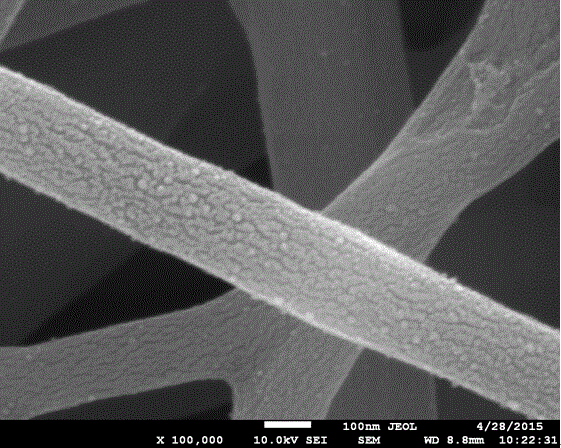

Ultraporous Nanofiber Mats And Uses Thereof

A porous electrospun polymeric nanofiber liquid filtration medium, such as an electrospun mats, used for the removal of viral particles (e.g., parvovirus) and other particles in the 18 nm to 30 nm size range from fluid streams, having a mean flow bubble point measured with perfluorohexane above 100 psi. The electrospun medium includes nanofibers having an average fiber diameter of about 6 nm to about 13 nm, and the nanofiber liquid filtration medium has a mean pore size ranging from about 0.01 um to about 0.03 um, a porosity ranging from about 80% to about 95%, a thickness ranging from about 1 um to about 100 um, and a liquid permeability greater than about 10 LMH / psi. The high porosity of the electro-spun mats enable much higher water fluxes, thus reducing the time required to complete virus filtration steps on a fluid stream.

Owner:MILLIPORE CORP

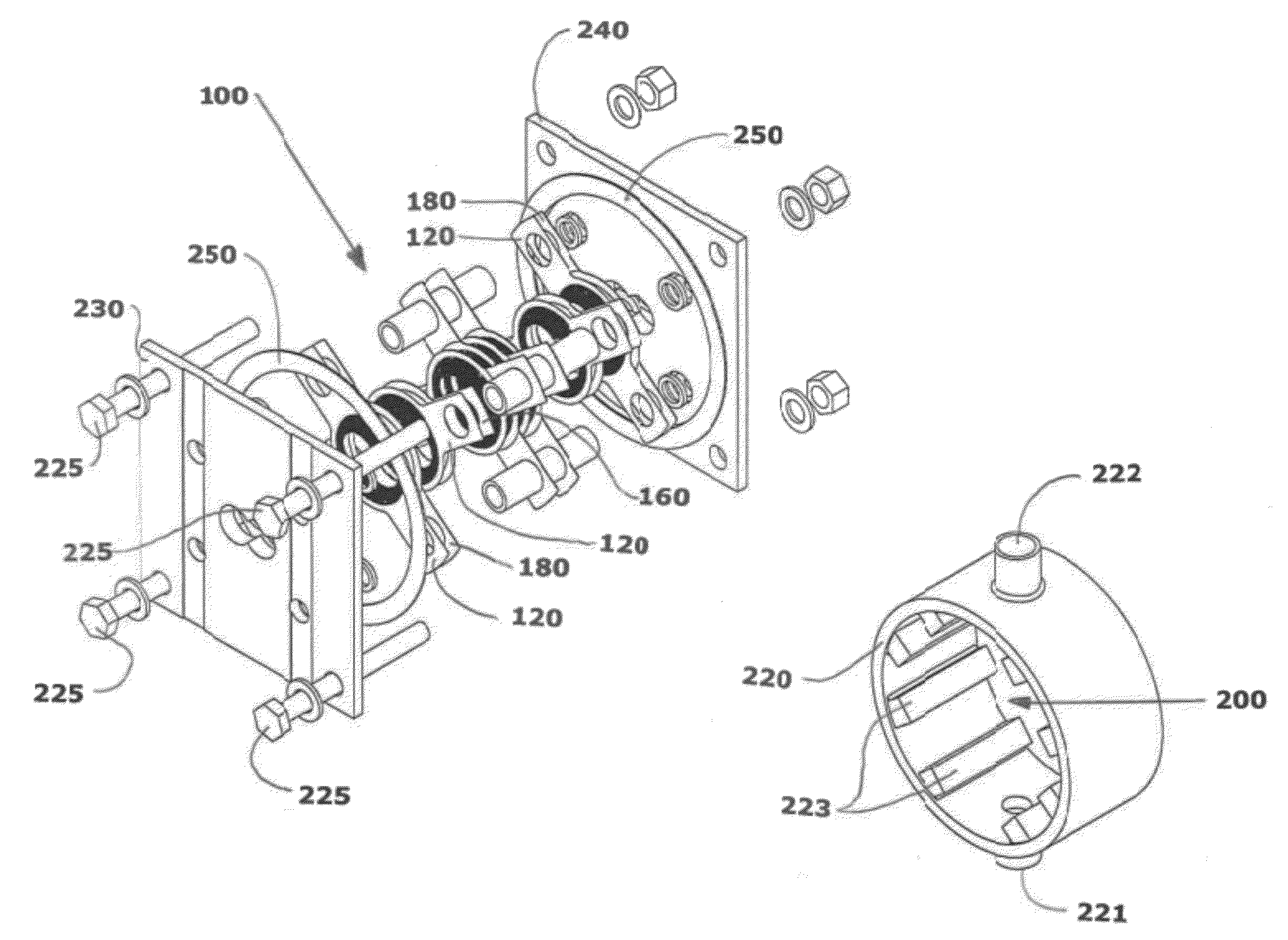

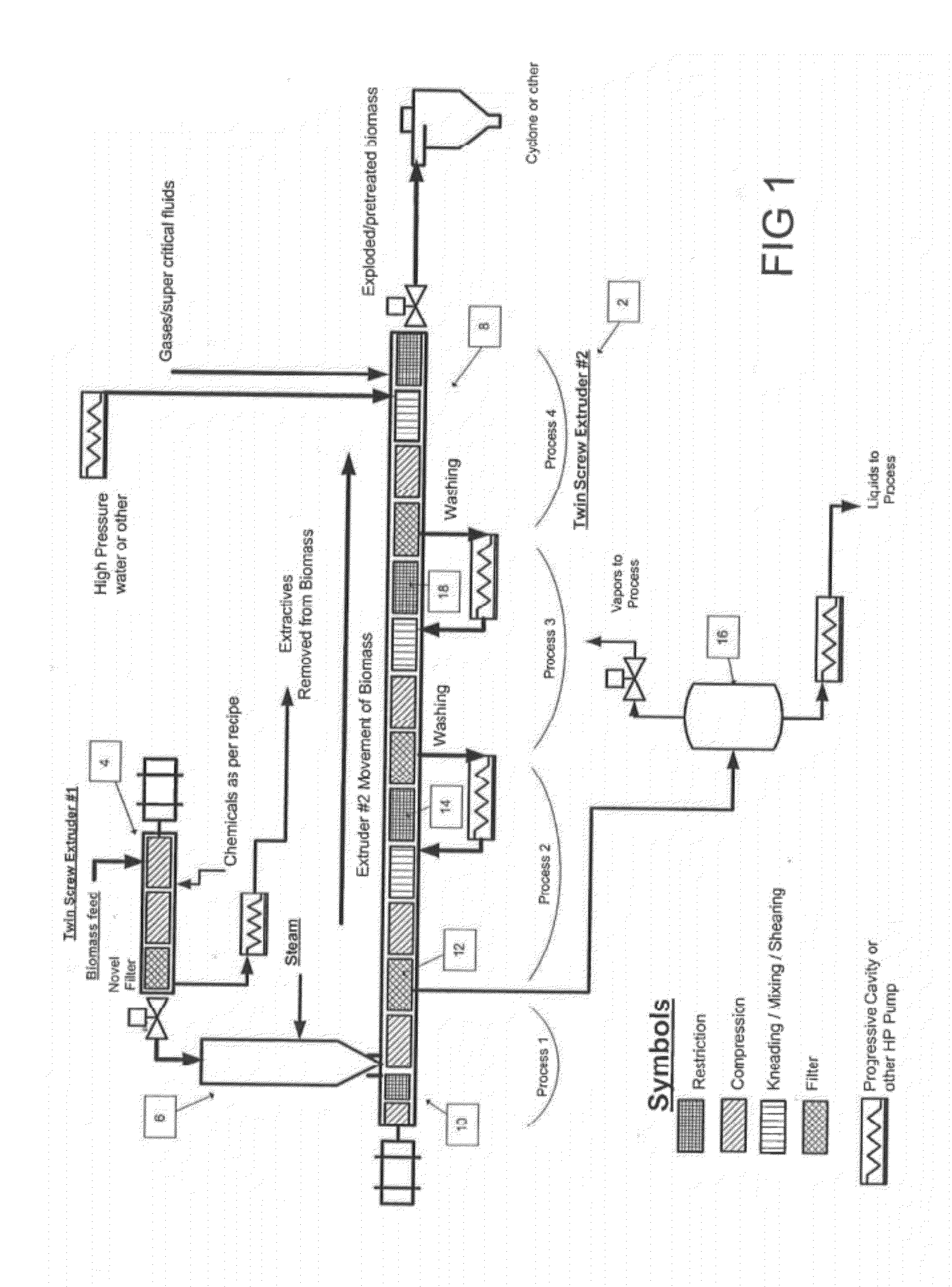

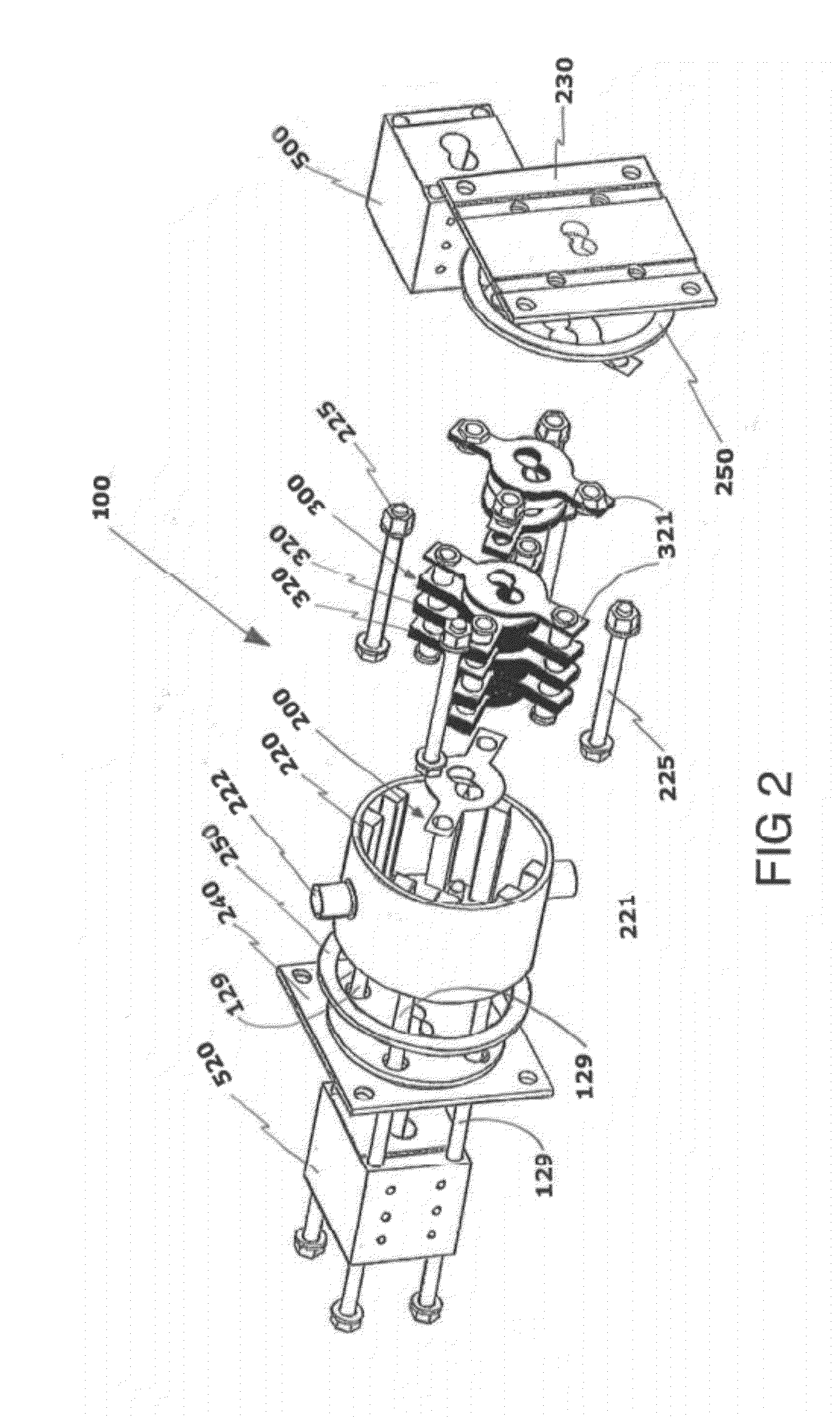

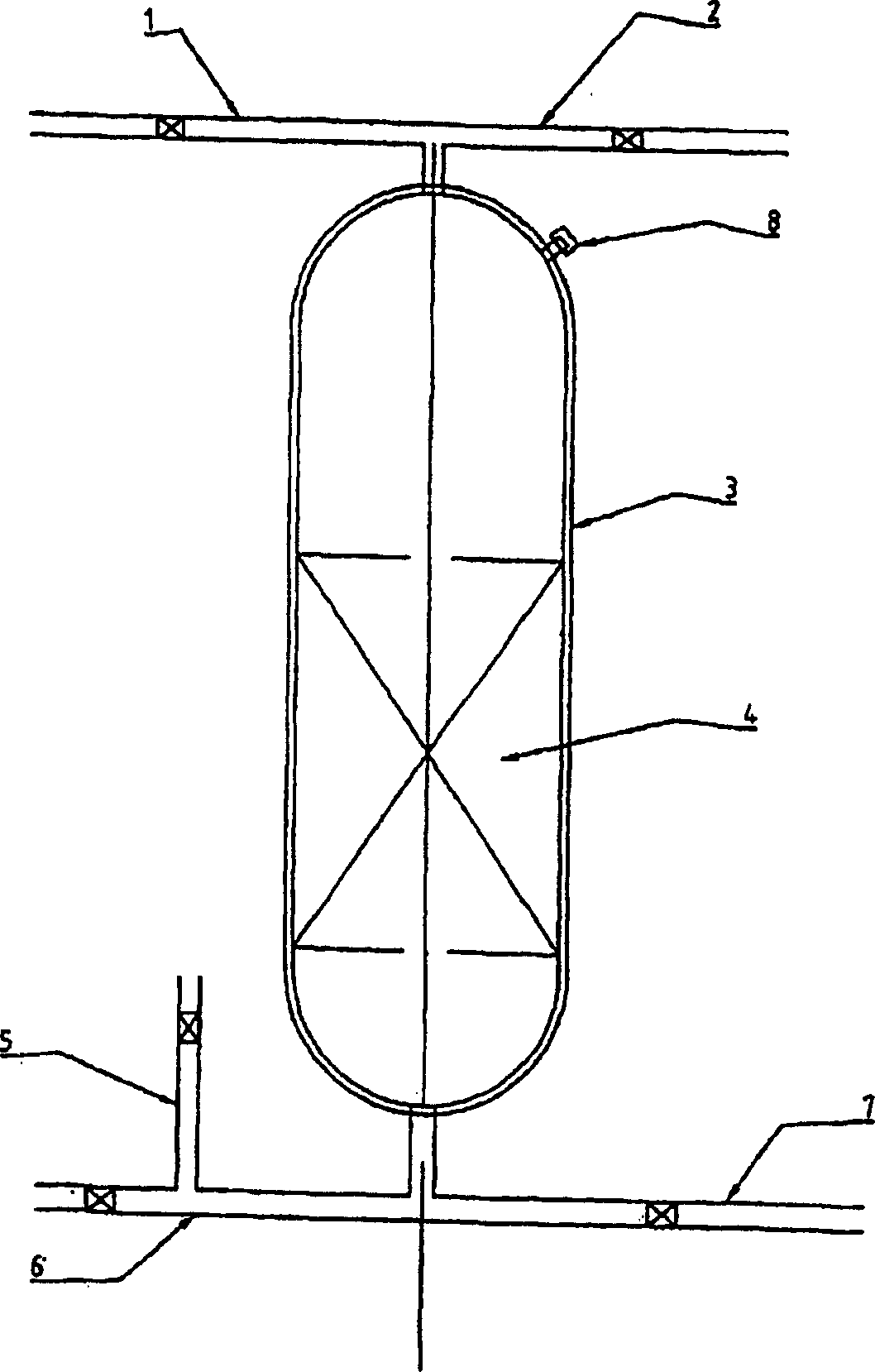

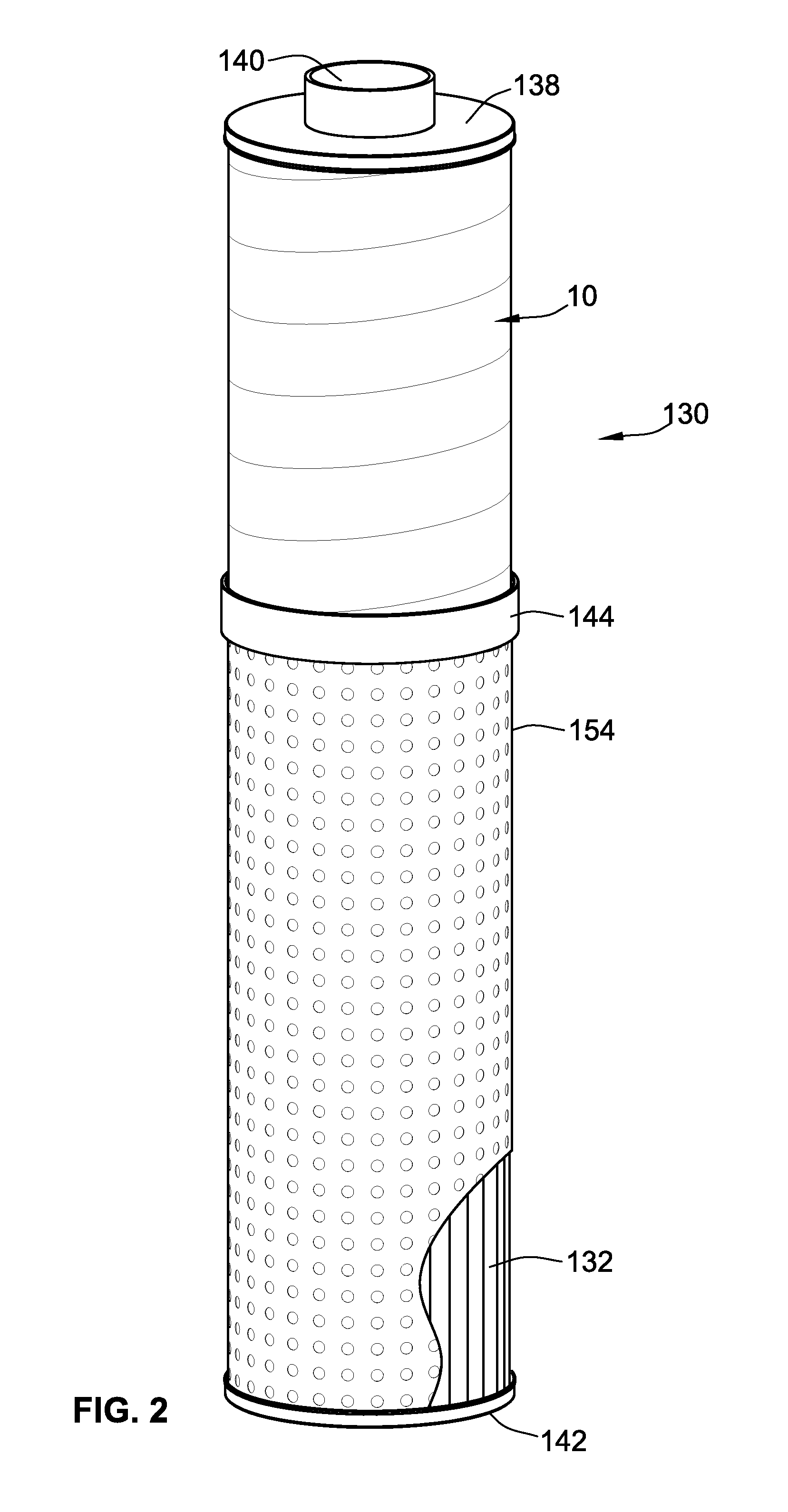

Solid/fluid separation device and method for treating biomass including solid/fluid separation

A solid / fluid separation module and pretreatment apparatus and method enables pretreatment of biomass at high temperature and pressure with the ability to vary residence and processing times.

Owner:GREENFIELD SPECIALTY ALCOHOLS

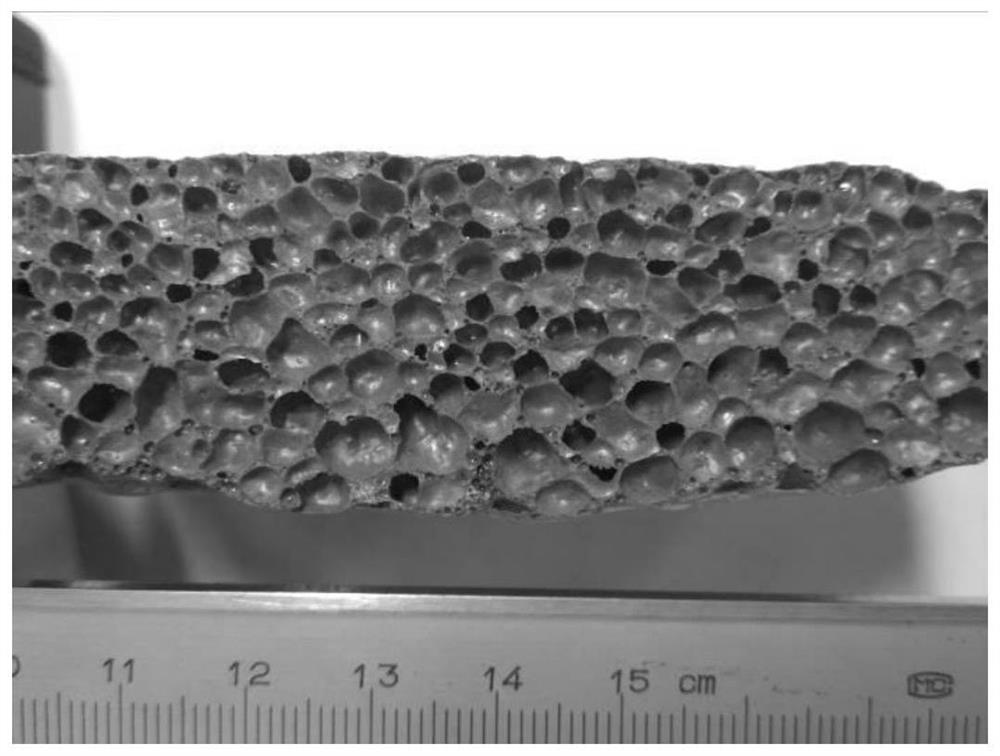

Preparation method of porous slurry green body

The invention relates to a preparation method of a porous slurry green body, belonging to the technical field of ceramic and refractory materials. The method comprises five steps of: foam preparation, slurry blending, foam and slurry mixing, green body pouring and green body maintenance. The invention specifically comprises the following steps of: prefabricating bubbles in advance under the action of compressed air through a foaming device by adopting a physical foaming agent so as to provide fine, uniform and stable bubbles; and mixing high-alumina cement, Suzhou clay, pyrophyllite, lime and calcium carbonate according to a required proportion and then adding water to prepare a prefabricated slurry, wherein in the slurry, the high-alumina cement is used as one of ingredients to provide aluminum oxide and calcium oxide, and meanwhile, the characteristics of fast-solidification and fast-hardening of the high-alumina cement are adopted to accelerate the solidification and the hardening of pouring a green pouring body so as to ensure that on one hand, the bubbles are fixed as soon as possible to reduce bubble loss, and on the other hand, the green body is enhanced to reduce the deformation of the green body. The invention can easily prepare a green body with a drying density of 0.34-0.45kg / m<3>, and the compression strength of a corresponding drying green body is 0.15-0.50MPa.

Owner:NANJING TECH UNIV

Compound filter material, method and application thereof

InactiveCN101596384AExtended service lifeHigh acid and alkali resistanceFiltration separationFolding enduranceAntistatic agent

The invention discloses a compound filter material, a method and application thereof, and relates to a filter material. The invention provides a compound filter material which has good folding endurance, corrosion resistance and wear resistance and can be used as a high-temperature environment filter material, a method and application thereof. The compound filter material comprises the following components in percentage by mass: 1 to 99 percent of basalt fiber and 1 to 99 percent of polytetrafluoroethylene fiber. The preparation method comprises the following steps of: mixing the basalt fiber and the polytetrafluoroethylene fiber to obtain a mixed fiber; and adding an antistatic agent to the mixed fiber for mixing to obtain the compound filter material. According to the mass percentage, the adding amount of the antistatic agent is 0.1 to 20 percent of the mixed fiber. The compound filter material can be used for directly preparing composite filter cloth with single-layer structure or multi-layer structure, and the prepared composite filter cloth with single-layer structure or multi-layer structure can be used for producing a filter device.

Owner:厦门美达斯环保工业有限公司

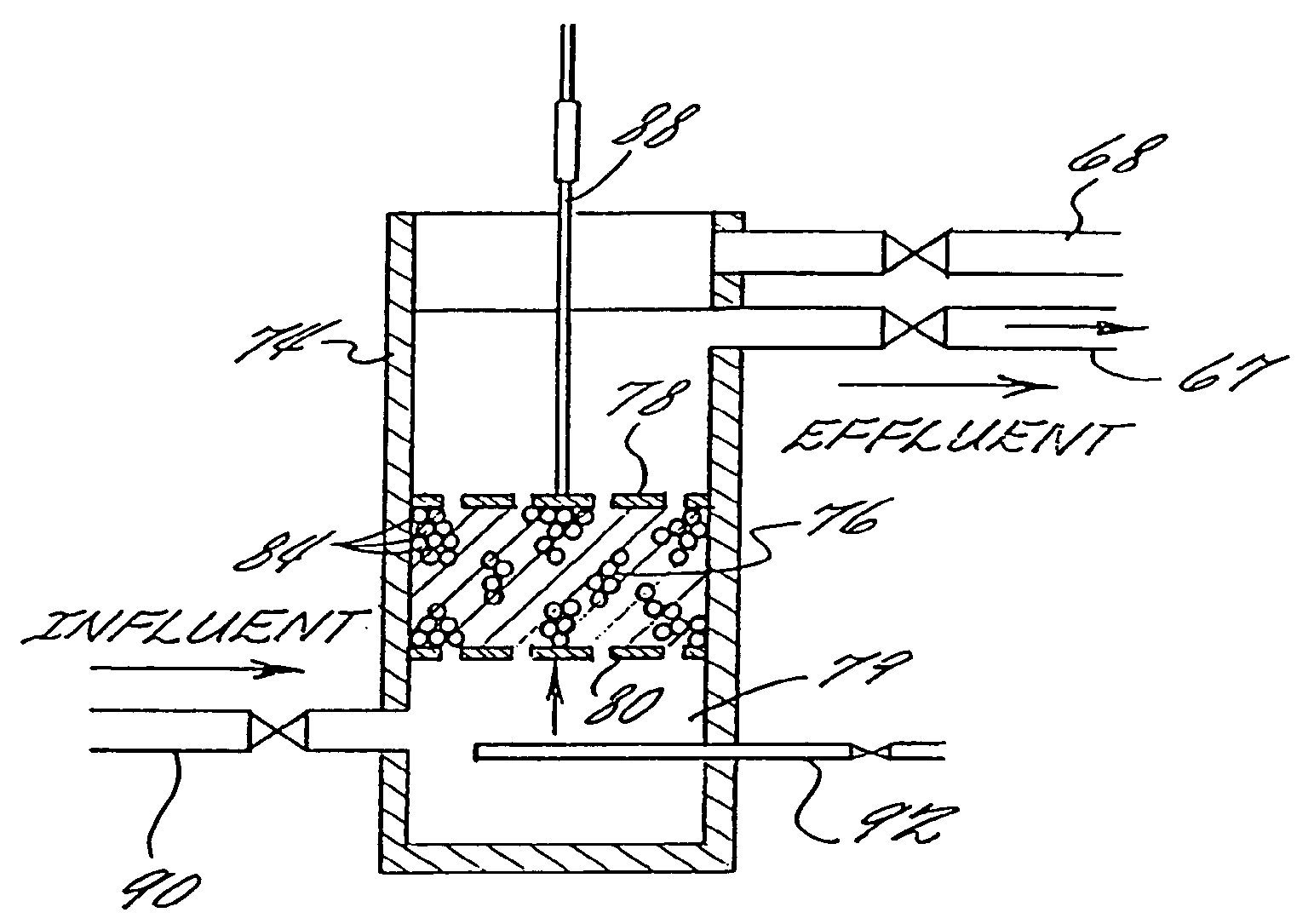

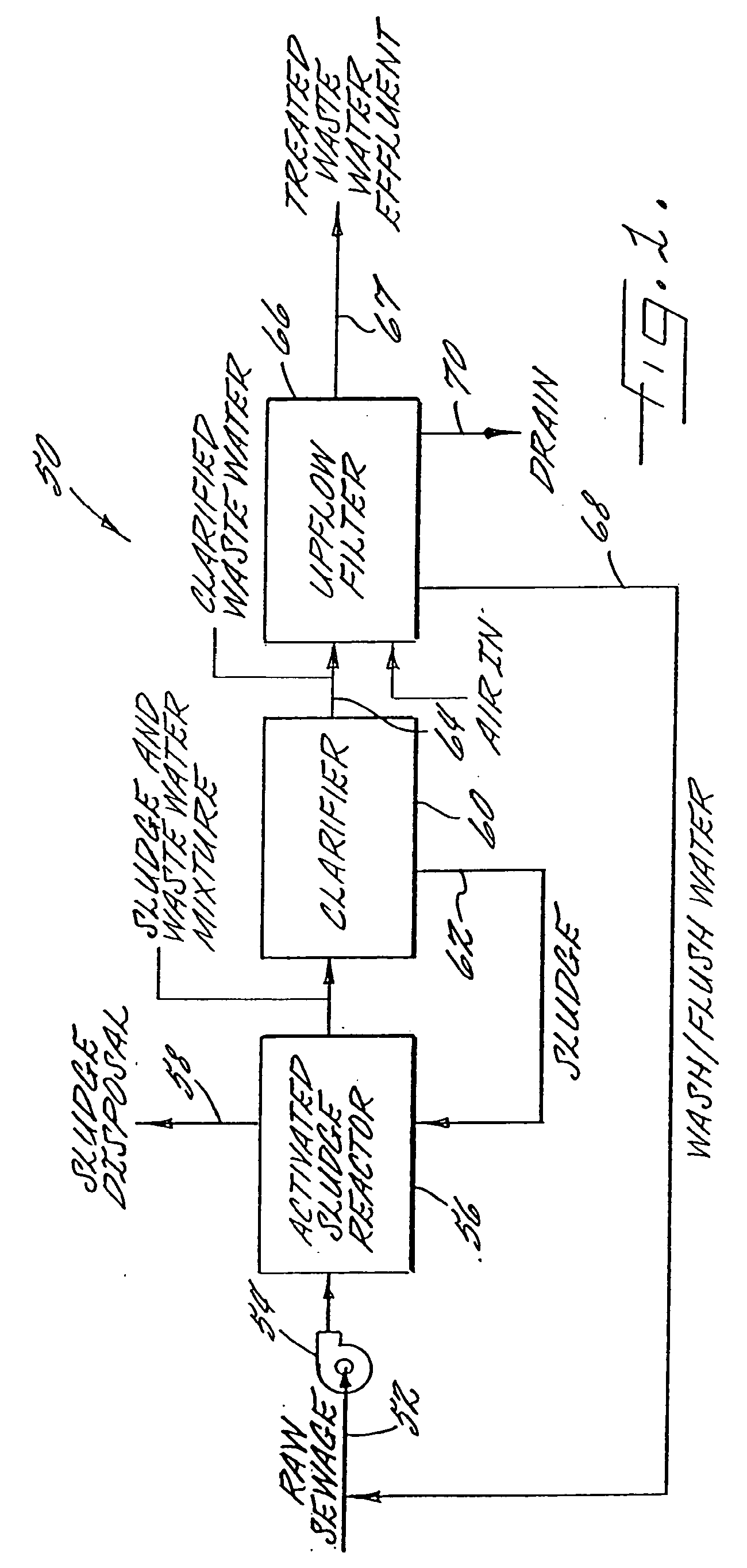

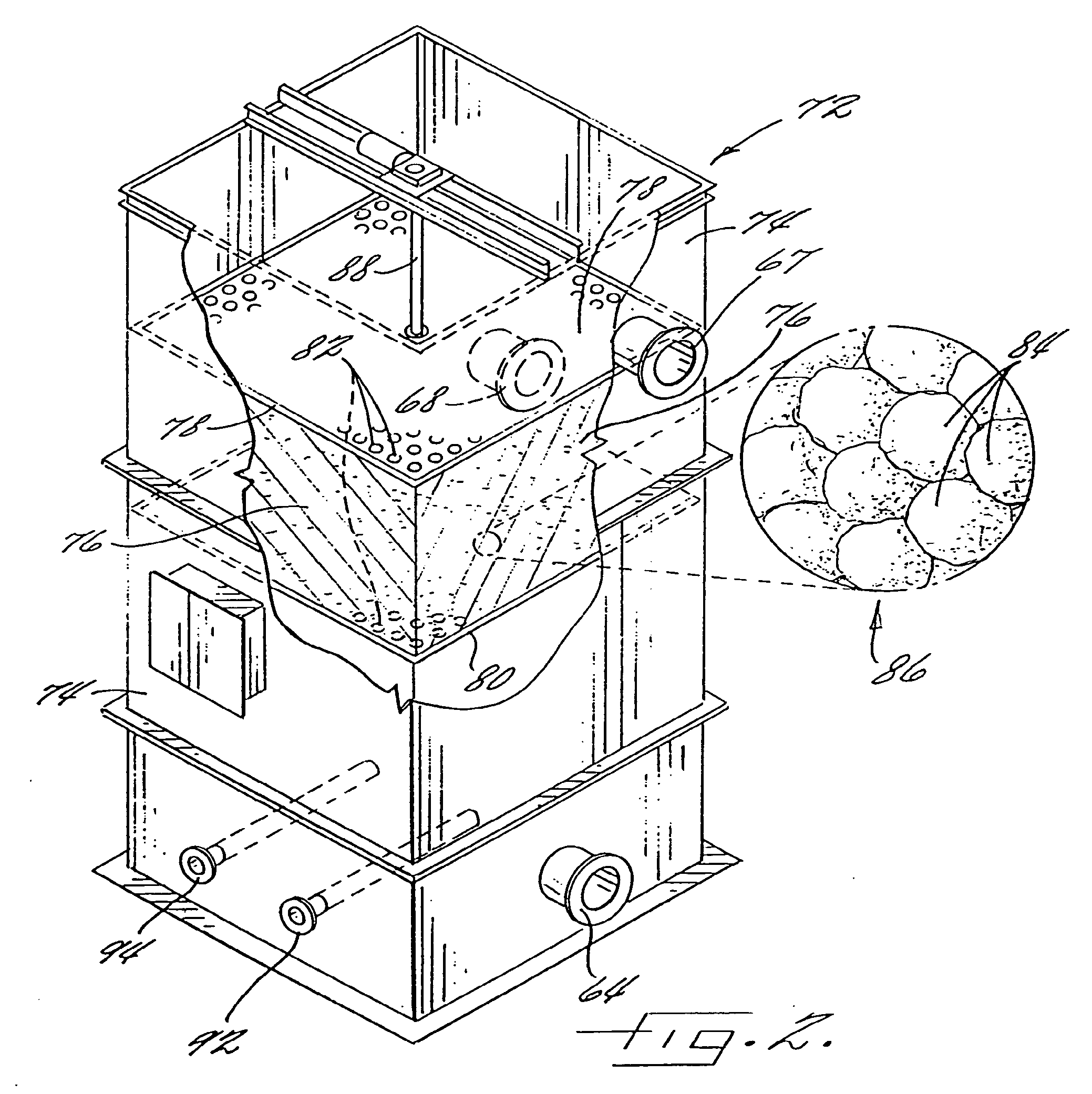

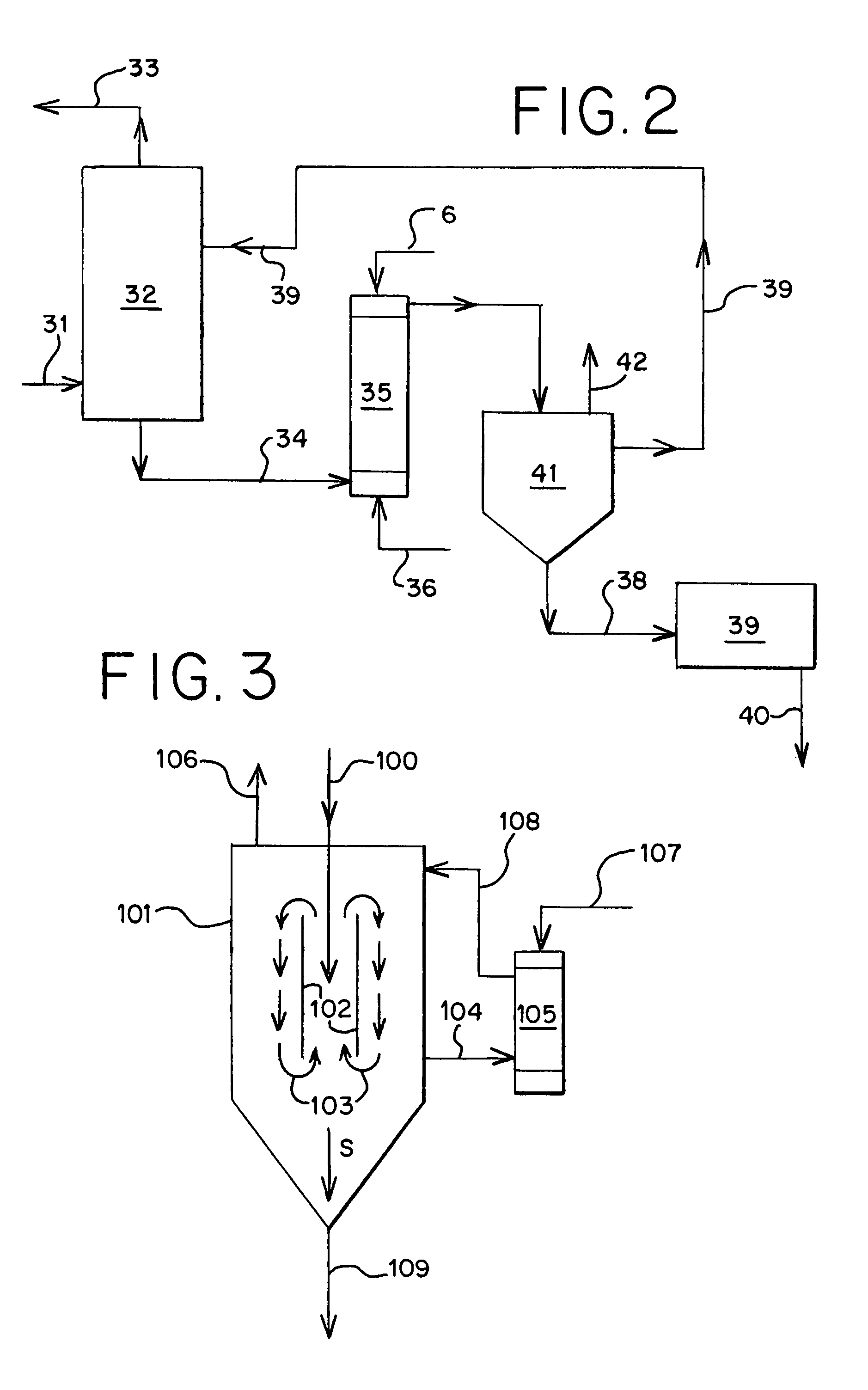

High Rate Filtration System

InactiveUS20080257805A1Uniform loadHigh rateWater cleaningWater/sewage treatmentSoil sciencePorous medium

A high rate, upflow filtration system is described in which a compressible, fibrous lump filtration media is compressed to adjust the porosity and collector size of the media in the bed and to provide a porosity gradient within the bed proceeding from more porous to less porous in a direction opposite to the flow of fluid so that filtration proceeds in a direction from a more porous to a less porous filter bed. Larger particles are removed by the more porous media and successively smaller particles are removed as the filter bed becomes less porous. The system is capable of reducing the turbidity of influent municipal wastewater from about 8 NTU to about 2 NTU at a wastewater flow rate of from about 820 to 1230 L / m2·min (20 to 30 gal / ft2·min), at a bed compression ration of from about 15 to 40 percent, and at a backwash rate of from about 1 to 6 percent based on the total wastewater passing through the filter.

Owner:SCHREIBER CORP

Alumina light-weight brick and preparation method thereof

The invention relates to an alumina light-weight brick and a preparation method thereof. The method adopts the technical scheme that: 50 to 80 weight percent of Al2O3 fine powder, 15 to 30 weight percent of alpha-Al2O3 micro-powder and 5 to 20 weight percent of rho-Al2O3 micro-powder serving as raw materials are mixed with 0.1 to 1 weight percent of sintering aid, 30 to 50 weight percent of water, 0.1 to 1 weight percent of water reducer and 0.1 to 2 weight percent of SiO2 for 3 to 5 minutes; furthermore, the mixture and 0.2 to 0.4 weight percent of foaming agent are mixed uniformly, and are cast and molded; and the mold is sintered at the temperature of between 1,450 and 1,700 DEG C after being dried, and is insulated for 3 to 5 hours. The method has the characteristics of simple process and energy conservation; and the prepared alumina light-weight brick has the volume density of between 0.6 and 1.1g / cm3, the heat conductivity of between 0.2 and 0.6w / (m.k) and the compression strength of 5 to 15Mpa, and has the advantages of higher strength, small volume density and low heat conductivity compared with hollow ball products.

Owner:WUHAN UNIV OF SCI & TECH

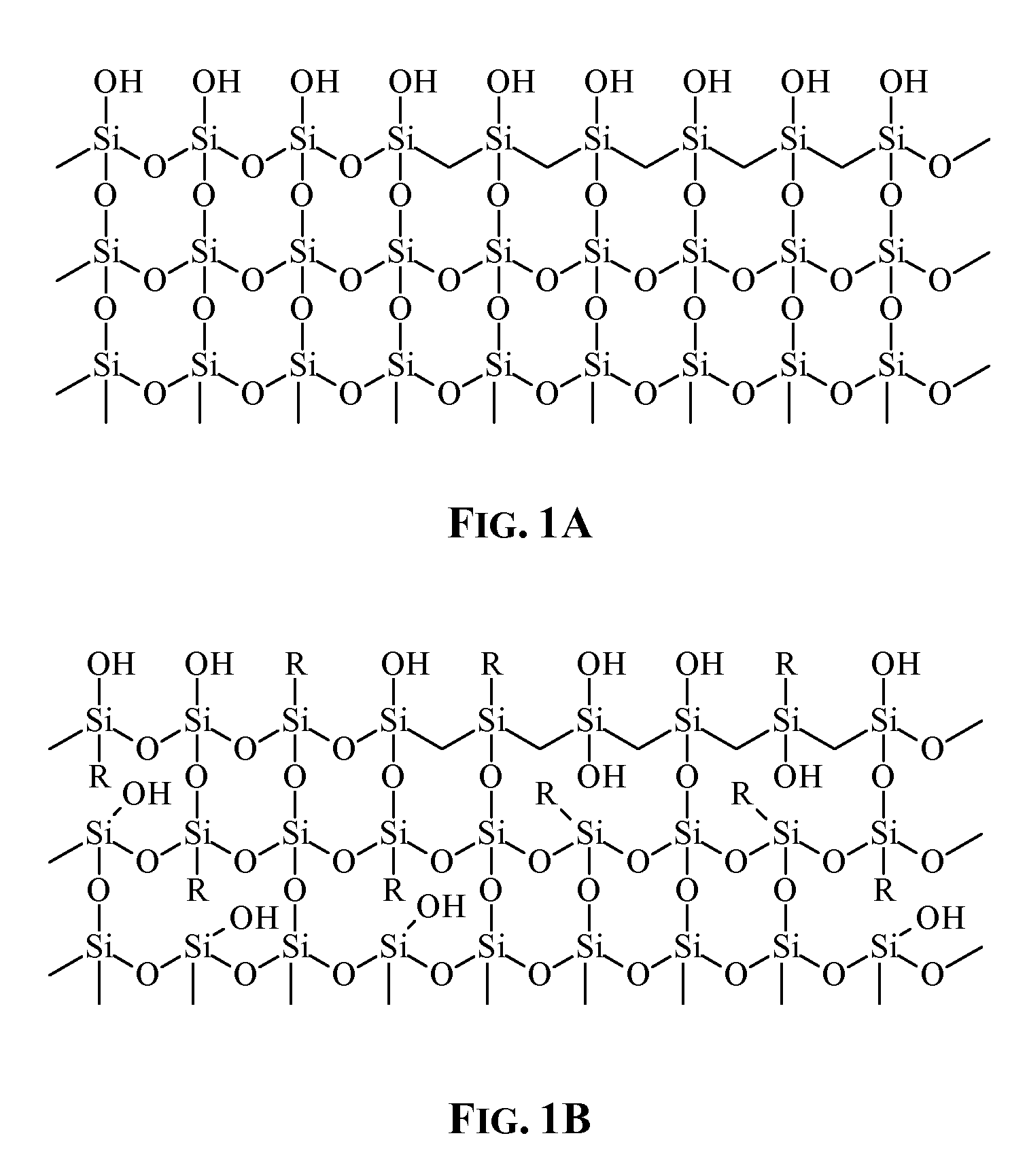

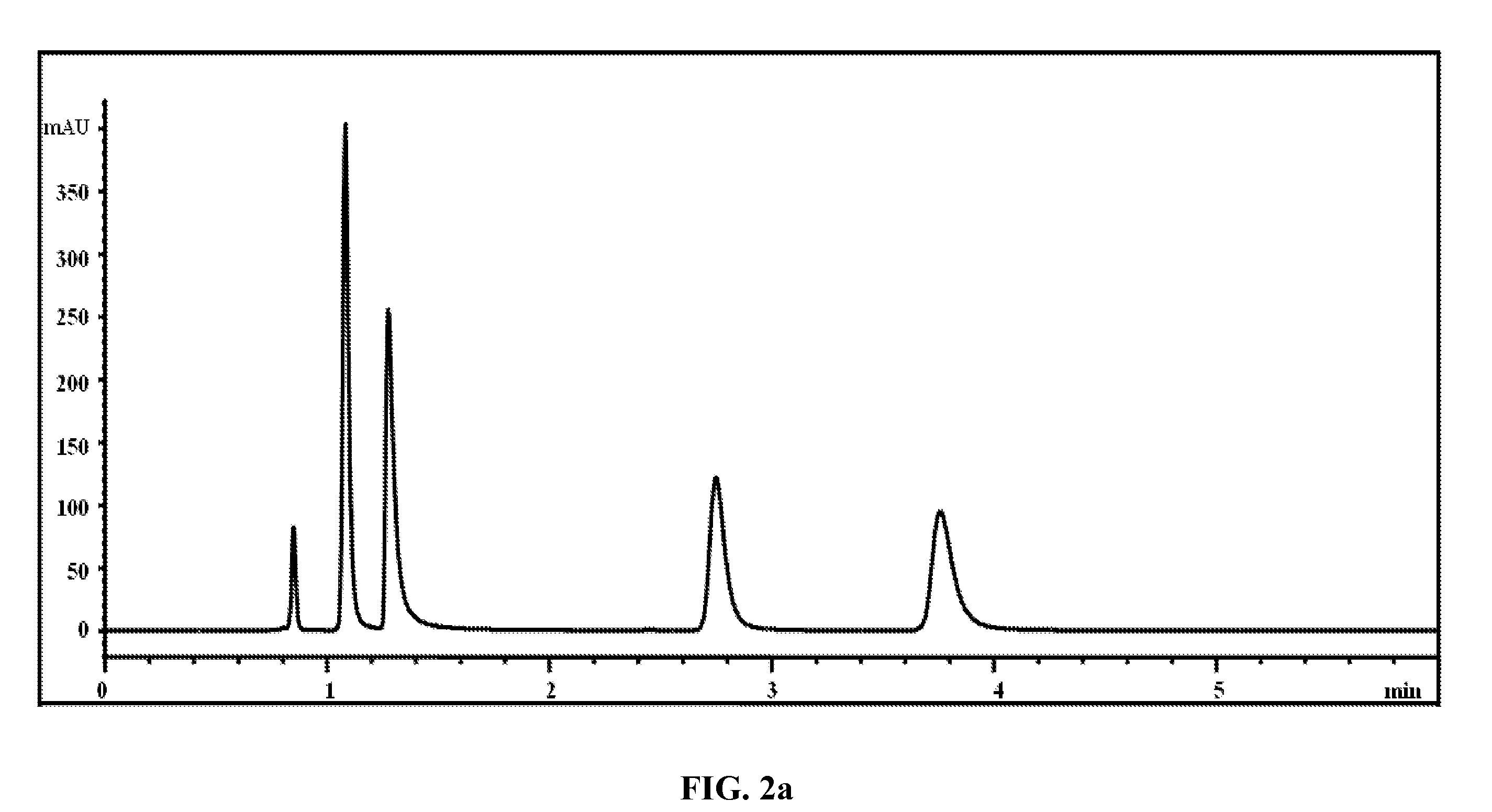

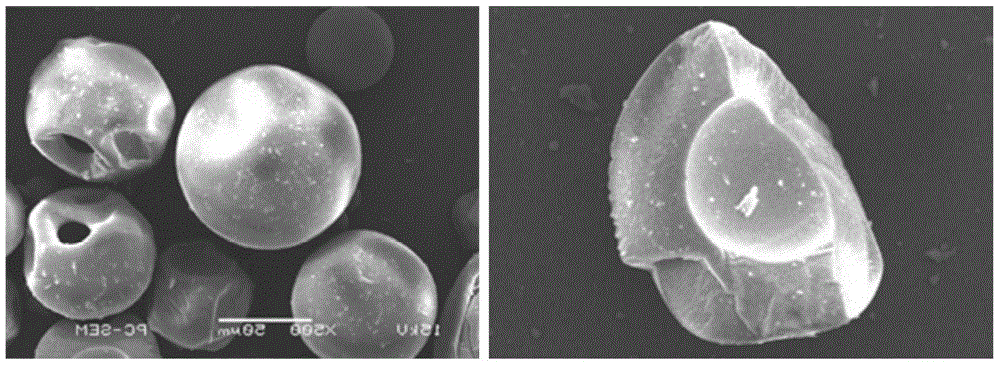

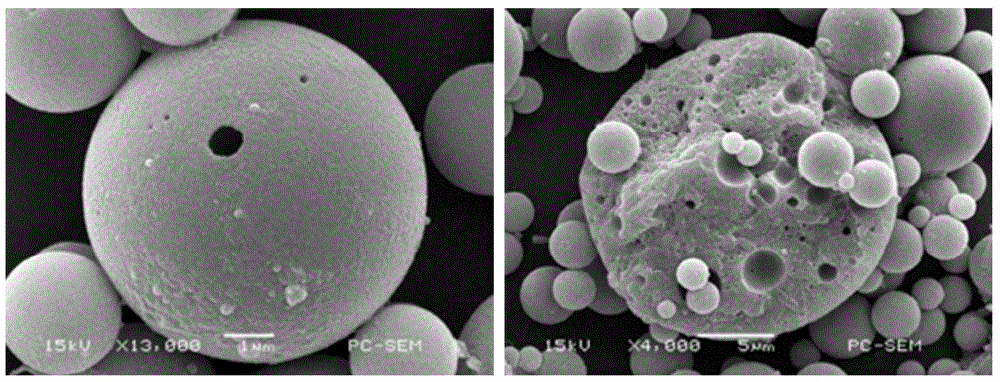

Porous silica microspheres having organosilane modified surfaces

ActiveUS20090311533A1Increase of pore size and volumeSmall pore sizePigmenting treatmentLiquid surface applicatorsPorous particleMicrosphere

A method for preparing functionalized porous particles is disclosed, the method comprising contacting a plurality of porous silica particles with water, at least one of an ionic fluoride such as HF or NH4F or a basic activator, and a multifunctional organosilane. Also disclosed are functionalized porous silica particles produced from the methods disclosed herein.

Owner:AGILENT TECH INC

High-temperature-resisting wet-process felt and preparation method thereof

ActiveCN104534223AHigh porosityLow thermal conductivityThermal insulationPipe protection by thermal insulationPorosityFiber

The invention discloses a high-temperature-resisting wet-process felt and a preparation method thereof. The porosity of the high-temperature-resisting wet-process felt is more than 93% and the thickness of the high-temperature-resisting wet-process felt is 6mm-22mm; a nano silicon dioxide coating is arranged on the outer surface of the high-temperature-resisting wet-process felt; the diameter of fiber monofilaments of the high-temperature-resisting wet-process felt is 0.1 micron-2 microns, and closed vacuum balls with the diameter being less than 20nm are uniformly arranged on the outer surfaces of the fiber monofilaments. By the aid of the high-temperature-resisting wet-process felt, the porosity of a fiber cotton felt is greatly improved and the heat conductivity coefficient of the fiber cotton felt is reduced; any binding agent is not added into the product so that the product has the advantages of no toxin, high temperature resistance, low moisture absorption rate, soft texture and small volume density, and can be repeatedly used at high and low temperatures, and the heat insulation performance is not obviously reduced when the product is used at the high temperature; the highest utilization temperature is up to 1000 DEG C; the high-temperature-resisting wet-process felt can be widely applied to fire prevention and heat insulation of high-temperature equipment and is particularly suitable for heat preservation and heat insulation of equipment which needs to be usually converted between high temperature and low temperature.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Preparation method for straw hydrogel composite material special for sewage treatment

InactiveCN105618006AImprove adsorptionLow costOther chemical processesWater contaminantsIonHeavy metals

The invention discloses a preparation method for a straw hydrogel composite material special for sewage treatment of metal ion adsorption. A hydrogel comprises the following components in parts by weight: 86 to 92 parts of polyvinyl alcohol, 0.5 to 4.0 parts of bentonite, 1.5 to 8 parts of straw and 1.0 to 2.0 parts of boric acid. Straw cellulosic fibers are adopted and added in the form of micro / nano fibrils; a nano cellulose hydrogel is an intelligent hydrogel, is a porous material, is small in pore diameter, is endowed with high water retaining capacity by the porosity, is a multifunctional adsorption material, has the characteristics of rapidness, high efficiency, high adsorption capacity and high selectivity, and has a remarkable effect on adsorbing heavy metal ions; meanwhile, the preparation process is simple, the cost is low and the operability is high, so that the hydrogel has a good application prospect in the field of sewage treatment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

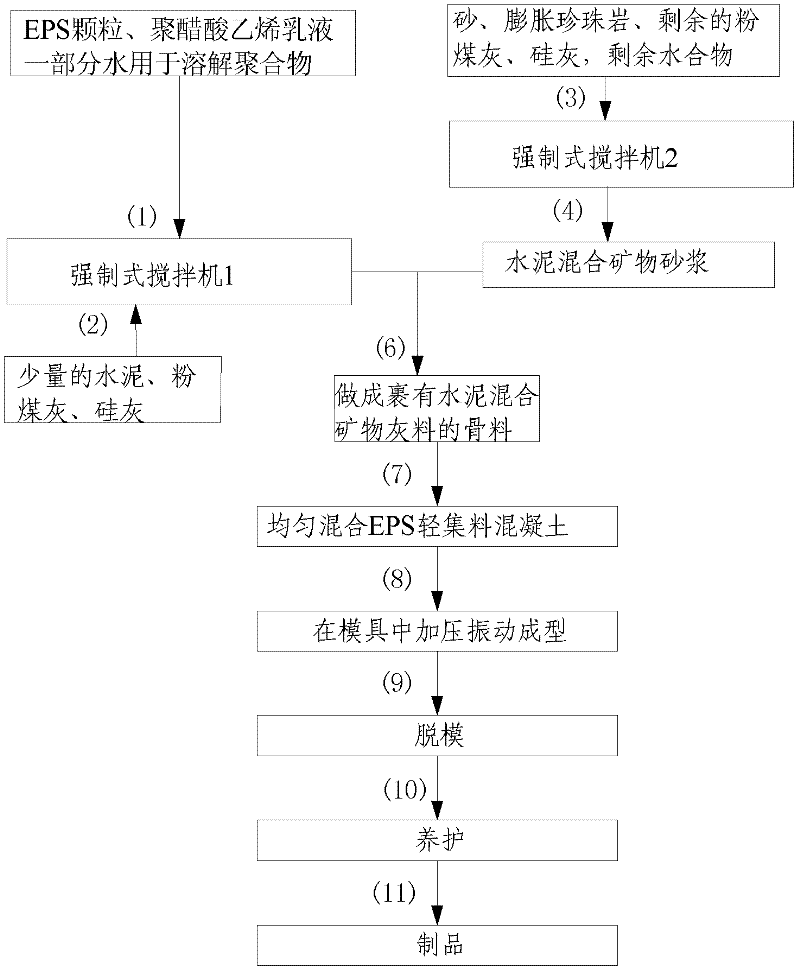

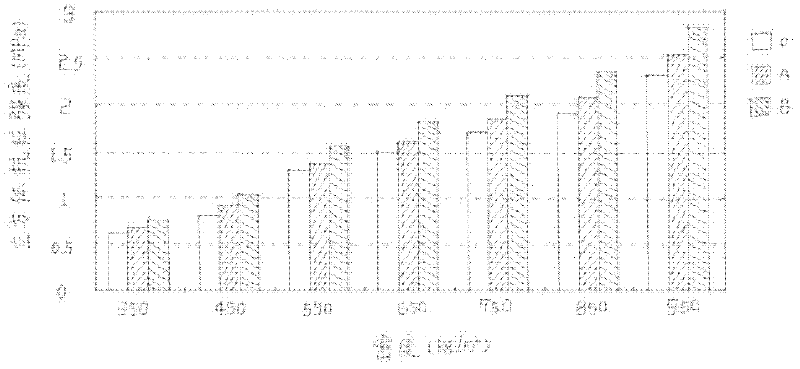

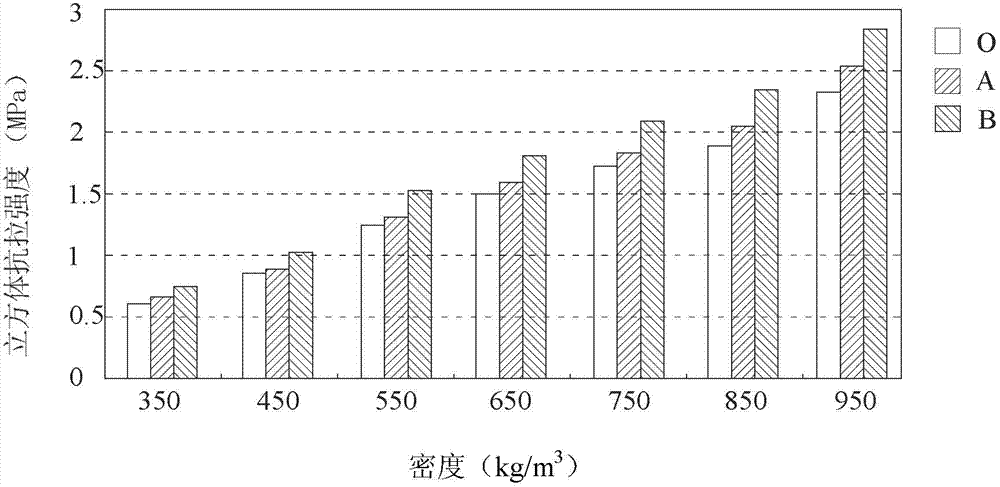

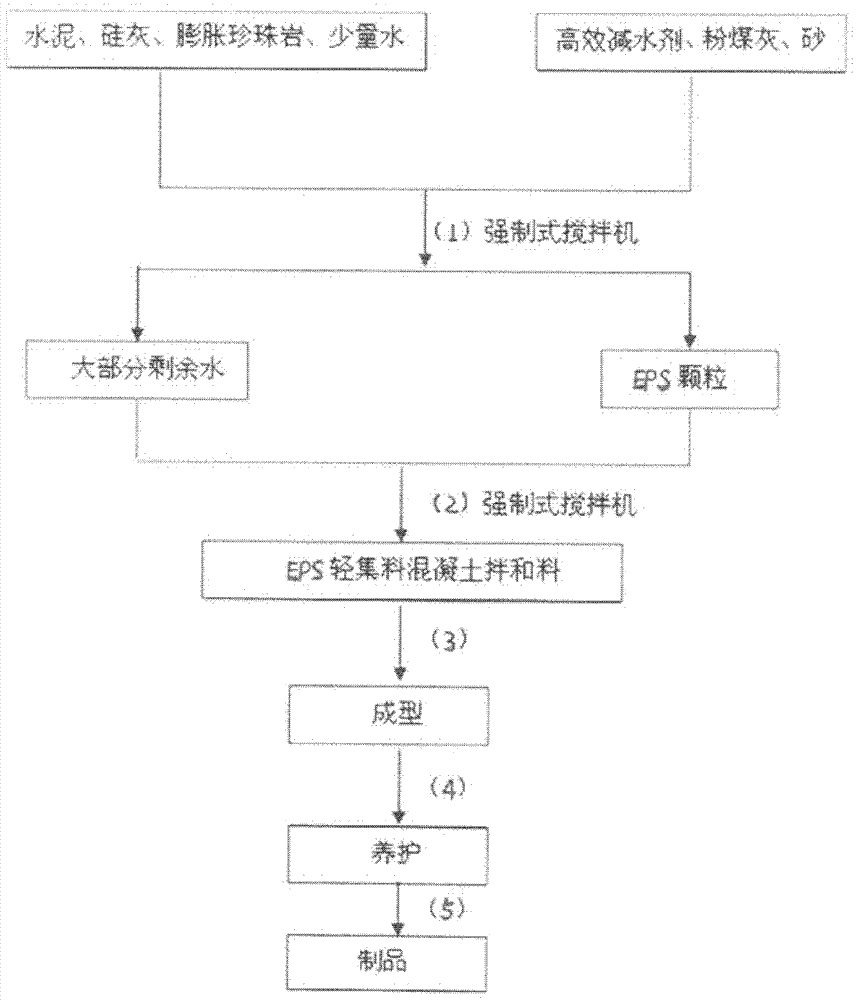

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

Nanometer high-weatherability colorful eco-friendly paint and preparation method thereof

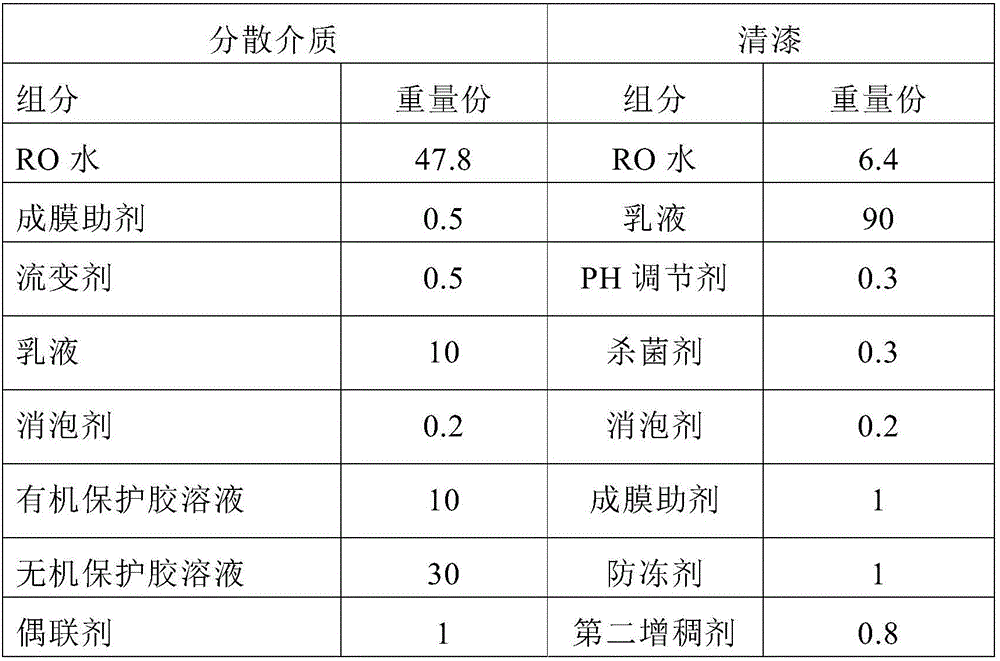

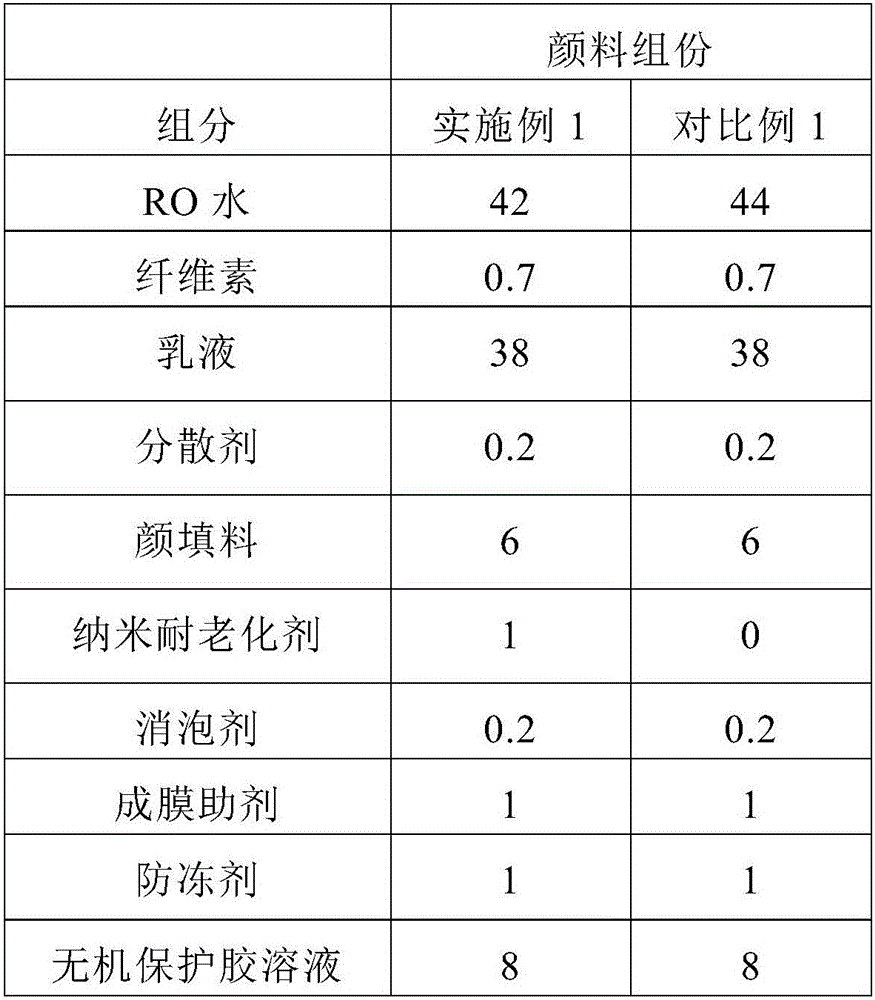

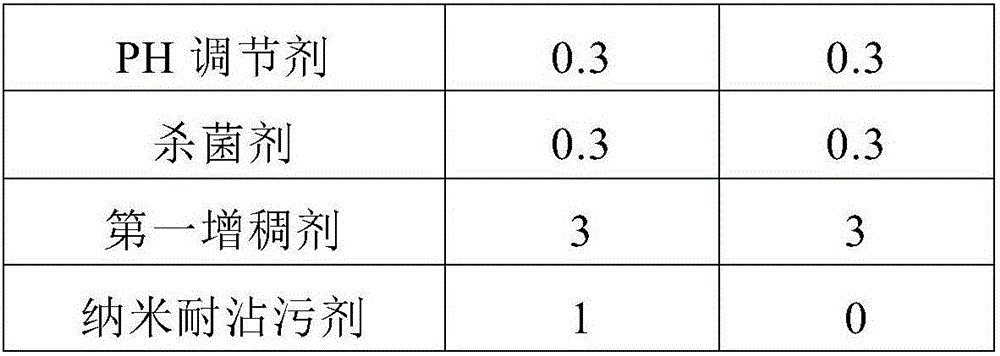

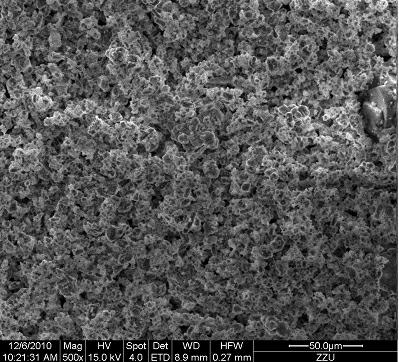

InactiveCN106256859AImprove self-cleaningImprove Nai Staining PerformanceAntifouling/underwater paintsPaints with biocidesCelluloseDispersed media

The invention relates to nanometer high-weatherability colorful eco-friendly paint. The nanometer high-weatherability colorful eco-friendly paint comprises a pigment component, a disperse medium and varnish. The pigment component comprises RO water cellulose, an emulsion, a dispersant, pigment and filling materials, a nanometer anti-aging agent, an antifoaming agent, a nanometer stain-resistant agent, a film forming auxiliary agent, an antifreezing agent, an inorganic protection glue solution, a pH adjustment agent, a bactericide and a first thickening agent. The disperse medium comprises RO water, a film forming auxiliary agent, a rheological agent, an emulsion, an organic protection glue solution, an antifoaming agent, an inorganic protection glue solution and a coupling agent. The varnish comprises RO water, an emulsion, a nanometer anti-aging agent, a pH adjustment agent, a bactericide, an antifoaming agent, a film forming auxiliary agent, an antifreezing agent and 0.3-1 part of a second thickening agent. Compared with the prior art, the preparation method utilizes the nanometer stain-resistant agent to reduce air organic dust adsorption, realize good coating film self-cleanliness and improve paint stain resistance and utilizes the nanometer anti-aging assistant to improve aging resistance of the aqueous colorful paint.

Owner:上海磐彩环保科技股份有限公司

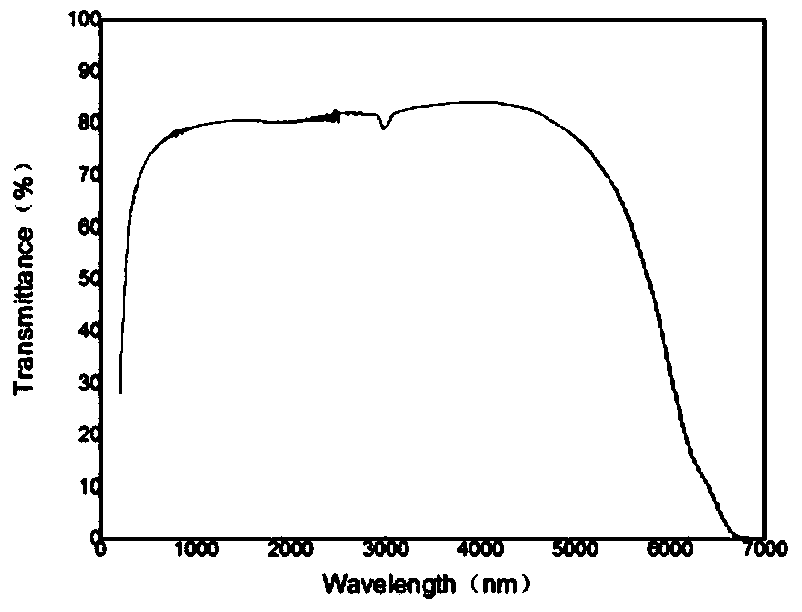

Novel integrated sio2-si3n4 composite material with wave-transmitting and heat-insulating functions and its preparation method

InactiveCN102285799AHigh mechanical strengthGood resistance to rain erosionRadiating element housingsElectricityThermal insulation

The invention belongs to the field of composite materials and particularly relates to a novel wave-transmission and thermal-insulation combined SiO2-Si3N4 composite material. The coefficient of thermal conductivity of the composite material is 0.08 to 0.1W / m.K, the dielectric constant epsilon is between 2.5 and 8, and the dielectric loss tg delta is 3*10<-3>. In the invention, sol-gel and freeze-drying combined technology is used for the first time to prepare porous ceramic, and the prepared Si3N4-based composite material has thermal-insulation and wave-transmission double effects and has a bright application prospect in fields of aerospace, military and national defense.

Owner:ZHENGZHOU UNIV

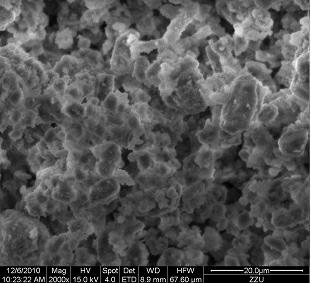

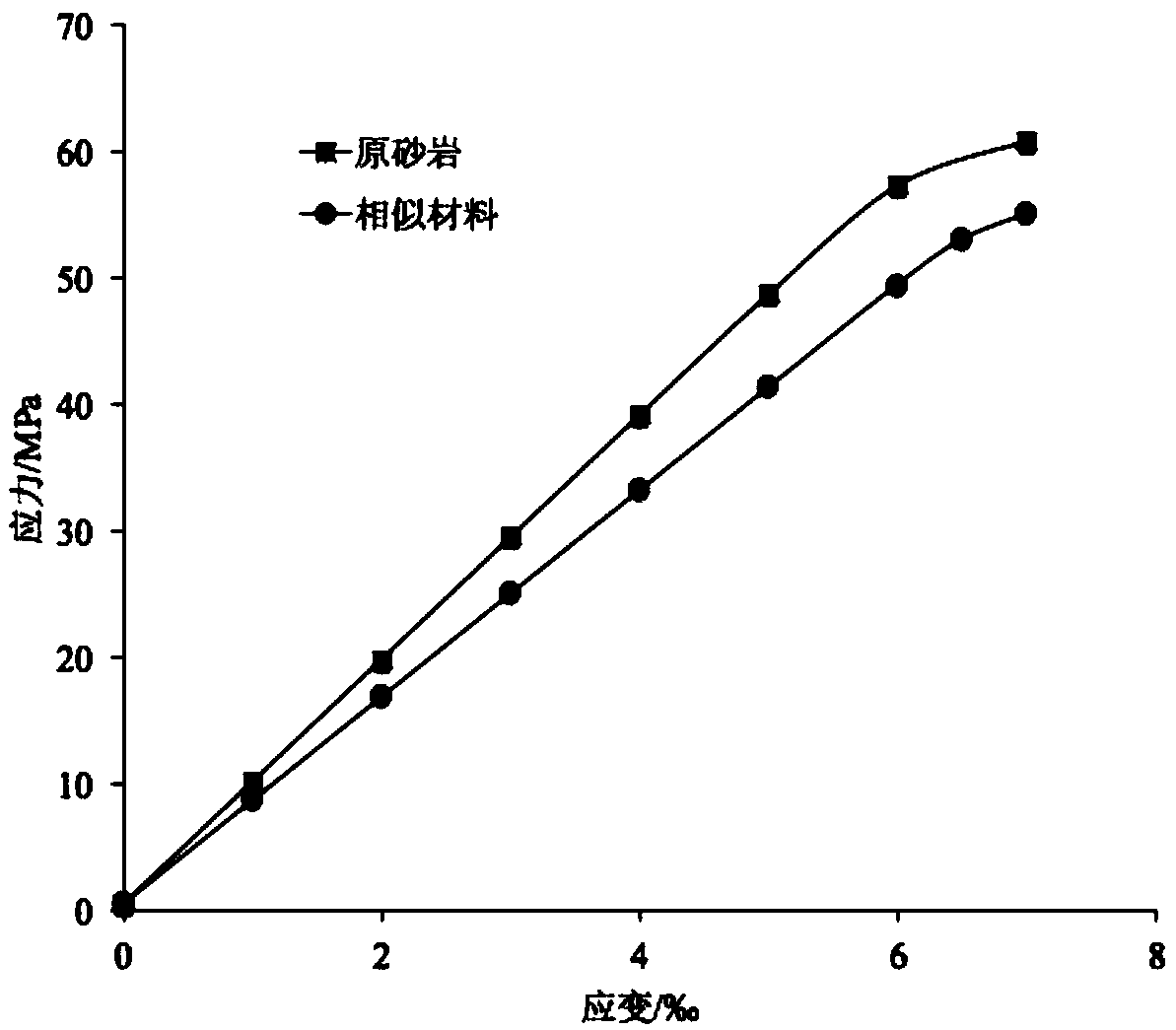

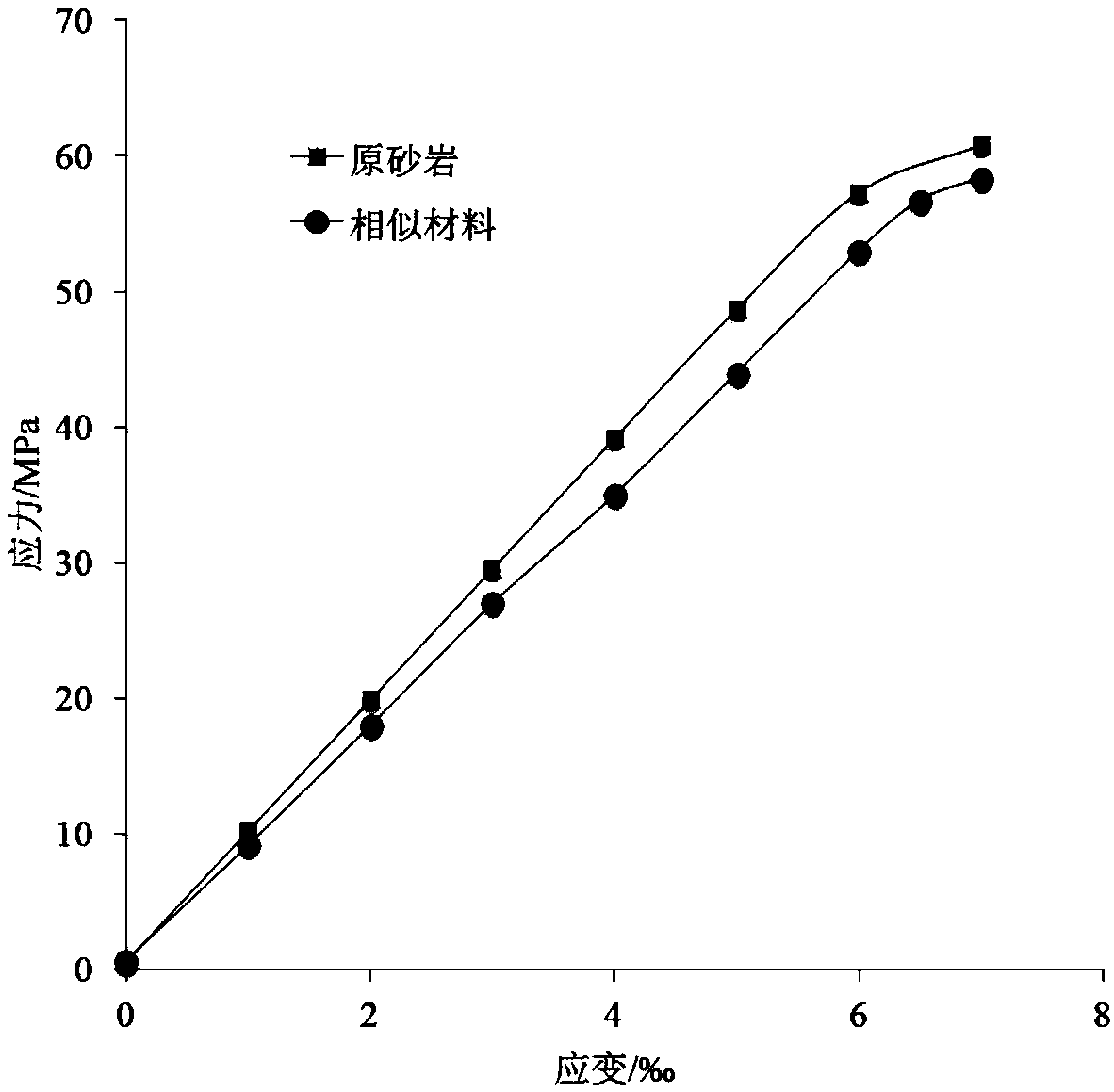

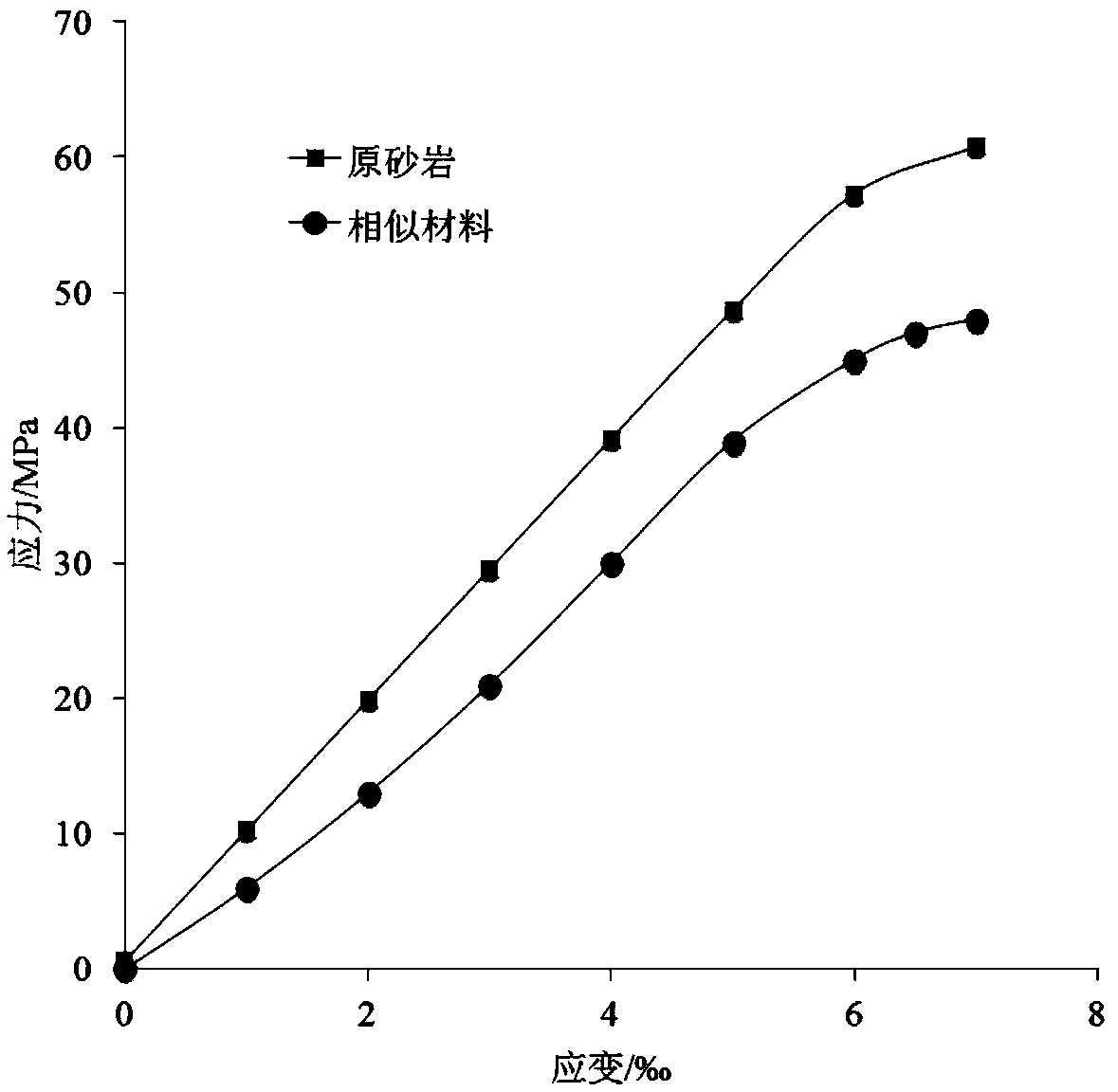

Sandstone similar material and preparation method thereof

InactiveCN109020364AImprove brittlenessHigh strengthSolid waste managementPreparing sample for investigationMechanical propertyWater reducer

The invention provides a sandstone high-strength high-brittleness similar material and a preparation method thereof. Raw materials comprise quartz sand, silicon powder, cement, distilled water and a water reducer. based on physical and mechanical properties and microscopic features of protolith, a method of regulating material properties by using aggregate is adopted, quartz sand is selected to improve brittleness of the material, and silicon powder is selected to raise strength of the material. Thereby, brittleness and strength of the sandstone similar material are achieved, and main physicaland mechanics parameters (density, elastic modulus, cohesion, internal friction angle, uniaxial compressive strength, tensile strength and Poisson's ratio, etc.) of the similar material and protolithmeet the similarity theory. Features of sandstone in rock slope of Xinjiang Tianshan highway are successively simulated. The types of required materials are less, and the cost is low. The manufactureefficiency is high. The material of the invention has wide practicality.

Owner:HUBEI ENG UNIV

Preparation method of transparent magnesia-alumina spinel ceramic

The invention provides a preparation method of transparent magnesia-alumina spinel ceramic MgO.nAl2O3, wherein n is larger than or equal to 1 and smaller than or equal to 2. The method specifically comprises the steps as follows: 1) MgO powder and alpha-Al2O3 are mixed and ball-milled, a solvent is removed, sieving is performed, and magnesia-alumina spinel powder is obtained after a high-temperature solid-phase reaction and sieving; 2) the magnesia-alumina spinel powder is placed in a graphite mold, the graphite mold is placed in spark plasma sintering equipment for forming and pre-sintering,and a pre-sintered body is obtained; 3) the pre-sintered body is placed in a muffle furnace to be sintered again, natural cooling is performed, and a pore-closed sintered body is obtained; 4) the pore-closed sintered body is subjected to hot isostatic pressing sintering treatment, a sintered sample is polished, and the transparent magnesia-alumina spinel ceramic is obtained. By means of the method, the sample composition can be controlled, high compactness can be obtained without addition of a sintering aid, large-scale industrial production can be performed through sintering in non-pressure air, and the production cost can be reduced.

Owner:WUHAN UNIV OF TECH

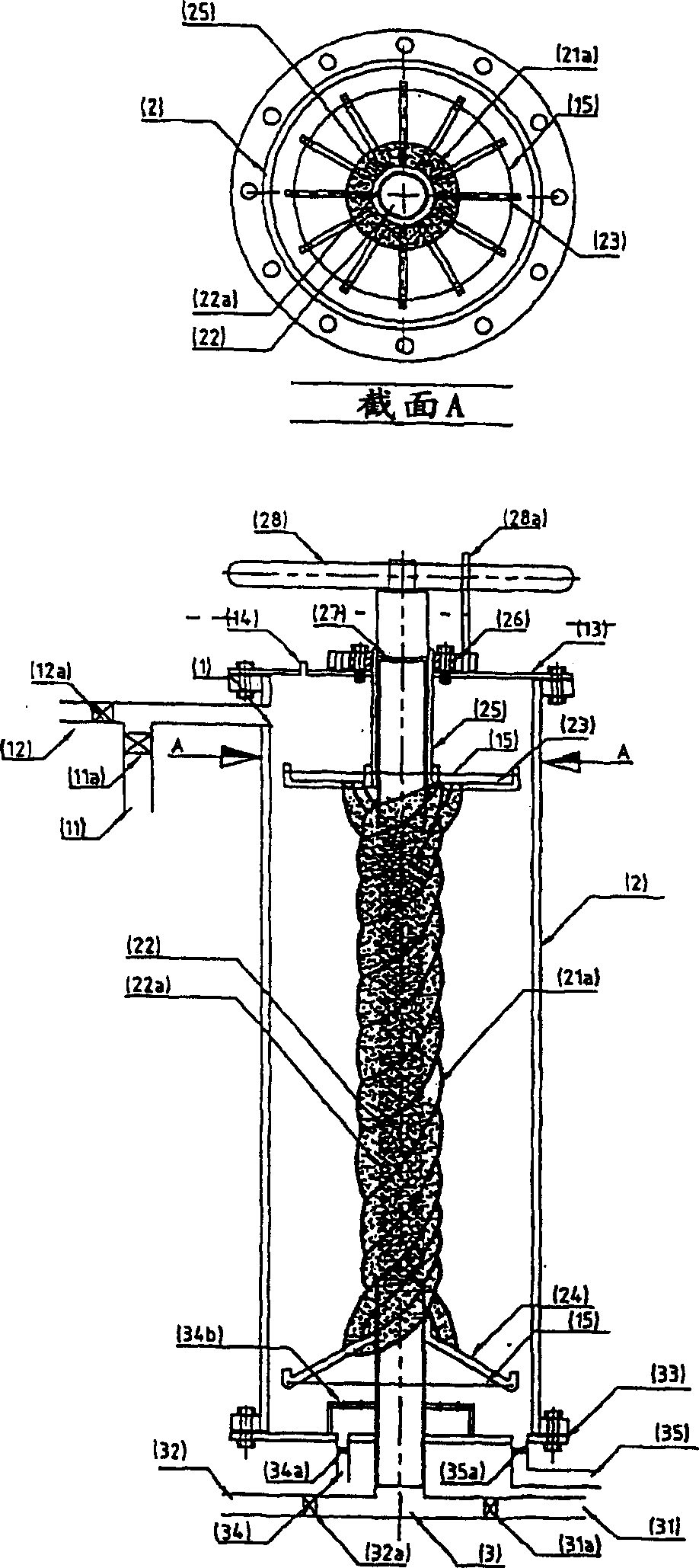

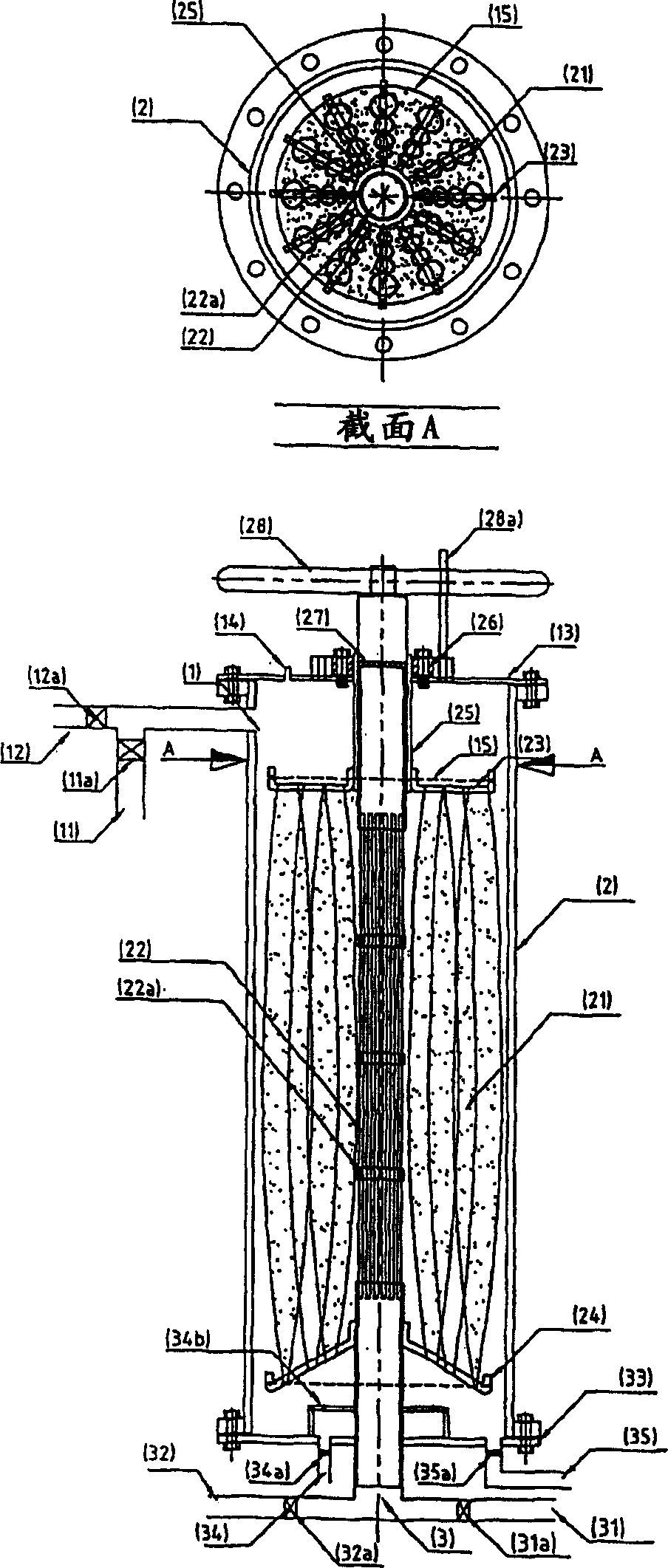

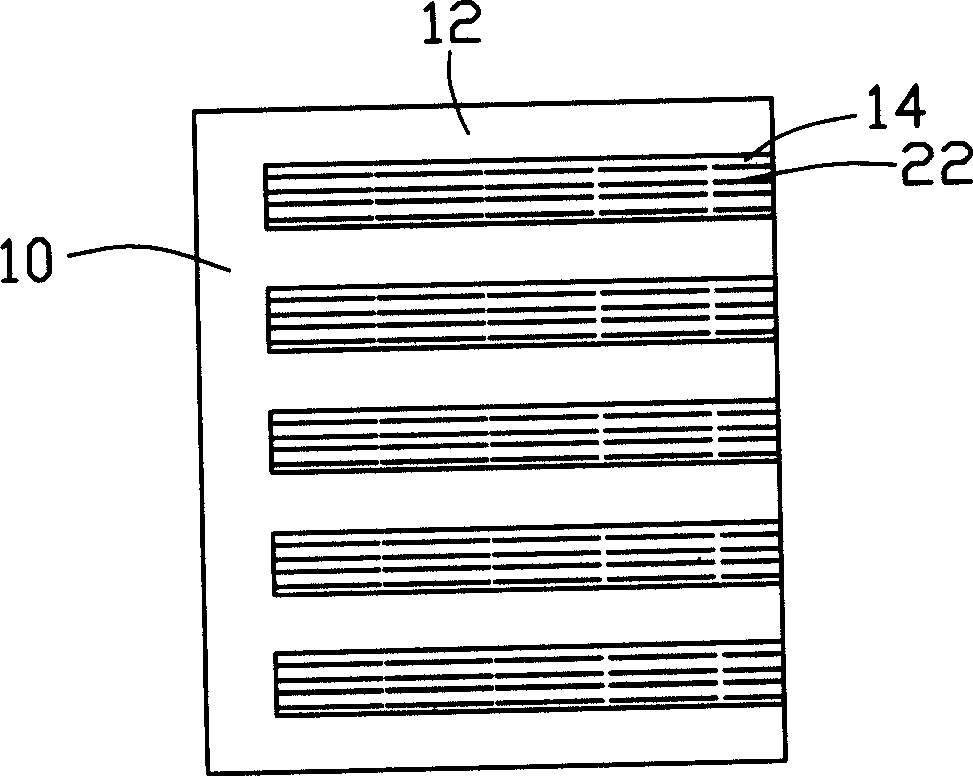

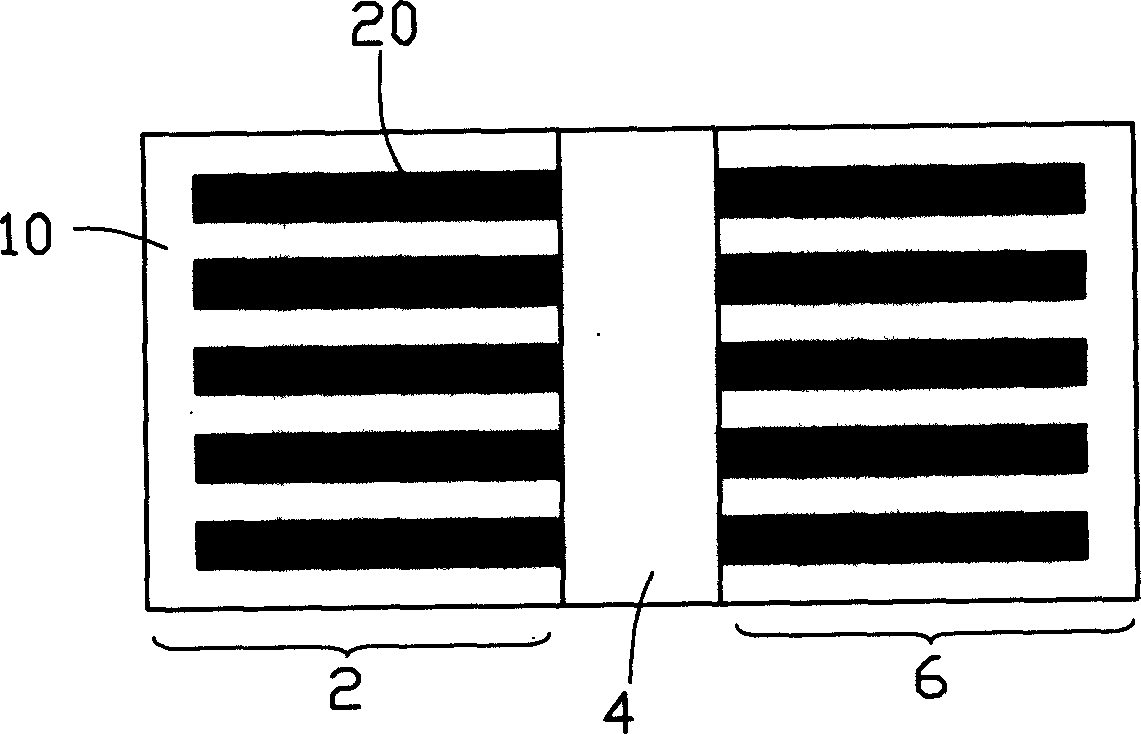

Filtering equipment of air gap control

InactiveCN1463201APromote expansionImprove featuresMembrane filtersStationary filtering element filtersPrimitive stateEngineering

The pore size controllable filter can separate and remove effectively the suspended solid and eliminate rapidly it captured by the device. The filtering materials (21) are built on the upper filtering material holder (23) and the lower filtering material holder (24) of radial type facing each other at a certain distance in the filtering tub (2), forming a filtering layer (21a). According to the direction and the degree of rotation of the upper handle (28) connected to the upper rotation axis, the filtering materials (21) come together to the center along the upper filtering material holder (23) and the lower filtering material holder (24). Then one side or both sides are twisted in opposite directions and concentrated around the perforated pipe (22) located at the central axis or restored to the original state. Accordingly, the size of the pore created between the filtering materials (21) can be adjusted, enabling to conduct filtering and washing operations at a proper level.

Owner:KINSIN ENG

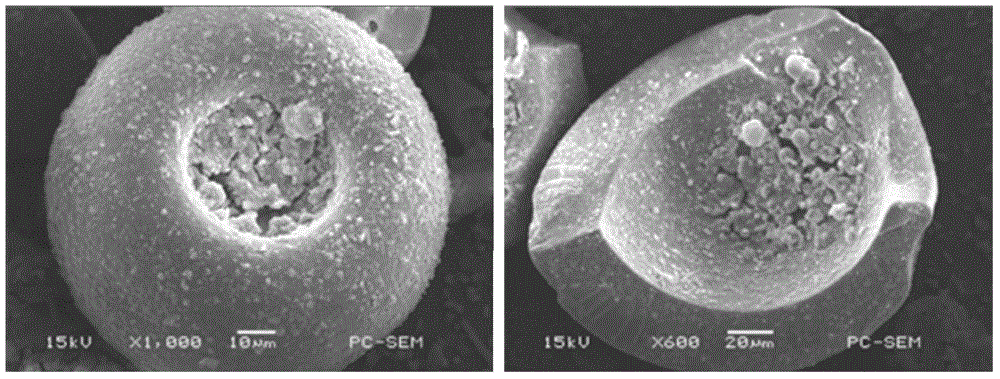

Hollow titanium dioxide microsphere based on gel sphere precursor and preparation method of hollow titanium dioxide microsphere

ActiveCN104310466AReduce usageReduce manufacturing costPhysical/chemical process catalystsTitanium dioxideMicrosphereSpherulite

The invention belongs to the technical field of inorganic functional material preparation, and particularly relates to a TiO2 hollow microsphere synthesizing technology by using gel spherulite as precursor. A hydrolyzing agent complexed tetra-n-butyl titanate is dispersed into a water solution of starch, and is subjected to hydrothermal treatment at 150 DEG C, the starch reacts with tetra-n-butyl titanate to form a gel sphere with a three-dimensional network structure; a hollow structure is formed in the gel sphere in the mineralizing and carbonizing processes due to volume shrinkage, and the carbon ingredient remained in the gel sphere is removed by a thermal treatment; and the substantial part of the hollow TiO2 microsphere is made of a porous material formed by nano-crystalline grains (8-10nm) and nano-scale passages. According to the synthesized TiO2 spheres, the specific surface area is 230m<2> / g, the porous volume is 0.34cm<3> / g, and the average pore diameter is 6.6nm. By adopting the synthesizing process, water is used as a dispersing medium, and starch participates in the reaction to form the gel spheres, and the process is environment-friendly.

Owner:佛山市卓尔特电器有限公司

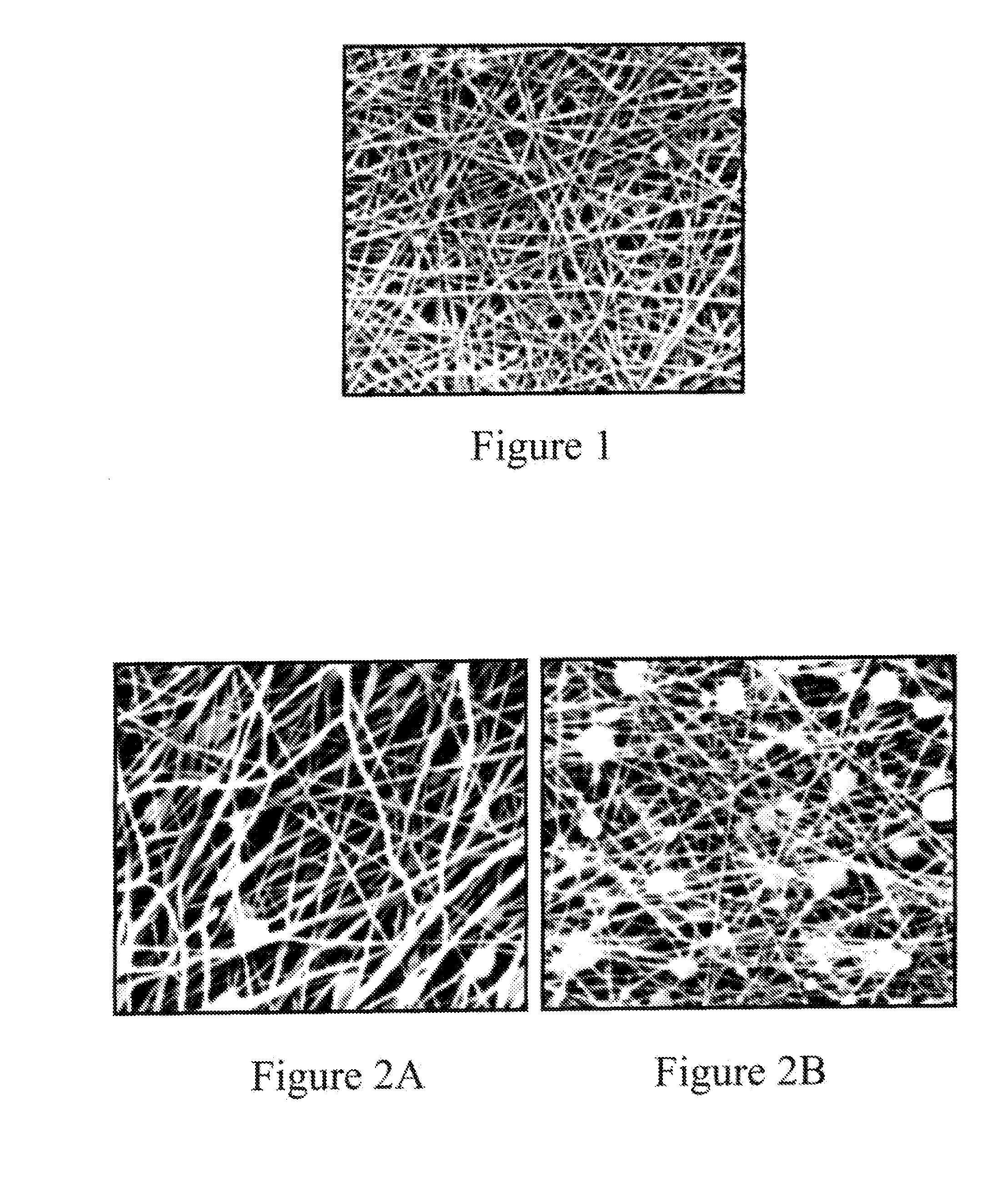

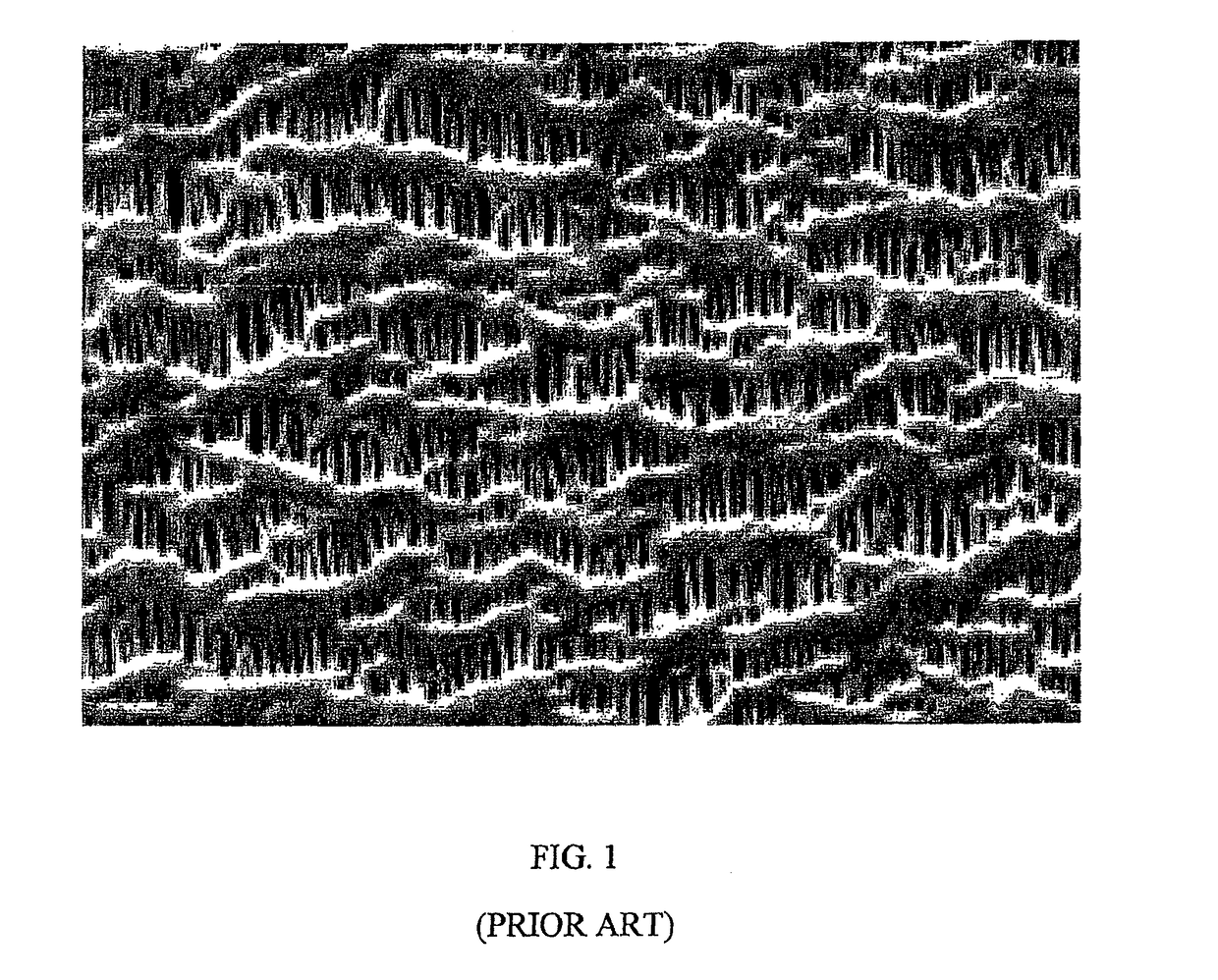

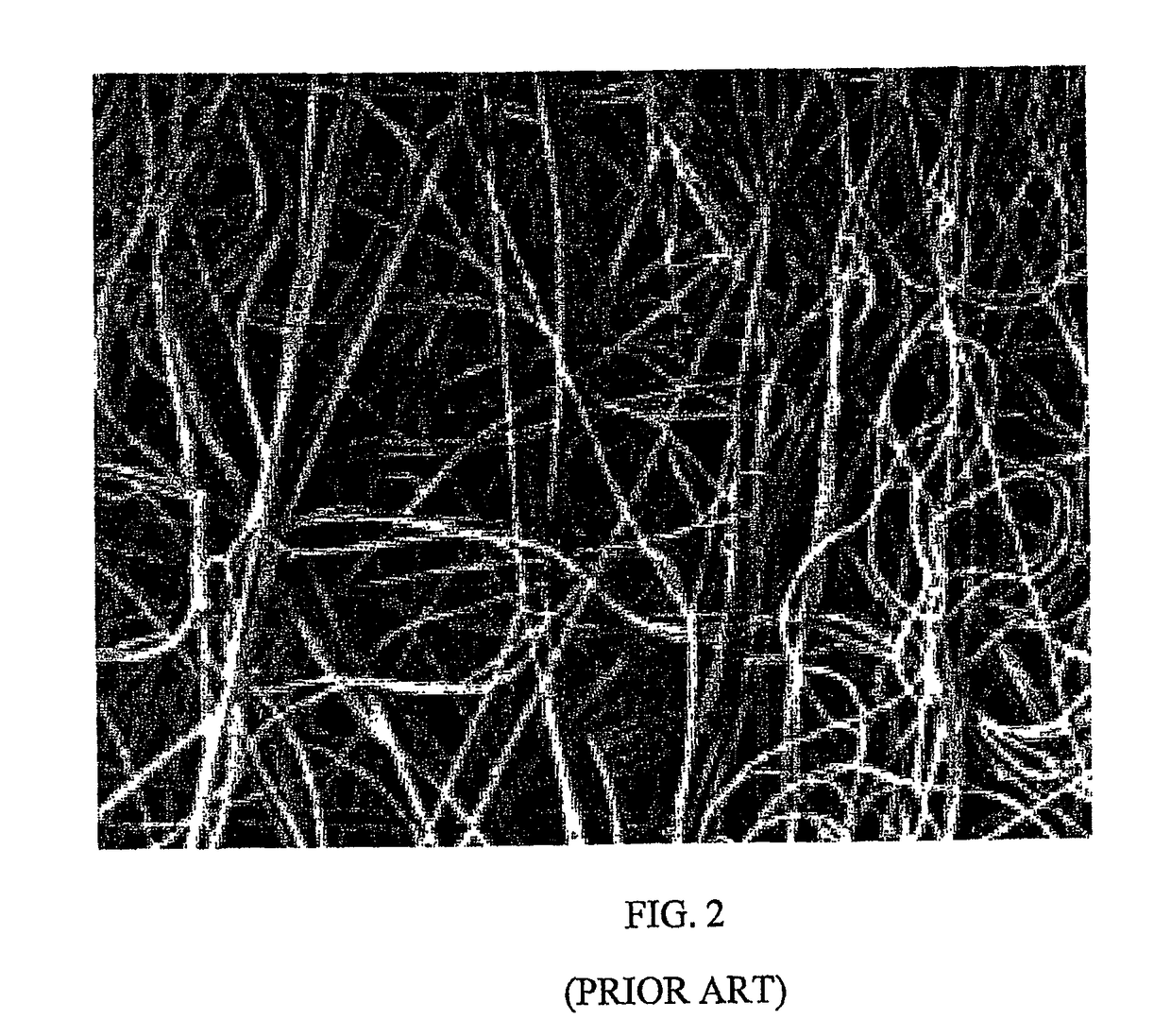

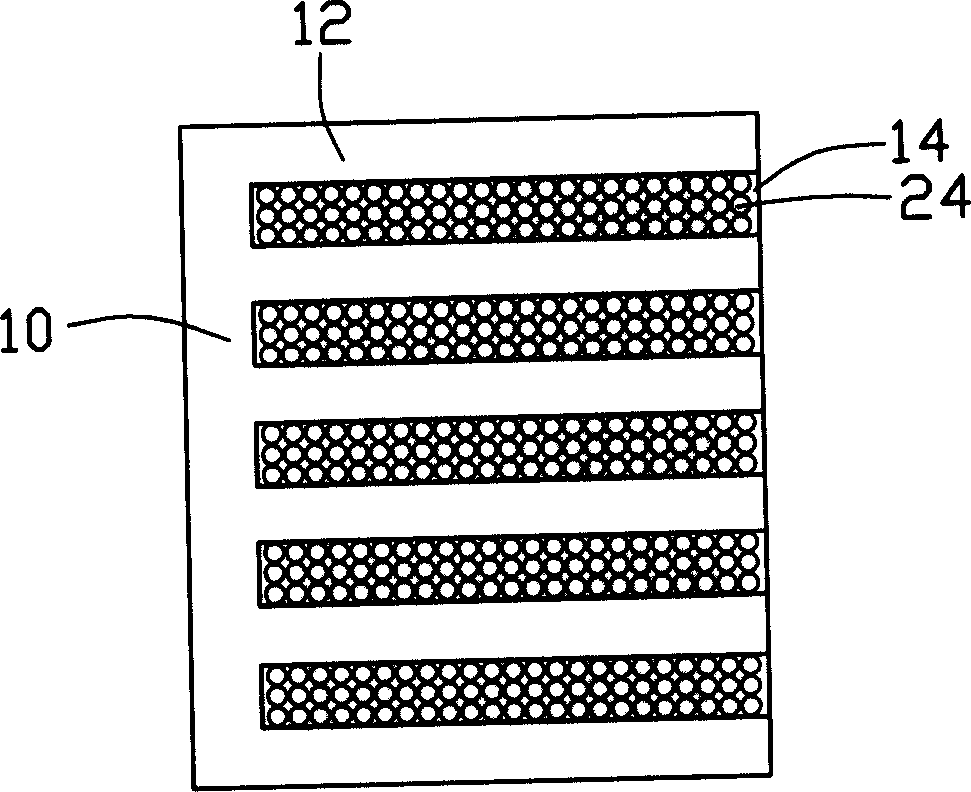

Methods of making single-layer lithium ion battery separators having nanofiber and microfiber constituents

ActiveUS9637861B1Easy to manufactureHigh porosityHybrid capacitor separatorsSemi-permeable membranesPorosityEngineering

An insulating (nonconductive) microporous polymeric battery separator comprised of a single layer of enmeshed microfibers and nanofibers is provided. Such a separator accords the ability to attune the porosity and pore size to any desired level through a single nonwoven fabric. Through a proper selection of materials as well as production processes, the resultant battery separator exhibits isotropic strengths, low shrinkage, high wettability levels, and pore sizes related directly to layer thickness. The overall production method is highly efficient and yields a combination of polymeric nanofibers within a polymeric microfiber matrix and / or onto such a substrate through high shear processing that is cost effective as well. The separator, a battery including such a separator, the method of manufacturing such a separator, and the method of utilizing such a separator within a battery device, are all encompassed within this invention.

Owner:DREAMWEAVER INT

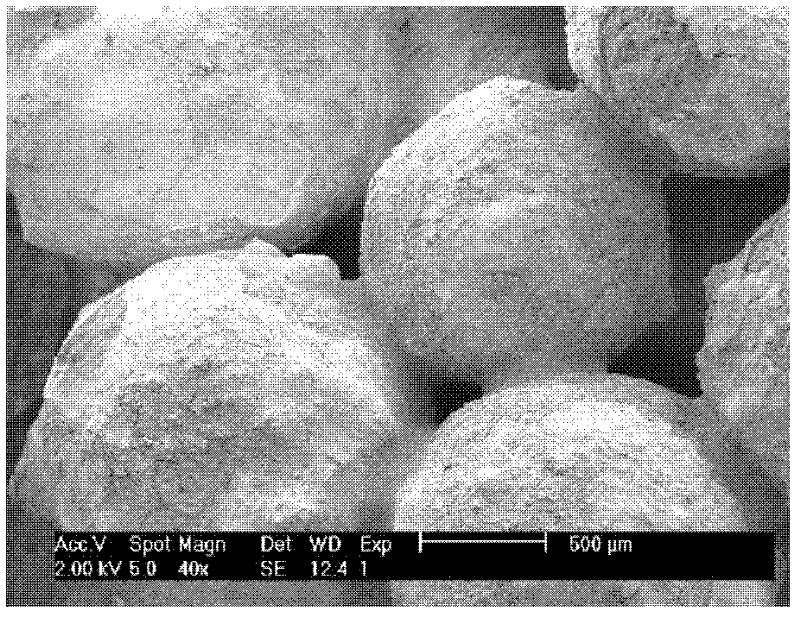

Expanded Polystyrene (EPS) light aggregate concrete and preparation method thereof

InactiveCN102875181AEvenly distributed pore structureImprove interface bondingSolid waste managementCeramic shaping apparatusExpanded polystyreneLarge deformation

The invention provides EPS light aggregate concrete and a preparation method thereof. The EPS light aggregate concrete effectively meets the requirements on a light-weight, uniform and dense structure of the concrete, and has an outstanding integrated performance; the EPS light aggregate concrete has a unit weight of up to 550 kg / m<3> and a cube crushing strength of up to 1.3 MPa which meets the using requirement; in addition, the light aggregate concrete has good thermal performance and durability. In a compression test for the concrete, a large deformation occurs before deformed breakage, and the toughness is improved. The light aggregate concrete comprises 350 parts of cement, 90 to 120 parts of coal ash, 30 to 70 parts of silica fume, 120 to 140 parts of river sand, 190 to 210 parts of water, 15 to 21 parts of EPS particles, 40 to 60 parts of perlite and 2 to 6 parts of water reducer. The light aggregate concrete prepared by the preparation method according to the proportion is uniform and dense in structure, and meets the design requirements on each performance and preparation, so as to have a good application prospect.

Owner:CHINA ELECTRIC POWER RES INST +1

Preparation method for porous carbon nanofiber dye-sensitized solar cell counter electrode material doped with sulfur-copper-indium nanocrystalline

InactiveCN105140037AThin diameterSmall pore sizeLight-sensitive devicesPhotovoltaic energy generationElectrolytic agentPorous carbon

The invention relates to a porous carbon nanofiber dye-sensitized solar cell counter electrode material doped with sulfur-copper-indium nanocrystalline, and a preparation method for the porous carbon nanofiber dye-sensitized solar cell counter electrode material doped with sulfur-copper-indium nanocrystalline. Through the electrostatic spinning of a blended solution of polyacrylonitrile and a sulfur-copper-indium precursor and the different volatilization speeds of a solution, the method obtains porous nanofibers, and the porous carbon nanofiber dye-sensitized solar cell counter electrode material doped with sulfur-copper-indium nanocrystalline is obtained through high-temperature carbonization. The material prepared through the method is extremely large in specific area, and facilitates the penetration of electrolyte and transmission of electrons. The sulfur-copper-indium nanocrystalline on the fibers provides more catalytic activity points for the redox reaction of an electrolysis pair. The material is simple in manufacturing technology, is low in cost, is environment-friendly, can serve as an effective counter electrode material for a dye-sensitized solar cell, and is good in application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

SiC nano-wire reinforced porous ceramic composite material and preparation method thereof

ActiveCN109020628ALarge specific surface areaImprove performanceCeramicwareMetallurgyInterface layer

The invention discloses a SiC nano-wire reinforced porous ceramic composite material and a preparation method thereof. The material has a bulk density of 0.5-1.8 g / cm<3> and a through-hole ratio of 50-80%, and is composed of porous ceramic, SiC nano-wires, an interface layer and a SiC matrix, the SiC nano-wires in situ grow in the porous ceramic, the surfaces of the SiC nano-wires and the porous ceramic are coated with the interface layer, and gaps of the porous ceramic and the SiC nano-wires are filled with the SiC matrix. The SiC nano-wires are used to reinforce a porous ceramic composite material, so the internal specific surface area of the porous ceramic is effectively improved, and the porous ceramic is structurally toughened and reinforced; and in-situ filling with the SiC matrix significantly improves the filtration performance and the high-temperature heat insulation performance of the porous ceramic composite material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Efficient thermal insulation cellucotton felt and production method thereof

ActiveCN104534224AHigh porosityLow thermal conductivityThermal insulationPipe protection by thermal insulationPorosityFiber

The invention discloses an efficient thermal insulation cellucotton felt and a production method thereof. According to the efficient thermal insulation cellucotton felt, the porosity is larger than 93%, the thickness is 5mm-20mm, the fiber monofilament diameter is smaller than or equal to 3mum, and closed vacuum balls that are smaller than 20nm in diameter are uniformly distributed on fiber monofilaments. According to the efficient thermal insulation cellucotton felt and the production method thereof, the porosity of the cellucotton felt is greatly improved, the thermal conductivity of the cellucotton felt is lowered, any binding agent is not added in the felt, the felt has the advantages that the felt is free of toxicity, resistant to high temperature, flexible in texture, small in volume density and reusable between high temperature and low temperature and the thermal insulating property is not remarkably reduced though the felt is used at the high temperature, the maximum using temperature can reach 1000 DEG C, and the felt can be widely applied to fire prevention and thermal insulation of high temperature devices and especially applied to heat preservation and thermal insulation of devices that are usually required to be switched between high and low temperatures.

Owner:南玻院(宿迁)新材料有限公司

Improved zirconium oxide fiber plate and preparation method thereof

The invention discloses an improved zirconium oxide fiber plate, which is characterized in that on the basis of the existing fiber plate preparation process, through the addition of inorganic bondingagents and infrared light-screening agents, the zirconium oxide fiber plate with high pressure-resistant intensity and low high-temperature heat conduction rate can be prepared, wherein the inorganicbonding agent is mainly basic silicon sol; the infrared light-screening agent is mainly rutile type titanium dioxide or potassium hexatitanate whiskers. The density of the prepared zirconium oxide fiber plate is 0.6 to 0.8 g / cm<3>; the room temperature pressure-resistant intensity is 3.0 to 5.0 MPa; when the thickness of the sample is 1 cm, in the stable state, the hot surface temperature is 1000DEG C; the cold surface temperature is 270 to 300 DEG C; the hot surface temperature is 1200 DEG C; the cold surface temperature is 310 to 330 DEG C.

Owner:南京理工宇龙新材料科技股份有限公司

Porous electrode and lithium secondary cell having same

InactiveCN1581545ANot easy to break awayPromote migrationFinal product manufactureElectrode carriers/collectorsLithiumElectric capacity

Porous electrode includes current collection body and an electrode active material. The current collection body includes a base and multiple holes inside the base. One end of hole is open end and the other end is closed. Electrode active material is filled into multiple holes, which makes surface area of electrode increase so as to raise electric capacity of battery and performance current collection. Electrode active material ordered arrangement in holes is in favor of migration of lithium ion. In the invention, holes are in small size. Thus, filled electrode active material is not easy to escape from current collection body. The invention also discloses lithium secondary battery possessing porous electrode.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Porous forsterite and akermanite composite ceramic material and preparation method thereof

InactiveCN104140246AAvoid secondary pollutionConducive to environmental protectionÅkermaniteComposite ceramic

The invention relates to a porous forsterite and akermanite composite ceramic material and a preparation method of the porous forsterite and akermanite composite ceramic material. According to the technical scheme, 60-70 wt% of dolomite powder, 25-28 wt% of silica powder and 5-15 wt% of magnesite powder serve as raw materials and are mixed, pulp liquid waste 5-8 wt% of the raw materials is added, and the mixture is stirred to be even and is mechanically pressed and formed; then a formed green body is aired for 16-24 hours under the condition of 110 DEG C, the temperature is kept for 3-8 hours under the condition of 1300-1450 DEG C, and then the porous forsterite and akermanite composite ceramic material is obtained. The particle sizes of the dolomite powder, the silica powder and the magnesite powder are smaller than 88 micrometers, and the pressure of mechanical pressing and forming is 30-100 MPa. The porous forsterite and akermanite composite ceramic material has the advantages of being environmentally friendly, being composed of dual phases, and being controllable in phase composition, pore size and size. The prepared porous forsterite and akermanite composite ceramic material is high in apparent porosity, high in intensity and good in high temperature performance, and can be used in the working environment lower than 1400 DEG C as a heat preservation material.

Owner:WUHAN UNIV OF SCI & TECH

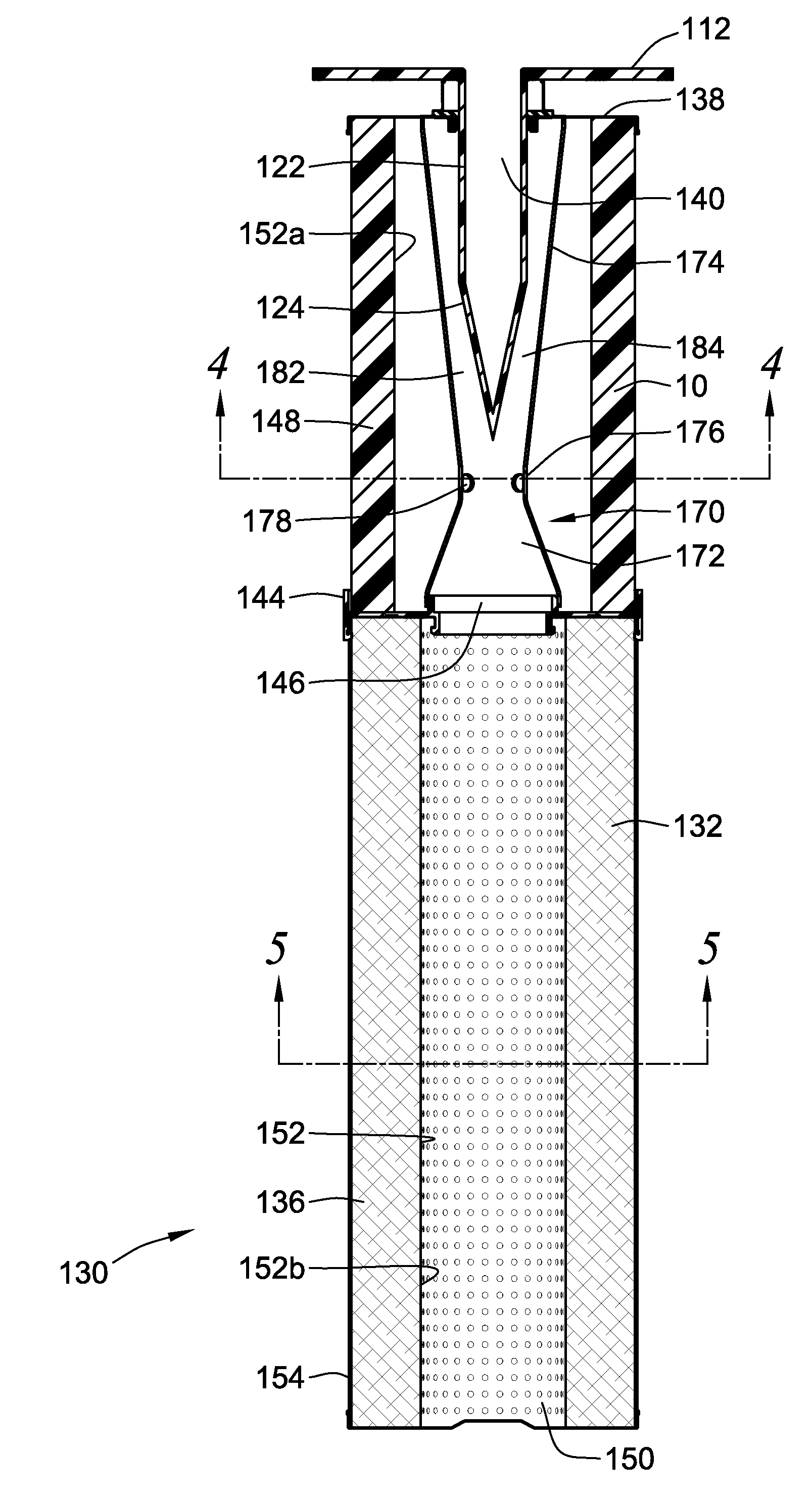

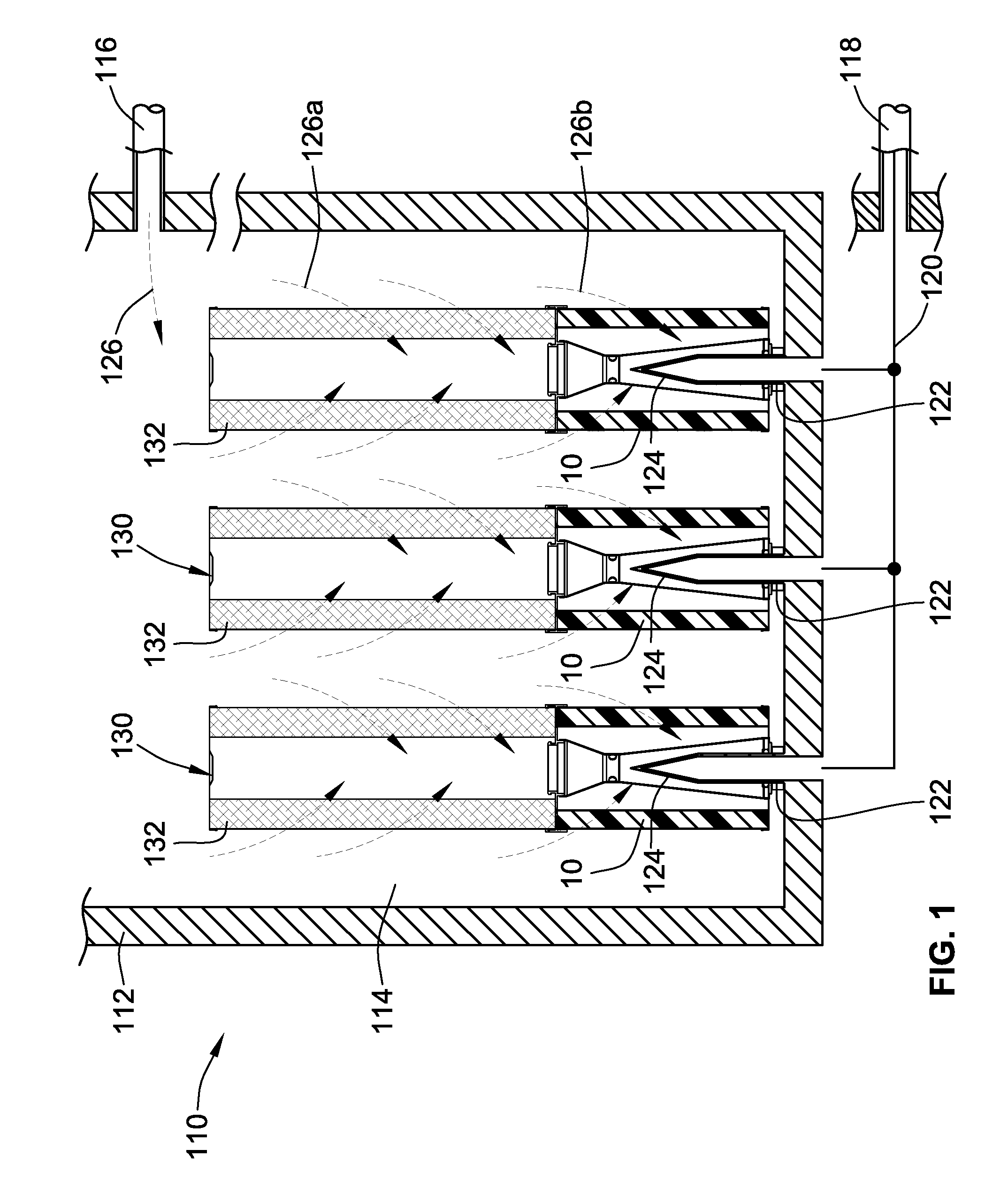

Particulate and Bypass Filter and Locomotive Oil Lube Filtration System

InactiveUS20120241366A1Small pore sizeLess restrictionMembrane filtersLoose filtering material filtersLubricationEngineering

A bypass filter cartridge is provided having a low efficiency filter element and a high efficiency filter element oriented in either parallel or series. The low efficiency filter element may comprise pleated filter sheet while the high efficiency filter element may include a tubular ring of depth media with considerable thickness or pleated media of varying types. The filter cartridge may be adapted and configured for use in specialized locomotive oil lubrication circuits with substantial benefit therein.

Owner:CLARK FILTER

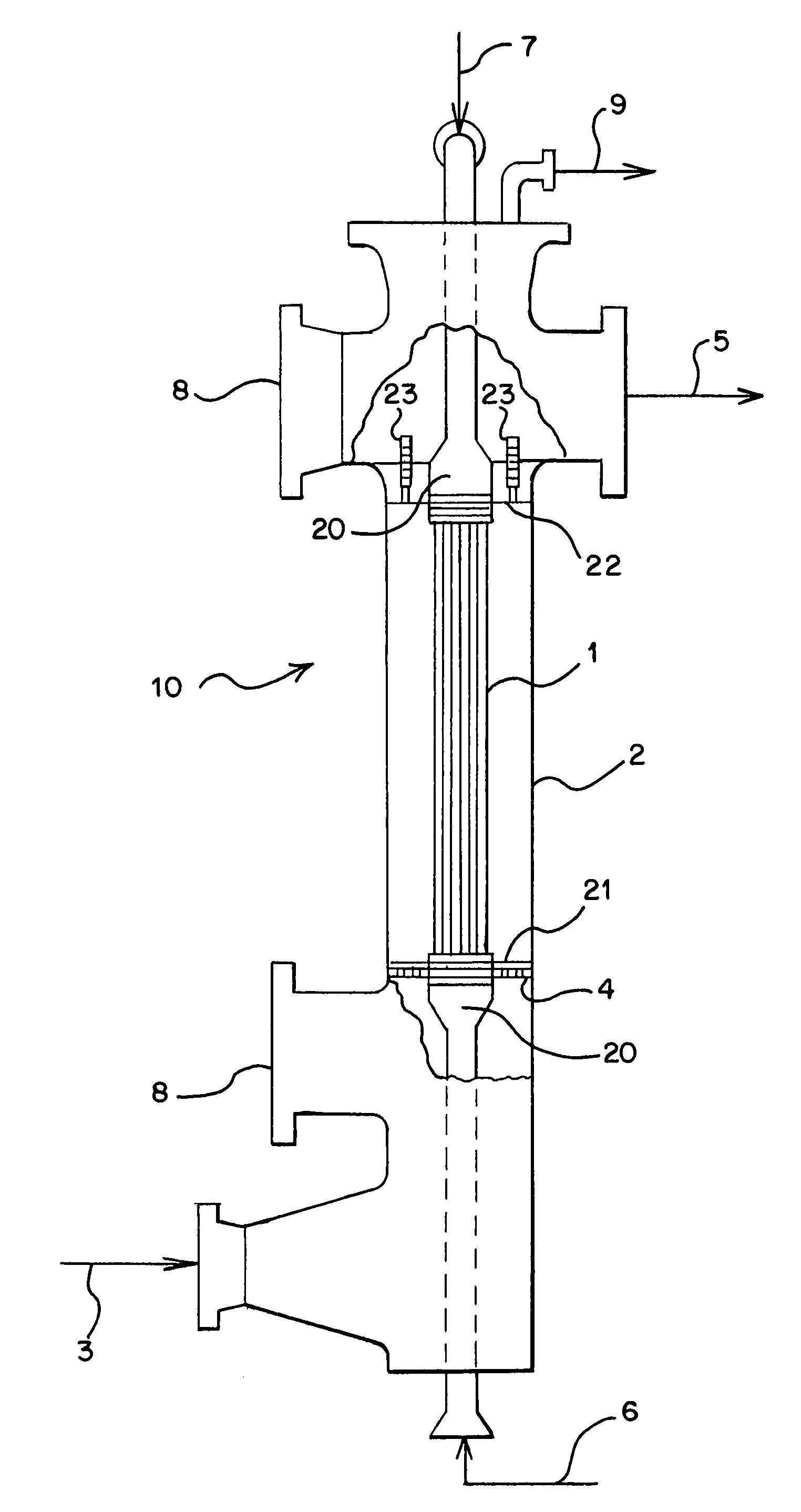

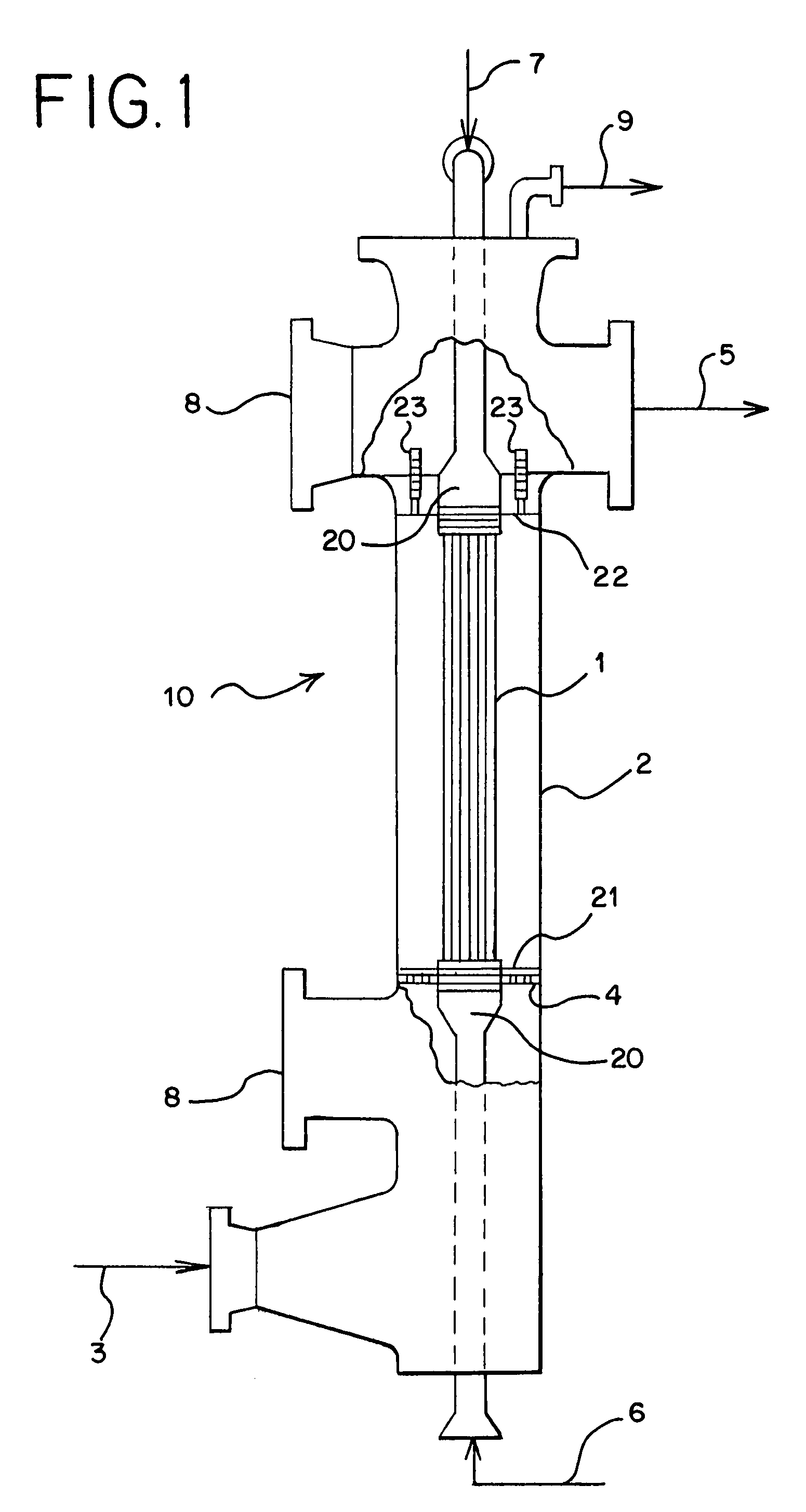

Oxidizer and oxidation process for a desulphurization process

ActiveUS7279148B1Small apertureReduce tensionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationOxygenOxidizing agent

An improved oxidizer for liquid reduction-oxidation desulphurization processes uses a hollow fiber membrane contactor. A pressurized, oxygen containing gas stream is introduced into the interior of the hollow fiber membrane while a liquid reduction-oxidation catalyst solution contacts the exterior of the membrane. Oxygen diffuses through the membrane into the liquid reduction-oxidation catalyst solution whereby the solution is oxidized and can be recycled for further use in a desulphurization process.

Owner:MERICHEM CO

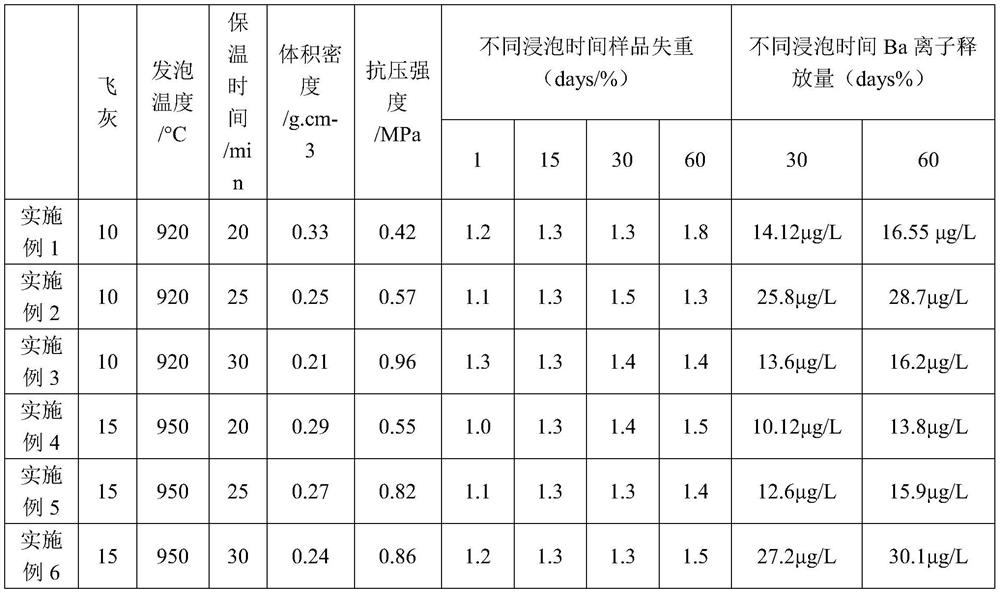

Foam glass prepared from fly ash as well as preparation method and application thereof

PendingCN112279498AEfficient decompositionAvoid harmGlass shaping apparatusFoaming agentPolluted environment

The invention discloses foam glass prepared from fly ash as well as a preparation method and application of the foam glass, and belongs to the technical field of foam glass preparation. Fly ash and glass powder are adopted as raw materials and mixed with a foaming agent, then a PVB alcoholic solution is added for granulation, and after molding, high-temperature foaming is conducted through two times of heating, so that the foam glass is obtained. Through two times of heating and heat preservation, part of dioxin can be effectively decomposed, and meanwhile, the formation amount of a high-temperature melt phase is promoted so as to effectively coat residual dioxin, high chlorine, high calcium and heavy metal components. According to the method, the high-temperature melt effectively coats the high chlorine, high calcium, heavy metal components and residual dioxin, the heavy metal elements are left to stand in water for a long time, leakage of the high calcium and high chlorine componentsis little, and harm of the components to the environment is avoided. The method is simple in process and suitable for large-scale production, the fly ash is adopted as the raw material, and the problem of environmental pollution is solved while the low-cost raw material is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

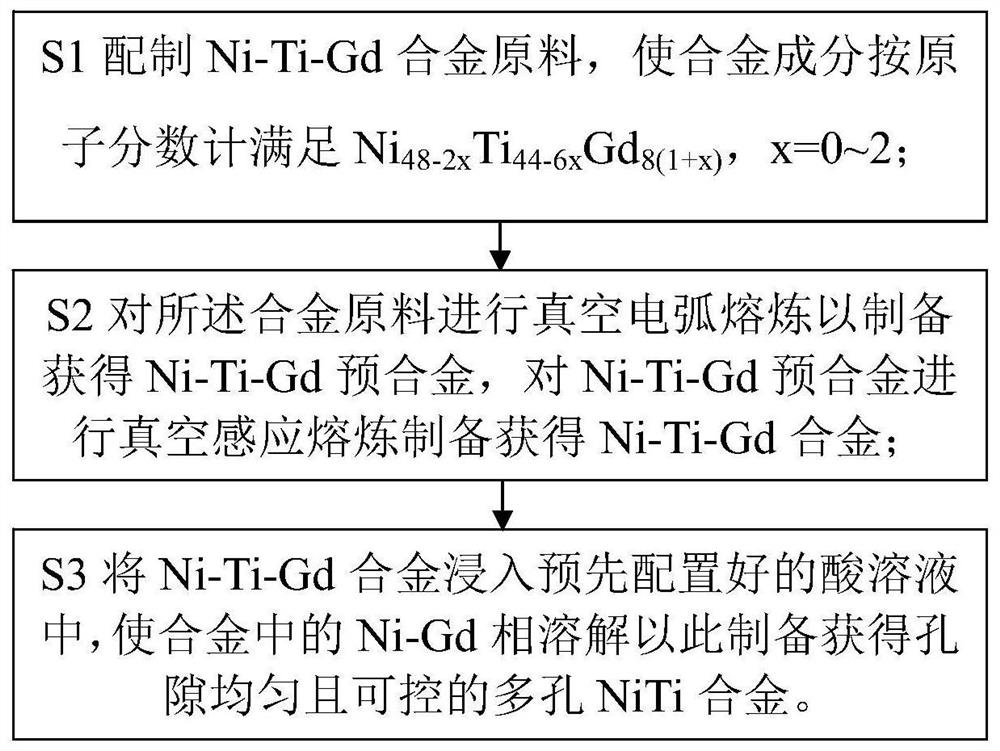

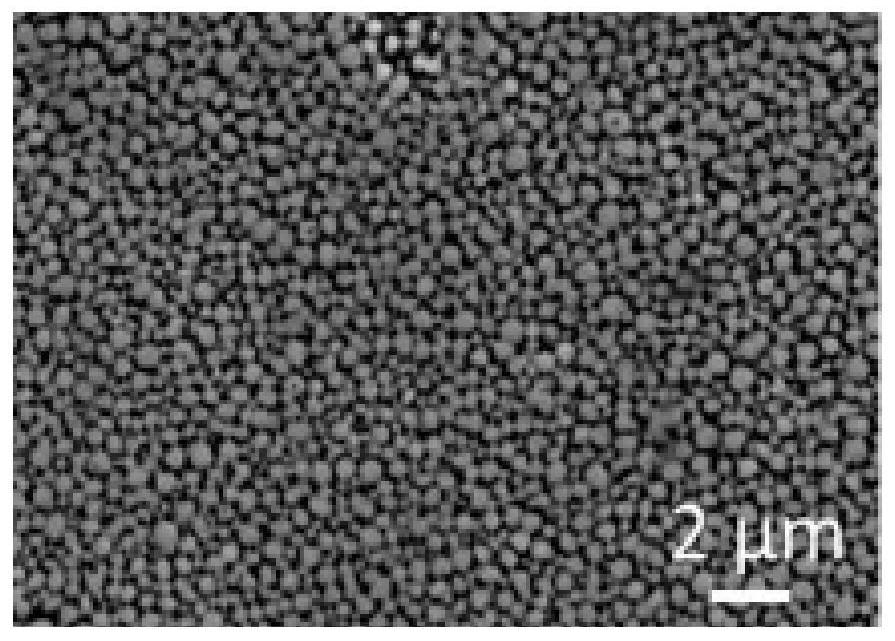

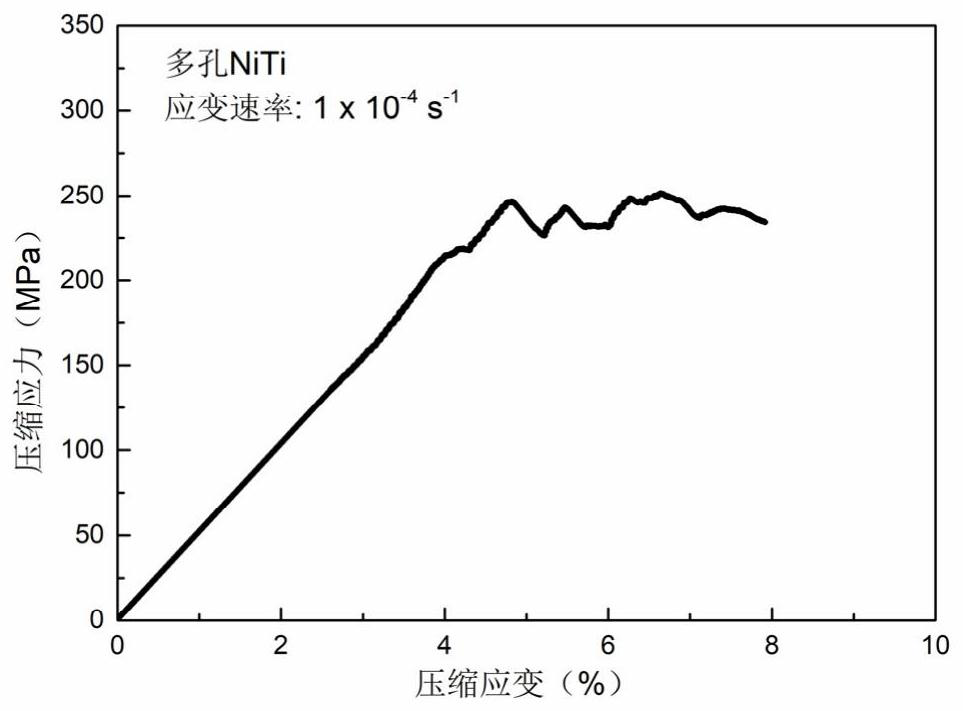

Preparation method for porous NiTi alloy based on selective dissolution and product

The invention belongs to the field of porous alloy preparation, and particularly discloses a preparation method for a porous NiTi alloy based on selective dissolution and a product. The preparation method comprises the following steps: adding a Gd element into a Ni-Ti binary alloy, based on the characteristic that the Gd element can react with the Ni element but not react with the Ti element, onlyNi-Ti and Ni-Gd phases are generated in the alloy, and then removing the Ni-Gd phases based on selective corrosion by using an acid solution to obtain the porous NiTi alloy with uniform and controllable pores. The method can be used for preparing the porous NiTi alloy with small pore size and uniform distribution, and has the advantages of simple and convenient operation process and lower cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com