Novel integrated sio2-si3n4 composite material with wave-transmitting and heat-insulating functions and its preparation method

A sio2-si3n4, composite material technology, applied in the direction of the radiation unit cover, can solve the problems of narrow application fields, and achieve the effects of good sand erosion performance, heat insulation effect, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

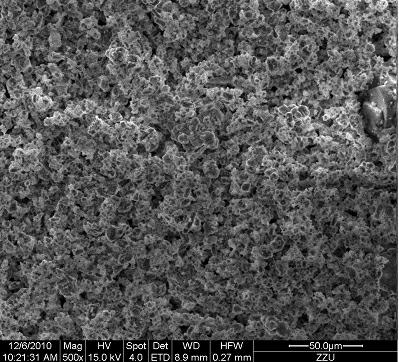

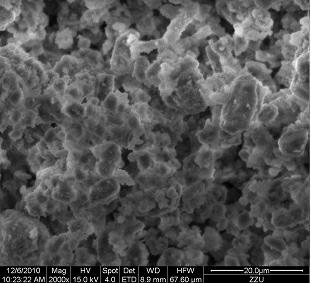

Image

Examples

Embodiment 1

[0020] Mix 23ml of tetraethyl orthosilicate, 35ml of ethanol, and 3ml of water in a 200ml beaker, and stir vigorously on a magnetic stirrer, and then follow the formula of silicon nitride: magnesium oxide: aluminum oxide (weight ratio, the same below) = 33 :2:5 Add 1.7gMgO, 4.3gAl in turn 2 o 3 , 28.6gSi 3 N 4 , stir until uniform; adjust the pH value to 9, put it in a constant temperature water bath with an initial temperature of 30°C, and then heat up and dry the gel after freezing at -40°C for 2 hours, from -20°C to 80°C Dry for 60 minutes, dry at 80°C for 9 hours; after drying, sinter under normal pressure, rise from 0°C to 300°C for 3 hours, and then rise from 300°C to 1200°C for 3 hours, keep warm for 1 hour, and cool in the furnace to get the block SiO 2 -Si 3 N 4 base composite material.

[0021] The thermal conductivity of the composite material is 0.08W / m·K, the dielectric constant ε=3, and the dielectric loss tgδ=2.5×10 -3 . The density is 0.5g / cm 3 .

[...

Embodiment 2

[0024] Mix 23ml of tetraethyl orthosilicate, 35ml of ethanol, and 3ml of water in a 200ml beaker, and stir vigorously on a magnetic stirrer, and then add 1.96 g MgO, 4.91 g Al 2 o 3 , 39.31g Si 3 N 4 , stir until uniform; adjust the pH value to 9, put it into a test tube and place it in a constant temperature water bath with an initial temperature of 30°C, and then heat and dry the obtained gel after freezing at -40°C for 2 hours, from -20°C to 80°C ℃ drying for 60 minutes, 80 ℃ constant temperature drying for 9 hours; after drying, sintering under normal pressure, 3 hours from 0 ℃ to 300 ℃, and then 3 hours from 300 ℃ to 1200 ℃, heat preservation for 1 hour and then cool in the furnace to get this product Invented bulk SiO 2 -Si 3 N 4 base composite material.

[0025] The thermal conductivity of the composite material is 0.09W / m·K, the dielectric constant ε=4, and the dielectric loss tgδ=2.2×10 -3 . The density is 0.7g / cm 3 , the porosity is about 70%.

Embodiment 3

[0027]Mix 23ml of tetraethyl orthosilicate, 35ml of ethanol, and 3ml of water in a 200ml beaker, and stir vigorously on a magnetic stirrer, and then add 2.42 gMgO, 6.06gAl 2 o 3 , 60.56Si 3 N 4 , stir until uniform; adjust the PH value to 9 and put it into a test tube in a constant temperature water bath with an initial temperature of 30°C. The resulting gel is frozen at -40°C for 2 hours and then dried for 10 hours: from -20°C to 80°C Dry for 60 minutes, dry at a constant temperature of 80°C for 9 hours; after drying, sinter under normal pressure, rise from 0°C to 300°C for 3 hours, and then rise from 300°C to 1200°C for 3 hours, keep warm for 1 hour and then cool with the furnace to obtain the present invention Bulk SiO 2 -Si 3 N 4 base composite material.

[0028] The thermal conductivity of the composite material is 0.1W / m·K, the dielectric constant ε=3, and the dielectric loss tgδ=2.8×10 -3 . The density is 0.8g / cm 3 , the porosity is about 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com